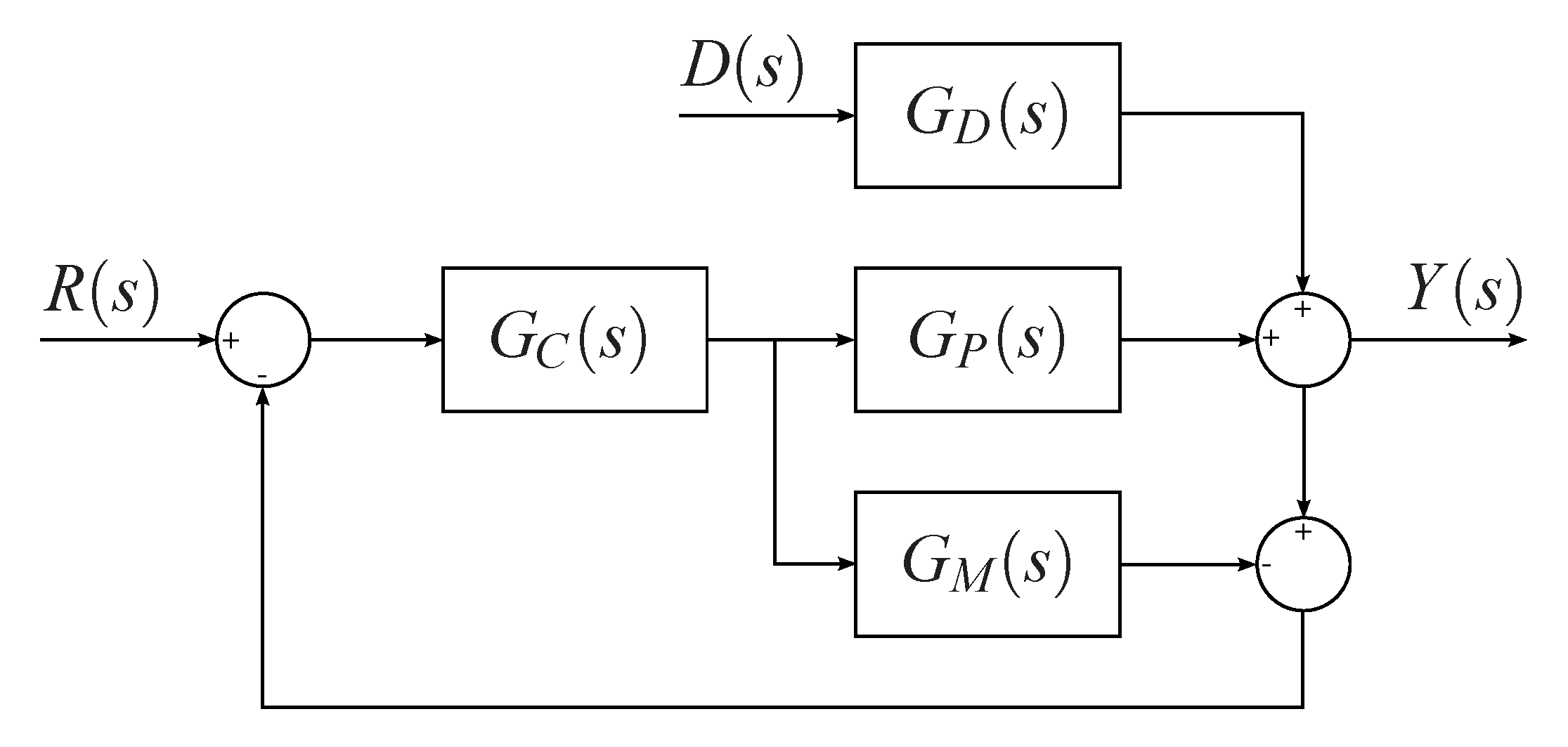

1. Introduction

Inverse response or non-minimum-phase systems have at least one zero located at the right-hand side of the complex plane [

1]. Their time response to a step input goes, at the beginning, towards the opposite direction of the steady-state value [

2]. Such behavior appears due to the combination of two opposite-dynamics phenomena: A small-gain fast-dynamics responsible for the inverse response, and a slow-dynamics with higher gain, which dominates the transient response [

3,

4,

5].

Since the inverse response phenomenon presents some similar characteristics to those in dead-time systems, it is usual to find tuning techniques with Smith predictor-like structures [

6,

7]. Other tuning techniques present the model of the non-minimum-phase zero as dead time, which allows one to use traditional tuning techniques developed for time-delayed systems [

8]; conservative controllers are obtained with such an approximation [

9,

10,

11]. Another traditional way to deal with inverse response dynamics is to reduce the order of the system and get a first-order model, which allows one to obtain PI controllers; however, these controllers can cause slower transient responses than the aforementioned techniques [

12].

The development of Proportional-Integral (PI) and Proportional-Integral-Derivative (PID) controllers for inverse response processes started around the 1970s. Waller and Nygardas [

13] compared lead-lag compensators to the conventional PID tuning proposed by Ziegler and Nichols [

14]. Then, Scali and Rachid [

15], Luyben [

16], Chien et al. [

17], and Sree and Chidambaram [

18], among others, reported different tuning techniques for PI/PID controllers used for inverse-response systems by considering, in general, set-point changes. One can find some references, such as Chen and Seborg [

19], Shamsuzzoha and Lee [

20], and Pai et al. [

9] that developed tuning equations for disturbance rejection. More recently, several PID tuning or controller design methods for processes whose dynamics include inverse-response, time-delay, and integrating characteristics have been developed [

21,

22,

23,

24,

25,

26]. Other authors gone beyond the PID controller and proposed the use of fractional control for non-minimum phase plus dead time systems [

27], and Sliding Mode Controllers applied to high-order long dead-time inverse-response processes [

28].

Other PID design methods based on frequency response techniques have been developed. For instance, Luyben [

29] presented a PI controller tuning procedure for an inverse-response integrating process; the author states that the controller tuning process for this kind of complex dynamics is not a trivial task. Chen and Seborg [

19] developed a design method for PID controllers based on direct synthesis; they demonstrated that the design method works very good for several processes, including those with non-minimum phase characteristics that appear when Pade’s approximation is used for systems with dead time. Such approximation induces an additional modeling error, which implies a decrease in the system’s bandwidth [

30]. Alfaro et al. [

31] used a nondimensional version of equations proposed by Chen and Seborg [

19] and found expressions in order to compute the minimum value of the tuning parameter,

, which bounds the maximum sensitivity.

Internal Model Control (IMC) has been used as an alternative for designing and tuning PID controllers since 1980s [

30]. It has resulted to be of particular interest in industry together with the PID algorithm [

32], since the equations for the controller’s parameters can be obtained from the transfer function of the process and the desired behavior of the closed-loop response; in most cases, only the closed-loop time constant is required as the user-defined tuning parameter, considering an appropriate trade-off between performance and robustness [

20,

33,

34,

35,

36,

37]. Additional works, regarding IMC, that have been developed more recently can be found in [

38,

39,

40,

41,

42,

43,

44].

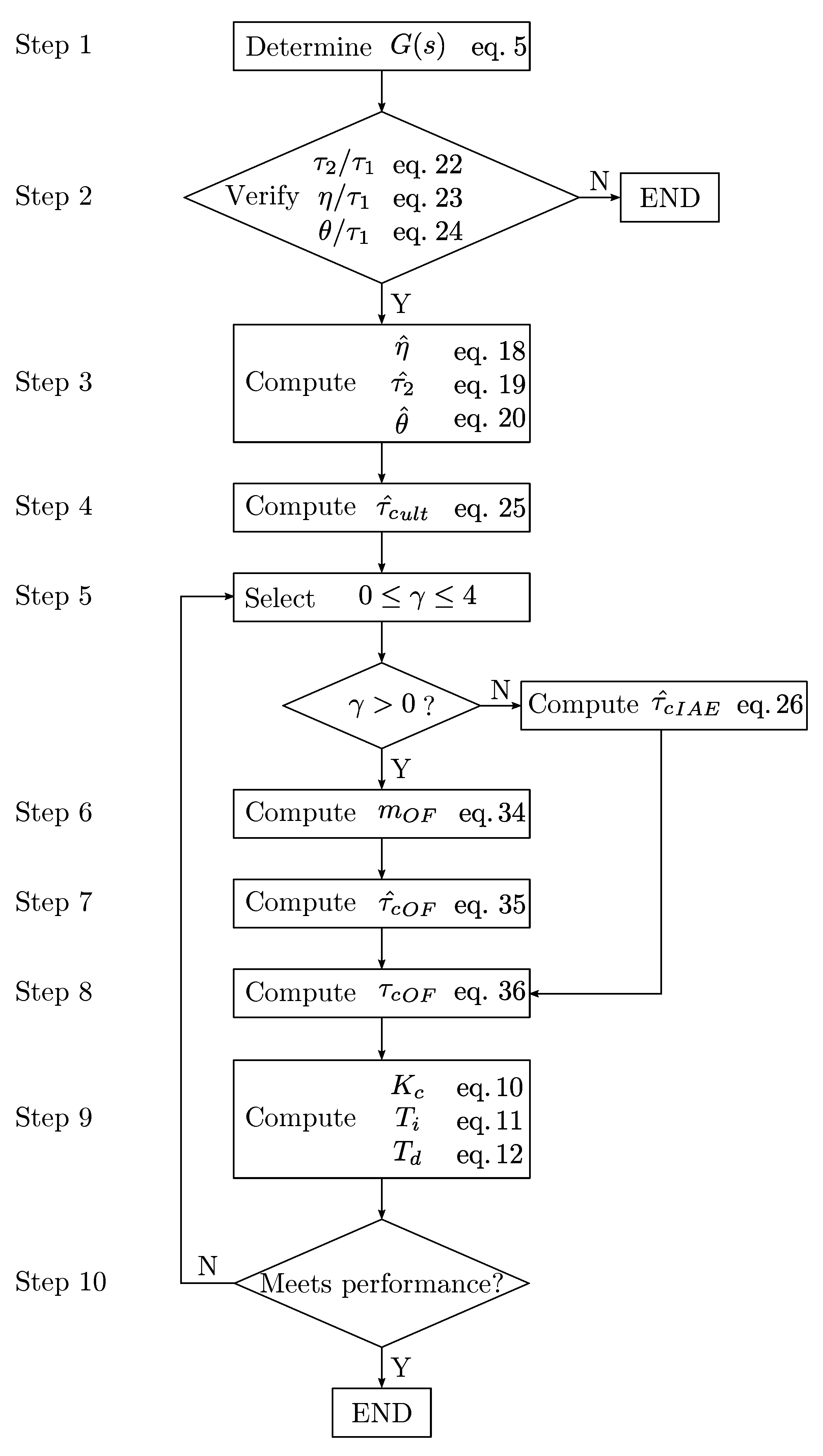

This work addresses the design of a tuning methodology for PID controllers, for inverse-response second-order plus dead time processes, extending the work of Chien and Fruehauf [

45], which has been recently studied in [

46], by using dimensional analysis and experimental design. The development of the tuning technique considers the optimization of an objective function that combines performance and robustness indexes: the Integral of the Absolute Value of the Error (IAE) and the Integral of the change in the Manipulated Variable (IMV). The obtained expressions are simple and can be applied by using the proposed ten-step methodology. The performance of a controller tuned with this method excels the performance offered by other well-known techniques for a wide range of parameters of the process.

The first section contains a description of process’ time response. Then, the design process of the tuning rules is addressed, by using dimensional analysis and experimental design. The third section contains the application methodology and the performance comparison for a controller tuned with the new rules and other tuning methods. Then, the robustness analysis for the variability of parameters is performed. Finally, the conclusions are presented.

2. Inverse Response Second Order Plus Dead Time System Model

The transfer function of an inverse-response second-order system, with total time delay

, can be written as

where

are the transfer functions of two opposite-dynamics phenomena: A small-gain fast-dynamics part (

3), and a slow-dynamics part with higher gain (

2).

and

are the gains, and

and

are the time constants. Substituting (

2) and (

3) into (

1) yields

As it can be seen in (

4), the process’ transfer function only considers the case with real different poles because the dynamics comes from parallel balances [

47]; this is a common case in industrial processes containing boilers, heat exchangers, tanks, distillation columns, chemical reactors, waste incinerators, among others [

2,

47].

Operating expressions in (

4) yields the transfer function of the process which is given by

where

, and

,

.

For this process, at the beginning, the time response slope’s sign is opposite to the sign of the gain, and as

increases, so does the inverse-response behaviour; then, control issues arise due to the fact that the non-minimum phase zero is closer to the imaginary axis [

4,

15,

48,

49]. Adding a left-hand side pole into (

5) decreases this inverse-response effect, but the settling time increases. When there are multiple non-minimum phase zeros, multiple inversions appear; however, such a system is not commonly found.

5. Discussion on Performance Analysis

This section contains a comparison for the performance of a controller tuned with the new proposed CCV method and three other well-known techniques. There are several PI/PID controller tuning techniques [

59], which are used for processes with specific dynamics characteristics. Regarding, inverse response processes, one can find that even recent literature still uses classical methods for comparison purposes or reference them as still valid and used for adjusting controller parameters. One can find recent literature in which new tuning methods, developed by Waller and Nygardas (WN) [

13] and Chien, Chung, Chen, and Chuang (CCCC) [

17] for inverse response systems, are compared to traditional methods; see for instance [

60,

61]. Additionally, one can find several works that compare the performance with one of the most traditional tuning methods developed by Ziegler and Nichols (ZN) [

14] during the 1940s, see for instance [

62,

63,

64]. The performance indexes are given by

, %TO·UT;

, (%TO)·UT;

, %CO;

(maximum peak), %TO;

where %TO: percentage of transmitter output, %CO: percentage of controller output, UT: units of time.

A central composite experimental design, as explained in the scaling section, was implemented in order to select a set of parameters of the process’ transfer function to test the performance and robustness of the closed-loop, for each controller, over a wide range of values. These values are within the defined ranges of the ratios given by (

22)–(

24). A tag

was assigned to each set, and their values are shown in

Table 3; these parameters are a subset extracted from the experimental region.

For each simulation, the system was excited with a unit-step input for changes in the disturbance and changes in the set-point. A value of

was assigned for all the simulations in order to penalize the behavior of the manipulated variable, considered in the second term of the optimization objective function (

13).

Table 4 contains the nondimensional controller parameters computed for each simulation set.

In order to assess the general performance of the control system (disturbance rejection and set-point tracking), with a PID controller tuned with the new and the traditional selected methods, a scoring system was established. For each performance index, a score between 0 and 4 was given to each tuning method; the controller with the best performance received 4 points, the next received 3 points, and so forth. When a tuning method generated a marginally stable or unstable response, it received 0 points in all indexes.

Table 5 contains the results of the performance indexes for each tuning method, when considering disturbance rejection for the set

of parameters of the process’ transfer function. Then, scores were assigned for each controller, when analyzing each performance index;

Table 6 contains the disturbance rejection scores for the set

.

Although the controllers were adjusted for disturbance rejection, the set-point tracking capabilities were also tested.

Table 7 shows the results of the performance indexes for each tuning method, when considering set-point tracking for the set

of parameters of the process’ transfer function. Then, scores were assigned for each controller when analyzing each performance index;

Table 8 contains the set-point tracking scores for the set

.

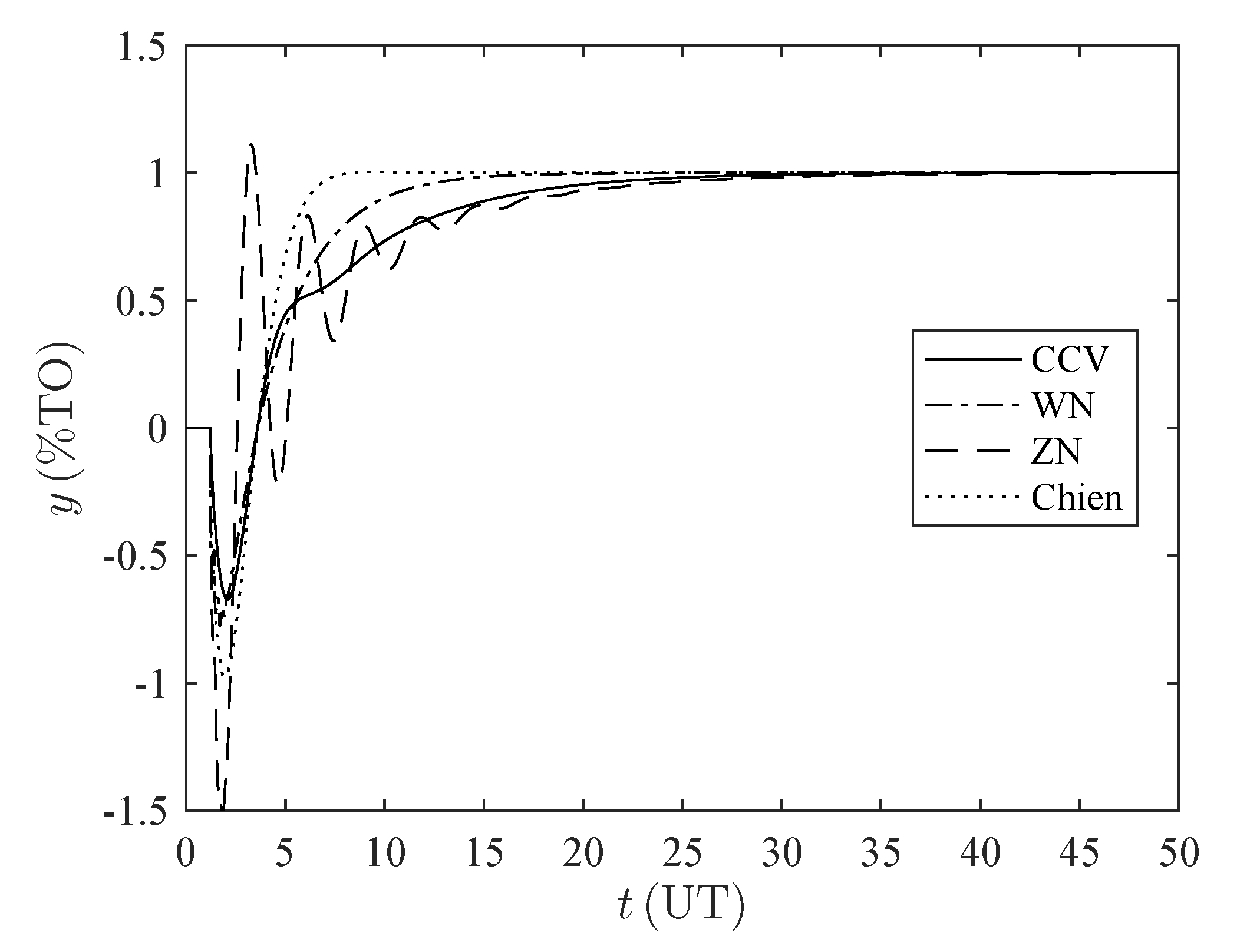

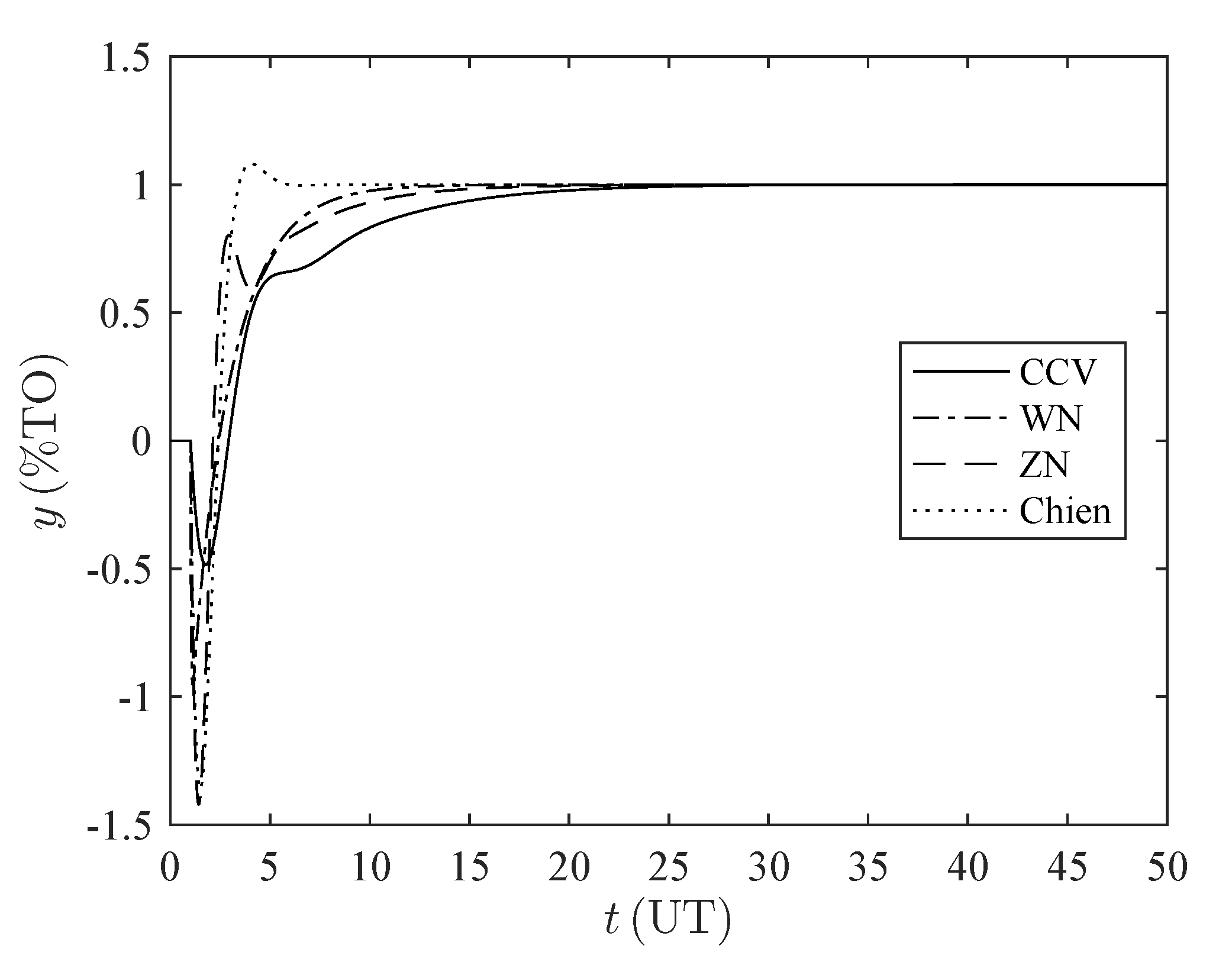

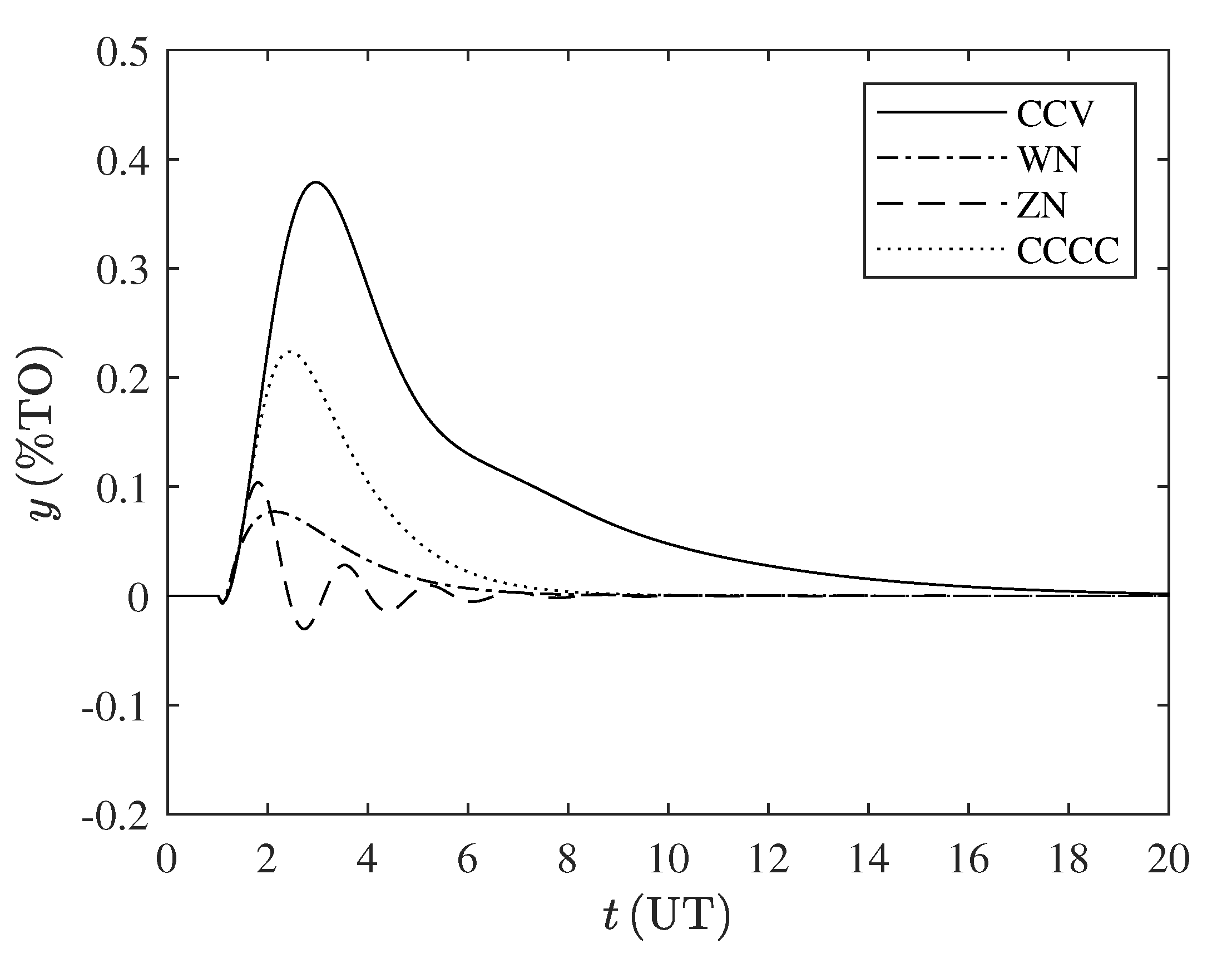

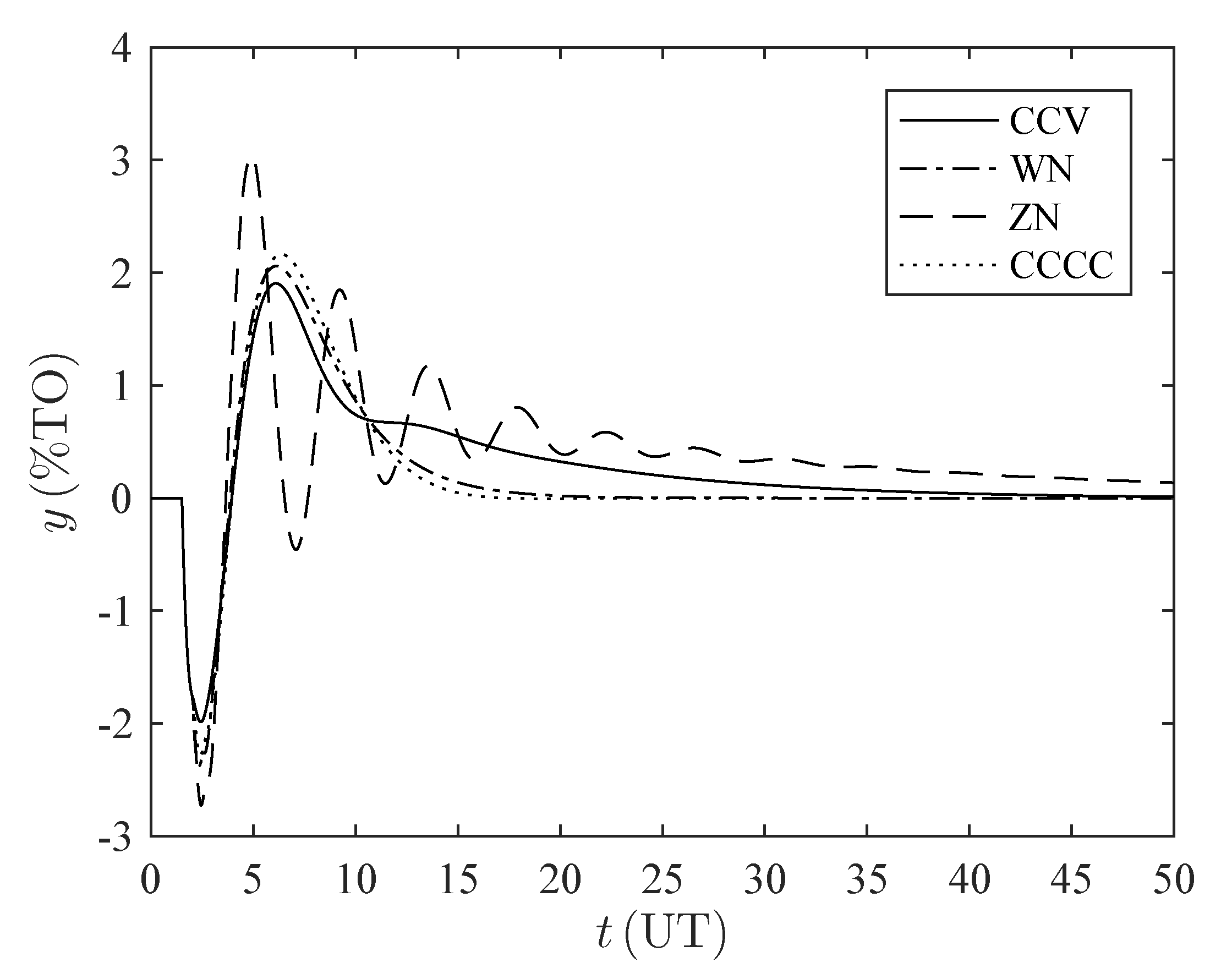

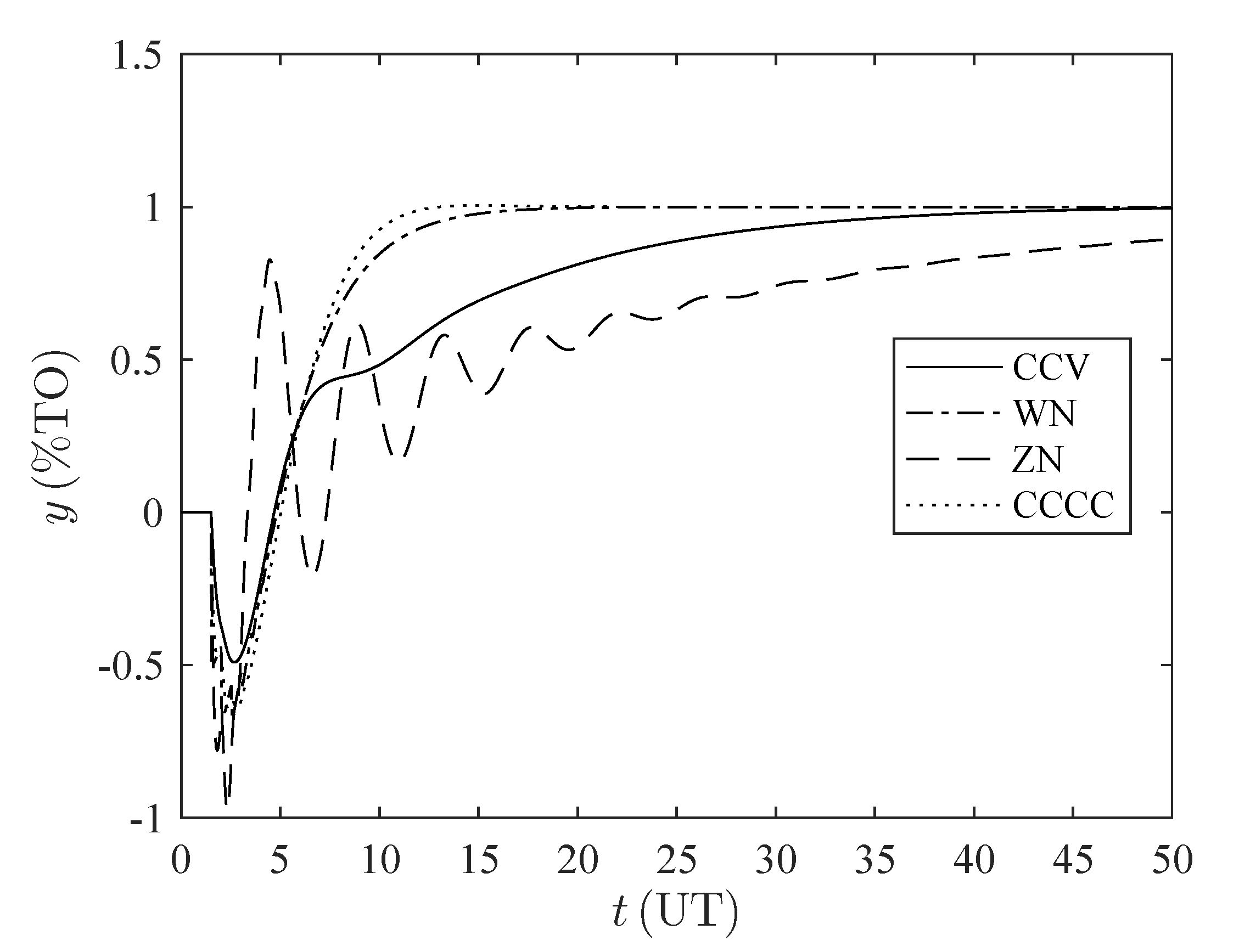

Figure 5 and

Figure 6 show the time response for the parameter set

, for both disturbance rejection and set-point tracking, respectively.

It can be noticed that the CCV controller has a high settling time; this occurs because of the high value assigned to the suppression factor (), in order to penalize the manipulated variable and increase the robustness, smooths the actuator’s behavior. Additionally, it can be noticed how the CCV controller decreases the inverse response effect.

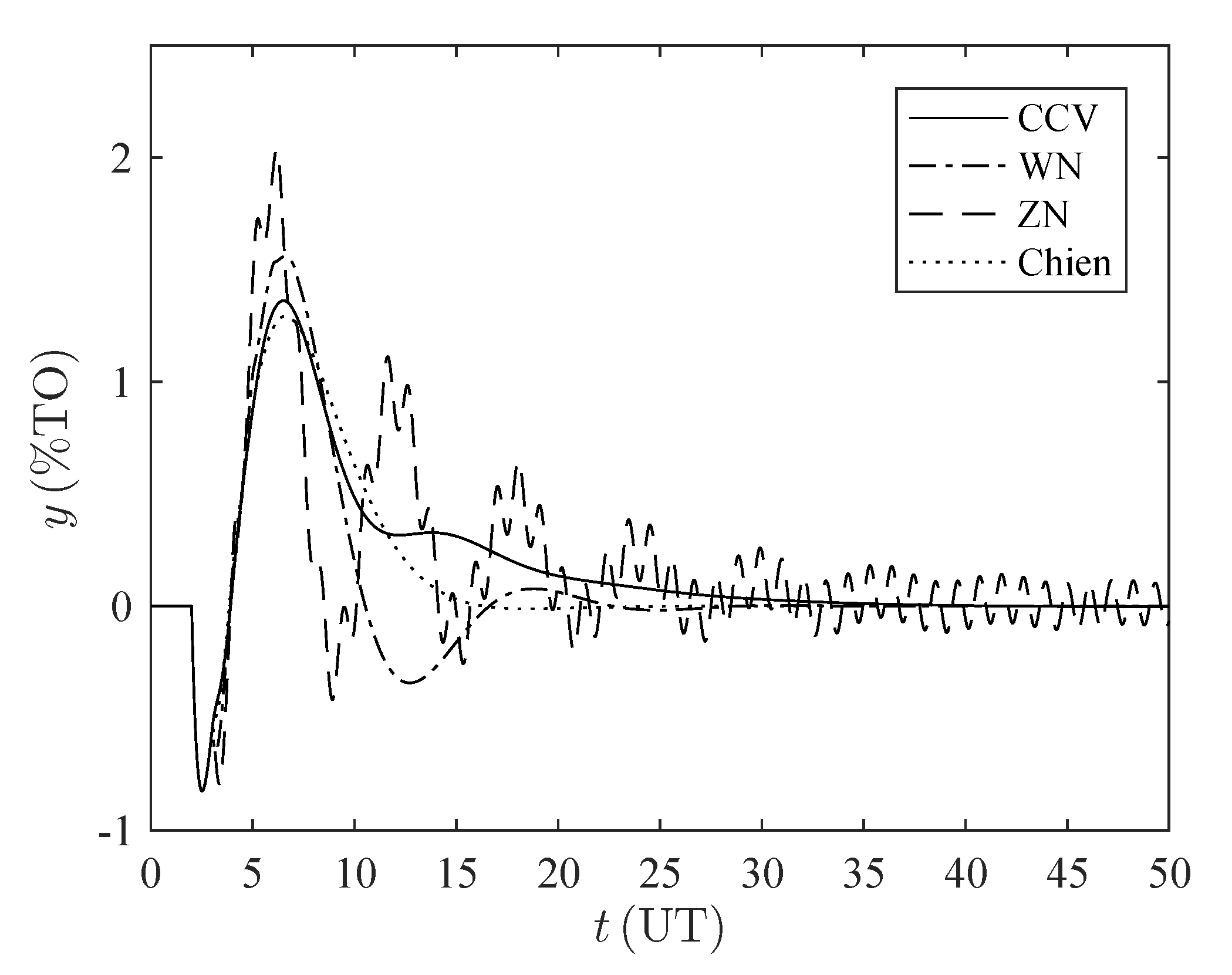

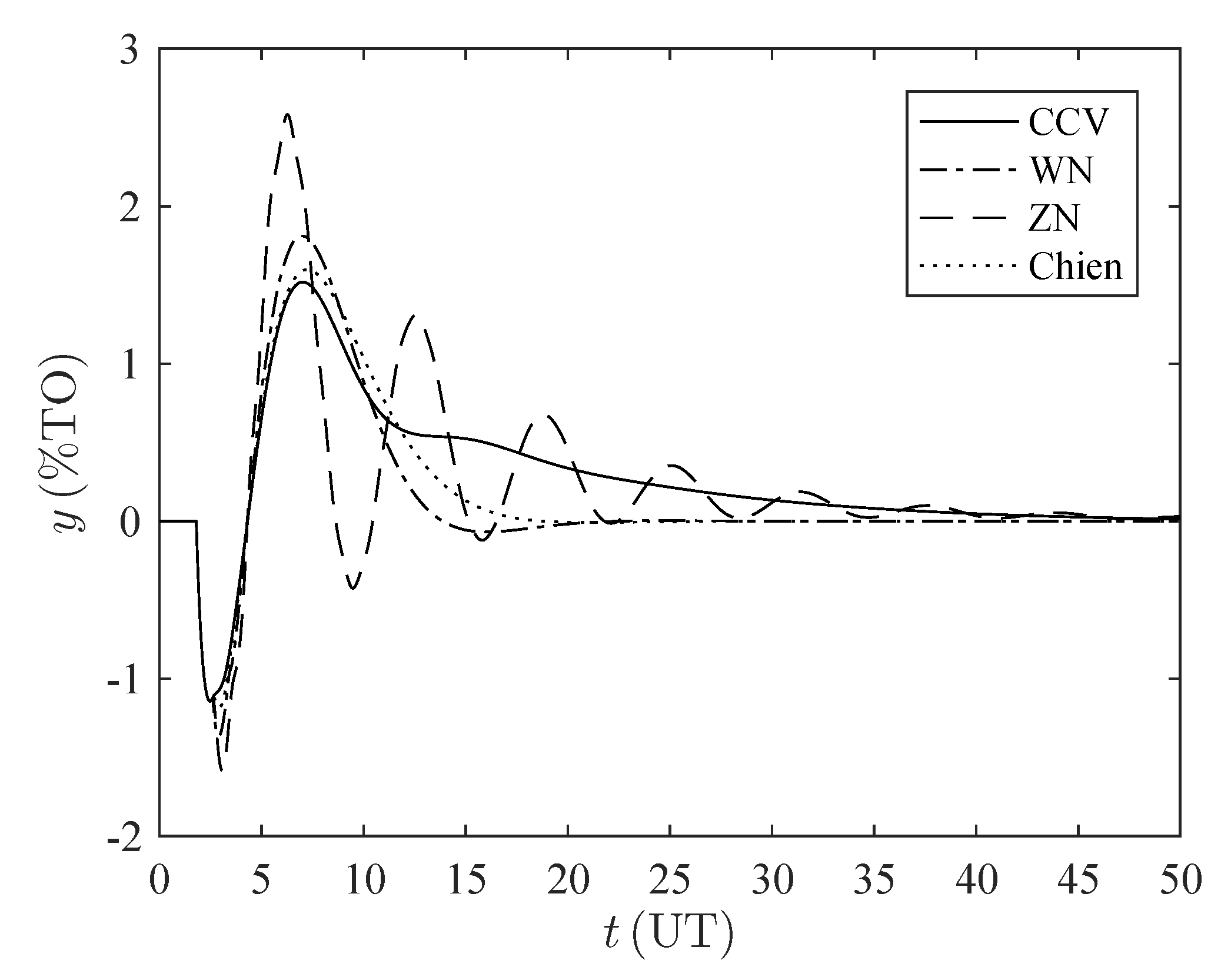

This procedure was followed for the other parameter sets. In

Appendix B,

Table A2,

Table A3,

Table A4,

Table A5,

Table A6,

Table A7,

Table A8 and

Table A9 contain the performance indexes for disturbance rejection and set-point tracking for the remaining sets of the parameters

,

,

, and

. In

Appendix C,

Figure A1,

Figure A2,

Figure A3,

Figure A4,

Figure A5,

Figure A6,

Figure A7 and

Figure A8 show the time response for the remaining sets of parameters:

,

,

, and

.

All the points obtained by each tuning method using the scoring system were added, by considering each performance index.

Table 9 shows the total scores for disturbance rejection and

Table 10 shows the total scores for set-point tracking.

As it can be noticed, the proposed CCV method shows the best over-all results for disturbance rejection, when considering a wide range of parameters of the process’ transfer function. Although the controller was tuned for disturbance rejection, it still offers a very good performance for set-point tracking, when considering the same wide range of parameters of the process’ transfer function. In both operations (servo and regulatory), the CCV method achieves the best performance in both the and indexes, which indicates that this tuning method benefits the durability of the actuator.

Although IMC is based on a pole-zero cancellation, which can lead to poor performance in the load regulation operation [

65] for lag-dominant processes [

66], in

Appendix D we provide another simulation for a set of parameters with small dead time and high time constant (

,

,

,

) that shows the wide application of the CCV method; this set is in the limits of the experimental region, but that was not given within the sets selected by the experimental design.

6. Discussion on Robustness Analysis

Romagnoli and Palazoglu [

6] stated that there are different techniques to evaluate uncertainties in a control system. One of them consists in the selection of a range of the parameters of the process’ transfer function, as in [

67], in which Arbogast et al. proposed a robust stability factor metric to examine the effect of plant-model mismatch in the process gain, dead time, and time constant for self-regulating processes. Such method uses the relation of the values of parameters that bring the system’s response to marginally stable conditions and the values of the parameters used for tuning.

Following such technique, in this work the robustness analysis consists on the study of the variability of parameters

and

from

Table 3 by considering a value for the suppression factor

. The analysis was done using a Simulink scenario in which small increments for the parameter of interest were done while keeping constant all the other parameters in the plant and the controller. Simulations stopped when the output reached a sustained-oscillation response (marginal stability conditions), hence, the ultimate value was found for each parameter. Results are found in

Table 11. The table indicates the value of the parameter that leads the response to reach sustained oscillations for each controller and for a particular set of parameters. Therefore, the higher the ultimate value the more robust is the technique with respect to changes in the parameter that is being analyzed.

The CCV controller is more robust with respect to variations in

, specially in the case when the dominant time constant and dead time are almost equal, or even equal. The ratio between dead time and the dominant time constant

, is known as the uncontrollability parameter and when it is near 1, it is more difficult to control the process [

68]. Therefore, the CCV tuning method becomes a technique suitable for high values of such parameter. On the contrary, for low values of

, the CCV controller does not achieve the better results. With respect to

, the CCV and CCCC controllers are more robust; both with similar results. However, the latter gets better results for low values of

.

7. Conclusions

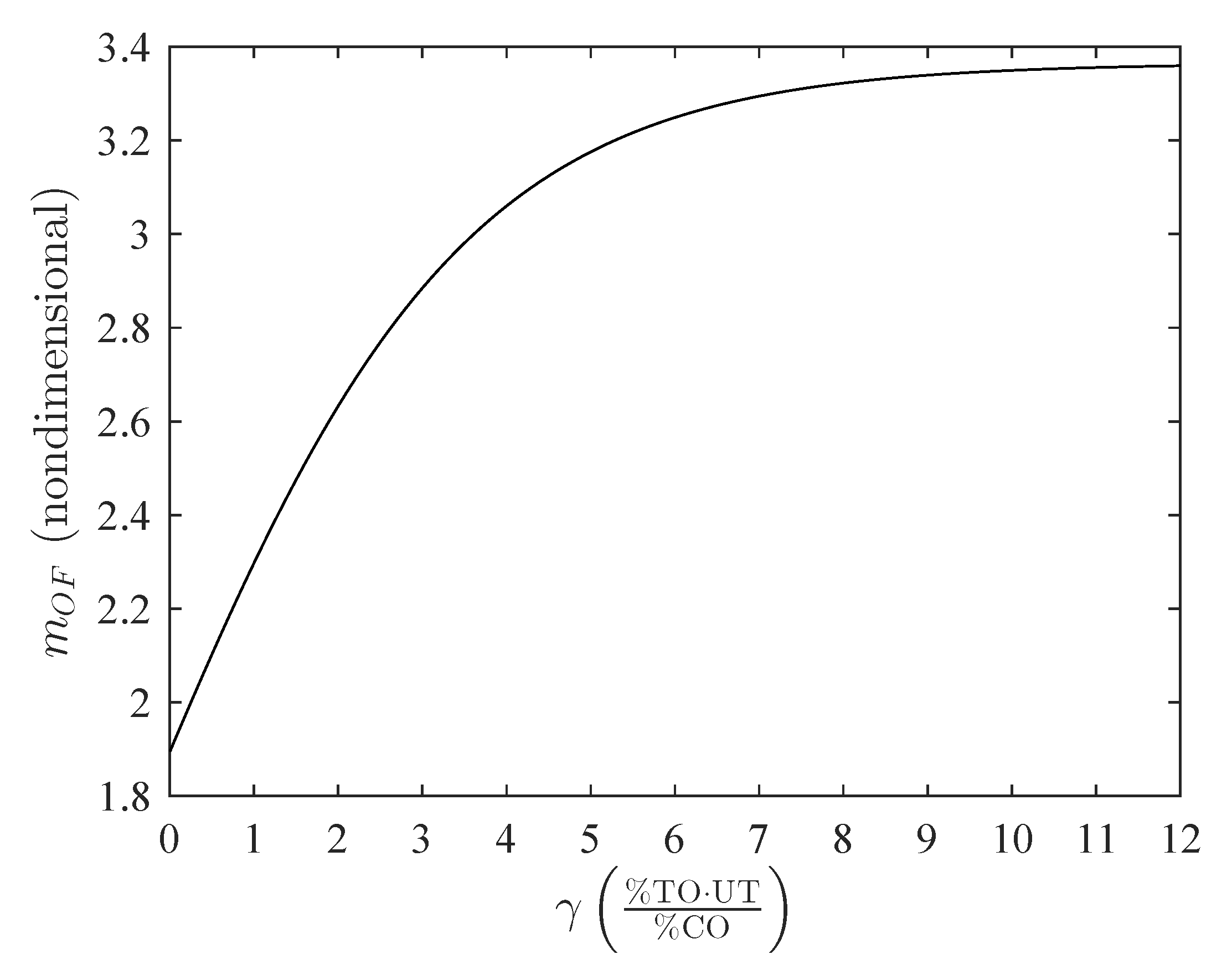

In this work, we proposed an IMC-based PID tuning method for inverse-response second-order plus dead time systems. The tuning rules are based on the optimization of an objective function that combines performance and robustness. The tuning method has been presented by using an easy-to-follow ten-step methodology with equations that are mathematically simple.

A correlation that allows one to compute the value of the tuning parameter that minimizes the objective function has been found. The tuning parameter , affects the stability of the closed-loop control system. Small values of increase the speed response of the system, but also produce an oscillatory response, to the point that the system can become unstable. Nondimensionalization reduced the number of parameters, which allows the reduction of simulations runs, saving computation time. The central composite experimental design allowed the authors to determine the appropriate number of simulations, and obtain goodness of fit for the proposed model.

The performance of a PID controller, tuned with the proposed CCV and other literature-existing tuning rules, was evaluated. The performance achieved with the proposed CCV method was excellent, not only for disturbance rejection but for set-point tracking, when considering a wide-range of parameters of the process’ transfer function. For both operations (servo and regulatory), the CCV method achieves the best performance in both the MP and IMV indexes, which indicates that this tuning method benefits the durability of the actuator. This is a very important result regarding continuous plant operation in industrial processes, since it can help avoiding unexpected plant stops caused by actuator failures.