Abstract

Numerous laboratory tests are used to determine the appropriateness of new formulations in the development process in the paint and coatings industry. New formulations are most often functionally inadequate, unacceptable for environmental or health reasons, or too expensive. Formulators are obliged to repeat laboratory tests until one of the formulations fulfills the minimum requirements. This is cumbersome, slow, and expensive, and can cause ecological problems, wasting materials on tests that do not produce the desired results. The purpose of this research was to find out if there might be a better way forward to increase efficiency and free up formulators to focus on new products. In this experiment, a new paints and coatings development process was redesigned based on the potential benefits of formulation digitalization. Instead of laboratory testing, a digital platform was used that has been developed and stocked with relevant, up-to-date, and complete, usable data. This study found that, by going digital, developers could vastly reduce non-value-added activities in the development process (by as much as 70%) and significantly shorten the entire process throughput time (by up to 48%). Using digital tools to facilitate the development process appears to be a possible way forward for the paint and coatings industry, saving time, materials, and money and protecting the environment.

1. Introduction

By analyzing the relevant scientific and technical literature, the most important challenges in the process of developing paints and coatings were identified. Products should meet the aesthetic criteria, as well as assure the long-term protection of the surface. Increasing requirements for effective surface protection, on the one hand, and continuous tightening of environmental regulations, on the other, can be observed [1,2]. An additional focus is achieving new product development and specifications in the shortest possible time. Because of these requirements, rapid development of technology offers more and more opportunities for the design of quality products; however, the development of new products becomes increasingly complex [3,4,5,6].

Continually evolving demands for greater capability, efficiency, and functionality of coatings; increasing regulatory complexity; and growing competition in this area account for the need for accelerated development of coatings’ raw materials, formulated products, and rapid problem-solving [7]. Because of the many raw material combinations and interactions that affect performance properties, additive formulating is resource-intensive and time-consuming for manufacturers [8].

With the requirement for safe, environmentally friendly coating components and the acceleration of material discovery, the need for rapid, reliable testing is becoming more important [9]. A number of accelerated tests have been developed to reduce the testing time and decrease environmental variability. Most importantly, the tests lead to qualitative results, which can be significantly different when various individual evaluators and different test instruments are compared [10].

Coating formulations include different raw materials, such as resins, additives, pigments, fillers, catalysts, solvents, co-solvents, water, etc. Therefore, exploring all possible combinations in search of the best formulation is impossible—especially on the benchtop, which allows for a limited number of options to be explored. To better visualize what that means, the senior manager of R&D Additives (Evonik Resource Efficiency GmbH) presents an example: “If 10 resins, 10 additives, 10 pigments, and 10 catalysts were to be considered for a formulation, 10,000 combinations are possible without considering different quantities for each.” It is necessary to explore a large number of possible combinations in order to find the optimal formulation, which is possible only with high-throughput technology [7].

Many papers deal with techniques, such as high-throughput testing [11], statistically planned experiments [12], multiscale modeling, and self-repair, which can make significant contributions to new product development. However, these techniques could be combined in a synergistic manner and thus develop new approaches to self-repair [4]. Data modeling, computer simulation, and visualization tools have also been developed to keep pace with increasingly large datasets. With the aim of the comprehensive evaluation of additives, they suggest the use of high-throughput tools, which facilitate the evaluation of a wider range of samples, usage levels, and formulations [8,13].

Evonik Resource Efficiency GmbH has developed a high-throughput system that automatically doses raw materials, formulates them into coatings, applies the coatings to substrates, and tests them. The system allows the formulation of 120 samples within 24 h. The company emphasizes that the system also completes labor-intensive tasks and thus allows laboratory staff to focus on experimental design and analysis [7]. It is clear that high-throughput regression methods will reduce lead optimization times, but such methods are of little help unless suitable high-quality materials are available for screening, and detailed correlative mechanistic studies are needed to subsequently extract the design principles [14,15]. More important than how much time one repetition of a R&D testing process takes is what to test in order to avoid superfluous testing.

The solution could be the use of information technology and digital transformation approaches. Those approaches are widely and successfully used in other industries [16]. It is time to transfer best practices to the paints and coatings industry, too. The 2019 chief information officer (CIO) of Gartner’s agenda [17] recommends that CIOs “secure a new foundation for digital business.” The agenda is based on a Gartner survey of 3102 CIO respondents in 89 countries and across major industries, representing $15 trillion in revenue and public sector budgets and $284 billion in information technology (IT) spending. The agenda recommends: (1) a business and operating model transformation, (2) secure consumer-centricity, (3) the use of targeted and capability-building techniques to move from projects to direct product delivery, and (4) the use of business-enabling technologies: machine learning, data analytics (including predictive analytics), cloud processing and storage (including XaaS), digital transformation, and more.

Digitalization is a completely different approach and requires significant changes to take place on many different levels throughout the entire organization and not only for the team responsible for strategy implementation. For the purpose of better serving their customers, organizations must strive to connect all business and management processes [18].

Some early signs that digitalization is becoming fact in the coatings area are already present. However, only a few companies have created digitalization strategies and established business groups focused on digitalization. However, most are adopting this approach only, for example, to improve customer experience or business processes, or to introduce new business models. In 2016, a white paper from the Digital Transformation Initiative for the chemistry and advanced materials industry was published. The paper emphasizes that, with digitalization driving operational optimization, one can expect improved efficiency, productivity, and safety across the whole supply chain of paints and coatings. It is known that digitalization opportunities go beyond and across functional areas, but the question is when they will be enforced. The director of digital and e-commerce says that the answer is dependent on technological maturity, business activities, and the strength and willingness of the company to digitalize, innovate, and change [18].

Some modern tools and technologies already exist, such as “blockchain,” “Internet of Things (IoT),” “quantum computing,” etc. However, the most important “digital transformation” tools are those that enable data and knowledge management along and across both internal functions and external networks, and that allow companies to find specific pieces of information within the huge ocean of data available in a structured way. Those tools can facilitate smart ways to combine systems that use internal product, customer, market, and manufacturing data. Companies that wish to benefit will also have to make some data available to the system. For example, in the marine coatings area, a “big data” service has become available, which helps select the optimal anti-biofouling coating, based on analysis of billions of data points. At the same time, “cloud-based” platform access and shared external and internal data enable estimated arrival times of ships at port, which helps to optimize delivery planning [15]. Also, a case of prediction profilers using historical data has been published. Prediction profilers can be used in combination with 3D data visualization tools to describe important results. The ability to predict performance reduces the number of formulations that need to be physically tested in a laboratory. Consequently, the development process is accelerated [7].

Both of the above examples are positive. However, a thorough and radical reengineering of key business processes could not be found, especially internal and external processes in a value chain at the same time. A business process is defined as “the sequence of activities in an organizational and technical environment with a structure that describes their logical order and dependence, with the main goal to produce the desired result” [19,20]. New technology can significantly improve effectiveness and efficiency, but it can also make the existing process more complex, reducing usability and causing more integration problems. As processes become more complex, problems with locating and correcting are increasing dramatically [21]. Business process adjustment is often carried out through business process redesign projects, which have the same goal: to achieve more efficient operations. According to Urh, Kern and Roblek [22], top managers are often faced with important questions: What is the level of business process performance efficiency? Is it necessary or reasonable to adapt the process? What adjustments must be made in business process performance? and How will the projected changes influence the business process performance efficiency?

These questions are also asked about the paints and coatings development process. The purpose of this research was to investigate whether the process can be dramatically and rationally improved using cloud-based information technology and a “big data” approach. In order to carry out the research, a sample of several companies involved in the production of paints and coatings was selected. The sample included small and medium-sized enterprises that carry out the development process in a classical manner—without the use of information technology that would enable digital transformation. The following sections describe the basis of the methodologies used (Section 2) and present research results (Section 3). This article concludes with a discussion of the research results and the conclusions reached (Section 4).

2. Methods

Significant progress in the paints and coatings R&D can be made by process re-engineering, not only by improving individual phases (e.g., lab testing). For radical improvement, it is necessary to use business process re-engineering (BPR) or business process management (BPM) and innovative information and communication technologies (ICT), combined with a digitalization approach.

For re-engineering the paints and coatings development process, a process analysis has to be performed for which relevant and up-to-date data has to be obtained, process models developed and a “technological enabler” selected [16]. Finally, the renewed process has to be validated by the simulation.

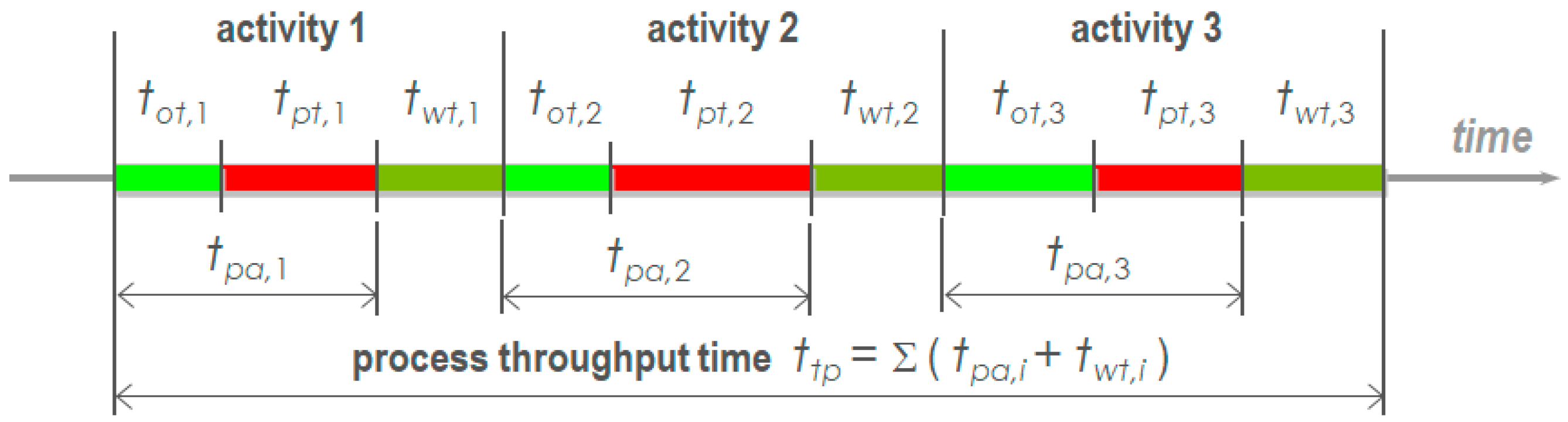

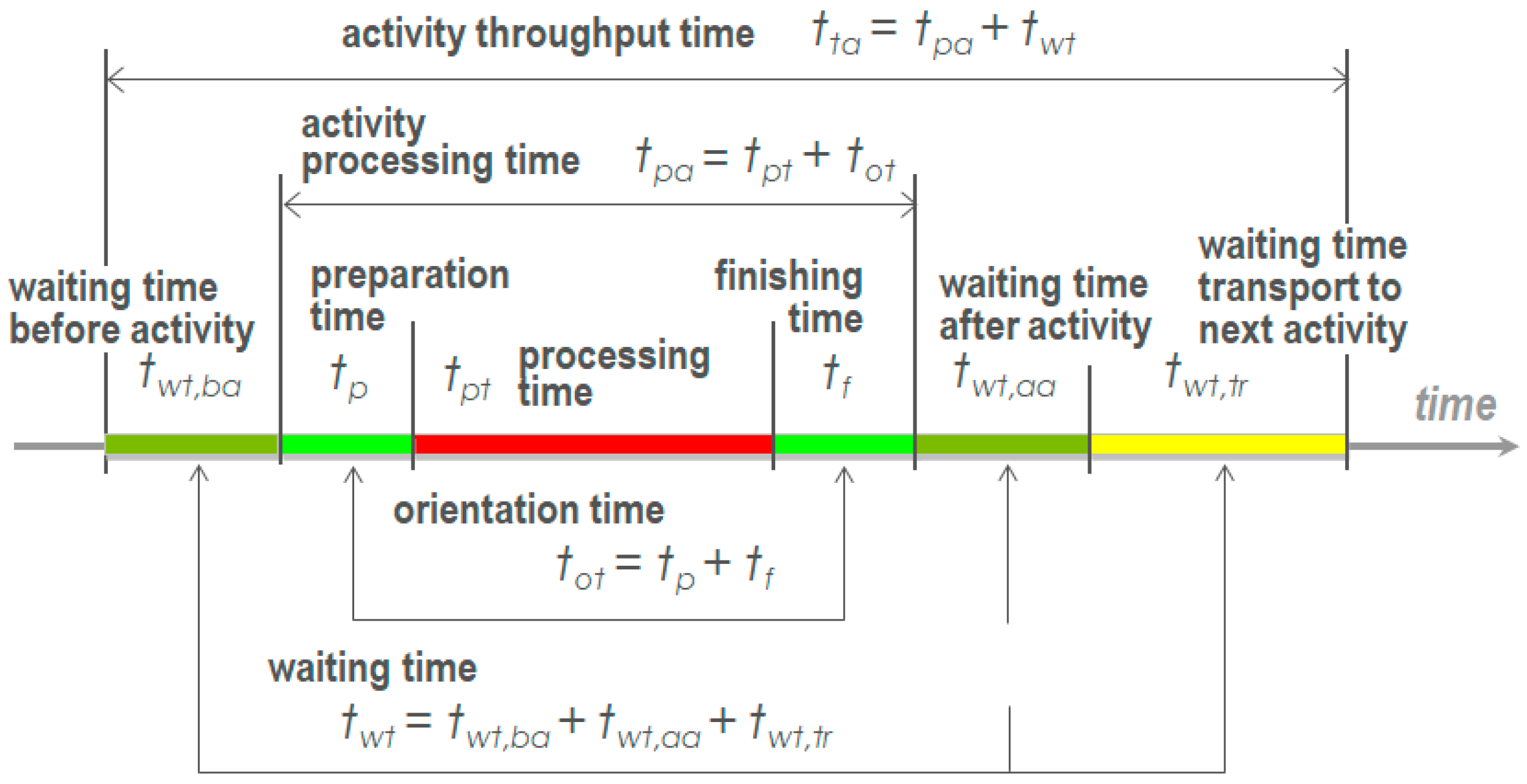

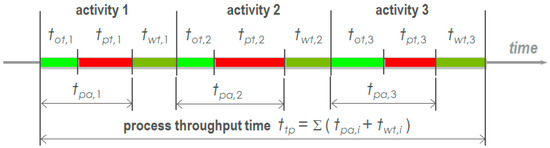

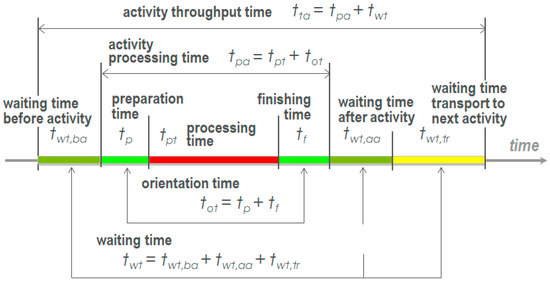

Process execution data were obtained through targeted interviews and modeling of the development process. In order to obtain the throughput time of individual phases and process activities, a deconstruction was done for each individual activity; into waiting time, orientation time (preparation‒finishing time), and processing time [23] (Figure 1). The deconstruction of time was simplified with regard to the structure of activity time, which is stated by Ljubič [24]: processing time, preparation‒finishing time, waiting time before and after activity, and transport time to the next activity (Figure 2). Time data can be measured in various time units, for example: seconds, minutes, hours, or days. Hours were used as the time unit in the present research.

Figure 1.

The structure of process throughput time.

Figure 2.

The structure of activity throughput time.

Based on the obtained sample, individual expected times with calculations from the PERT method were predicted [25]: optimistic, most probable, and pessimistic time:

te = (to + 4tm + tp)/6

- te—expected time

- to—optimistic time

- tm—most probable time

- tp—pessimistic time.

This is a development process with a relatively small number of repetitions, therefore possible errors in determining the actual values of time should not be ignored. However, this error was canceled out, since the same time values were taken into account in the proposal of the renewed process. Thus, the relationship with which the development process was supported with the latest information technology was justified, remains the same.

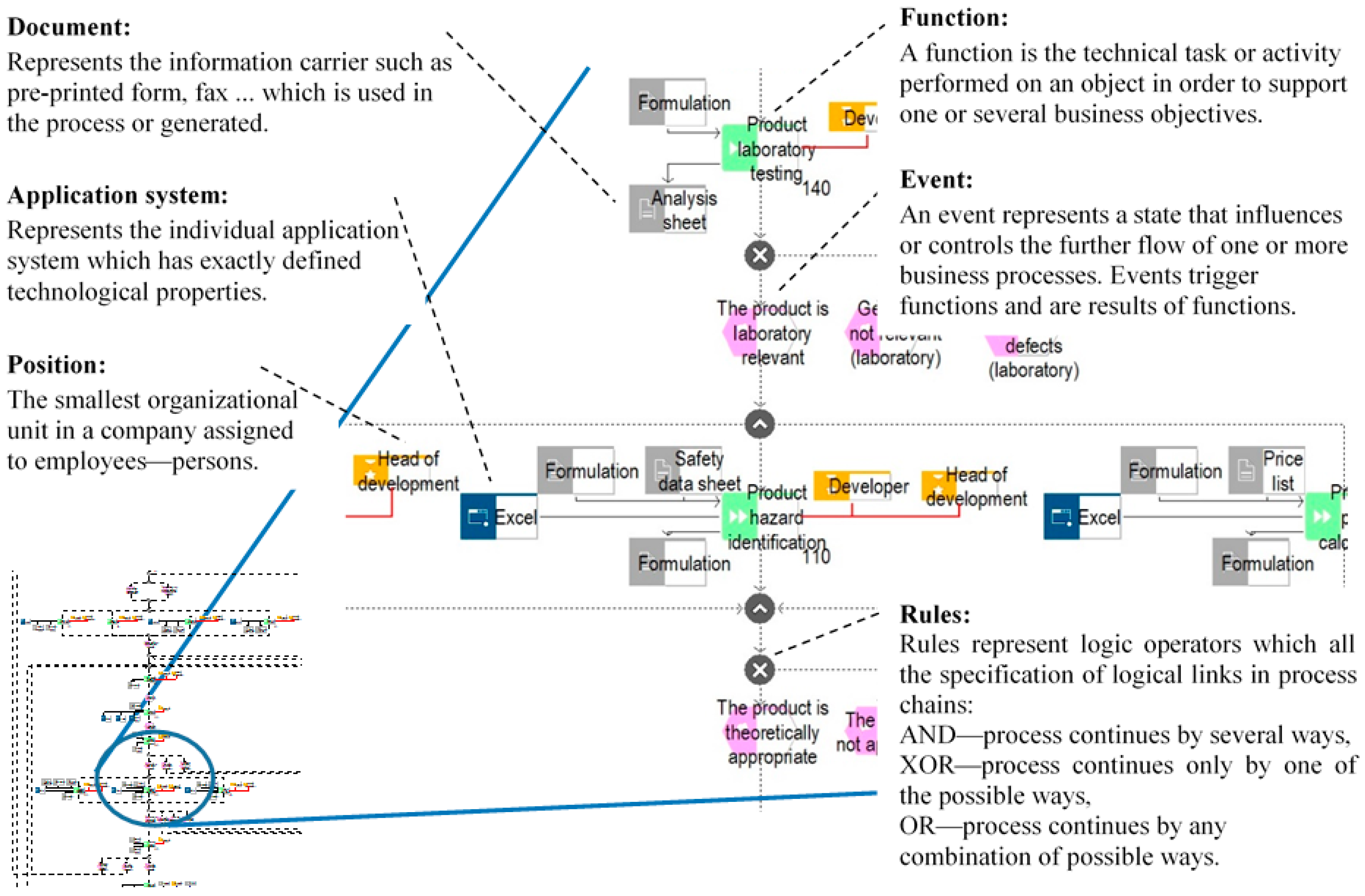

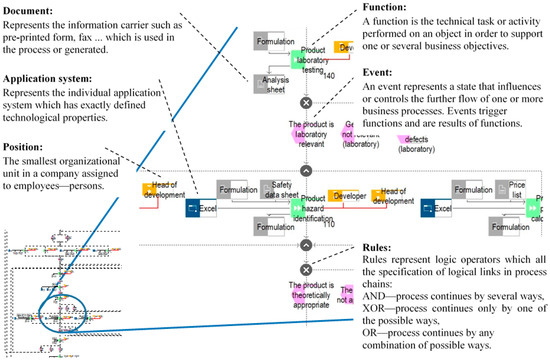

The business process simulation was conditioned by having process models in the appropriate repository. It is only possible to perform a simulation with a proper set of data. Architecture of integrated information systems (ARIS) methodology, more specifically an event-driven process chain model (EPC model type), was used for modeling because it presents a user perspective of the process [26,27,28]. This model is based on the logic that an event triggers an activity (task) or several activities. Consequently, the activity ends with a new event or several events.

Standard symbols [23] for business objects and relations were used (an example of a process section is given in Figure 3). The rules for using logical operators are also shown in the example.

Figure 3.

Process example and description of symbols used in business process mapping with the event-driven process chain (EPC) model type.

Through the literature review a lot of recommendations for process performance efficiency assessment were encountered [19,29,30], which can be performed based on the operational and structural efficiency indicators. The first indicators are connected with time, costs, and/or quality [31,32], whereas structural efficiency indicators are connected with business process structural complexity [33,34,35,36].

For each performance dimension, it was possible to identify different key performance indicators. Due to the simulation, the focus was on the time dimension and the following indicators were identified [32,37]:

- the waiting time—time spent waiting for a resource to become available. It is possible to measure the waiting time for each activity or for the whole case; attributes specify the wait time accrued for process folders as a rule;

- the service (processing) time—the actual work time put into the case. In the case of concurrency, the total service time (the sum of the time spent on the execution of various activities) may exceed the execution time. However, the service time is usually only part of the execution time; attributes specify the duration of time that may elapse between the start time and end time of a task;

- the orientation time—attributes specify the orientation times required for a function or resource based on the last simulation run;

- the lead (throughput) time—the total time from beginning to end of an individual case of process execution. The average execution time can also be measured, while the level of variance is important: it is not the same if all the cases last for about two weeks or if the individual lasts only a few hours and others for more than one month. The total time for carrying out a function one time should be the sum of the processing time and the orientation time, excluding the wait time.

The simulation is generally an imitation of the operation of a real-world process or system. It is used to assist decision-making by providing a tool that allows the current behavior of a system to be analyzed and understood. It is also able to help predict the performance of that system under a number of scenarios determined by the decision-maker [38]. Simulation modeling has been used for many years in the manufacturing sector and has become a mainstream tool in business situations. This is partly because of the popularity of business process re-engineering (BPR) and other process-based improvement methods that use simulation to help analyze changes in process design [39].

Simulation, in general, covers a large area of interest (e.g., business system performance prediction, providing performance measures). Simulation can refer to a range of model types, from spreadsheet models (static models) to system dynamic and discrete event simulation (dynamic models) [39]:

- static simulation—static models include the linear programming technique, which is an example of an analytical mathematical approach that can be used to solve management decision-making problems. A computer spreadsheet is an example of a numerical static model in which relationships can be constructed and the system behavior studied for different scenarios.

- dynamic simulation—a dynamic mathematical model allows changes in system attributes to be derived as a function of time. The derivation may be made with an analytical solution or with a numerical computation, depending upon the complexity of the model (process). Models that are of a dynamic nature and cannot be solved analytically must use the simulation approach. A classification is made between continuous and discrete event simulation model types. A discrete system changes only at discrete points in time. In practice, most continuous systems can be modeled as discrete at different levels of abstraction.

In the validation and verification of the simulation model, the dynamic simulation was used. Also, the static simulation was used for the impact assessment of the proposed changes in the process implementation. For static simulation execution Excel spreadsheets were used and for dynamic simulation execution the Aris tool was used. Discrete event simulation (DES) in the Aris tool works by modeling individual events that occur using a time-based engine, taking into account resources, constraints, and interaction with other events. This technique can easily reflect the process rules, randomness, and variability that affect the behavior of real-life systems and complex operating environments [40]. The simulation execution steps are as follows:

- defining simulation objectives;

- identifying the system/process;

- collecting and analyzing system/process data;

- preparation of the simulation model and program;

- simulation model evaluation;

- simulation execution;

- analysis of simulation results;

- simulation conclusion.

A technical enabler for the proposed improvement of development process has already been developed and is used as an information tool of the fourth generation [41]. The tool is at the stage of prototype testing and, according to this research, is the only all-in-one tool that enables online, real-time searching for raw materials, virtual formulation of paints and coatings, and the creation of digital technical and safety data sheets. It enables the formation of paints and coatings formulations based on data about binders, pigments, additives, and solvents. The formulator uses materials data from the structured database, which is available in digital form in a cloud. The re-engineering point is that the formulator has instant and free access to a large number of raw materials and is guided by the platform to select only those that are functionally relevant, safe, environmentally acceptable, and affordable, even before the individual formulation is laboratory-tested. This method significantly reduces the number of unnecessary laboratory tests and consequently significantly reduces the paints and coatings development throughput time. The advantage of the reengineering is that the data for the product are already generated, available, and ready to use for the preparation of necessary documentation (i.e., safety data sheets, technical data sheets, and hazard labels).

3. Results

Referring to the simulation execution steps, defining simulation objectives (1), identifying the system/process (2), and collecting data (3) have already been defined in previous sections. The research goal was to optimize the throughput time of the paints and coatings development process.

Different development processes (which are performed in practice by individual companies) without the use of the latest cloud-based ICT, can be roughly separated into two variants of the process:

- development of a new product without ICT support (classical process),

- development of a new product with ICT support and local database use.

A dissection of the process execution variants into key activities and the possible support of their execution with appropriate ICT equipment is presented in Table 1.

Table 1.

Key activities of process variants and their support with information and communication technologies (ICT).

Since the research goal was to analyze the throughput time of the development process execution, data about the structure of individual activity times in the process were collected: waiting time, orientation time, and processing time. In the branching or aggregating processes, the probability assessment was also obtained (Table 2).

Table 2.

Activity time estimates and the probability of new product development process without ICT support.

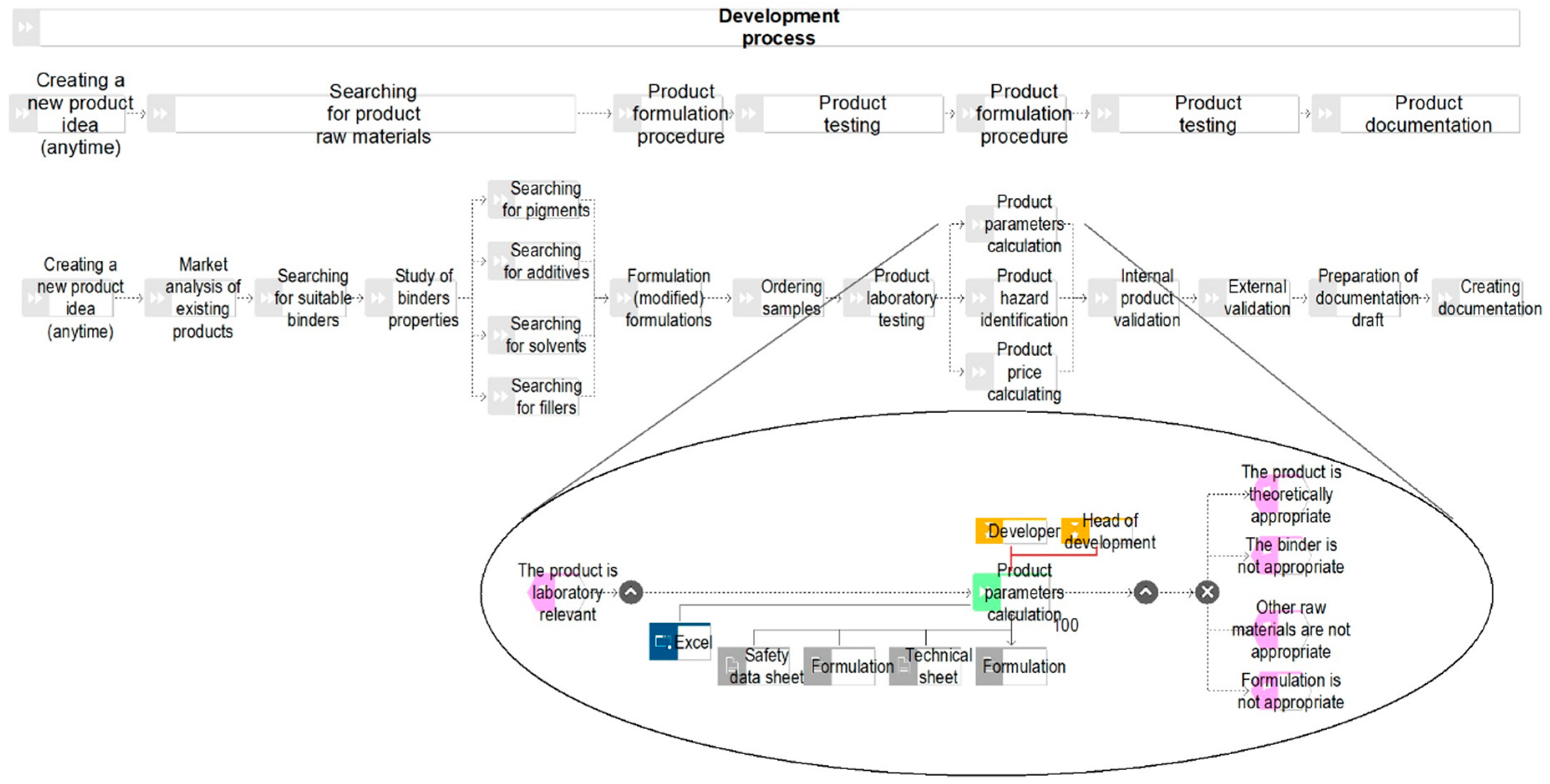

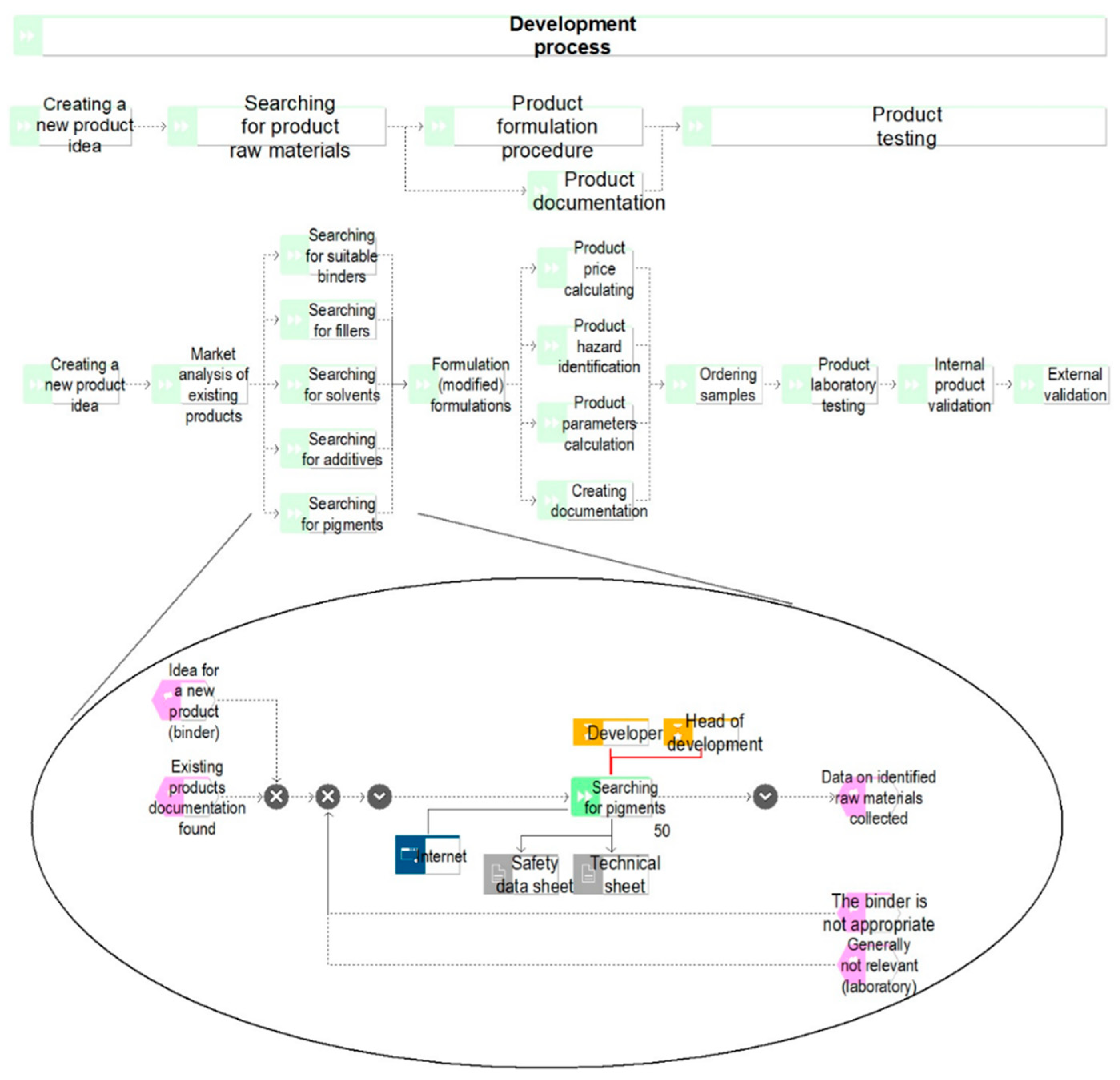

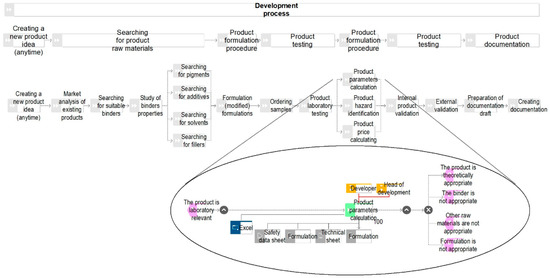

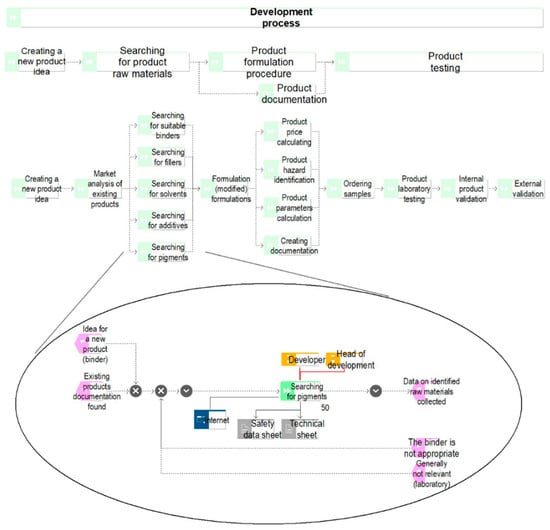

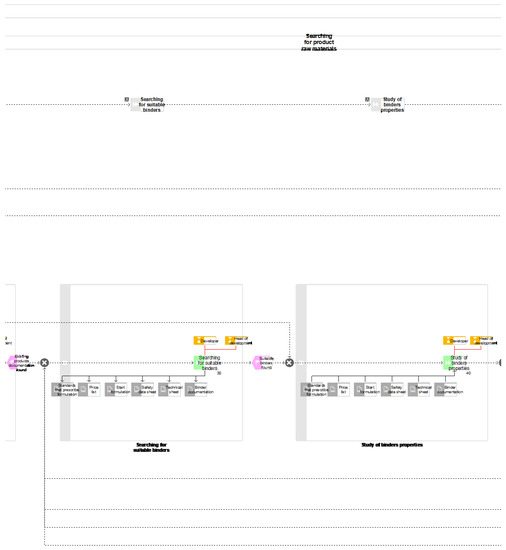

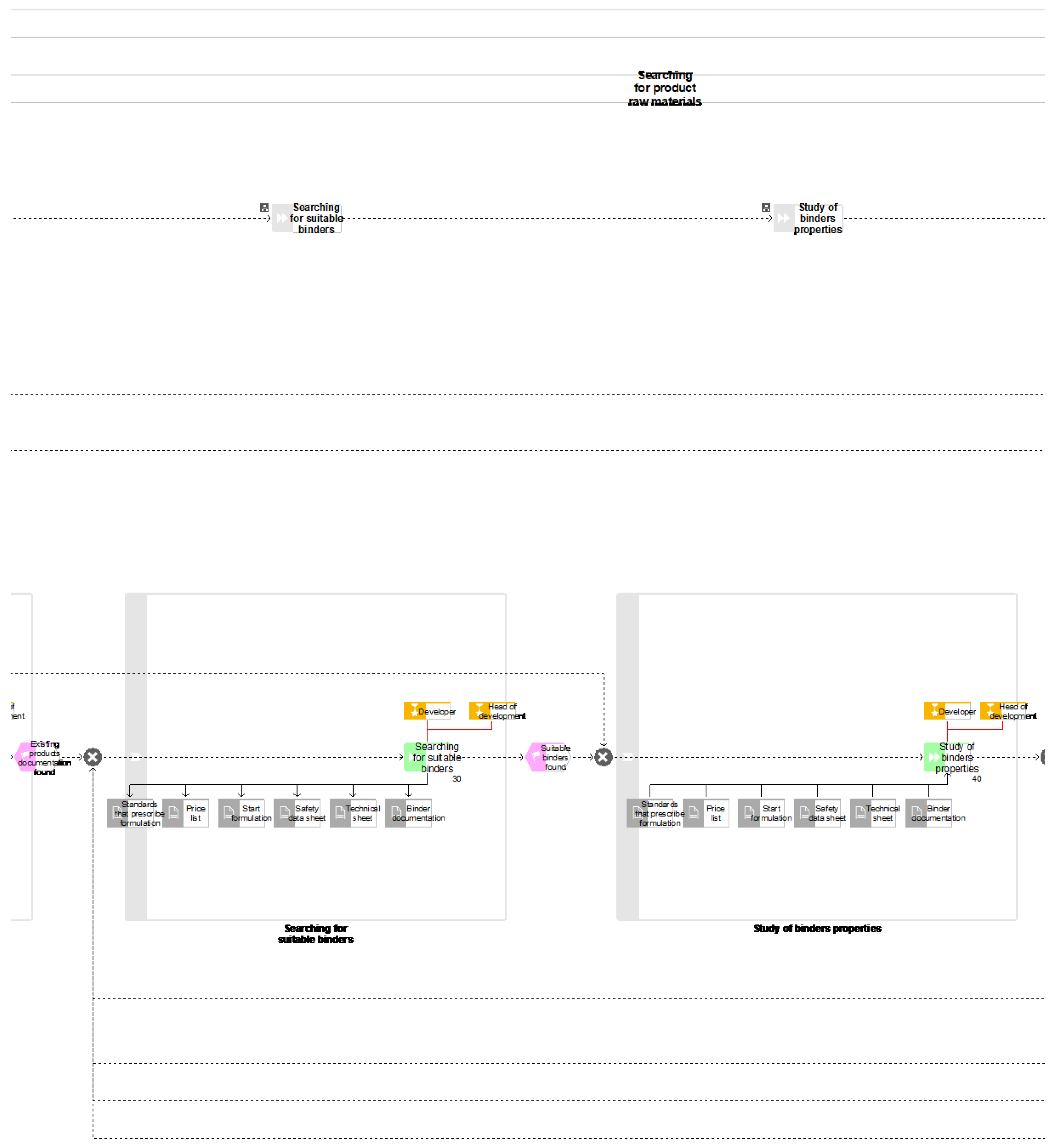

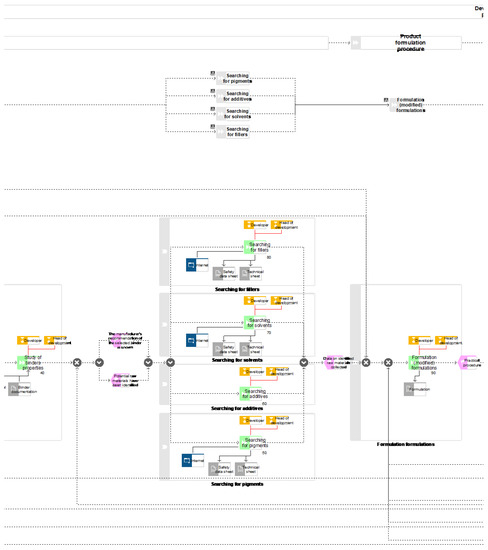

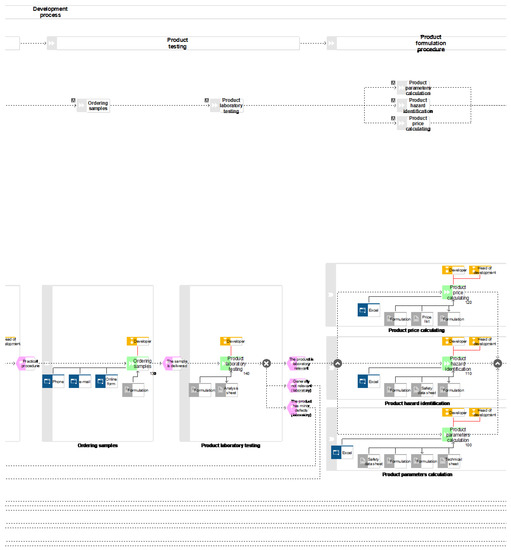

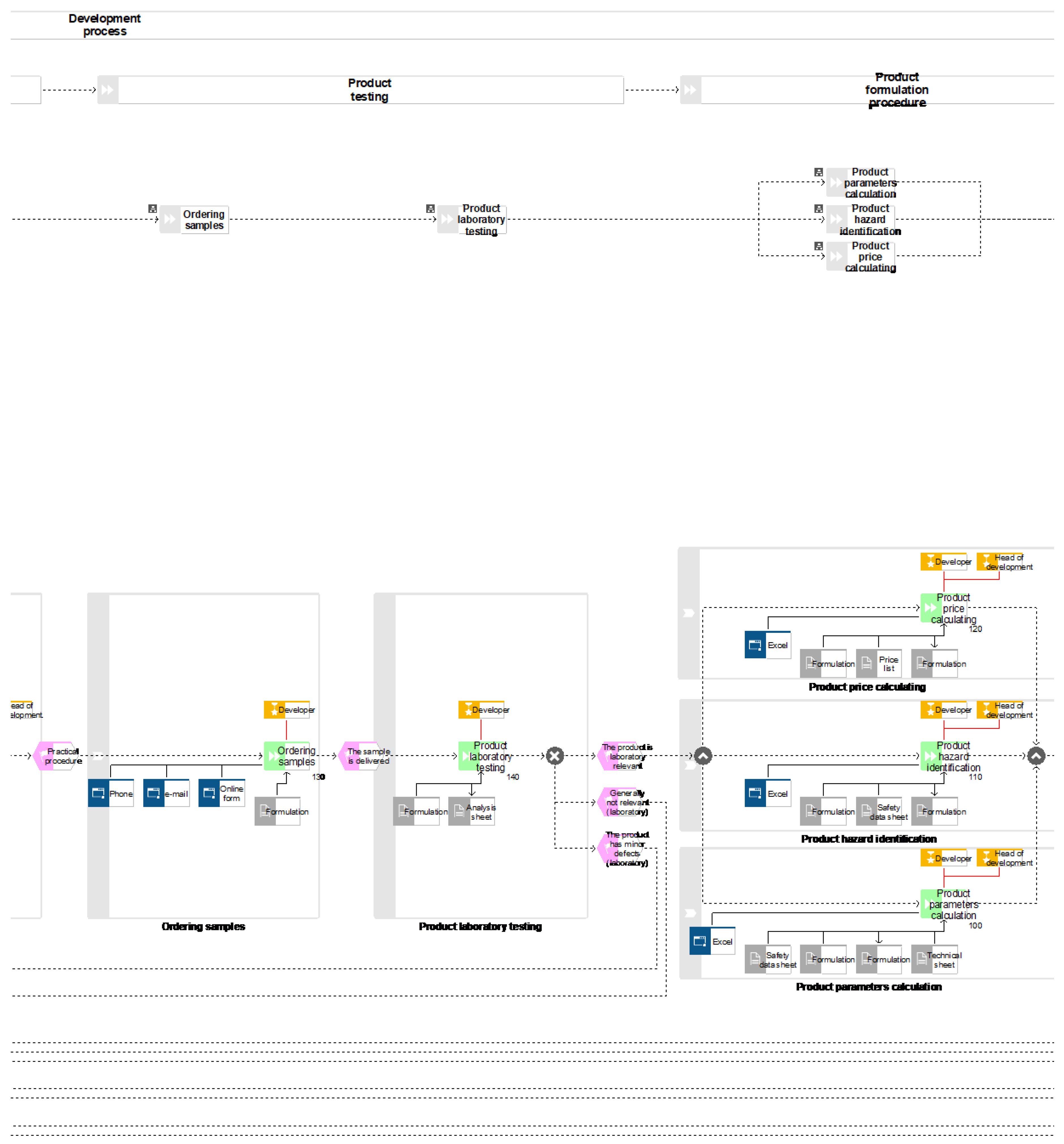

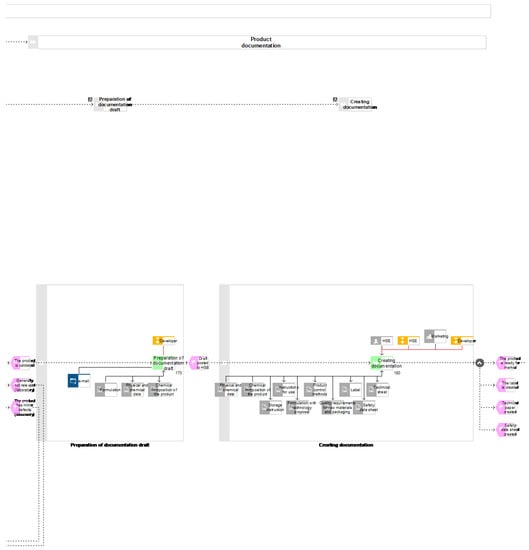

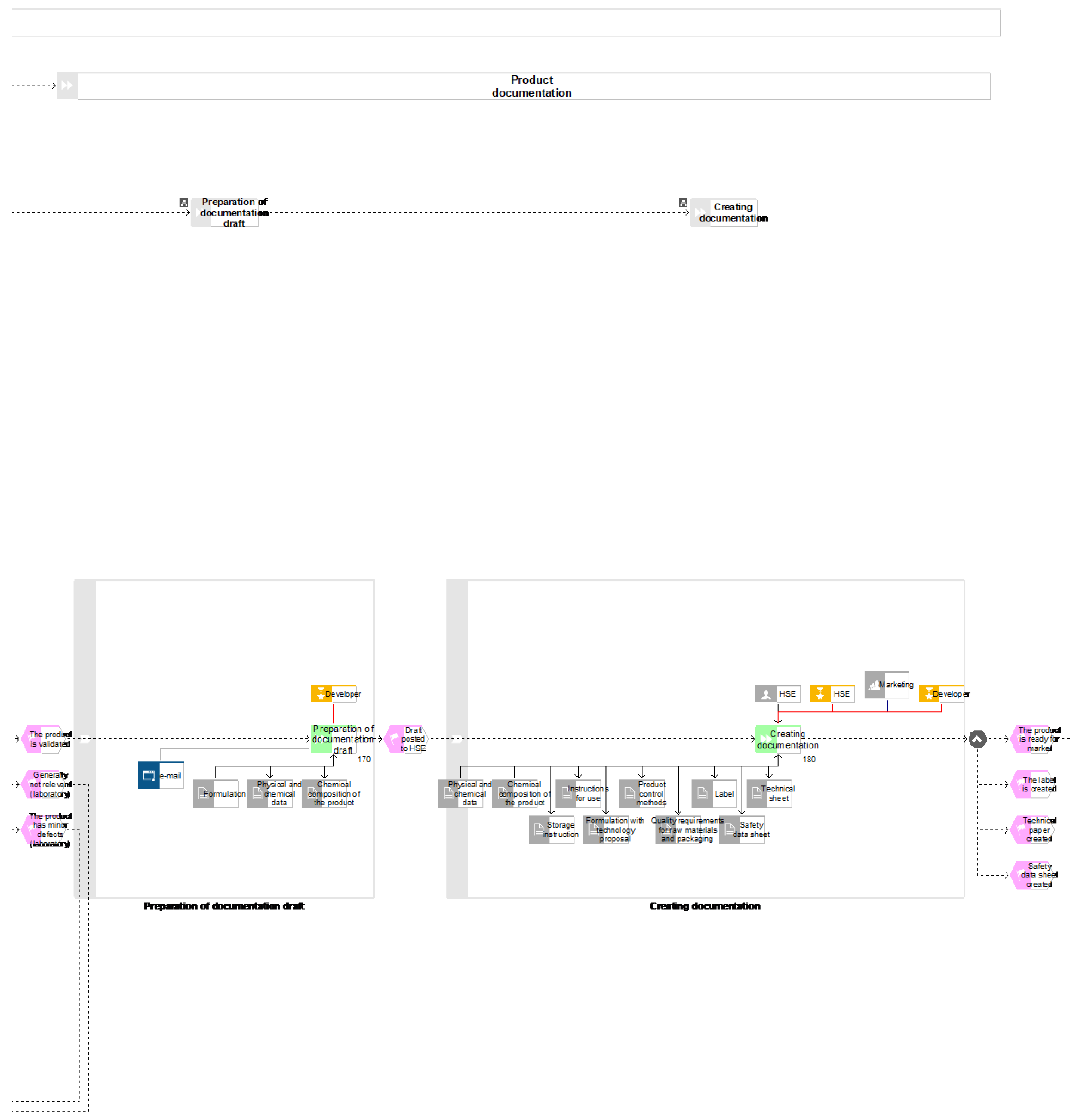

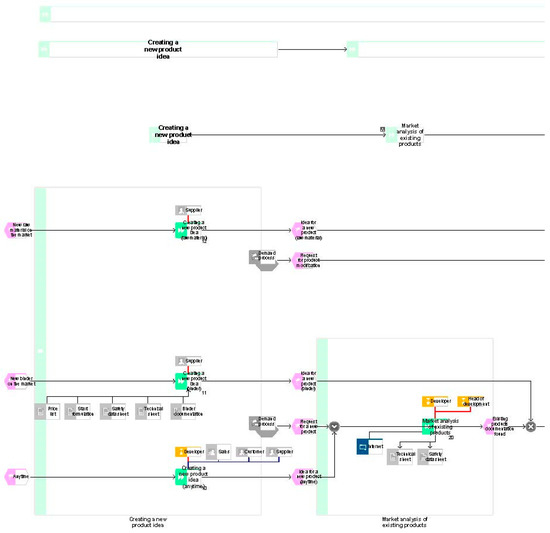

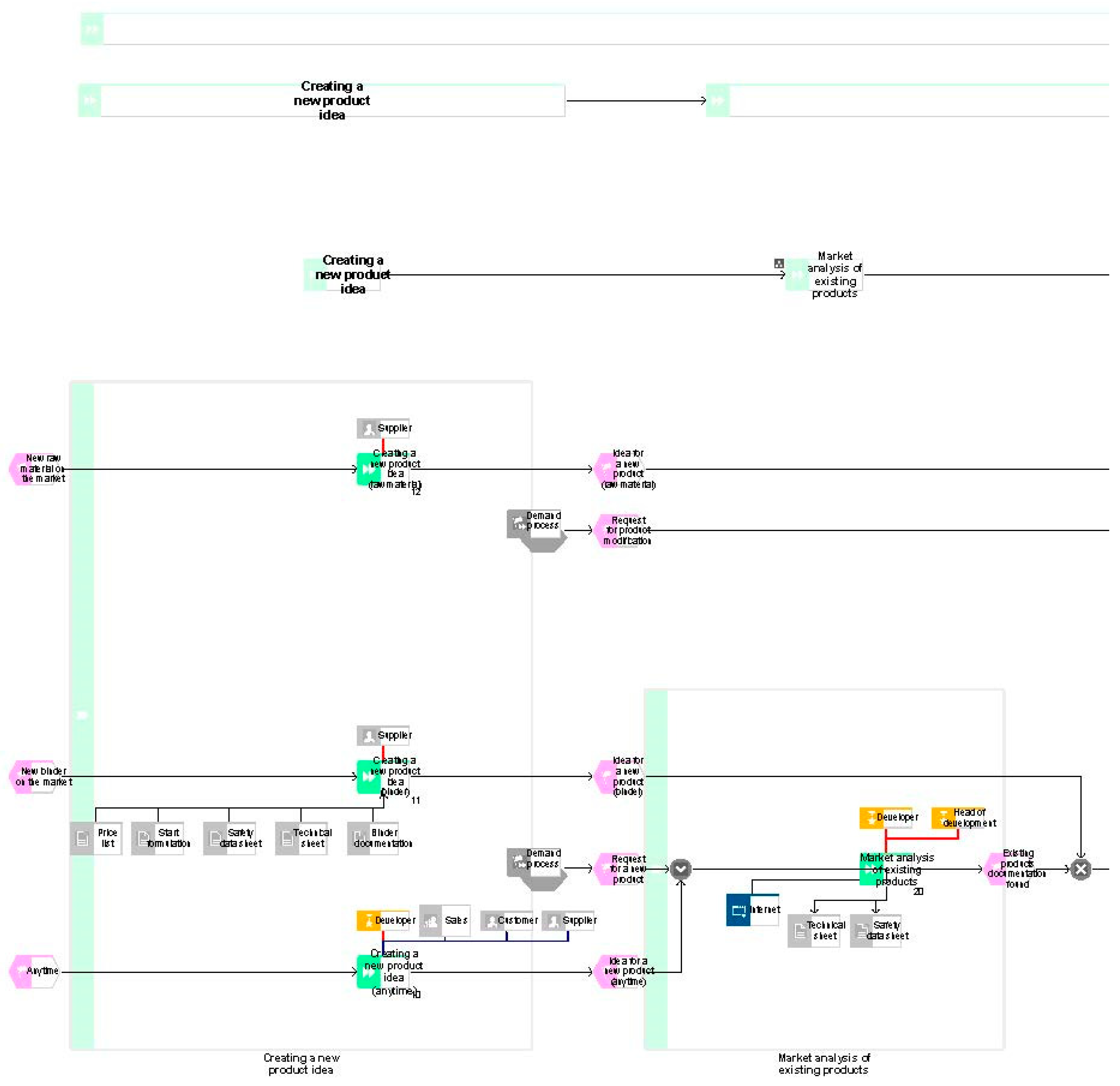

On the basis of the collected data and targeted interviews (with leading employees in the processes), the simulation model (4) in the Aris tool was designed. The simulation model is shown in Figure 4. The figure represents a value-added diagram of the existing process in three levels of decomposition. The improvement of the process is presented below.

Figure 4.

Model overview of the existing new product development process without the support of ICT. (Due to the size of the process model, only two segments of the detailed process model are shown; the entire model is shown in Appendix A).

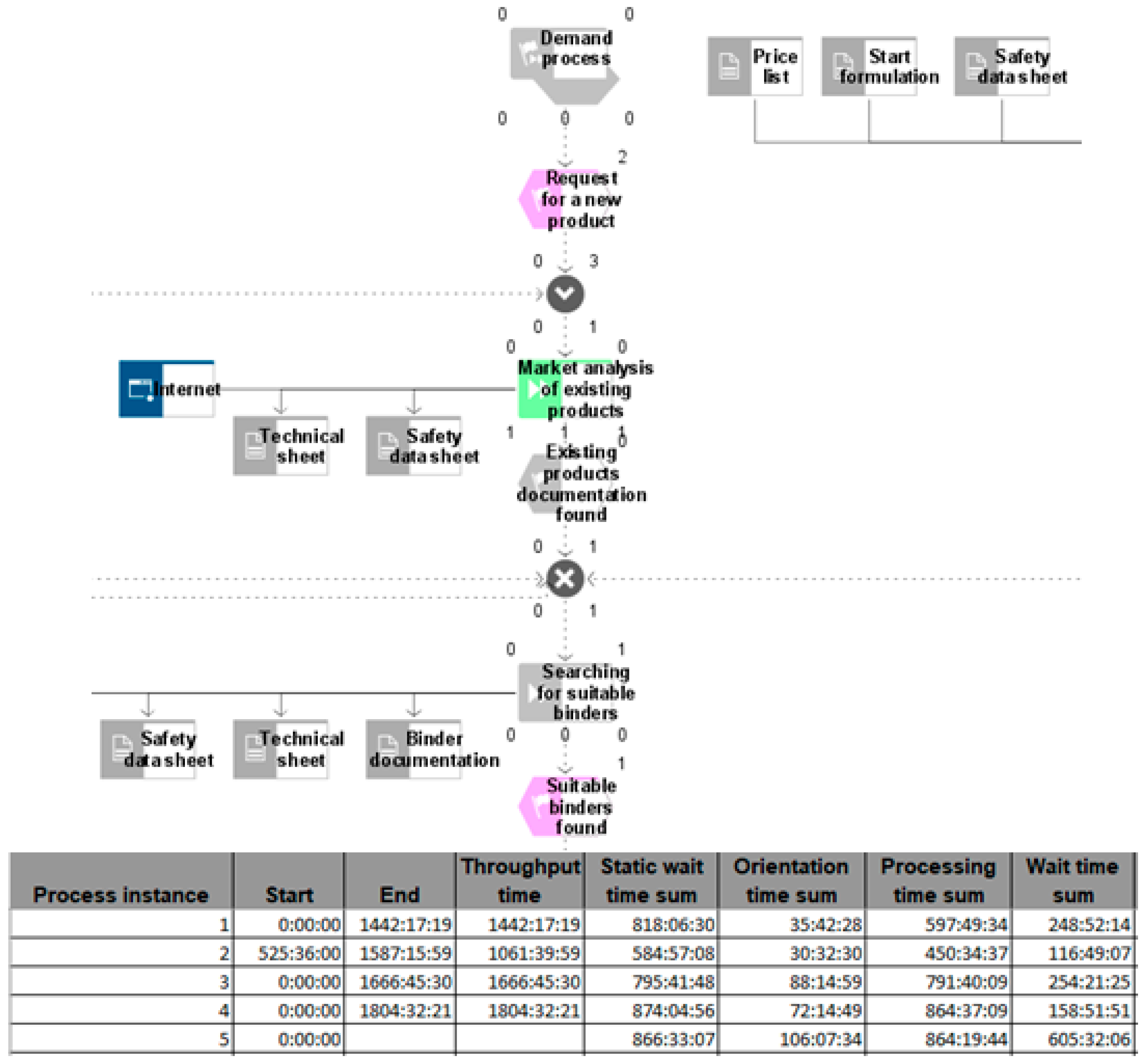

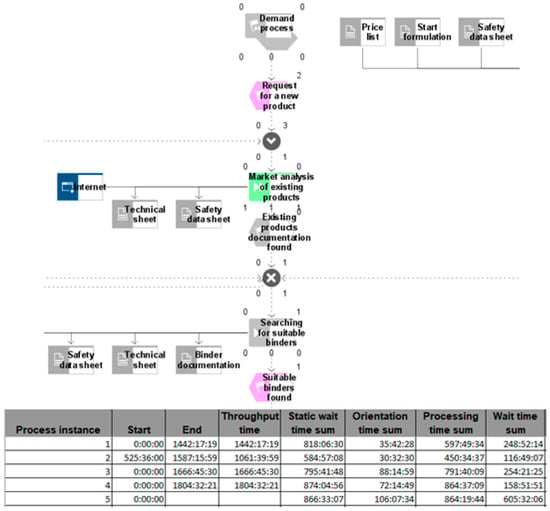

The process model was validated and verified (5) with a dynamic simulation of the process execution. The process model segment during the simulation and part of the results report are shown in Figure 5.

Figure 5.

The segment of the existing process model and part of the dynamic simulation results.

The simulation was carried out for a period of one working year (231 working days, eight hours per day). The simulation results were completed within 14 min. These theoretical results were compared with the actual results achieved by the companies in question. Also, the transition time for a successfully executed repetition of the process and the number of successful process executions in one year were compared. The simulation results were consistent with the actual data, so the simulation model of the existing state could be verified. A possible error can only be relative to the execution time of individual activities. By collecting data through multiple iterations of an information supported process, this error will be eliminated.

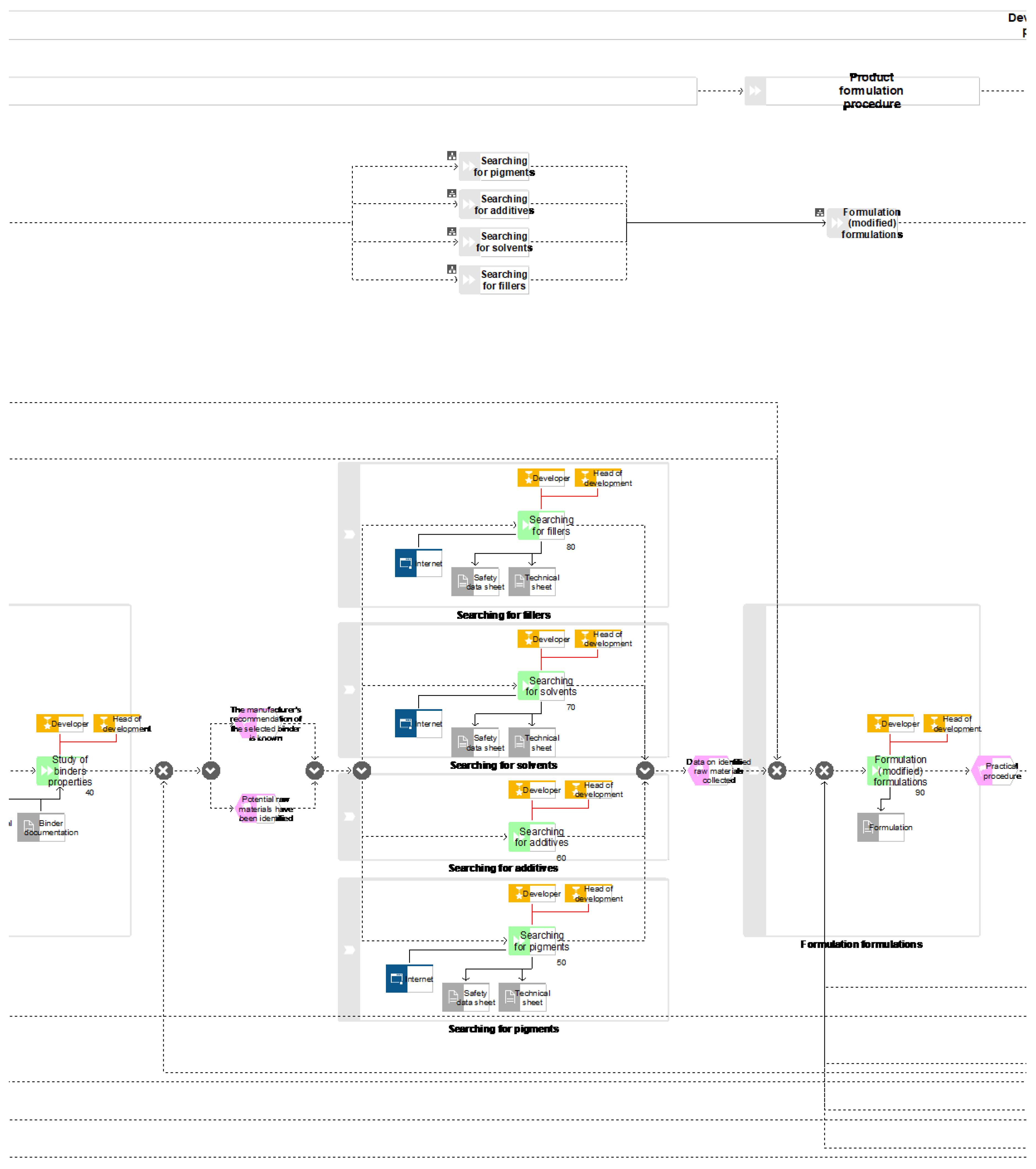

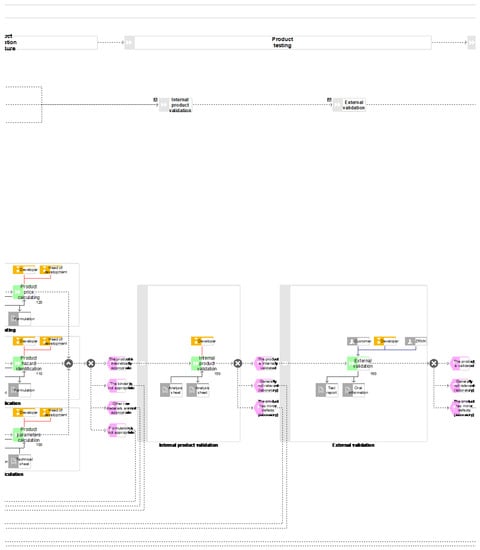

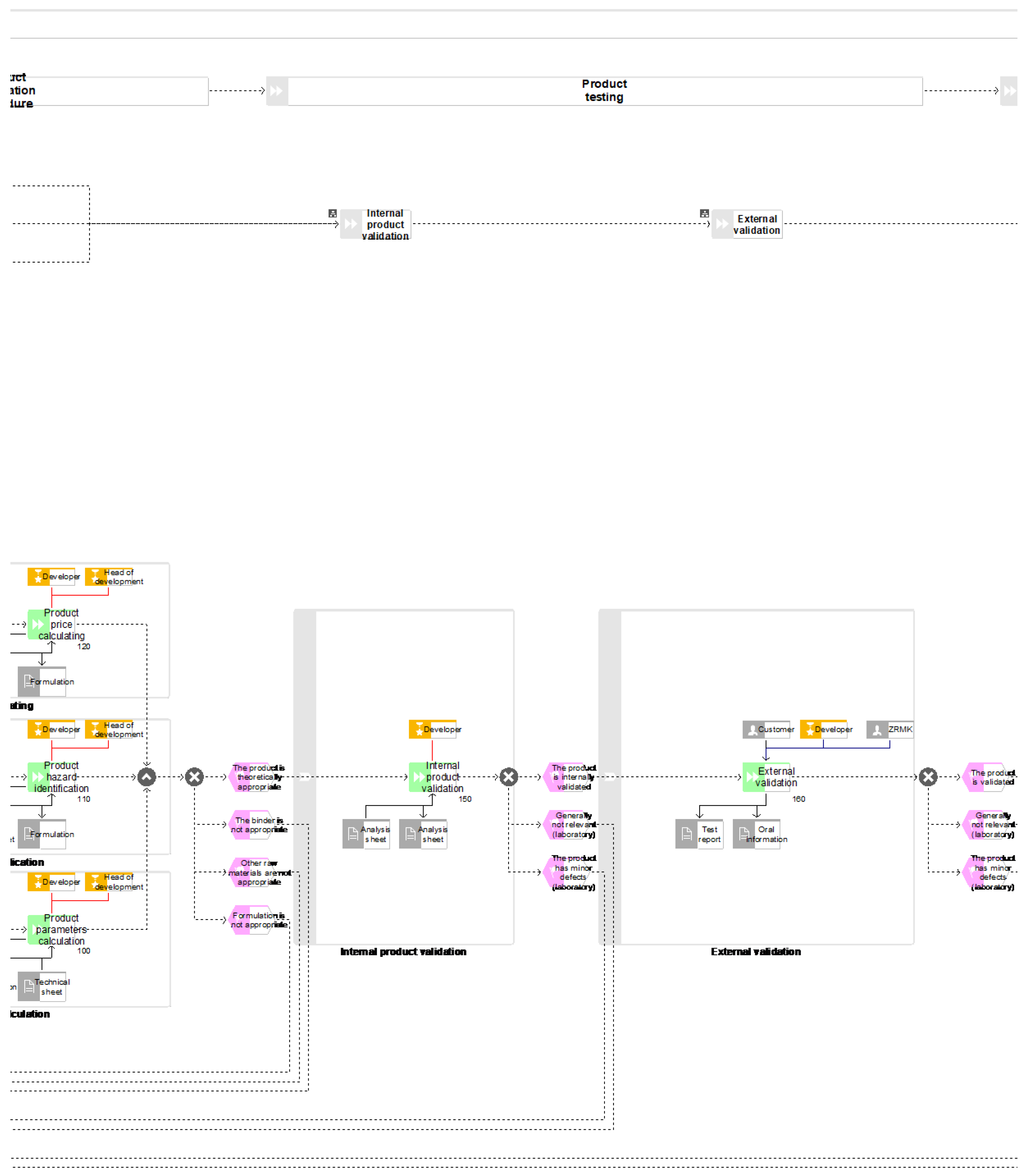

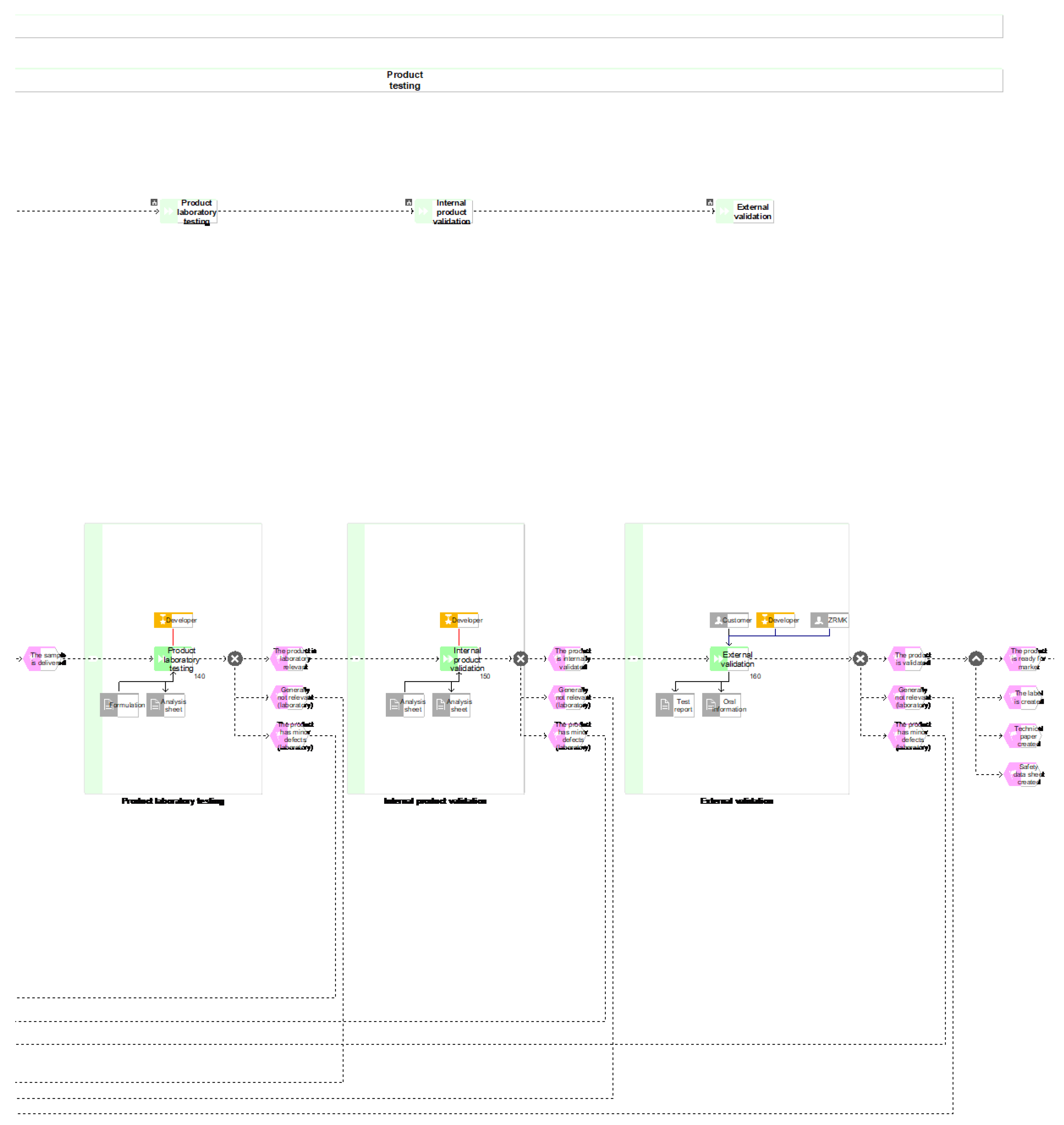

For the purpose of simulating (6) the impact of the proposed changes on the process execution, an appropriate model of the renewed process was developed (shown in Figure 6). It took into account the possibilities offered by the inclusion of process support with modern ICT and the use of a cloud-based database, which allowed for the changed sequence of key activities execution in the process (Table 3). This significantly influenced the time required for the successful execution of the renewed process.

Figure 6.

The model overview of the modified (renewed) new product development process with ICT support and the use of a cloud-based database. (Due to the size of the process model, only one segment of the detailed process model is shown; the entire model is shown in Appendix B).

Table 3.

Key activities of the new product development process with ICT support and the use of cloud-based database.

The process was checked in a medium-sized company which develops and produces paints and coatings using this technical enabler [41]. The tool is used to help with the safety data sheets preparation in developing new products [42]. The company can eliminate formulations that will be inadequate, in terms of environmental hazards or cost, in the first stage of the development process. It must be noted that the local database includes a finite amount of the raw materials data that are currently available. The results of the process verification confirmed the simulation results.

The impact of changes on the throughput time was verified by static simulation execution. The simulation of a new product development process without ICT support (taking into account the data in Table 2), as well as a simulation of the renewed process with cloud-based ICT support (taking into account the data in Table 4), were executed.

Table 4.

Activity time estimates and the probability of the new product development process with ICT support and the use of a cloud-based database.

Table 5 presents the results of the executed simulation (7) for the new product development process without ICT support and for the renewed process with appropriate ICT support and a cloud-based database.

Table 5.

Results of the new product development process static simulation without ICT support and results with ICT support and the use of a cloud-based database.

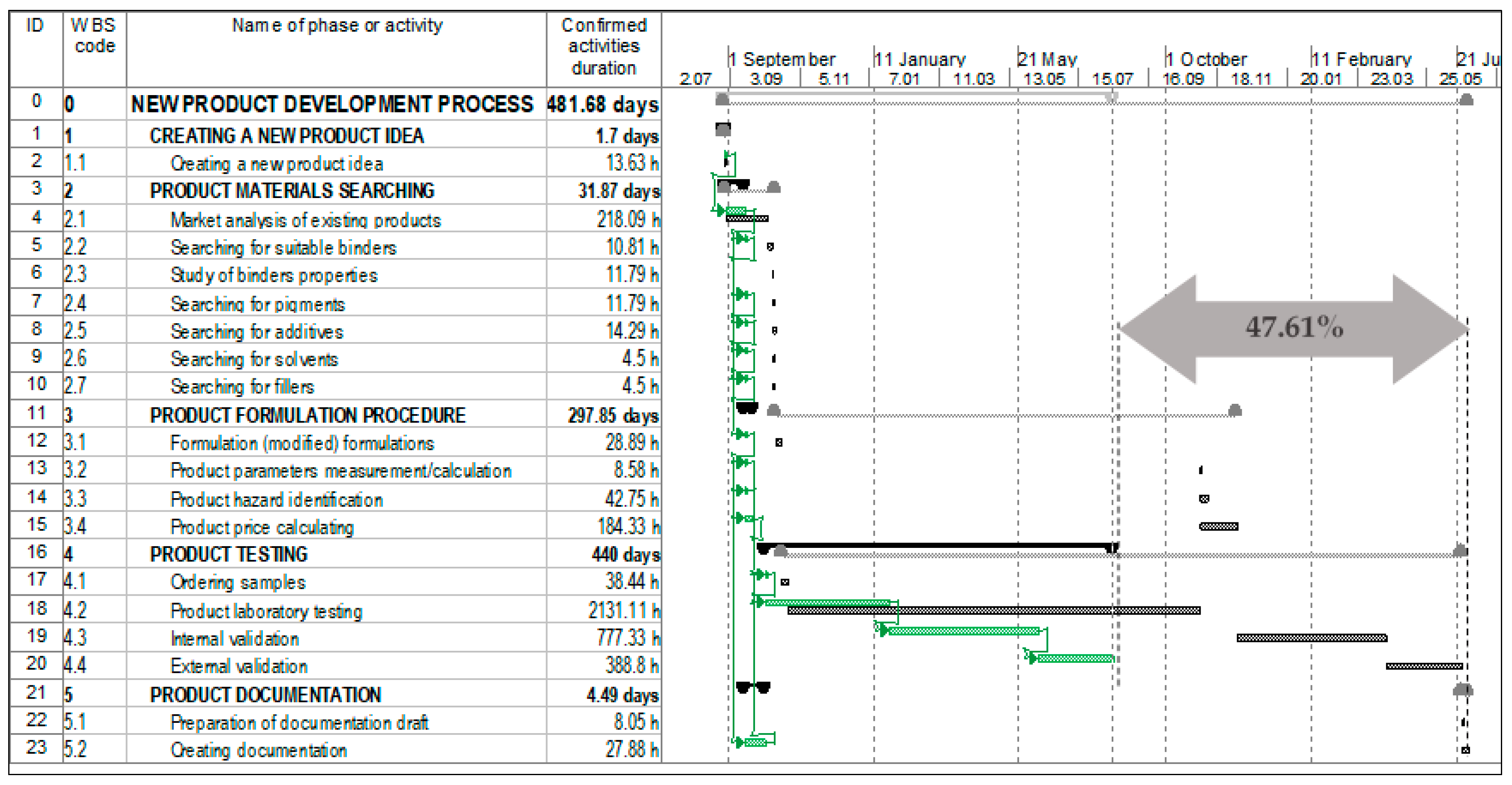

Based on the comparison of both simulations results (Table 5), the following conclusions about the executed simulation can be drawn (8); the inclusion of the appropriate ICT support and cloud-based database in the new product development process execution results in the following:

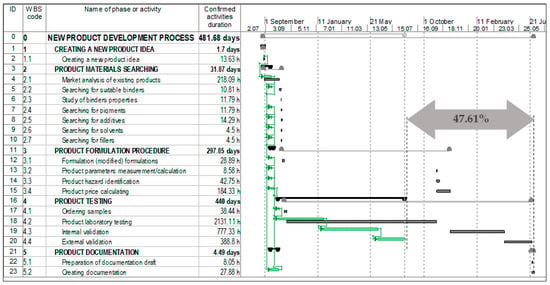

- the entire development process throughput time was reduced by 47.61% (1835 out of 3853 h) as is shown in Figure 7,

Figure 7. Gantt chart comparison of the existing new product development process (gray) and the modified (renewed) process (green).

Figure 7. Gantt chart comparison of the existing new product development process (gray) and the modified (renewed) process (green). - the activity throughput time on which the cloud-based ICT has impact was reduced by 69.88% (1726 out of 2469 h),

- surprisingly, even the activity throughput time on which the cloud-based ICT has no impact, due to relevant information from the previous activities, was reduced by 7.88% (109 out of 1384 h).

Additionally, some other advantages of the renewed process were observed: environmental friendliness, lower cost, innovative, broader offerings, the possibility of manufacturing excellent (optimal) products, the ability to track progress, and a greater possibility of manufacturing niche products in smaller series.

A reduced number of laboratory tests leads to efficient reduction of the waste quantity generated during laboratory tests. Therefore, it helps to reduce the pollution degree (environmental advantage). Laboratory tests are much more expensive than computer simulations. The reason is the price of equipment, human work, energy, and materials (cost advantage). The repetitive work performed by formulators in the laboratory is tiring. With a reduced number of repetitions, formulators have more time to develop new products (innovative advantage).

Smaller companies that have insufficient laboratory capacities can also develop excellent products; there are 3865 such companies in the EU [43] (broader offerings). When the raw materials database is complete (containing thousands or tens of thousands of raw materials), the possibility that optimal raw materials will be selected for a certain product is much greater than in cases in which a formulator executes laboratory tests only from a selection of dozens or hundreds of raw materials (e.g., only those with which they are familiar or those that exist in their local database (manufacturing optimal products)). When the data exist in a global database, manufacturers have their own interest in constantly updating that database. In such a way, companies always have access to the most up-to-date raw materials data. The data changes are accessible to all users (the ability to track progress). The demand for such products increases constantly. In such a manner, it is possible to work on the engineering-to-order (EtO) principle and to use the mass customization principle (manufacturing niche products).

4. Discussion and Conclusions

In this research (which was performed in 2018), models of paints and coatings development processes in international companies were mapped. Data about development process’s throughput times and data about the structure of process activities throughput times were collected. Moreover, data about return-loops in processes were ascertained. Significant differences were found between ICT-supported processes and processes executed in the classical way.

Static and dynamic temporal analyses were prepared. The analysis results showed that the most time was saved by a reduction in often-repetitious and time- and resource-consuming laboratory testing activities. According to customer requirements for products with better functionality, laboratory testing activities are necessary. Additionally, there is an increasing supply of raw materials (binders, pigments, additives, solvents and fillers), which lead to more complex development processes. Environmental acceptability and product price are determined only after the laboratory tests (in the classic process), and because of that, more laboratory tests in the development process are necessary. If, upon the completion of a laboratory test, all these properties are not within the limits of expectation and product functionality (both in terms of its functional use and its potential success on the market), the development process returns to the beginning. With requests for shorter processes, companies are faced with a difficult problem: “How can customer requests be fulfilled in a more streamlined manner?”

Companies try to solve the problem by the shortening of individual laboratory tests. In the literature, one can find many innovative solutions that companies either already use or plan to introduce. The majority of these ideas are connected with new technologies or equipment. This can enable the shortening of individual laboratory tests and consequently shorten the development process. However, this is not the final solution to the problem. Because of the increasing complexity of development processes, the implementation of technological changes is not sufficient. Too many, ultimately unnecessary, laboratory tests are regularly undertaken, which slows down the process and can be wasteful in terms of time and materials.

In the present study, an alternative approach to problem resolution was explored. This was the digitalization concept, which is already used in other industries and has yielded excellent results. The fact that technology itself cannot offer the final solution to the problem was also taken into consideration. Technology can only become the “technical enabler,” which leads to a renovation of the processes, allowing them to become radically more efficient. To this end, two knowledge areas were explored in detail: new technologies and business processes renovation.

The latest findings on business processes renovation were reviewed. It was found that radical improvements can be achieved by reducing the number of activities. It was also ascertained that laboratory tests are often repeated, and they are on the processes critical path. Accordingly, the focus was shifted to the reduction of the number of laboratory tests, which can be accomplished through adequate selection of formulations ahead of time, before entering the lab. As the environmental acceptability and product price, mainly depend on the raw materials, these can be calculated without laboratory testing. Therefore, it is possible to find which formulations are not acceptable from an environmental or economic standpoint, and they can be excluded from further consideration. Only those formulations that are environmentally and economically acceptable can be included in laboratory testing. This leads to a radical reduction in laboratory testing repetitions and also enables efficient reduction of the development process throughput time.

However, a necessary condition for the approach mentioned above is digital access to relevant, up-to-date, and complete, useable data on raw materials. It was explored whether accessible databases exist and it was found that the majority of data from various manufacturers are publicly available only in the form of safety data sheets, which must be enclosed with the substances or products. However, these data are mainly available in unstructured forms (PDF format), and as such are useless for formulation purposes, because combining data in unstructured documents is time-consuming and impractical. Formulators prefer to execute laboratory tests because that is often easier than searching through a large quantity of data on raw materials, which then will not be laboratory-relevant.

Therefore, technology that enabled rapid, efficient access to relevant data was explored and an ICT solution that supports the development process through the creation of technical documentation (safety data sheets and print labels) found. This technical enabler is unique because it not only supports the creation of technical documentation in PDF format (based on local documents), but also enables the use of global databases. These global databases could be filled with data from raw materials manufacturers and are used by companies that produce paints and coatings when they prepare safety data sheets. Safety data sheets are not in PDF format, but exist in a structured form. Technical documentation is thus only presented as a printout. Formulators can prepare formulations and simultaneously observe all product characteristics. When data about raw material prices are available, the product price can also be calculated.

It was found that the technical enabler could be used in the initial stages of the development process, when the formulator designs the formulation. Instead of executing laboratory tests on a large quantity of formulations and checking the environmental and economic acceptability of formulations only after laboratory tests have been completed, the process was reversed. In the beginning, simulations of possible formulations were prepared using the technical enabler platform. Then, only those formulations that were within the range of tolerance, in terms of hazards and price points, were included in analog laboratory testing. The result was a large number of virtual simulations and a small number of actual laboratory tests. When the data for simulations were accessible, up-to-date simulations could be performed in a very short time and with no waste in terms of materials and non-value-added time. Therefore, the “vision” is to encourage raw materials manufacturers to import the product data into the cloud-based database, where data will be accessible to all formulators. When critical mass is achieved, the greater advantages of this approach will become evident in practice.

Author Contributions

Conceptualization, T.K.; methodology, T.K. and B.U.; software, B.U.; validation, T.K., E.K., and B.U.; formal analysis, E.K. and B.U.; investigation, E.K., M.S., and B.U.; resources, T.K.; data curation, T.K. and B.U.; writing—original draft preparation, E.K., M.S., and B.U.; writing—review and editing, T.K.; visualization, B.U.; supervision, T.K.; project administration, T.K. All authors (T.K., E.K., M.S., and B.U.) read and approved the final manuscript.

Funding

This research received no external funding.

Acknowledgments

The authors are grateful to the Laboratory of Enterprise Engineering, Faculty of Organizational Sciences, University of Maribor for supporting the project. The authors would also like to thank Noah Charney for proof-reading the article.

Conflicts of Interest

The authors declare no conflict of interest.

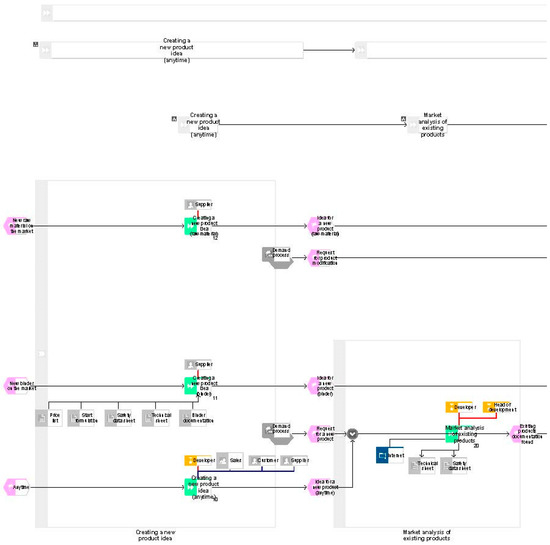

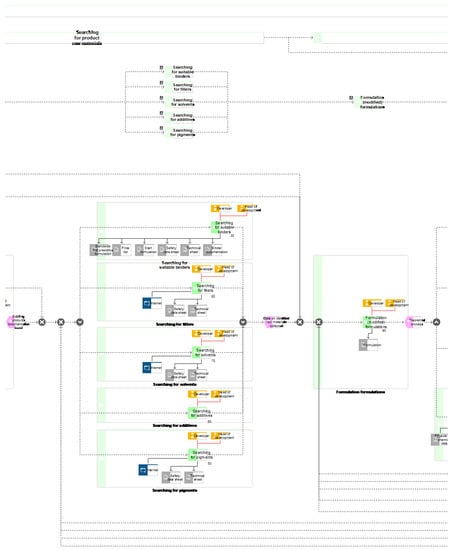

Appendix A

Figure A1.

Model overview of the existing new product development process without the support of ICT (part 1).

Figure A1.

Model overview of the existing new product development process without the support of ICT (part 1).

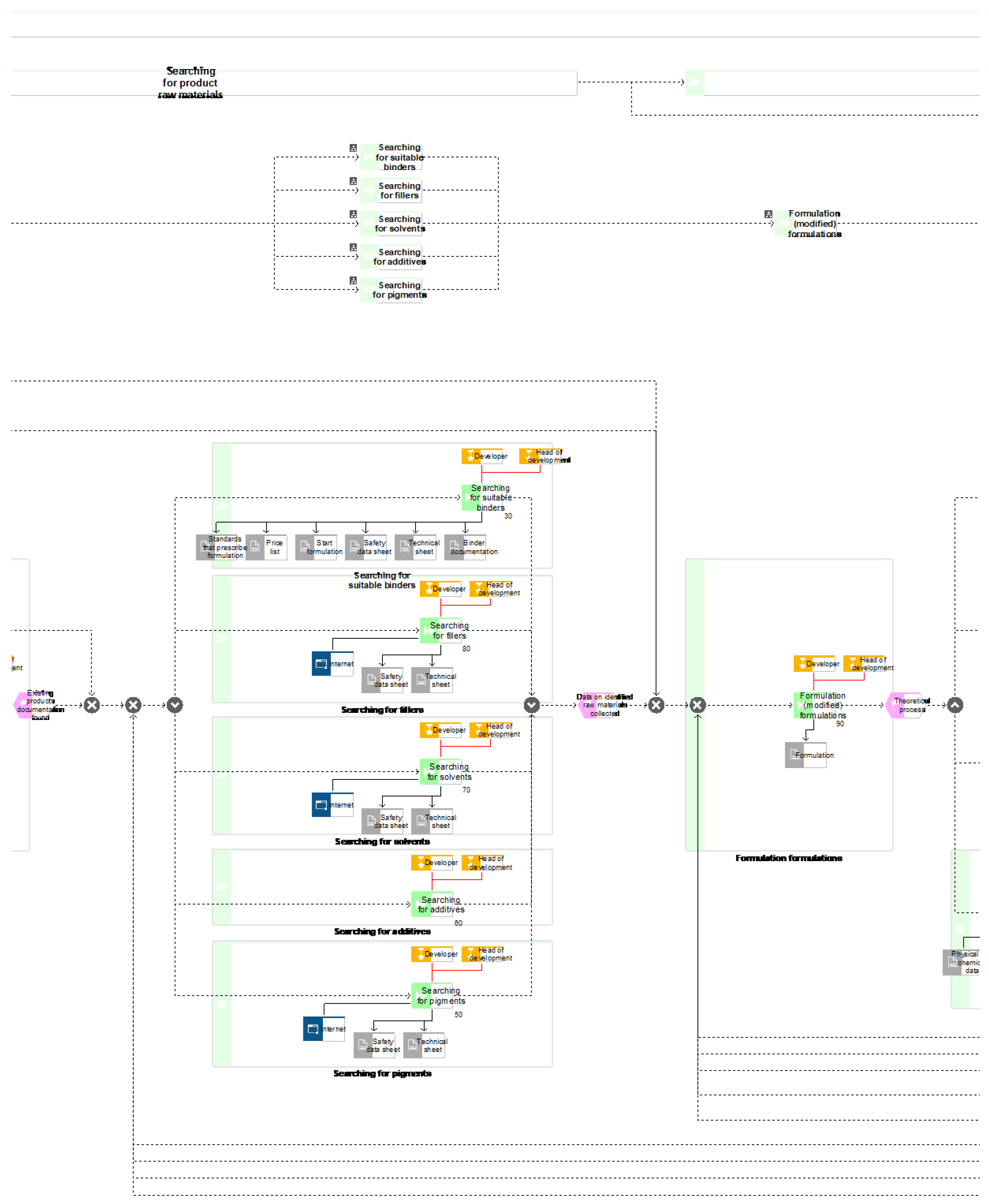

Figure A2.

Model overview of the existing new product development process without the support of ICT (part 2).

Figure A2.

Model overview of the existing new product development process without the support of ICT (part 2).

Figure A3.

Model overview of the existing new product development process without the support of ICT (part 3).

Figure A3.

Model overview of the existing new product development process without the support of ICT (part 3).

Figure A4.

Model overview of the existing new product development process without the support of ICT (part 4).

Figure A4.

Model overview of the existing new product development process without the support of ICT (part 4).

Figure A5.

Model overview of the existing new product development process without the support of ICT (part 5).

Figure A5.

Model overview of the existing new product development process without the support of ICT (part 5).

Figure A6.

Model overview of the existing new product development process without the support of ICT (part 6).

Figure A6.

Model overview of the existing new product development process without the support of ICT (part 6).

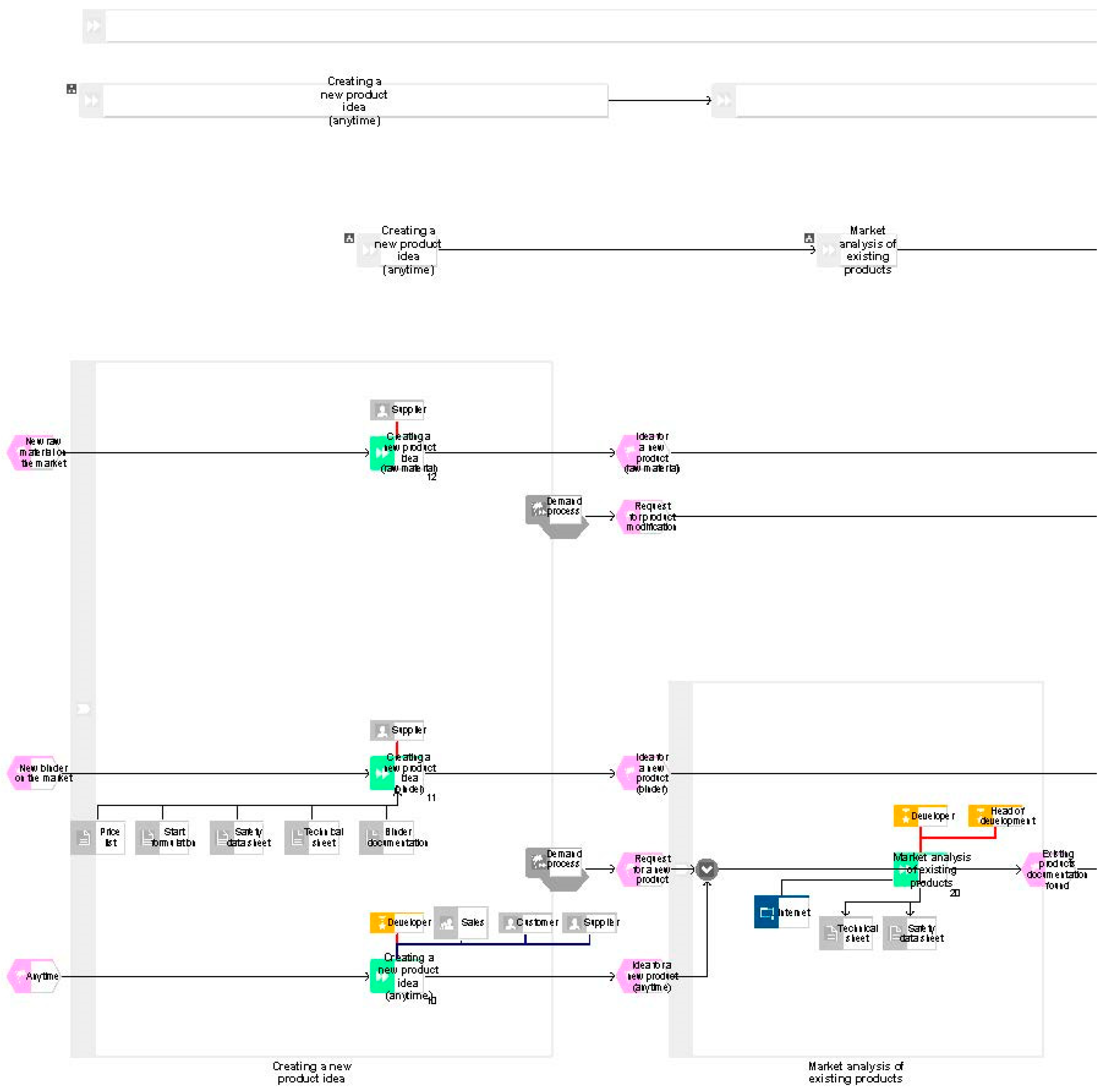

Appendix B

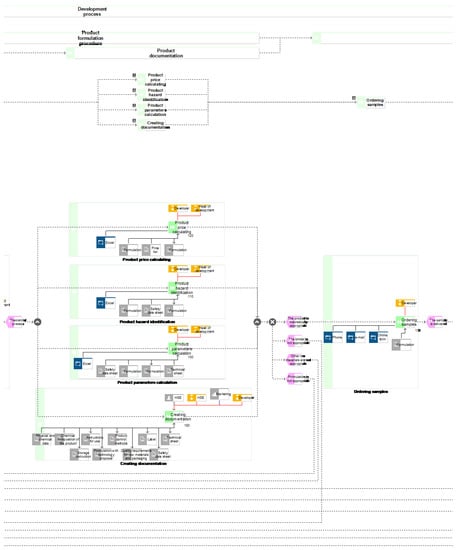

Figure A7.

The model overview of the modified (renewed) new product development process with ICT support and the use of a cloud-based database (part 1).

Figure A7.

The model overview of the modified (renewed) new product development process with ICT support and the use of a cloud-based database (part 1).

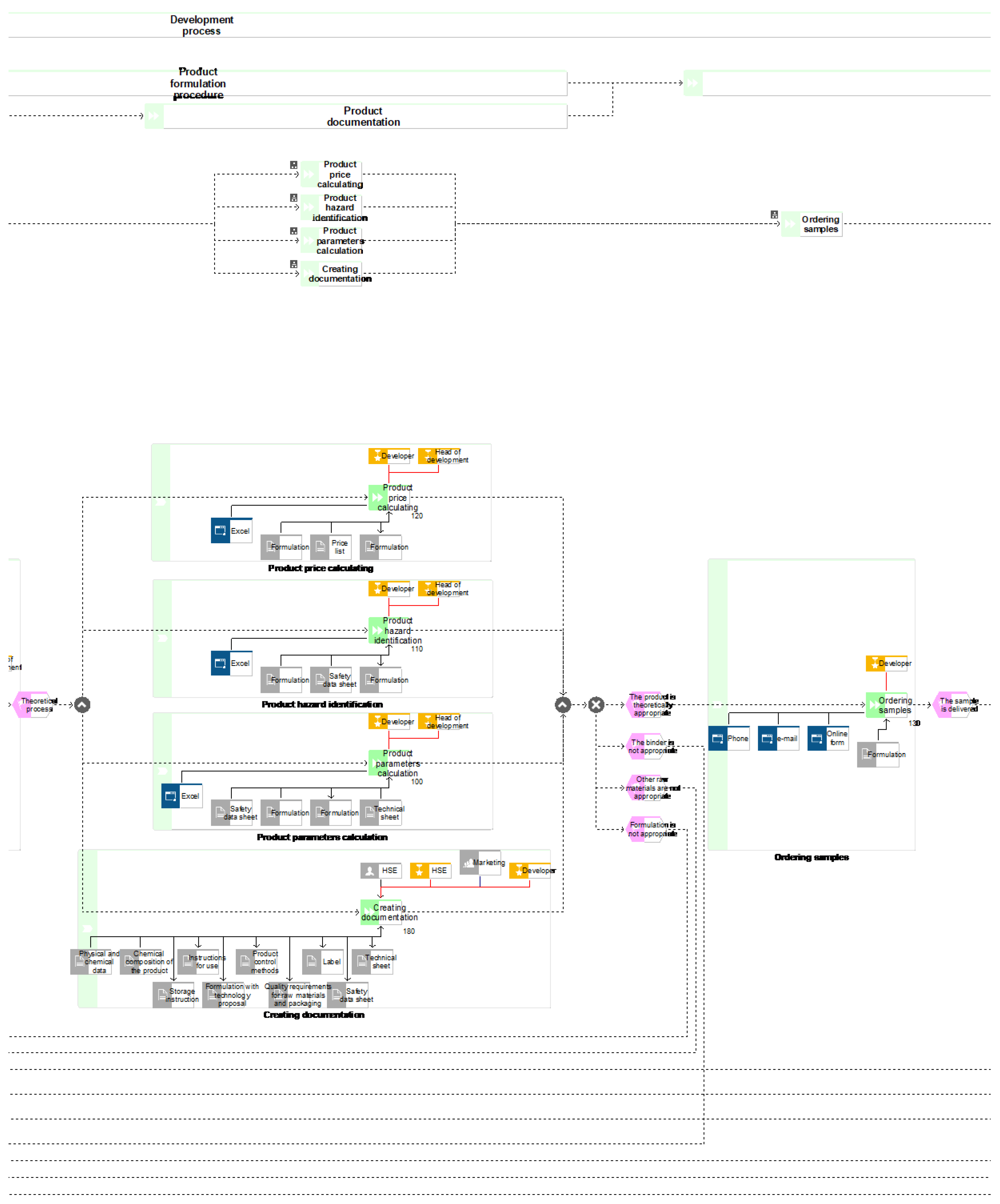

Figure A8.

The model overview of the modified (renewed) new product development process with ICT support and the use of a cloud-based database (part 2).

Figure A8.

The model overview of the modified (renewed) new product development process with ICT support and the use of a cloud-based database (part 2).

Figure A9.

The model overview of the modified (renewed) new product development process with ICT support and the use of a cloud-based database (part 3).

Figure A9.

The model overview of the modified (renewed) new product development process with ICT support and the use of a cloud-based database (part 3).

Figure A10.

The model overview of the modified (renewed) new product development process with ICT support and the use of a cloud-based database (part 4).

Figure A10.

The model overview of the modified (renewed) new product development process with ICT support and the use of a cloud-based database (part 4).

References

- Nurioglu, A.G.; Esteves, A.C.C. Non-toxic, non-biocide-release antifouling coatings based on molecular structure design for marine applications. J. Mater. Chem. B 2015, 3, 6547–6570. [Google Scholar] [CrossRef]

- Akafuah, N.K.; Poozesh, S.; Salaimeh, A.; Patrick, G.; Lawler, K.; Saito, K. Evolution of the automotive body coating process—A review. Coatings 2016, 6, 24. [Google Scholar] [CrossRef]

- Staring, E.; Dias, A.A.; Van Benthem, R.A. New challenges for R&D in coating resins. Prog. Org. Coat. 2002, 45, 101–117. [Google Scholar] [CrossRef]

- Cole, I.S.; Hughes, A.E. Designing molecular protection: New paradigm for developing corrosion resistant materials uniting hightroughput studies, multiscale modelling and self-repair. Corros. Eng. Sci. Technol. 2014, 49, 109–115. [Google Scholar] [CrossRef]

- Bohorquez, S.J.; van den Berg, P.; Akkerman, J.; Mestach, D.; van Loon, S.; Repp, J. High-throughput paint optimisation by use of a pigment-dispersing polymer. Surf. Coat. Int. 2015, 98, 85–89. [Google Scholar]

- Björklund, S.; Goel, S.; Joshi, S. Function-dependent coating architectures by hybrid powder suspension plasma spaying: Injectordesign, processing and concept validation. Mater. Des. 2018, 142, 56–65. [Google Scholar] [CrossRef]

- Coatingstech, Coatings Xperience: Accelerating Coatings Development with High Troughput Technology. Available online: https://www.paint.org/article/accelerating-coatings-development-high-throughput-technology/ (accessed on 29 October 2018).

- Langille, M.; Izmitli, A.; Lan, T.; Agrawall, A.; Liu, C.; Henderson, K.; Lu, Y.J. Balancing performance of slip/mar additives using a high throughput approach. Coatingstech 2018, 14, 52–56. [Google Scholar]

- Nameer, S.; Johansson, M. Fully bio-based aliphatic thermoset polyesters via self-catalyzed self-condensation of multifunctional epoxy monomers directly extracted from natural sources. J. Coat. Technol. Res. 2017, 14, 757–765. [Google Scholar] [CrossRef]

- Taylor, S.R.; Contu, F.; Calle, L.M.; Curran, J.P.; Li, W. Predicting the long-term field performance of coating systems on steel using a rapid electrochemical test: The damage tolerance test. Corros. J. Sci. Eng. 2012, 68. [Google Scholar] [CrossRef]

- Wu, L.; Baghdachi, J. Functional Polymer Coatings: Principles, Methods, and Applications, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Qureshi, S.A.; Shafeeq, A.; Ijaz, A.; Butt, M.M. Development and regression modeling dirt resistive latex façade paint. Coatings 2019, 9, 150. [Google Scholar] [CrossRef]

- Javierre, E. Modeling self-healing mechanisms in coatings: Approaches and perspectives. Coatings 2019, 9, 122. [Google Scholar] [CrossRef]

- Dennis, R.V.; Patil, V.; Andrews, J.L.; Aldinger, J.P.; Yaday, G.D.; Banarjee, S. Hybrid nanostructured coatings for corrosion protection of base materials: A sustainability perspective. Mater. Res. Express 2015, 2. [Google Scholar] [CrossRef]

- Prat, D.; Wells, A.; Hayler, J.; Sneddon, H.; McElroy, R.; Abou-Shehada, S.; Dunn, P.J. CHEM21 selection guide of classical- and less-classical-solvents. Green Chem. 2016, 18. [Google Scholar] [CrossRef]

- DKE Deutsche Kommission Elektrotechnik Elektronik Informationstechnik in DIN und VDE, German Standardization Roadmap, Industrie 4.0. Available online: https://www.din.de/blob/65354/57218767bd6da1927b181b9f2a0d5b39/roadmap-i4-0-e-data.pdf (accessed on 30 November 2018).

- Gartner, the 2019 CIO Agenda: Securing a New Foundation for Digital Business. Available online: https://www.gartner.com/doc/3891665/cio-agenda-securing-new-foundation (accessed on 30 November 2018).

- Challener, C. The paint and coatings industry in the age of digitalization. Jct Coat. 2018, 15, 54–60. [Google Scholar]

- Aguilar-Savén, R.S. Business process modelling: Review and framework. Int. J. Prod. Econ. 2004, 90, 129–149. [Google Scholar] [CrossRef]

- Weske, M. Business Process Management: Concepts, Languages, Architectures, 1st ed.; Springer: Berlin, Germany, 2007. [Google Scholar]

- Cheng, C. Complexity and Usability Models for Business Process Analysis. Doctoral Dissertation, The Graduate School College of Engineering, Pennsylvania State University, PA, USA, 21 August 2008. [Google Scholar]

- Urh, B.; Kern, T.; Roblek, M. Business Process Modification Management, In Encyclopedia of Networked and Virtual Organizations, 1st ed.; Putnik, G., Cunha, M.M., Eds.; Information Science Reference: Hershey, CA, USA; New York, NY, USA, 2008; pp. 112–120. [Google Scholar]

- Davis, R. ARIS Design Platform: Advanced Process Modelling and Administration, 1st ed.; Springer: Berlin, Germany, 2008. [Google Scholar]

- Ljubič, T. Operational Management of Production, 1st ed.; Modern organization: Kranj, Slovenia, 2006. [Google Scholar]

- Cottrell, W.D. Simplified Program Evaluation and Review Technique (PERT). J. Constr. Eng. Manag. 1999, 125, 16–22. [Google Scholar] [CrossRef]

- Scheer, A.W. ARIS—Business Process Framework, 2nd ed.; Springer: Berlin, Germany, 1998. [Google Scholar]

- Pavlović, I.; Kern, T.; Miklavčič, D. Comparison of paper-based and electronic data collection process in clinical trials: Costs simulation study. Contemp. Clin. Trials 2009, 30, 300–316. [Google Scholar] [CrossRef]

- Sánchez González, L.; García Rubio, F.; Ruiz González, F.; Piattini Velthuis, M. Measurement in business processes: A systematic review. Bus. Process Manag. J. 2010, 16, 114–134. [Google Scholar] [CrossRef]

- Frederiksen, H.; Mathiassen, L. A Contextual Approach to Improving Software Metrics Practices. IEEE Trans. Eng. Manag. 2008, 55, 602–616. [Google Scholar] [CrossRef]

- Sharma, A. Implementing Balance Scorecard for Performance Measurement. ICFAI J. Bus. Strategy 2009, 6, 7–16. [Google Scholar]

- Valiris, G.; Glykas, M. Business analysis metrics for business process redesign. Bus. Process Manag. J. 2004, 10, 445–480. [Google Scholar] [CrossRef]

- van der Aalst, W.M.P. Business process management: A comprehensive survey. ISRN Softw. Eng. 2013, 2013. [Google Scholar] [CrossRef]

- Rolón, E.; Ruiz, F.; Garcia, F.; Piatiini, M. Applying Software Metrics to evaluate Business Process Models. CLEI Electron. J. 2006, 9, 1–15. [Google Scholar] [CrossRef]

- Mendling, J.; Moser, M.; Neumann, G.; Verbeek, H.M.W.; Van Dongen, B.F.; van der Aalst, W.M.P. A Quantitative Analysis of Faulty EPCs in the SAP Reference Model. BPM Rep. 2006, 0608, 1–49. [Google Scholar]

- Cardoso, J.; Mendling, J.; Neumann, G.; Reijers, H.A. A discourse on complexity of process models. In Business Process Management Workshop, 1st ed.; Eder, J., Dustdar, S., Eds.; Springer: Berlin, Germany, 2006; pp. 117–128. [Google Scholar]

- Cardoso, J. Business Process Control-Flow Complexity: Metric, Evaluation and Validation. Int. J. Web Serv. Res. 2008, 5, 49–76. [Google Scholar] [CrossRef]

- Determine Your Process Costs and Times (Klein, E.). Available online: https://www.ariscommunity.com/users/eva-klein/2011-01-17-determine-your-process-costs-and-times (accessed on 4 December 2018).

- Banks, J.; Carson, J.S.; Nelson, B.L.; Nicol, D.M. Discrete-Event System Simulation, 5th ed.; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Greasley, A. The case for the organisational use of simulation. J. Manuf. Technol. Manag. 2004, 15, 560–566. [Google Scholar] [CrossRef]

- Lanner Group Ltd, What Is Predictive Simulation? Available online: https://www.lanner.com/en-gb/pages/what-is-predictive-simulation.html (accessed on 25 October 2018).

- Allchemist. Available online: https://allchemist2018.av-studio.agency/ (accessed on 16 January 2019).

- ECHA, European Chemicals Agency. Available online: https://echa.europa.eu/regulations/reach/legislation (accessed on 25 January 2019).

- Eurostat, Industry by Employment Size Class—Economical Indicator for Structural Business Statistics—Enterprises Number. Available online: https://ec.europa.eu/eurostat/data/database (accessed on 25 January 2019).

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).