Flow Behavior and Hot Processing Map of GH4698 for Isothermal Compression Process

Abstract

:1. Introduction

2. Materials and Experiments

2.1. Materials

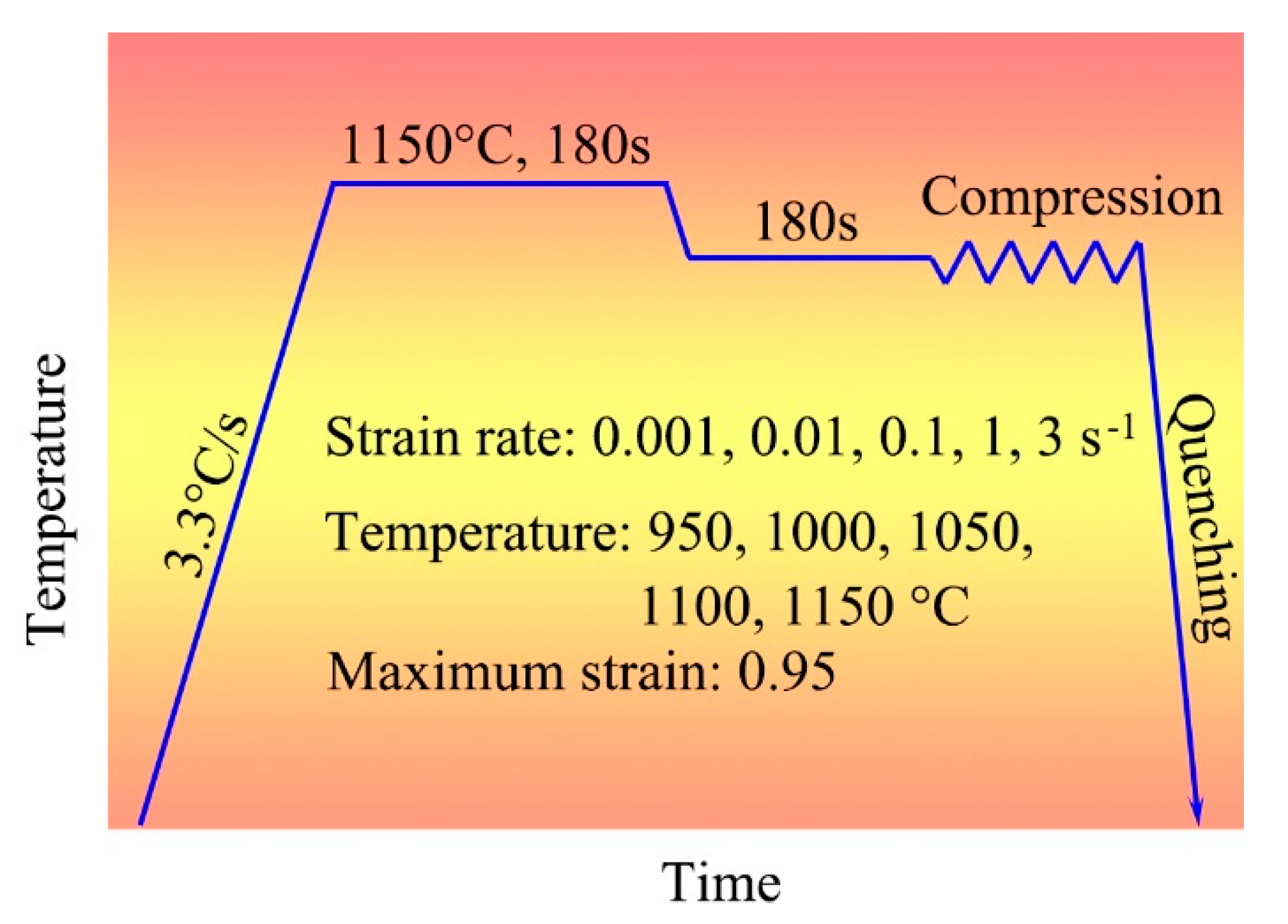

2.2. Experiments

3. Results and Discussion

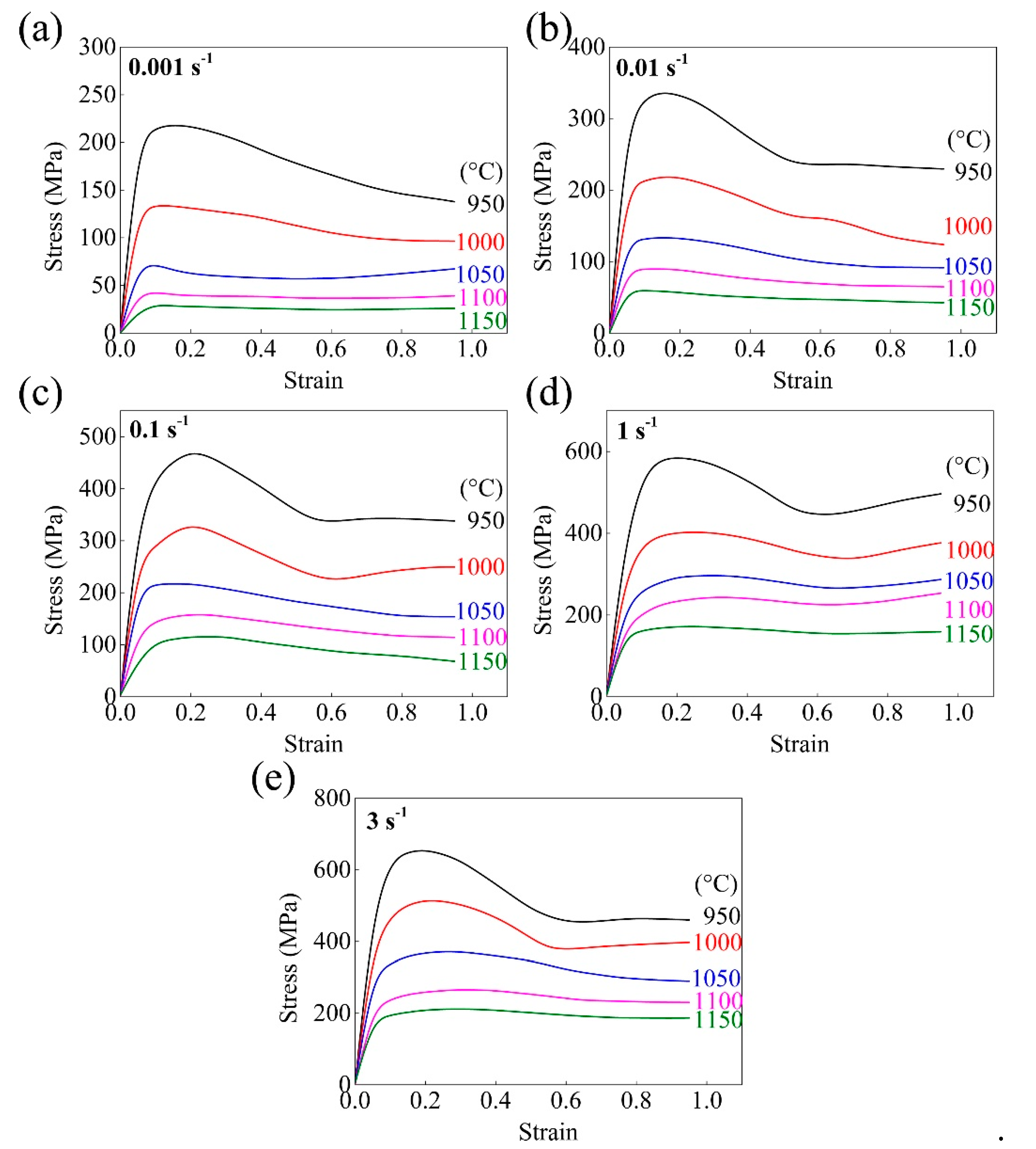

3.1. Flow Behaviors

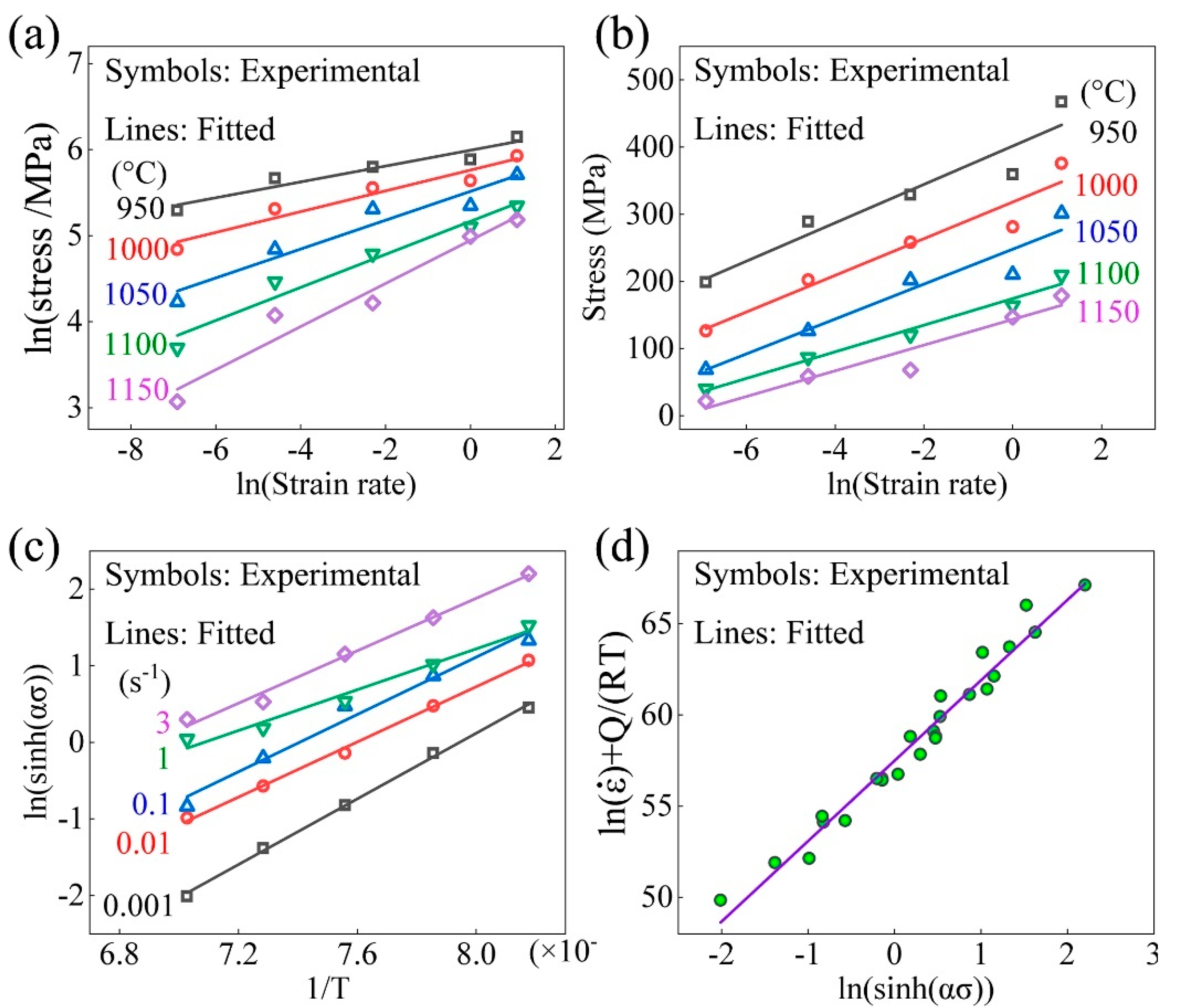

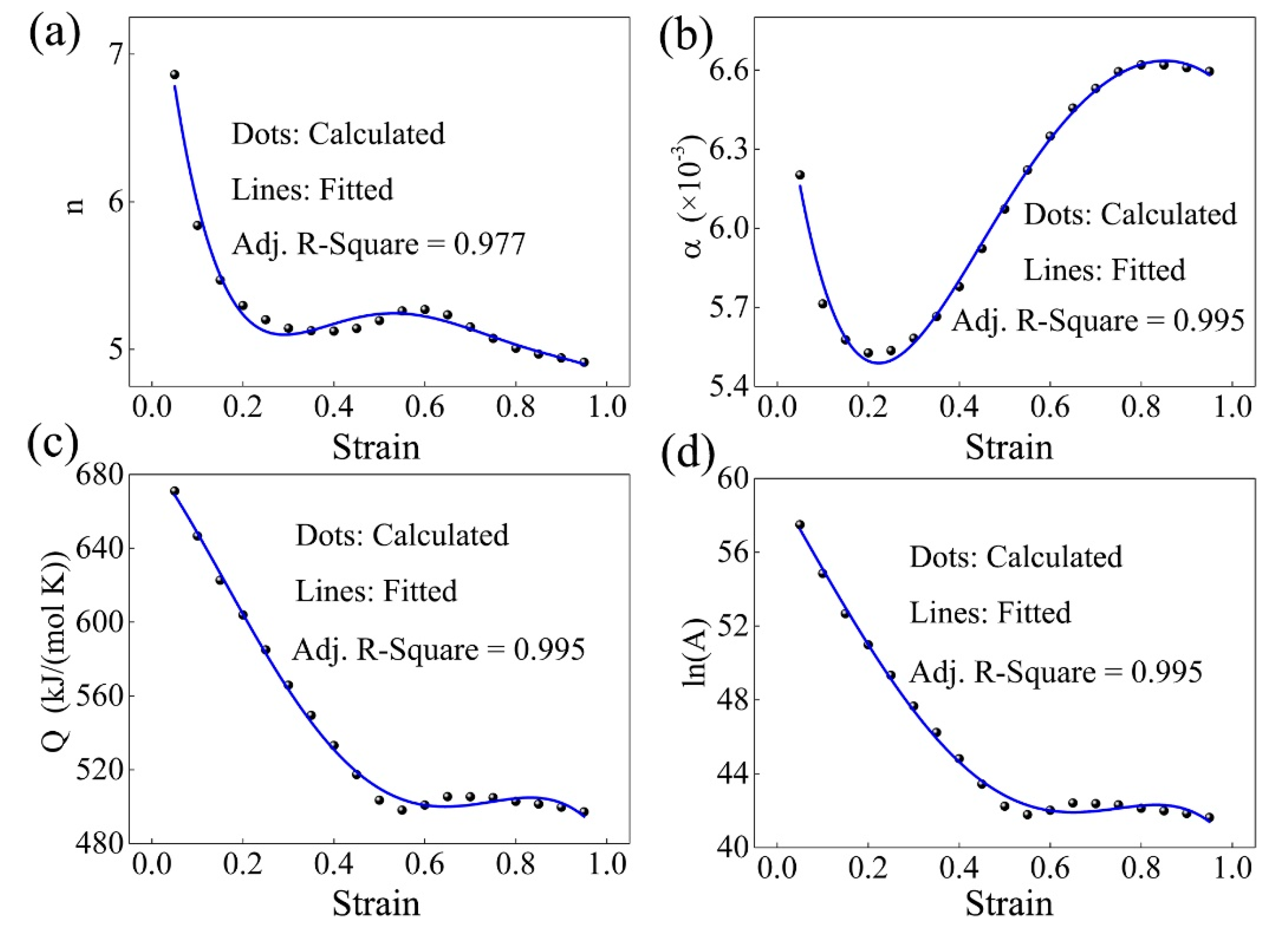

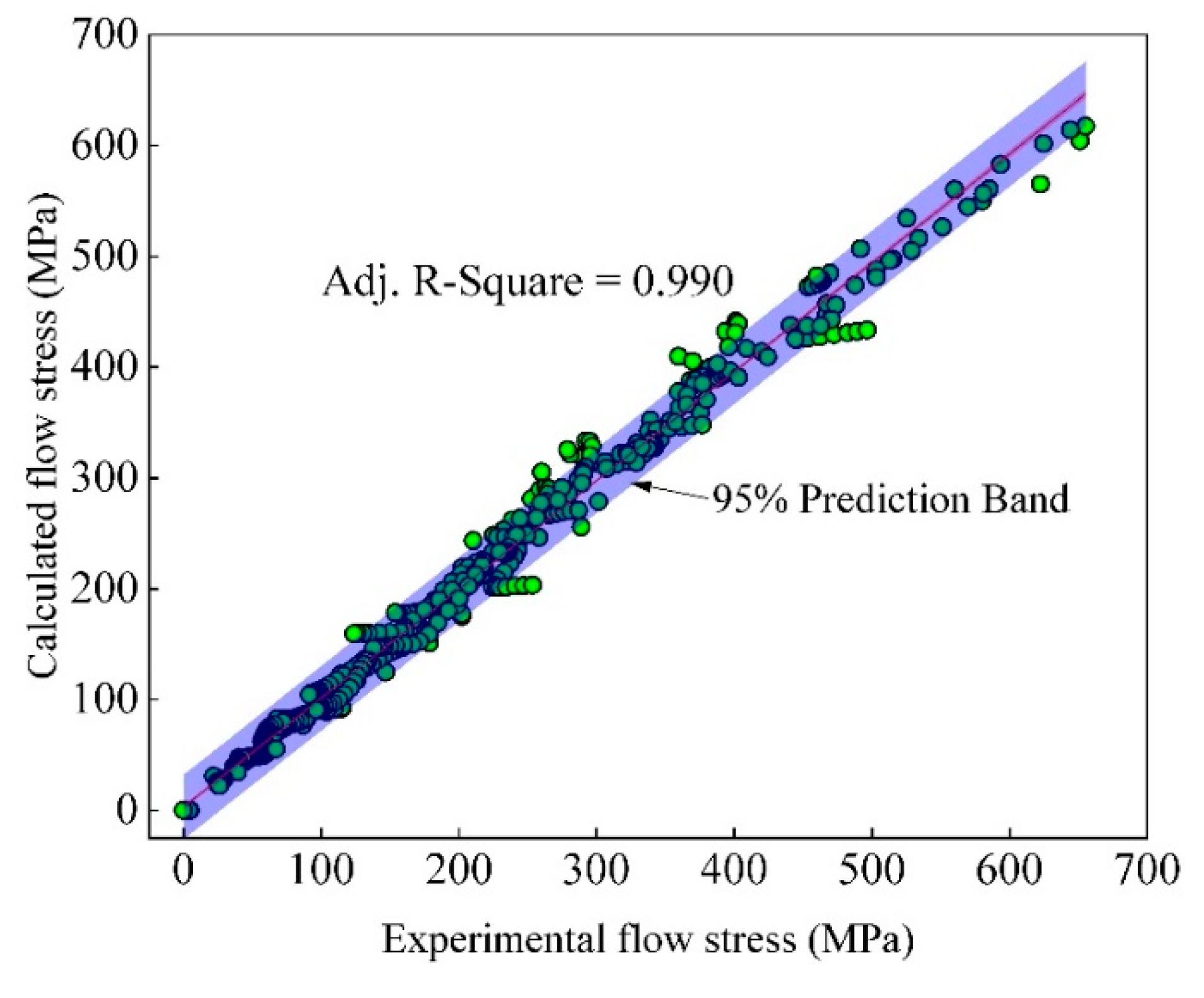

3.2. Flow Stress Modeling

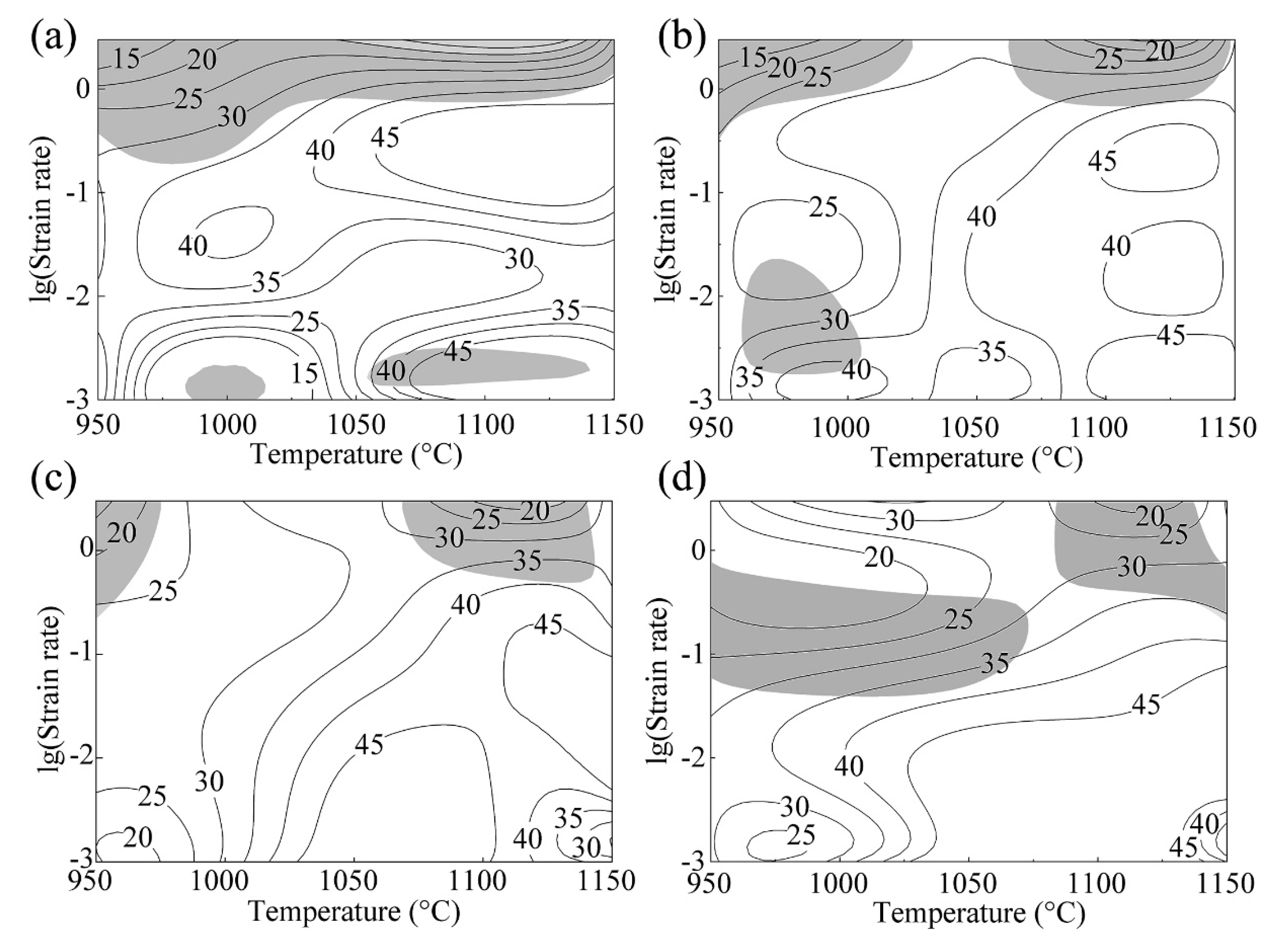

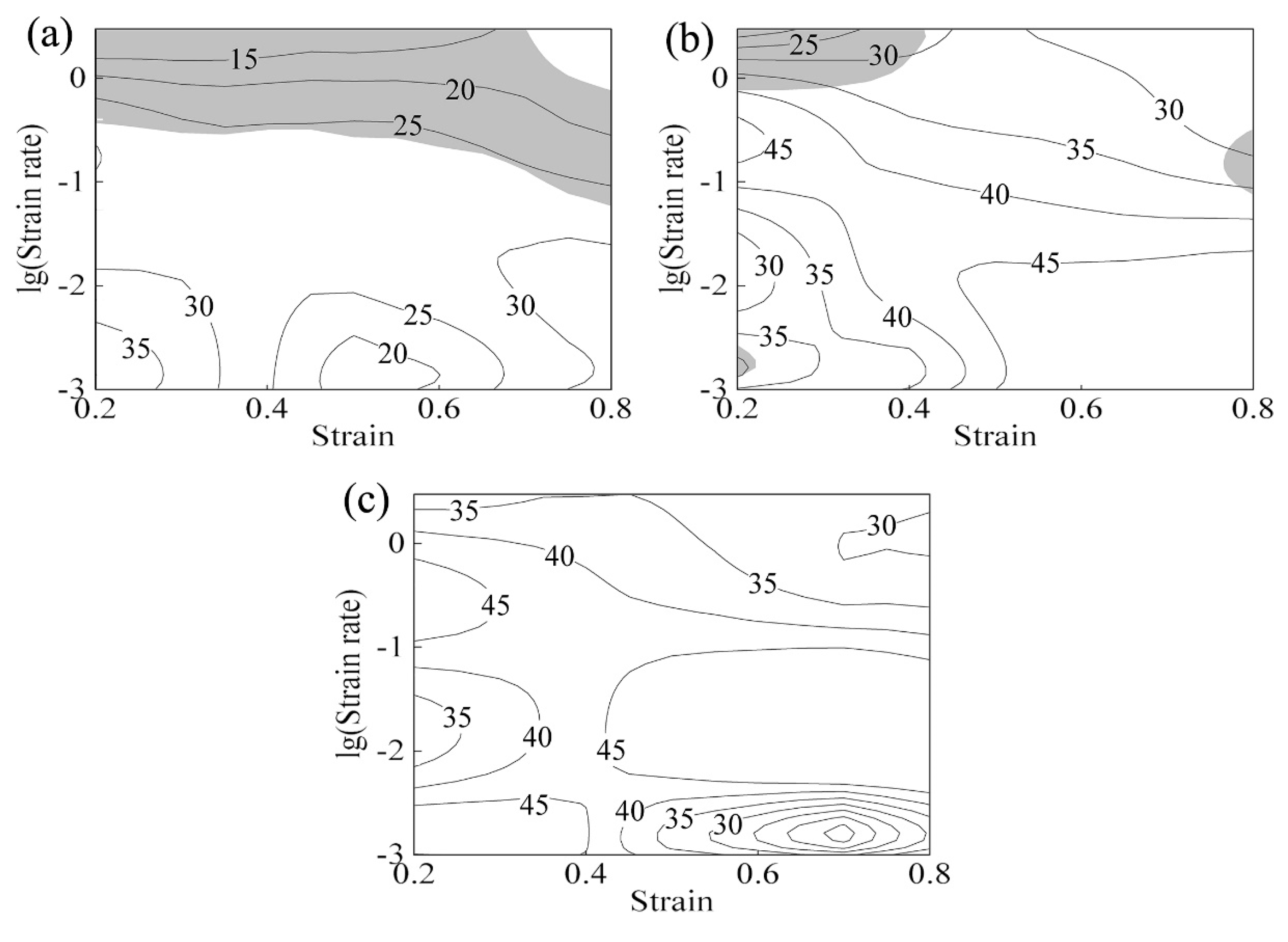

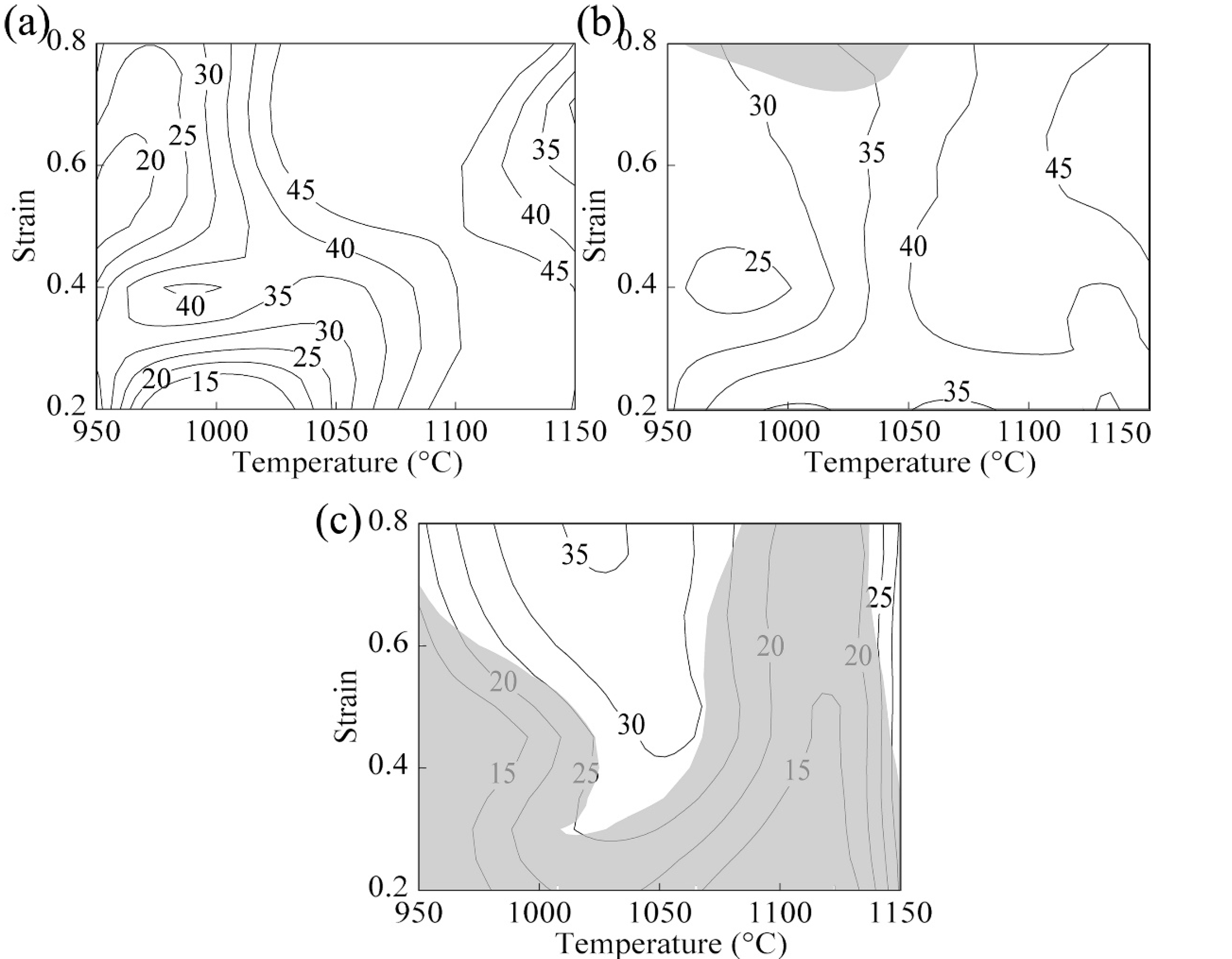

3.3. Processing Maps

4. Conclusions

- (1)

- The stress-strain curves of GH4698 were single-peaked at various compression conditions, owing to dislocation motions during dynamic recrystallizations. The peak flow stress agreed well with the results in the literature, but the stress-strain curve shapes were different, which may be attributed to differences in the as-received material states.

- (2)

- An Arrhenius model was established to calculate the stress evolutions under various strain rates, temperatures, and strains. The average calculation error was 10.96 MPa (5.90%), showing that the model could accurately describe the flow behaviors of GH4698 at high temperatures.

- (3)

- The processing maps of GH4698 revealed that the hot working ability of GH4698 markedly decreased under lower temperatures (950–1080 °C) and high strain rates (0.1–3 s−1). The optimal hot working parameters were suggested as 1080–1150 °C and 0.004–0.1 s−1. Moreover, according to this study, the GH4698 alloy was suitable for low-speed isothermal forgings at high temperatures (1080–1150 °C).

Author Contributions

Funding

Conflicts of Interest

References

- Huang, B.; Li, C.; Shi, L. Nonferrous Metal materials and engineering. In China Materials Engineering Canon; Chemical Industry Press: Beijing, China, 2005; Volume 4, pp. 378–391. [Google Scholar]

- Wang, J.; Guo, W.; Li, P. Modified Johnson-Cook description of wide temperature and strain rate measurements made on a nickel-base superalloy. Mater. High Temp. 2017, 34, 157–165. [Google Scholar] [CrossRef]

- Shamsolhodaei, A.; Zarei-Hanzaki, A.; Ghambari, M. The high temperature flow behavior modeling of NiTi shape memory alloy employing phenomenological and physical based constitutive models: A comparative study. Intermetallics 2014, 53, 140–149. [Google Scholar] [CrossRef]

- Chen, R.; Zheng, Z.; Li, J. Constitutive Modelling and Hot Workability Analysis by Microstructure Examination of GH4169 Alloy. Crystals 2018, 8, 282. [Google Scholar] [CrossRef]

- Wang, L.; Liu, F.; Cheng, J. Arrhenius-Type Constitutive Model for High Temperature Flow Stress in a Nickel-Based Corrosion-Resistant Alloy. J. Mater. Eng. Perform. 2016, 25, 1394–1406. [Google Scholar] [CrossRef]

- Gu, S.; Zhang, L.; Zhang, C. Constitutive Modeling for Flow Stress Behavior of Nimonic 80A Superalloy During Hot Deformation Process. High Temp. Mater. Process. 2016, 35, 327–336. [Google Scholar] [CrossRef]

- Linl, Y.C.; Nong, F.Q.; Chen, X.M. Microstructural evolution and constitutive models to predict hot deformation behaviors of a nickel-based superalloy. Vacuum 2017, 137, 104–114. [Google Scholar] [CrossRef]

- Wang, T.; Wan, Z.; Sun, Y. Dynamic Softening Behavior and Microstructure Evolution of Nickel Base Superalloy. Acta Metall. Sin. 2018, 54, 83–92. [Google Scholar] [CrossRef]

- Lin, Y.C.; Wen, D.X.; Li, X.H. Hot deformation characteristics and dislocation substructure evolution of a nickel-base alloy considering effects of δ phase. J. Alloys Compd. 2018, 764, 1008–1020. [Google Scholar] [CrossRef]

- Haan, J.; Bezold, A.; Broeckmann, C. Interaction between particle precipitation and creep behavior in the NI-base Alloy 617B: Microstructural observations and constitutive material model. Mater. Sci. Eng. A 2015, 640, 305–313. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, H.; Liu, J. Prediction of Flow Stresses for a Typical Nickel-Based Superalloy During Hot Deformation Based on Dynamic Recrystallization Kinetic Equation. Rare Met. Mater. Eng. 2018, 47, 3329–3337. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, M.; Xie, X. Hot deformation characteristics and processing map analysis of a new designed nickel-based alloy for 700 °C A-USC power plant. J. Alloys Compd. 2016, 656, 119–131. [Google Scholar] [CrossRef]

- Wang, L.; Liu, F.; Zuo, Q. Processing Map and Mechanism of Hot Deformation of a Corrosion-Resistant Nickel-Based Alloy. J. Mater. Eng. Perform. 2017, 26, 392–406. [Google Scholar] [CrossRef]

- Wang, L.; Liu, F.; Cheng, J. Hot deformation characteristics and processing map analysis for Nickel-based corrosion resistant alloy. J. Alloys Compd. 2015, 623, 69–78. [Google Scholar] [CrossRef]

- Jiang, H.; Dong, J.; Zhang, M. Hot deformation characteristics of Alloy 617B nickel-based superalloy: A study using processing map. J. Alloys Compd. 2015, 647, 338–350. [Google Scholar] [CrossRef]

- Kang, F.; Zhang, X.; Sun, J. Hot Deformation Behavior and Processing Map of a Nickel-Base Superalloy GH4169. Adv. Mater. Res. 2013, 834, 432–436. [Google Scholar] [CrossRef]

- Gegel, H.L. Synthesis of Atomistics and Continuum Modeling to Describe Microstructure: Computer Simulation in Material Science; ASM Park: Geauga, OH, USA, 1984; pp. 291–344. [Google Scholar]

- Malas, J.C.; Seetharaman, V. Using material behavior models to develop process control strategies. JOM 1992, 44, 8–13. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Seshachryuly, T. Modelling of hot deformation for microstructural control. Int. Mater. Rev. 1988, 43, 243–252. [Google Scholar] [CrossRef]

- Murty, S.V.S.N.; Rao, B.N. On the development of instability criteria during hot working with reference to IN 718. Mater. Sci. Eng. A 1998, 254, 76–82. [Google Scholar] [CrossRef]

- Zhou, G.; Ding, H.; Cao, F.R.; Han, Y.B.; Zhang, B.J. Flow instability criteria in processing map of superalloy GH79. Trans. Nonferrous Met. Soc. Chin. 2012, 22, 1575–1581. [Google Scholar] [CrossRef]

- Zhang, P.; Hu, C.; Zhu, Q. Hot compression deformation and constitutive modeling of GH4698 alloy. Mater. Des. 2015, 65, 1153–1160. [Google Scholar] [CrossRef]

- Chen, R.; Zheng, Z.; Li, N. In-situ investigation of phase transformation behaviors of 300M steel in continuous cooling process. Mater. Charact. 2018, 144, 400–410. [Google Scholar] [CrossRef]

- Chen, R.; Zheng, Z.; Li, J. In Situ Investigation of Grain Evolution of 300M Steel in Isothermal Holding Process. Materials 2018, 11, 1862. [Google Scholar] [CrossRef] [PubMed]

- Chen, R.; Guo, P.; Zheng, Z. Dislocation Based Flow Stress Model of 300M Steel in Isothermal Compression Process. Materials 2018, 11, 972. [Google Scholar] [CrossRef] [PubMed]

- Prasad, Y.V.R.K.; Gegel, H.L.; Doraivelu, S.M. Modeling of dynamic material behavior in hot deformation: Forging of Ti6242. Metall. Trans. A 1984, 15, 1883–1892. [Google Scholar] [CrossRef]

- Yin, F.; Hua, L.; Mao, H. Constitutive modeling for flow behavior of GCr15 steel under hot compression experiments. Mater. Des. 2013, 43, 393–401. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, L.; Li, J. Flow behaviors and constitutive model of 300M high strength steel at elevated temperature. J. Cent. South Univ. 2017, 48, 1439–1447. [Google Scholar] [CrossRef]

| Composition | C | Al | Fe | Cr | Nb | Zr | Mo | Ti | Ni |

|---|---|---|---|---|---|---|---|---|---|

| Mass Percentage (%) | 0.08 | 1.55 | 1.51 | 14.43 | 1.95 | 0.05 | 2.90 | 2.62 | Balance |

| Coefficients | k0 | k1 | k2 | k3 | k4 | k5 |

|---|---|---|---|---|---|---|

| n | 7.993 × 100 | −2.922 × 101 | 1.083 × 102 | −1.825 × 102 | 1.426 × 102 | −4.233 × 101 |

| α | 6.731 × 10−3 | −1.372 × 10−2 | 5.024 × 10−2 | −7.115 × 10−2 | 4.724 × 10−2 | −1.283 × 10−2 |

| Q | 6.870 × 105 | −3.307 × 105 | −7.459 × 105 | 1.830 × 106 | −7.715 × 105 | −1.887 × 105 |

| lnA | 5.492 × 101 | −4.353 × 101 | −1.359 × 100 | 3.554 × 101 | 4.416 × 101 | −5.413 × 101 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, R.; Xiao, H.; Wang, M.; Li, J. Flow Behavior and Hot Processing Map of GH4698 for Isothermal Compression Process. Processes 2019, 7, 491. https://doi.org/10.3390/pr7080491

Chen R, Xiao H, Wang M, Li J. Flow Behavior and Hot Processing Map of GH4698 for Isothermal Compression Process. Processes. 2019; 7(8):491. https://doi.org/10.3390/pr7080491

Chicago/Turabian StyleChen, Rongchuang, Haifeng Xiao, Min Wang, and Jianjun Li. 2019. "Flow Behavior and Hot Processing Map of GH4698 for Isothermal Compression Process" Processes 7, no. 8: 491. https://doi.org/10.3390/pr7080491

APA StyleChen, R., Xiao, H., Wang, M., & Li, J. (2019). Flow Behavior and Hot Processing Map of GH4698 for Isothermal Compression Process. Processes, 7(8), 491. https://doi.org/10.3390/pr7080491