Modelling Acetification with Artificial Neural Networks and Comparison with Alternative Procedures

Abstract

1. Introduction

1.1. Modelling of Bioprocesses

- Regression models [11,12], which are usually based on polynomial equations relating the response variables (viz., the dependent variables or outputs) to the factors (viz., the independent variables or inputs) of a process. Regression models are typically used to examine the influence of experimental factors on process outputs, as well as potential interactions between factors.

- Artificial neural networks (ANNs) [13] consist of so-called “neurons”. These are elemental computation or processing units that operate in parallel [14] and are mutually connected across a network comprising various layers. The ANNs used to model bioprocesses use mathematical combinations of basis functions that can be fitted to experimental data by determining their connection weights and biases. This makes ANNs highly accurate approximators to both static and dynamic non-linear functions. The process, which is known as “supervised training” or “supervised learning”, minimizes differences between ANN outputs and experimental responses to specific inputs (training patterns) by using algorithms such as back-propagation [15]. Topologically, ANNs comprise an input layer that connects process inputs, an output layer that provides the process outputs, and one or more hidden layers between the input and output layer that reflect the black-box behaviour of the ANN. Architecturally, the ANNs typically used with bioprocesses are either feed-forward networks [16], where the only connections between neurons are those from inputs to outputs, or recurrent networks [17], where some outputs are fed back to the input layer (e.g., in models for dynamic systems). Bioprocesses can also be modelled with neuro-fuzzy networks, which use fuzzy logics [18] to increase extrapolability.

1.2. Modelling Acetification

1.3. Objectives of the Work

2. Materials and Methods

2.1. Experimental Conditions

2.2. Models for Acetic Acid Fermentation

2.2.1. First-Principles Model

- , , , and are the concentrations of viable cells, dead cells, ethanol, acetic acid and dissolved oxygen (all in g·L−1), respectively.

- is the time (h).

- is the volume of the medium (L), the raw material feed rate (L·h−1), the concentration of ethanol in the fed raw material (g·L−1) and the dissolved oxygen in equilibrium with air (g·L−1).

- is the cell growth rate (g cell·L−1·h−1), the cell death rate (g cell·L−1·h−1), the cell lysis rate (g cell·L−1·h−1), the ethanol uptake rate (g ethanol·L−1·h−1), the acetic acid formation rate (g acetic acid·L−1·h−1) and the dissolved oxygen uptake rate (g oxygen·L−1·h−1).

- is the specific growth rate (h−1), its maximum value (h−1) and , and are terms representing the influence of ethanol, acetic acid and dissolved oxygen on cell growth, respectively; is the ethanol saturation constant (g ethanol·L−1), is the ethanol inhibition constant (g ethanol·L−1), is the acetic acid inhibition constant (g acetic acid·L−1) and is the dissolved oxygen saturation constant (g oxygen·L−1); is the specific cell death rate (h−1), its minimum possible value (h−1) and and are terms representing the influence of ethanol and acetic acid on cell death, respectively; and are the ethanol and acetic acid-induced cell death rate constants (g·L−1), respectively; is the specific cell lysis rate (h−1).

- is the ethanol yield factor required to supply the amount of energy needed for biomass growth (determined experimentally as 116.96 g ethanol·g−1 cell), is the stoichiometric coefficient of ethanol uptake for acetic acid formation (0.767 g ethanol·g−1 acetic acid) and is the stoichiometric coefficient of ethanol relative to oxygen (1.44 g ethanol·g−1 oxygen).

- is a constant encompassing the following factors: is the overall volumetric coefficient of mass transfer for the liquid phase (determined experimentally as 500 h−1), is the ratio of the air feed rate to the volume of the medium (h−1), is the universal gas constant (0.082 atm·L·K−1·mol−1), is the temperature (K), is the Henry’s constant (atm·L·mol−1) and is the air feed rate (L·h−1).

2.2.2. Black-Box Polynomial Model

2.3. Multilayer Perceptron (MLP)

2.4. Experimental Data and ANN Training

3. Results and Discussion

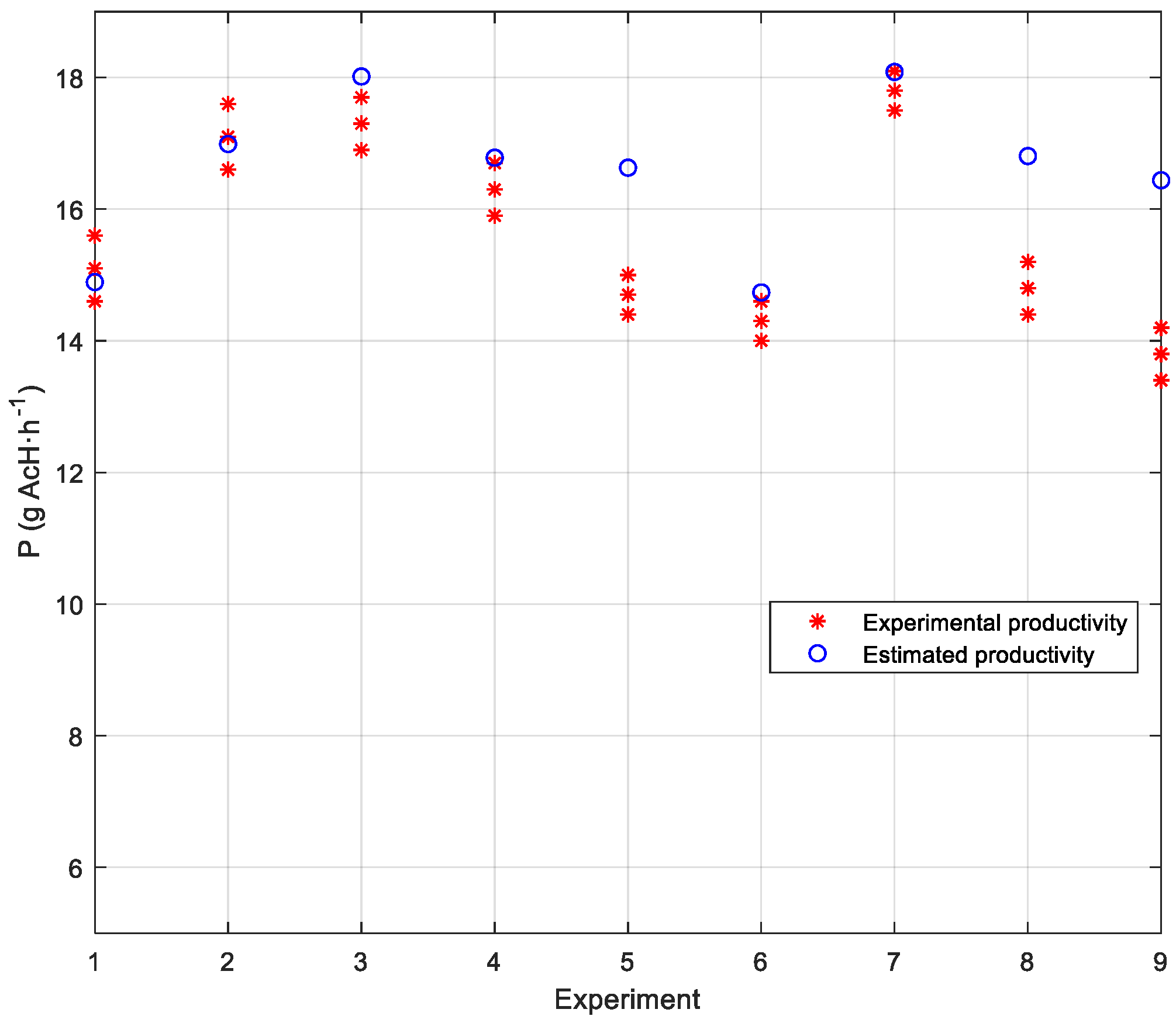

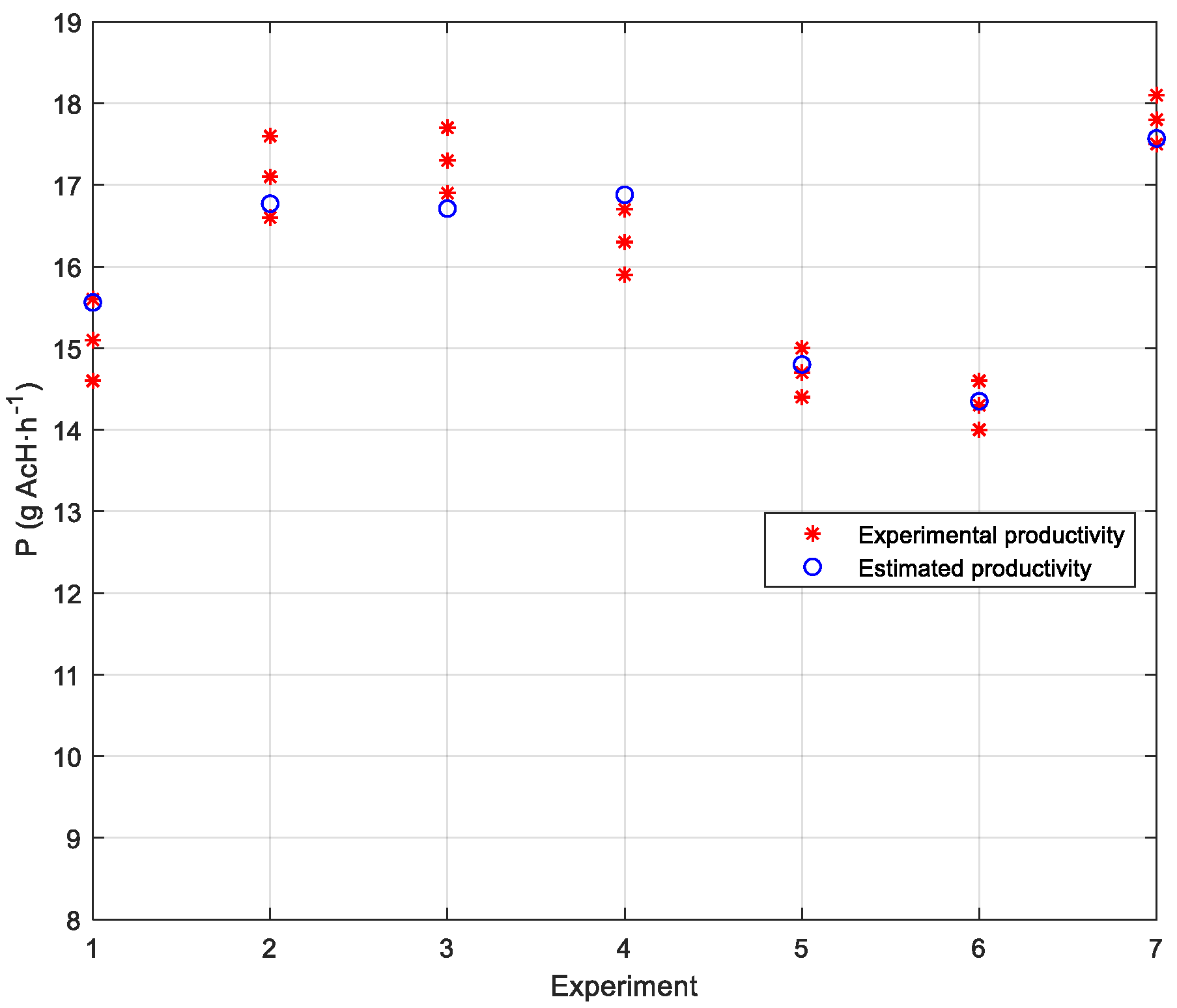

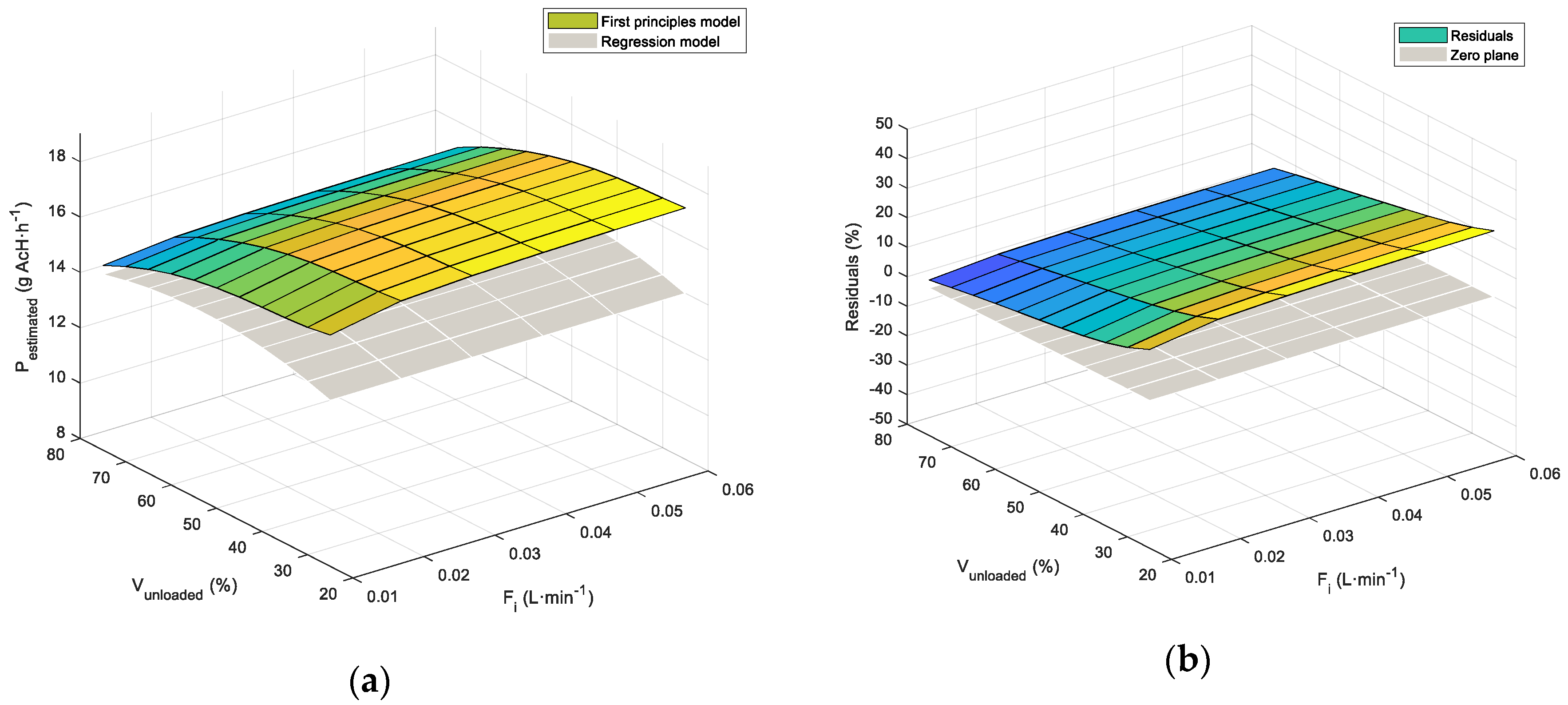

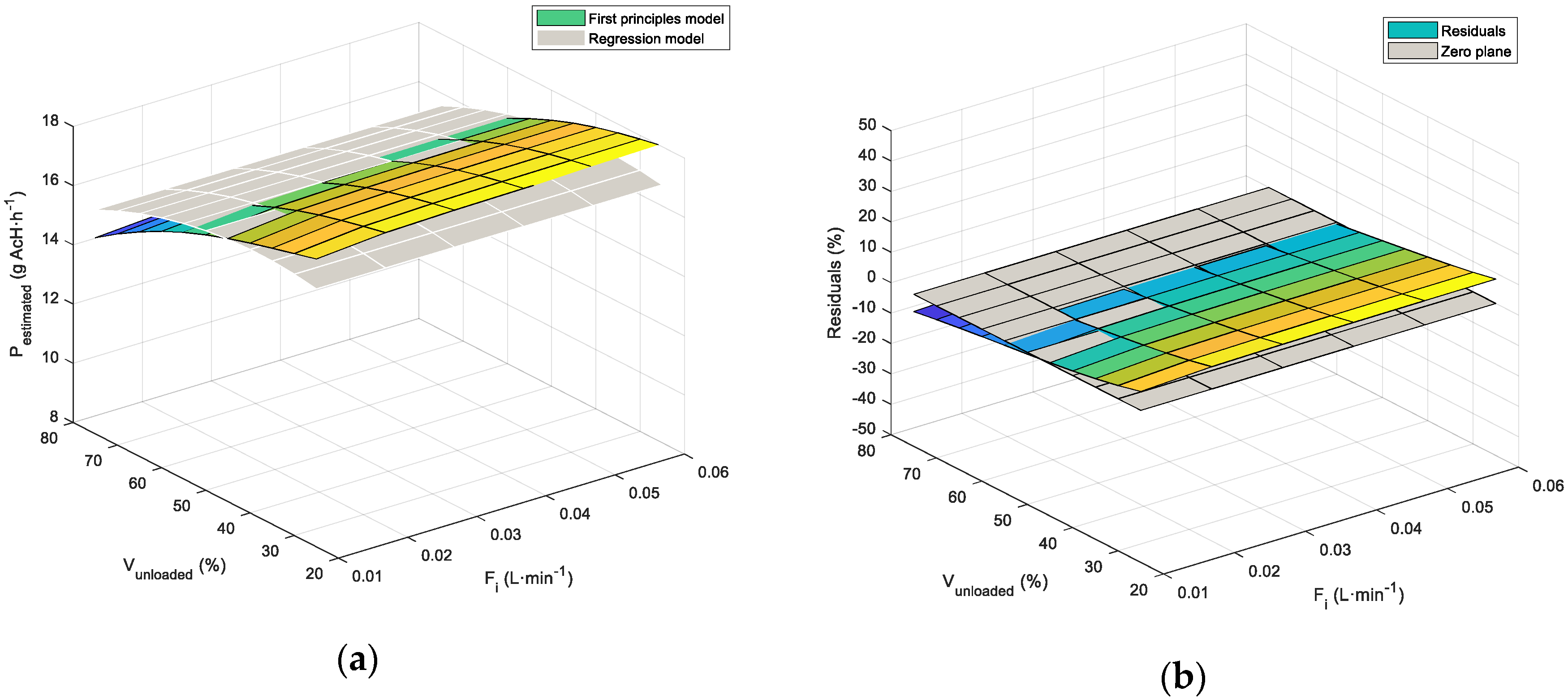

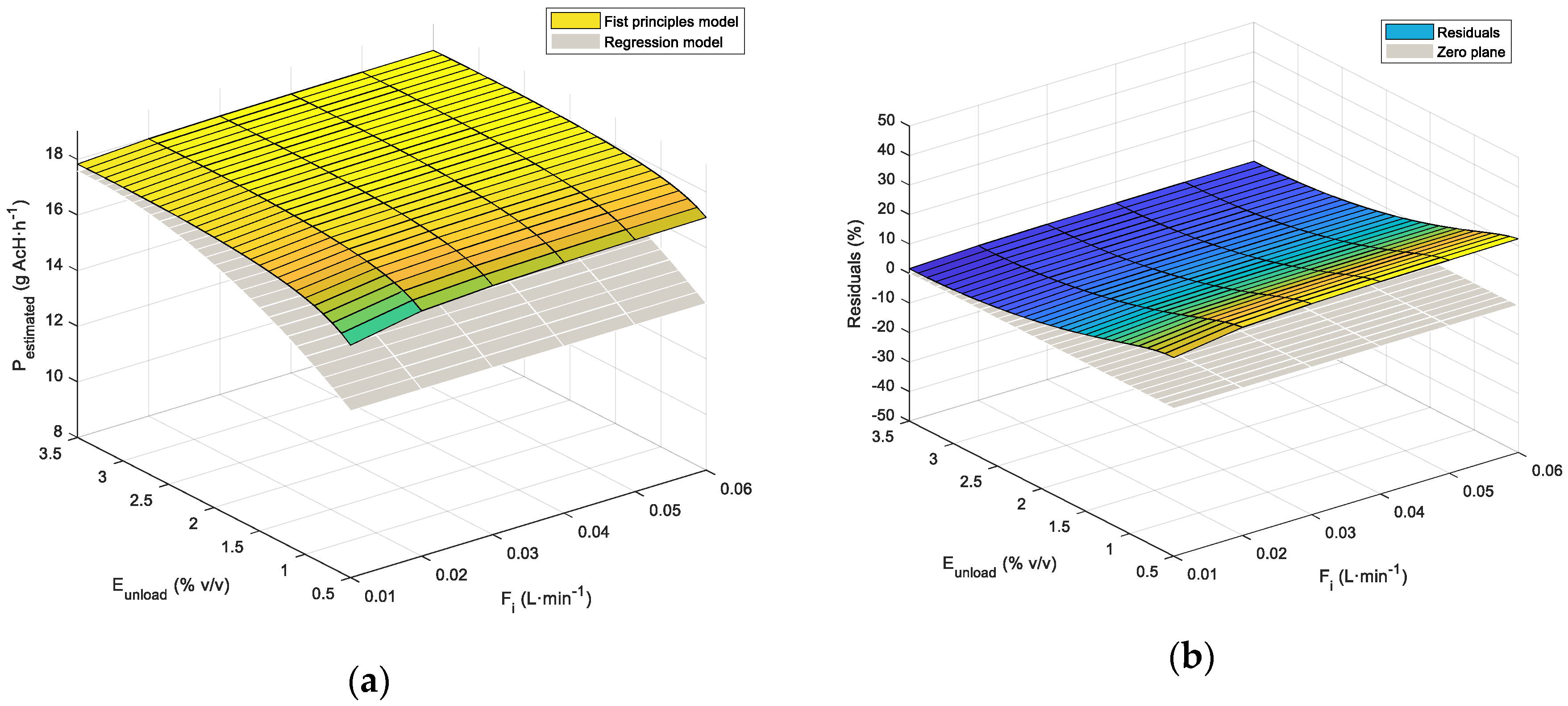

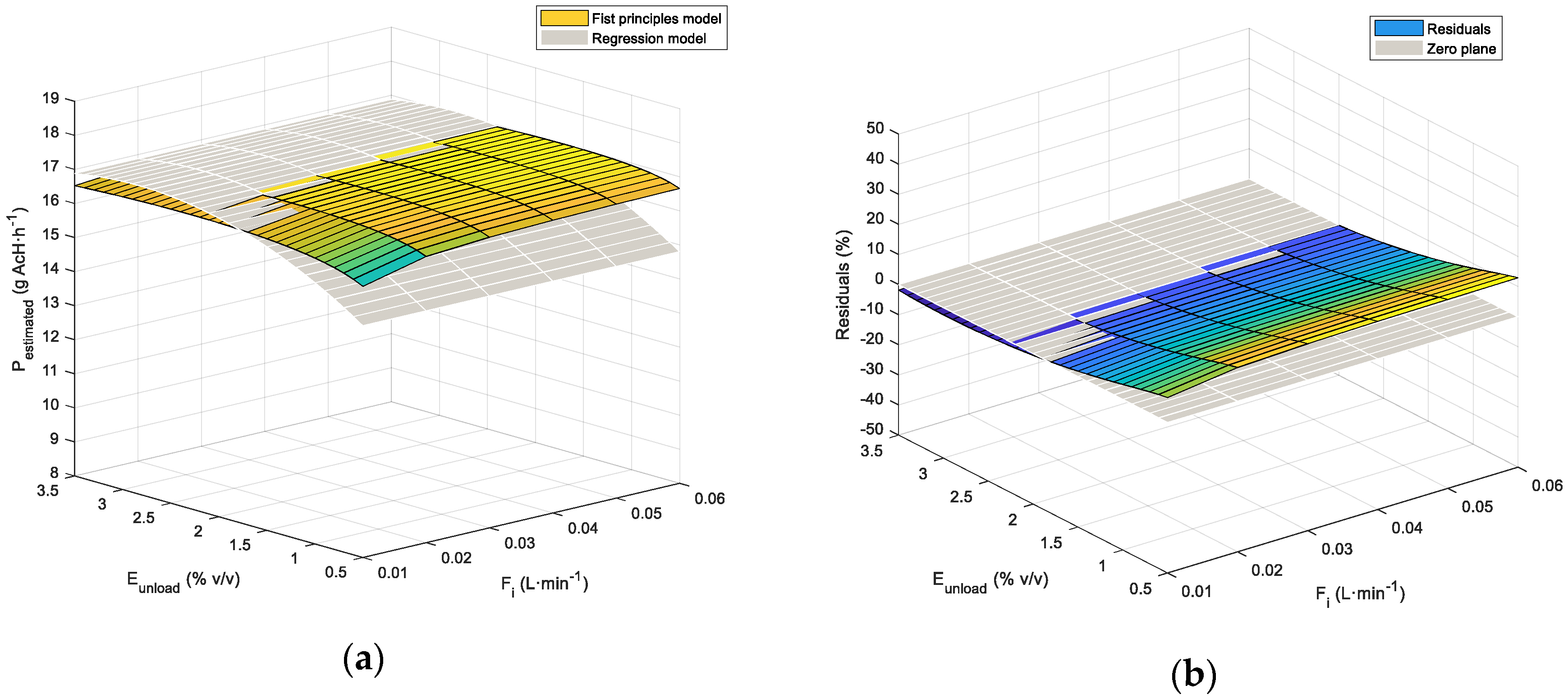

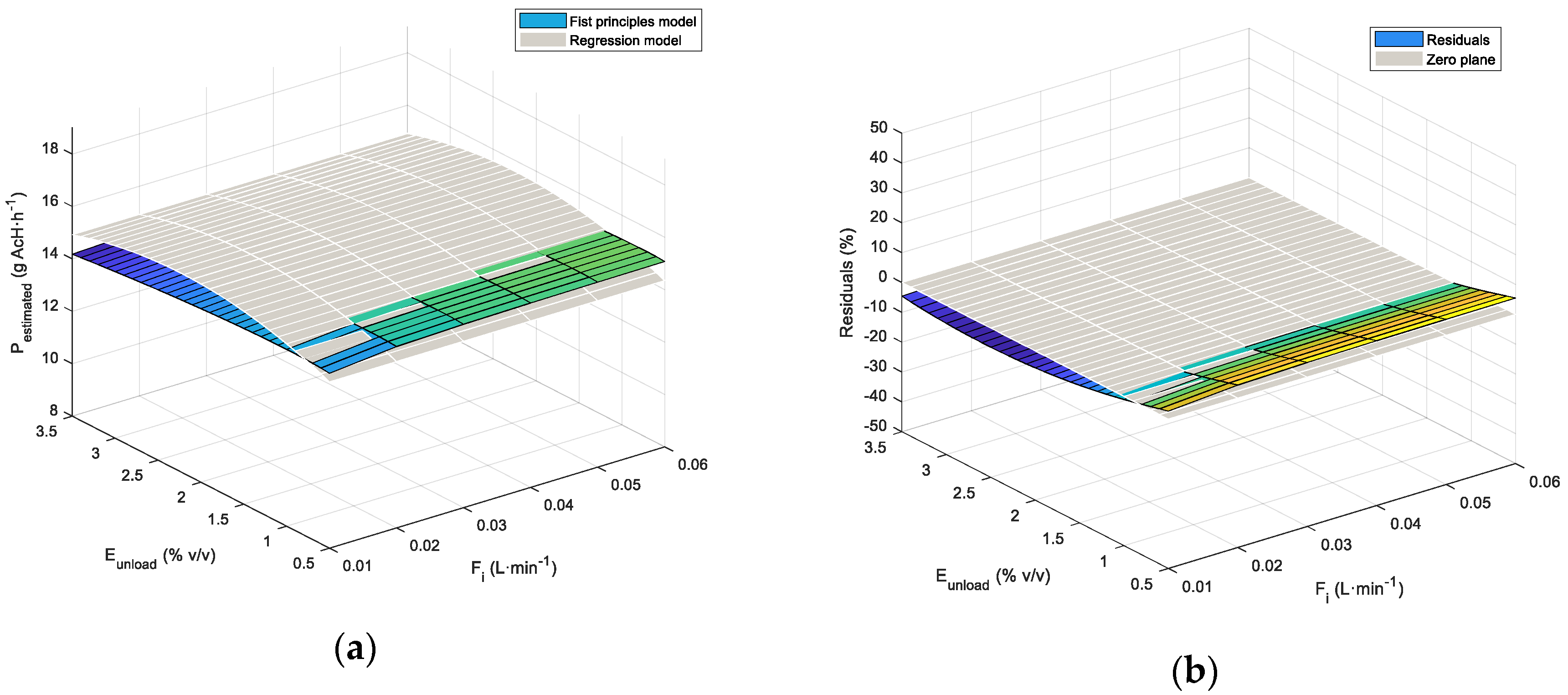

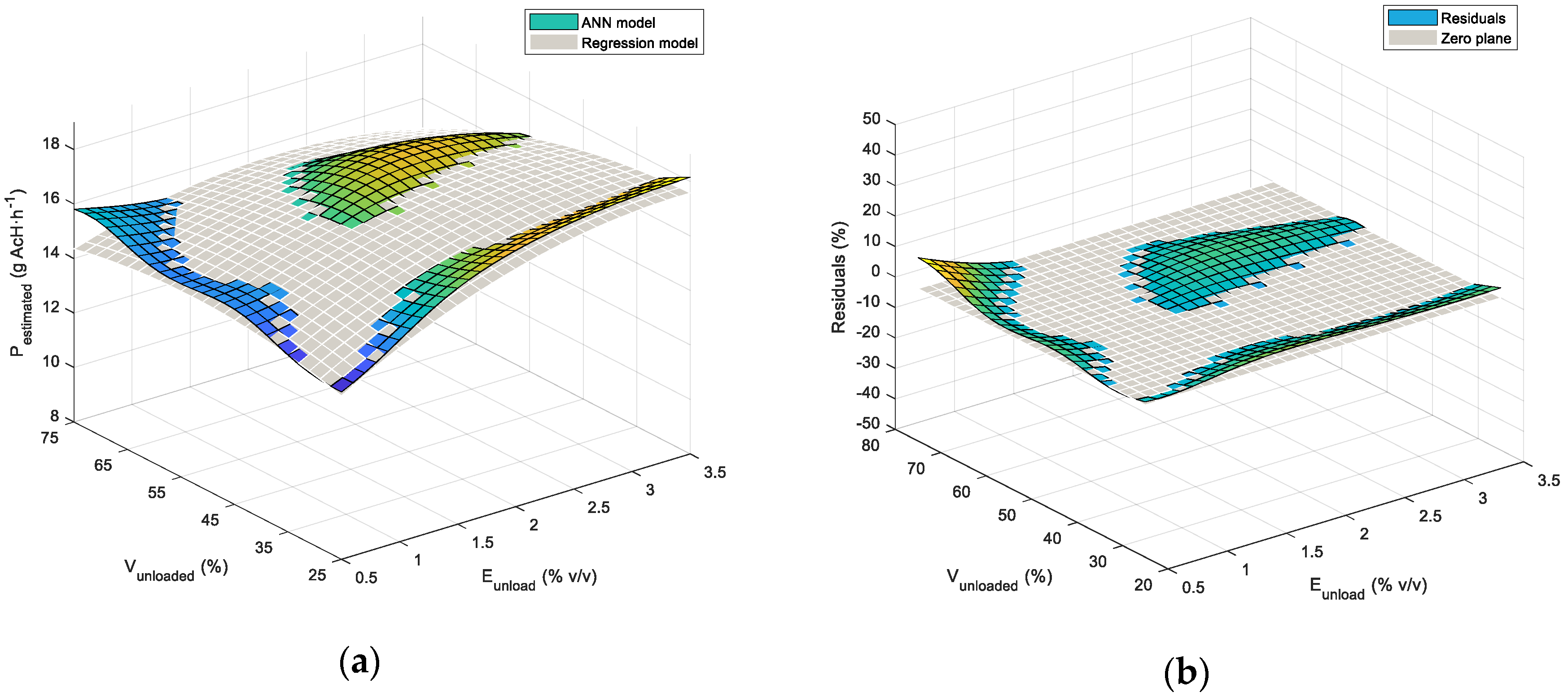

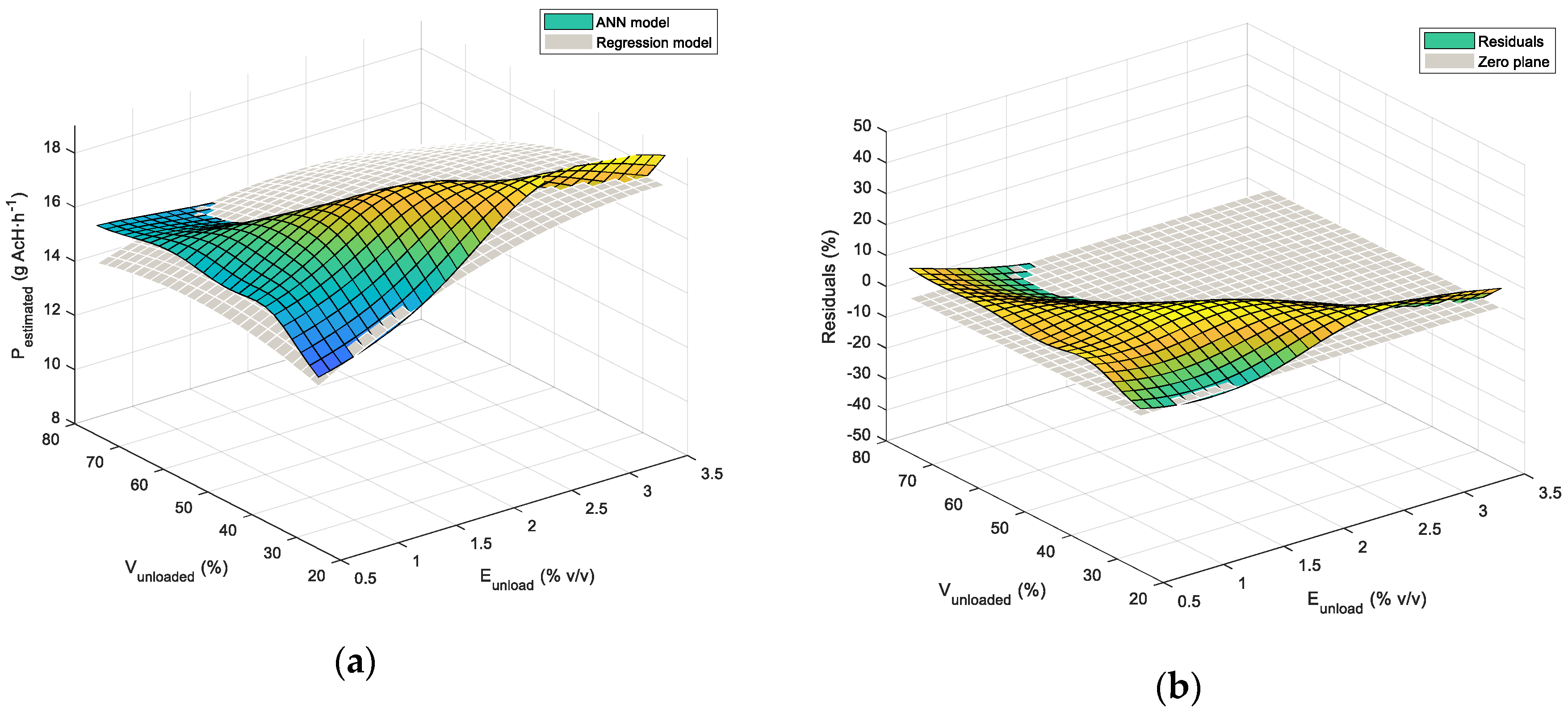

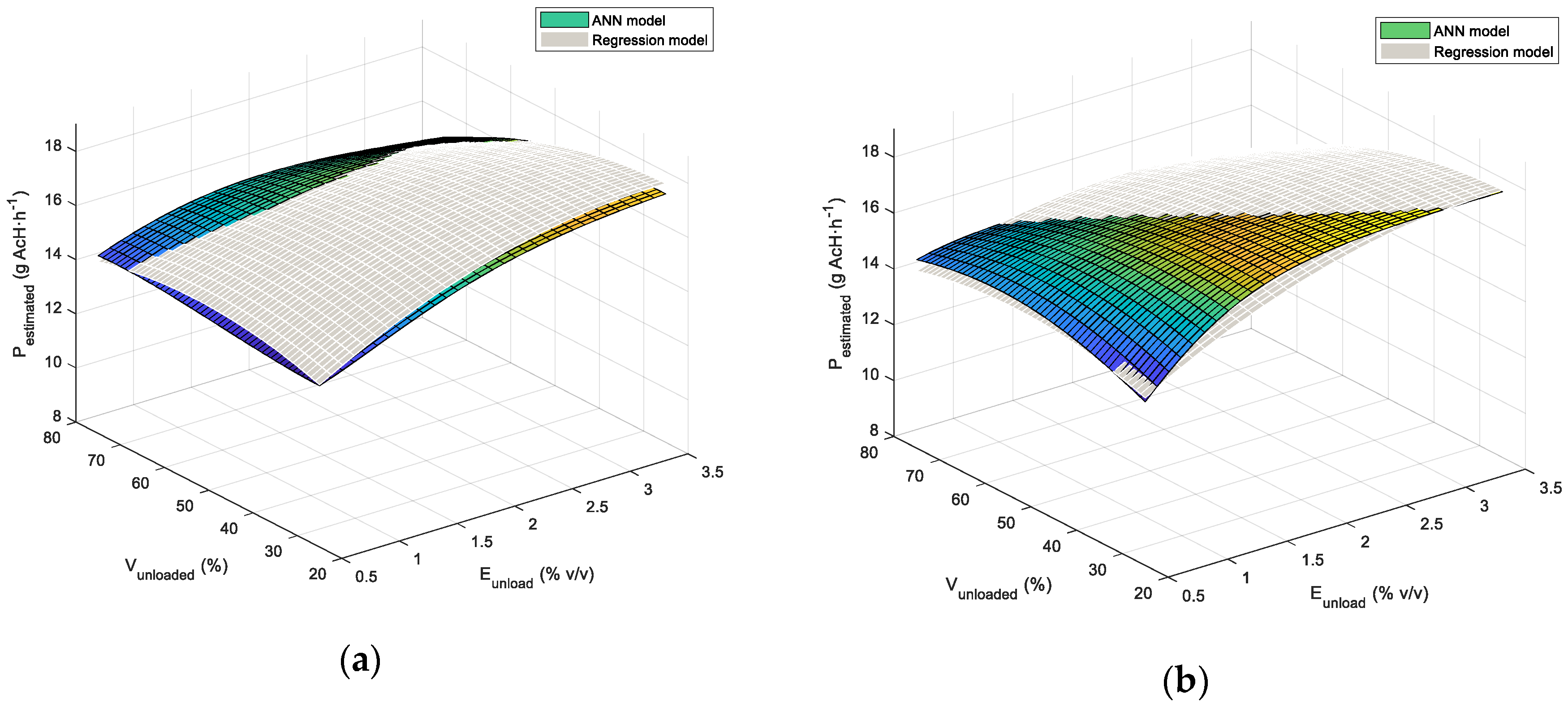

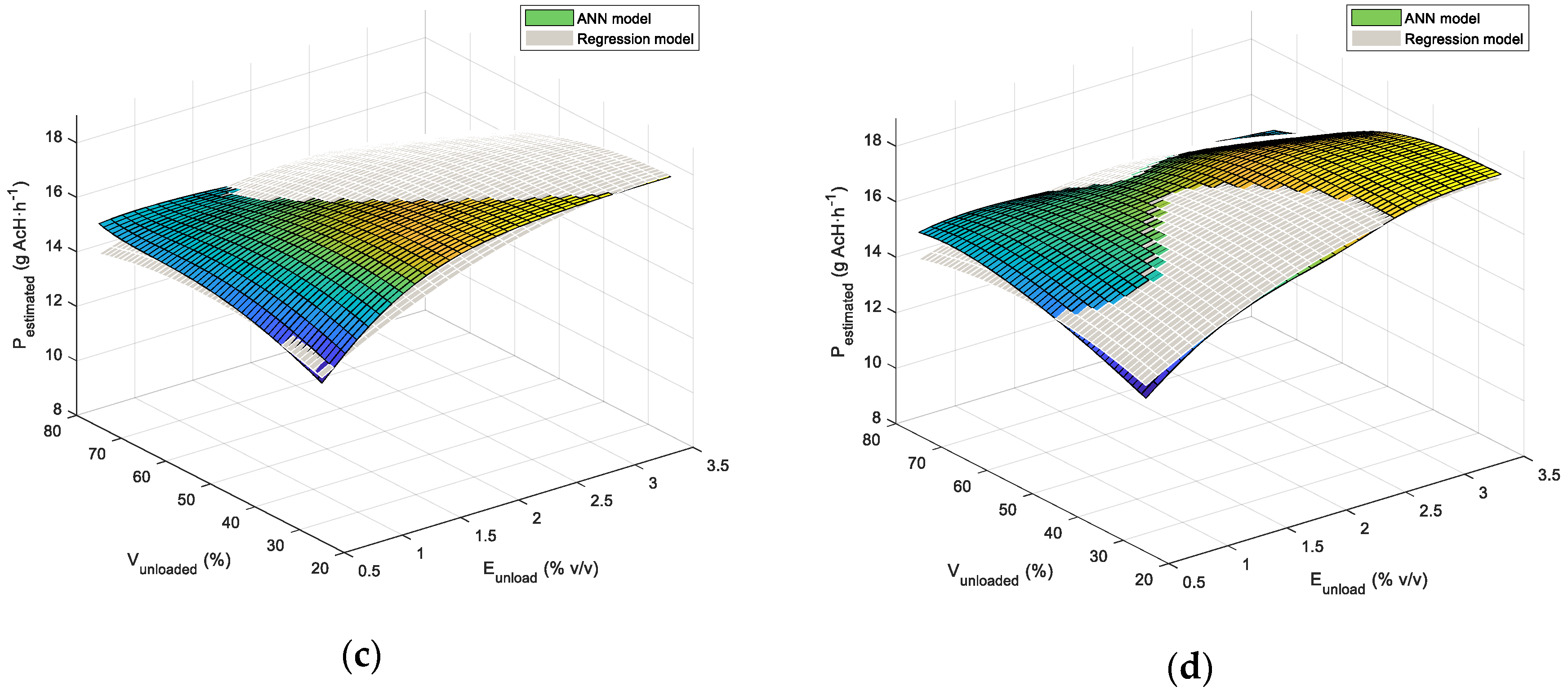

3.1. Comparing the First-Principles and Black-Box Models

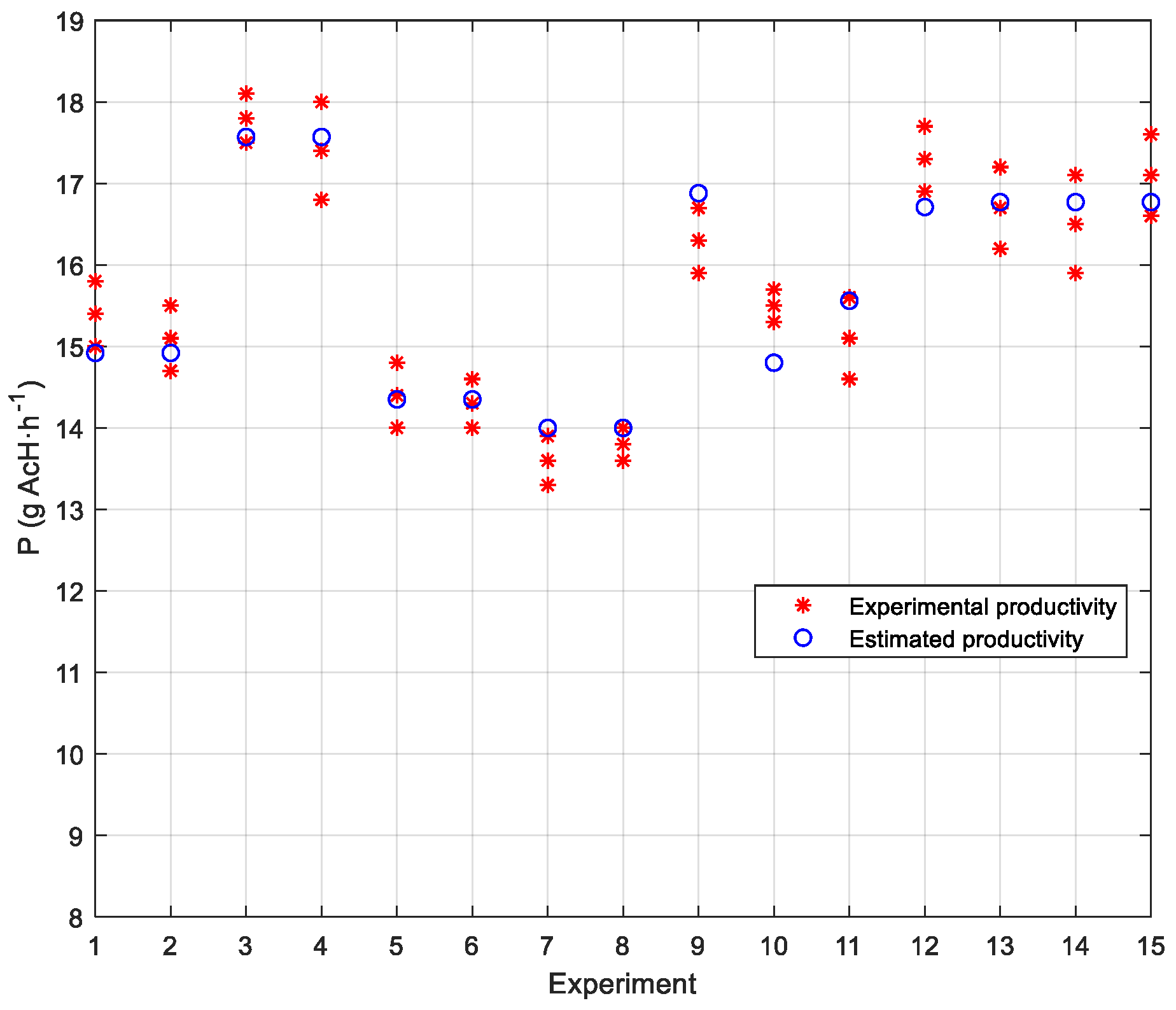

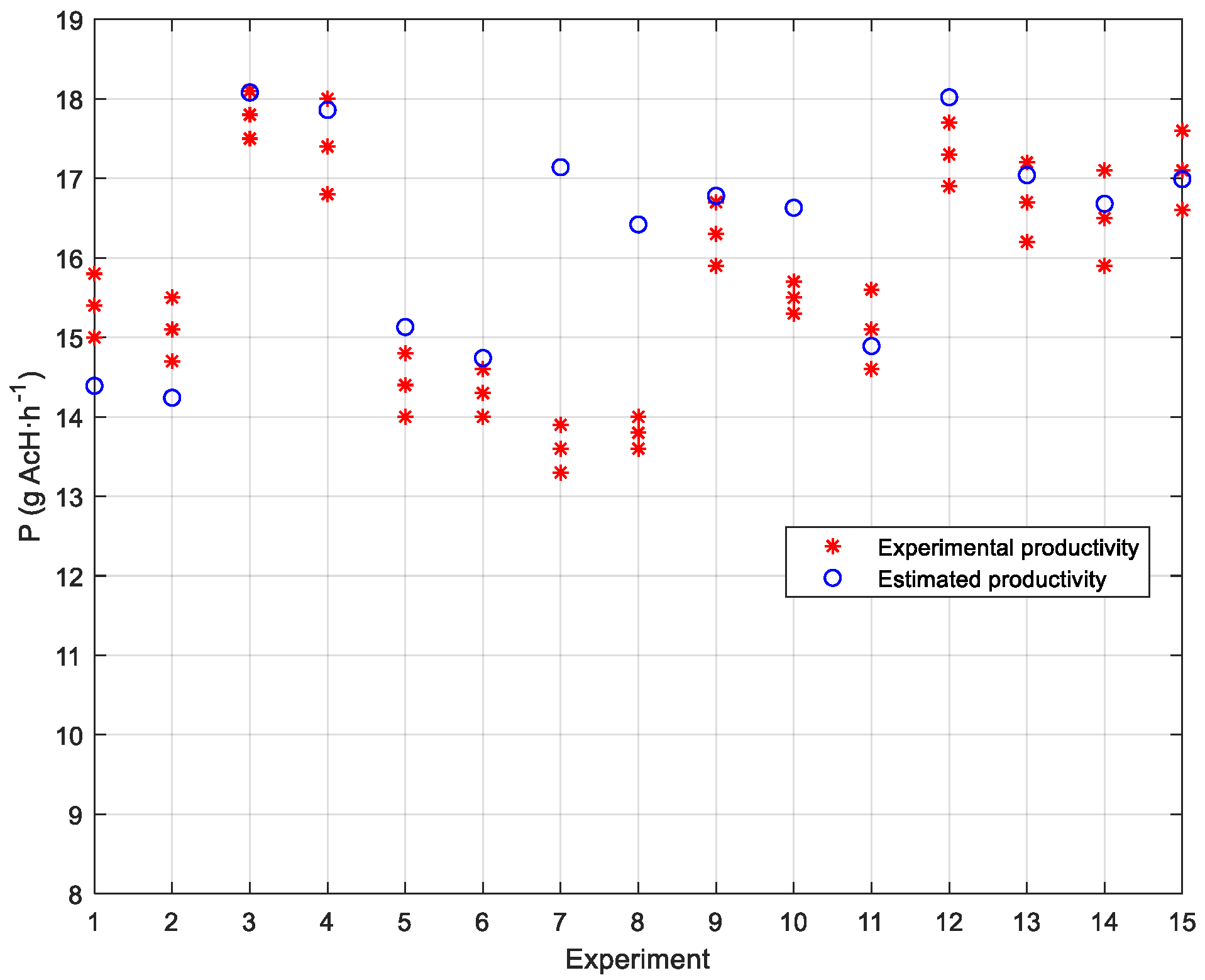

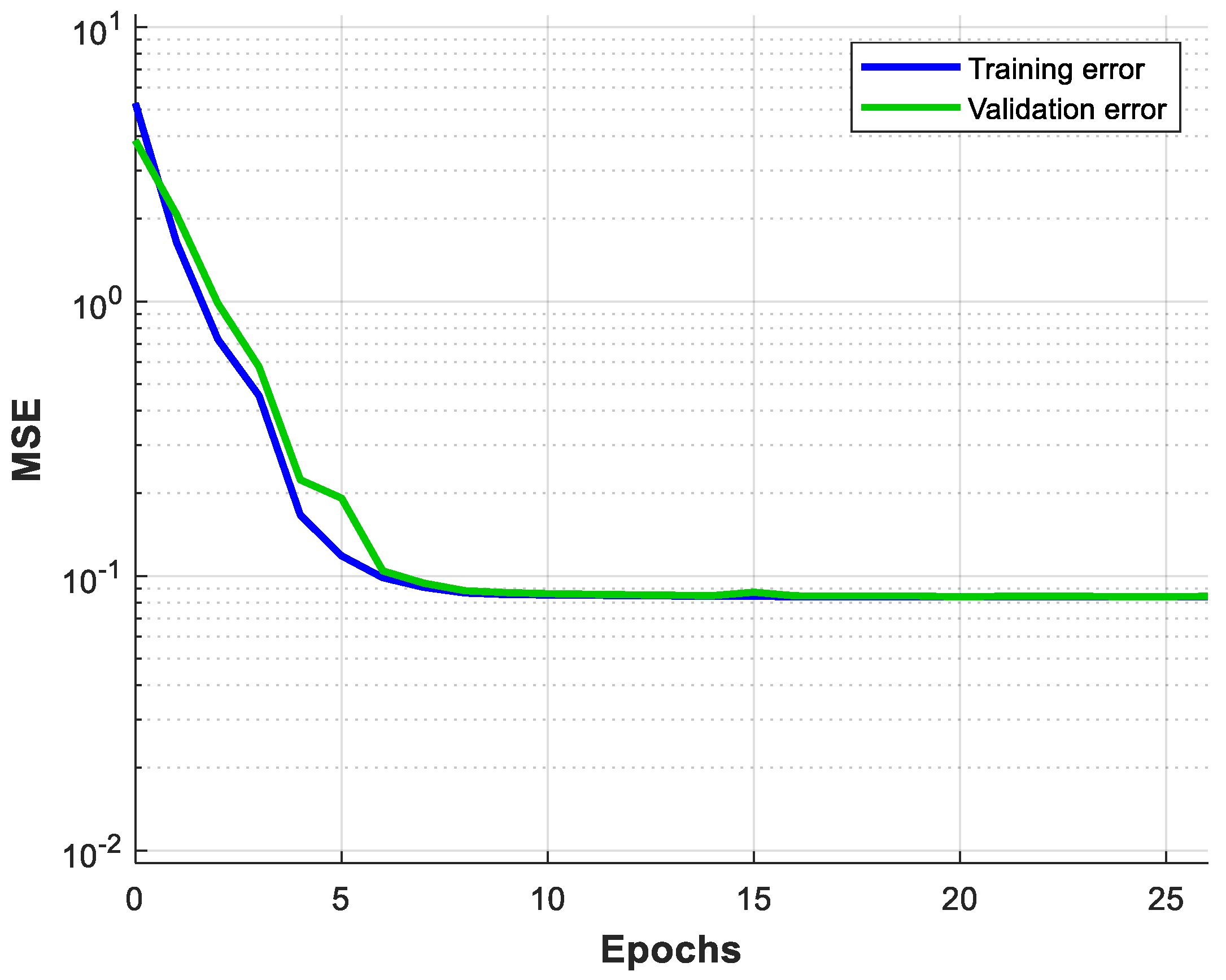

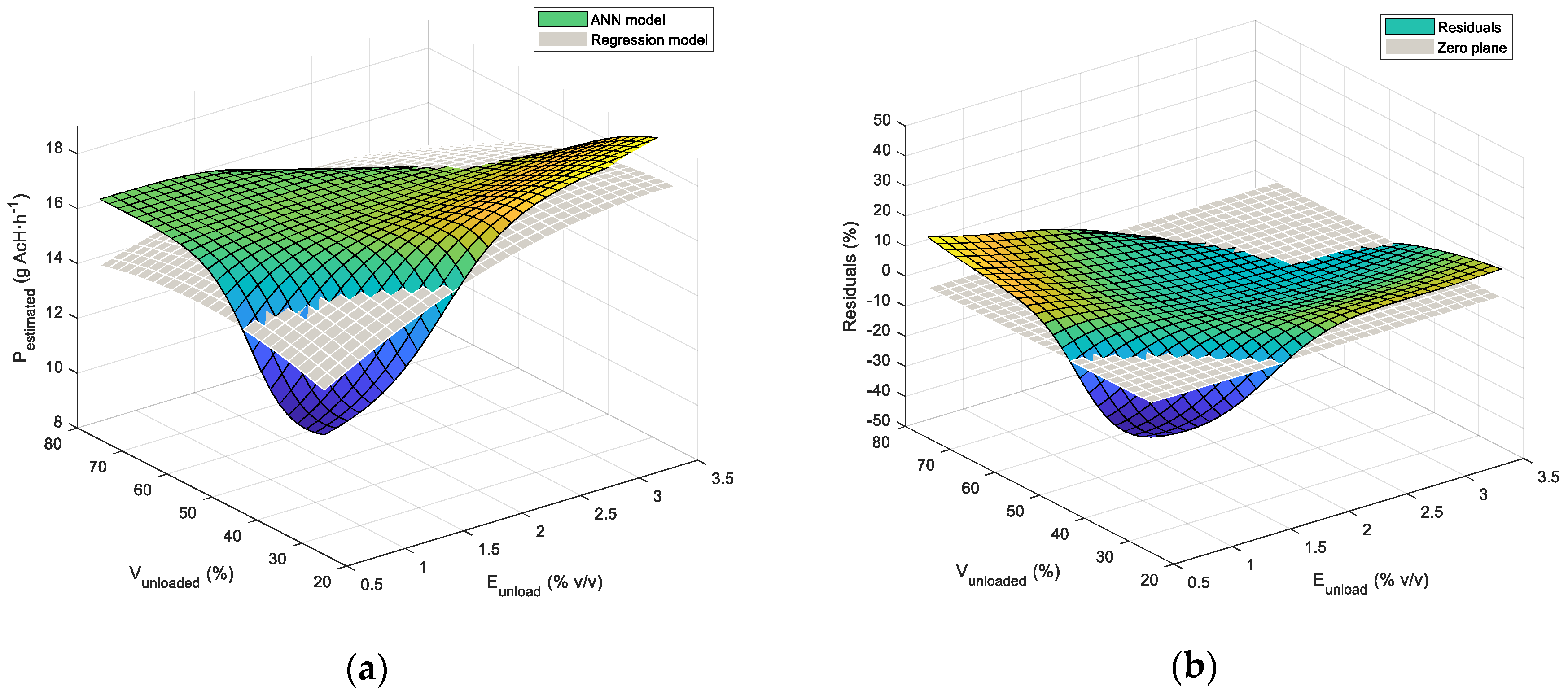

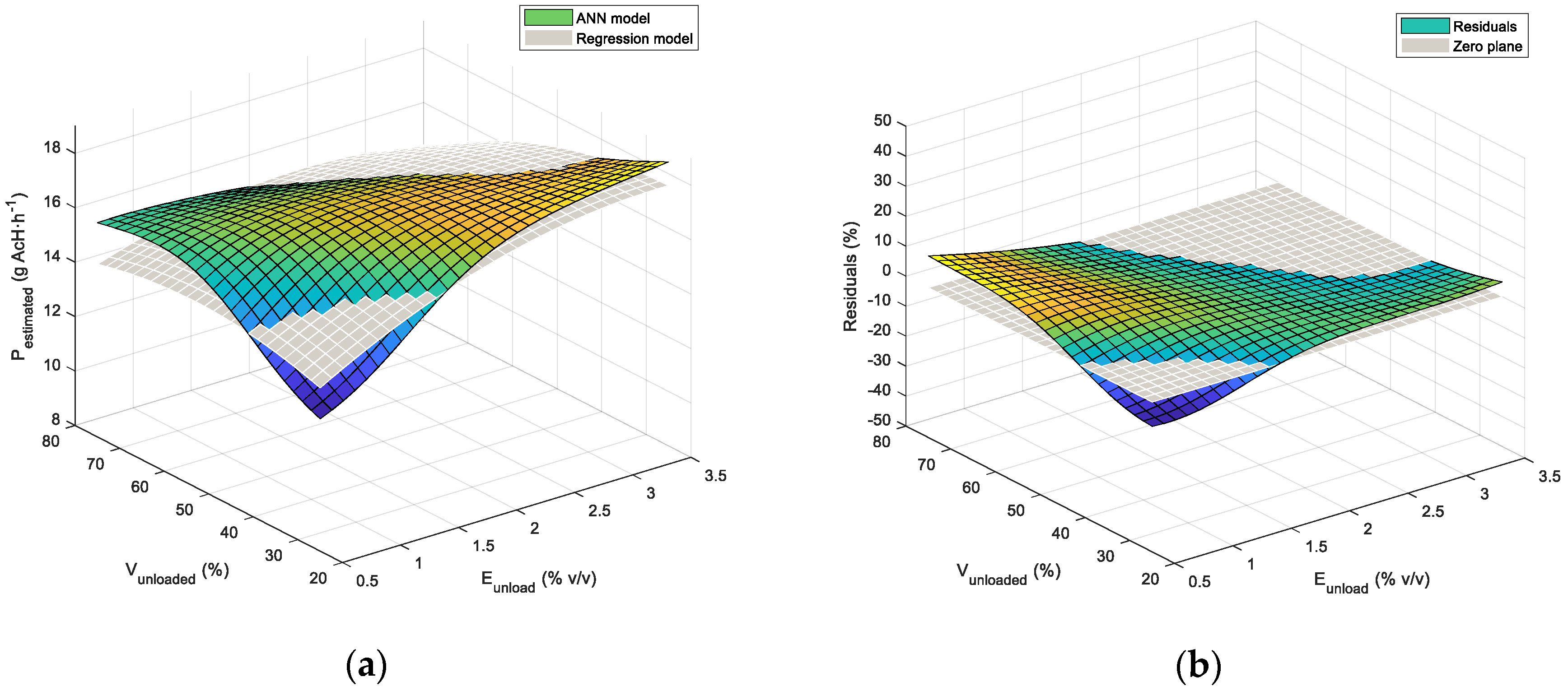

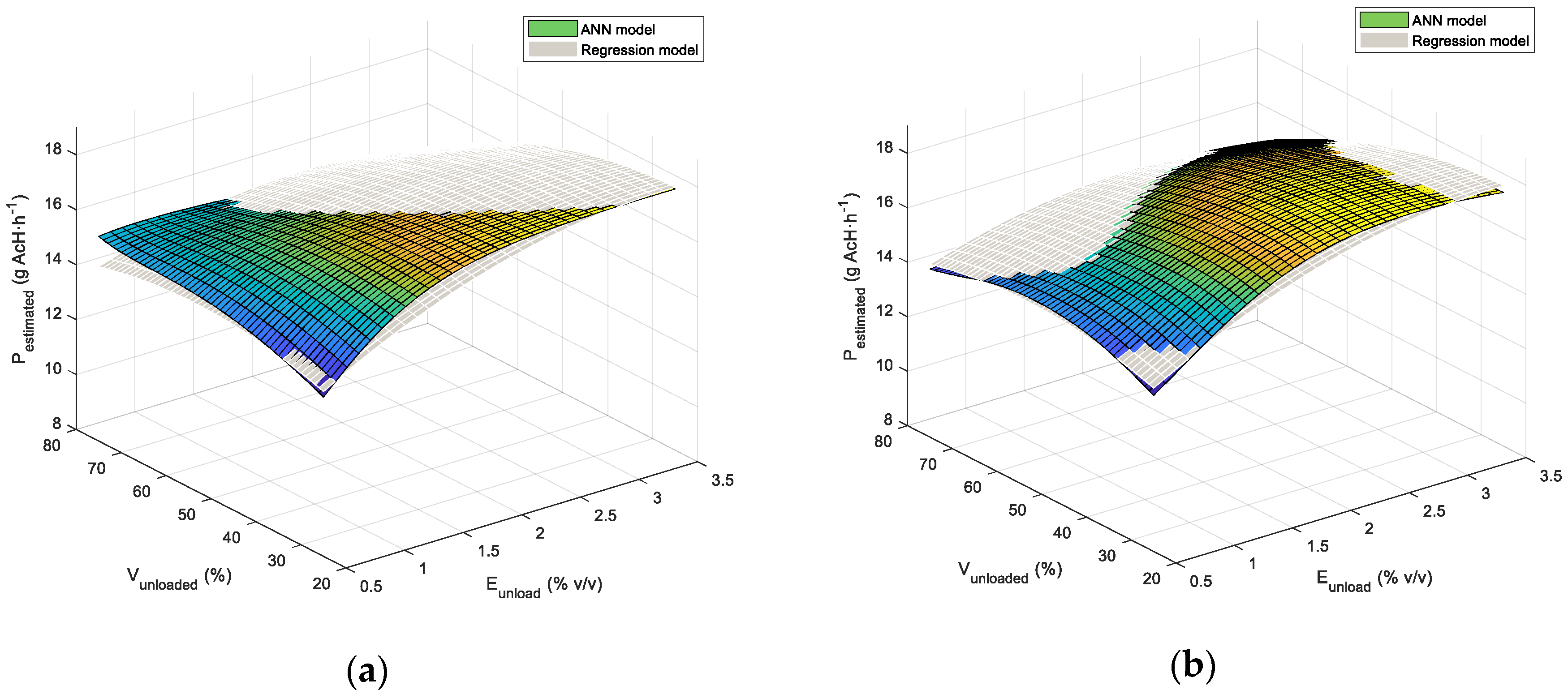

3.2. Artificial Neural Network Model for Productivity in the Acetic Fermentation Process

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- García-García, I.; Santos-Dueñas, I.M.; Jiménez-Ot, C.; Jiménez-Hornero, J.E.; Bonilla-Venceslada, J.L. Vinegar engineering. In Vinegars of the World; Solieri, L., Giudici, P., Eds.; Springer: Milano, Italy, 2009; Chapter 9; pp. 97–120. [Google Scholar] [CrossRef]

- Julien, C.; Whitford, W. Bioreactor Monitoring, Modeling, and Simulation. BioProcess Int. 2007, 5, S10–S17. [Google Scholar]

- Agger, T.; Nielsen, J. Mathematical Modelling of Microbial Processes-Motivation and Means. In Engineering and Manufacturing for Biotechnology. Focus on Biotechnology; Hofman, M., Thonart, P., Eds.; Springer: Dordrecht, The Netherlands, 2001; Volume 4, pp. 61–75. [Google Scholar] [CrossRef]

- Gernaey, K.V.; Lantz, A.E.; Tufvesson, P.; Woodley, J.M.; Sin, G. Application of mechanistic models to fermentation and biocatalysis for next-generation processes. Trends Biotechnol. 2010, 28, 346–354. [Google Scholar] [CrossRef]

- Jiménez-Hornero, J.E. Contribuciones al Modelado y Optimización del Proceso de Fermentación Acética. Ph.D. Thesis, Universidad Nacional de Educación a Distancia, Madrid, Spain, 2007. [Google Scholar]

- Jiménez-Hornero, J.E.; Santos-Dueñas, I.M.; García-García, I. Optimization of biotechnological processes. The acetic acid fermentation. Part I: The proposed model. Biochem. Eng. J. 2009, 45, 1–6. [Google Scholar] [CrossRef]

- Banga, J.R.; Balsa-Canto, E.; Moles, C.G.; Alonso, A.A. Improving food processing using modern optimization methods. Trends Food Sci. Technol. 2003, 14, 131–144. [Google Scholar] [CrossRef]

- Jiménez-Hornero, J.E.; Santos-Dueñas, I.M.; Garcia-Garcia, I. Structural identifiability of a model for the acetic acid fermentation process. Math. Biosci. 2008, 216, 154–162. [Google Scholar] [CrossRef]

- Jiménez-Hornero, J.E.; Santos-Dueñas, I.M.; Garcia-Garcia, I. Optimization of biotechnological processes. The acetic acid fermentation. Part II: Practical identifiability analysis and parameter estimation. Biochem. Eng. J. 2009, 45, 7–21. [Google Scholar] [CrossRef]

- Ljung, L. System Identification: Theory for the User; Prentice-Hall: Englewood Cliffs, NJ, USA, 1987; p. 519. [Google Scholar]

- Santos-Dueñas, I.M. Modelización Polinominal y Optimización de la Acetificación de Vino. Ph.D. Thesis, Universidad de Córdoba, Córdoba, Spain, 2009. [Google Scholar]

- Miller, N.; Miller, C. Estadística y Quimiometria para Quimica Analitica, 4th ed.; Pearson educación SA: Madrid, España, 2002; p. 296. [Google Scholar]

- Anderson, J.A. An Introduction to Neural Networks; MIT Press: Cambridge, MA, USA, 1995; p. 672. [Google Scholar]

- Bogaerts, P.; Hanus, R. Macroscopic Modelling of Bioprocesses with a View to Engineering Applications. In Engineering and Manufacturing for Biotechnology. Focus on Biotechnology; Hofman, M., Thonart, P., Eds.; Springer: Dordrecht, The Netherlands, 2001; Volume 4, pp. 77–109. [Google Scholar] [CrossRef]

- Rumelhart, D.E.; Hinton, G.E.; Williams, R.J. Learning representations by back-propagating errors. Nature 1986, 323, 533–536. [Google Scholar] [CrossRef]

- Jeong, D.H.; Lee, J.M. Enhancement of modifier adaptation scheme via feedforward decision maker using historical disturbance data and deep machine learning. Comput. Chem. Eng. 2018, 108, 31–46. [Google Scholar] [CrossRef]

- Petsagkourakis, P.; Orson Sandoval, I.; Bradford, E.; Zhang, D.; del Rio-Chanona, E.A. Reinforcement Learning for Batch-to-Batch Bioprocess Optimisation. Comput. Aided Chem. Eng. 2019, 46, 919–924. [Google Scholar] [CrossRef]

- Nelles, O. Nonlinear System Identification; Springer: Berlin/Heidelberg, Germany, 2001; p. 785. [Google Scholar] [CrossRef]

- Baena-Ruano, S.; Jiménez-Ot, C.; Santos-Dueñas, I.M.; Jiménez-Hornero, J.E.; Bonilla-Venceslada, J.L.; Álvarez-Cáliz, C.; García-García, I. Influence of the final ethanol concentration on the acetification and production rate in the wine vinegar process. J. Chem. Technol. Biotechnol. 2010, 85, 908–912. [Google Scholar] [CrossRef]

- Álvarez-Cáliz, C.; Santos-Dueñas, I.M.; García-Martínez, T.; Cañete-Rodríguez, A.M.; Millán-Pérez, M.C.; Maurico, J.C.; García-García, I. Effect of biological ageing of wine on its nitrogen composition for producing high quality vinegar. Food Bioprod. Process 2014, 92, 291–297. [Google Scholar] [CrossRef]

- Baena-Ruano, S.; Jiménez-Ot, C.; Santos-Dueñas, I.M.; Cantero-Moreno, D.; Barja, F.; García-García, I. Rapid method for total, viable and non-viable acetic acid bacteria determination during acetification process. Process Biochem. 2006, 41, 1160–1164. [Google Scholar] [CrossRef]

- García-García, I.; Cantero-Moreno, D.; Jiménez-Ot, C.; Baena-Ruano, S.; Jiménez-Hornero, J.; Santos-Duenas, I.; Bonilla-Venceslada, J.L.; Barja, F. Estimating the mean acetification rate via on-line monitored changes in ethanol during a semi-continuous vinegar production cycle. J. Food Eng. 2007, 80, 460–464. [Google Scholar] [CrossRef]

- Álvarez-Cáliz, C.; Santos-Dueñas, I.M.; Cañete-Rodríguez, A.M.; García-Martínez, T.; Maurico, J.C.; García-García, I. Free amino acids, urea and ammonium ion contents for submerged wine vinegar production: Influence of loading rate and air-flow rate. Acetic Acid Bact. 2012, 1, 1–6. [Google Scholar] [CrossRef]

- Santos-Dueñas, I.M.; Jimenez-Hornero, J.E.; Cañete-Rodríguez, A.M.; García-García, I. Modeling and optimization of acetic acid fermentation: A polynomial-based approach. Biochem. Eng. J. 2015, 99, 35–43. [Google Scholar] [CrossRef]

- Packett, R.L.; Burman, J.P. The desing of optimum multi-factorial experiments. Biometrika 1946, 33, 305–325. [Google Scholar] [CrossRef]

- Box, G.E.P.; Behnken, D.W. Some new three-level designs for the study of quantitative variables. Technometrics 1960, 2, 455–475. [Google Scholar] [CrossRef]

- Morgan, E. Chemometrics: Experimental Design; Wiley: Chichester, UK, 1991; p. 275. [Google Scholar]

- Castro Mejías, R.; Natera Marín, R.; García Moreno, M.V.; García Barroso, C. Optimisation of headspace solid-phase microextraction for analysis of aromatic compounds in vinegar. J. Chromatogr. A 2002, 953, 7–15. [Google Scholar] [CrossRef]

- Ramis Ramos, G.; García Álvarez-Coque, M.C. Quimiometría; Sintesis: Madrid, Spain, 2001; p. 240. [Google Scholar]

- Grierson, D.E. Pareto multi-criteria decision making. Adv. Eng. Inform. 2008, 22, 371–384. [Google Scholar] [CrossRef]

- Jiménez-Hornero, J.E.; Santos-Dueñas, I.M.; Garcia-Garcia, I. Optimization of biotechnological processes. The acetic acid fermentation. Part III: Dynamic optimization. Biochem. Eng. J. 2009, 45, 22–29. [Google Scholar] [CrossRef]

- García-García, I.; Jiménez-Hornero, J.E.; Santos-Dueñas, I.M.; González-Granados, Z.; Cañete-Rodríguez, A.M. Modelling and optimization of acetic acid fermentation. In Advances in Vinegar Production; Bekatorou, A., Ed.; CRC Press: Boca Raton, FL, USA, 2019; Chapter 15; pp. 97–120. ISBN 978-0-815-36599-0. [Google Scholar]

- Saichana, N.; Matsushita, K.; Adachi, O.; Frébort, I.; Frebortova, J. Acetic acid bacteria: A group of bacteria with versatile biotechnological applications. Biotechnol. Adv. 2015, 33, 1260–1271. [Google Scholar] [CrossRef] [PubMed]

- Matsushita, K.; Toyama, H.; Tonouchi, N.; Okamoto-Kainuma, A. (Eds.) Acetic Acid Bacteria: Ecology and Physiology; Springer: Osaka, Japan, 2016; ISBN 978-4-431-55931-3. [Google Scholar]

- Mamlouk, D.; Gullo, M. Acetic Acid Bacteria: Physiology and Carbon Sources Oxidation. Indian J. Microbiol. 2013, 53, 377–384. [Google Scholar] [CrossRef] [PubMed]

- Deppenmeier, U.; Ehrenreich, A. Physiology of Acetic Acid Bacteria in Light of the Genome Sequence of Gluconobacter oxydans. J. Mol. Microbiol. Biotechnol. 2009, 16, 69–80. [Google Scholar] [CrossRef] [PubMed]

- Adler, P.; Frey, L.J.; Berger, A.; Bolten, C.J.; Hansen, C.E.; Wittmann, C. The key to acetate: Metabolic fluxes of acetic acid bacteria under cocoa pulp fermentation-simulating conditions. Appl. Environ. Microbiol. 2014, 80, 4702–4716. [Google Scholar] [CrossRef]

- James, G.; Witten, D.; Hastie, T.; Tibshirani, R. An Introduction to Statistical Learning with Application in R; Springer: Berlin, Germany, 2017; ISBN 978-1-461-47137-0. [Google Scholar]

- Park, Y.S.; Fukaya, M.; Okumura, H.; Kawamura, Y.; Toda, K. Production of acetic acid by a repeated batch culture with cell recycle of Acetobacter aceti. Biotechnol. Lett. 1991, 13, 271–276. [Google Scholar] [CrossRef]

- Romero, L.E.; Gómez, J.M.; Caro, I.; Cantero, D. A kinetic model for growth of Acetobacter aceti in submerged culture. Chem. Eng. J. Biochem. Eng. J. 1994, 54, B15–B24. [Google Scholar] [CrossRef]

- González-Sáiz, J.M.; Pizarro, C.; Garrido-Vidal, D. Evaluation of kinetic models for industrial acetic fermentation: Proposal of a new model optimized by genetic algorithms. Biotechnol. Prog. 2003, 19, 599–611. [Google Scholar] [CrossRef]

- Hornik, K. Approximation capabilities of multilayer feedforward networks. Neural Netw. 1991, 4, 251–257. [Google Scholar] [CrossRef]

| Experiment No | Loading Mode | ||||||

|---|---|---|---|---|---|---|---|

| 1 | Continuous | - | 2 | 75 | 0.035 | 95 ± 1 | 15.1 ± 0.5 |

| 2 | Continuous | - | 2 | 50 | 0.035 | 98 ± 1 | 17.1 ± 0.5 |

| 3 | Continuous | - | 2 | 25 | 0.035 | 97 ± 1 | 17.3 ± 0.4 |

| 4 | Continuous | - | 3.5 | 50 | 0.035 | 78 ± 5 | 16.3 ± 0.4 |

| 5 | Continuous | - | 0.5 | 50 | 0.035 | 111 ± 1 | 14.7 ± 0.3 |

| 6 | Continuous | - | 0.5 | 75 | 0.01 | 110 ± 1 | 14.3 ± 0.3 |

| 7 | Continuous | - | 3.5 | 25 | 0.06 | 81 ± 1 | 17.8 ± 0.3 |

| 8 | Semi-continuous | 5 | 1.5 | 50 | 0.02 | 101 ± 2 | 14.8 ± 0.4 |

| 9 | Semi-continuous | 5 | 0.5 | 50 | 0.02 | 110 ± 2 | 13.8 ± 0.4 |

| Experiment No | |||||

|---|---|---|---|---|---|

| 1 | 3.5 | 75 | 0.06 | 81 ± 1 | 15.4 ± 0.4 |

| 2 | 3.5 | 75 | 0.01 | 81 ± 1 | 15.1 ± 0.4 |

| 3 | 3.5 | 25 | 0.06 | 81 ± 1 | 17.8 ± 0.3 |

| 4 | 3.5 | 25 | 0.01 | 81 ± 1 | 17.4 ± 0.6 |

| 5 | 0.5 | 75 | 0.06 | 108 ± 1 | 14.4 ± 0.4 |

| 6 | 0.5 | 75 | 0.01 | 110 ± 1 | 14.3 ± 0.3 |

| 7 | 0.5 | 25 | 0.06 | 112 ± 1 | 13.6 ± 0.3 |

| 8 | 0.5 | 25 | 0.01 | 111 ± 1 | 13.8 ± 0.2 |

| 9 | 3.5 | 50 | 0.035 | 78 ± 1 | 16.3 ± 0.4 |

| 10 | 0.5 | 50 | 0.035 | 111 ± 1 | 15.5 ± 0.2 |

| 11 | 2 | 75 | 0.035 | 95 ± 1 | 15.1 ± 0.5 |

| 12 | 2 | 25 | 0.035 | 97 ± 1 | 17.3 ± 0.4 |

| 13 | 2 | 50 | 0.06 | 95 ± 1 | 16.7 ± 0.5 |

| 14 | 2 | 50 | 0.01 | 95 ± 1 | 16.5 ± 0.6 |

| 15 | 2 | 50 | 0.035 | 98 ± 1 | 17.1 ± 0.5 |

| Parameter | Estimated Value |

|---|---|

| 0.62 h−1 | |

| 3.8 g ethanol·L−1 | |

| 10.63 g ethanol·L−1 | |

| 98.6 g acetic acid·L−1 | |

| 3.33 × 10−4 g oxygen·L−1 | |

| 2.94 × 10−5 h−1 | |

| 36.81 g ethanol·L−1 | |

| 12.51 g acetic acid·L−1 | |

| 0.52 h−1 |

| Network no. | Number of Neurons | Estimation MSE | Validation MSE | Estimation R2 | Number of Epochs |

|---|---|---|---|---|---|

| 1 | 3 | 0.0839 | 0.0838 | 0.97452 | 20 |

| 2 | 5 | 0.0836 | 0.0795 | 0.975 | 7 |

| 3 | 10 | 0.0838 | 0.0852 | 0.975 | 6 |

| 4 | 20 | 0.0831 | 0.0822 | 0.97485 | 3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiménez-Hornero, J.E.; Santos-Dueñas, I.M.; García-García, I. Modelling Acetification with Artificial Neural Networks and Comparison with Alternative Procedures. Processes 2020, 8, 749. https://doi.org/10.3390/pr8070749

Jiménez-Hornero JE, Santos-Dueñas IM, García-García I. Modelling Acetification with Artificial Neural Networks and Comparison with Alternative Procedures. Processes. 2020; 8(7):749. https://doi.org/10.3390/pr8070749

Chicago/Turabian StyleJiménez-Hornero, Jorge E., Inés María Santos-Dueñas, and Isidoro García-García. 2020. "Modelling Acetification with Artificial Neural Networks and Comparison with Alternative Procedures" Processes 8, no. 7: 749. https://doi.org/10.3390/pr8070749

APA StyleJiménez-Hornero, J. E., Santos-Dueñas, I. M., & García-García, I. (2020). Modelling Acetification with Artificial Neural Networks and Comparison with Alternative Procedures. Processes, 8(7), 749. https://doi.org/10.3390/pr8070749