Technical Aspects of Biofuel Production from Different Sources in Malaysia—A Review

Abstract

:1. Introduction

2. Possible Biomass Sources for Biofuels Production in Malaysia

3. Biofuel Production in Malaysia

3.1. Bioethanol Production

3.2. Biodiesel Production

3.3. Biohydrogen Production

3.4. Biogas Production

4. Life Cycle Assessment and GHG Emission

4.1. LCA Analyses of Bioethanol Production

4.2. LCA Analyses of Biodiesel Production

4.3. LCA Analyses of Biogas Production

5. Government Strategies and Policies

6. Conclusions and Future Perspectives

- Lignocellulosic biomass and POME are two main sources to produce different biofuel types.

- Their potential is comparable with other sources in other countries and could be considered as green since they can reduce GHG significantly.

- Bioethanol production in Malaysia is based on using different woody and lignocellulosic biomass with the range of 0.3–4.5 g/g biomass to ethanol.

- An LCA analysis revealed the effectiveness of palm-based biodiesel compared to petrol in terms of energy output and GHG reduction.

- As biofuel production and export are increasing year by year in Malaysia, the government needs to have some initiatives for stakeholders to facilitate their production by providing advanced technologies.

- The outlook of biofuel in Malaysia depends on several sectors, such as the government, industries, and stakeholders, which need more integration to reach the country’s needs.

Author Contributions

Funding

Conflicts of Interest

References

- Izmirlioglu, G.; Demirci, A. Improved simultaneous saccharification and fermentation of bioethanol from industrial potato waste with co-cultures of Aspergillus niger and Saccharomyces cerevisiae by medium optimization. Fuel 2016, 185, 684–691. [Google Scholar] [CrossRef]

- Derman, E.; Abdulla, R.; Marbawi, H.; Sabullah, M.K. Oil palm empty fruit bunches as a promising feedstock for bioethanol production in Malaysia. Renew. Energy 2018, 129, 285–298. [Google Scholar] [CrossRef]

- Correa, D.F.; Beyer, H.L.; Fargione, J.E.; Hill, J.D.; Possingham, H.P.; Thomas-Hall, S.R.; Schenk, P.M. Towards the implementation of sustainable biofuel production systems. Renew. Sustain. Energy Rev. 2019, 107, 250–263. [Google Scholar] [CrossRef]

- Haldar, D.; Purkait, M.K. Lignocellulosic conversion into value-added products: A review. Process Biochem. 2020, 89, 110–133. [Google Scholar] [CrossRef]

- Van Fan, Y.; Perry, S.; Klemeš, J.J.; Lee, C.T. A review on air emissions assessment: Transportation. J. Clean. Prod. 2018, 194, 673–684. [Google Scholar] [CrossRef]

- Naik, S.N.; Goud, V.V.; Rout, P.K.; Dalai, A.K. Production of first and second generation biofuels: A comprehensive review. Renew. Sustain. Energy Rev. 2010, 14, 578–597. [Google Scholar] [CrossRef]

- Jiang, Y.; Lv, Y.; Wu, R.; Sui, Y.; Chen, C.; Xin, F.; Zhou, J.; Dong, W.; Jiang, M. Current status and perspectives on biobutanol production using lignocellulosic feedstocks. Bioresour. Technol. Rep. 2019, 7, 100245. [Google Scholar] [CrossRef]

- Zabed, H.; Sahu, J.N.; Boyce, A.N.; Faruq, G. Fuel ethanol production from lignocellulosic biomass: An overview on feedstocks and technological approaches. Renew. Sustain. Energy Rev. 2016, 66, 751–774. [Google Scholar] [CrossRef]

- Kamyab, H.; Chelliapan, S.; Shahbazian-Yassar, R.; Din, M.F.M.; Khademi, T.; Kumar, A.; Rezania, S. Evaluation of lipid content in microalgae biomass using palm oil mill effluent (Pome). JOM 2017, 69, 1361–1367. [Google Scholar] [CrossRef]

- Abdullah, B.; Muhammad, S.A.F.S.; Shokravi, Z.; Ismail, S.; Kassim, K.A.; Mahmood, A.N.; Aziz, M.M.A. Fourth generation biofuel: A review on risks and mitigation strategies. Renew. Sustain. Energy Rev. 2019, 107, 37–50. [Google Scholar] [CrossRef]

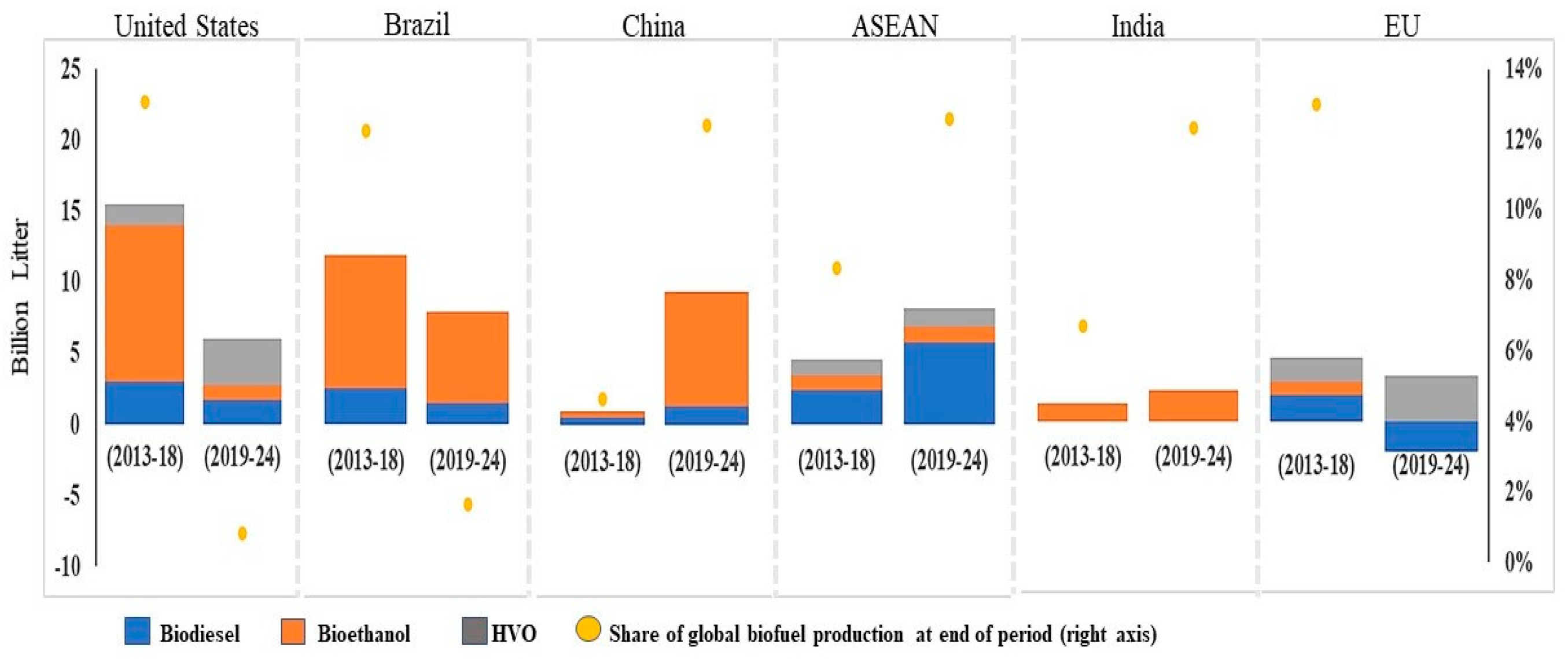

- IEA. Biofuels Production Growth by Country/Region. IEA: Paris, France. Available online: https://www.iea.org/data-and-statistics/charts/biofuels-production-growth-by-country-region (accessed on 10 May 2020).

- Renewables 2019 Market Analysis and Forecast from 2019 to 2024. Available online: https://www.iea.org/reports/renewables-2019 (accessed on 10 May 2020).

- Birol, F. Renewables 2018: Market Analysis and Forecast from 2018 to 2023; International Energy Agency: Paris, France, 2018. [Google Scholar]

- Jayed, M.H.; Masjuki, H.H.; Kalam, M.A.; Mahlia, T.M.I.; Husnawan, M.; Liaquat, A.M. Prospects of dedicated biodiesel engine vehicles in Malaysia and Indonesia. Renew. Sustain. Energy Rev. 2011, 15, 220–235. [Google Scholar] [CrossRef]

- Mukherjee, I.; Sovacool, B.K. Palm oil-based biofuels and sustainability in southeast Asia: A review of Indonesia, Malaysia, and Thailand. Renew. Sustain. Energy Rev. 2014, 37, 1–12. [Google Scholar] [CrossRef]

- Chua, S.C.; Oh, T.H. Review on Malaysia’s national energy developments: Key policies, agencies, programmes and international involvements. Renew. Sustain. Energy Rev. 2010, 14, 2916–2925. [Google Scholar] [CrossRef]

- Ong, H.C.; Mahlia, T.M.I.; Masjuki, H.H. A review on energy pattern and policy for transportation sector in Malaysia. Renew. Sustain. Energy Rev. 2012, 16, 532–542. [Google Scholar] [CrossRef]

- How, B.S.; Ngan, S.L.; Hong, B.H.; Lam, H.L.; Ng, W.P.Q.; Yusup, S.; Ghani, W.A.W.A.K.; Kansha, Y.; Chan, Y.H.; Cheah, K.W.; et al. An outlook of Malaysian biomass industry commercialisation: Perspectives and challenges. Renew. Sustain. Energy Rev. 2019, 113, 109277. [Google Scholar] [CrossRef]

- Department of Statistics Current Population Estimates, Malaysia, 2018–2019. Available online: https://www.dosm.gov.my (accessed on 15 June 2020).

- Mekhilef, S.; Saidur, R.; Safari, A.; Mustaffa, W. Biomass energy in Malaysia: Current state and prospects. Renew. Sustain. Energy Rev. 2011, 15, 3360–3370. [Google Scholar] [CrossRef]

- Fazeli, A.; Bakhtvar, F.; Jahanshaloo, L.; Sidik, N.A.C.; Bayat, A.E. Malaysia’s stand on municipal solid waste conversion to energy: A review. Renew. Sustain. Energy Rev. 2016, 58, 1007–1016. [Google Scholar] [CrossRef]

- Wu, Q.; Qiang, T.C.; Zeng, G.; Zhang, H.; Huang, Y.; Wang, Y. Sustainable and renewable energy from biomass wastes in palm oil industry: A case study in Malaysia. Int. J. Hydrog. Energy 2017, 42, 23871–23877. [Google Scholar] [CrossRef] [Green Version]

- Rezania, S.; Ponraj, M.; Din, M.F.M.; Songip, A.R.; Sairan, F.M.; Chelliapan, S. The diverse applications of water hyacinth with main focus on sustainable energy and production for new era: An overview. Renew. Sustain. Energy Rev. 2015, 41, 943–954. [Google Scholar] [CrossRef]

- Rezania, S.; Din, M.F.M.; Mohamad, S.E.; Sohaili, J.; Taib, S.M.; Yusof, M.B.M.; Kamyab, H.; Darajeh, N.; Ahsan, A. Review on pretreatment methods and ethanol production from cellulosic water hyacinth. BioResources 2017, 12, 2108–2124. [Google Scholar]

- Malaysian Palm Oil Board (MPOB). 2019. Available online: http://bepi.mpob.gov.my/news/detail.php?id=28372 (accessed on 16 June 2020).

- Malaysian Palm Oil Council (MPOC). Palm Oil Inventory Could Rise in Next Few Months. 2018. Available online: http://mpoc.org.my/palm-oil-inventory-could-rise-in-next-few-months (accessed on 10 January 2020).

- Kamyab, H.; Chelliapan, S.; Din, M.F.M.; Rezania, S.; Khademi, T.; Kumar, A. Palm oil mill effluent as an environmental pollutant. Palm Oil 2018, 13, 13–28. [Google Scholar]

- Szulczyk, K.R.; Khan, M.A.R. The potential and environmental ramifications of palm biodiesel: Evidence from Malaysia. J. Clean. Prod. 2018, 203, 260–272. [Google Scholar] [CrossRef]

- Palamae, S.; Dechatiwongse, P.; Choorit, W.; Chisti, Y.; Prasertsan, P. Cellulose and hemicellulose recovery from oil palm empty fruit bunch (EFB) fibers and production of sugars from the fibers. Carbohydr. Polym. 2017, 155, 491–497. [Google Scholar] [CrossRef] [PubMed]

- Ghani, W.A.W.A.K.; Salleh, M.A.M.; Adam, S.N.; Shafri, H.Z.M.; Shaharum, S.N.; Lim, K.L.; Rubinsin, N.J.; Lam, H.L.; Hasan, A.; Samsatli, S.; et al. Sustainable bio-economy that delivers the environment–food–energy–water nexus objectives: The current status in Malaysia. Food Bioprod. Process. 2019, 118, 167–186. [Google Scholar] [CrossRef]

- Rezania, S.; Oryani, B.; Cho, J.; Talaiekhozani, A.; Sabbagh, F.; Hashemi, B.; Rupani, P.F.; Mohammadi, A.A. Different pretreatment technologies of lignocellulosic biomass for bioethanol production: An overview. Energy 2020, 199, 117457. [Google Scholar] [CrossRef]

- Hosseini, S.E.; Wahid, M.A. Utilization of palm solid residue as a source of renewable and sustainable energy in Malaysia. Renew. Sustain. Energy Rev. 2014, 40, 621–632. [Google Scholar] [CrossRef]

- Tye, Y.Y.; Lee, K.T.; Abdullah, W.N.W.; Leh, C.P. Second-generation bioethanol as a sustainable energy source in Malaysia transportation sector: Status, potential and future prospects. Renew. Sustain. Energy Rev. 2011, 15, 4521–4536. [Google Scholar] [CrossRef]

- de Carvalho, A.L.; Antunes, C.H.; Freire, F. Economic-energy-environment analysis of prospective sugarcane bioethanol production in Brazil. Appl. Energy 2016, 181, 514–526. [Google Scholar] [CrossRef]

- Aditiya, H.B.; Chong, W.T.; Mahlia, T.M.I.; Sebayang, A.H.; Berawi, M.A.; Nur, H. Second generation bioethanol potential from selected Malaysia’s biodiversity biomasses: A review. Waste Manag. 2016, 47, 46–61. [Google Scholar] [CrossRef]

- Lamers, P.; Hamelinck, C.; Junginger, M.; Faaij, A. International bioenergy trade—A review of past developments in the liquid biofuel market. Renew. Sustain. Energy Rev. 2011, 15, 2655–2676. [Google Scholar] [CrossRef]

- Biofuel Annual Malaysia-USDA Gain Reports. 2017. Available online: https://apps.fas.usda.gov/newgainapi/api/report/downloadreportbyfilename?filename=Biofuels Annual_Kuala Lumpur_Malaysia_10-24-2017.pdf (accessed on 10 May 2020).

- Ayodele, B.V.; Alsaffar, M.A.; Mustapa, S.I. An overview of integration opportunities for sustainable bioethanol production from first-and second-generation sugar-based feedstocks. J. Clean. Prod. 2020, 245, 118857. [Google Scholar] [CrossRef]

- Sebayang, A.H.; Masjuki, H.H.; Chyuan, H.; Dharma, S.; Silitonga, A.S.; Kusumo, F.; Milano, J. Optimization of bioethanol production from sorghum grains using artificial neural networks integrated with ant colony. Ind. Crop. Prod. 2017, 97, 146–155. [Google Scholar] [CrossRef]

- Shun, J.; Phapugrangkul, P.; Keong, C.; Lai, Z.; Hafizi, M.; Bakar, A.; Murugan, P. Biocatalysis and Agricultural Biotechnology Banana frond juice as novel fermentation substrate for bioethanol production by Saccharomyces cerevisiae. Biocatal. Agric. Biotechnol. 2019, 21, 101293. [Google Scholar]

- Aditiya, H.B.; Mahlia, T.M.I.; Chong, W.T.; Nur, H.; Sebayang, A.H. Second generation bioethanol production: A critical review. Renew. Sustain. Energy Rev. 2016, 66, 631–653. [Google Scholar] [CrossRef]

- Abdullah, M.; Alharbi, H.; Hirai, S.; Tuan, H.A.; Akioka, S.; Shoji, W. Effects of chemical composition, mild alkaline pretreatment and particle size on mechanical, thermal, and structural properties of binderless lignocellulosic biopolymers prepared by hot-pressing raw microfibrillated Phoenix dactylifera and Cocos nucifera. Polym. Test. 2020, 84, 106384. [Google Scholar]

- Soplah, S.; Abdullah, S.; Shirai, Y.; Amiruddin, A.; Ali, M.; Mustapha, M.; Ali, M.; Mill, P.O.I.L.; Mill, P.O.I.L. Case study: Preliminary assessment of integrated palm biomass biorefinery for bioethanol production utilizing non-food sugars from oil palm frond petiole. Energy Convers. Manag. 2016, 108, 233–242. [Google Scholar]

- Kannan, S.; Rajkumar, T.; Kumar, D.; Saleh, A. Microwave assisted acid hydrolysis for bioethanol fuel production from sago pith waste. Waste Manag. 2019, 86, 80–86. [Google Scholar]

- Rajendran, K.; Drielak, E.; Varma, V.S.; Muthusamy, S.; Kumar, G. Updates on the pretreatment of lignocellulosic feedstocks for bioenergy production—A review. Biomass Convers. Biorefinery 2018, 8, 471–483. [Google Scholar] [CrossRef]

- Kazemi, H.; Panahi, S.; Dehhaghi, M.; Aghbashlo, M.; Karimi, K.; Tabatabaei, M. Conversion of residues from agro-food industry into bioethanol in Iran: An under-valued biofuel additive to phase out MTBE in gasoline. Renew. Energy 2020, 145, 699–710. [Google Scholar] [CrossRef]

- Azhar, S.H.M.; Abdulla, R.; Jambo, S.A.; Marbawi, H.; Gansau, J.A.; Faik, A.A.M.; Rodrigues, K.F. Yeasts in sustainable bioethanol production: A review. Biochem. Biophys. Rep. 2017, 10, 1–11. [Google Scholar]

- Aditiya, H.B.; Sing, K.P.; Hanif, M.; Mahlia, T.M.I. Effect of acid pretreatment on enzymatic hydrolysis in bioethanol production from rice straw. Int. J. Technol. 2015, 2011, 3–10. [Google Scholar] [CrossRef]

- Jung, Y.H.; Kim, I.J.; Kim, H.K.; Kim, K.H. Bioresource Technology Dilute acid pretreatment of lignocellulose for whole slurry ethanol fermentation. Bioresour. Technol. 2013, 132, 109–114. [Google Scholar] [CrossRef] [PubMed]

- Wan, L.; Cheng, G.; Seak, A.; Chua, M.; Fazly, M.; Patah, A. Chemical Engineering & Processing: Process Intensi fi cation Process intensi fi cation of cellulase and bioethanol production from sugarcane bagasse via an integrated sacchari fi cation and fermentation process. Chem. Eng. Process. Process Intensif. 2019, 142, 107528. [Google Scholar]

- Ko, C.-H.; Yang, B.-Y.; Lin, L.-D.; Chang, F.-C.; Chen, W.-H. Impact of pretreatment methods on production of bioethanol and nanocrystalline cellulose. J. Clean. Prod. 2020, 254, 119914. [Google Scholar] [CrossRef]

- Hafid, H.S.; Nor’Aini, A.R.; Mokhtar, M.N.; Talib, A.T.; Baharuddin, A.S.; Kalsom, M.S.U. Over production of fermentable sugar for bioethanol production from carbohydrate-rich Malaysian food waste via sequential acid-enzymatic hydrolysis pretreatment. Waste Manag. 2017, 67, 95–105. [Google Scholar] [CrossRef]

- Lin, T.; Guo, G.; Hwang, W.; Huang, S. Biomass and Bioenergy The addition of hydrolyzed rice straw in xylose fermentation by Pichia stipitis to increase bioethanol production at the pilot-scale. Biomass Bioenergy 2016, 91, 204–209. [Google Scholar] [CrossRef]

- Kamoldeen, A.A.; Keong, L.C.; Nadiah, W.; Abdullah, W.; Peng, L.C. Enhanced ethanol production from mild alkali-treated oil-palm empty fruit bunches via co-fermentation of glucose and xylose. Renew. Energy 2017, 107, 113–123. [Google Scholar] [CrossRef]

- Tan, L.; Wang, M.; Li, X.; Li, H.; Zhao, J.; Qu, Y.; May, Y. Bioresource Technology Fractionation of oil palm empty fruit bunch by bisulfite pretreatment for the production of bioethanol and high value products. Bioresour. Technol. 2016, 200, 572–578. [Google Scholar] [CrossRef]

- Chyuan, H.; Mohamed, B.; Wen, C.; Fauzi, H.; Chen, W. Biomass and Bioenergy Effects of organosolv pretreatment and acid hydrolysis on palm empty fruit bunch (PEFB) as bioethanol feedstock. Biomass Bioenergy 2016, 95, 78–83. [Google Scholar]

- Rezania, S.; Din, M.F.; Taib, S.M. Ethanol Production from Water Hyacinth (Eichhornia crassipes) Using Various Types of Enhancers Based on the Consumable Sugars. Waste Biomass Valoriz. 2017, 9, 939–946. [Google Scholar] [CrossRef]

- Rezania, S.; Oryani, B.; Park, J.; Hashemi, B.; Yadav, K.K.; Kwon, E.E.; Hur, J.; Cho, J. Review on transesterification of non-edible sources for biodiesel production with a focus on economic aspects, fuel properties and by-product applications. Energy Convers. Manag. 2019, 201, 112155. [Google Scholar] [CrossRef]

- Mansir, N.; Teo, S.H.; Rashid, U.; Saiman, M.I.; Tan, Y.P.; Alsultan, G.A.; Taufiq-Yap, Y.H. Modified waste egg shell derived bifunctional catalyst for biodiesel production from high FFA waste cooking oil. A review. Renew. Sustain. Energy Rev. 2018, 82, 3645–3655. [Google Scholar] [CrossRef]

- Kumar, S.; Shrestha, P.; Salam, P.A. A review of biofuel policies in the major biofuel producing countries of ASEAN: Production, targets, policy drivers and impacts. Renew. Sustain. Energy Rev. 2013, 26, 822–836. [Google Scholar] [CrossRef]

- Mohammadi, S.; Arshad, F.M.; Ibragimov, A. Future prospects and policy implications for biodiesel production in Malaysia: A system dynamics approach. Inst. Econ. 2017, 8, 42–57. [Google Scholar]

- Quah, R.V.; Tan, Y.H.; Mubarak, N.M.; Khalid, M.; Abdullah, E.C.; Nolasco-Hipolito, C. An overview of biodiesel production using recyclable biomass and non-biomass derived magnetic catalysts. J. Environ. Chem. Eng. 2019, 7, 103219. [Google Scholar] [CrossRef]

- Singh, D.; Sharma, D.; Soni, S.L.; Sharma, S.; Sharma, P.K.; Jhalani, A. A review on feedstocks, production processes, and yield for different generations of biodiesel. Fuel 2019, 262, 116553. [Google Scholar] [CrossRef]

- Demirbas, A. Production of biodiesel fuels from linseed oil using methanol and ethanol in non-catalytic SCF conditions. Biomass Bioenergy 2009, 33, 113–118. [Google Scholar] [CrossRef]

- Ashnani, M.H.M.; Johari, A.; Hashim, H.; Hasani, E. A source of renewable energy in Malaysia, why biodiesel? Renew. Sustain. Energy Rev. 2014, 35, 244–257. [Google Scholar] [CrossRef]

- Takase, M.; Zhao, T.; Zhang, M.; Chen, Y.; Liu, H.; Yang, L.; Wu, X. An expatiate review of neem, jatropha, rubber and karanja as multipurpose non-edible biodiesel resources and comparison of their fuel, engine and emission properties. Renew. Sustain. Energy Rev. 2015, 43, 495–520. [Google Scholar] [CrossRef]

- Jayakumar, S.; Yusoff, M.M.; Rahim, M.H.A.; Maniam, G.P.; Govindan, N. The prospect of microalgal biodiesel using agro-industrial and industrial wastes in Malaysia. Renew. Sustain. Energy Rev. 2017, 72, 33–47. [Google Scholar] [CrossRef] [Green Version]

- Yusuf, N.; Kamarudin, S.K.; Yaakub, Z. Overview on the current trends in biodiesel production. Energy Convers. Manag. 2011, 52, 2741–2751. [Google Scholar] [CrossRef]

- Niculescu, R.; Clenci, A.; Iorga-Siman, V. Review on the use of diesel–Biodiesel–Alcohol blends in compression ignition engines. Energies 2019, 12, 1194. [Google Scholar] [CrossRef] [Green Version]

- Mahmudul, H.M.; Hagos, F.Y.; Mamat, R.; Adam, A.A.; Ishak, W.F.W.; Alenezi, R. Production, characterization and performance of biodiesel as an alternative fuel in diesel engines—A review. Renew. Sustain. Energy Rev. 2017, 72, 497–509. [Google Scholar] [CrossRef]

- Ali, M.A.M.; Gimbun, J.; Lau, K.L.; Cheng, C.K.; Vo, D.-V.N.; Lam, S.S.; Yunus, R.M. Biodiesel synthesized from waste cooking oil in a continuous microwave assisted reactor reduced PM and NOx emissions. Environ. Res. 2020, 185, 109452. [Google Scholar]

- Ibrahim, M.L.; Khalil, N.N.A.N.A.; Islam, A.; Rashid, U.; Ibrahim, S.F.; Mashuri, S.I.S.; Taufiq-Yap, Y.H. Preparation of Na2O supported CNTs nanocatalyst for efficient biodiesel production from waste-oil. Energy Convers. Manag. 2020, 205, 112445. [Google Scholar] [CrossRef]

- Farooq, M.; Ramli, A.; Naeem, A.; Noman, M.; Shah, L.A.; Khattak, N.S.; Perveen, F. A green route for biodiesel production from waste cooking oil over base heterogeneous catalyst. Int. J. Energy Res. 2019, 43, 5438–5446. [Google Scholar] [CrossRef]

- Tan, Y.H.; Abdullah, M.O.; Kansedo, J.; Mubarak, N.M.; San Chan, Y.; Nolasco-Hipolito, C. Biodiesel production from used cooking oil using green solid catalyst derived from calcined fusion waste chicken and fish bones. Renew. Energy 2019, 139, 696–706. [Google Scholar] [CrossRef]

- Lim, S.; Yap, C.Y.; Pang, Y.L.; Wong, K.H. Biodiesel synthesis from oil palm empty fruit bunch biochar derived heterogeneous solid catalyst using 4-benzenediazonium sulfonate. J. Hazard. Mater. 2019, 390, 121532. [Google Scholar] [CrossRef]

- Manaf, I.S.A.; Rahim, M.H.A.; Govindan, N.; Maniam, G.P. A first report on biodiesel production from Aglaia korthalsii seed oil using waste marine barnacle as a solid catalyst. Ind. Crops Prod. 2018, 125, 395–400. [Google Scholar] [CrossRef]

- Wong, W.-Y.; Lim, S.; Pang, Y.-L.; Shuit, S.-H.; Chen, W.-H.; Lee, K.-T. Synthesis of renewable heterogeneous acid catalyst from oil palm empty fruit bunch for glycerol-free biodiesel production. Sci. Total Environ. 2020, 727, 138534. [Google Scholar] [CrossRef]

- Zhao, S.; Niu, S.; Yu, H.; Ning, Y.; Zhang, X.; Li, X.; Zhang, Y.; Lu, C.; Han, K. Experimental investigation on biodiesel production through transesterification promoted by the La-dolomite catalyst. Fuel 2019, 257, 116092. [Google Scholar] [CrossRef]

- Dincer, I.; Acar, C. Smart energy solutions with hydrogen options. Int. J. Hydrog. Energy 2018, 43, 8579–8599. [Google Scholar] [CrossRef]

- Shao, W.; Wang, Q.; Rupani, P.F.; Krishnan, S.; Ahmad, F.; Rezania, S.; Rashid, M.A.; Sha, C.; Din, M.F.M. Biohydrogen production via thermophilic fermentation: A prospective application of Thermotoga species. Energy 2020, 197, 117199. [Google Scholar] [CrossRef]

- Rezania, S.; Din, M.F.M.; Taib, S.M.; Sohaili, J.; Chelliapan, S.; Kamyab, H.; Saha, B.B. Review on fermentative biohydrogen production from water hyacinth, wheat straw and rice straw with focus on recent perspectives. Int. J. Hydrog. Energy 2017, 42, 20955–20969. [Google Scholar] [CrossRef]

- Lee, D.-H. Building evaluation model of biohydrogen industry with circular economy in Asian countries. Int. J. Hydrog. Energy 2019, 44, 3278–3289. [Google Scholar] [CrossRef]

- Alshati, A.; Almohammedawi, M.; Sachdev, M.S.; Kachaamy, T. Endoscopic management of colovaginal fistulas in advanced cancer patients. VideoGIE 2019, 4, 279–283. [Google Scholar] [CrossRef] [Green Version]

- Aziz, M.M.A.; Kassim, K.A.; ElSergany, M.; Anuar, S.; Jorat, M.E.; Yaacob, H.; Ahsan, A.; Imteaz, M.A. Recent advances on palm oil mill effluent (POME) pretreatment and anaerobic reactor for sustainable biogas production. Renew. Sustain. Energy Rev. 2019, 119, 109603. [Google Scholar] [CrossRef]

- Mishra, P.; Krishnan, S.; Rana, S.; Singh, L.; Sakinah, M.; Ab Wahid, Z. Outlook of fermentative hydrogen production techniques: An overview of dark, photo and integrated dark-photo fermentative approach to biomass. Energy Strateg. Rev. 2019, 24, 27–37. [Google Scholar] [CrossRef]

- Sivagurunathan, P.; Kumar, G.; Mudhoo, A.; Rene, E.R.; Saratale, G.D.; Kobayashi, T.; Xu, K.; Kim, S.-H.; Kim, D.-H. Fermentative hydrogen production using lignocellulose biomass: An overview of pre-treatment methods, inhibitor effects and detoxification experiences. Renew. Sustain. Energy Rev. 2017, 77, 28–42. [Google Scholar] [CrossRef]

- Mishra, P.; Thakur, S.; Singh, L.; Ab Wahid, Z.; Sakinah, M. Enhanced hydrogen production from palm oil mill effluent using two stage sequential dark and photo fermentation. Int. J. Hydrog. Energy 2016, 41, 18431–18440. [Google Scholar] [CrossRef] [Green Version]

- Singh, L.; Wahid, Z.A. Enhancement of hydrogen production from palm oil mill effluent via cell immobilisation technique. Int. J. Energy Res. 2015, 39, 215–222. [Google Scholar] [CrossRef]

- Radhakrishnan, S.; Prasad, S.; Kumar, S.; Subramanian, D. Production of Biohydrogen from Lignocellulosic Feedstocks. Lignocellul. Biorefin. Technol. 2020, 47–67. [Google Scholar]

- Mamimin, C.; Kongjan, P.; Sompong, O.; Prasertsan, P. Enhancement of biohythane production from solid waste by co-digestion with palm oil mill effluent in two-stage thermophilic fermentation. Int. J. Hydrog. Energy 2019, 44, 17224–17237. [Google Scholar] [CrossRef]

- Abdullah, M.F.; Jahim, J.M.; Abdul, P.M.; Mahmod, S.S. Effect of carbon/nitrogen ratio and ferric ion on the production of biohydrogen from palm oil mill effluent (POME). Biocatal. Agric. Biotechnol. 2020, 23, 101445. [Google Scholar] [CrossRef]

- del Pilar Anzola-Rojas, M.; da Fonseca, S.G.; da Silva, C.C.; de Oliveira, V.M.; Zaiat, M. The use of the carbon/nitrogen ratio and specific organic loading rate as tools for improving biohydrogen production in fixed-bed reactors. Biotechnol. Rep. 2015, 5, 46–54. [Google Scholar] [CrossRef] [Green Version]

- Mishra, P.; Thakur, S.; Singh, L.; Krishnan, S.; Sakinah, M.; Ab Wahid, Z. Fermentative hydrogen production from indigenous mesophilic strain Bacillus anthracis PUNAJAN 1 newly isolated from palm oil mill effluent. Int. J. Hydrog. Energy 2017, 42, 16054–16063. [Google Scholar] [CrossRef] [Green Version]

- Valle, A.; Cantero, D.; Bolívara, J. Metabolic engineering for the optimization of hydrogen production in Escherichia coli: A review. Biotechnol. Adv. 2019, 37, 616–633. [Google Scholar] [CrossRef]

- Akhbari, A.; Zinatizadeh, A.A.; Vafaeifard, M.; Mohammadi, P.; Syirat, Z.B.; Ibrahim, S. Effect of operational variables on biological hydrogen production from palm oil mill effluent by dark fermentation using response surface methodology. Desalin. Water Treat 2019, 137, 101–113. [Google Scholar] [CrossRef]

- Mishra, P.; Singh, L.; Ab Wahid, Z.; Krishnan, S.; Rana, S.; Islam, M.A.; Sakinah, M.; Ameen, F.; Syed, A. Photohydrogen production from dark-fermented palm oil mill effluent (DPOME) and statistical optimization: Renewable substrate for hydrogen. J. Clean. Prod. 2018, 199, 11–17. [Google Scholar] [CrossRef]

- Mohammadi, P.; Ibrahim, S.; Annuar, M.S.M.; Khashij, M.; Mousavi, S.A.; Zinatizadeh, A. Optimization of fermentative hydrogen production from palm oil mill effluent in an up-flow anaerobic sludge blanket fixed film bioreactor. Sustain. Environ. Res. 2017, 27, 238–244. [Google Scholar] [CrossRef] [Green Version]

- Taifor, A.F.; Zakaria, M.R.; Yusoff, M.Z.M.; Toshinari, M.; Hassan, M.A.; Shirai, Y. Elucidating substrate utilization in biohydrogen production from palm oil mill effluent by Escherichia coli. Int. J. Hydrog. Energy 2017, 42, 5812–5819. [Google Scholar] [CrossRef]

- Azman, N.F.; Abdeshahian, P.; Al-Shorgani, N.K.N.; Hamid, A.A.; Kalil, M.S. Production of hydrogen energy from dilute acid-hydrolyzed palm oil mill effluent in dark fermentation using an empirical model. Int. J. Hydrog. Energy 2016, 41, 16373–16384. [Google Scholar] [CrossRef]

- Khandaker, N.R.; Islam, S.M.S.; Shakin, U.F. Biogas Generation from Rice Cooking Wastewater. J. Environ. Treat. Tech. 2020, 8, 794–796. [Google Scholar]

- Parsaee, M.; Kiani, M.K.D.; Karimi, K. A review of biogas production from sugarcane vinasse. Biomass Bioenergy 2019, 122, 117–125. [Google Scholar] [CrossRef]

- Meyer, A.K.P.; Ehimen, E.A.; Holm-Nielsen, J.B. Future European biogas: Animal manure, straw and grass potentials for a sustainable European biogas production. Biomass Bioenergy 2018, 111, 154–164. [Google Scholar] [CrossRef]

- Wellinger, A.; Murphy, J.D.; Baxter, D. The Biogas Handbook: Science, Production and Applications; Elsevier: London, UK, 2013; ISBN 0857097415. [Google Scholar]

- Abdeshahian, P.; Lim, J.S.; Ho, W.S.; Hashim, H.; Lee, C.T. Potential of biogas production from farm animal waste in Malaysia. Renew. Sustain. Energy Rev. 2016, 60, 714–723. [Google Scholar] [CrossRef]

- Hosseini, S.E.; Wahid, M.A. Feasibility study of biogas production and utilization as a source of renewable energy in Malaysia. Renew. Sustain. Energy Rev. 2013, 19, 454–462. [Google Scholar] [CrossRef]

- Yong, Z.; Dong, Y.; Zhang, X.; Tan, T. Anaerobic co-digestion of food waste and straw for biogas production. Renew. Energy 2015, 78, 527–530. [Google Scholar] [CrossRef]

- Gebrezgabher, S.A.; Meuwissen, M.P.M.; Prins, B.A.M.; Lansink, A.G.J.M.O. Economic analysis of anaerobic digestion—A case of Green power biogas plant in The Netherlands. NJAS-Wagening. J. Life Sci. 2010, 57, 109–115. [Google Scholar] [CrossRef] [Green Version]

- Çelik, İ.; Demirer, G.N. Biogas production from pistachio (Pistacia vera L.) processing waste. Biocatal. Agric. Biotechnol. 2015, 4, 767–772. [Google Scholar] [CrossRef]

- Loh, S.K.; Nasrin, A.B.; Azri, S.M.; Adela, B.N.; Muzzammil, N.; Jay, T.D.; Eleanor, R.A.S.; Lim, W.S.; Choo, Y.M.; Kaltschmitt, M. First Report on Malaysia’s experiences and development in biogas capture and utilization from palm oil mill effluent under the Economic Transformation Programme: Current and future perspectives. Renew. Sustain. Energy Rev. 2017, 74, 1257–1274. [Google Scholar] [CrossRef]

- Pazuch, F.A.; Nogueira, C.E.C.; Souza, S.N.M.; Micuanski, V.C.; Friedrich, L.; Lenz, A.M. Economic evaluation of the replacement of sugar cane bagasse by vinasse, as a source of energy in a power plant in the state of Paraná, Brazil. Renew. Sustain. Energy Rev. 2017, 76, 34–42. [Google Scholar] [CrossRef]

- Christy, P.M.; Gopinath, L.R.; Divya, D. A review on anaerobic decomposition and enhancement of biogas production through enzymes and microorganisms. Renew. Sustain. Energy Rev. 2014, 34, 167–173. [Google Scholar] [CrossRef]

- Yadav, M.; Singh, A.; Balan, V.; Pareek, N.; Vivekanand, V. Biological treatment of lignocellulosic biomass by Chaetomium globosporum: Process derivation and improved biogas production. Int. J. Biol. Macromol. 2019, 128, 176–183. [Google Scholar] [CrossRef] [PubMed]

- Suksong, W.; Kongjan, P.; Prasertsan, P.; Sompong, O. Thermotolerant cellulolytic Clostridiaceae and Lachnospiraceae rich consortium enhanced biogas production from oil palm empty fruit bunches by solid-state anaerobic digestion. Bioresour. Technol. 2019, 291, 121851. [Google Scholar] [CrossRef] [PubMed]

- Zulfah, Z.; Nazaitulshila, R.; Noor, A.U.; Shahrul, I. The effect of two pre-treatment methods on biogas production potential from cow manure. J. Sustain. Sci. Manag. 2019, 14, 12–16. [Google Scholar]

- Chin, K.L.; Nurliyana, M.Y.; San H’ng, P.; Lee, C.L.; Go, W.Z.; San Khoo, P.; Nazrin, R.A.R.; Ashikin, S.N. Effects of Bacterial Bio-augmentation on the Methane Potential from Facultative Digestion of Palm Oil Mill Effluent and Empty Fruit Bunch. Waste Biomass Valoriz. 2019, 1–12. [Google Scholar] [CrossRef]

- Suksong, W.; Tukanghan, W.; Promnuan, K.; Kongjan, P.; Reungsang, A.; Insam, H.; Sompong, O. Biogas production from palm oil mill effluent and empty fruit bunches by coupled liquid and solid-state anaerobic digestion. Bioresour. Technol. 2020, 296, 122304. [Google Scholar] [CrossRef]

- Sawyerr, N.; Trois, C.; Workneh, T. Optimization of Biogas Yield through co-digestion of Cassava Biomass and Vegetable & Fruits waste at Mesophilic Temperatures. Int. J. Renew. Energy Res. 2019, 9, 771–782. [Google Scholar]

- Zulkifli, Z.B.; Rasit, N.B.; Umor, N.A.; Ismail, S. The effect of A. Fumigatus SK1 and trichoderma sp. on the biogas production from cow manure. Malays. J. Fundam. Appl. Sci. 2018, 14, 353–359. [Google Scholar] [CrossRef] [Green Version]

- Dollhofer, V.; Dandikas, V.; Dorn-In, S.; Bauer, C.; Lebuhn, M.; Bauer, J. Accelerated biogas production from lignocellulosic biomass after pre-treatment with Neocallimastix frontalis. Bioresour. Technol. 2018, 264, 219–227. [Google Scholar] [CrossRef] [PubMed]

- Aziz, N.I.H.A.; Hanafiah, M.M.; Gheewala, S.H. A review on life cycle assessment of biogas production: Challenges and future perspectives in Malaysia. Biomass Bioenergy 2019, 122, 361–374. [Google Scholar] [CrossRef]

- Abdul-Manan, A.F.N.; Baharuddin, A.; Chang, L.W. Application of theory-based evaluation for the critical analysis of national biofuel policy: A case study in Malaysia. Eval. Program Plan. 2015, 52, 39–49. [Google Scholar] [CrossRef] [PubMed]

- Hassan, M.N.A.; Jaramillo, P.; Griffin, W.M. Life cycle GHG emissions from Malaysian oil palm bioenergy development: The impact on transportation sector’s energy security. Energy Policy 2011, 39, 2615–2625. [Google Scholar] [CrossRef]

- Elbehri, A.; Segerstedt, A.; Liu, P. Biofuels and the Sustainability Challenge: A Global Assessment of Sustainability Issues, Trends and Policies for Biofuels and Related Feedstocks; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2013; ISBN 9251074143. [Google Scholar]

- Lam, M.K.; Lee, K.T.; Mohamed, A.R. Life cycle assessment for the production of biodiesel: A case study in Malaysia for palm oil versus jatropha oil. Biofuels Bioprod. Biorefin. Innov. Sustain. Econ. 2009, 3, 601–612. [Google Scholar] [CrossRef]

- Abdul-Manan, A.F.N. Lifecycle GHG emissions of palm biodiesel: Unintended market effects negate direct benefits of the Malaysian Economic Transformation Plan (ETP). Energy Policy 2017, 104, 56–65. [Google Scholar] [CrossRef]

- International Organization for Standardization. Environmental Management: Life Cycle Assessment; Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Prasad, S.; Singh, A.; Korres, N.E.; Rathore, D.; Sevda, S.; Pant, D. Sustainable utilization of crop residues for energy generation: A life cycle assessment (LCA) perspective. Bioresour. Technol. 2020, 303, 122964. [Google Scholar] [CrossRef]

- Hanif, M.; Mahlia, T.M.I.; Aditiya, H.B.; Bakar, A. Energy and environmental assessments of bioethanol production from Sri Kanji 1 cassava in Malaysia. Biofuel Res. J. 2017, 4, 537–544. [Google Scholar] [CrossRef] [Green Version]

- YUSOF, M.; Hanim, S.J.; Roslan, A.M.; Ibrahim, K.N.; ABDULLAH, S.; Soplah, S.; Zakaria, M.R.; Hassan, M.A.; Shirai, Y. Life Cycle Assessment for Bioethanol Production from Oil Palm Frond Juice in an Oil Palm Based Biorefinery. Sustainability 2019, 11, 6928. [Google Scholar] [CrossRef] [Green Version]

- Yee, K.F.; Tan, K.T.; Abdullah, A.Z.; Lee, K.T. Life cycle assessment of palm biodiesel: Revealing facts and benefits for sustainability. Appl. Energy 2009, 86, S189–S196. [Google Scholar] [CrossRef]

- Farid, M.A.A.; Roslan, A.M.; Hassan, M.A.; Hasan, M.Y.; Othman, M.R.; Shirai, Y. Net energy and techno-economic assessment of biodiesel production from waste cooking oil using a semi-industrial plant: A Malaysia perspective. Sustain. Energy Technol. Assess. 2020, 39, 100700. [Google Scholar] [CrossRef]

- Chin, M.J.; Poh, P.E.; Tey, B.T.; Chan, E.S.; Chin, K.L. Biogas from palm oil mill effluent (POME): Opportunities and challenges from Malaysia’s perspective. Renew. Sustain. Energy Rev. 2013, 26, 717–726. [Google Scholar] [CrossRef]

- Aziz, N.I.H.A.; Hanafiah, M.M. Life cycle analysis of biogas production from anaerobic digestion of palm oil mill effluent. Renew. Energy 2020, 145, 847–857. [Google Scholar] [CrossRef]

- Sharvini, S.R.; Noor, Z.Z.; Chong, C.S.; Stringer, L.C.; Glew, D. Energy generation from palm oil mill effluent: A life cycle assessment of two biogas technologies. Energy 2020, 191, 116513. [Google Scholar] [CrossRef]

- Choo, Y.M.; Muhamad, H.; Hashim, Z.; Subramaniam, V.; Puah, C.W.; Tan, Y. Determination of GHG contributions by subsystems in the oil palm supply chain using the LCA approach. Int. J. Life Cycle Assess. 2011, 16, 669–681. [Google Scholar] [CrossRef]

- Ab Hamid, M.F.; Basar, U.A.; Asid, R.; Sulaiman, W.F.W.; Bahri, E.N.A.; Sulaiman, N.F.C.; Ramli, N. Issues and Challenges in the Malaysian Economy: Towards Inclusive Growth; Emerald Group Publishing: Bingley, UK, 2019; ISBN 1838674799. [Google Scholar]

- Chang, R.-D.; Zuo, J.; Zhao, Z.-Y.; Zillante, G.; Gan, X.-L.; Soebarto, V. Evolving theories of sustainability and firms: History, future directions and implications for renewable energy research. Renew. Sustain. Energy Rev. 2017, 72, 48–56. [Google Scholar] [CrossRef]

- Kaman, Z.K.; Salleh, S.F.; Ishak, W.W.M. Renewable Energy (RE) and Theory on Business Sustainability: Malaysia Policy Development. Int. J. Eng. Adv. Technol. 2019, 8, 623–627. [Google Scholar]

- Johari, A.; Nyakuma, B.B.; Nor, S.H.M.; Mat, R.; Hashim, H.; Ahmad, A.; Zakaria, Z.Y.; Abdullah, T.A.T. The challenges and prospects of palm oil based biodiesel in Malaysia. Energy 2015, 81, 255–261. [Google Scholar] [CrossRef]

- Rahim, N.A.; Che, H.S.; Hasanuzzaman, M.; Habib, A. Toward Cleaner Cities: Renewable Energy Initiatives in Malaysia. In Devising a Clean Energy Strategy for Asian Cities; Springer: New York, NY, USA, 2019; pp. 165–185. [Google Scholar]

| State | Cultivation Area (Million Hectares/Year) | ||

|---|---|---|---|

| 2016 | 2017 | 2018 | |

| Peninsular Malaysia | 2.3 | 2.4 | 2.4 |

| Sabah and Sarawak | 2.7 | 2.7 | 2.8 |

| Total | 5.0 | 5.1 | 5.2 |

| Feedstock | Pretreatment Type | Experiment Condition | Fermentation Condition (Temperature, pH, Duration) | Ethanol Yield | Reference |

|---|---|---|---|---|---|

| Sugarcane bagasse | NaOH | Anaerobic condition without agitation | 50 °C for 2 days | 4.5 g/100 g | [50] |

| Formosana wood chips | Acid steam explosion, bleached acid steam explosion | 25 °C–160 °C, heating rate of 1.5 °C for 180 min | 37 °C for 120 h | 4.18 & 3.62 g/g | [51] |

| Frond part of banana plant | Ammonia | 0.1 M NaOH 0.1 M H2SO4 | 30 °C, pH 6.8 57 h | 45.75 g/L | [40] |

| Food waste | Hydrothermal and dilute acid pretreatment | Aseptic conditions | 30 °C, pH at 6.5–7.0 for 120 h | 0.42 g/g | [52] |

| Rice straw | Diluted acid | 50 °C, pH 5.0 72 h | 30 °C, pH 6.0 | 0.51 g/g | [53] |

| Oil-palm | Alkali | 3% NaOH solid-liquid charge (1:8) 110 °C, 45 min | 30 °C, 14–16 h | 0.33 g/g | [54] |

| Oil palm frond | Hydrothermal | 121 °C for 30 min | 30 °C, 24 h | 0.48 g/g | [43] |

| Oil palm empty fruit bunch | Bisulfite | 180 °C for 30 min | 30 °C, 24 h | 48 g/L | [55] |

| Sago pith waste | Microwave-assisted acid | Drying: 2 h Milling: 1 min Hydrolysis:1 min | 30 °C, 36 h | 0.31 g/g | [44] |

| Palm empty fruit bunch | Organosolv | 60 min at 120 °C | 100 °C for 45 min | 133.17 mg/L | [56] |

| Water Hyacinth | Acid | 70 °C for 24 h | 30 °C, 72 h | 0.42 g/g | [57] |

| Feedstock | Catalyst Type | Experiment Condition | Biodiesel Yield (%) | Reference | |||

|---|---|---|---|---|---|---|---|

| Catalyst Loading (wt%) | Molar Ratio | Reaction Time (min) | Reaction Temperature (°C) | ||||

| Palm oil based WCO | LBC | 5.47 | 12.21:1 | 55.26 | up to 96.65 | [71] | |

| WCO | Na2O impregnated-CNTs nanocatalyst | 5 | 20:1 | 240 | 90 | 97 | [72] |

| WCO | BaSnO3 | 6 | 10:1 | 120 | 90 | 96 | [73] |

| WCO | calcined fusion waste chicken and fish bones | 1.98 | 10:1 | 114 | 65 | 89.5 | [74] |

| OPEFB | (4-BDS) | 20 | 420 | 110 | 98.1 | [75] | |

| A. korthalsii seeds | Marine barnacle | 4.7% | 12.2:1 | 180 | 65 | 97.12 ± 0.49 | [76] |

| OPEFB | carbon-based solid acid | 10% | 50:1 | 480 | 100 | FAME yield of 50.5% | [77] |

| Palm oil | La-dolomite catalyst | 7 | 180 | 65 | 98.7 | [78] | |

| Feedstock | Pretreatment Type | Experiment Condition (Inoculum) | Fermentation (Temperature, pH) | Biohydrogen Yield | Reference |

|---|---|---|---|---|---|

| POME | No pretreatment | POME heat treated sludge (80 °C for 60 min) | 55 °C/6.0 | 1.88 mol H2/mol sugar | [91] |

| POME | Ultrasonicated POME | POME heat treated sludge (heated at 70 °C for 10 min; 90 °C and 110 °C for 10 min) | 37 °C/5.5 | 14.62 mL H2 h−1 g−1 | [85] |

| POME | Pre-settled by keeping 24 h in cold treatment 4 °C | POME heated treated anaerobic sludge at 80 °C for 50 min | 38 °C/5.5 | 3.2 mol H2/mol Sugar | [95] |

| POME | Pre-dark fermentation by Bacillus anthracis | Rhodo pseudomanas palustris in photo anaerobic sludge | 30 °C/7.0 | 3.07 ± 0.66 H2/mol-acetate | [96] |

| POME | Pre-settled by keeping 24 h in cold treatment 4 °C | POME digested sludge (heated 100 °C for 60 min) | 38 °C/5.5 | 0.31 L H2 g−1 COD | [97] |

| POME | No pretreatment | Anaerobic sludge was heat treated at 75 °C, 85 °C and 110 °C for 10 min | 37 °C/N. A. | 352 mL H2 h−1 g−1 | [93] |

| POME | pH 8.5 with autoclave at 121 °C for 20 min | Engineered E. coli strain in LB medium, growth at 37 °C | 37 °C/N. A. | 0.66 mol H2/mol Sugar | [98] |

| POME | Acid hydrolysis by HCL (37% v/v) | Saccharification by Clostridium acetobutylicum (YM1) | 38 °C/5.85 | 108.35 mL H2 g−1 | [99] |

| Industry Type | Generation (Million tons/year) | Type of Generated Biomass | Potential Energy * (Million Tonnes) |

|---|---|---|---|

| Municipal solid waste | 4.35 | Municipal solid waste | - |

| Palm oil | 59.8 | Empty fruit bunches | 5.53 |

| Fronds and trunk | - | ||

| Fiber | 3.99 | ||

| Shell | 1.89 | ||

| Paddy | 2.14 | Palm kernel | 95 |

| Rice husk | 0.17 | ||

| Rice straw | 0.28 | ||

| Sugar | 1.11 | Bagasse | 0.069 |

| Wood | 0.3 | Plywood residue | 0.024 |

| 1.67 | Sawdust | 0.44 | |

| Stool ** | N. A. | Animal wastes | 8.27 × 109 kWh/year |

| Feedstock | Pretreatment Type | Experiment Condition (Inoculum) | Hydrolyze and Acetogenesis Stages pH | Biogas Production Yield (L/g Fresh Mass) | Reference |

|---|---|---|---|---|---|

| Wheat and pearl millet straw | Biological treatment by Chaetomium globosporum | 1.5 g/L | 6 | 0.568 | [112] |

| Oil palm empty fruit bunches | Prehydrolysis and bioaugmentation | 20.7 g/L | 7.2–7.5 | 0.349 | [113] |

| Cow manure | Physical | 0.5 g/L | N. A. | 0.27 | [114] |

| Food waste | N. A. | N. A. | 4.8 | 0.7 | [115] |

| POME | N. A. | 75–80 g/L | 3–3.2 | 0.06 | [116] |

| Fresh cow dung | Physical (chopping) | N. A. | 7 | 1.1–1.6 | [117] |

| Cow manure | N. A. | N. A. | 6.23–6.92 | 0.011 | [118] |

| A mixture of grass silage, maize silage, hay, straw, molassess, and Bovigold | Biological pretreatment using Neocallimastix frontalis strains | N. A. | N. A. | 0.6 | [119] |

| System | CO2 kg/kWh | SO2 kg/kWh |

|---|---|---|

| CSTR | 0.39 | 2.06 |

| CLB | 4.09 | 0.15 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rezania, S.; Oryani, B.; Cho, J.; Sabbagh, F.; Rupani, P.F.; Talaiekhozani, A.; Rahimi, N.; Lotfi Ghahroud, M. Technical Aspects of Biofuel Production from Different Sources in Malaysia—A Review. Processes 2020, 8, 993. https://doi.org/10.3390/pr8080993

Rezania S, Oryani B, Cho J, Sabbagh F, Rupani PF, Talaiekhozani A, Rahimi N, Lotfi Ghahroud M. Technical Aspects of Biofuel Production from Different Sources in Malaysia—A Review. Processes. 2020; 8(8):993. https://doi.org/10.3390/pr8080993

Chicago/Turabian StyleRezania, Shahabaldin, Bahareh Oryani, Jinwoo Cho, Farzaneh Sabbagh, Parveen Fatemeh Rupani, Amirreza Talaiekhozani, Negar Rahimi, and Majid Lotfi Ghahroud. 2020. "Technical Aspects of Biofuel Production from Different Sources in Malaysia—A Review" Processes 8, no. 8: 993. https://doi.org/10.3390/pr8080993

APA StyleRezania, S., Oryani, B., Cho, J., Sabbagh, F., Rupani, P. F., Talaiekhozani, A., Rahimi, N., & Lotfi Ghahroud, M. (2020). Technical Aspects of Biofuel Production from Different Sources in Malaysia—A Review. Processes, 8(8), 993. https://doi.org/10.3390/pr8080993