A Method and Device for Detecting the Number of Magnetic Nanoparticles Based on Weak Magnetic Signal

Abstract

1. Introduction

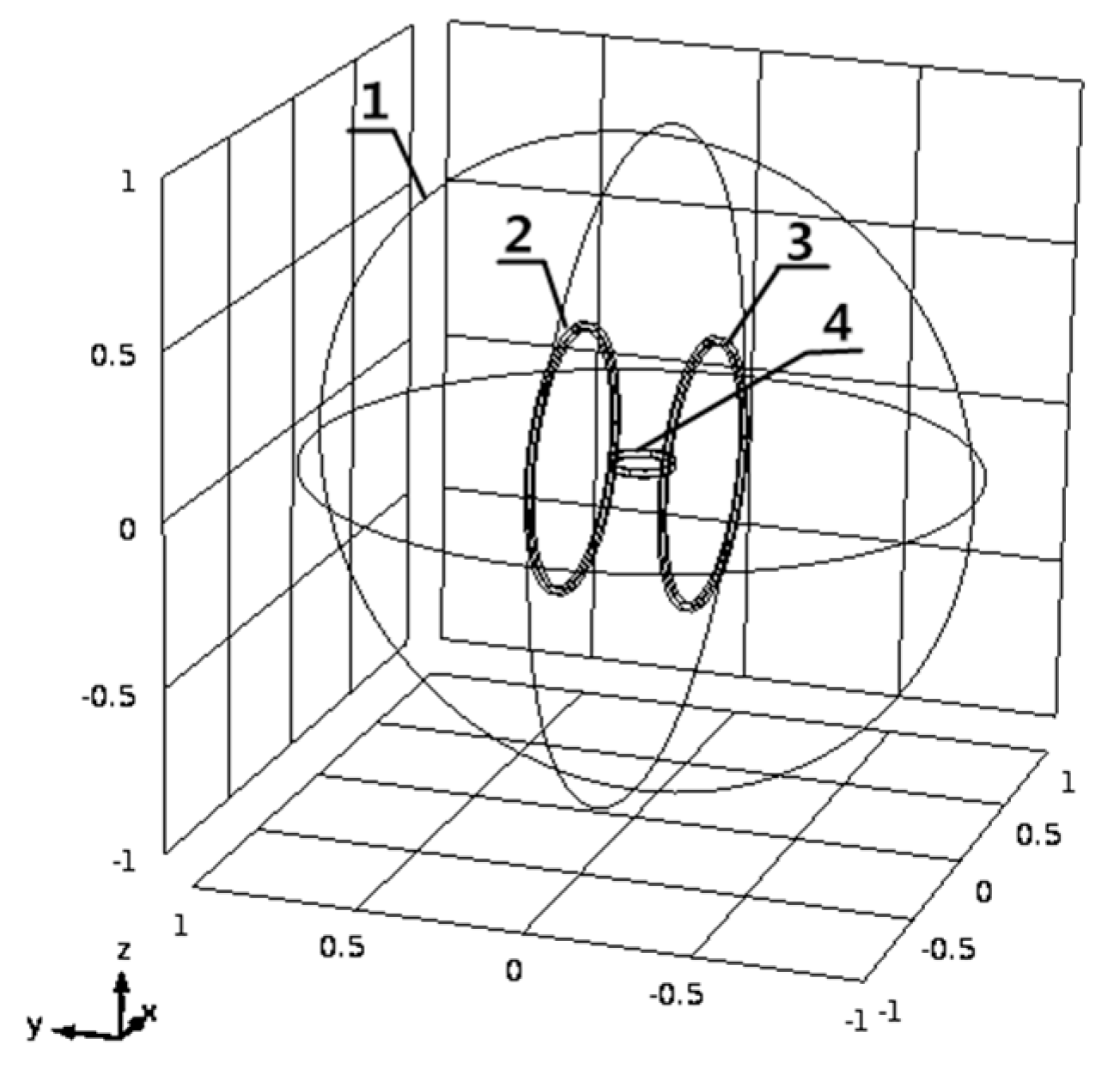

2. Design and Optimization of Detection Platform

2.1. Design of Detection Platform

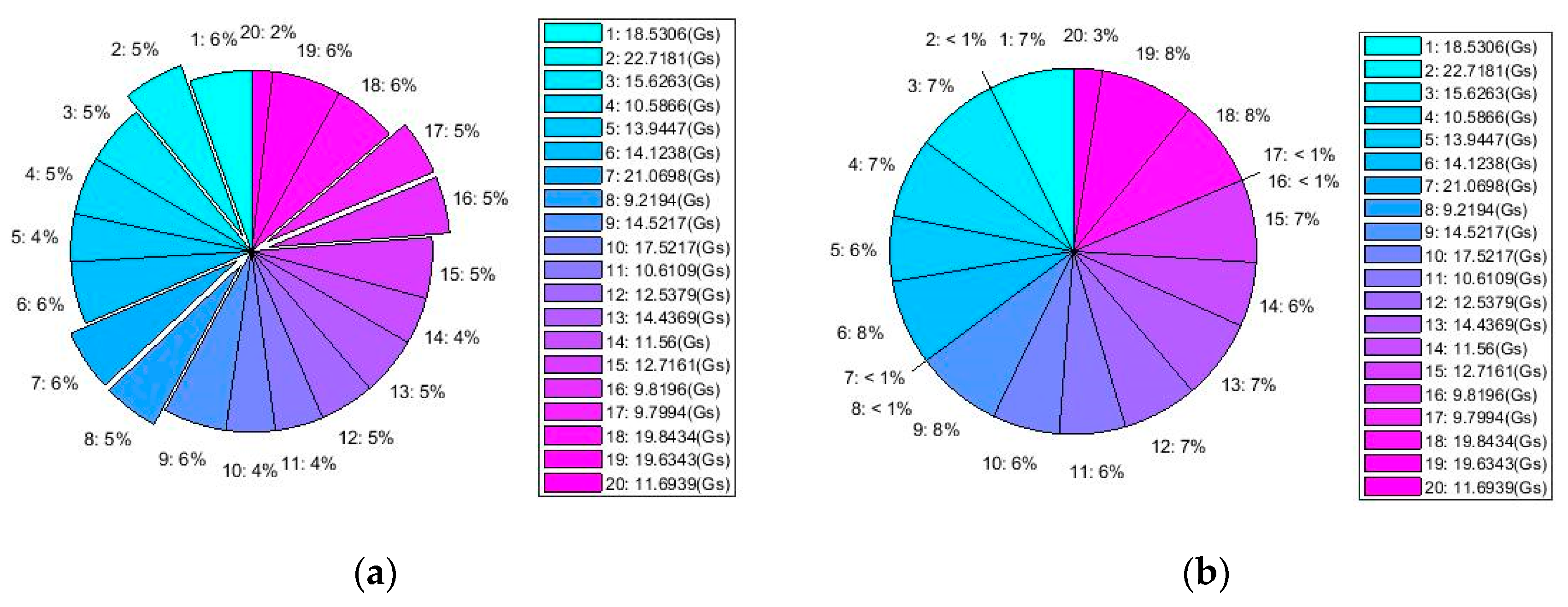

2.2. Optimization of Detection Platform through Genetic Algorithm

2.2.1. Wide Adaptability of the Platform to the Size of Magnetic Nanoparticle Device

2.2.2. Design of Fitness Evaluation Function of Genetic Algorithm

2.2.3. Setting of Penalty Function and Elitist Preservation Strategy

2.2.4. Parameter Settings of Genetic Algorithm

2.3. Optimization Results of Detection Platform by Using Genetic Algorithm

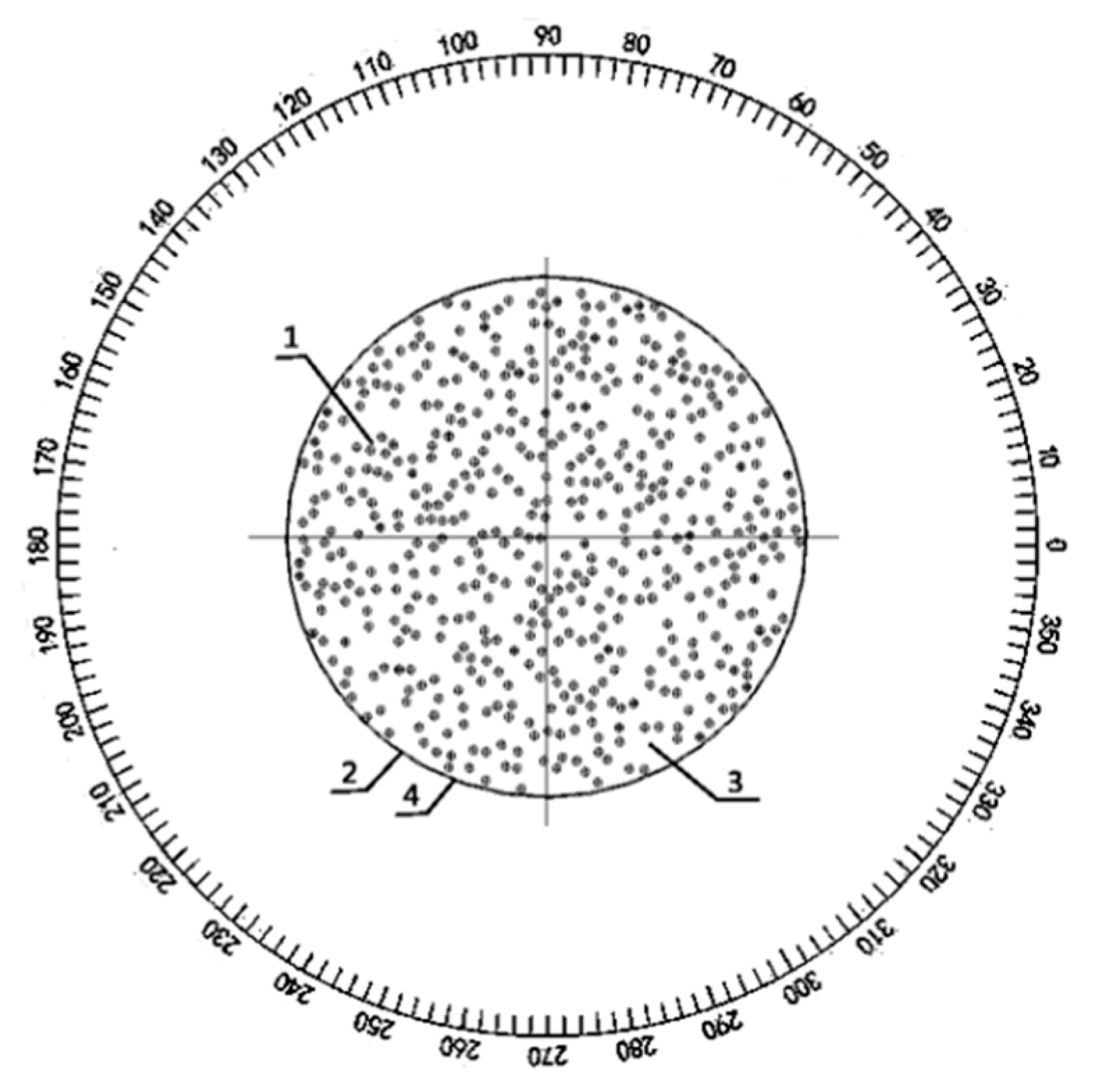

3. Decision of MNPs Detection Positions

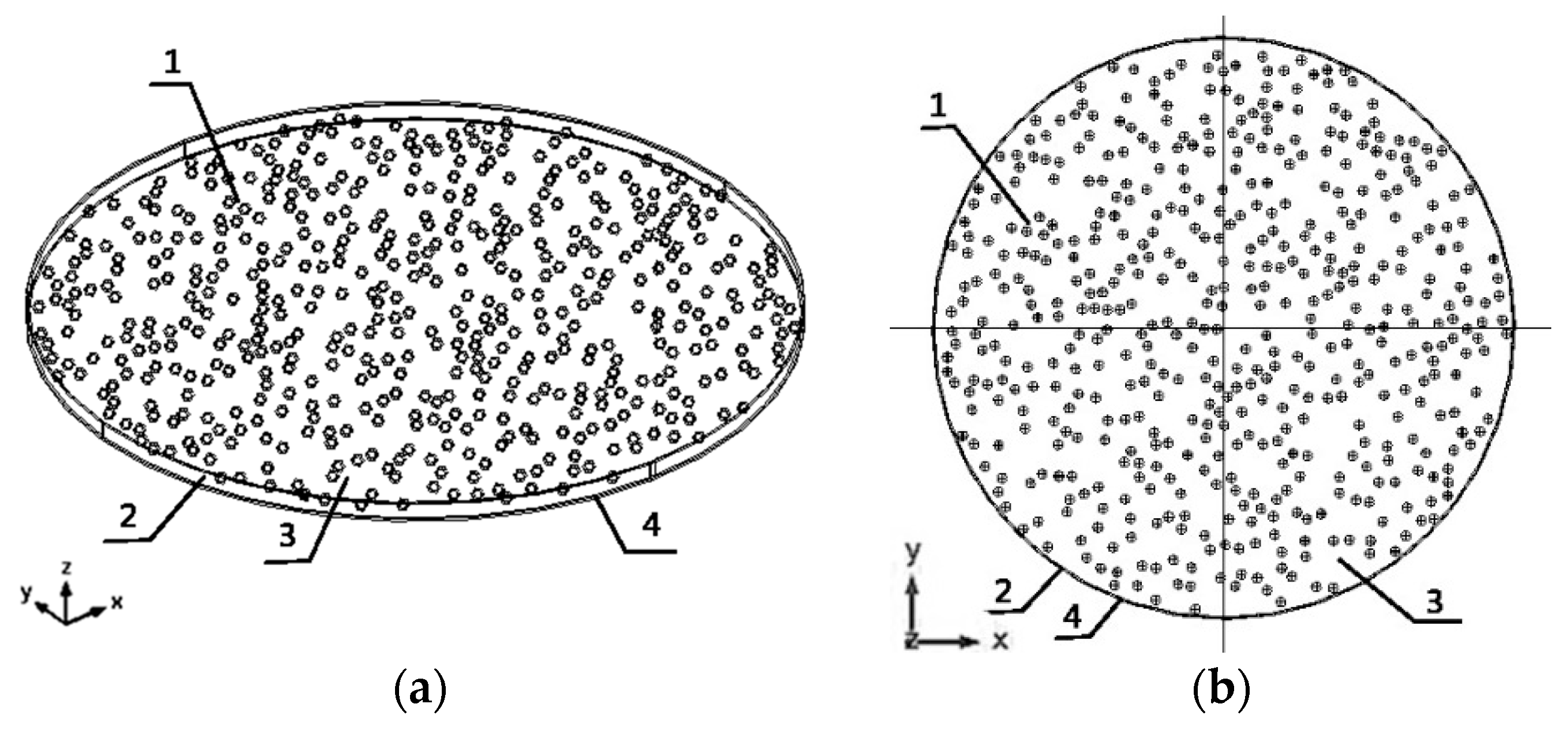

3.1. Generation and Preservation of MNPs Measurement Models in Detection Platform

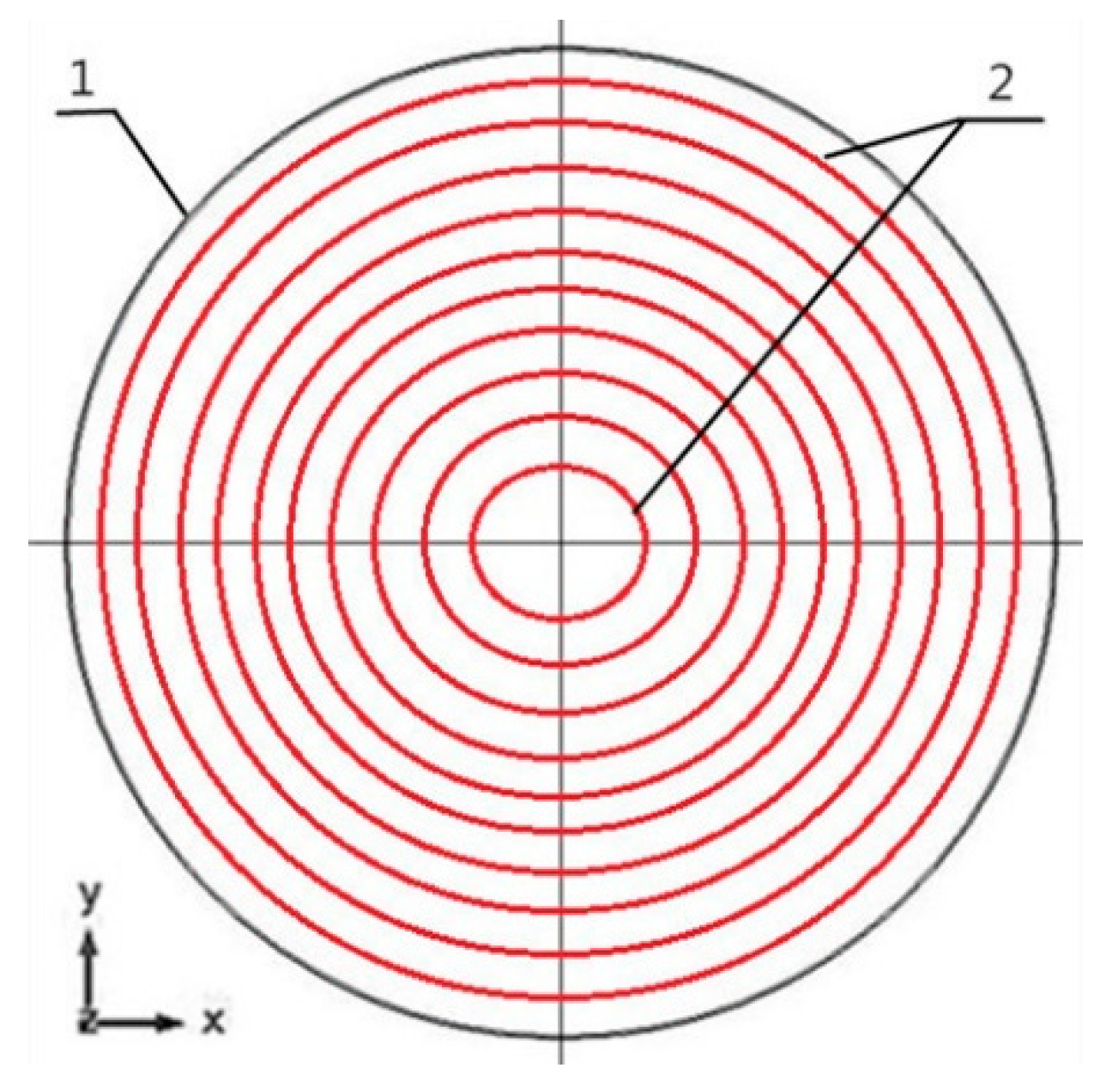

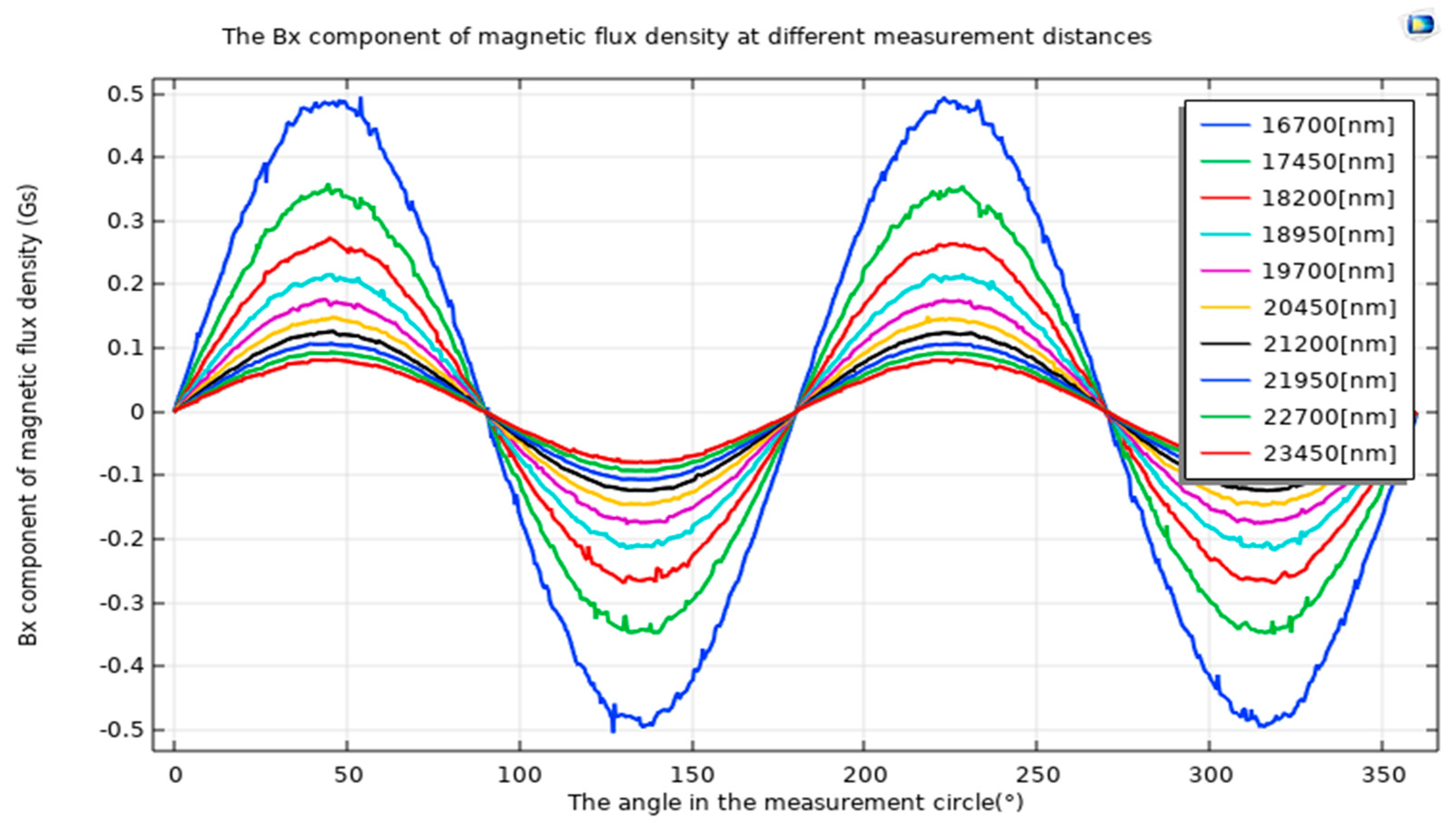

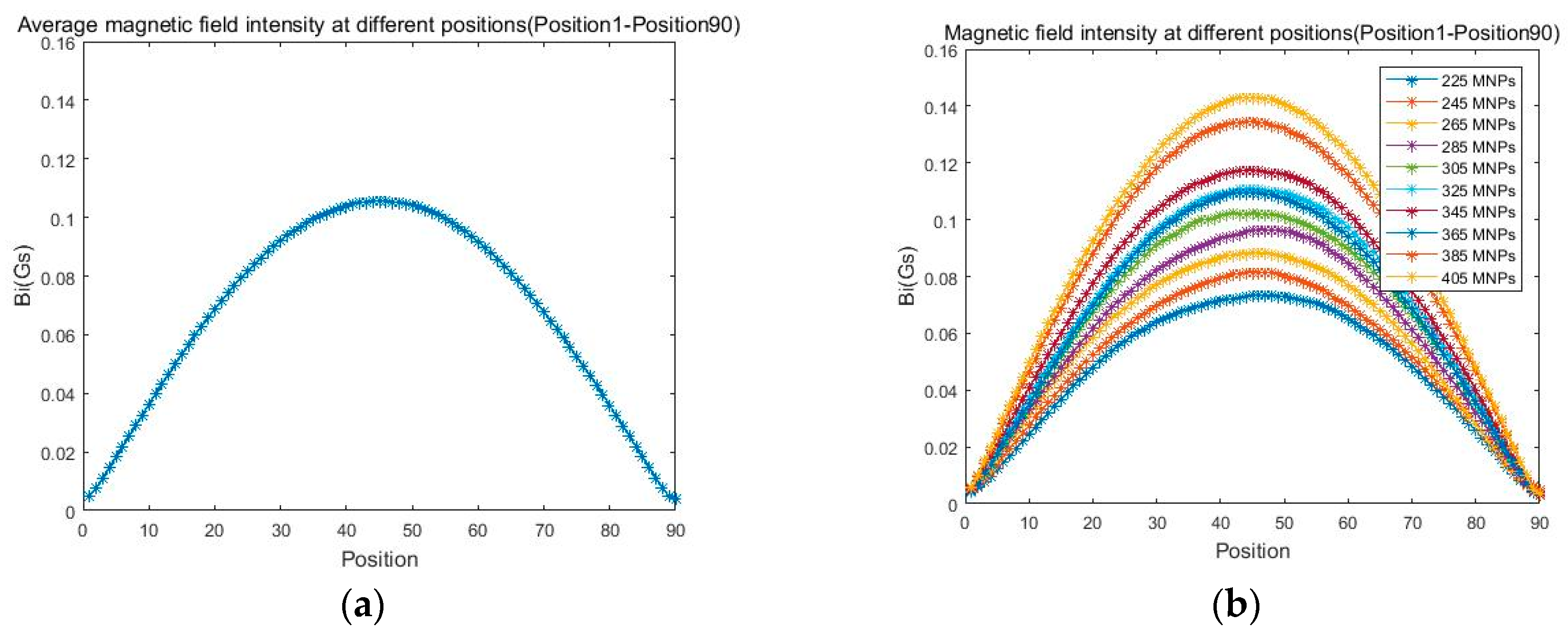

3.2. Optimization of Detection Distance of MNPs

3.3. Establishment of MNPs Measurement Models at Different Detection Positions

3.3.1. Establishment of Sample Sets Corresponding to Different Detection Positions

3.3.2. Establishment of MNPs Measurement Models through Simulated Annealing Neural Network

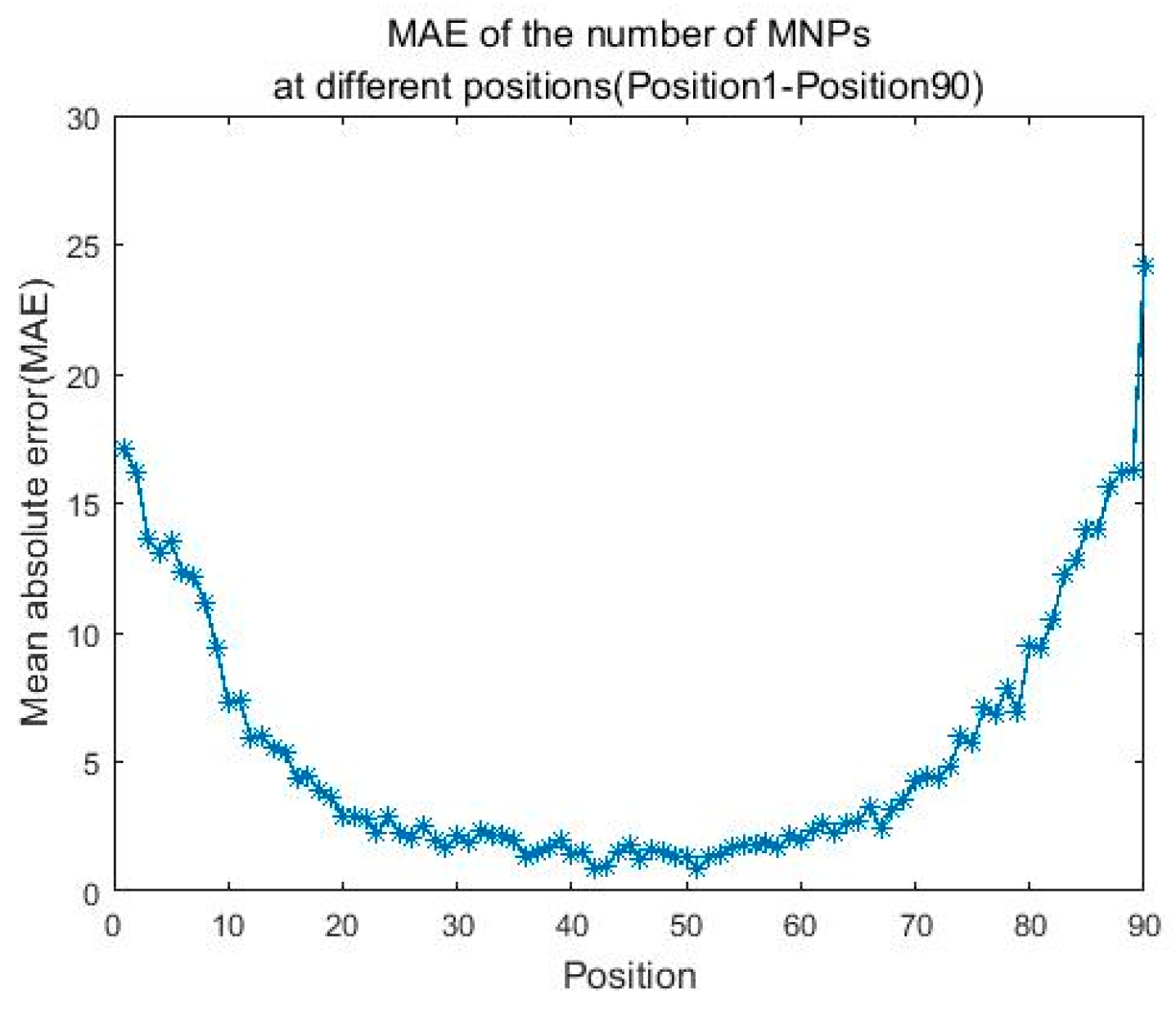

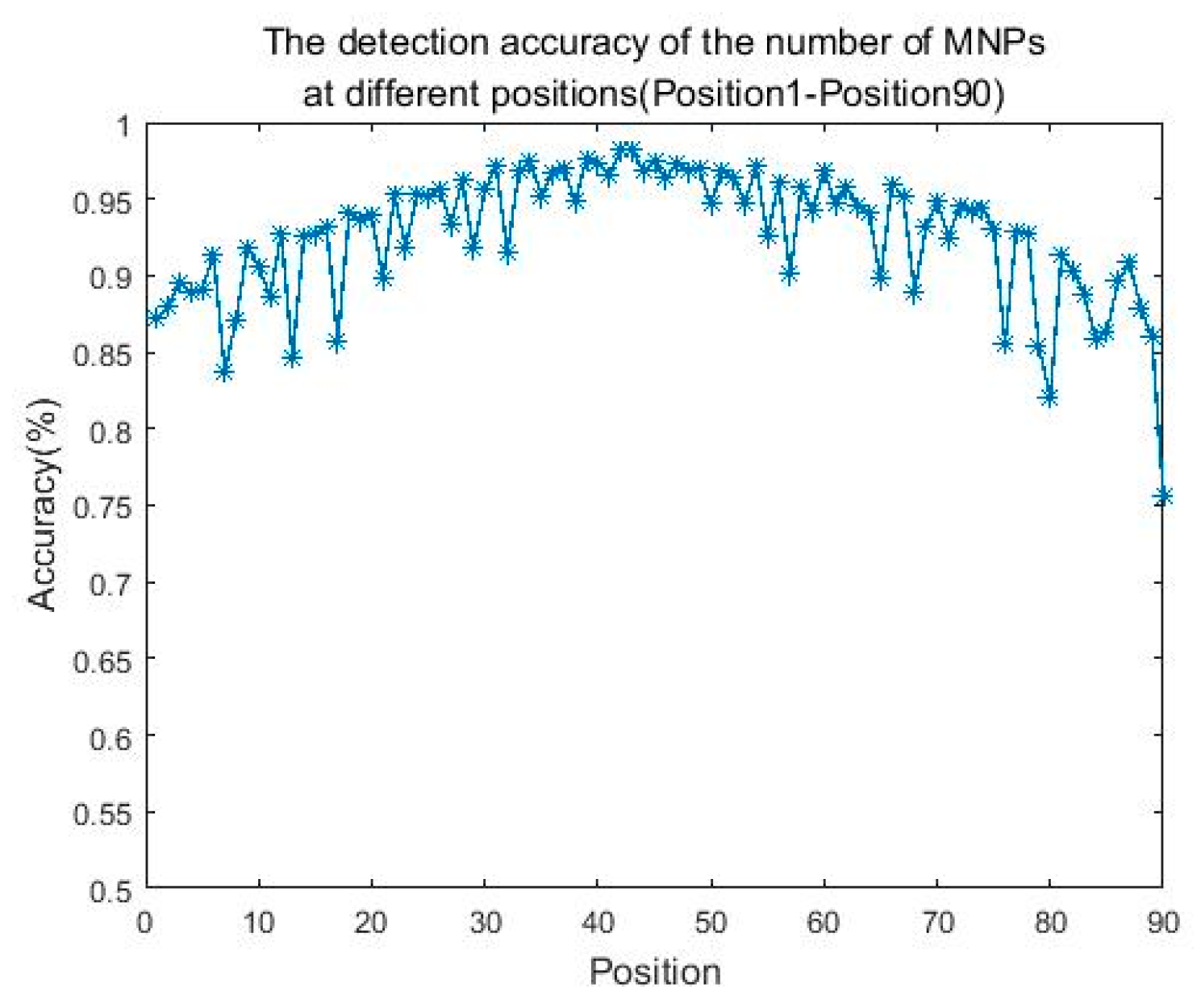

3.4. Construction of the Detection Positions Evaluation Function

3.5. Obtaining of the Optimal Detection Positions

4. Establishment and Comparison of MNPs Number Detection Models

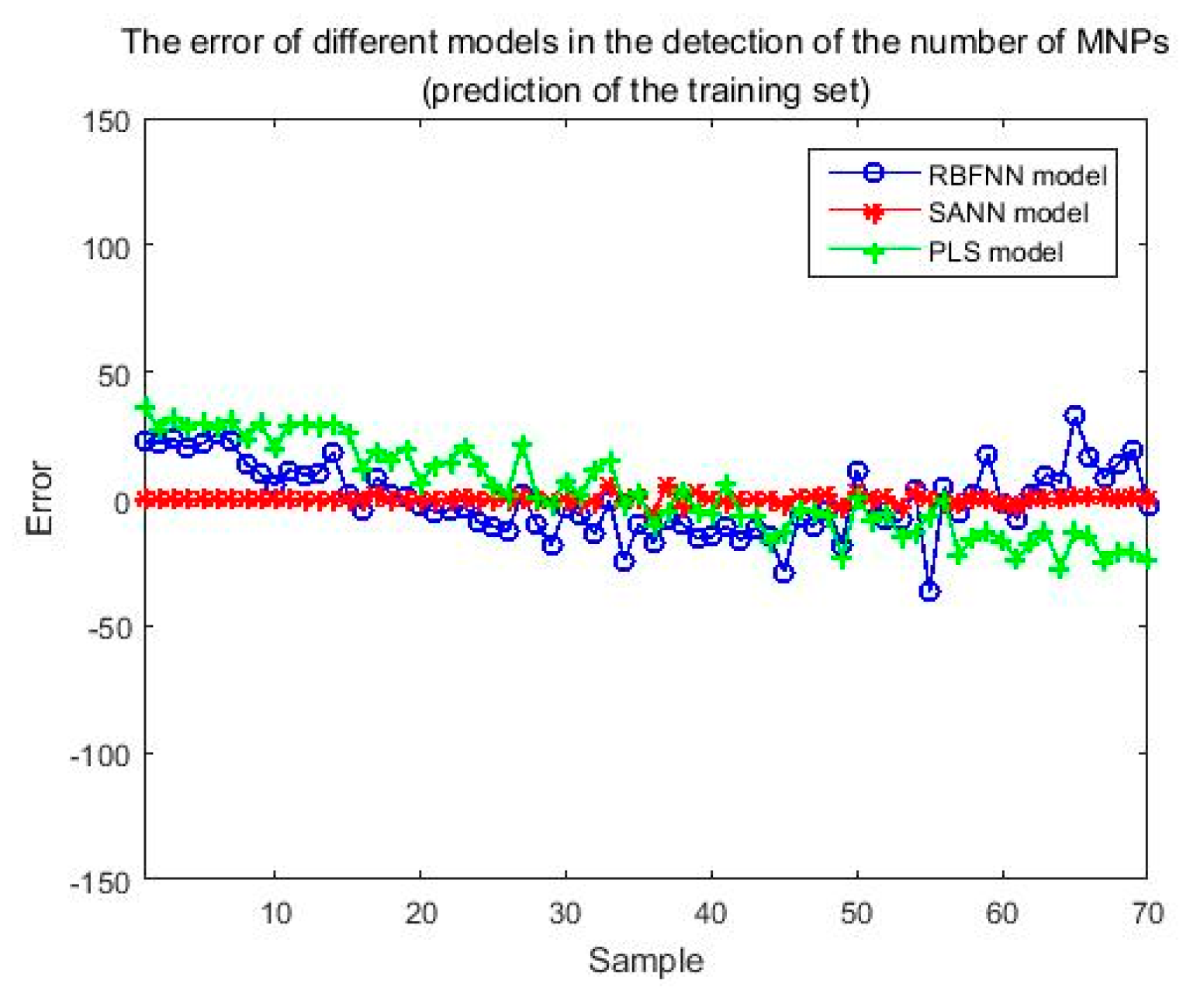

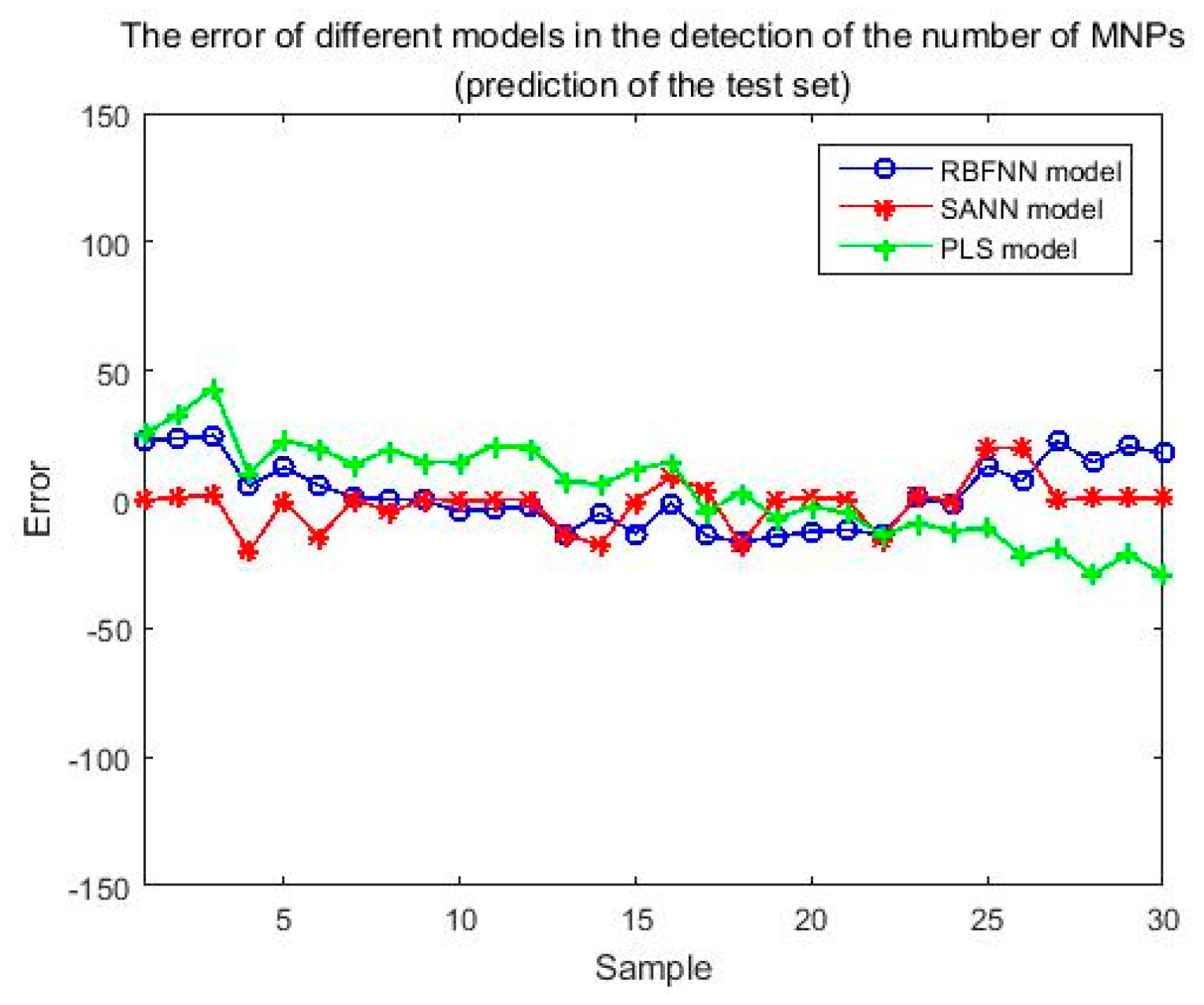

4.1. MNPs Number Detection Model Based on RBF Neural Network

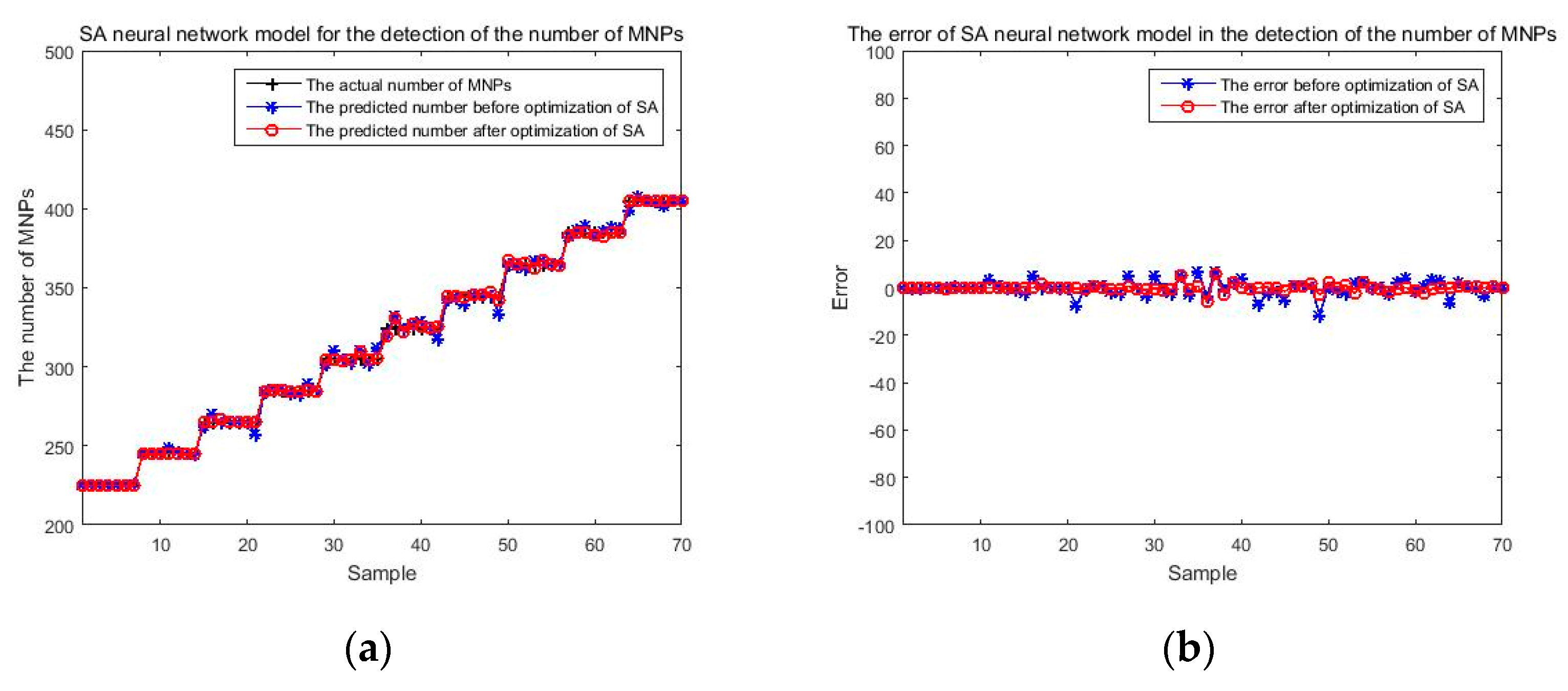

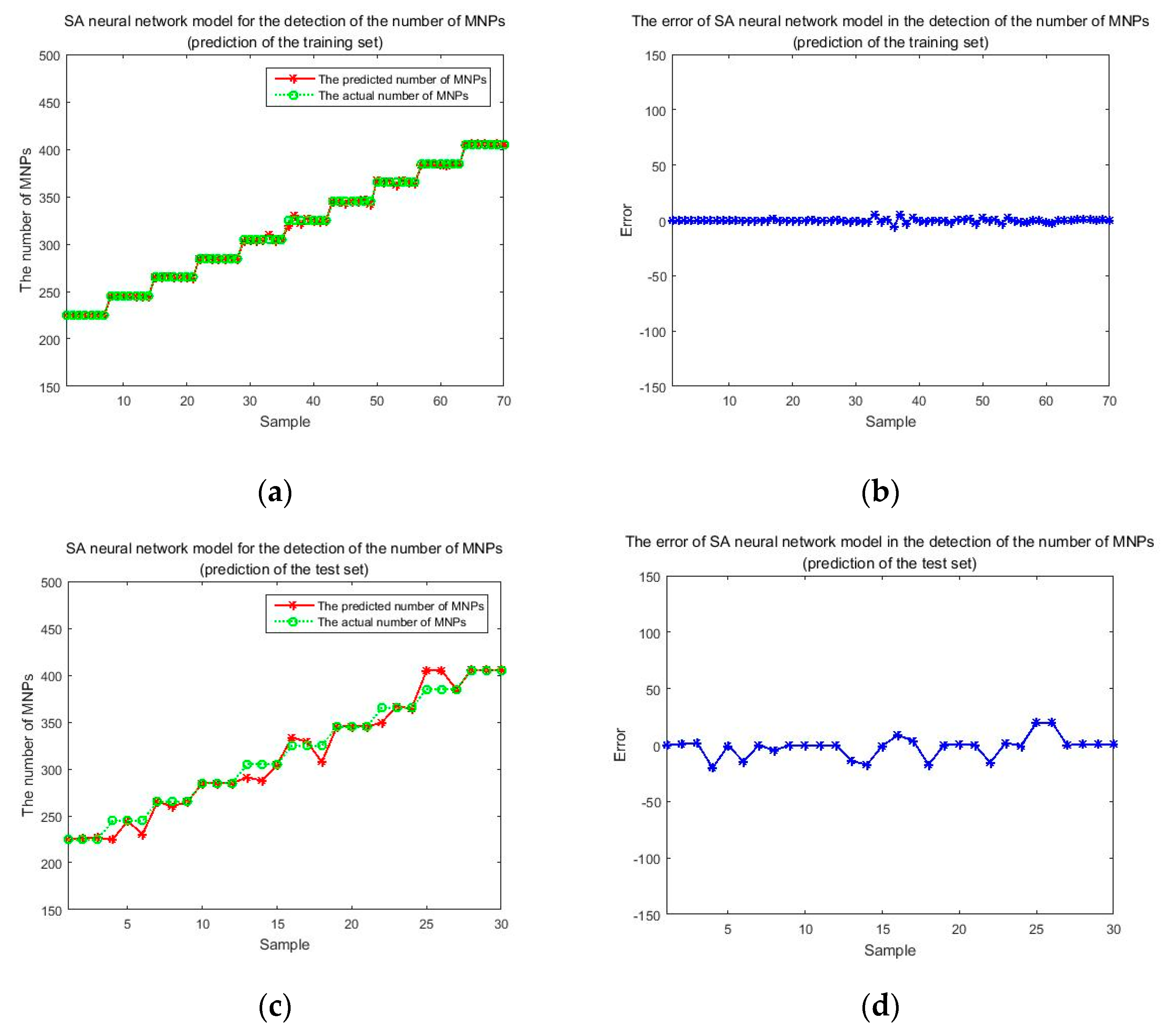

4.2. MNPs Number Detection Model Based on Simulated Annealing Neural Network

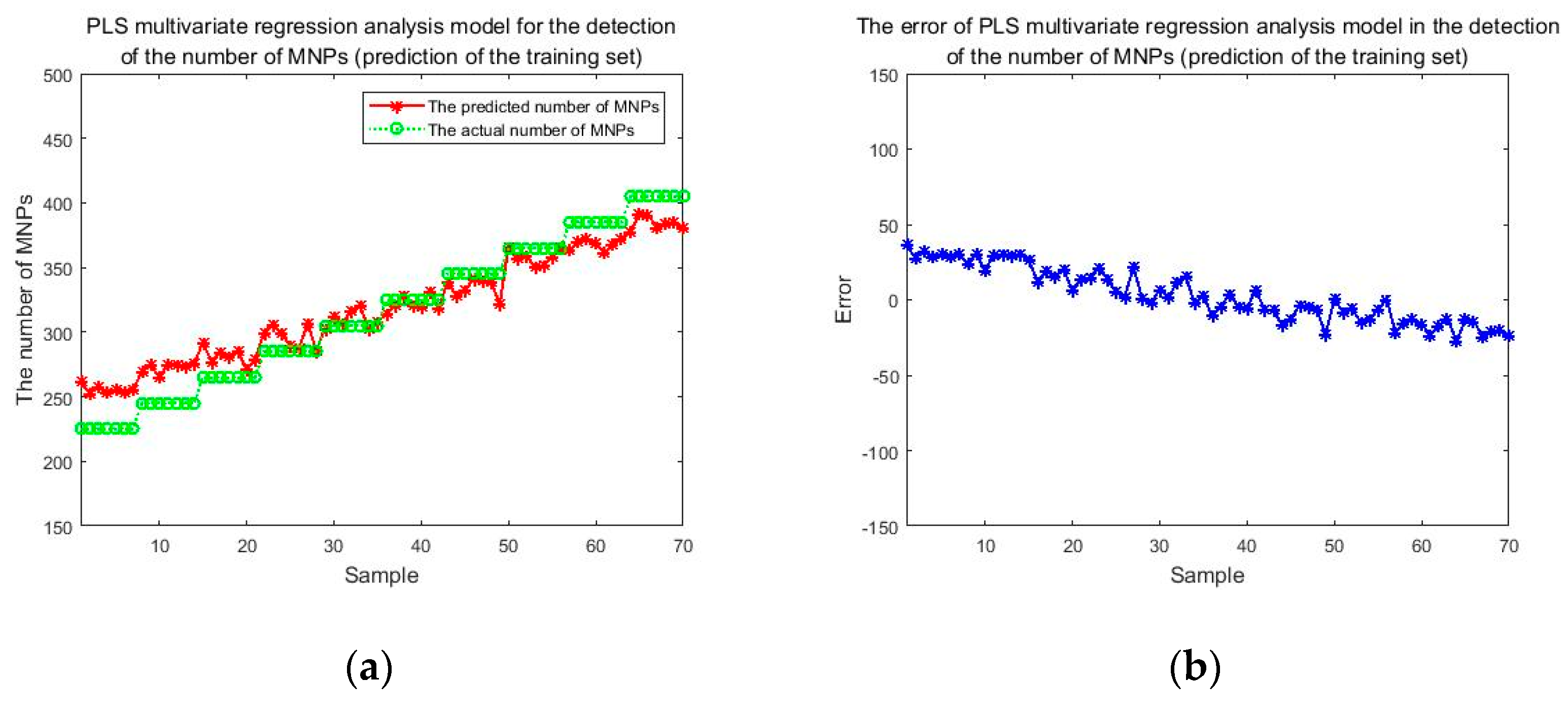

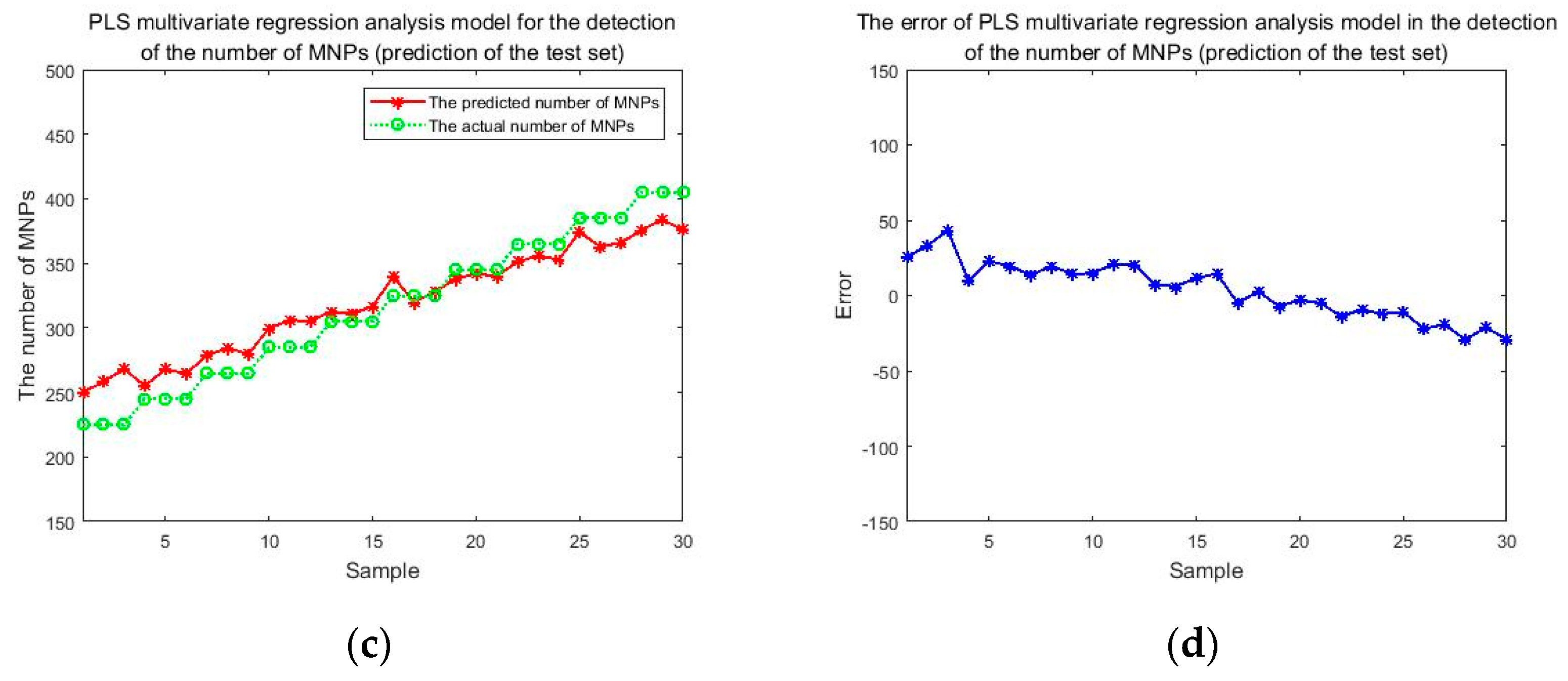

4.3. MNPs Number Detection Model Based on PLS Multivariate Regression Analysis

4.4. Comparison and Discussion of Different MNPs Number Detection Models

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Beveridge, J.S.; Stephens, J.R.; Williams, M.E. The Use of Magnetic Nanoparticles in Analytical Chemistry. Annu. Rev. Anal. Chem. 2011, 4, 251–273. [Google Scholar] [CrossRef] [PubMed]

- Caroccia, B.; Fassina, A.; Seccia, T.M. Isolation of Human Adrenocortical Aldosterone- Producing Cells by a Novel Immunomagnetic Beads Method. Endocrinology 2010, 151, 1375–1380. [Google Scholar] [CrossRef] [PubMed]

- Nishiya, Y.; Hibi, T.; Oda, J.I. A purification method of the diagnostic enzyme Bacillus uricase using magnetic beads and non-specific protease. Protein Expr. Purif. 2002, 25, 426–429. [Google Scholar] [CrossRef]

- Yoza, B.; Arakaki, A.; Matsunaga, T. DNA extraction using bacterial magnetic particles modified with hyperbranched polyamidoamine dendrimer. J. Biotechnol. 2003, 101, 219–228. [Google Scholar] [CrossRef]

- Verpoorte, E.; Rooij, N.F.D. Microfluidics meets MEMS. Proc. IEEE 2003, 91, 930–953. [Google Scholar] [CrossRef]

- Gilmartin, N.; O’Kennedy, R. Nanobiotechnologies for the detection and reduction of pathogens. Chin. J. Anal. Chem. 2011, 39, 1307–1312. [Google Scholar] [CrossRef] [PubMed]

- Peng, J.; Xu, Y.; Wu, Y.; Chuan, N.; Gan, J.; Tian, P. Determination of E.coli with Electrochemical Impedance on Homemade Microfluidic Chip. Enzym. Microb. Technol. 2012, 50, 87–95. [Google Scholar]

- Simmonds, M.B. Method and Apparatus for Making Quantitave Measurements of Localized Accumulations of Magnetic Particles. U.S. Patent 6,046,585, 4 April 2004. [Google Scholar]

- Kotitz, R.; Matz, H.; Trahms, L. SQUID based remanence measurements for immunoassays. IEEE Trans. Appl. Supercond. 1997, 7, 3678–3681. [Google Scholar] [CrossRef]

- Koh, I.; Josephson, L. Magnetic Nanoparticle Sensors. Sensors 2009, 9, 8130–8145. [Google Scholar] [CrossRef]

- Lee, H.; Shin, T.H.; Cheon, J. Recent Developments in Magnetic Diagnostic Systems. Chem. Rev. 2015, 115, 10690–10724. [Google Scholar] [CrossRef]

- Issadore, D.; Min, C.; Liong, M. Miniature magnetic resonance system for point-of-care diagnostics. Lab Chip 2011, 11, 2282–2287. [Google Scholar] [CrossRef]

- Imtiaz, W.; Ghafoor, H.A.; Sehar, R. Evaluating the Performance Estimators via Machine Learning Supervised Learning Algorithms for Dataset Threshold. Int. J. Comput. Appl. 2015, 119, 1–6. [Google Scholar] [CrossRef]

- Sutton, R.; Barto, A.; Sehar, R. Reinforcement Learning: An Introduction (Adaptive Computation and Machine Learning). IEEE Trans. Neural Netw. 1998, 9, 1054. [Google Scholar] [CrossRef]

- Yan, W.; Wang, K.; Xu, H. Machine Learning Approach to Enhance the Performance of MNP-Labeled Lateral Flow Immunoassay. Nano-Micro Lett. 2019, 11, 7. [Google Scholar] [CrossRef]

- Khosravi, A.; Malekan, M.; Williams, M.E. Effect of the magnetic field on the heat transfer coefficient of a Fe3O4 water ferrofluid using artificial intelligence and CFD simulation. Eur. Phys. J. Plus 2019, 134, 88. [Google Scholar] [CrossRef]

- Min, H.; Pi-suo, C. A dynamic RBF neural network algorithm used in pattern recognition. J. Dalian Univ. Technol. 2006, 46, 746–751. [Google Scholar]

- Li, T.; Wang, X. Non-synchronous signal monitoring based on simulated annealing neural network. In Proceedings of the IEEE International Conference on Granular Computing, Nanchang, China, 17–19 August 2009; IEEE: Piscataway, NJ, USA, 2009. [Google Scholar]

- Elden, L. Partial least-squares vs. Lanczos bidiagonalization-I: Analysis of a projection method for multiple regression. Comput. Stat. Data Anal. 2004, 46, 11–31. [Google Scholar] [CrossRef]

- Trout, S.R. Use of Helmholtz coils for magnetic measurements. IEEE Trans. Magn. 1988, 24, 2108–2111. [Google Scholar] [CrossRef]

- Feng, Y. Simulation and Experimental Research on the Aggregation Performance of Magnetic Particles under Magnetic Field; Huazhong University of Science and Technology: Wuhan, China, 2016. [Google Scholar]

- Khashan, S.A.; Furlani, E.P. Coupled particle-fluid transport and magnetic separation in microfluidic systems with passive magnetic functionality. J. Phys. D Appl. Phys. 2013, 46, 125002. [Google Scholar] [CrossRef]

- Udy, J.; Hansen, B.; Maddux, S.; Petersen, D.; Heilner, S.; Stevens, K.; Lignell, D.; Hedengren, J.D. Review of field development optimization of waterflooding, eor, and well placement focusing on history matching and optimization algorithms. Processes 2017, 5, 34. [Google Scholar]

- Osyczka, A.; Kundu, S. A New Method to Solve Generalized Multcriteria Optimization Problems Using the Simple Genetic Algorithm. Struct. Multidiscip. Optim. 1995, 10, 94–99. [Google Scholar] [CrossRef]

- Vose, M.D. The Simple Genetic Algorithm: Foundations and Theory; MIT Press: Cambridge, MA, USA, 1999. [Google Scholar]

- Chen, T.Y.; Chen, C.J. IMPROVEMENTS OF SIMPLE GENETIC ALGORITHM IN STRUCTURAL DESIGN. Int. J. Numer. Methods Eng. 2015, 40, 1323–1334. [Google Scholar] [CrossRef]

- Ha, Y.H.; Han, B.H.; Lee, S.Y. Magnetic propulsion of a magnetic device using three square-Helmholtz coils and a square-Maxwell coil. Med. Biol. Eng. Comput. 2010, 48, 139–145. [Google Scholar] [CrossRef] [PubMed]

- Jiang, B.C.; Wang, C.C.; Liu, H.C. Liquid crystal display surface uniformity defect inspection using analysis of variance and exponentially weighted moving average techniques. Int. J. Prod. Res. 2005, 43, 67–80. [Google Scholar] [CrossRef]

- Zhang, D.H.; Ren, B.; Liu, S. Discuss on Evaluation of Film Cooling Uniformity. Turbine Technol. 2013, 55, 171–174. [Google Scholar]

- Mishra, S. Weighting method for bi-level linear fractional programming problems. Eur. J. Oper. Res. 2007, 183, 296–302. [Google Scholar] [CrossRef]

- Dixon, P.; Just, M.A. Normalization of irrelevant dimensions in stimulus comparisons. J. Exp. Psychol. Hum. Percept. Perform. 1978, 4, 36–46. [Google Scholar] [CrossRef]

- Gréwal, G.; Coros, S. Comparing a genetic algorithm penalty function and repair heuristic in the DSP application domain. In Proceedings of the Iasted International Conference on Artificial Intelligence & Applications, Innsbruck, Austria, 13–16 February 2006. [Google Scholar]

- Kaya, M. The effects of a new selection operator on the performance of a genetic algorithm. Appl. Math. Comput. 2011, 217, 7669–7678. [Google Scholar] [CrossRef]

- Liang, Y.; Leung, K.S. Genetic Algorithm with adaptive elitist-population strategies for multimodal function optimization. Appl. Soft Comput. 2011, 11, 2017–2034. [Google Scholar] [CrossRef]

- Min, H.; Zhuo, W.; Linghui, H. The Study of Optimizing of Physical Distribution Routing Problem System with Time Windows Based on Genetic Algorithm. In Proceedings of the 2010 International Forum on Information Technology and Applications, Kunming, China, 16–18 July 2010. [Google Scholar]

- Li, X.; Yao, K. The cluster-moving Monte Carlo method simulates the aggregation behavior of magnetic nanoparticles under uniform magnetic field. In Proceedings of the Second National Forum on Complex Dynamical Networks, Beijing, China, 16–19 October 2005. [Google Scholar]

- Satoh, A. A new technique for metropolis Monte Carlo simulation to capture aggregate structures of fine particles: Cluster-moving Monte Carlo algorithm. J. Colloid Interface Sci. 1992, 150, 461–472. [Google Scholar] [CrossRef]

- Aoshima, M.; Satoh, A. Two-dimensional Monte Carlo simulations of a colloidal dispersion composed of polydisperse ferromagnetic particles in an applied magnetic field. J. Colloid Interface Sci. 2005, 288, 475–488. [Google Scholar] [CrossRef] [PubMed]

- Peng, X.; Min, Y.; Ma, T.; Luo, W.; Yan, M. Two-dimensional Monte Carlo simulations of structures of a suspension comprised of magnetic and nonmagnetic particles in uniform magnetic fields. J. Magn. Magn. Mater. 2009, 321, 1221–1226. [Google Scholar] [CrossRef]

- Sadeghi, B.H.W. A BP-neural network predictor model for plastic injection molding process. J. Mater. Process. Technol. 2000, 103, 411–416. [Google Scholar] [CrossRef]

- Gazzaz, N.M.; Yusoff, M.K.; Aris, A.Z.; Juahir, H.; Ramli, M.F. Artificial neural network modeling of the water quality index for Kinta River (Malaysia) using water quality variables as predictors. Mar. Pollut. Bull. 2012, 64, 2409–2420. [Google Scholar] [CrossRef] [PubMed]

- Alrefaei, M.H.; Andradóttir, S. A Simulated Annealing Algorithm with Constant Temperature for Discrete Stochastic Optimization. Manag. Sci. 1995, 45, 748–764. [Google Scholar] [CrossRef]

- Gupta, R.; Bera, J.N.; Mitra, M. Development of an embedded system and MATLAB-based GUI for online acquisition and analysis of ECG signal. Measurement 2010, 43, 1119–1126. [Google Scholar] [CrossRef]

- Baruah, P.J.; Tamura, M.; Oki, K.; Nishimura, H. Neural network modeling of surface chlorophyll and sediment content in inland water from Landsat Thematic Mapper imagery using multidate spectrometer data. Proc. Spie 2002, 4488, 205–212. [Google Scholar]

- Yun, Z.; Quan, Z.; Caixin, S.; Shaolan, L.; Yuming, L.; Yang, S. RBF Neural Network and ANFIS-Based Short-Term Load Forecasting Approach in Real-Time Price Environment. IEEE Trans. Power Syst. 2008, 23, 853–858. [Google Scholar]

- Qiao, X.; Chang, W.; Zhou, S.; Lu, X. A prediction model of hard landing based on RBF neural network with K-means clustering algorithm. In Proceedings of the 2016 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bali, Indonesia, 4–7 December 2016. [Google Scholar]

- Gong, Z.W. Least-square method to priority of the fuzzy preference relations with incomplete information. Int. J. Approx. Reason. 2008, 47, 258–264. [Google Scholar] [CrossRef]

- Gil-García, C.J.; Rigol, A.; Vidal, M. Comparison of mechanistic and PLS-based regression models to predict radiocaesium distribution coefficients in soils. J. Hazard. Mater. 2011, 197, 11–18. [Google Scholar]

- Geladi, P.; Kowalski, B.R. Partial Least-Squares Regression: A Tutorial. Anal. Chim. Acta 1986, 185, 1–17. [Google Scholar] [CrossRef]

- Nandi, S.; Bagchi, M.C. Activity Prediction of Some Nontested Anticancer Compounds Using GA-Based PLS Regression Models. Chem. Biol. Drug Des. 2011, 78, 587–595. [Google Scholar] [CrossRef] [PubMed]

| Type of MNPs | Particle Radius (nm) | Particle Density(kg·m−3) | Relative Permeability |

|---|---|---|---|

| MyOne | 500 | 1.8 × 103 | 3.625 |

| Node Number (1–1000) | Magnetic Flux Density (T) | The Bx Component of Magnetic Flux Density (T) |

|---|---|---|

| 1 | 0.0018998022371254652 | 3.639288164784647 × 10−8 |

| 2 | 0.0018998022329738582 | 3.639052640106748 × 10−8 |

| 3 | 0.0018998022288057607 | 3.638817048925243 × 10−8 |

| 4 | 0.0018998022246213377 | 3.638581400841419 × 10−8 |

| 5 | 0.0018998022204207545 | 3.638345705080822 × 10−8 |

| 6 | 0.0018998022162041775 | 3.638109970918461 × 10−8 |

| 7 | 0.0018998022119717725 | 3.6378742077567414 × 10−8 |

| 8 | 0.0018998022077237077 | 3.6376384248496674 × 10−8 |

| 9 | 0.0018998022034601506 | 3.637402631464796 × 10−8 |

| 10 | 0.0018998021991812701 | 3.637166836978104 × 10−8 |

| Evolution Generation | Input current Intensity I (A) | Coil Distance L (m) | Coil Turns N | Average New Fitness Value |

|---|---|---|---|---|

| Initial population | 2.5 | 0.1713 | 293 | 0.5743 |

| The 100th generation | 2.75 | 0.1771 | 300 | 0.9244 |

| Evolution Generation | Magnetic Flux Density (Gs) | Bx component of Magnetic Flux Density (T) | Uniformity of Magnetic Flux Density | Uniformity of Bx Component of Magnetic Flux Density | Maximum New Fitness Value |

|---|---|---|---|---|---|

| Initial population | 17.2111 | 1.3583 × 10−10 | 0.0028 | 1.9896 × 10−11 | 0.8832 |

| The 100th generation | 19.3294 | 4.8775 × 10−11 | 3.7008 × 10−4 | 1.1209 × 10−11 | 0.9281 |

| Model Name | Model1 | Model2 | Model3 | Model4 | Model5 |

| Detection distance (nm) | 21,200 | 21,950 | 23,450 | 19,700 | 18,200 |

| Model Name | Model6 | Model7 | Model8 | Model9 | Model10 |

| Detection distance (nm) | 22,700 | 18,200 | 22,700 | 18,200 | 18,950 |

| Ranking | Position Number (Position1–90) | Specific Position Information | Mean Absolute Error | Number Detection Accuracy of MNPs | Average Response Magnetic Field Intensity | Comprehensive Evaluation Value |

|---|---|---|---|---|---|---|

| 1 | 42 | 42, 138, 222, 318 | 0.8545 | 0.9822 | 0.1050 | 0.997047 |

| 2 | 43 | 43, 137, 223, 317 | 0.9937 | 0.9821 | 0.1053 | 0.996562 |

| 3 | 45 | 45, 135, 225, 315 | 1.7483 | 0.9744 | 0.1057 | 0.978213 |

| 4 | 47 | 47, 133, 227, 313 | 1.6237 | 0.9735 | 0.1054 | 0.977285 |

| 5 | 51 | 51, 129, 231, 309 | 0.8506 | 0.9689 | 0.1036 | 0.973964 |

| 6 | 49 | 49, 131, 229, 311 | 1.3213 | 0.9694 | 0.1048 | 0.973458 |

| 7 | 44 | 44, 136, 224, 316 | 1.5279 | 0.9687 | 0.1056 | 0.972935 |

| 8 | 40 | 40, 140, 220, 320 | 1.4523 | 0.9731 | 0.1039 | 0.972866 |

| 9 | 48 | 48, 132, 228, 312 | 1.5588 | 0.9680 | 0.1052 | 0.969948 |

| 10 | 46 | 46, 134, 226, 314 | 1.2564 | 0.9634 | 0.1056 | 0.969317 |

| Sample Sets | The Number of Samples | The Number of MNPs |

|---|---|---|

| Training sets | 70 | 225, 245, 265, 285, 305, 325, 345, 365, 385, 405 |

| Test sets | 30 | 225, 245, 265, 285, 305, 325, 345, 365, 385, 405 |

| The Bx Components of Magnetic Flux Density (Gs) | The Number of MNPs | |||||

|---|---|---|---|---|---|---|

| Bx1 | Bx2 | Bx3 | Bx4 | True Value | Predicted Value | Absolute Error |

| 0.0685 | −0.0785 | 0.0682 | −0.0736 | 225 | 224.7257 | 0.2743 |

| 0.0845 | −0.0754 | 0.0838 | −0.0746 | 245 | 244.8628 | 0.1372 |

| 0.0897 | −0.0926 | 0.0835 | −0.0869 | 265 | 265.0186 | 0.0186 |

| 0.1050 | −0.0912 | 0.0866 | −0.1026 | 285 | 285.5560 | 0.5560 |

| 0.1112 | −0.0959 | 0.1021 | −0.0935 | 305 | 304.4048 | 0.5952 |

| 0.1178 | −0.1062 | 0.1135 | −0.1040 | 325 | 324.3668 | 0.6332 |

| 0.1190 | −0.1129 | 0.1219 | −0.1225 | 345 | 345.5862 | 0.5862 |

| 0.1373 | −0.1207 | 0.1286 | −0.1283 | 365 | 364.3140 | 0.6860 |

| 0.1390 | −0.1323 | 0.1251 | −0.1392 | 385 | 384.6628 | 0.3372 |

| 0.1502 | −0.1331 | 0.1493 | −0.1399 | 405 | 405.4670 | 0.4670 |

| The Bx Components of Magnetic Flux Density (Gs) | The Number of MNPs | |||||

|---|---|---|---|---|---|---|

| Bx1 | Bx2 | Bx3 | Bx4 | True Value | Predicted Value | Absolute Error |

| 0.0685 | −0.0785 | 0.0682 | −0.0736 | 225 | 252.6964 | 27.6964 |

| 0.0845 | −0.0754 | 0.0838 | −0.0746 | 245 | 275.0619 | 30.0619 |

| 0.0897 | −0.0926 | 0.0835 | −0.0869 | 265 | 285.4051 | 20.4051 |

| 0.1050 | −0.0912 | 0.0866 | −0.1026 | 285 | 306.0959 | 21.0959 |

| 0.1112 | −0.0959 | 0.1021 | −0.0935 | 305 | 316.7038 | 11.7038 |

| 0.1178 | −0.1062 | 0.1135 | −0.1040 | 325 | 331.6455 | 6.6455 |

| 0.1190 | −0.1129 | 0.1219 | −0.1225 | 345 | 341.3461 | 3.6539 |

| 0.1373 | −0.1207 | 0.1286 | −0.1283 | 365 | 365.2167 | 0.2167 |

| 0.1390 | −0.1323 | 0.1251 | −0.1392 | 385 | 369.6733 | 15.3267 |

| 0.1502 | −0.1331 | 0.1493 | −0.1399 | 405 | 390.6575 | 14.3425 |

| Sample Sets | RBFNN Model | SANN Model | PLS Model |

|---|---|---|---|

| MNPs number detection accuracy | 96.47% | 98.22% | 94.45% |

| MAE | 11.3953 | 0.8545 | 15.3111 |

| RMSE for training sets | 13.9393 | 1.5134 | 18.1921 |

| RMSE for test sets | 13.1770 | 9.2931 | 18.7699 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Zhou, T.; Niu, Q.; Hui, Y.; Hou, Z. A Method and Device for Detecting the Number of Magnetic Nanoparticles Based on Weak Magnetic Signal. Processes 2019, 7, 480. https://doi.org/10.3390/pr7080480

Wang L, Zhou T, Niu Q, Hui Y, Hou Z. A Method and Device for Detecting the Number of Magnetic Nanoparticles Based on Weak Magnetic Signal. Processes. 2019; 7(8):480. https://doi.org/10.3390/pr7080480

Chicago/Turabian StyleWang, Li, Tong Zhou, Qunfeng Niu, Yanbo Hui, and Zhiwei Hou. 2019. "A Method and Device for Detecting the Number of Magnetic Nanoparticles Based on Weak Magnetic Signal" Processes 7, no. 8: 480. https://doi.org/10.3390/pr7080480

APA StyleWang, L., Zhou, T., Niu, Q., Hui, Y., & Hou, Z. (2019). A Method and Device for Detecting the Number of Magnetic Nanoparticles Based on Weak Magnetic Signal. Processes, 7(8), 480. https://doi.org/10.3390/pr7080480