Effects of Pulse Voltage Duration on Open–Close Dynamic Characteristics of Solenoid Screw-In Cartridge Valves

Abstract

:1. Introduction

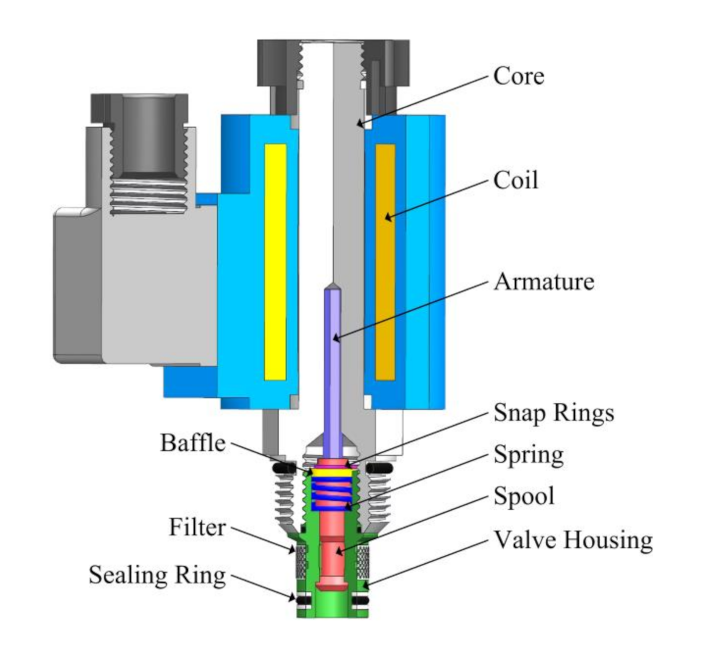

2. Valve Configuration

3. Mathematical Modeling

3.1. Mechanical Characteristics

3.2. Electromagnetic Characteristics

3.3. Hydrodynamic Characteristics

3.4. Dynamic Characteristic Analysis

- A large driving voltage Uon is effective to reduce teon. When Uoff is less than Ieoff, a small or even negative voltage is effective in diminishing teoff;

- A small initial current Ioff is helpful to decrease teoff at the closing stage;

- A small spring preload force is conducive to make teon smaller at the opening stage, but a large spring preload force is beneficial to decrease teoff at the closing stage.

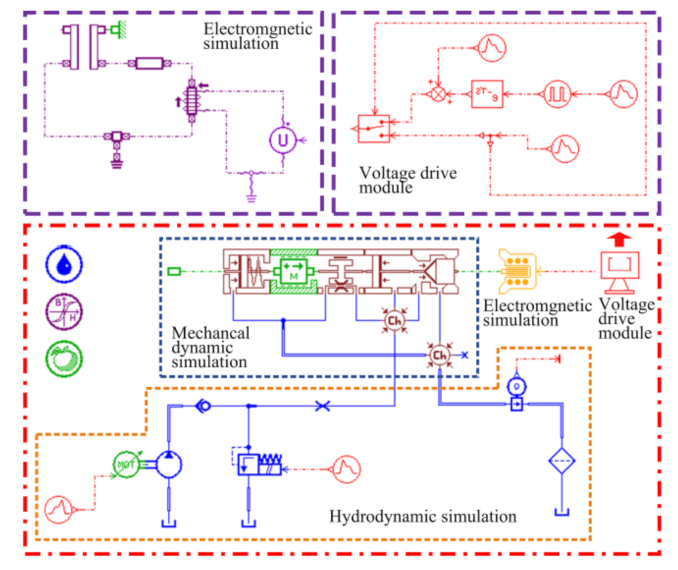

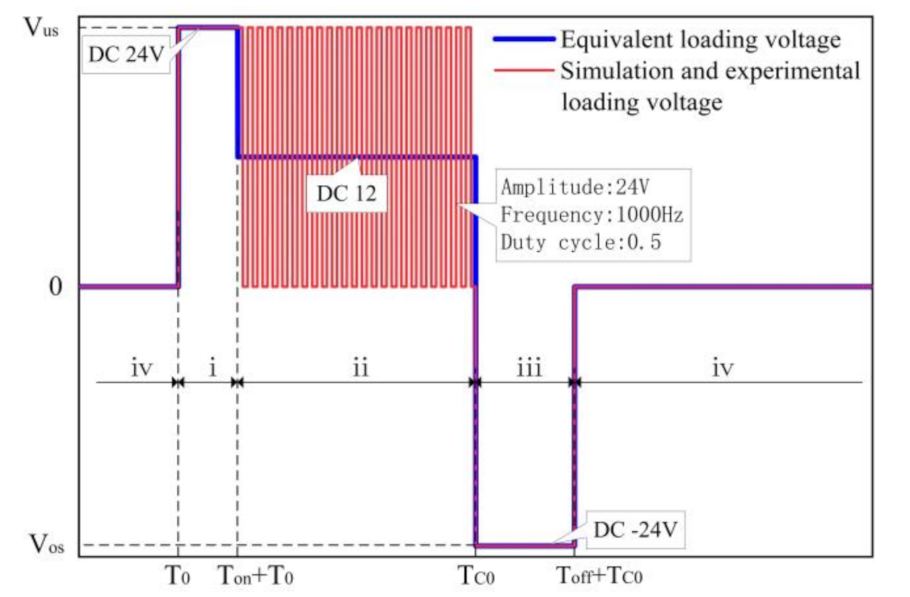

4. Simulation Modeling and Control Strategy

5. Simulation and Experimental Results

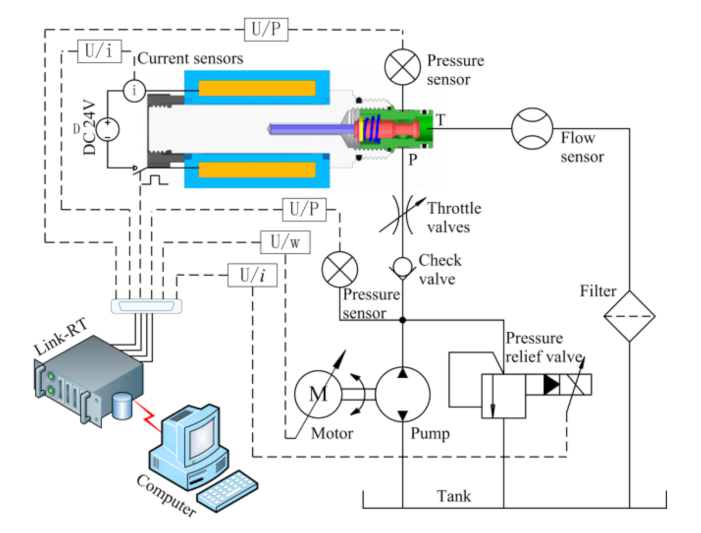

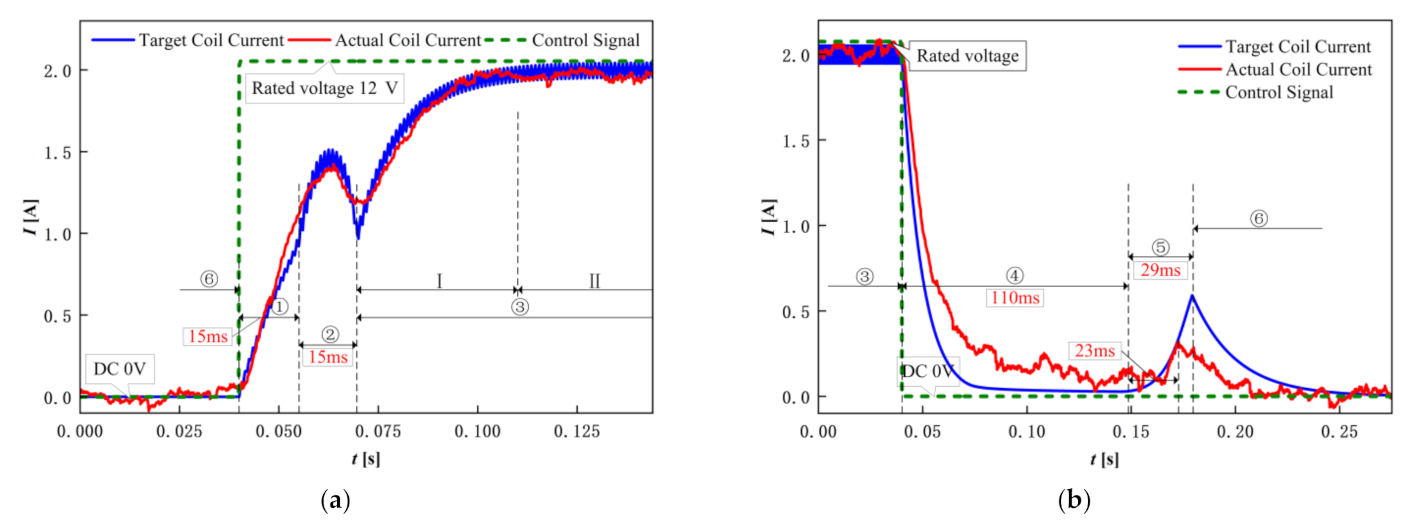

5.1. Experimental Validation of Simulation Model

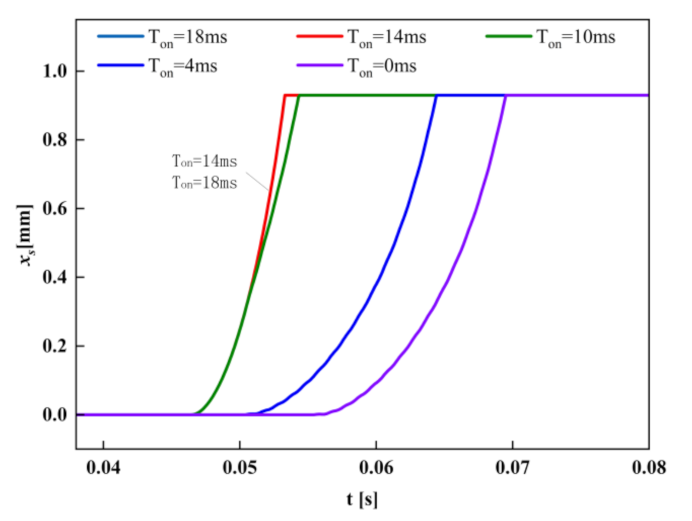

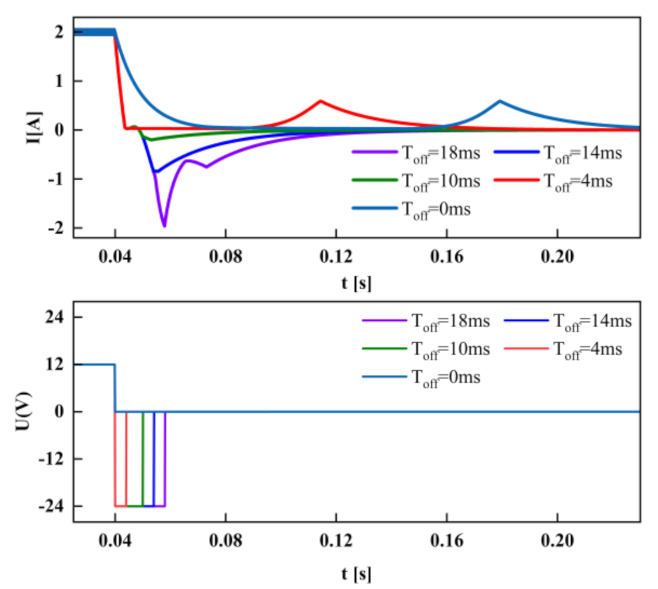

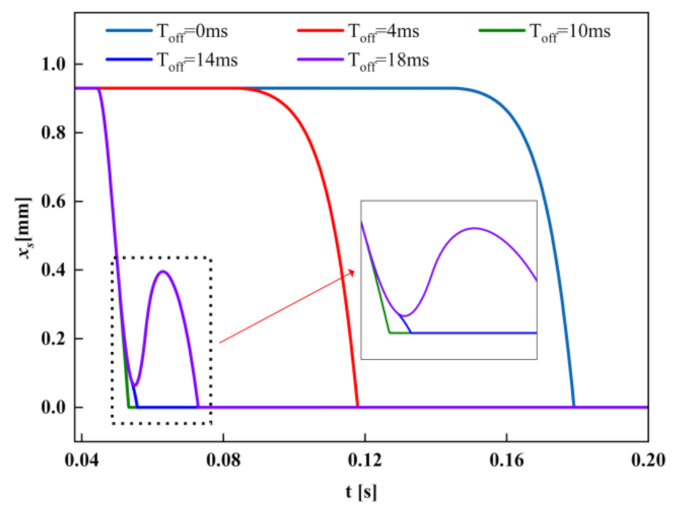

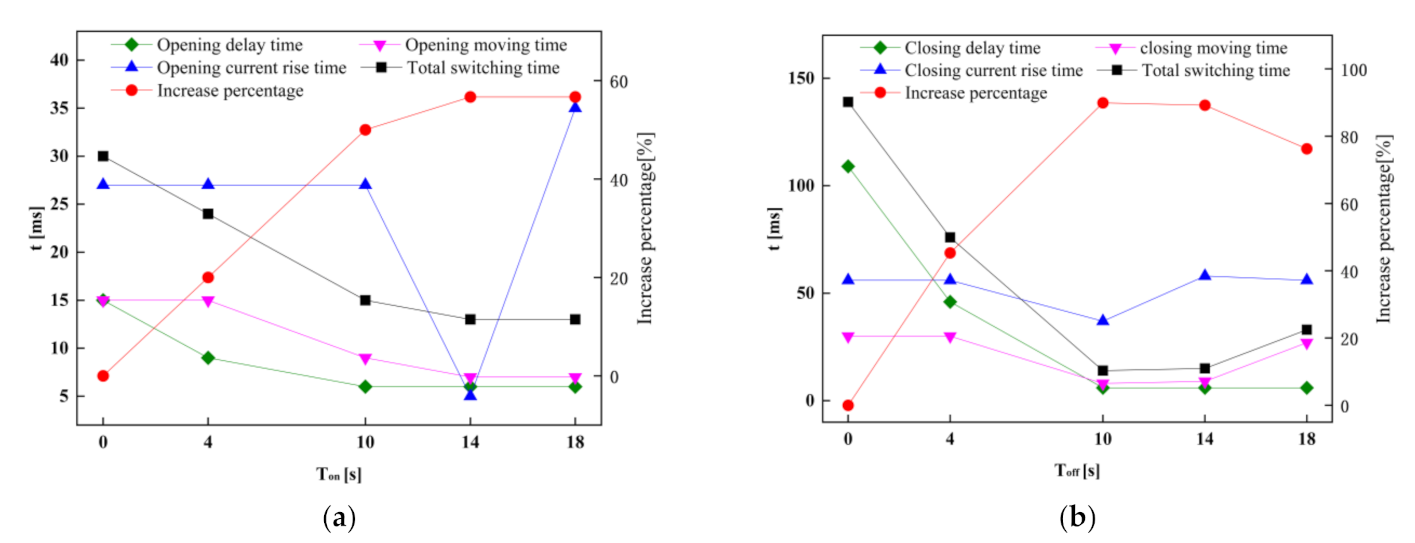

5.2. Effects of the Different Ton and Toff on Open–Close Characteristics of the SCV

5.3. Experimental Verification

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Passarini, L.C.; Nakajima, P.R. Development of a high-speed solenoid valve: An investigation of the importance of the armature mass on the dynamic response. J. Braz. Soc. Mech. Sci. Eng. 2003, 25, 329–335. [Google Scholar] [CrossRef]

- Aturman, O.E.; Park, W. Digital Fuel Injector, Injection and Hydraulic Valve Actuation Module and Engine and High Pressure Pump Methods and Apparatus. US Patent 8342153 B2, 14 April 2009. [Google Scholar]

- Shuai, W.; Xiangyu, Z.; Chunfang, L.; Zongxia, J.; Fengyu, Q. Multiobjective Optimization of a Hollow Plunger Type Solenoid for High Speed On/Off Valve. IEEE Trans. Ind. Electron. 2018, 65, 3115–3124. [Google Scholar]

- Meng, S.; Jian, R.; Sheng, L.; Jianbo, G.; Minjian, L. Brief Indroduction of 2D Digital Servo Valve. Hydraul. Pneum. Seals 2012, 32, 64–67. [Google Scholar]

- Haibing, J.; Jian, R.; Sheng, L.; Xiqing, Z.; Ying, C. Design and Experiment of 2D Electrohydraulic High-speed On-off Valve. Trans. Chin. Soc. Agric. Mach. 2015, 46, 328–334. [Google Scholar]

- Guowen, L.; Jian, R.; Shen, L.; Bin, M. Design and experimental study of two-dimensional (2D) electro-hydraulic proportional directional valve. In Proceedings of the 2015 International Conference on Fluid Power and Mechatronics (FPM), Harbin, China, 5–7 August 2015; pp. 276–282. [Google Scholar]

- Xiaowu, K.; Shizhen, L. Dynamic performance of high speed solenoid valve with parallel coils. Chin. J. Mech. Eng. 2014, 27, 816–821. [Google Scholar]

- Yuliang, M.; Aihua, L.; Mingfan, P.; Jianjun, Z. Performance of Pulsed Jet On-off Valve Based on Giant Magnetostrictive Actuator. Trans. Chin. Soc. Agric. Mach. 2010, 08, 211–215. [Google Scholar]

- Yanping, S.; Yongzhong, Z.; Chengwen, L. Study and design of a high-speed on-off valve taken rare earth alloy material as actuator. J. Nanjing Univ. Sci. Technol. 2004, 28, 385–389. [Google Scholar]

- Yanping, S.; Chengwen, L.; Yongzhong, Z. Design and study of a new kind of larger flow rate high-speed on-off valve. Chin. J. Mech. Eng. 2004, 04, 195–198. [Google Scholar]

- Juntao, Y.; Zongxia, J.; Shuai, W. Design, Simulation and Test of High-flow High-speed on/off Valve Driven by Piezoelectric. J. Mech. Eng. 2020, 56, 226–234. [Google Scholar] [CrossRef]

- Ming, S. Investigation on Control Characteristics and Method of Solenoid High Speed on/off Valve. Ph.D. Thesis, Guizhou University, Guiyang, China, 2010. [Google Scholar]

- Jianhui, Z.; Pengfei, Y.; Grekhov, L.; Xiuzhen, M. Hold current effects on the power losses of high-speed solenoid valve for common-rail injector. Appl. Therm. Eng. 2018, 128, 1579–1587. [Google Scholar]

- Jianhui, Z.; Meiling, W.; Zhangjun, W.; Grekhov, L.; Tao, Q.; Xiuzhen, M. Different boost voltage effects on the dynamic response and energy losses of high-speed solenoid valves. Appl. Therm. Eng. 2017, 123, 1494–1503. [Google Scholar]

- Ill-Yeong, L. Switching response improvement of a high speed on/off solenoid valve by using a 3 power source type valve driving circuit. In Proceedings of the 2006 IEEE International Conference on Industrial Technology, Mumbai, India, 15–17 December 2006; pp. 1823–1828. [Google Scholar]

- Zhong, Q.; Zhang, B.; Hong, H.-c.; Yang, H.-y. Three power sources excitation control strategy of high speed on/off valve based on current feedback. J. Zhejiang Univ. 2018, 52, 8–15. [Google Scholar]

- Qi, Z.; Bin, Z.; Huayong, Y.; Ji-En, M.; Rong-Fong, F. Performance analysis of a high-speed on/off valve based on an intelligent pulse-width modulation control. Adv. Mech. Eng. 2017, 9, 1–11. [Google Scholar]

- Qiang, G.; Yuchuan, Z.; Zhang, L.; Bruno, N. Investigation on adaptive pulse width modulation control for high speed on/off valve. J. Mech. Sci. Technol. 2020, 34, 1711–1722. [Google Scholar]

- Qiang, G.; Yuchuan, Z.; Zhang, L.; Xiaoming, C. Analysis and optimization on compound PWM control strategy of high-speed on /off valve. J. Beijing Univ. Aeronaut. Astronaut. 2019, 45, 1129–1136. [Google Scholar]

| Device Name | Parameter | Value |

|---|---|---|

| Inverter motor | Operating speed (r/min) | 1000 |

| Pilot-operated solenoid relief valve | Setting pressure (MPa) | 5 |

| Fixed displacement pump | Flow rate (L/min) | 10 |

| High frequency pressure | Measuring range (MPa) | 0–16 |

| Output signals (V) | DC 0–5 | |

| Accuracy class | 0.5% F.S | |

| Solenoid screw-in cartridge valves | Rated voltage (V) | DC 12 |

| Nominal pressure (MPa) | 25 | |

| Rated flow (L/min) | 12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yue, D.; Li, L.; Wei, L.; Liu, Z.; Liu, C.; Zuo, X. Effects of Pulse Voltage Duration on Open–Close Dynamic Characteristics of Solenoid Screw-In Cartridge Valves. Processes 2021, 9, 1722. https://doi.org/10.3390/pr9101722

Yue D, Li L, Wei L, Liu Z, Liu C, Zuo X. Effects of Pulse Voltage Duration on Open–Close Dynamic Characteristics of Solenoid Screw-In Cartridge Valves. Processes. 2021; 9(10):1722. https://doi.org/10.3390/pr9101722

Chicago/Turabian StyleYue, Daling, Linfei Li, Liejiang Wei, Zengguang Liu, Chao Liu, and Xiukun Zuo. 2021. "Effects of Pulse Voltage Duration on Open–Close Dynamic Characteristics of Solenoid Screw-In Cartridge Valves" Processes 9, no. 10: 1722. https://doi.org/10.3390/pr9101722

APA StyleYue, D., Li, L., Wei, L., Liu, Z., Liu, C., & Zuo, X. (2021). Effects of Pulse Voltage Duration on Open–Close Dynamic Characteristics of Solenoid Screw-In Cartridge Valves. Processes, 9(10), 1722. https://doi.org/10.3390/pr9101722