CVD Synthesis, Functionalization and CO2 Adsorption Attributes of Multiwalled Carbon Nanotubes

Abstract

1. Introduction

2. Materials and Methods

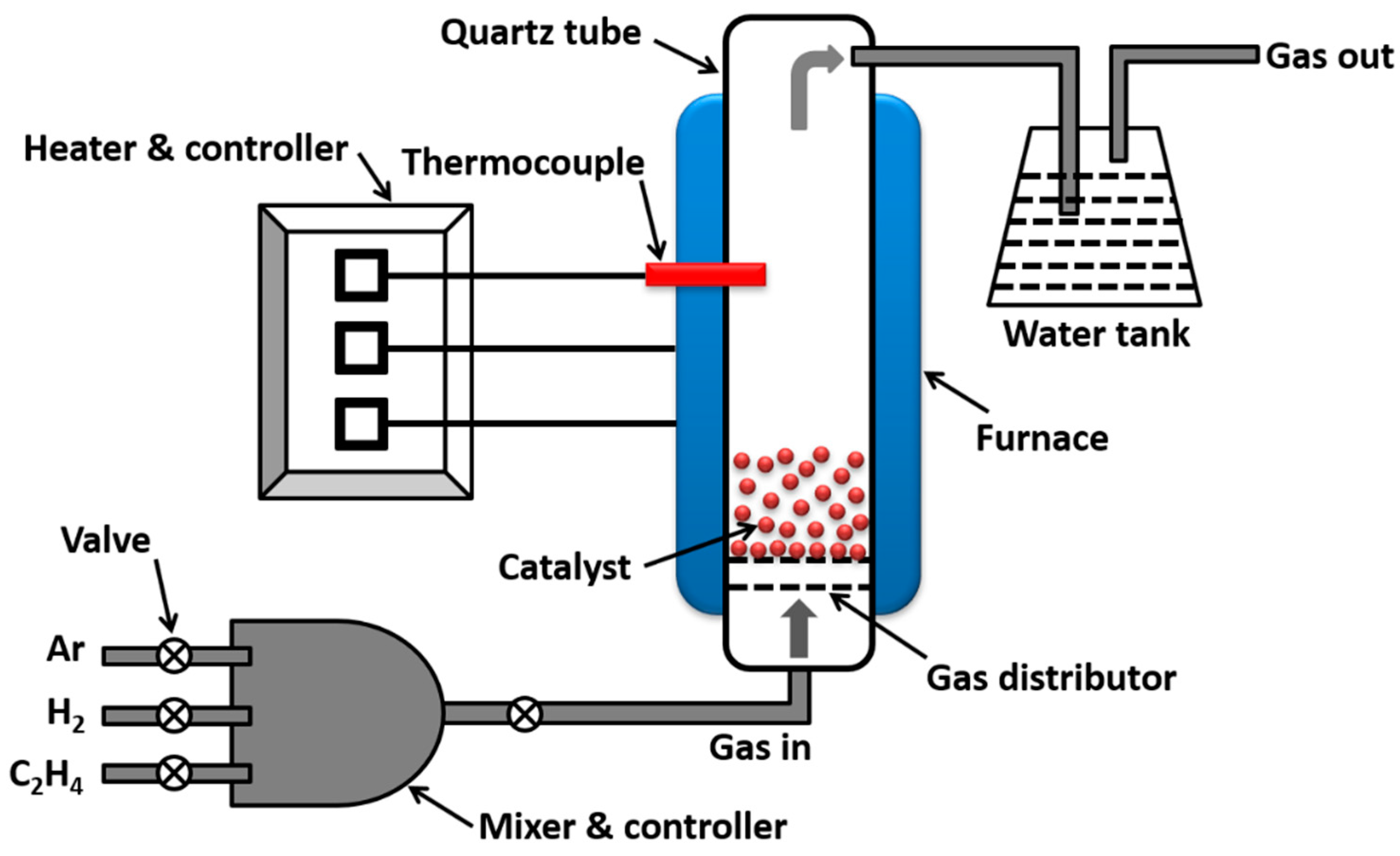

2.1. Fluidized Bed CVD Synthesis of MWCNTs

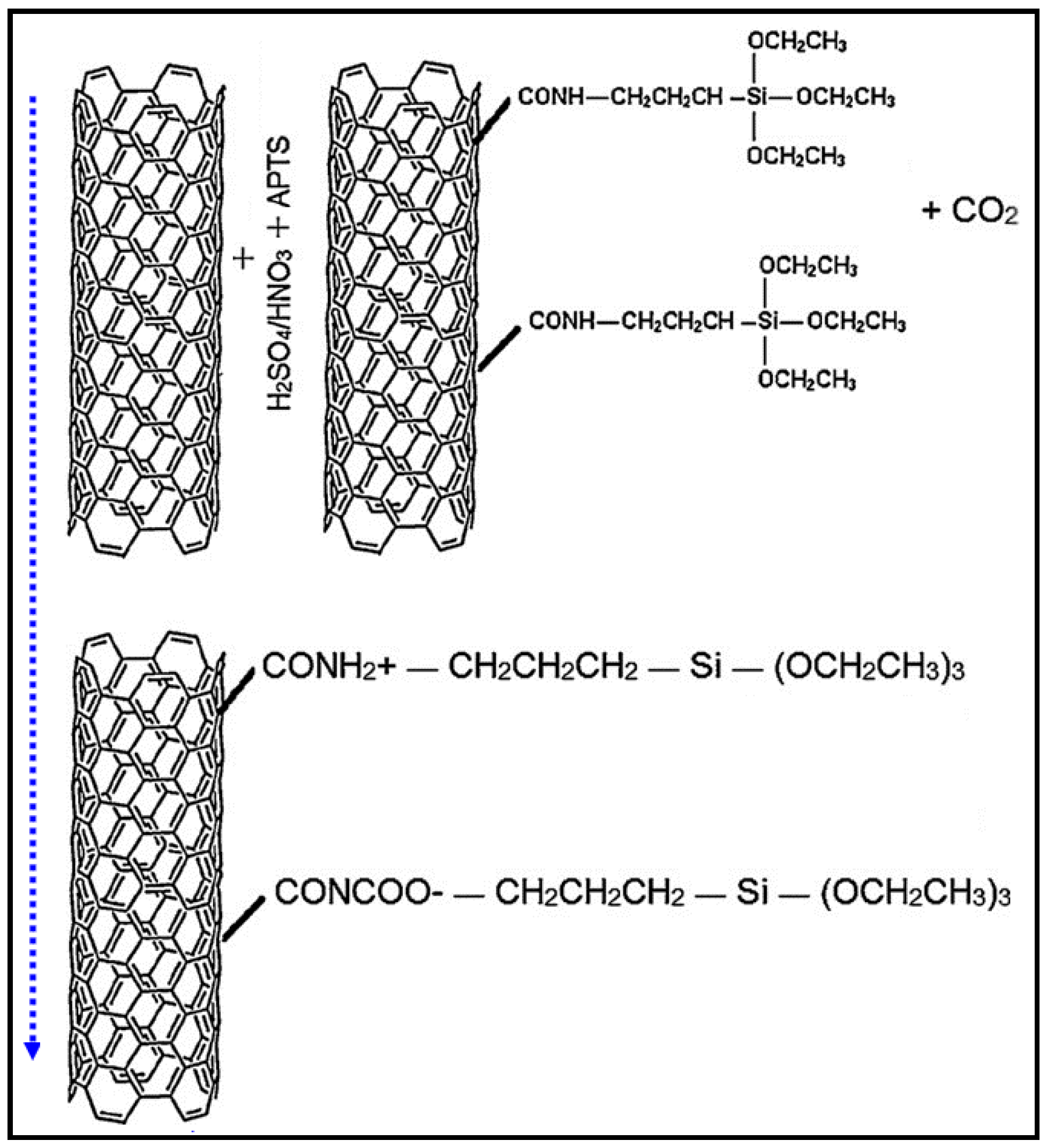

2.2. Acid Treatment and Functionalization

2.3. CO2 Adsorption Test

3. Results and Discussion

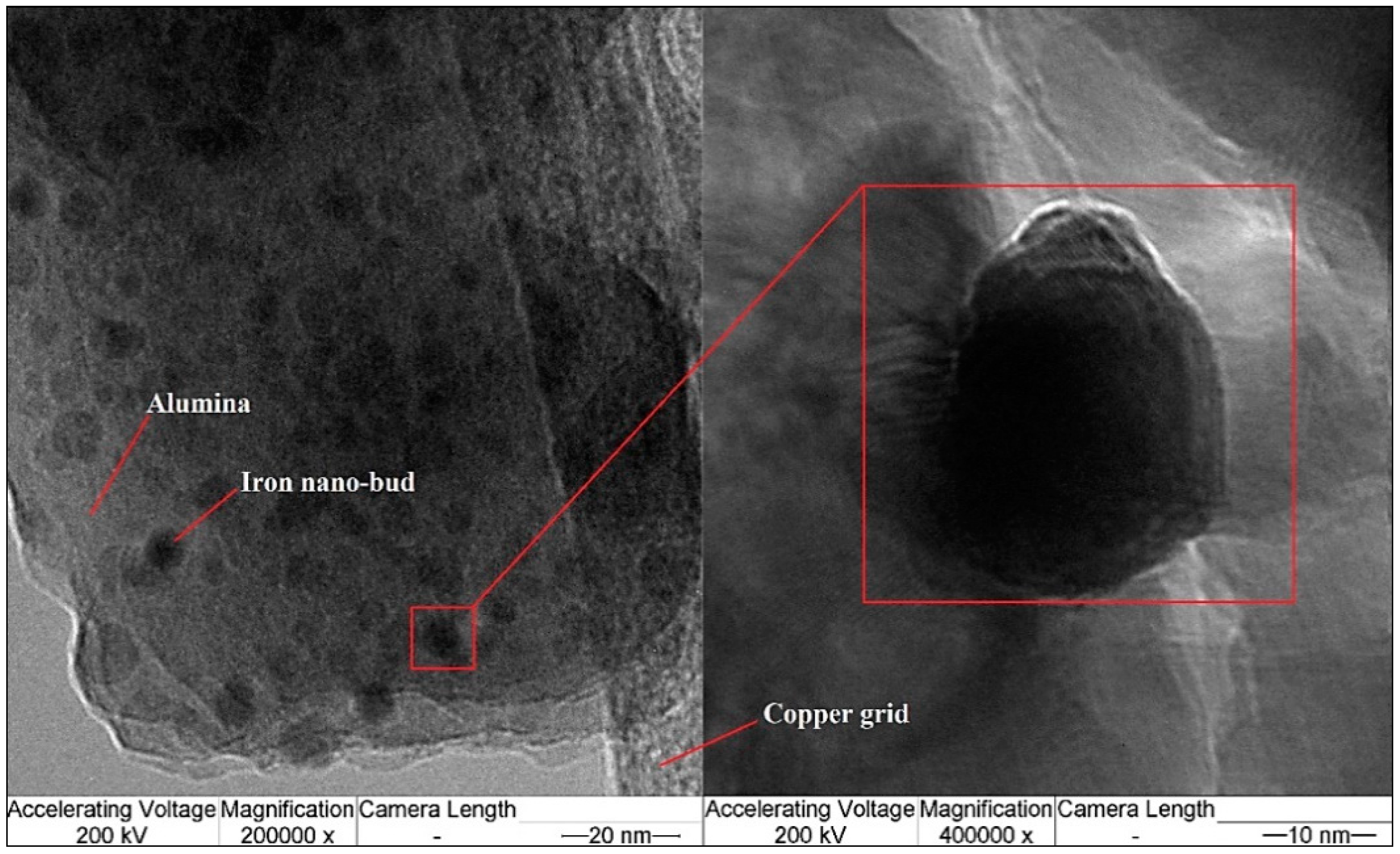

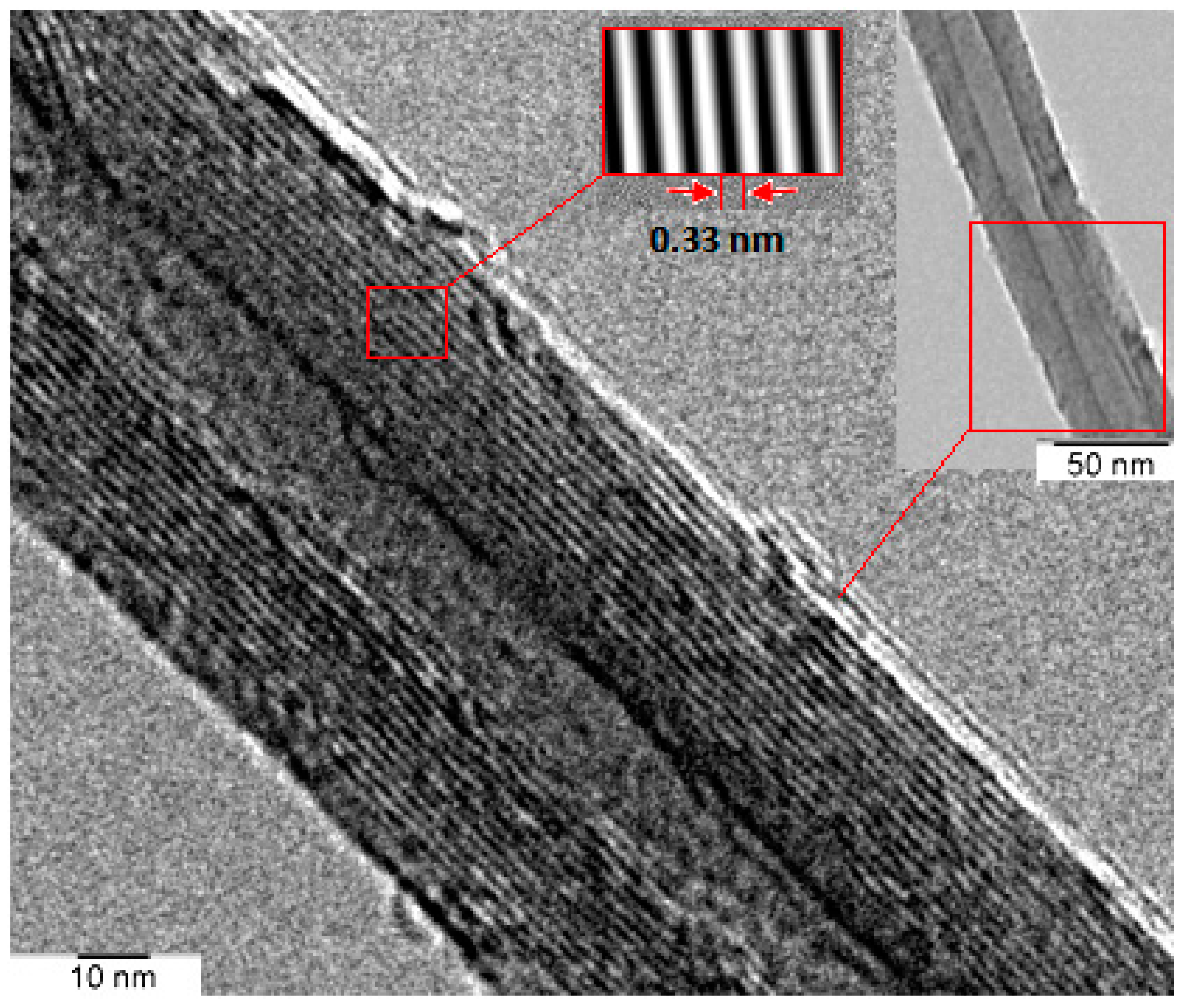

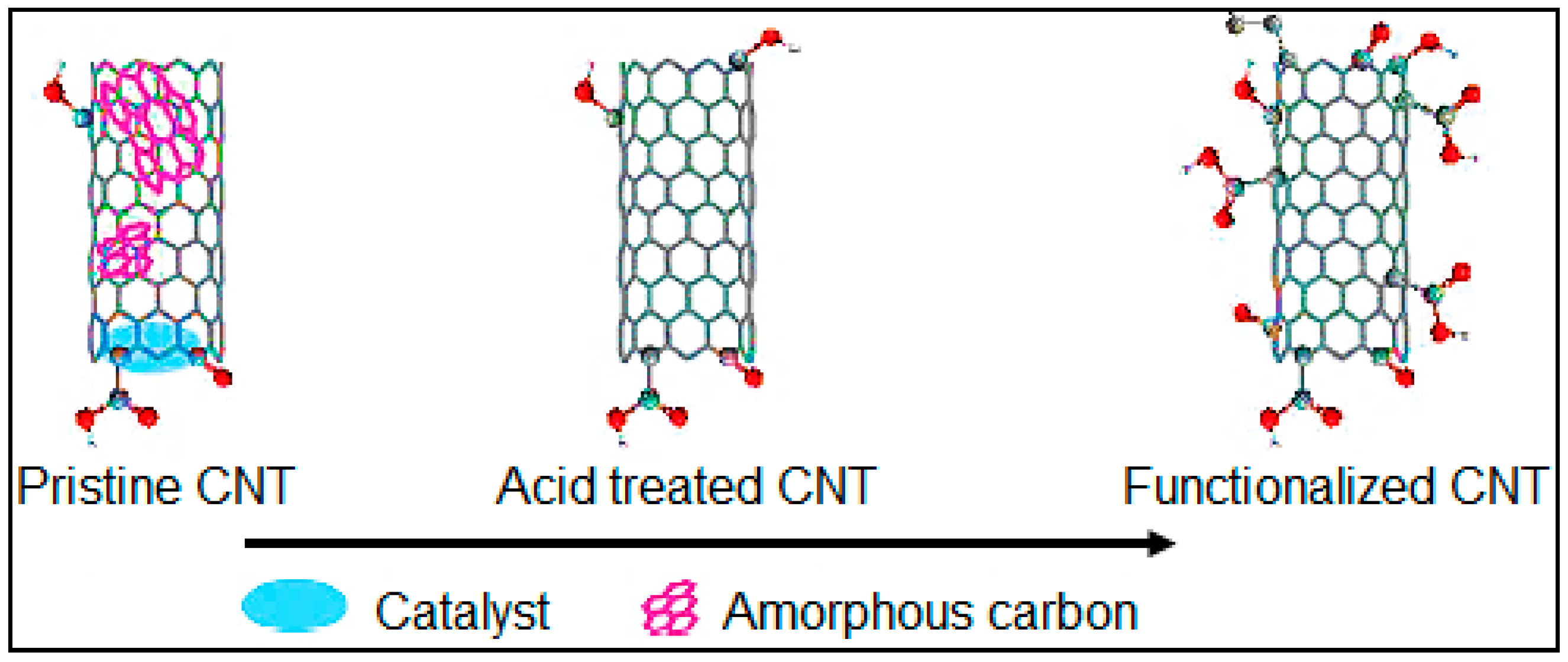

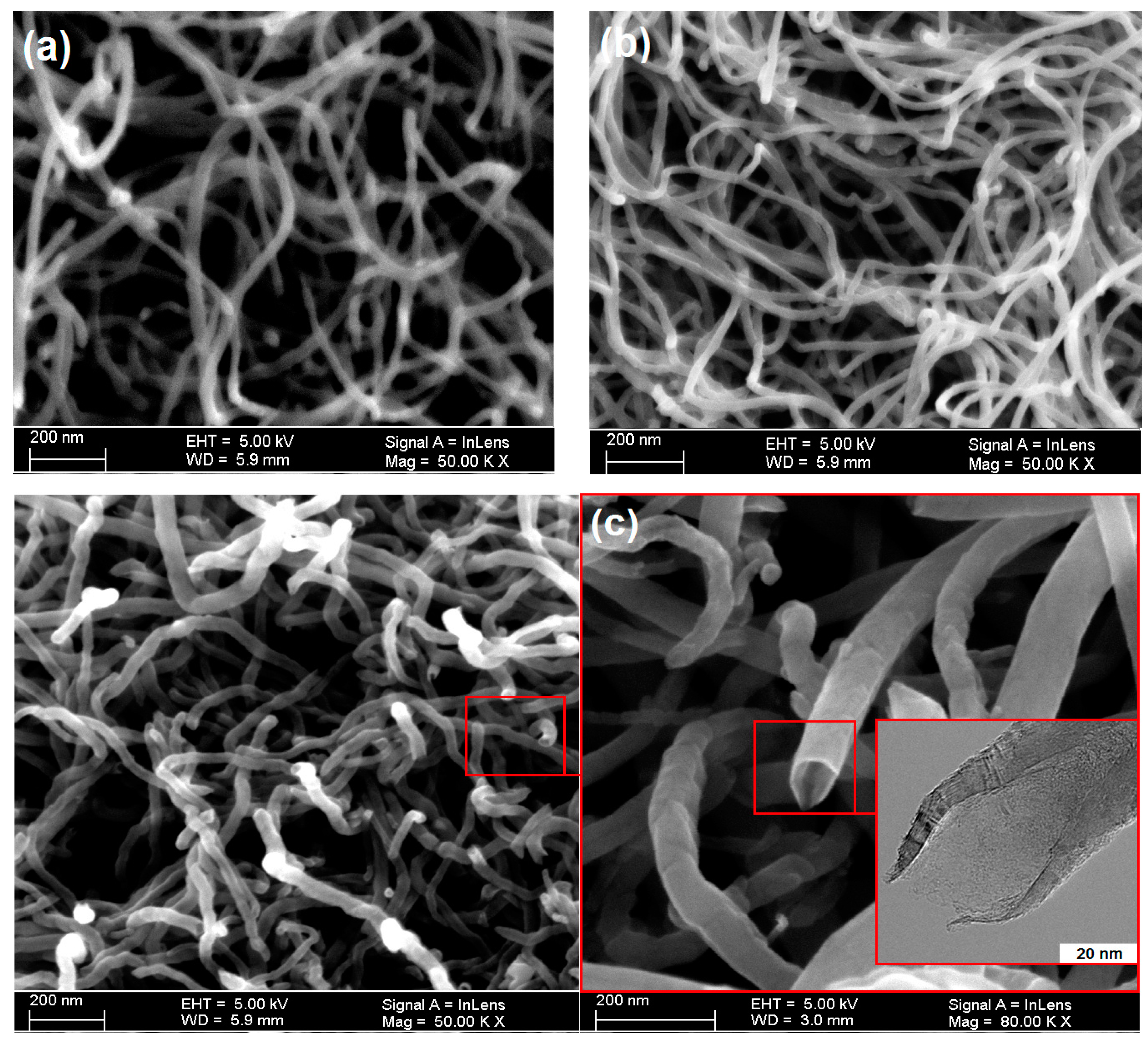

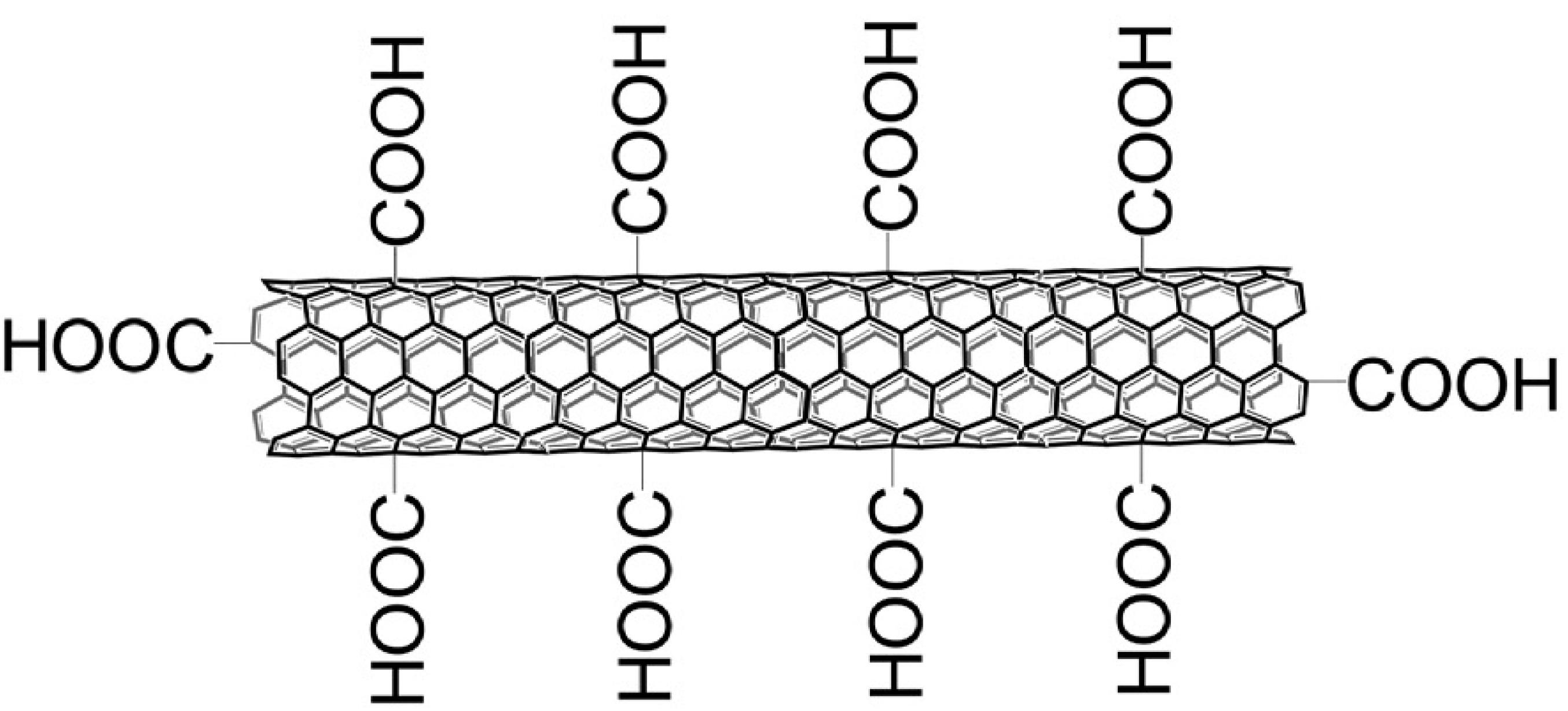

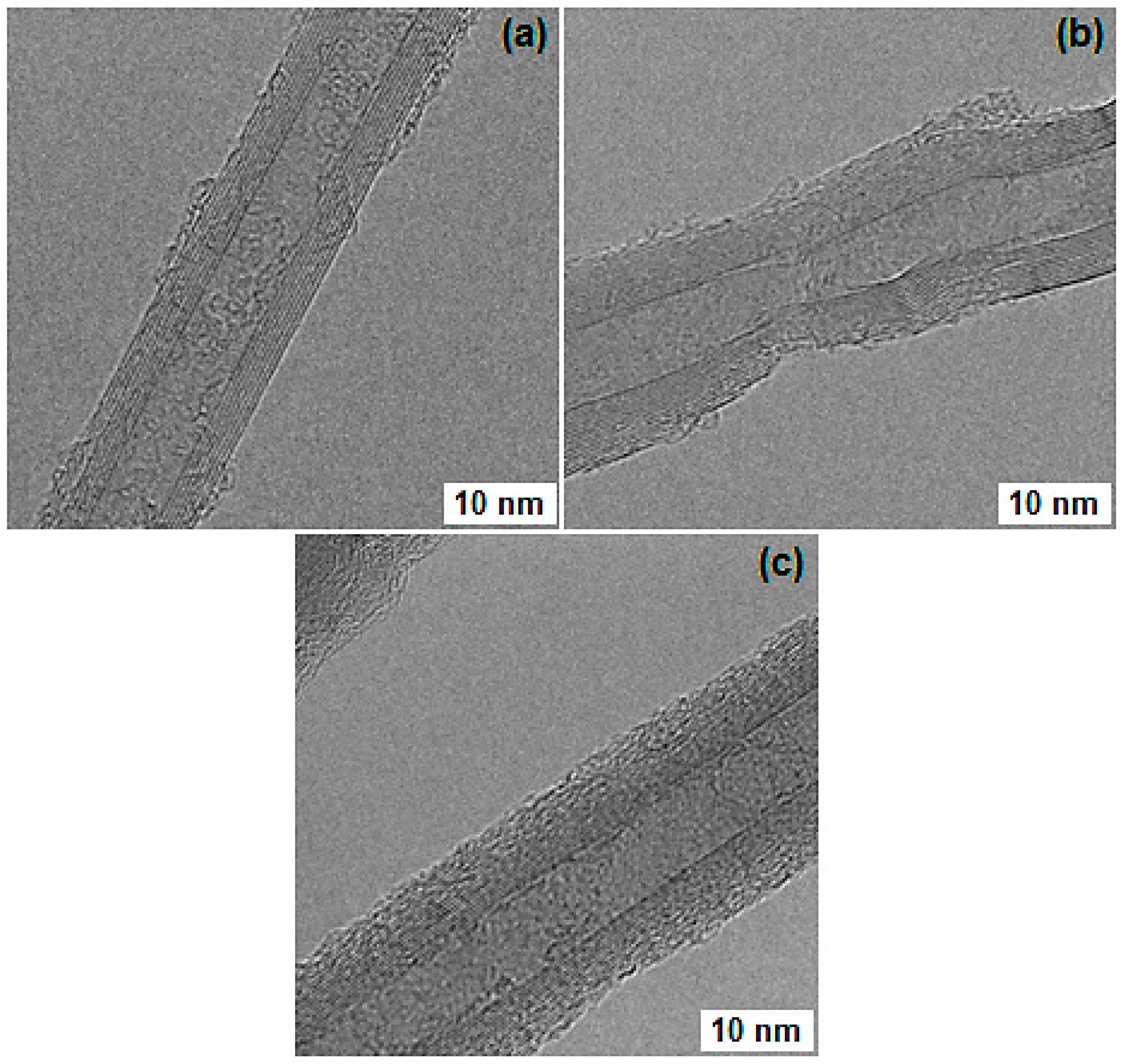

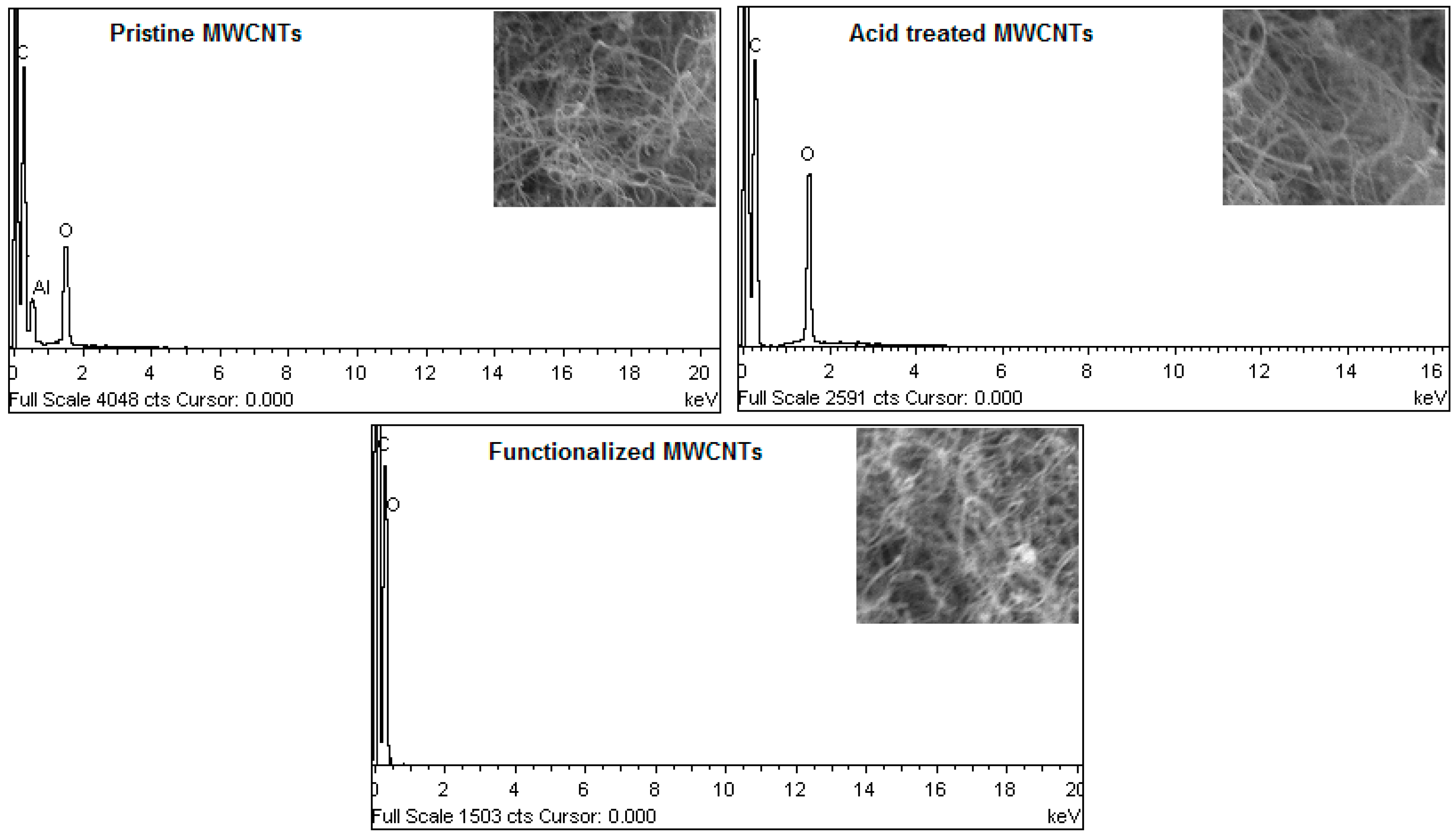

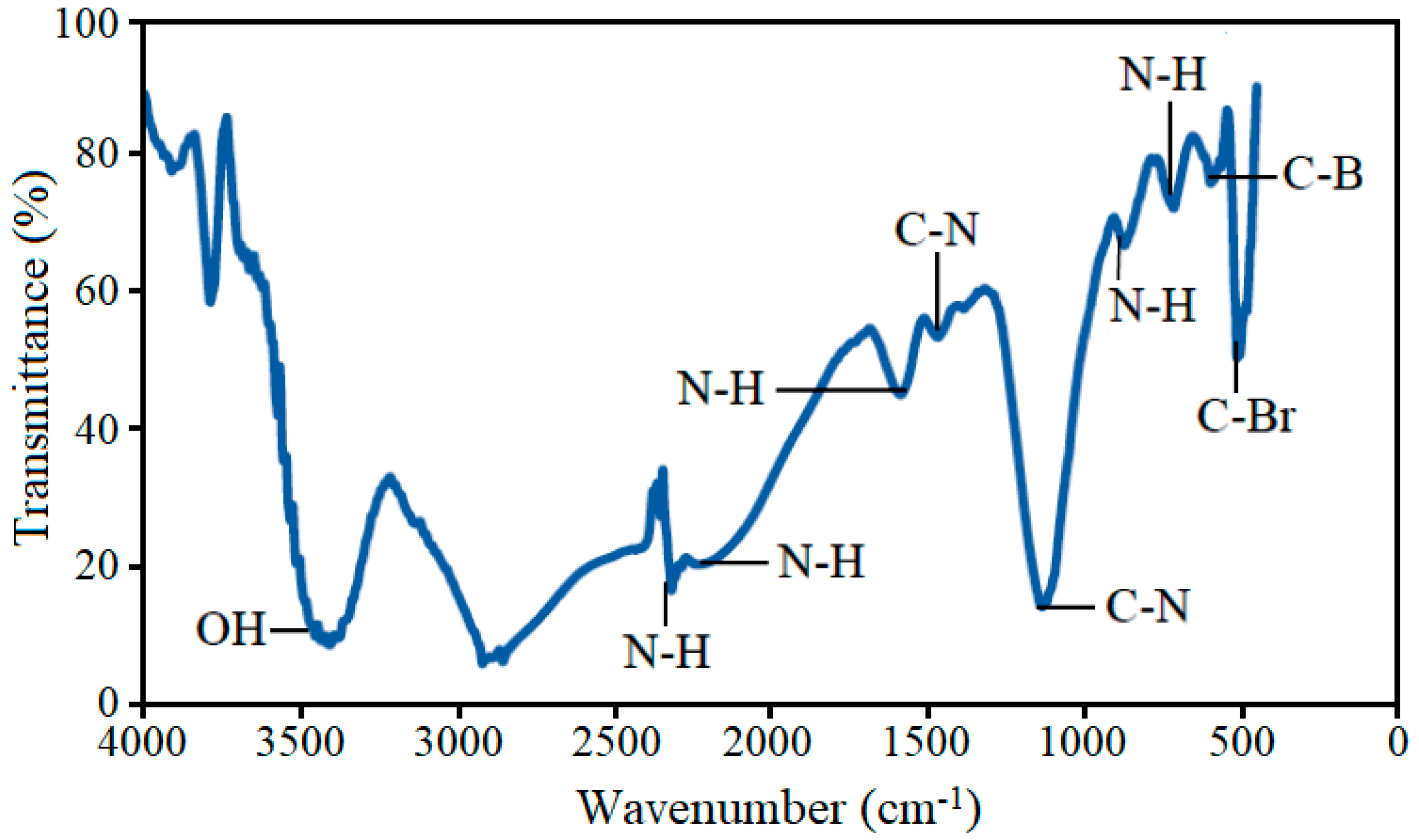

3.1. Morphology of Pristine and Chemically Modified MWCNTs

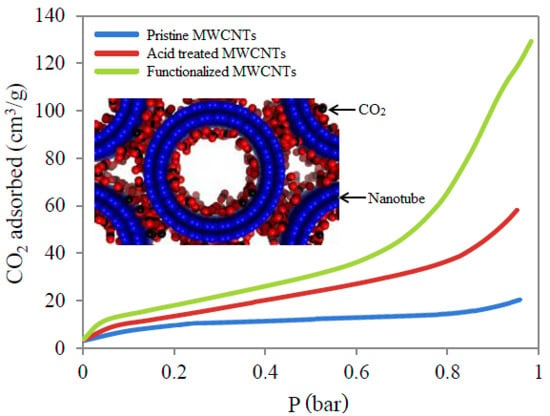

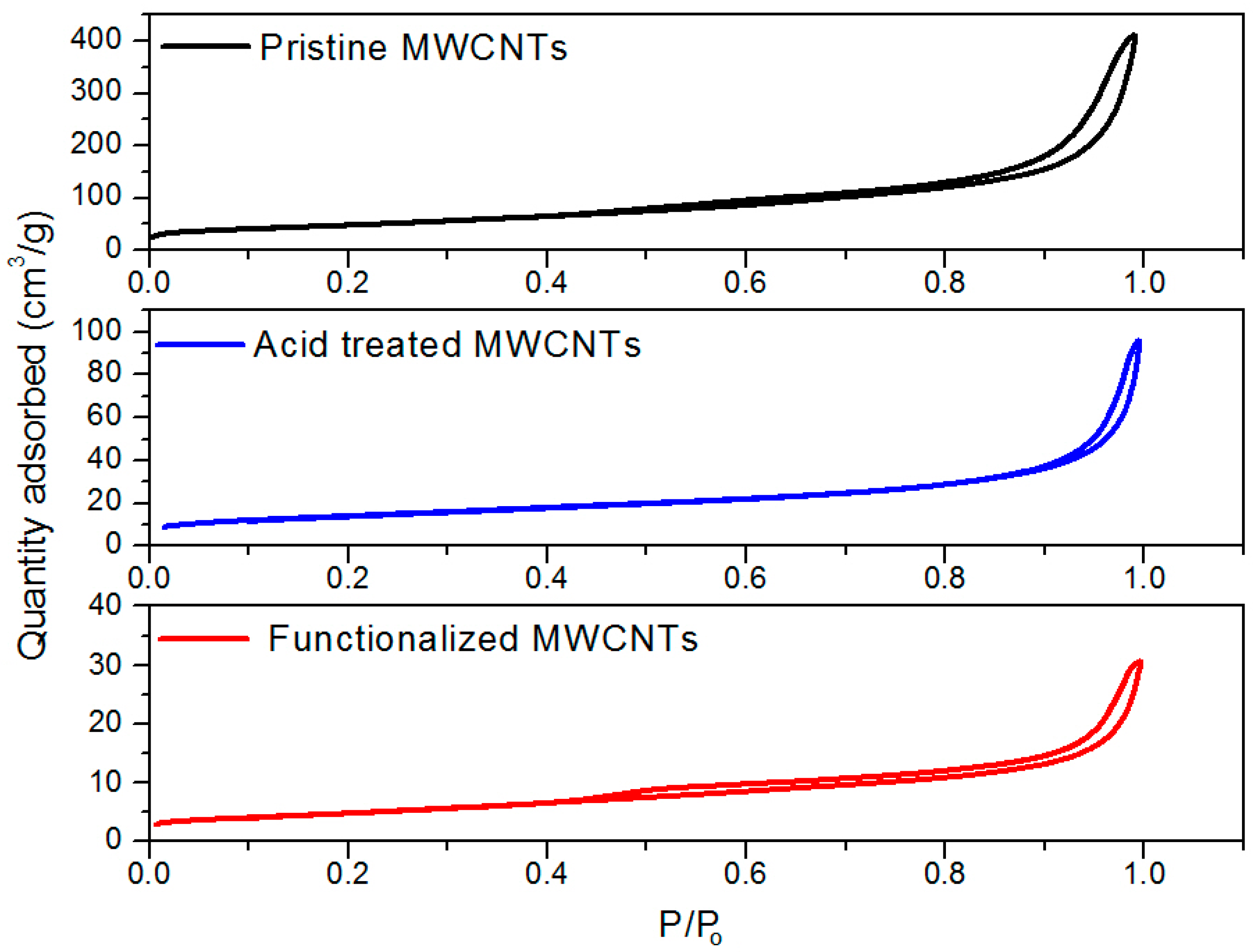

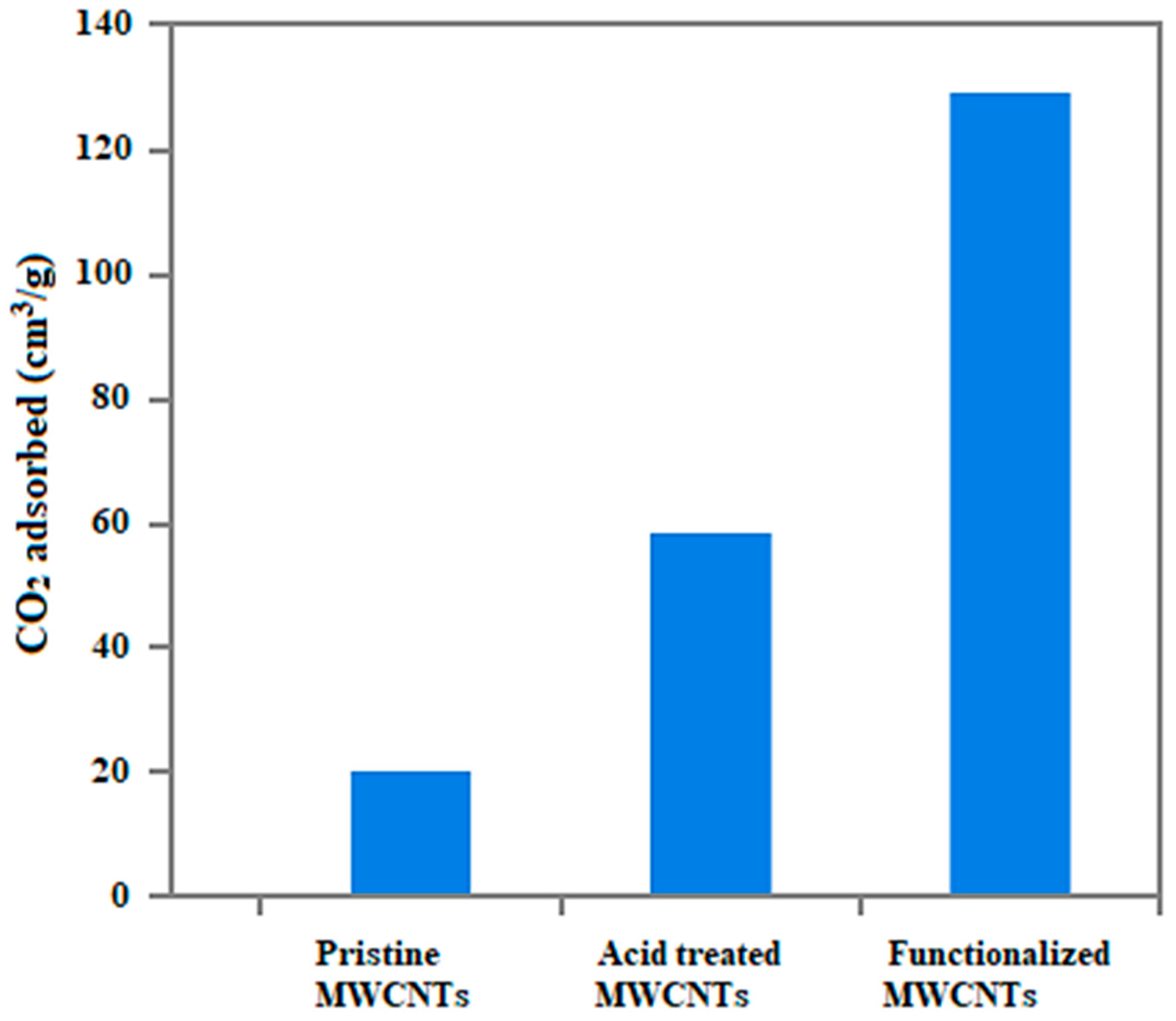

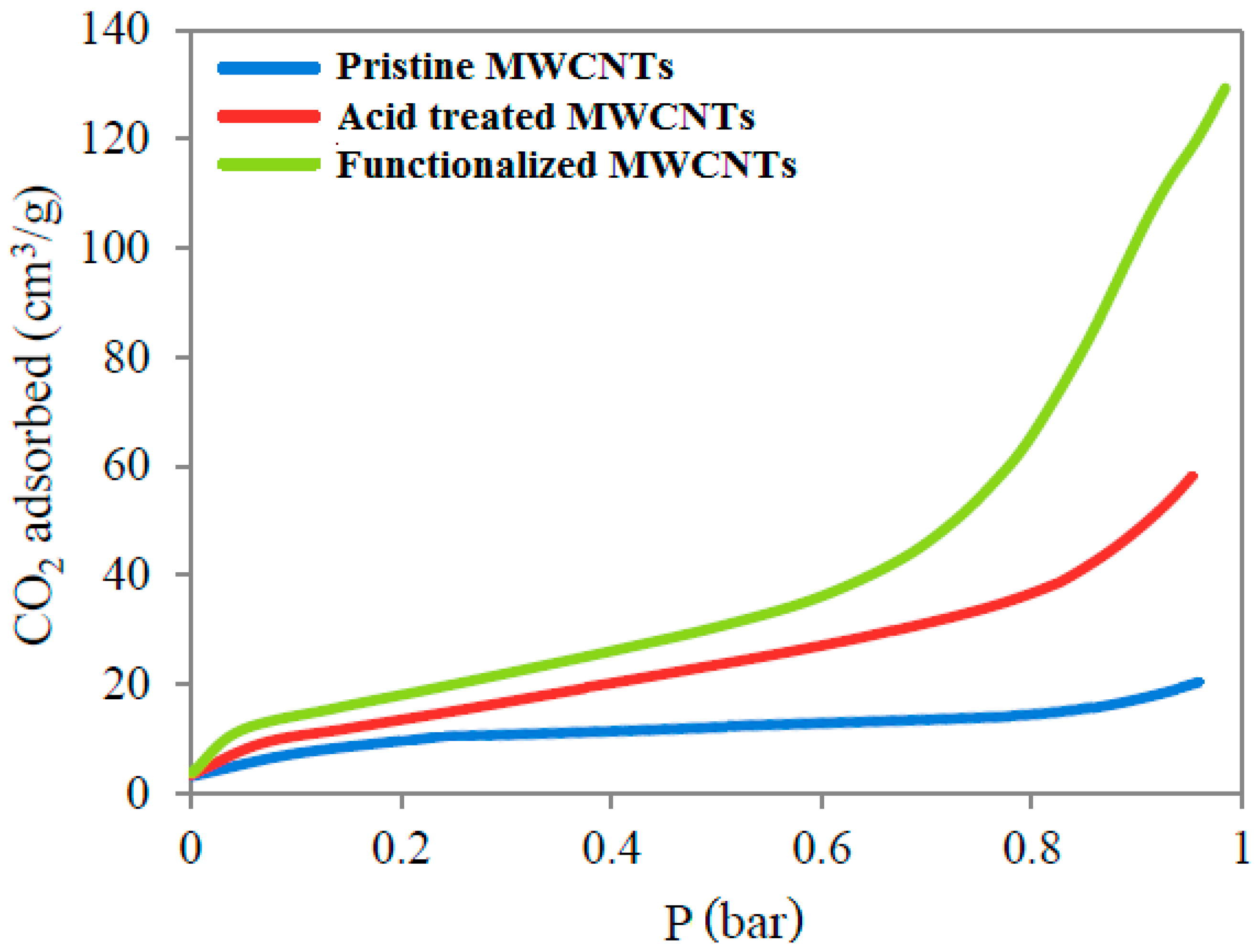

3.2. CO2 Adsorption Capacity of MWCNTs

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Naz, M.Y.; Sulaiman, S.A. Slow release coating remedy for nitrogen loss from conventional urea: A review. J. Control. Release 2016, 225, 109–120. [Google Scholar] [CrossRef] [PubMed]

- Gutierrez, J.P.; Erdmann, E.; Manca, D. Optimal Design of a Carbon Dioxide Separation Process with Market Uncertainty and Waste Reduction. Processes 2019, 7, 342. [Google Scholar] [CrossRef]

- Khalili, S.; Ghoreyshi, A.A.; Jahanshahi, M. Carbon dioxide captured by multiwalled carbon nanotube and activated charcoal: A comparative study. Ind. Eng. Chem. Res. 2013, 19, 153–164. [Google Scholar]

- Chen, C.; Ahn, W.S. CO2 capture using mesoporous alumina prepared by a sol-gel process. Chem. Eng. J. 2011, 166, 646–651. [Google Scholar] [CrossRef]

- Gui, M.M.; Yap, Y.X.; Chai, S.-P.; Mohamed, A.R. Multi-walled carbon nanotubes modified with (3-aminopropyl)triethoxysilane for effective carbon dioxide adsorption. Int. J. Greenh. Gas Control 2013, 14, 65–73. [Google Scholar] [CrossRef]

- Drage, T.C.; Blackman, J.M.; Pevida, C.; Snape, C.E. Evaluation of Activated Carbon Adsorbents for CO2 Capture in Gasification. Energy Fuels 2009, 23, 2790–2796. [Google Scholar] [CrossRef]

- Lua, A.C.; Guo, J. Activated carbon prepared from oil palm stone by one-step CO2 activation for gaseous pollutant removal. Carbon 2000, 38, 1089–1097. [Google Scholar] [CrossRef]

- Gui, M.M.; Yap, Y.X.; Chai, S.-P.; Mohamed, A.R. Amine-functionalization of multi-walled carbon nanotubes for adsorption of carbon dioxide. Asia-Pac. J. Chem. Eng. 2013, 8, 262–270. [Google Scholar] [CrossRef]

- Su, F.; Lu, C. CO2 capture from gas stream by zeolite 13X using a dual-column temperature/vacuum swing adsorption. Energy Environ. Sci. 2012, 5, 9021–9027. [Google Scholar] [CrossRef]

- Shukrullah, S.; Mohamed, N.M.; Shaharun, M.S. Optimum temperature on structural growth of multiwalled carbon nanotubes with low activation energy. Diam. Relat. Mater. 2015, 58, 129–138. [Google Scholar] [CrossRef]

- See, C.H.; Harris, A.T. A Review of Carbon Nanotube Synthesis via Fluidized-Bed Chemical Vapor Deposition. Ind. Eng. Chem. Res. 2007, 46, 997–1012. [Google Scholar] [CrossRef]

- Shukrullah, S.; Mohamed, N.M.; Shaharun, M.S.; Naz, M.Y. Parametric study on vapor-solid-solid growth mechanism of multiwalled carbon nanotubes. Mater. Chem. Phys. 2016, 176, 32–43. [Google Scholar] [CrossRef]

- Echeverria, J.; Morera, M.; Mazkiarán, C.; Garrido, J. Characterization of the porous structure of soils: Adsorption of nitrogen (77 K) and carbon dioxide (273 K), and mercury porosimetry. Eur. J. Soil Sci. 1999, 50, 497–503. [Google Scholar] [CrossRef]

- Kaneko, K.; Cracknell, R.F.; Nicholson, D. Nitrogen adsorption in slit pores at ambient temperatures: Comparison of simulation and experiment. Langmuir 1994, 10, 4606–4609. [Google Scholar] [CrossRef]

- Tanthana, J. In Situ Infrared and Mass Spectroscopic Study on Amine-Immobilized Silica for CO2 Capture: Investigation of Mechanisms and Degradation. Ph.D. Thesis, University of Akron, Akron, OH, USA, 2011. [Google Scholar]

- Nagaraju, N.; Fonseca, A.; Konya, Z.; Nagy, J.B. Alumina and silica supported metal catalysts for the production of carbon nanotubes. J. Mol. Catal. A Chem. 2002, 181, 57–62. [Google Scholar] [CrossRef]

- Kumar, M.; Ando, Y. Chemical Vapor Deposition of Carbon Nanotubes: A Review on Growth Mechanism and Mass Production. J. Nanosci. Nanotechnol. 2010, 10, 3739–3758. [Google Scholar] [CrossRef] [PubMed]

- Ago, H.; Nakamura, K.; Uehara, N.; Tsuji, M. Roles of Metal−Support Interaction in Growth of Single- and Double-Walled Carbon Nanotubes Studied with Diameter-Controlled Iron Particles Supported on MgO. J. Phys. Chem. B 2004, 108, 18908–18915. [Google Scholar] [CrossRef]

- Hao, W.Z.; Kim, H.S.; Kim, H.T.; Gong, J.; Kim, I.J. Synthesis and growth of multi-walled carbon nanotubes (MWNTs) by CCVD using Fe-supported zeolite templates. J. Ceram. Process. Res. 2011, 12, 392–397. [Google Scholar]

- Shukrullah, S.; Naz, M.Y.; Mohamed, N.M.; Ibrahim, K.A.; Ghaffar, A.; AbdEl-Salam, N.M. Production of bundled CNTs by floating a compound catalyst in an atmospheric pressure horizontal CVD reactor. Results Phys. 2019, 12, 1163–1171. [Google Scholar] [CrossRef]

- Murugesan, S.; Myers, K.; Subramanian, V. Amino-functionalized and acid treated multi-walled carbon nanotubes as supports for electrochemical oxidation of formic acid. Appl. Catal. B Environ. 2011, 103, 266–274. [Google Scholar] [CrossRef]

- Goyanes, S.; Rubiolo, G.R.; Salazar, A.; Jimeno, A.; Corcuera, M.A.; Mondragon, I. Carboxylation treatment of multiwalled carbon nanotubes monitored by infrared and ultraviolet spectroscopies and scanning probe microscopy. Diam. Relat. Mater. 2007, 16, 412–417. [Google Scholar] [CrossRef]

- van Thu, L.; Long, N.C.; Trung, L.Q.; Tung, N.T.; Nghia, N.D.; Thanh, V.M. Surface modification and functionalization of carbon nanotube with some organic compounds. Adv. Nat. Sci. Nanosci. Nanotechnol. 2013, 4, 035017. [Google Scholar]

- Okpalugo, T.I.T.; Papakonstantinou, P.; Murphy, H.; McLaughlin, J.; Brown, N.M.D. High resolution XPS characterization of chemical functionalised MWCNTs and SWCNTs. Carbon 2005, 43, 153–161. [Google Scholar] [CrossRef]

- Khalili, S.; Ghoreyshi, A.A.; Jahanshahi, M.; Pirzadeh, K. Enhancement of Carbon Dioxide Capture by Amine-Functionalized Multi-Walled Carbon Nanotube. Clean Soil Air Water 2013, 41, 939–948. [Google Scholar] [CrossRef]

- Zhao, C.; Ji, L.; Liu, H.; Hu, G.; Zhang, S.; Yang, M.; Yang, Z. Functionalized carbon nanotubes containing isocyanate groups. J. Solid State Chem. 2004, 177, 4394–4398. [Google Scholar] [CrossRef]

- Pan, B.; Xing, B. Adsorption Mechanisms of Organic Chemicals on Carbon Nanotubes. Environ. Sci. Technol. 2008, 42, 9005–9013. [Google Scholar] [CrossRef]

- Buang, N.A.; Fadil, F.; Majid, Z.A.; Shahir, S. Characteristic of mild acid functionalized multiwalled carbon nanotubes towards high dispersion with low structural defects. Dig. J. Nanomater. Biostruct. 2012, 7, 33–39. [Google Scholar]

- Ma, P.C.; Mo, S.Y.; Tang, B.Z.; Kim, J.K. Dispersion, interfacial interaction and re-agglomeration of functionalized carbon nanotubes in epoxy composites. Carbon 2010, 48, 1824–1834. [Google Scholar] [CrossRef]

- Kyotani, T.; Nakazaki, S.; Xu, W.H.; Tomita, A. Chemical modification of the inner walls of carbon nanotubes by HNO3 oxidation. Carbon 2001, 39, 782–785. [Google Scholar] [CrossRef]

- Su, F.; Lu, C.; Chen, H.-S. Adsorption, Desorption, and Thermodynamic Studies of CO2 with High-Amine-Loaded Multiwalled Carbon Nanotubes. Langmuir 2011, 27, 8090–8098. [Google Scholar] [CrossRef]

- Lu, C.; Bai, H.; Wu, B.; Su, F.; Hwang, J.F. Comparative Study of CO2 Capture by Carbon Nanotubes, Activated Carbons, and Zeolites. Energy Fuels 2008, 22, 3050–3056. [Google Scholar] [CrossRef]

- Ye, Q.; Jiang, J.; Wang, C.; Liu, Y.; Pan, H.; Shi, Y. Adsorption of Low-Concentration Carbon Dioxide on Amine-Modified Carbon Nanotubes at Ambient Temperature. Energy Fuels 2012, 26, 2497–2504. [Google Scholar] [CrossRef]

- Grondein, A.; Belanger, D. Chemical modification of carbon powders with aminophenyl and aryl-aliphatic amine groups by reduction of in situ generated diazonium cations: Applicability of the grafted powder towards CO2 capture. Fuel 2011, 90, 2684–2693. [Google Scholar] [CrossRef]

- Zhao, W.; Zhang, Z.; Li, Z.; Cai, N. Continuous CO2 Capture in Dual Fluidized Beds Using Silica Supported Amine. Energy Procedia 2013, 37, 89–98. [Google Scholar] [CrossRef]

- Speight, J.G.; Ozum, B. Petroleum Refining Processes; Chemical Industries, Taylor & Francis: New York, NY, USA, 2002; Volume 85, p. 706. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shukrullah, S.; Naz, M.Y.; Mohamed, N.M.; Ibrahim, K.A.; AbdEl-Salam, N.M.; Ghaffar, A. CVD Synthesis, Functionalization and CO2 Adsorption Attributes of Multiwalled Carbon Nanotubes. Processes 2019, 7, 634. https://doi.org/10.3390/pr7090634

Shukrullah S, Naz MY, Mohamed NM, Ibrahim KA, AbdEl-Salam NM, Ghaffar A. CVD Synthesis, Functionalization and CO2 Adsorption Attributes of Multiwalled Carbon Nanotubes. Processes. 2019; 7(9):634. https://doi.org/10.3390/pr7090634

Chicago/Turabian StyleShukrullah, Shazia, Muhammad Yasin Naz, Norani M. Mohamed, Khalid A. Ibrahim, Nasser M. AbdEl-Salam, and Abdul Ghaffar. 2019. "CVD Synthesis, Functionalization and CO2 Adsorption Attributes of Multiwalled Carbon Nanotubes" Processes 7, no. 9: 634. https://doi.org/10.3390/pr7090634

APA StyleShukrullah, S., Naz, M. Y., Mohamed, N. M., Ibrahim, K. A., AbdEl-Salam, N. M., & Ghaffar, A. (2019). CVD Synthesis, Functionalization and CO2 Adsorption Attributes of Multiwalled Carbon Nanotubes. Processes, 7(9), 634. https://doi.org/10.3390/pr7090634