Surface Roughness Prediction and Optimization in the Orthogonal Cutting of Graphite/Polymer Composites Based on Artificial Neural Network

Abstract

:1. Introduction

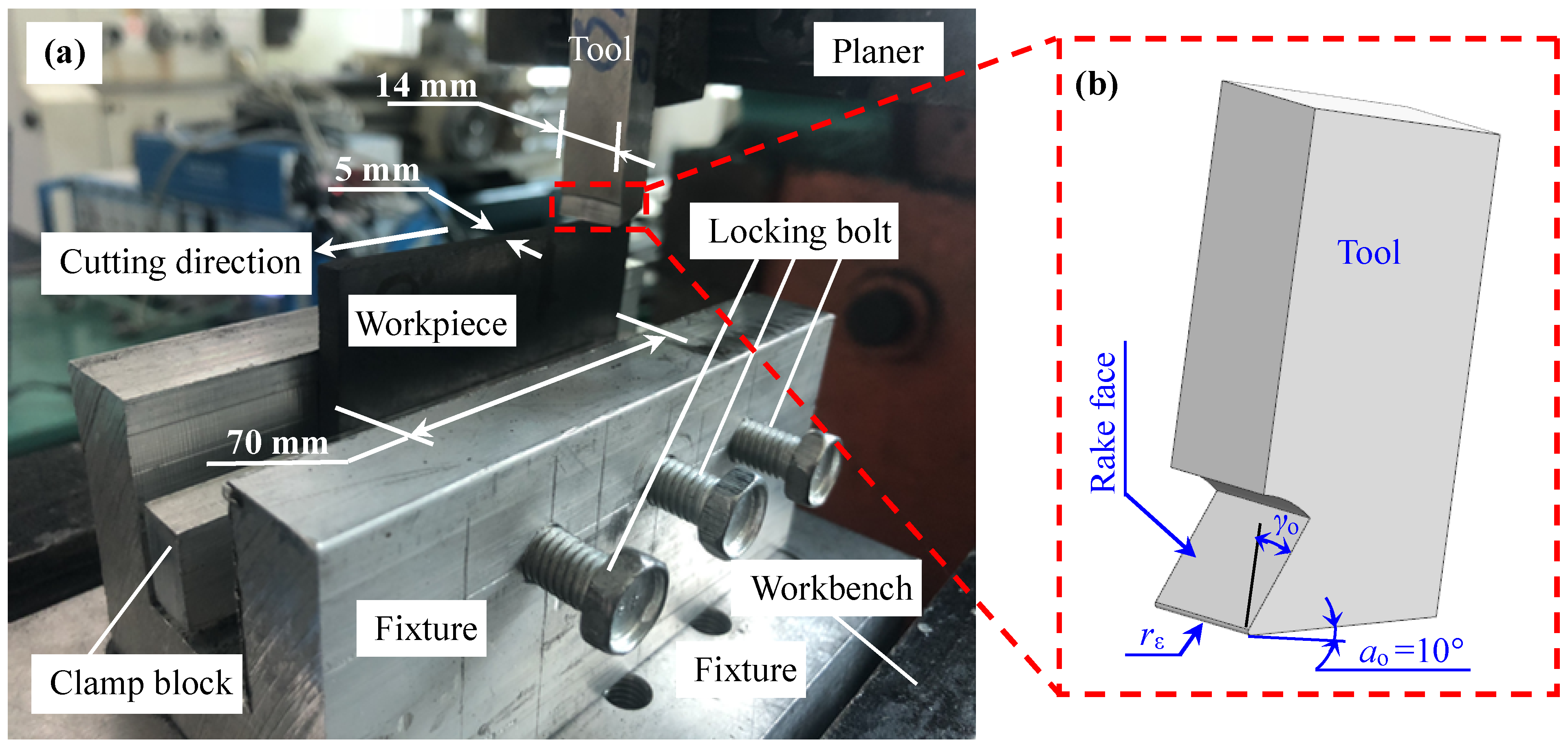

2. Experimental Methodologies

2.1. Experimental Method

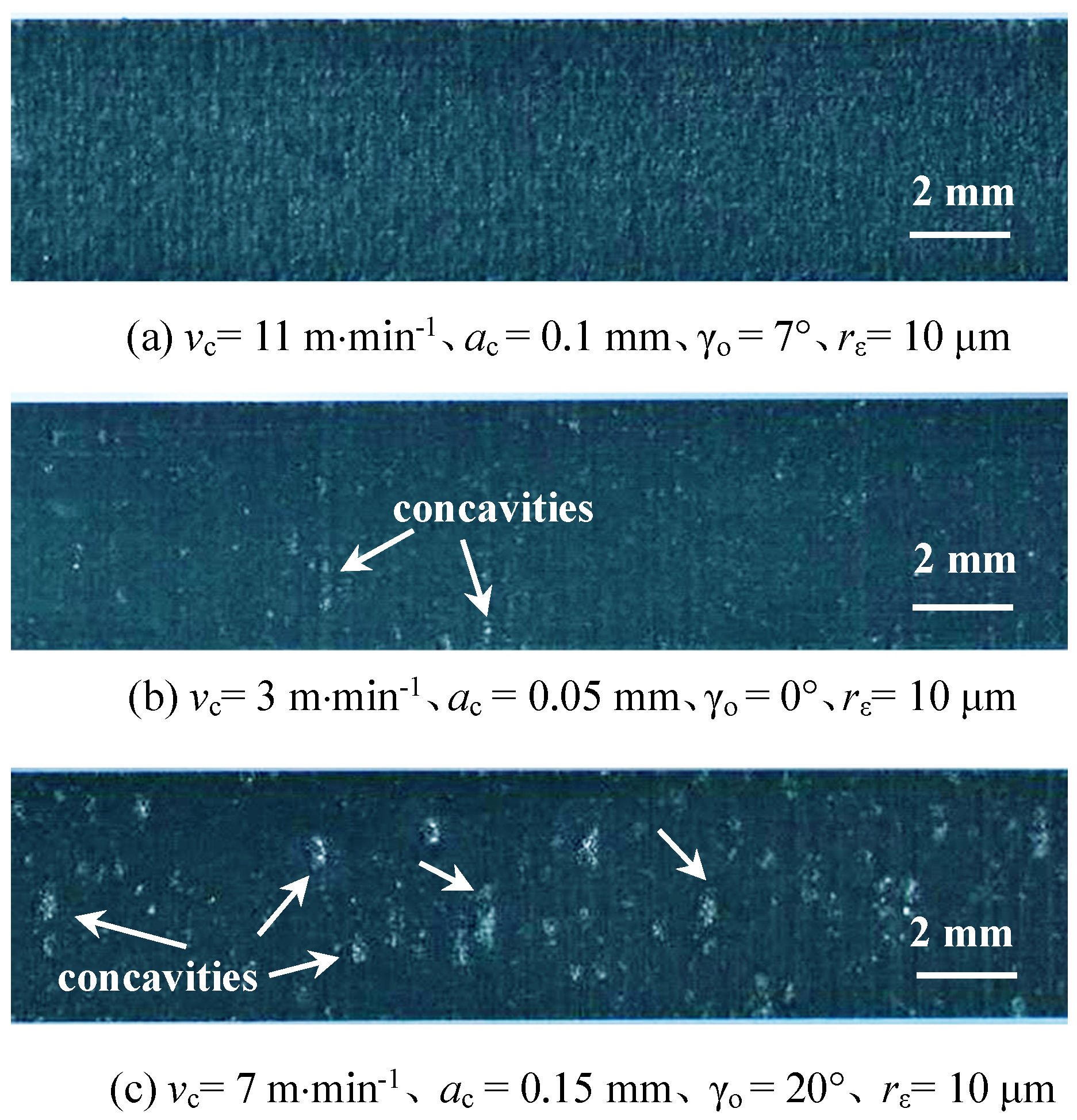

2.2. Machined Surface Roughness at Different Cutting Parameters

3. Establishment of the Roughness Prediction Model

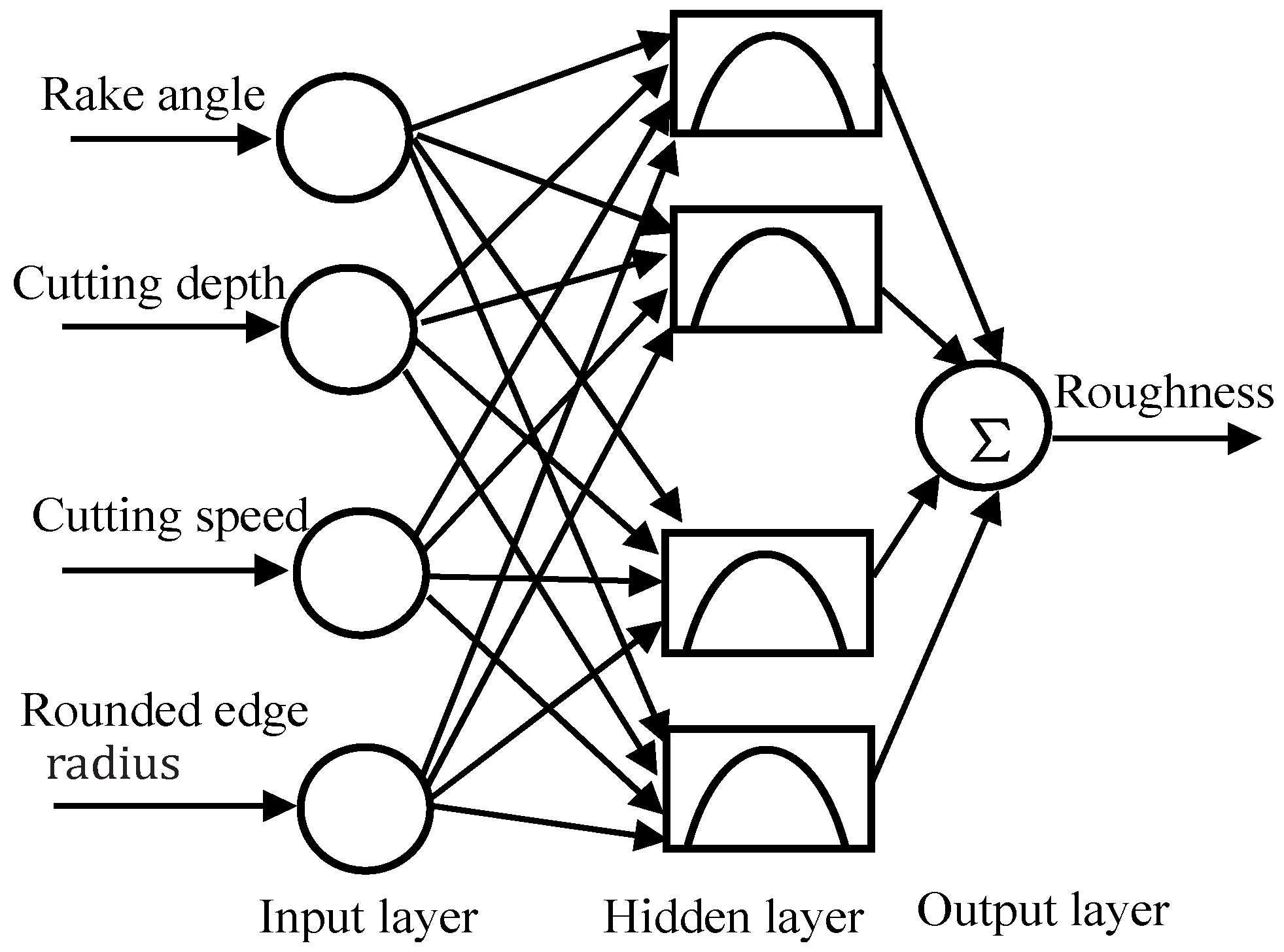

3.1. The Selection of the ANN

3.2. The Structure of the ANN

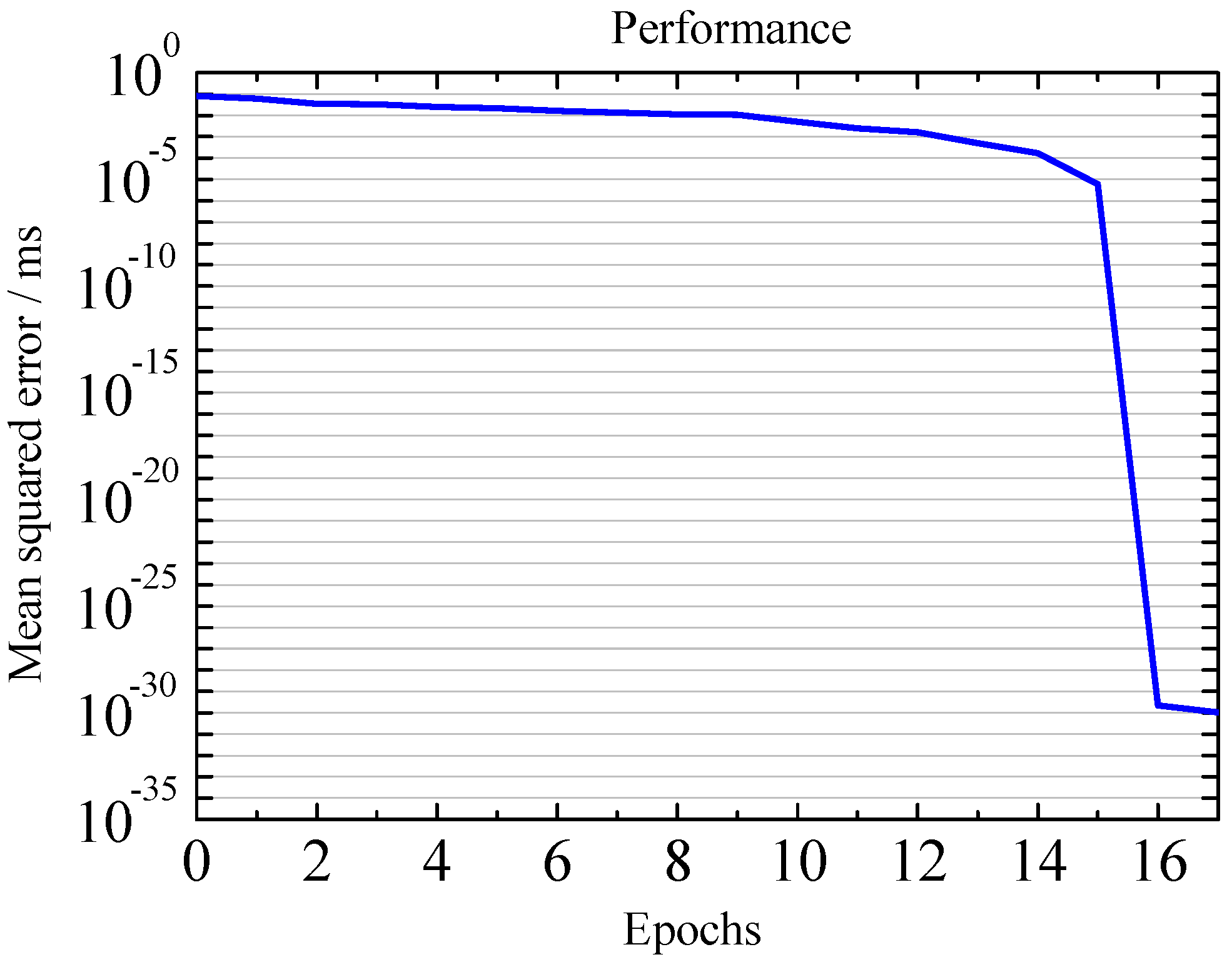

3.3. ANN Training

4. Optimization of the ANN Prediction Model

4.1. Optimization Model

s. t.

3 ≤ x1 ≤ 12

0.05 ≤ x2 ≤ 0.3

0° ≤ x3 ≤ 20°

10 ≤ x4 ≤ 90

4.2. Solving Process

5. Comparative Analysis and Experimental Verification

5.1. Grey Relational Analysis (GRA)

5.2. Verification Experiment

6. Conclusions

- (1)

- The machined surface roughness data of graphite/polymer composites in orthogonal cutting process were used as training samples of ANN, and then a machined surface roughness prediction model for graphite/polymer composites was established based on RBF ANN. The prediction accuracy of the trained ANN exceeds 93%.

- (2)

- The prediction results of the ANN optimized by the GA showed that the lowest machined surface roughness of graphite/polymer composites was 1.81 μm, and the corresponding cutting speed, cutting depth, tool rake angle, and rounded edge radius after decoding were 11.2 m/min, 0.1 mm, 6.85°, and 11.16 μm, respectively. It should be noted that some of the data in the above process parameters are difficult to apply in reality, such as rake angle and rounded edge radius. In actual applications, they can be taken as integers close to the computational process parameters. Therefore, the recommended optimal process parameters are cutting speed of 11 m/min, cutting depth of 0.1 mm, tool rake angle of 7°, and rounded edge radius of 10 μm.

- (3)

- The verification experiment showed that the machined surface roughness of graphite/polymer composites during the orthogonal cutting process was 3.11 μm, when the optimal parameters obtained by the GRA were used. The machined surface roughness was only 1.95 μm at the cutting parameters obtained by the optimized ANN, and the corresponding prediction error of the ANN was approximately 7%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Starý, V.; Bačáková, L.; Horník, J.; Chmelk, V. Bio-compatibility of the surface layer of pyrolytic graphite. Thin Solid Films 2003, 433, 191–198. [Google Scholar] [CrossRef]

- Kang, K.; Park, S.; Jo, A.; Lee, K.; Ju, H. Development of ultralight and thin bipolar plates using epoxy-carbon fiber prepregs and graphite composites. Int. J. Hydrog. Energ. 2017, 42, 1691–1697. [Google Scholar] [CrossRef]

- Zeis, M. Deformation of thin graphite electrodes with high aspect ratio during sinking electrical discharge machining. CIRP Ann. 2017, 66, 185–188. [Google Scholar] [CrossRef]

- Tan, D.; Chen, Z.; Li, J.; Luo, J.; Yang, D.; Cui, S.; Zhang, Z. Effects of swirl and boiling heat transfer on the performance enhancement and emission reduction for a medium diesel engine fueled with biodiesel. Processes 2021, 9, 568. [Google Scholar] [CrossRef]

- Zhang, Z.; Ye, J.; Tan, D.; Feng, Z.; Luo, J.; Tan, Y.; Huang, Y. The effects of Fe2O3 based DOC and SCR catalyst on the combustion and emission characteristics of a diesel engine fueled with biodiesel. Fuel 2021, 290, 120039. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiaqiang, E.; Chen, J.; Zhao, X.; Zhang, B.; Deng, Y.; Peng, Q.; Yin, Z. Effects of boiling heat transfer on the per-formance enhancement of a medium speed diesel engine fueled with diesel and rapeseed methyl ester. Appl. Therm. Eng. 2020, 169, 114984. [Google Scholar] [CrossRef]

- Masuda, M.; Kuroshima, Y.; Chujo, Y. The machinability of sintered carbons based on the correlation between tool wear rate and physical and mechanical properties. Wear 1996, 195, 178–185. [Google Scholar] [CrossRef]

- Wan, Z.; Yang, D.; Lu, L.; Wu, J.; Tang, Y. Mechanism of material removal during orthogonal cutting of graphite/polymer composites. Int. J. Adv. Manuf. Tech. 2016, 82, 1815–1821. [Google Scholar] [CrossRef]

- Wang, C.; Zhou, L.; Fu, H.; Hu, Z. High speed milling of graphite electrode with endmill of small diameter. Chin. J. Mech. Eng. 2007, 20, 27–31. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, C.; Qin, Z. Investigation of chip formation characteristics in orthogonal cutting of graphite. Mater. Manuf. Process. 2009, 24, 1365–1372. [Google Scholar] [CrossRef]

- Huo, D.; Lin, C.; Dalgarno, K. An experimental investigation on micro machining of fine-grained graphite. Int. J. Adv. Manuf. Tech. 2014, 72, 943–953. [Google Scholar] [CrossRef]

- Yang, D.; Wan, Z.; Xu, P.; Lu, L. Rake angle effect on a machined surface in orthogonal cutting of graphite/polymer composites. Adv. Mater. Sci. Eng. 2018, 2018, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Shie, J.R.; Huang, C.H. Optimization of dry machining parameters for high-purity graphite in end-milling process. Mater. Manuf. Process. 2006, 21, 832–837. [Google Scholar] [CrossRef]

- Yang, Y.; Chuang, M.; Lin, S. Optimization of dry machining parameters for high-purity graphite in end milling process via design of experiments methods. J. Mater. Process. Tech. 2009, 209, 4395–4400. [Google Scholar] [CrossRef]

- Shie, J.R. Optimization of dry machining parameters for high-purity graphite in end-milling process by artificial neural networks: A case study. Mater. Manuf. Process. 2006, 21, 838–845. [Google Scholar] [CrossRef]

- Alzaeemi, S.A.; Sathasivam, S. Artificial immune system in doing 2-satisfiability based reverse analysis method via a radial basis function neural network. Processes 2020, 8, 1295. [Google Scholar] [CrossRef]

- Kant, G.; Sangwan, K.S. Predictive Modelling and Optimization of Machining Parameters to Minimize Surface Roughness using Artificial Neural Network Coupled with Genetic Algorithm. Procedia CIRP 2015, 31, 453–458. [Google Scholar] [CrossRef] [Green Version]

- Liu, G.; Liu, W.; He, Y.; Gong, J.; Li, Q. Research on influence of exhaust characteristics and control strategy to DOC-assisted active regeneration of DPF. Processes 2021, 9, 1403. [Google Scholar] [CrossRef]

- Wang, X.; Fang, H.; Fang, S. An integrated approach for exploitation block selection of shale gas—based on cloud model and grey relational analysis. Resour. Policy 2020, 68, 101797. [Google Scholar] [CrossRef]

- Martin, M.P.; Jozef, J. Machining of inserts with pcd cutting-edge technology and determination of optimum machining conditions based on roundness deviation and chip-cross section of aw 5083 al-alloy verified with grey relation analysis. Processes 2021, 9, 1485. [Google Scholar]

- Sindhu, D.; Thakur, L.; Chandna, P. Multi-objective optimization of rotary ultrasonic machining parameters for quartz glass using Taguchi-Grey Relational Analysis (GRA). Silicon 2019, 11, 2033–2044. [Google Scholar] [CrossRef]

- Yang, C.B.; Lin, C.G.; Chiang, H.L.; Chen, C.C. Single and multiobjective optimization of Inconel 718 nickel-based superalloy in the wire electrical discharge machining. Int. J. Adv. Manuf. Tech. 2017, 93, 3075–3084. [Google Scholar] [CrossRef]

- Rajmohan, T.; Palanikumar, K. Optimization of machining parameters for multi-performance characteristics in drilling hybrid metal matrix composites. J. Compos. Mater. 2012, 46, 869–878. [Google Scholar] [CrossRef]

- Venkatachalam, A.; Anurag, P.V.S.; Sadanand, T.D.; Nachimuthu, R. Optimization of the milling parameters for an Al/Si3N4 functionally graded composite using grey relational analysis. Mater. Test. 2018, 60, 215–221. [Google Scholar] [CrossRef]

| A vc/m·min−1 | B ac/mm | C γo/° | D rε/μm | |

|---|---|---|---|---|

| 1 | 3 | 0.05 | 0 | 10 |

| 2 | 7 | 0.15 | 10 | 50 |

| 3 | 12 | 0.30 | 20 | 90 |

| Performance | Density | Shore Hardness | Tensile Strength | Compressive Strength | Elastic Modulus | Porosity |

|---|---|---|---|---|---|---|

| Parameter | 1.9 g/cm3 | 75 | 17.3 MPa | 107.2 MPa | 15.9 GPa | 0.5% |

| No. | vc/m·min−1 | ac/mm | γo/° | rε/μm | Ra/μm | Sample Description | |

|---|---|---|---|---|---|---|---|

| 1 | 3 | 0.05 | 0 | 10 | 3.09 | Orthogonal experiments | ANN training samples |

| 2 | 3 | 0.15 | 10 | 50 | 4.83 | ||

| 3 | 3 | 0.30 | 20 | 90 | 8.13 | ||

| 4 | 7 | 0.05 | 10 | 90 | 6.99 | ||

| 5 | 7 | 0.15 | 20 | 10 | 5.80 | ||

| 6 | 7 | 0.30 | 0 | 50 | 7.75 | ||

| 7 | 12 | 0.05 | 20 | 50 | 4.29 | ||

| 8 | 12 | 0.15 | 0 | 90 | 5.57 | ||

| 9 | 12 | 0.30 | 10 | 10 | 8.53 | ||

| 10 | 3 | 0.05 | 0 | 50 | 4.38 | ||

| 11 | 3 | 0.15 | 20 | 90 | 5.54 | ||

| 12 | 7 | 0.30 | 20 | 50 | 7.34 | ||

| 13 | 7 | 0.15 | 0 | 90 | 5.92 | ||

| 14 | 12 | 0.15 | 0 | 10 | 5.00 | ||

| 15 | 10 | 0.10 | 10 | 10 | 3.38 | ||

| 16 | 5 | 0.20 | 10 | 10 | 4.56 | ||

| 17 | 5 | 0.25 | 10 | 10 | 4.96 | ||

| 18 | 7 | 0.10 | 10 | 10 | 3.81 | ANN prediction samples | |

| 19 | 3 | 0.10 | 10 | 10 | 3.42 | ||

| 20 | 12 | 0.10 | 10 | 10 | 3.15 | ||

| 21 | 5 | 0.10 | 10 | 50 | 5.26 | ||

| 22 | 5 | 0.10 | 10 | 90 | 6.43 | ||

| No. | Factor | Data Processing Result | Grey Relational Grade | |||

|---|---|---|---|---|---|---|

| A | B | C | D | |||

| 1 | 1 | 1 | 1 | 1 | 1.000 | 1.000 |

| 2 | 1 | 2 | 2 | 2 | 0.680 | 0.610 |

| 3 | 1 | 3 | 3 | 3 | 0.074 | 0.351 |

| 4 | 2 | 1 | 2 | 3 | 0.283 | 0.411 |

| 5 | 2 | 2 | 3 | 1 | 0.502 | 0.501 |

| 6 | 2 | 3 | 1 | 2 | 0.143 | 0.368 |

| 7 | 3 | 1 | 3 | 2 | 0.779 | 0.693 |

| 8 | 3 | 2 | 1 | 3 | 0.544 | 0.523 |

| 9 | 3 | 3 | 2 | 1 | 0.000 | 0.333 |

| Factor | Average Grey Relational Grade | ||

|---|---|---|---|

| Level 1 | Level 2 | Level 3 | |

| A | 0.654 * | 0.427 | 0.516 |

| B | 0.701 * | 0.545 | 0.351 |

| C | 0.630 * | 0.451 | 0.515 |

| D | 0.611 * | 0.557 | 0.428 |

| vc/m·min−1 | ac/mm | γo/° | rε/μm | Surface Roughness/μm | ||

|---|---|---|---|---|---|---|

| Optimal | Experimental | |||||

| GA optimization | 11 | 0.10 | 7 | 10 | 1.81 | 1.95 |

| GRA | 3 | 0.05 | 0 | 10 | 3.09 | 3.11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, D.; Guo, Q.; Wan, Z.; Zhang, Z.; Huang, X. Surface Roughness Prediction and Optimization in the Orthogonal Cutting of Graphite/Polymer Composites Based on Artificial Neural Network. Processes 2021, 9, 1858. https://doi.org/10.3390/pr9101858

Yang D, Guo Q, Wan Z, Zhang Z, Huang X. Surface Roughness Prediction and Optimization in the Orthogonal Cutting of Graphite/Polymer Composites Based on Artificial Neural Network. Processes. 2021; 9(10):1858. https://doi.org/10.3390/pr9101858

Chicago/Turabian StyleYang, Dayong, Qingda Guo, Zhenping Wan, Zhiqing Zhang, and Xiaofang Huang. 2021. "Surface Roughness Prediction and Optimization in the Orthogonal Cutting of Graphite/Polymer Composites Based on Artificial Neural Network" Processes 9, no. 10: 1858. https://doi.org/10.3390/pr9101858

APA StyleYang, D., Guo, Q., Wan, Z., Zhang, Z., & Huang, X. (2021). Surface Roughness Prediction and Optimization in the Orthogonal Cutting of Graphite/Polymer Composites Based on Artificial Neural Network. Processes, 9(10), 1858. https://doi.org/10.3390/pr9101858