Special Issue: Modeling and Simulation of Energy Systems

Abstract

:1. Introduction

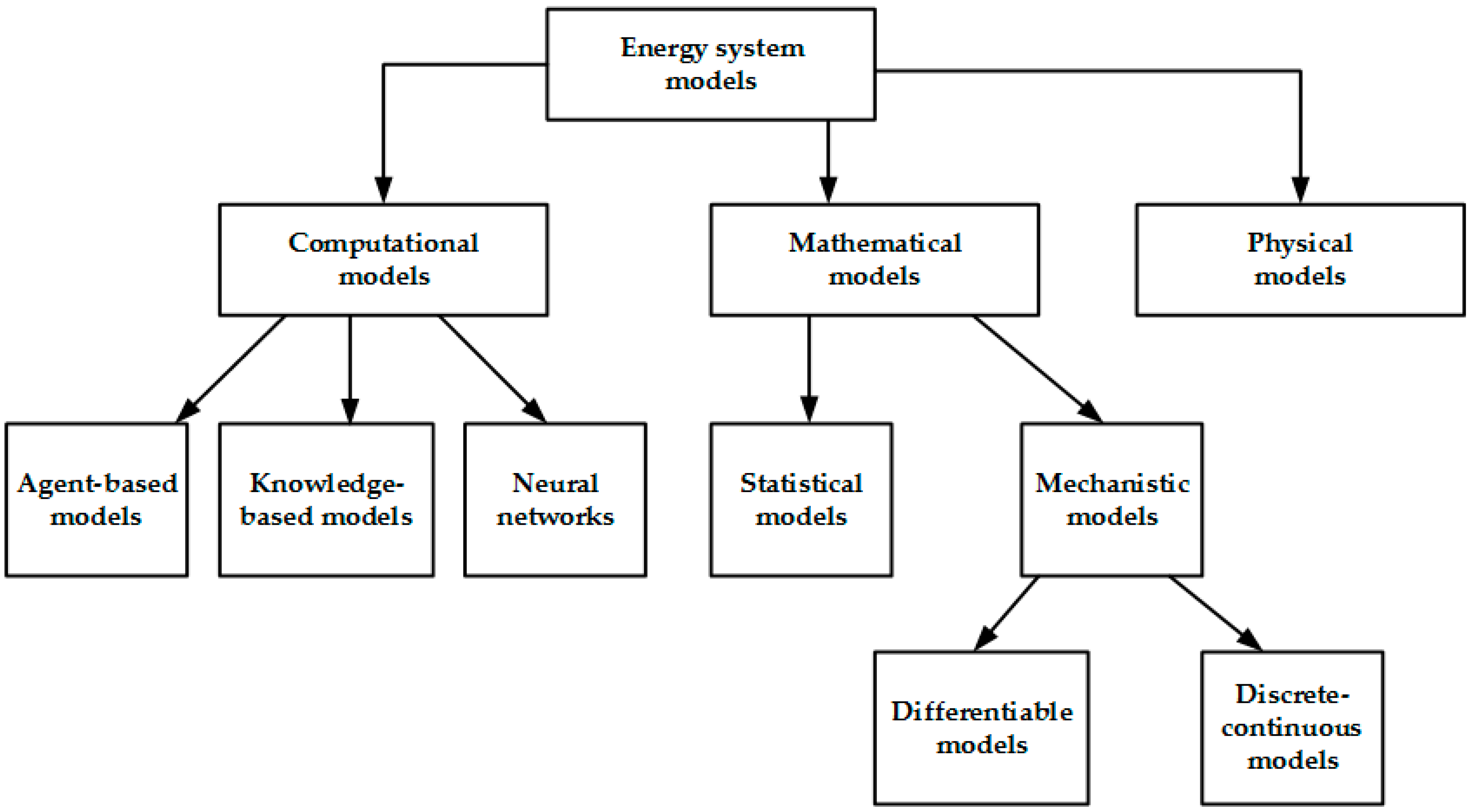

2. Modeling Types

3. Implementation and Solution Frameworks

4. Issue Summary

Funding

Conflicts of Interest

References

- Subramanian, A.S.R.; Gundersen, T.; Adams, T.A., II. Modeling and simulation of energy systems: A review. Processes 2018, 6, 238. [Google Scholar] [CrossRef]

- Riboldi, L.; Nord, L.O. Offshore power plants integrating a wind farm: Design optimization and techno-economic assessment based on surrogate modeling. Processes 2018, 6, 249. [Google Scholar] [CrossRef]

- Zimmerman, N.; Kyprianidis, L.; Lindberg, C.-F. Waste fuel combustion: Dynamic modeling and control. Processes 2018, 6, 222. [Google Scholar] [CrossRef]

- Surindra, M.D.; Caesarendra, W.; Prasetyo, T.; Mahlia, T.M.I. Comparison of the utilization of 110 °C and 120 °C heat sources in a geothermal energy system using organic Rankine cycle (ORC) with R235fa, R123, and mixed-ratio fluids as working fluids. Processes 2019, 7, 113. [Google Scholar] [CrossRef]

- Mussati, S.F.; Mansouri, S.S.; Gernaey, K.V.; Morosuk, T.; Mussati, M.C. Model-based cost optimization of double-effect water-lithium bromide absorption refrigeration systems. Processes 2019, 7, 50. [Google Scholar] [CrossRef]

- Yadav, G.; Fabiano, L.A.; Soh, L.; Zimmerman, J.; Sen, R.; Seider, W.D. Supercritical CO2 transesterification of triolein to methyl-oleate in a batch reactor: Experimental and simulation results. Processes 2019, 7, 16. [Google Scholar] [CrossRef]

- Vikse, M.; Watson, H.A.J.; Gundersen, T.; Barton, P.I. Simulation of dual mixed refrigerant natural gas liquefaction processes using a nonsmooth framework. Processes 2018, 6, 193. [Google Scholar] [CrossRef]

- Ridha, T.; Li, Y.; Gençer, E.; Siirola, J.J.; Miller, J.T.; Ribeiro, F.H.; Agrawal, R. Valorization of shale gas condensate to liquid hydrocabons through catalytic dehydrogenation and oligomerization. Processes 2018, 6, 139. [Google Scholar] [CrossRef]

- Stuber, M.D. A differentiable model for optimizing hybridization of industrial process heat systems with concentrating solar thermal power. Processes 2018, 6, 76. [Google Scholar] [CrossRef]

- Al-Aboosi, F.Y.; El-Halwagi, M.M. An integrated approach to water-energy nexus in shale-gas production. Processes 2018, 6, 52. [Google Scholar] [CrossRef]

- Li, J.; Demirel, S.E.; Hasan, M.M.F. Building block-based synthesis and intensification of work-heat exchanger networks (WHENS). Processes 2019, 7, 23. [Google Scholar] [CrossRef]

- Sarda, P.; Hedrick, E.; Reynolds, K.; Bhattacharyya, D.; Zitney, S.E.; Omell, B. Development of a dynamic model and control system for load-following studies of supercritical pulverized coal power plants. Processes 2018, 6, 226. [Google Scholar] [CrossRef]

- Rahman, M.; Zaccaria, V.; Zhao, X.; Kyprianidis, K. Diagnostics-oriented modelling of micro gas turbines for fleet monitoring and maintenance operation. Processes 2018, 6, 216. [Google Scholar] [CrossRef]

- Pravin, P.S.; Gudi, R.D.; Bhartiya, S. Dynamic modeling and control of an integrated reformer-membrane-fuel cell system. Processes 2018, 6, 169. [Google Scholar]

- Decardi-Nelson, B.; Liu, S.; Liu, J. Improving flexibility and energy efficiency of post-combustion CO2 capture plants using economic model predictive control. Processes 2018, 6, 135. [Google Scholar] [CrossRef]

- Chen, C.; Bollas, G.M. Dynamic optimization of a subcritical steam power plant under time-varying power load. Processes 2018, 6, 114. [Google Scholar] [CrossRef]

- Corengia, M.; Torres, A.I. Effect of tariff policy and battery degradation on optimal energy storage. Processes 2018, 6, 204. [Google Scholar] [CrossRef]

- Kazda, K.; Li, X. Approximating nonlinear relationships for optimal operation of natural gas transport networks. Processes 2018, 6, 198. [Google Scholar] [CrossRef]

- Du, J.; Cluett, W.R. Modelling of a naphtha recovery unit (NRU) with implications for process optimization. Processes 2018, 6, 74. [Google Scholar] [CrossRef]

- Miller, I.; Gençer, E.; O’Sullivan, F.M. A general model for estimating emissions from integrated power generation and energy storage. Case study: Integration of solar photovoltaic power and wind power with batteries. Processes 2018, 6, 267. [Google Scholar] [CrossRef]

- Siddiqui, M.E.; Taimoor, A.A.; Almitani, K.H. Energy and exergy analysis of the S-CO2 Brayton cycle coupled with bottoming cycles. Processes 2018, 6, 153. [Google Scholar] [CrossRef]

| Authors/Ref | Application | Models and Software | Comments |

|---|---|---|---|

| Reviews | |||

| Subramanian, Gundersen, and Adams [1] | Field-wide survey of models in energy systems. | Modelling taxonomy proposed | Proposed connecting the PSE-style bottom-up approach with top-down approach used in energy economics. |

| Energy System Design | |||

| Riboldi and Nord [2] | Offshore power plants, integrated with renewables. | 1st Principles + Kriging. Thermoflex, Plant Engineering, and Construction Estimator, MATLAB. | Dynamic considerations with regard to wind and electricity demand. Surrogate models used for optimization purposes. |

| Surindra, Caesarendra, Prasetyo, Mahlia, and Taufik [4] | Organic Rankine cycles in geothermal energy systems. | 1st Principles of thermodynamic cycles. | Blends physical models (experimental apparatus) with mathematical ones. |

| Mussati, Mansouri, Gernaey, Morosuk, and Mussati [5] | Adsorption refrigeration cycles. | 1st Principles. GAMS. | Optimal design with a superstructure approach. |

| Yadav, Fabiano, Soh, Zimmerman, Sen, and Seider [6] | Transesterification of triolein to methyl-oleate (biofuels). | 1st Principles. Aspen Plus with custom models. | Experimental validation of models in some conditions. Models used to predict performance in other conditions. |

| Vikse, Watson, Gundersen, and Barton [7] | Multi-stream heat exchanger (MHEX) design for natural gas liquefaction. | 1st Principles. Julia. Aspen Plus for comparison. | Presents nonsmooth framework and algorithm for designing optimal MHEXs when standard methods fail. |

| Ridha, Li, Gençer, Siirola, Miller, Ribeiro, and Agrawal [8] | Shale gas condensate to oligomers and alkanes at the wellhead. | 1st Principles. Aspen Plus, Aspen Economic Analyzer. | Techno-economic analysis. Premise: Cheaper to transport oligomers than Natural Gas Liquids. |

| Stuber [9] | Concentrated solar power with thermal energy storage. | 1st Principles with empirical elements. JuliaPro/JuMP. | Equation oriented, differentiable model for determination of optimal design params. |

| Al-Aboosi and El-Halwagi [10] | Integrated water and energy between systems. | Mostly empirical models. LINGO. | Optimal design of integrated multi-product, multi-source systems considering time-varying solar. |

| Li, Demirel, and Hasan [11] | Automatically generate work-heat exchanger networks (WHEN). | 1st Principles. GAMS. Phenomena level models. | Algorithm to create optimal WHENs from sources and sinks using building block superstructures. |

| Control Systems | |||

| Sarda, Hedrick, Reynolds, Bhattacharyya, Zitney, and Omell [12] | Load-following Supercritical pulverized coal (SCPC). | 1st Principles with reduced models. Aspen Plus Dynamics, Aspen Custom Modeler, Aspen Exchanger, and Design Rating. | Plant-wide dynamic model for designing and simulating plant-wide control system. |

| Zimmerman, Kyprianidis, and Lindberg [3] | Combustion of fuel derived from waste (refuse). | 1st Principles. Modellica. | MPC with feedforward system developed. Soft sensors. Experimental validation. |

| Rahman, Zaccaria, Zhao, and Kyprianidis [13] | Micro gas turbine systems. | 1st Principles with data-driven model tuning. EVA (in-house). | Dynamic models. Fault detection and diagnostics. |

| Pravin, Guidi, and Bhartiya [14] | Integrated reformer-membrane fuel cell systems. | 1st Principles ODEs with some empirical characteristics. MATLAB. | Controllability analysis. Certain design considerations must be made for controllability purposes. |

| Decardi-Nelson, Liu, and Liu [15] | Flexible post-combustion CO2 capture systems. | 1st Principles. casADI, Python, Aspen Properties. | Economic MPC for disturbances. Look-up table made from Aspen Properties for fast use. |

| Flexible Operations and Operational Strategies | |||

| Chen and Bollas [16] | Flexible, load-following subcritical coal power plant. | 1st Principles. Dymola. Modelon Thermal-Power Library, MATLAB. | Dynamic optimization of transitions during load changes. |

| Corengia and Torres [17] | Optimal operating schedule of grid-scale battery energy storage. | 1st Principles. GAMS. | Considers degradation of the batteries, demand cycles, and local tariff policies. |

| Kazda and Li [18] | Optimal operations of natural gas transport networks. | 1st Principles. GAMS. | Created piecewise linear models to capture nonlinearities with optimization problem tractability. |

| Du and Cluett [19] | Operational improvements to existing Naphtha recovery units. | 1st Principles and statistical models (Principle Component Analysis). Aspen Plus, Minitab. | Aspen Models released. Statistical models suggest unintuitive options, explained by Aspen model. |

| Systems Analysis | |||

| Miller, Gençer, and O’Sullivan [20] | Life cycle analysis (LCA) of integrated solar PV, wind, and batteries. | Empirical/data driven models. SoLCAT (in-house). Ecoinvent. PVWatts. | LCA focused on emissions from use/manufacture of various power sources in several case studies. |

| Siddiqui, Taimoor, and Almitan. [21] | Supercritical CO2 Brayton cycles coupled with bottoming cycles. | 1st Principles. Aspen HYSYS. | Energy and exergy cycle analysis for working fluid screening. |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adams, T.A., II. Special Issue: Modeling and Simulation of Energy Systems. Processes 2019, 7, 523. https://doi.org/10.3390/pr7080523

Adams TA II. Special Issue: Modeling and Simulation of Energy Systems. Processes. 2019; 7(8):523. https://doi.org/10.3390/pr7080523

Chicago/Turabian StyleAdams, Thomas A., II. 2019. "Special Issue: Modeling and Simulation of Energy Systems" Processes 7, no. 8: 523. https://doi.org/10.3390/pr7080523

APA StyleAdams, T. A., II. (2019). Special Issue: Modeling and Simulation of Energy Systems. Processes, 7(8), 523. https://doi.org/10.3390/pr7080523