A Laboratory Approach on the Hybrid-Enhanced Oil Recovery Techniques with Different Saline Brines in Sandstone Reservoirs

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Wettability Measurement

2.2.2. Interfacial Tension and Foam Stability Measurement

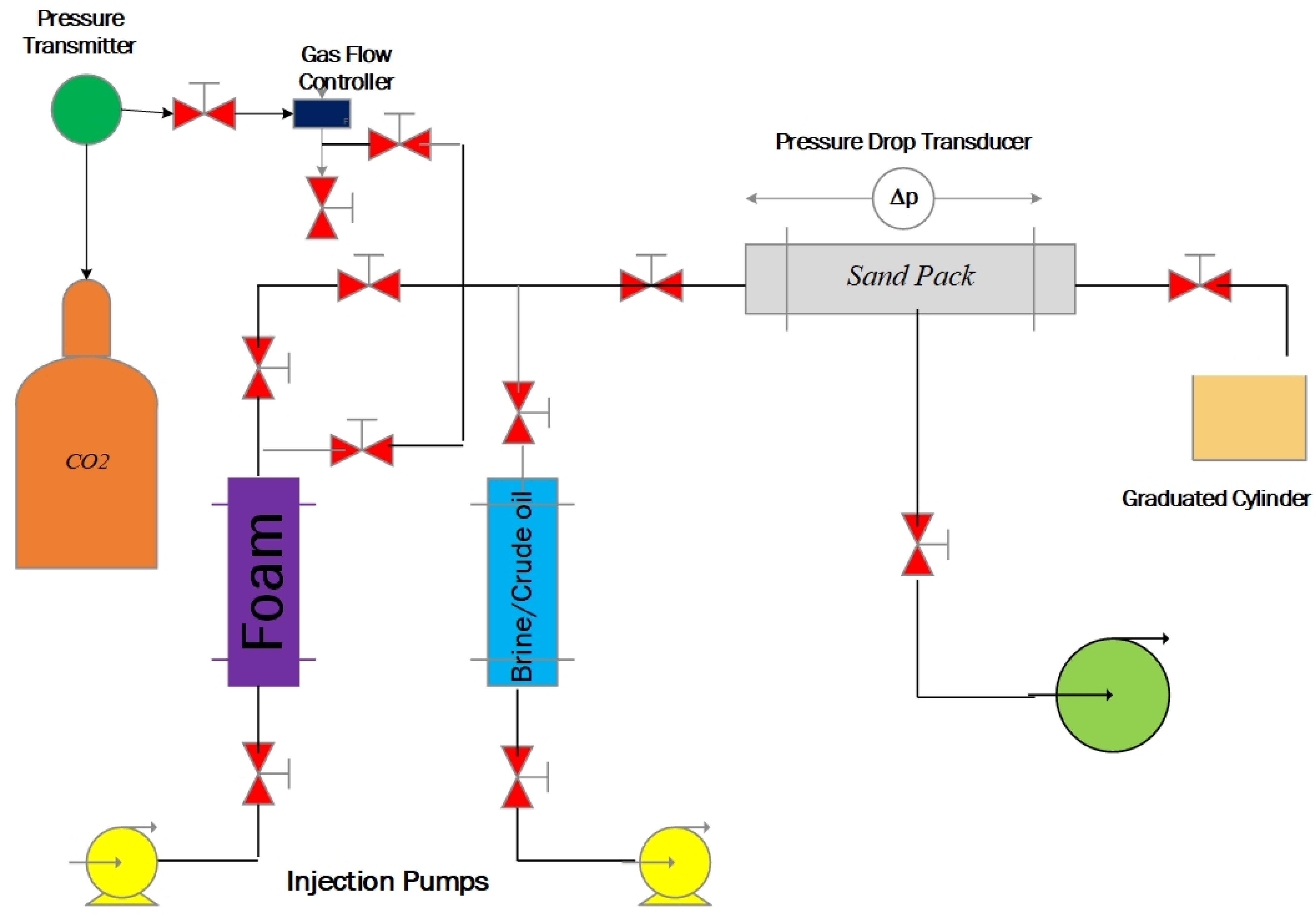

2.2.3. Core Flooding Procedure

3. Results and Discussion

3.1. Interfacial Tension

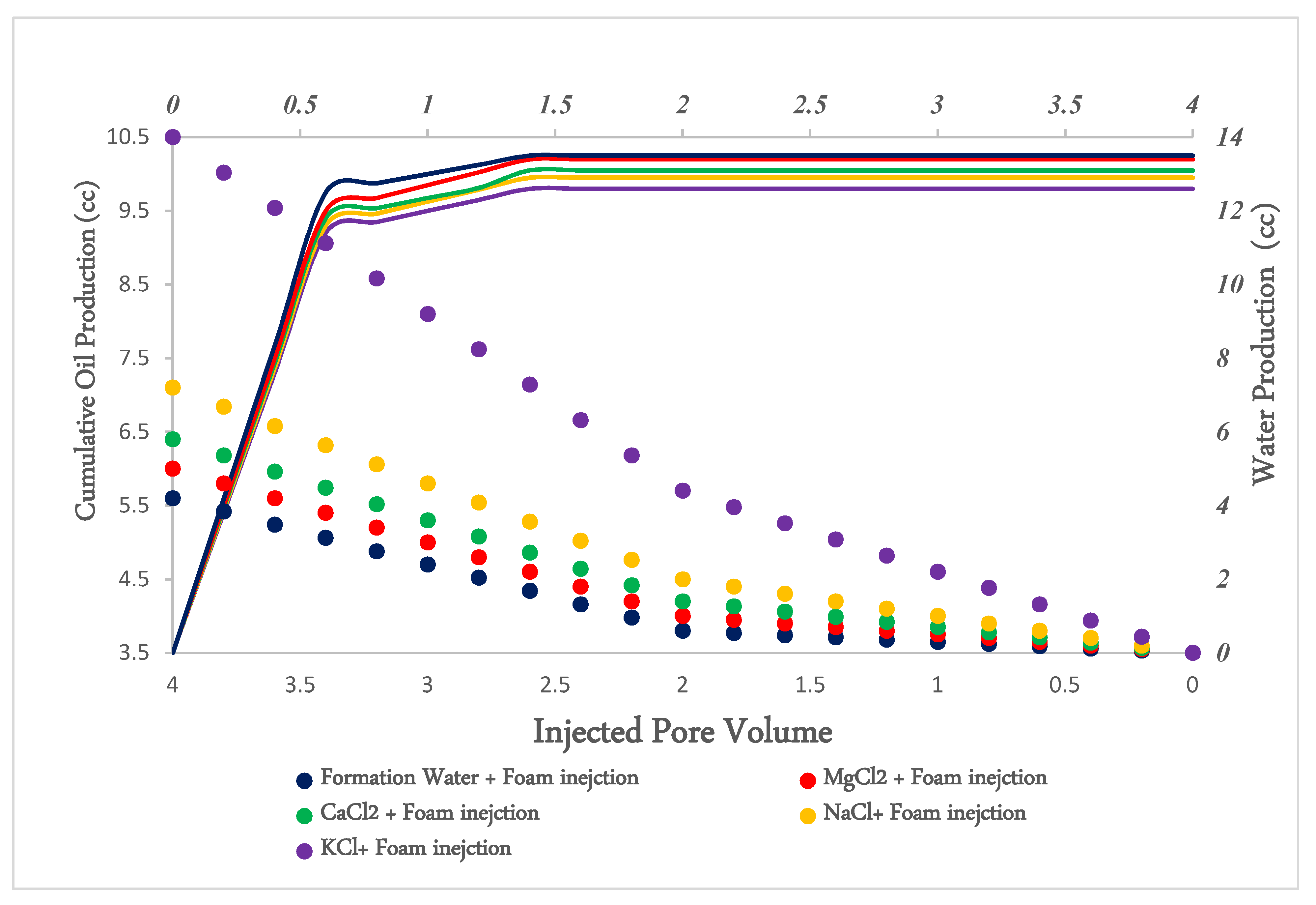

3.2. Cumulative Oil and Water Production

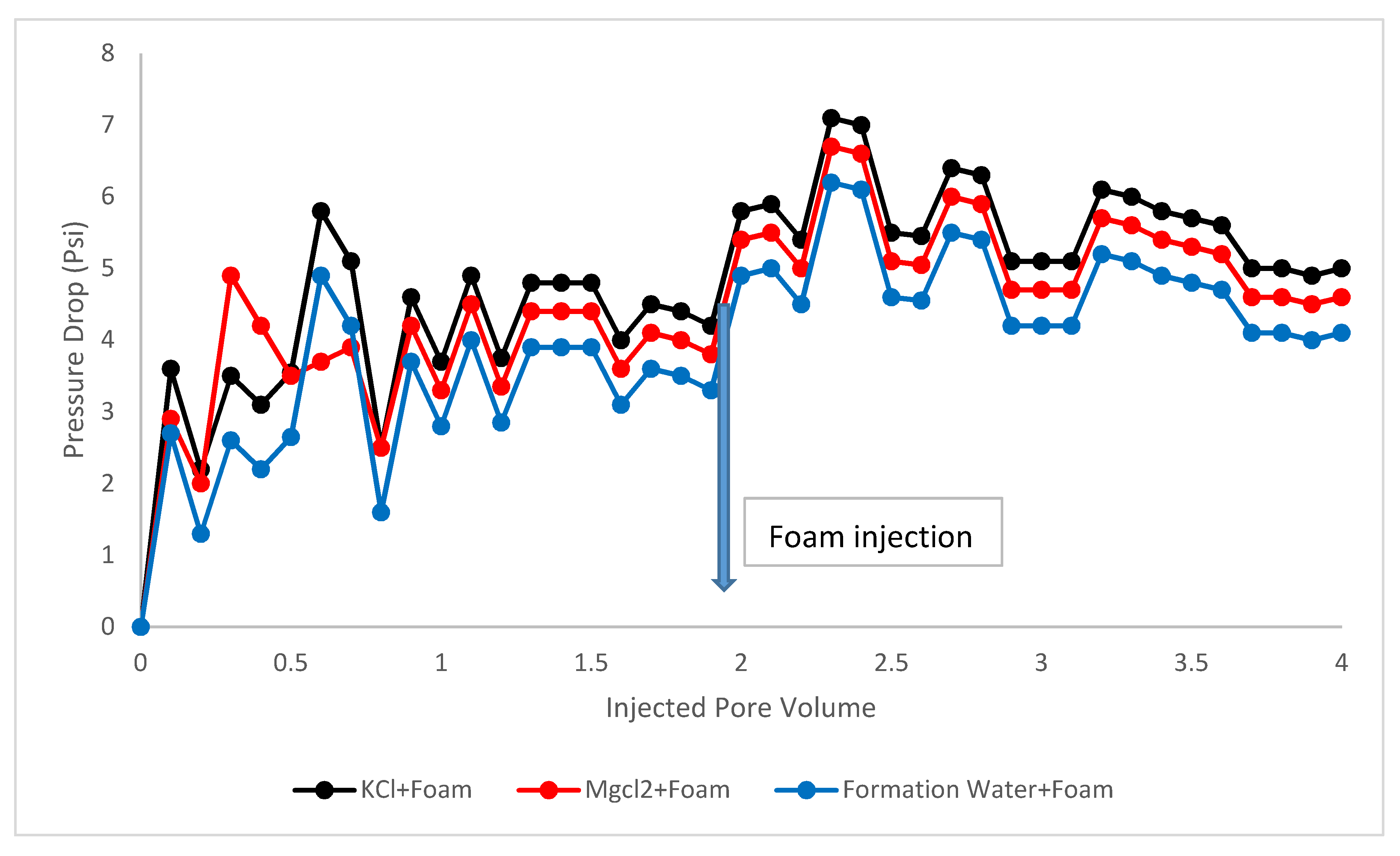

3.3. Pressure Drop

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lager, A.; Webb, K.J.; Black, C.J.J.; Singleton, M.; Sorbie, K.S. Low salinity oil recovery-an experimental investigation. Petrophysics 2008, 49, 28–35. [Google Scholar]

- Gao, Y.; Zhao, M.; Wang, J.; Zong, C. Performance and gas breakthrough during CO2 immiscible flooding in ultra-low permeability reservoirs. Pet. Explor. Dev. 2014, 41, 88–95. [Google Scholar] [CrossRef]

- Bartels, W.-B.; Mahani, H.; Berg, S.; Hassanizadeh, S. Literature review of low salinity waterflooding from a length and time scale perspective. Fuel 2019, 236, 338–353. [Google Scholar] [CrossRef]

- Takeya, M.; Shimokawara, M.; Elakneswaran, Y.; Nawa, T.; Takahashi, S. Predicting the electrokinetic properties of the crude oil/brine interface for enhanced oil recovery in low salinity water flooding. Fuel 2019, 235, 822–831. [Google Scholar] [CrossRef]

- Pan, F.; Zhang, Z.; Zhang, X.; Davarpanah, A. Impact of anionic and cationic surfactants interfacial tension on the oil recovery enhancement. Powder Technol. 2020, 373, 93–98. [Google Scholar] [CrossRef]

- Davarpanah, A. A feasible visual investigation for associative foam >\ polymer injectivity performances in the oil recovery enhancement. Eur. Polym. J. 2018, 105, 405–411. [Google Scholar] [CrossRef]

- Mahani, H.; Sorop, T.; Ligthelm, D.J.; Brooks, D.; Vledder, P.; Mozahem, F.; Ali, Y. Analysis of field responses to low-salinity waterflooding in secondary and tertiary mode in Syria. In Proceedings of the SPE Europec/EAGE Annual Conference and Exhibition, Vienna, Austria, 23–26 May 2011. [Google Scholar]

- Nasralla, R.A.; Alotaibi, M.B.; Nasr-El-Din, H.A. Efficiency of Oil Recovery by Low Salinity Water Flooding in Sandstone Reservoirs. In Proceedings of the SPE Western North American Region Meeting, Anchorage, AK, USA, 7–11 May 2011. [Google Scholar]

- Akai, T.; Blunt, M.J.; Bijeljic, B. Pore-scale numerical simulation of low salinity water flooding using the lattice Boltzmann method. J. Colloid Interface Sci. 2020, 566, 444–453. [Google Scholar] [CrossRef]

- Takeya, M.; Shimokawara, M.; Elakneswaran, Y.; Okano, H.; Nawa, T. Effect of Acid Number on the Electrokinetic Properties of Crude Oil during Low-Salinity Waterflooding. Energy Fuels 2019, 33, 4211–4218. [Google Scholar] [CrossRef]

- Haiyan, Z.; Davarpanah, A. Hybrid Chemical Enhanced Oil Recovery Techniques: A Simulation Study. Symmetry 2020, 12, 1086. [Google Scholar]

- Esfandyari, H.; Shadizadeh, S.R.; Esmaeilzadeh, F.; Davarpanah, A. Implications of anionic and natural surfactants to measure wettability alteration in EOR processes. Fuel 2020, 278, 118392. [Google Scholar] [CrossRef]

- McPhee, C.A.; Tehrani, A.D.H.; Jolly, R.P.S. Foam flooding of cores under North Sea reservoir conditions. In Proceedings of the SPE Enhanced Oil Recovery Symposium, Tulsa, OK, USA, 16–21 April 1988. [Google Scholar]

- Davarpanah, A.; Mirshekari, B. A mathematical model to evaluate the polymer flooding performances. Energy Rep. 2019, 5, 1651–1657. [Google Scholar] [CrossRef]

- Davarpanah, A.; Mirshekari, B. Mathematical modeling of injectivity damage with oil droplets in the waste produced water re-injection of the linear flow. Eur. Phys. J. Plus 2019, 134, 180. [Google Scholar] [CrossRef]

- Hu, X.; Xie, J.; Cai, W.; Wang, R.; Davarpanah, A. Thermodynamic effects of cycling carbon dioxide injectivity in shale reservoirs. J. Pet. Sci. Eng. 2020. [Google Scholar] [CrossRef]

- Schramm, L.L.; Wassmuth, F. Foams: Basic Principles; American Chemical Society: Washington, DC, USA, 1994; pp. 3–45. [Google Scholar]

- Wang, J.; Nguyen, N.-T.; Farrokhpay, S. A critical review of the growth, drainage and collapse of foams. Adv. Colloid Interface Sci. 2016, 228, 55–70. [Google Scholar] [CrossRef]

- Stevenson, P. Foam Engineering: Fundamentals and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Yu, X.; Jiang, N.; Miao, X.; Li, F.; Wang, J.; Zong, R.; Lu, S. Comparative studies on foam stability, oil-film interaction and fire extinguishing performance for fluorine-free and fluorinated foams. Process Saf. Environ. Prot. 2020, 133, 201–215. [Google Scholar] [CrossRef]

- Lu, W.; Davarpanah, A. An experimental investigation to consider thermal methods efficiency on oil recovery enhancement. Heat Transf. 2020, 49, 3066–3074. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, H.; Song, M.; Huang, J. Marangoni effect on microbubbles emission boiling generation during pool boiling of self-rewetting fluid. Int. J. Heat Mass Transf. 2019, 134, 10–16. [Google Scholar] [CrossRef]

- Ezquerro, J.; Sánchez, P.S.; Bello, A.; Rodríguez, J.; Lapuerta, V.; Laveron-Simavilla, A. Experimental evidence of thermocapillarity in phase change materials in microgravity: Measuring the effect of Marangoni convection in solid/liquid phase transitions. Int. Commun. Heat Mass Transf. 2020, 113, 104529. [Google Scholar] [CrossRef]

- Abir, F.M.; Barua, S.; Barua, S.; Saha, S. Numerical analysis of Marangoni effect on natural convection in two-layer fluid structure inside a two-dimensional rectangular cavity. In Proceedings of the 8th BSME International Conference on Thermal Engineering, Dhaka, Bangladesh, 19–21 December 2018. [Google Scholar]

- Davarpanah, A.; Mirshekari, B. Numerical simulation and laboratory evaluation of alkali–surfactant–polymer and foam flooding. Int. J. Environ. Sci. Technol. 2019, 17, 1123–1136. [Google Scholar] [CrossRef]

- Boinovich, L.B. Boundary layers and surface forces in pure non-aqueous liquids. Curr. Opin. Colloid Interface Sci. 2019, 44, 85–93. [Google Scholar] [CrossRef]

- Ma, T.; Zhou, L.; Du, X.; Yang, Y. Simultaneous measurements of thin film thickness using total internal reflection fluorescence microscopy and disjoining pressure using Scheludko cell. Rev. Sci. Instrum. 2019, 90, 045118. [Google Scholar] [CrossRef] [PubMed]

- Zeng, L.; Chen, Y.; Lu, Y.; Lau, H.C.; Hossain, M.; Saeedi, A.; Xie, Q. Interpreting Water Uptake by Shale with Ion Exchange, Surface Complexation, and Disjoining Pressure. Energy Fuels 2019, 33, 8250–8258. [Google Scholar] [CrossRef]

- Skauge, A.; Solbakken, J.; Ormehaug, P.A.; Aarra, M.G. Foam Generation, Propagation and Stability in Porous Medium. Transp. Porous Media 2019, 131, 5–21. [Google Scholar] [CrossRef]

- Li, Q.; Prigiobbe, V. Studying the generation of foam in the presence of nanoparticles using a microfluidic system. Chem. Eng. Sci. 2020, 215, 115427. [Google Scholar] [CrossRef]

- Asiaei, S.; Zadehkafi, A.; Siavashi, M. Multi-layered Porous Foam Effects on Heat Transfer and Entropy Generation of Nanofluid Mixed Convection Inside a Two-Sided Lid-Driven Enclosure with Internal Heating. Transp. Porous Media 2018, 126, 223–247. [Google Scholar] [CrossRef]

- Sheng, J.J. Enhanced Oil Recovery Field Case Studies; Gulf Professional Publishing: Houston, TX, USA, 2013. [Google Scholar]

- Osei-Bonsu, K.; Shokri, N.; Grassia, P. Foam stability in the presence and absence of hydrocarbons: From bubble- to bulk-scale. Colloids Surf. Physicochem. Eng. Asp. 2015, 481, 514–526. [Google Scholar] [CrossRef]

- Soltanian, M.R.; Hajirezaie, S.; Hosseini, S.A.; Dashtian, H.; Amooie, M.A.; Meyal, A.; Ershadnia, R.; Ampomah, W.; Islam, A.; Zhang, X. Multicomponent reactive transport of carbon dioxide in fluvial heterogeneous aquifers. J. Nat. Gas Sci. Eng. 2019, 65, 212–223. [Google Scholar] [CrossRef]

- Dashtian, H.; Shokri, N.; Sahimi, M. Pore-network model of evaporation-induced salt precipitation in porous media: The effect of correlations and heterogeneity. Adv. Water Resour. 2018, 112, 59–71. [Google Scholar] [CrossRef]

- Nell, M. Oil Foam Interaction: Simulation of Foam Displacement with Oil. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2015. [Google Scholar]

- Khanamiri, H.H.; Enge, I.B.; Nourani, M.; Stensen, J.Å.; Torsæter, O.; Hadia, N. EOR by Low Salinity Water and Surfactant at Low Concentration: Impact of Injection and in Situ Brine Composition. Energy Fuels 2016, 30, 2705–2713. [Google Scholar] [CrossRef]

- Dang, C.; Nghiem, L.; Fedutenko, E.; Gorucu, S.E.; Yang, C.; Mirzabozorg, A.; Nguyen, N.; Chen, Z.; Gorocu, S.E. AI based mechanistic modeling and probabilistic forecasting of hybrid low salinity chemical flooding. Fuel 2020, 261, 116445. [Google Scholar] [CrossRef]

- Bakhshian, S.; Rabbani, H.S.; Hosseini, S.A.; Shokri, N. New Insights into Complex Interactions Between Heterogeneity and Wettability Influencing Two-Phase Flow in Porous Media. Geophys. Res. Lett. 2020, 47, e2020GL088187. [Google Scholar] [CrossRef]

- Feng, D.; Wu, K.; Bakhshian, S.; Hosseini, S.A.; Li, J.; Li, X. Nanoconfinement Effect on Surface Tension: Perspectives from Molecular Potential Theory. Langmuir 2020. [Google Scholar] [CrossRef] [PubMed]

- Awolayo, A.N.; Sarma, H.; Nghiem, L.X. Brine-Dependent Recovery Processes in Carbonate and Sandstone Petroleum Reservoirs: Review of Laboratory-Field Studies, Interfacial Mechanisms and Modeling Attempts. Energies 2018, 11, 3020. [Google Scholar] [CrossRef]

- Jackson, M.; Vinogradov, J.; Hamon, G.; Chamerois, M. Evidence, mechanisms and improved understanding of controlled salinity waterflooding part 1: Sandstones. Fuel 2016, 185, 772–793. [Google Scholar] [CrossRef]

- Hu, X.; Li, M.; Peng, C.; Davarpanah, A. Hybrid Thermal-Chemical Enhanced Oil Recovery Methods; An Experimental Study for Tight Reservoirs. Symmetry 2020, 12, 947. [Google Scholar] [CrossRef]

- Shabib-Asl, A.; Ayoub, M.; Elraies, K.A. Laboratory Investigation into Wettability Alteration by different Low Salinity Water Compositions in Sandstone Rock. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Nusa Dua, Indonesia, 20–22 October 2015. [Google Scholar]

| Brine Type | TDS (mg/L) | pH (25 ) | pH (85 ) | Density (25 ) g/cm3 | Density (85 ) g/cm3 |

|---|---|---|---|---|---|

| KCl | 1000–6000 | 6.6–6.9 | 6.5–6.8 | 1–1.0045 | 0.985–0.99 |

| MgCl2 | 1000–6000 | 6.8–7.1 | 6.65–7 | 0.95–1 | 0.98–0.985 |

| CaCl2 | 1000–6000 | 6.7–7.1 | 6.5–7 | 1.0002–1.003 | 0.98–0.985 |

| NaCl | 1000–6000 | 6.21–6.68 | 6.12–6.53 | 1–1.0025 | 0.975–0.98 |

| Formation Brine | 120,000 | 7.2 | 7.05 | 1.025 | 0.98 |

| Parameter | KCL + Foam | MgCl2 + Foam | Formation brine + Foam |

|---|---|---|---|

| Initial oil saturation | 0.840 | 0.841 | 0.832 |

| Initial water saturation | 0.160 | 0.158 | 0.161 |

| Residual oil saturation | 0.58 | 0.58 | 0.58 |

| Oil recovery (%) | 63.14 | 41.21 | 36.51 |

| Original oil in place (%) | 77.5 | 50.34 | 42.7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Y.; Cheng, Q.; Yang, J.; Zhang, L.; Davarpanah, A. A Laboratory Approach on the Hybrid-Enhanced Oil Recovery Techniques with Different Saline Brines in Sandstone Reservoirs. Processes 2020, 8, 1051. https://doi.org/10.3390/pr8091051

Hu Y, Cheng Q, Yang J, Zhang L, Davarpanah A. A Laboratory Approach on the Hybrid-Enhanced Oil Recovery Techniques with Different Saline Brines in Sandstone Reservoirs. Processes. 2020; 8(9):1051. https://doi.org/10.3390/pr8091051

Chicago/Turabian StyleHu, Yisheng, Qiurong Cheng, Jinping Yang, Lifeng Zhang, and Afshin Davarpanah. 2020. "A Laboratory Approach on the Hybrid-Enhanced Oil Recovery Techniques with Different Saline Brines in Sandstone Reservoirs" Processes 8, no. 9: 1051. https://doi.org/10.3390/pr8091051

APA StyleHu, Y., Cheng, Q., Yang, J., Zhang, L., & Davarpanah, A. (2020). A Laboratory Approach on the Hybrid-Enhanced Oil Recovery Techniques with Different Saline Brines in Sandstone Reservoirs. Processes, 8(9), 1051. https://doi.org/10.3390/pr8091051