Evaluation of Water Hammer for Seawater Treatment System in Offshore Floating Production Unit

Abstract

1. Introduction

2. Mathematical Model

- Homogeneous fluid;

- Linearly elastic fluid and pipe wall;

- One-dimensional flow;

- Longitudinal stresses (Poisson’s effect) are neglected;

- Inertia of the pipe is neglected.

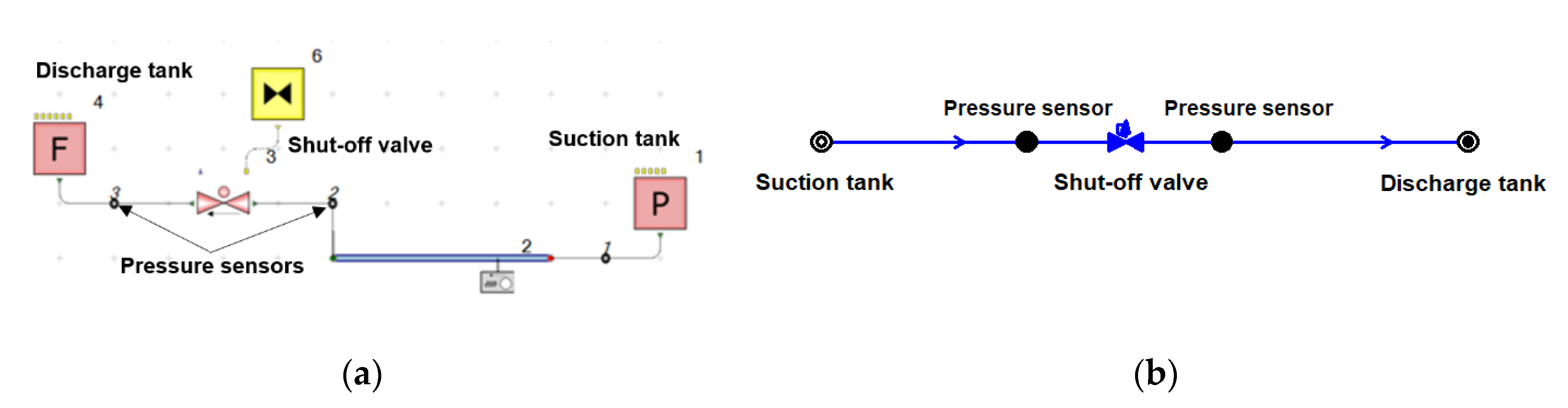

3. Validation of the 1D Simulation Model

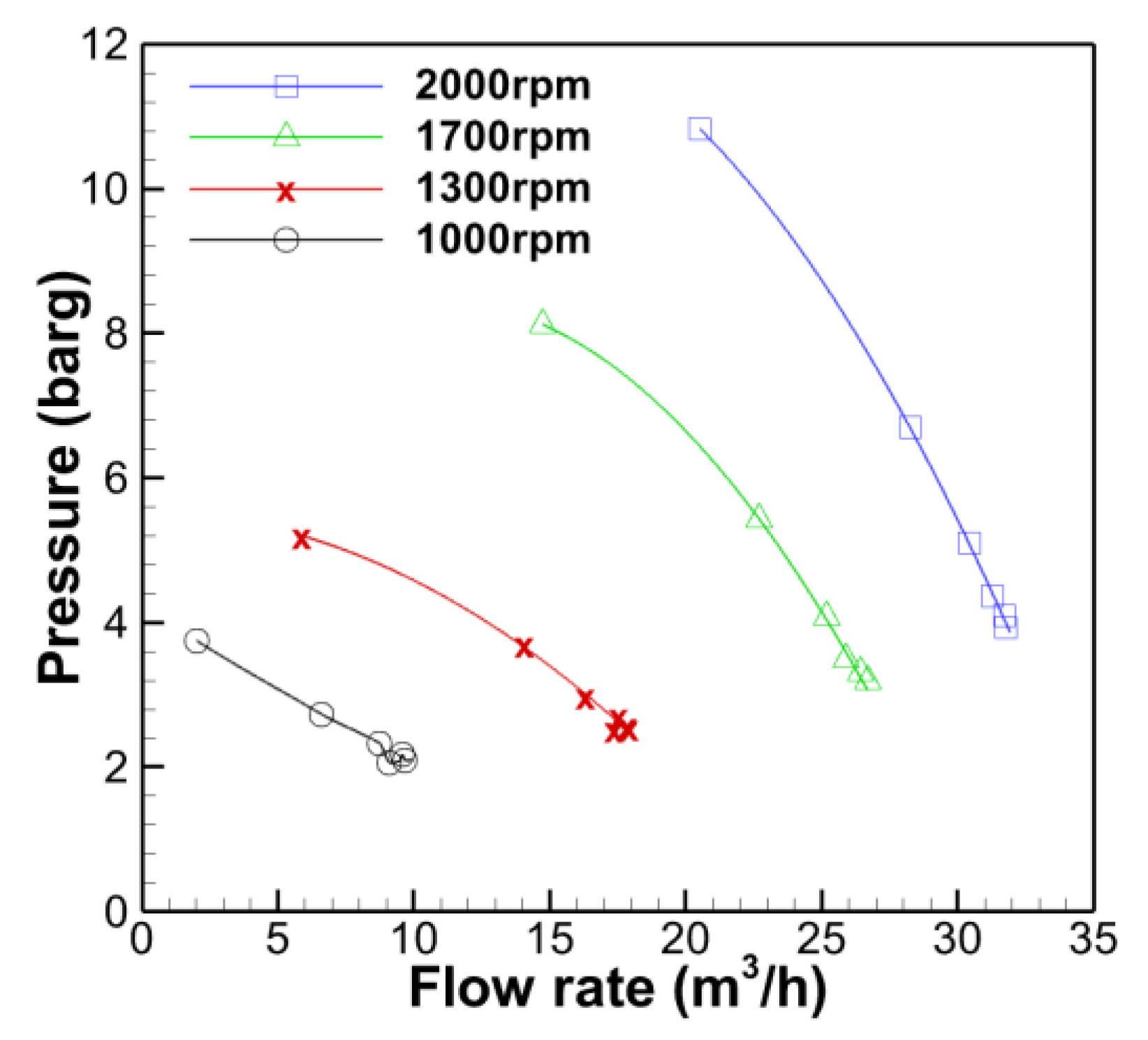

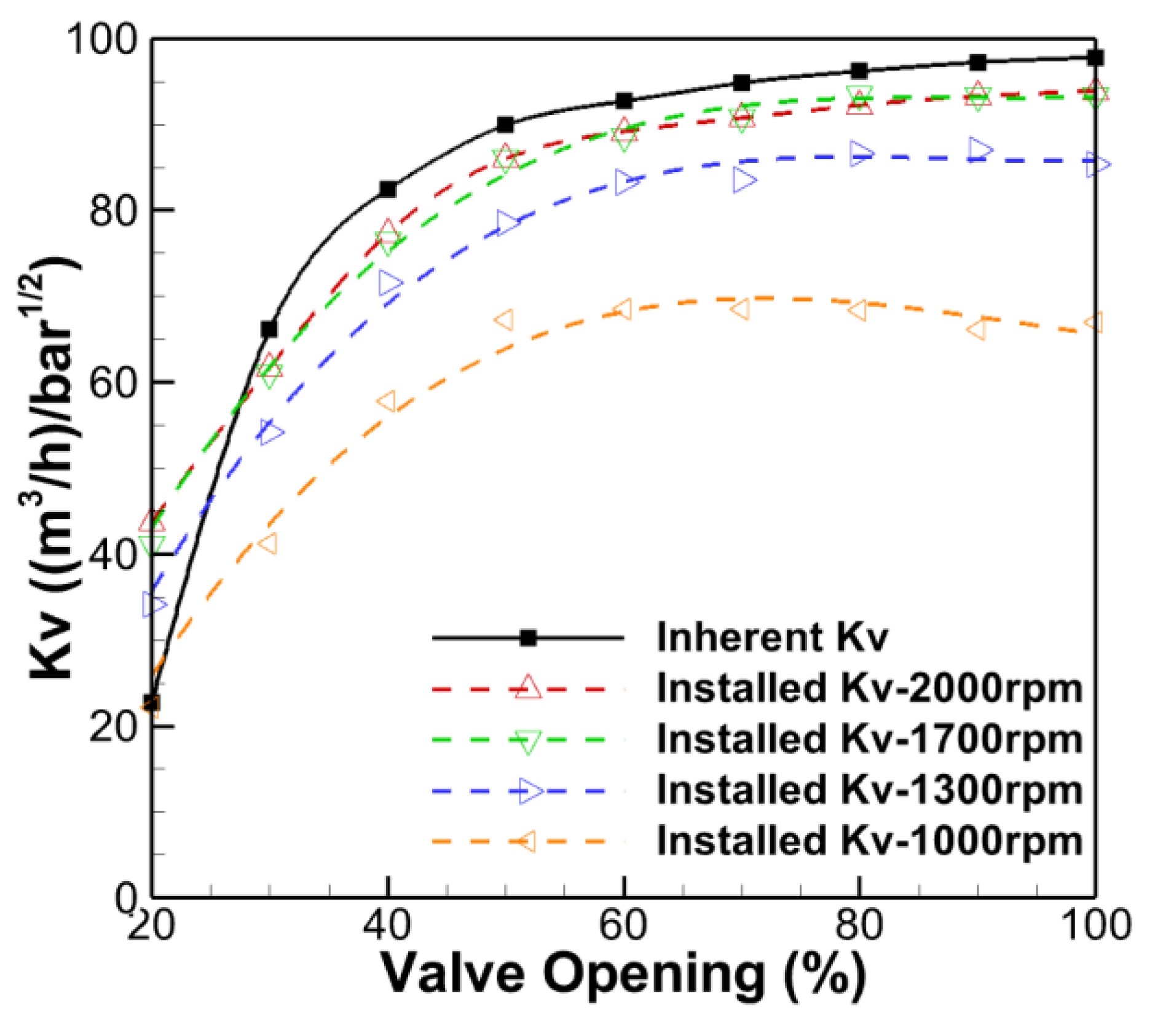

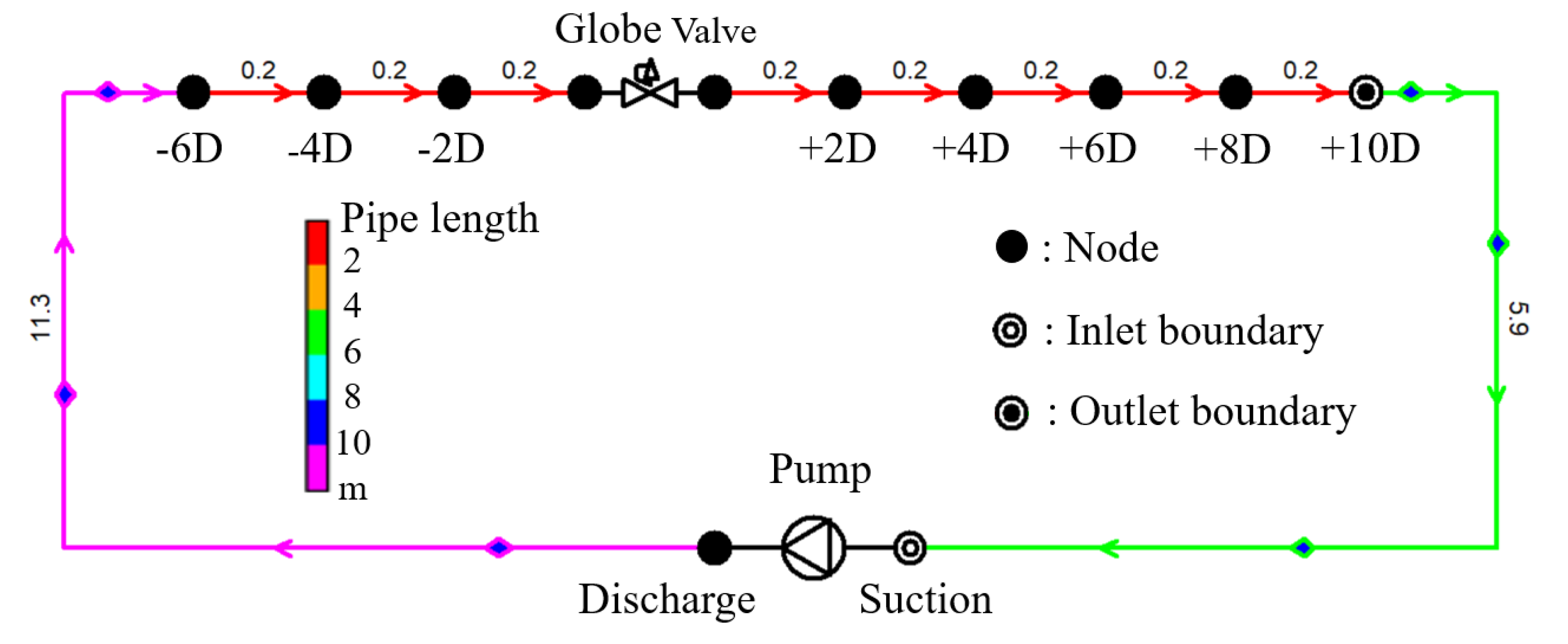

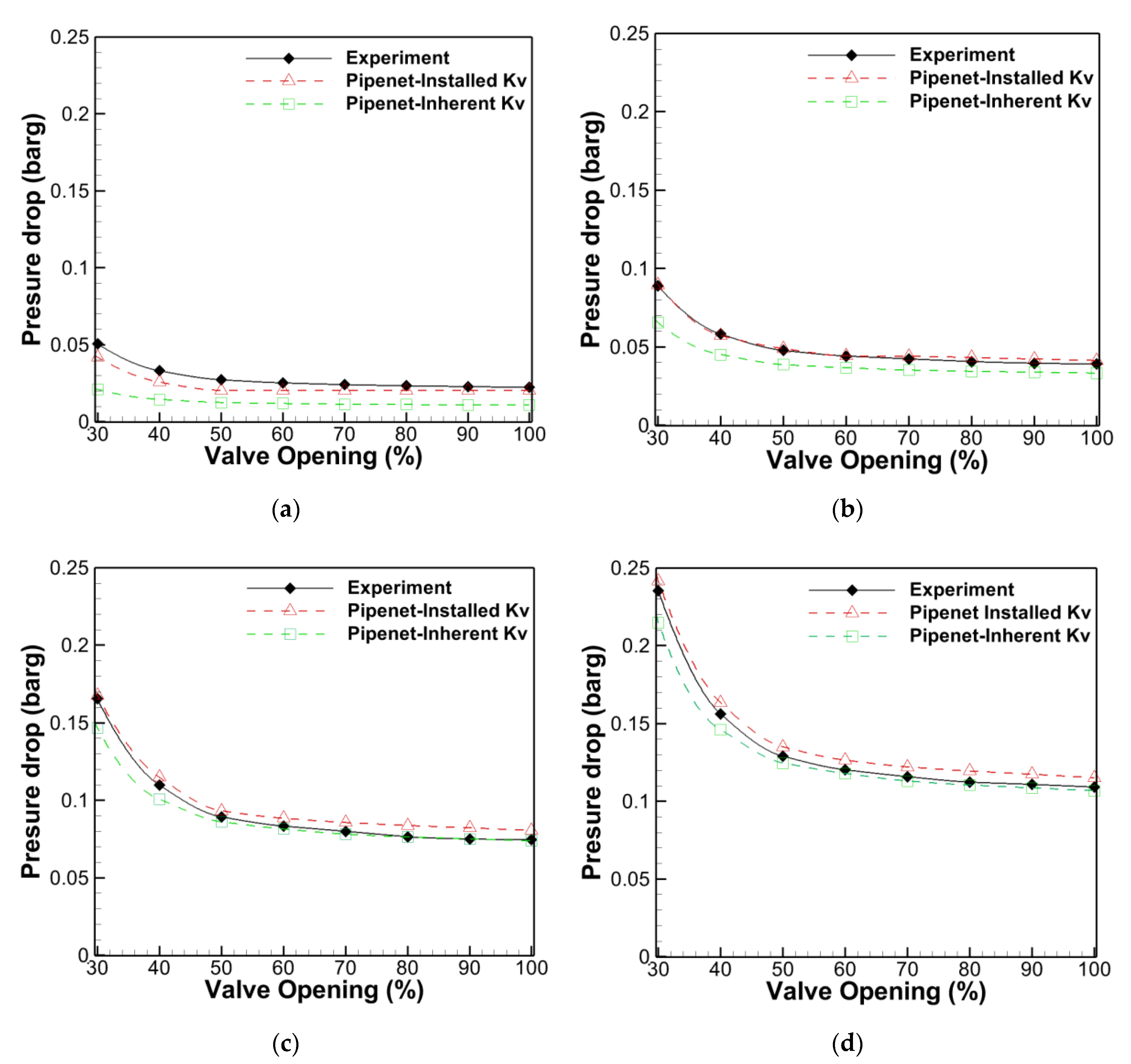

3.1. Validation for the 1D Steady State Simulation Model

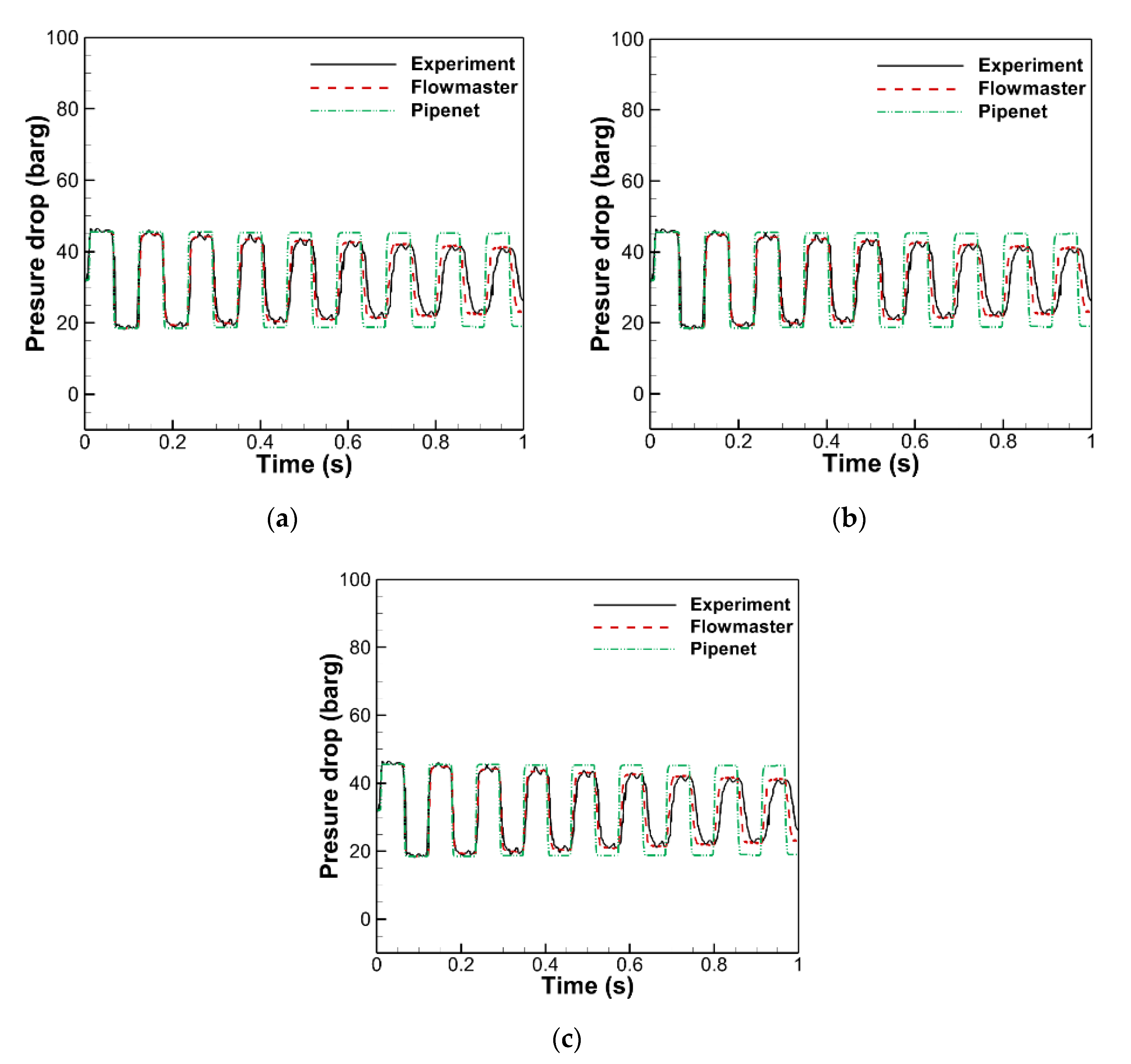

3.2. Validation for 1D Transient Analysis

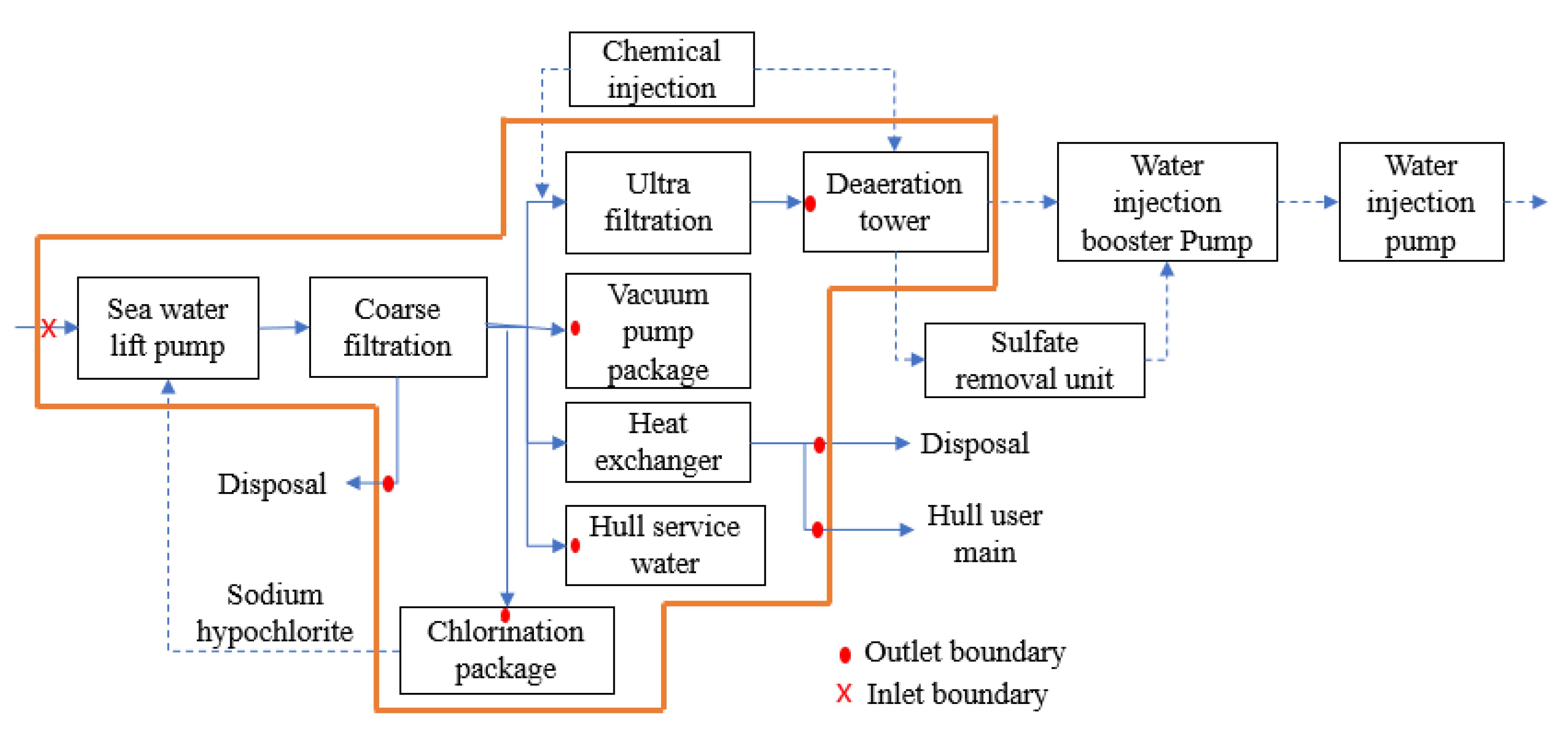

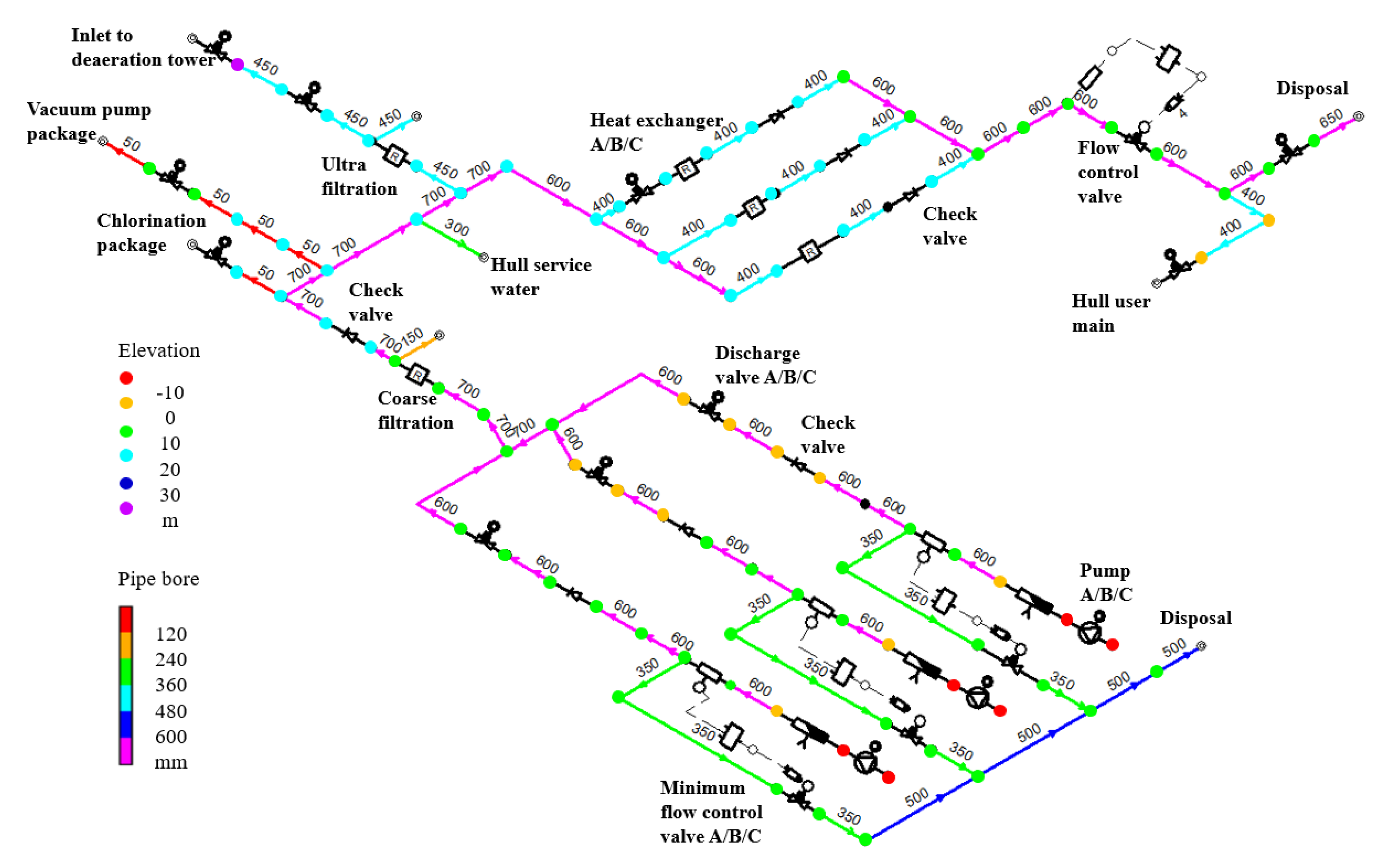

4. Case Study: Seawater Treatment System

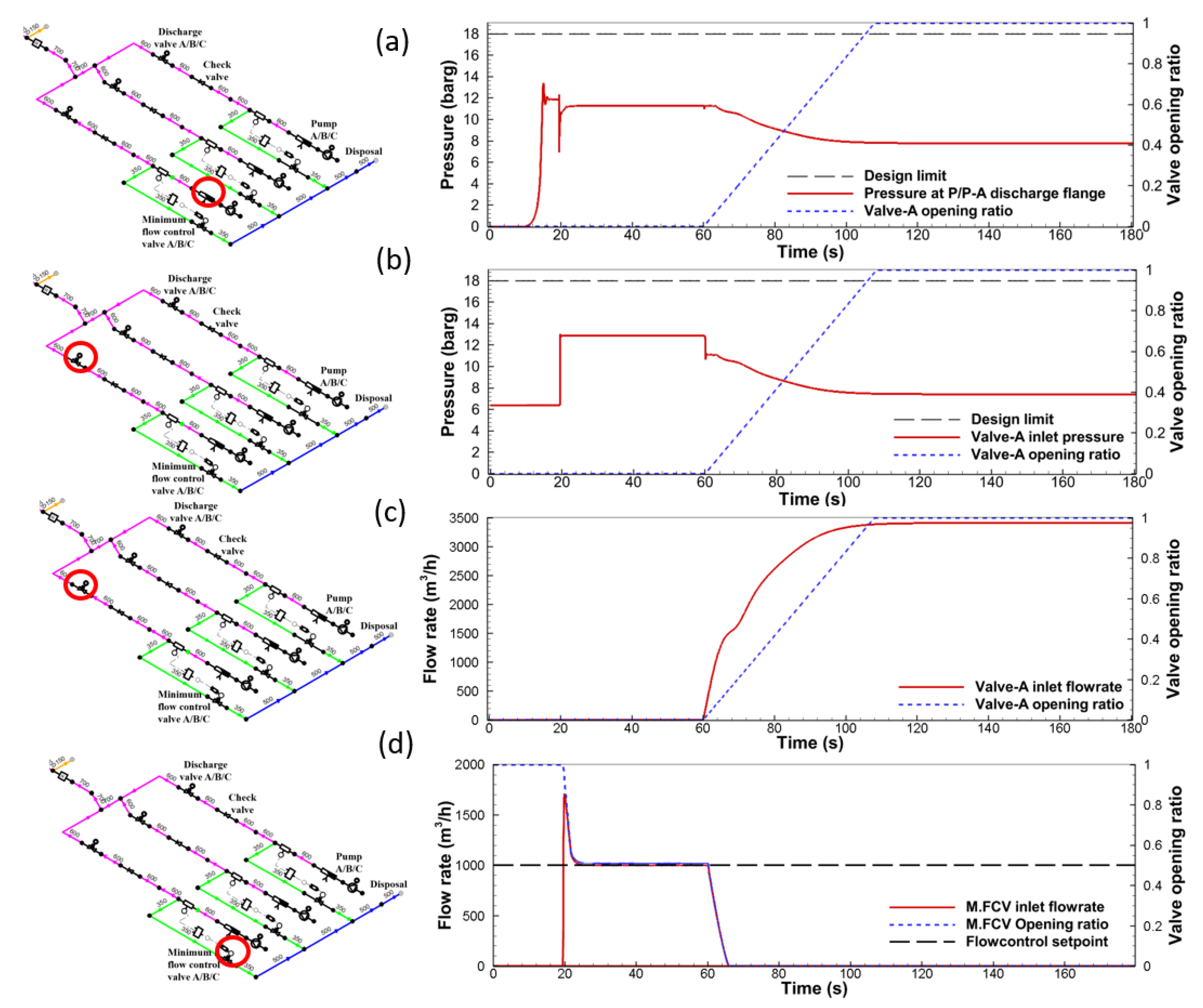

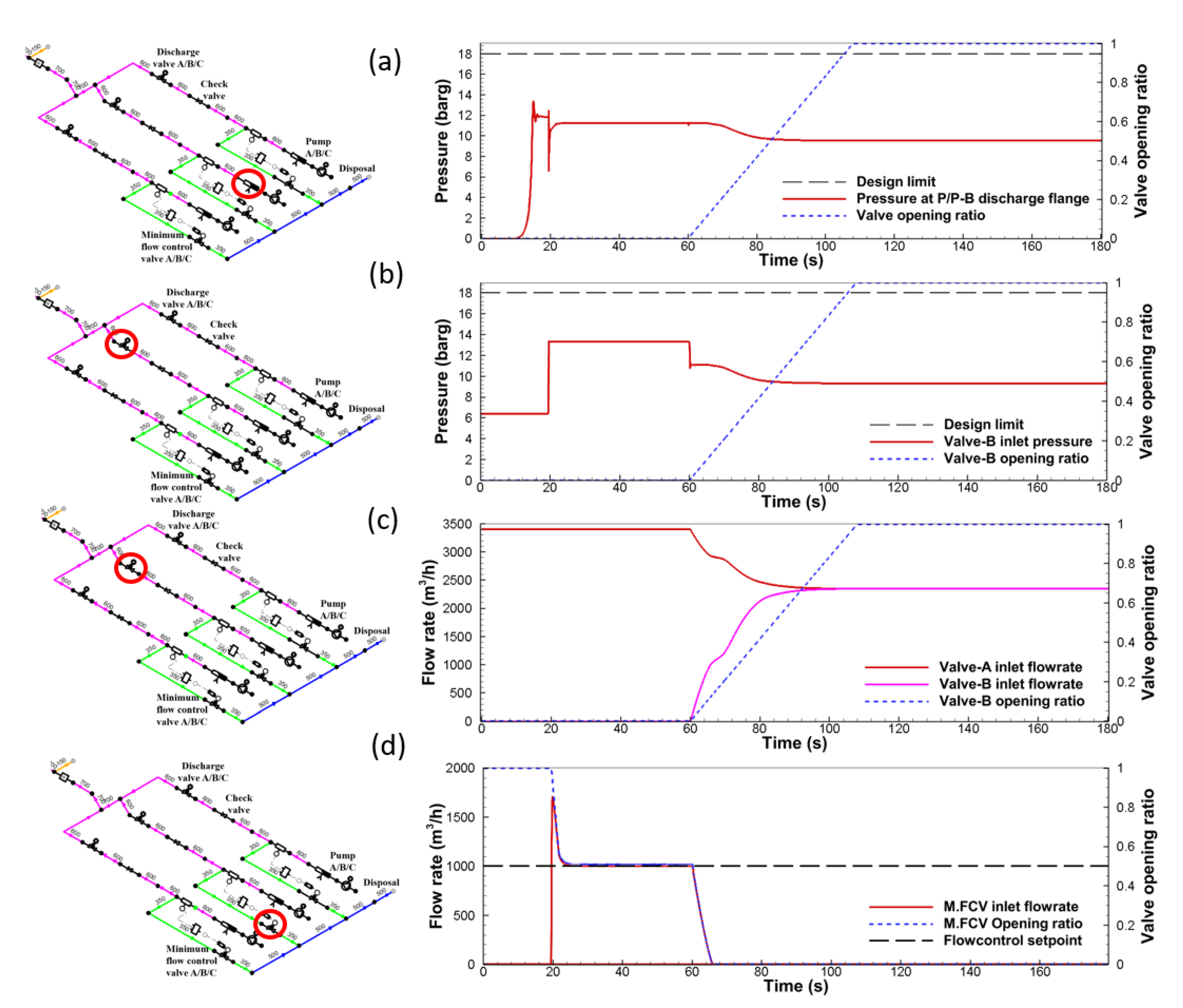

4.1. Operating Scenario 1: Pump A Start-Up Followed by Pump B Start-Up

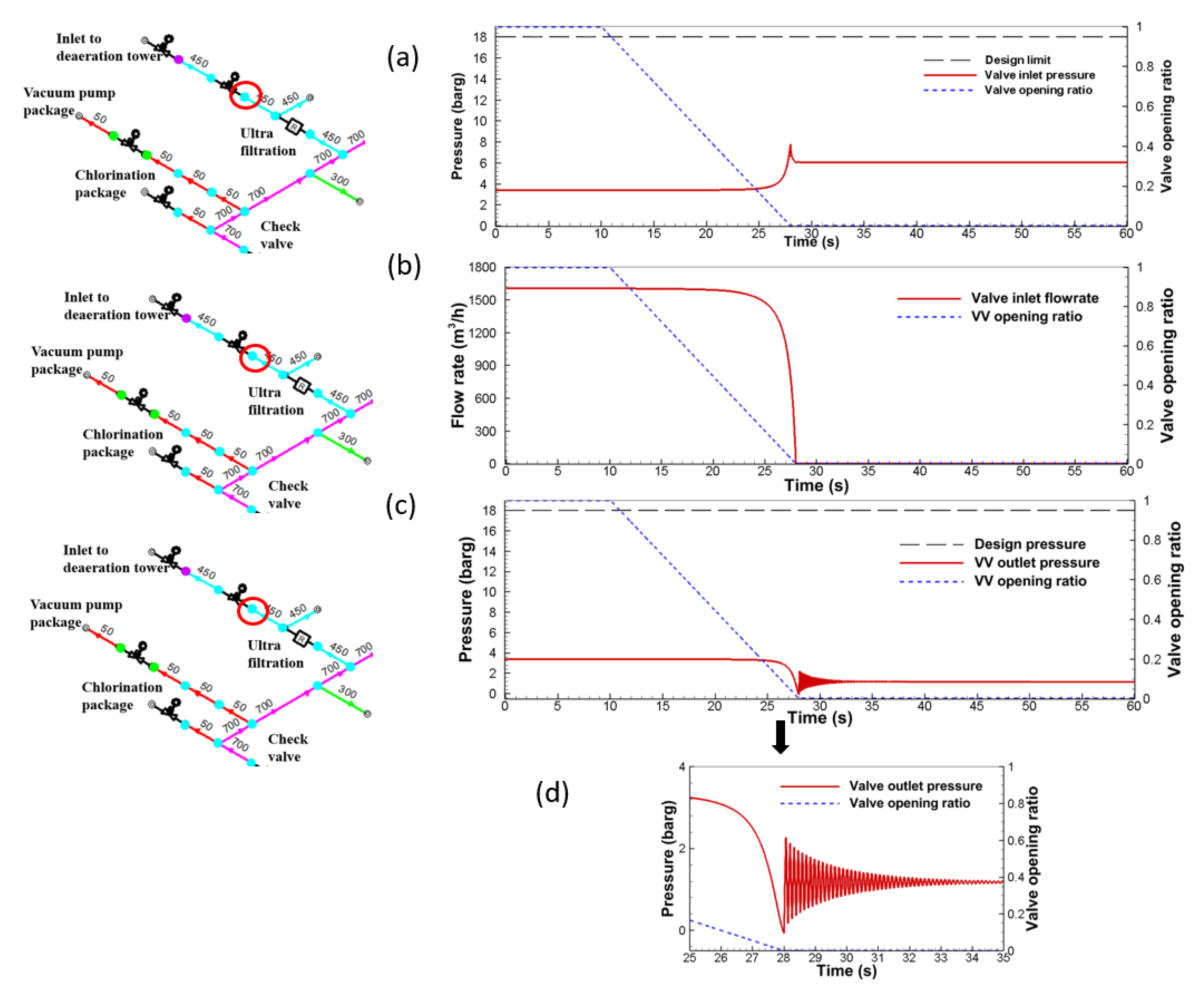

4.2. Operating Scenarios 2: Valve Closure—Deaeration Tower Inlet

4.3. Operating Scenario 3: Valve Closure—Hull Seawater System Inlet

4.4. Parametric Study on Scenario 2

5. Results and Discussion

5.1. Result of Scenario 1: Pump A Start-Up Followed by Pump B Start-Up

5.2. Result of Scenario 2: Valve Closure—Deaeration Tower Inlet

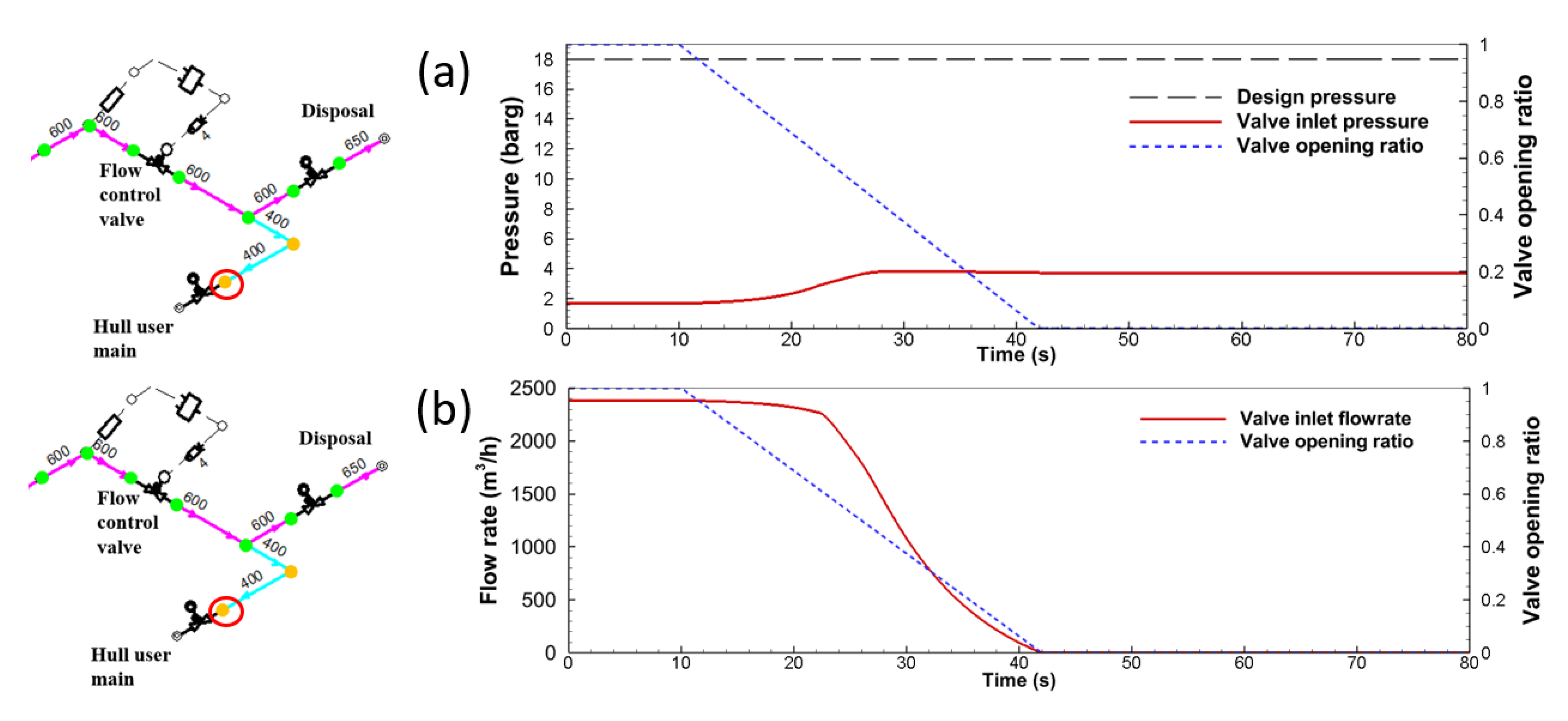

5.3. Result of Scenario 3: Valve Closure—Hull Seawater System Inlet

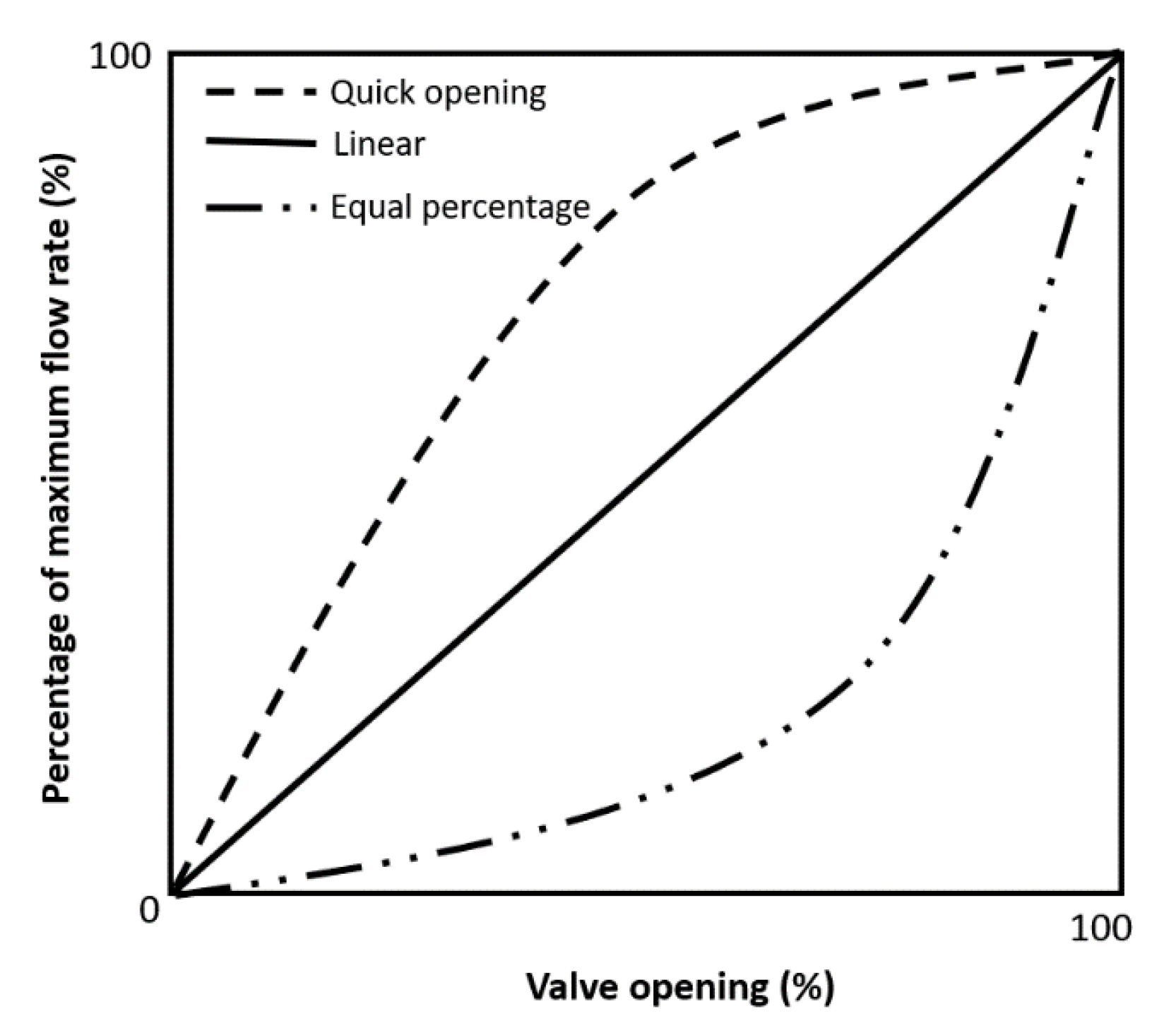

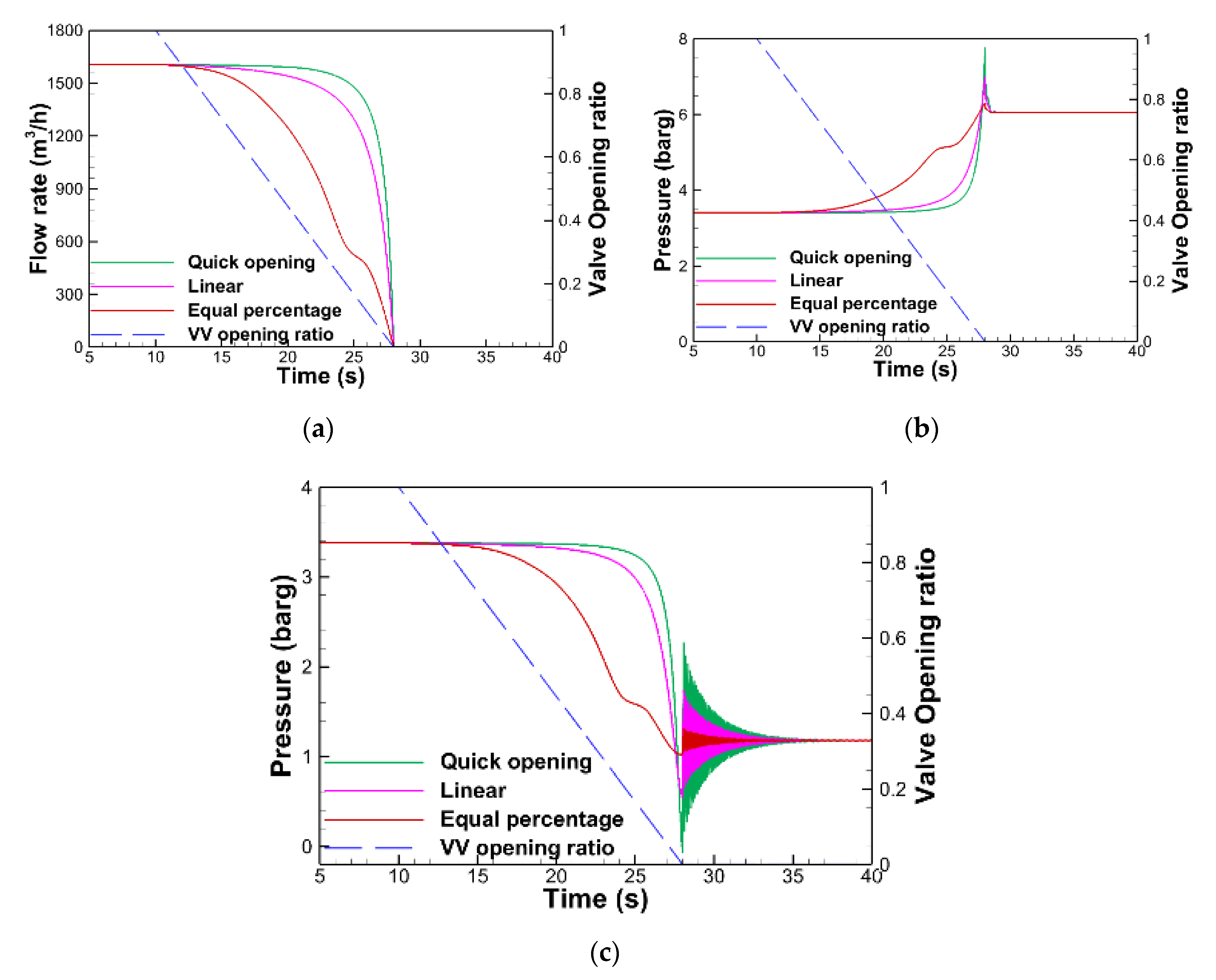

5.4. Effect of Valve Flow Characteristics

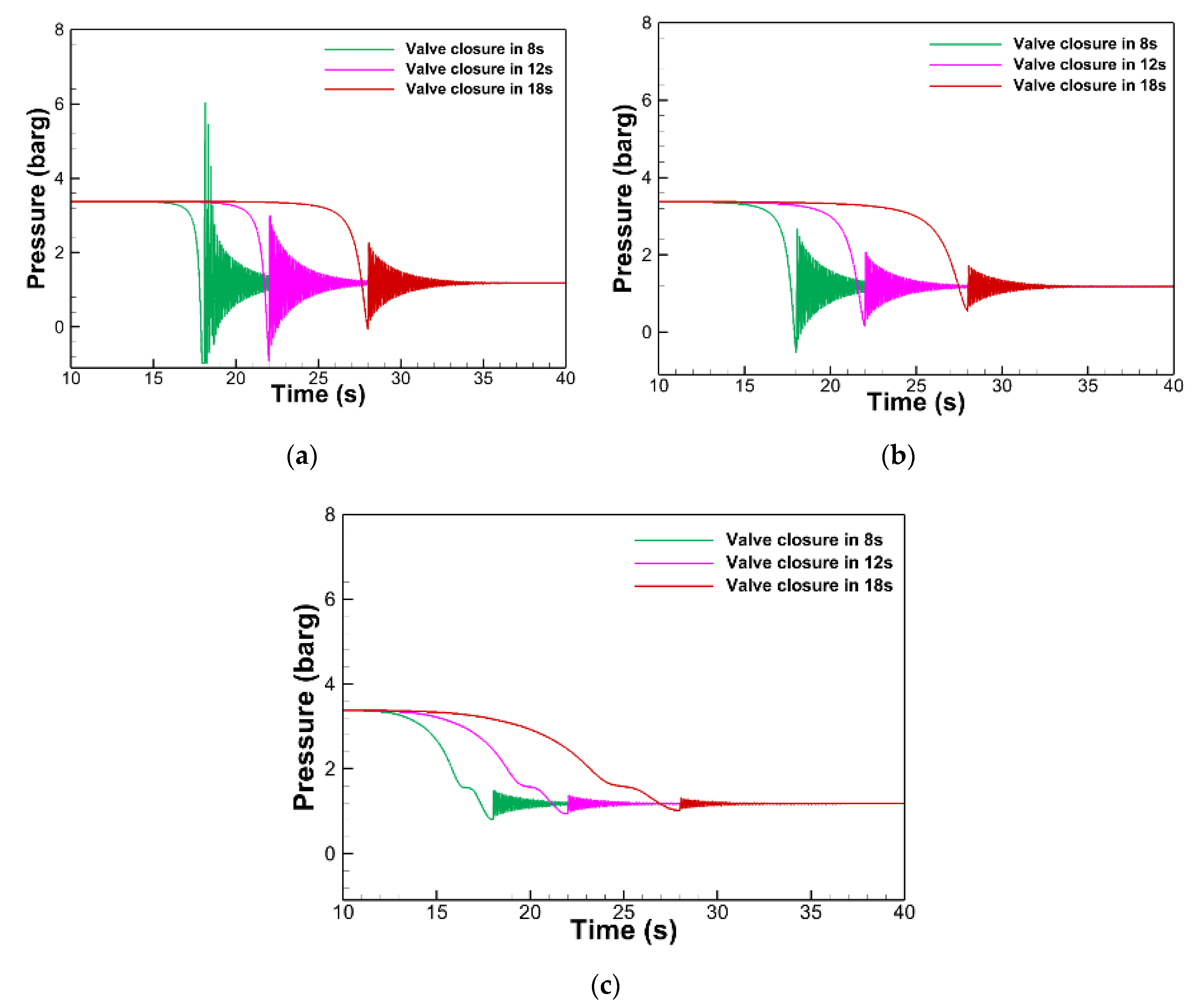

5.5. Effect of Valve Closure Time

6. Conclusions

- The 1D simulation model based on MOC could predict the pressure drop through the valve well using the inherent flow coefficient at a high Reynold number. If the installed flow coefficient could be provided for the real piping system, the results might be more accurate for whole regions of the pump speed. Furthermore, the simulation could estimate the surge pressure well until at least the second pressure peak. Moreover, this model with its quasi-steady friction term is likely to efficiently evaluate the maximum surge pressure caused by water hammer.

- The case study was performed for various scenarios of pump start-up and valve closure in the seawater treatment system. In the case of pump start-up (Case 1), a slight pressure increase was observed at the inlet of the discharge valve, but the predicted pressure was lower than the design pressure of the pipe. When the valve at the system inlet closed (Case 3), noticeable pressure increases did not occur because another branch of disposal pipe allowed the flow rate.

- However, pressure oscillations were observed downstream from the valve when the valve of the inlet part closed (Case 2). The pressure oscillation might be caused by air pockets entrapped at the valve outlet when the valve was rapidly closed. The amplitude of the oscillation was less than the design pressure of the piping system, but it may cause a severe damage to the system by vibration or making the flow efficiency worse.

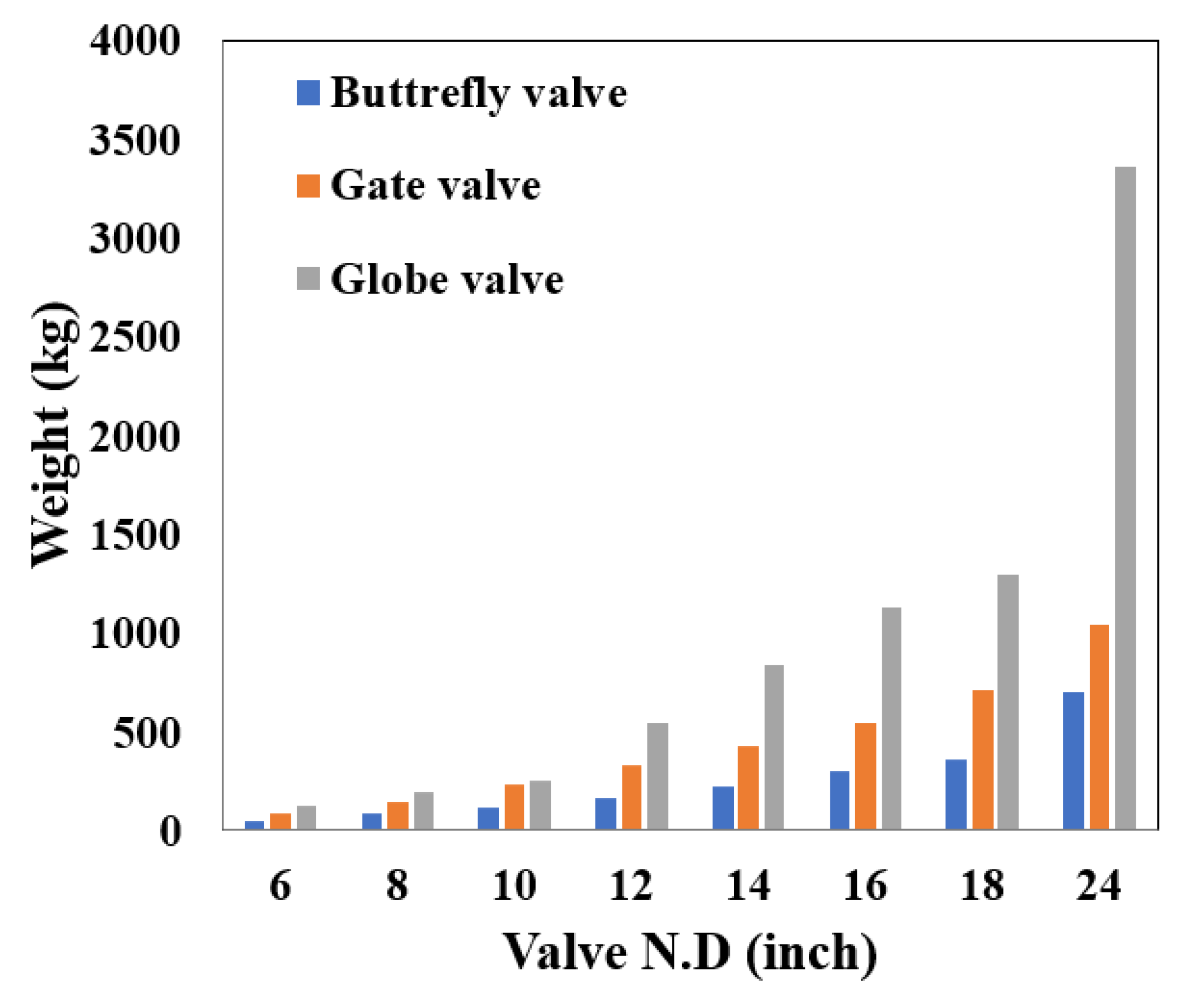

- To mitigate the pressure oscillation and improve the efficiency of the seawater treatment system, it is suggested to use a butterfly valve with equal percentage flow characteristic. Based on the comparison study with the gate valve (quick opening characteristic) and globe valve (linear characteristic), the advantages of using the butterfly valve can be followed:

- Reducing the pressure surge and amplitude by 1–1.8 barg;

- Allowing a 10 s decrease in the valve closure time;

- Reducing the weight of valve by 50% in consideration with the dynamic effect of the piping structure.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Walters, T.W.; Leishear, R.A. When the Joukowsky Equation Does Not Predict Maximum Water Hammer Pressures. In Proceedings of the ASME 2018 Pressure Vessels and Piping Conference, Prague, Czech, 15–20 July 2018. Abstract number PVP2018-84050. [Google Scholar]

- Simpson, A.R. Large Water Hammer Pressures Due to Column Separation in Sloping Pipes. Ph.D. Thesis, Department of Civil Engineering, University of Michigan, Ann Arbor, MI, USA, 1986. [Google Scholar]

- Simpson, A.R.; Bergant, A. Numerical comparison of pipe column separation models. J. Hydraul. Eng. 1994, 120, 361–377. [Google Scholar] [CrossRef]

- Kwon, H.J. Analysis of Transient Flow in a Piping system. J. Civil Eng. 2007, 11, 209–214. [Google Scholar] [CrossRef]

- Jinping, L.I.; Peng, W.; Jiandong, Y. CFD numerical simulation of water hammer in pipeline based on the Navier-Stokes equation. In Proceedings of the V European Conference on Computational Fluid Dynamics (ECCOMAS CFD), Lisbon, Portugal, 14–17 June 2010. [Google Scholar]

- Martins, N.M.C.; Brunone, B.; Meniconi, S.; Ramos, H.M.; Covas, D.I.C. CFD and 1D approaches for the unsteady friction analysis of low Reynolds number turbulent flows. J. Hydraul. Eng. 2017, 143, 04017050. [Google Scholar] [CrossRef]

- Mandair, S.; Karney, B.; Magnan, R.; Morissette, J.F. Comparing Pure CFD and 1-D Solvers for the Classic Water Hammer Models of a Pipe-Reservoir System. In Proceedings of the 1st International WDSA/CCWI 2018 Joint Conference, Kingston, ON, Canada, 23–25 July 2018. [Google Scholar]

- Wang, C.; Nilsson, H.; Yang, J.; Petit, O. 1D–3D coupling for hydraulic system transient simulations. J.CPC 2017, 210, 1–9. [Google Scholar] [CrossRef]

- Ghidaoui, M.; Zhao, M.; McInnis, D.; Axworthy, D. A Review of Water Hammer Theory and Practice. Appl. Mech. Rev 2005, 58, 49–76. [Google Scholar] [CrossRef]

- Korteweg, D.J. Ueber die Fortpflanzungsgeschwindigkeit des Schalles in elastischen Röhren (“On the velocity of propagation of sound in elastic tubes.”). Ann. Phys. 1878, 241, 525–542. [Google Scholar] [CrossRef]

- Vardy, A.E.; Hwang, K.L. A characteristics model of transient friction in pipes. J. Hydraul. Res. 1991, 29, 669–684. [Google Scholar] [CrossRef]

- Daily, W.J.; Hankey, W.L.; Olive, R.W.; Jordaan, J.M. Resistance coefficients for accelerated and decelerated flows through smooth tubes and orifices. Trans. ASME 1956, 1071–1077. [Google Scholar]

- Shuy, E. Wall shear stress in accelerating and decelerating turbulent pipe flows. J. Hydraul. Res. 1996, 34, 173–183. [Google Scholar] [CrossRef]

- Brunone, B.; Golia, U.M.; Greco, M. Some remarks on the momentum equation for fast transients. In Proceedings of the International Meeting on Hydraulic Transients with Column Separation, Valenica, Spain, 4–6 September 1991; pp. 201–209. [Google Scholar]

- Lister, M. The Numerical Solution of Hyperbolic Partial Defferential Equations by the Method of Characteristics; Wiley: New York, NY, USA, 1960; pp. 165–179. [Google Scholar]

- Wylie, E.B.; Streeter, V.L. Fluid Transients in Systems, 1st ed.; Prentice Hall: Englewood Cliffs, NJ, USA, 1993. [Google Scholar]

- PIPENET: Leading the Way in Fluid Flow Analysis. Available online: https://www.sunrise-sys.com/ (accessed on 20 July 2020).

- Nguyen, Q.K.; Jung, K.H.; Lee, G.N.; Suh, S.B.; To, P. Experimental Study on Pressure Distribution and Flow Coefficient of Globe Valve. Processes 2020, 8, 875. [Google Scholar] [CrossRef]

- Bergant, A.; Simpson, A.; Vitkovsky, J. Review of unsteady friction models in transient pipe flow. In Proceedings of the 9th International Meeting on the Behaviour of Hydraulic Machinery Under Steady Oscillatory Conditions, International Assocication of Hydraulic Research, Brno, Czech, 7–9 September 1999. [Google Scholar]

- Colebrook, C.F.; Blench, T.; Chatley, H.; Essex, E.; Finniecome, J.; Lacey, G.; Macdonald, G. Turbulent flow in pipes, with particular reference to the transition region between the smooth and rough pipe laws. J. Inst. Civil Eng. 1939, 12, 393–422. [Google Scholar] [CrossRef]

- FloMASTER: Fluid Thinking for Systems Engineers. Available online: https://www.mentor.com/products/mechanical/flomaster/flomaster/ (accessed on 20 July 2020).

- Mahgerefteh, H.; Rykov, Y.; Denton, G. Courant, Friedrichs and Lewy (CFL) impact on numerical convergence of highly transient flows. Chem. Eng. Sci. 2009, 64, 4969–4975. [Google Scholar] [CrossRef]

| Properties | Value |

|---|---|

| Outside diameter (OD) | 22.1 mm |

| Wall thickness of the pipe (e) | 1.63 mm |

| Roughness | 0.0013 mm |

| Wave speed | 1319 m/s |

| Water density at 15.4 °C | 999 kg/m3 |

| Vapor pressure | 0.02062 barg |

| Total simulation time | 1 s |

| Total length of the pipe | 37.23 m |

| Properties | Value |

|---|---|

| Fluid | Seawater |

| Temperature | 20 °C |

| Specific gravity | 1.025 |

| Viscosity | 1.23 cP |

| Bulk modulus | 2.2 Gpa |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.S.; Nguyen, Q.K.; Lee, G.N.; Jung, K.H.; Park, H.; Suh, S.B. Evaluation of Water Hammer for Seawater Treatment System in Offshore Floating Production Unit. Processes 2020, 8, 1041. https://doi.org/10.3390/pr8091041

Park JS, Nguyen QK, Lee GN, Jung KH, Park H, Suh SB. Evaluation of Water Hammer for Seawater Treatment System in Offshore Floating Production Unit. Processes. 2020; 8(9):1041. https://doi.org/10.3390/pr8091041

Chicago/Turabian StylePark, Jun Sung, Quang Khai Nguyen, Gang Nam Lee, Kwang Hyo Jung, Hyun Park, and Sung Bu Suh. 2020. "Evaluation of Water Hammer for Seawater Treatment System in Offshore Floating Production Unit" Processes 8, no. 9: 1041. https://doi.org/10.3390/pr8091041

APA StylePark, J. S., Nguyen, Q. K., Lee, G. N., Jung, K. H., Park, H., & Suh, S. B. (2020). Evaluation of Water Hammer for Seawater Treatment System in Offshore Floating Production Unit. Processes, 8(9), 1041. https://doi.org/10.3390/pr8091041