Innovative Effluent Capture and Evacuation Device that Increases COD Removal Efficiency in Subsurface Flow Wetlands

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemical Oxygen Demand (COD)

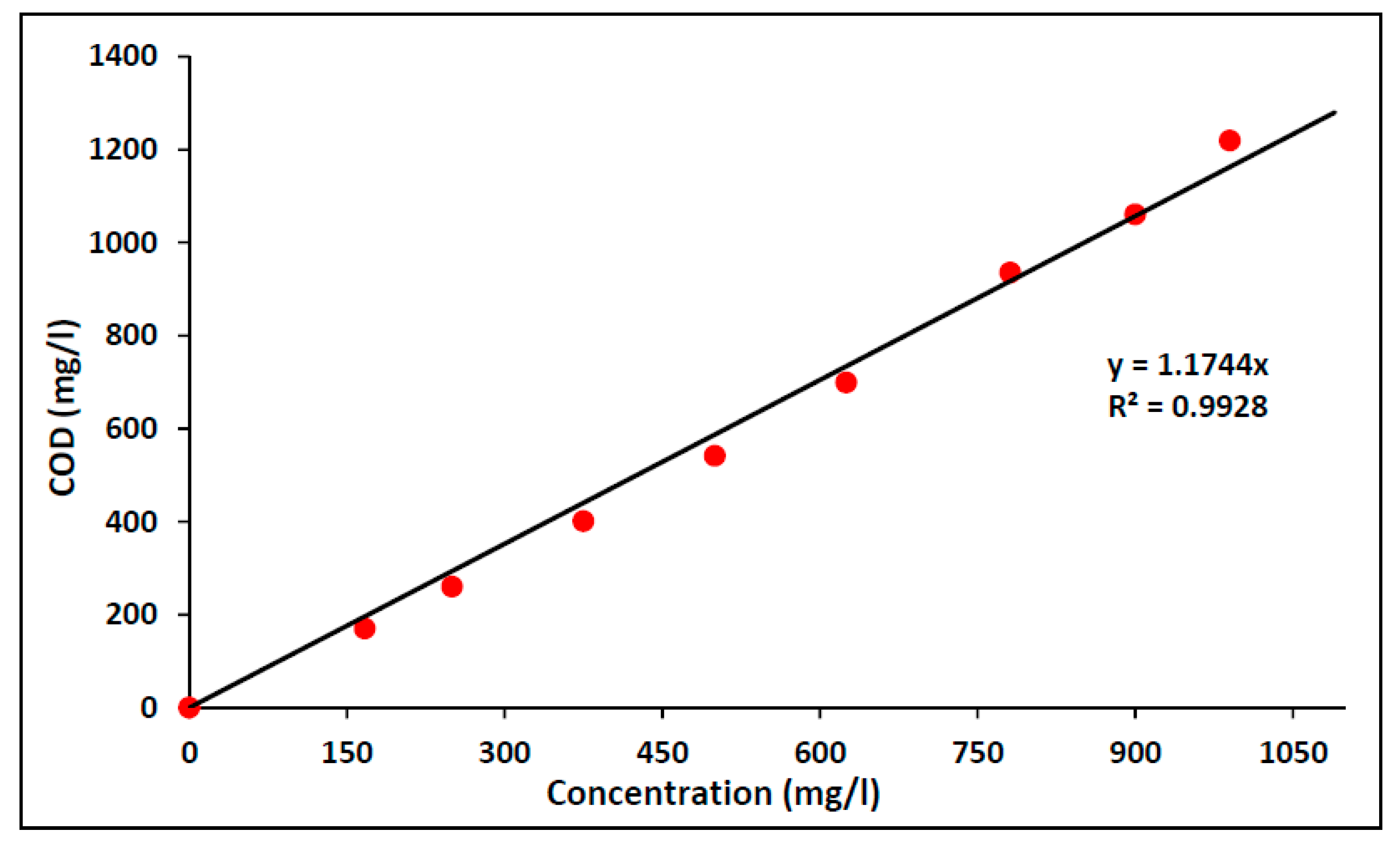

Determination of Chemical Oxygen Demand (COD)–Substrate Relationships

2.2. Experimental Methodology

2.2.1. Pilot Wetland

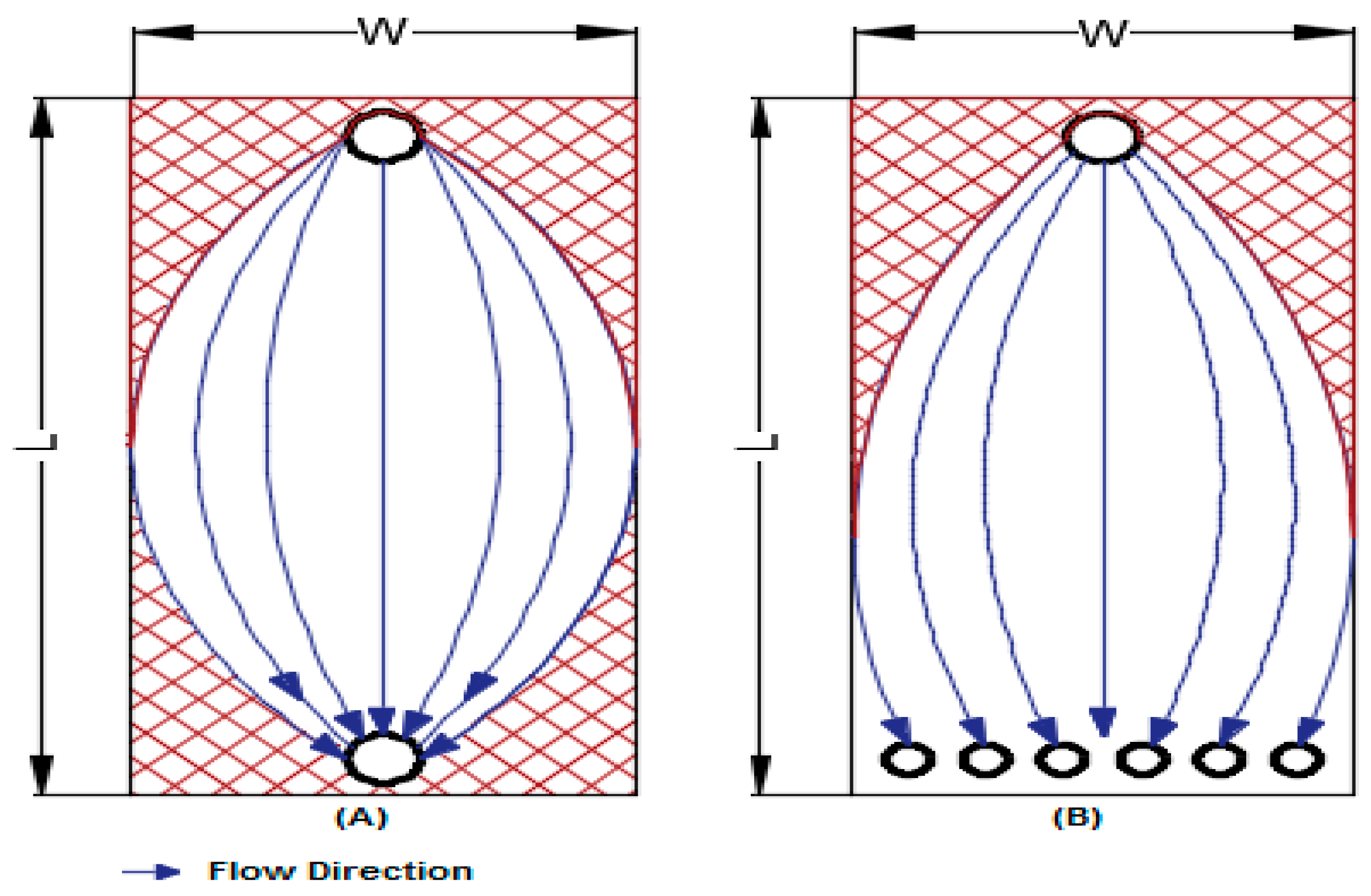

2.2.2. Description of Conventional and Innovative Output Devices

Conventional Exit Device

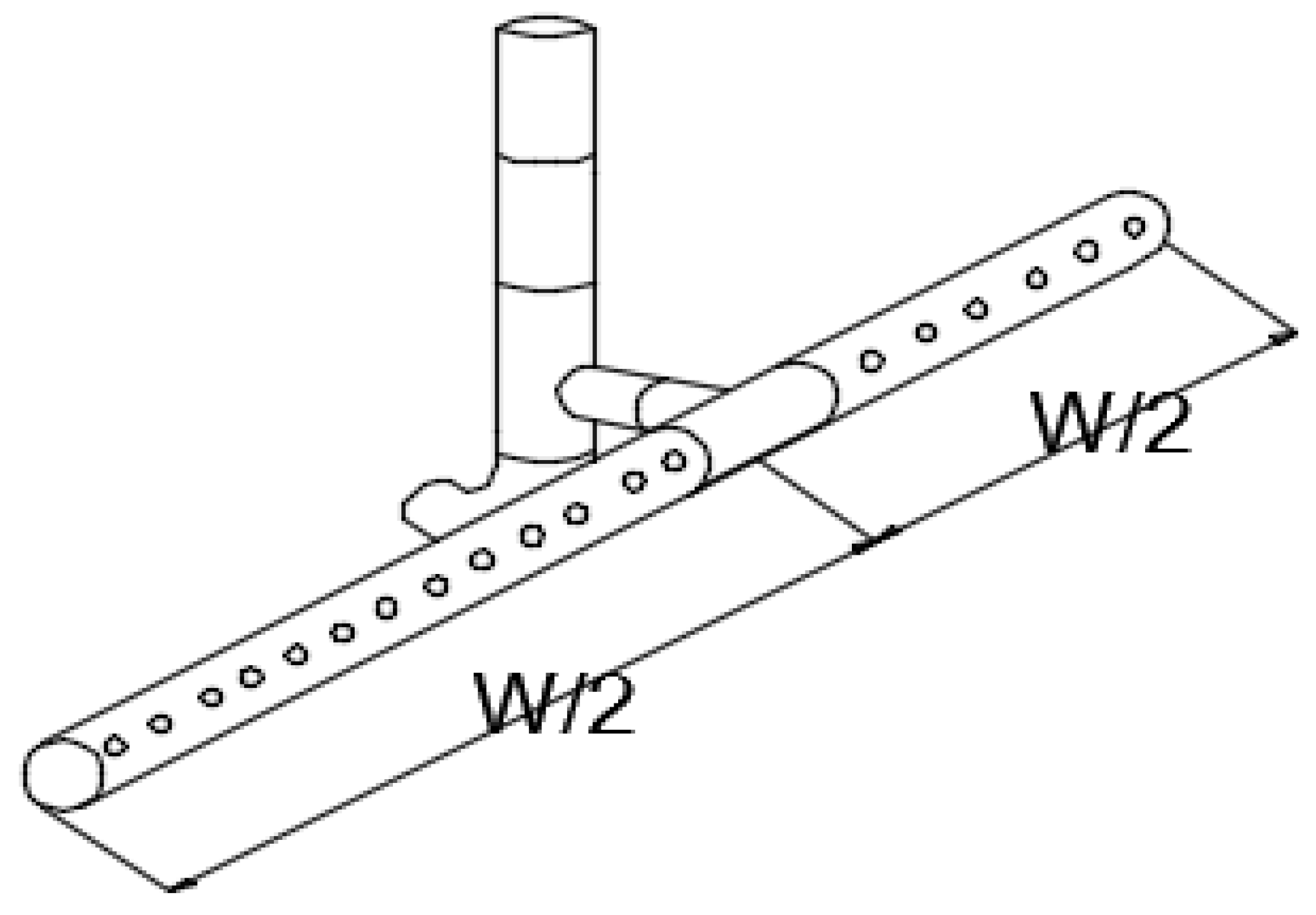

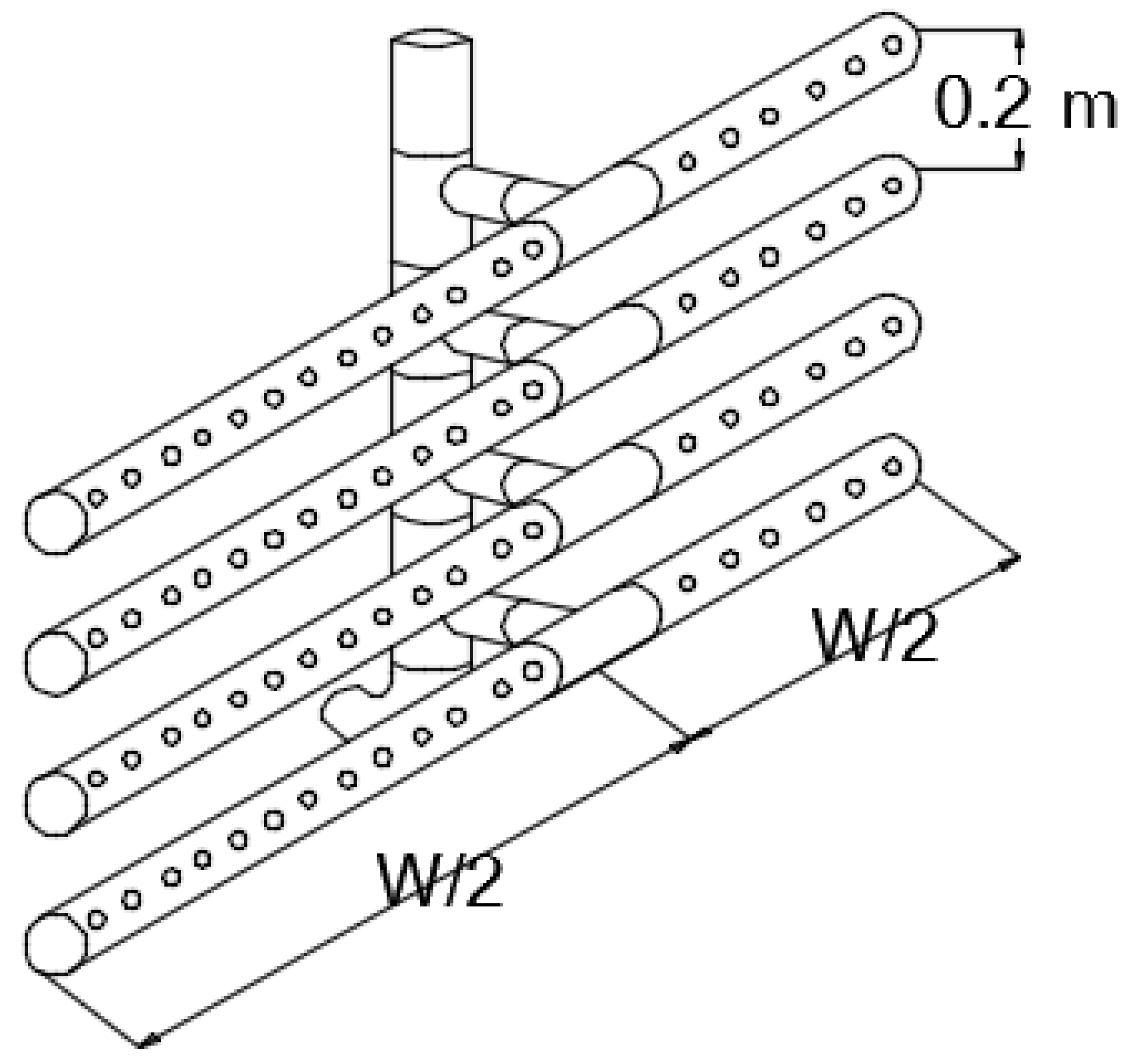

Description of the Innovative Device

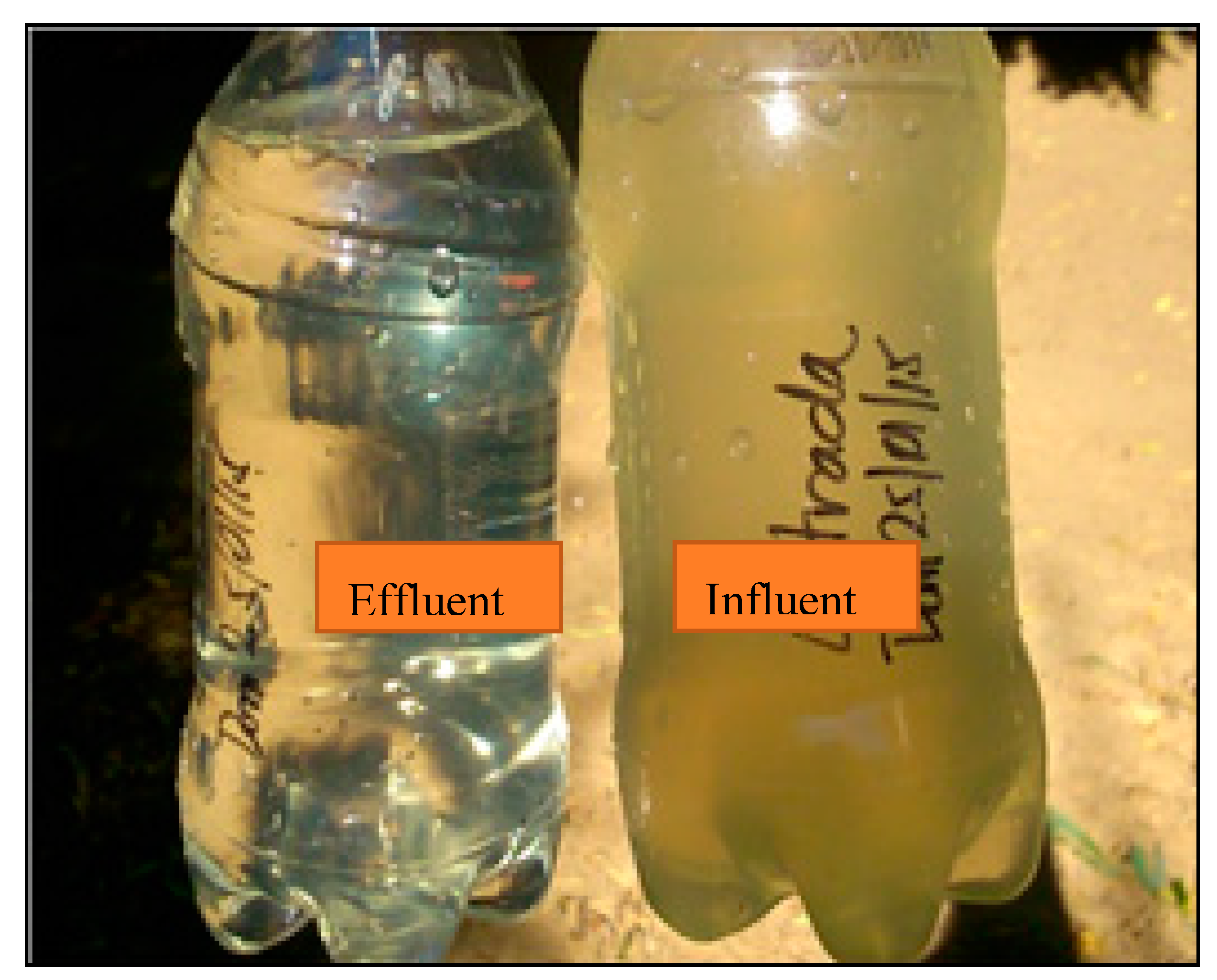

2.2.3. Sampling and Operation of the Constructed Wetland

3. Results and Discussion

3.1. COD Concentration–Saccharose Relationships

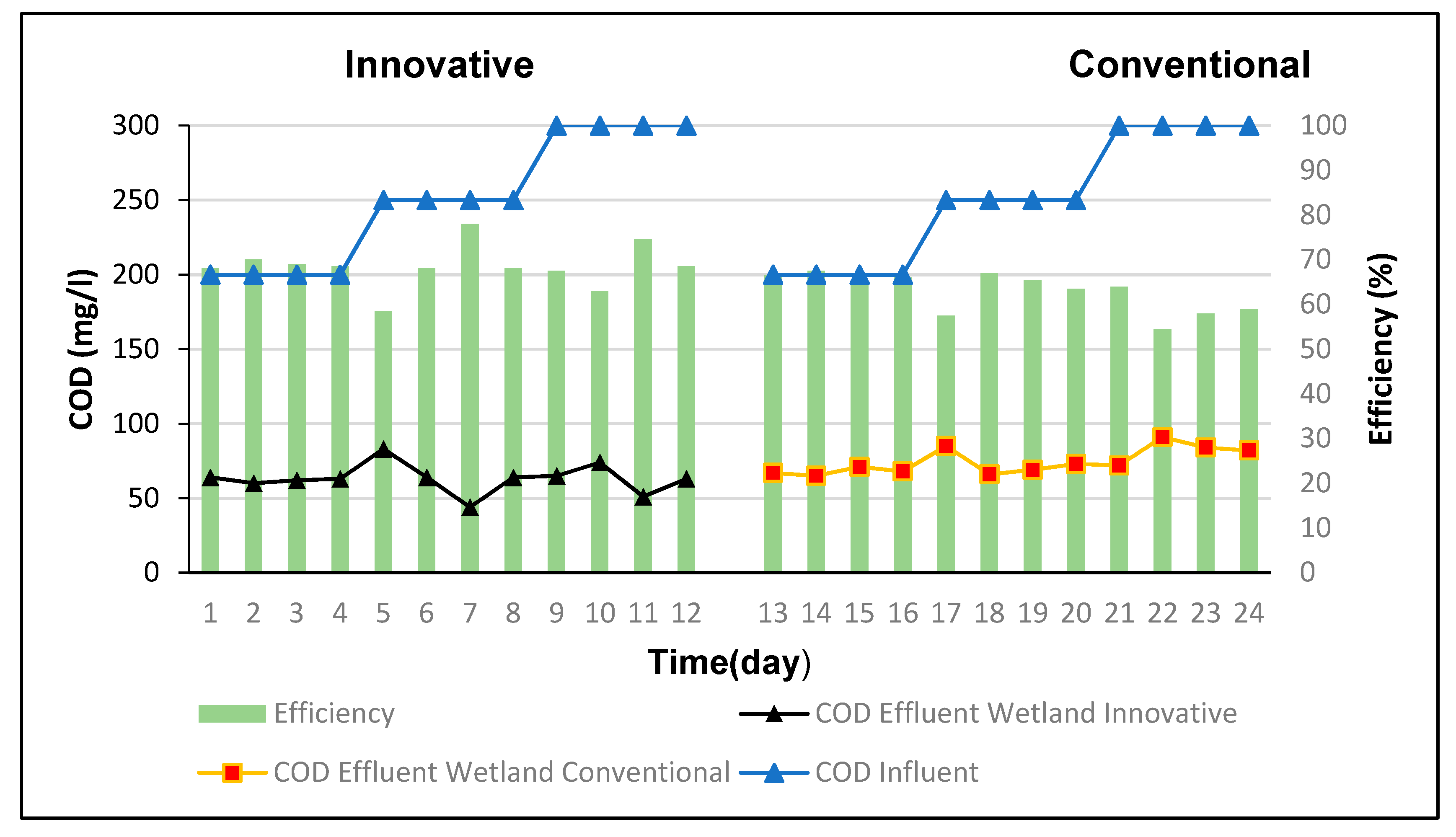

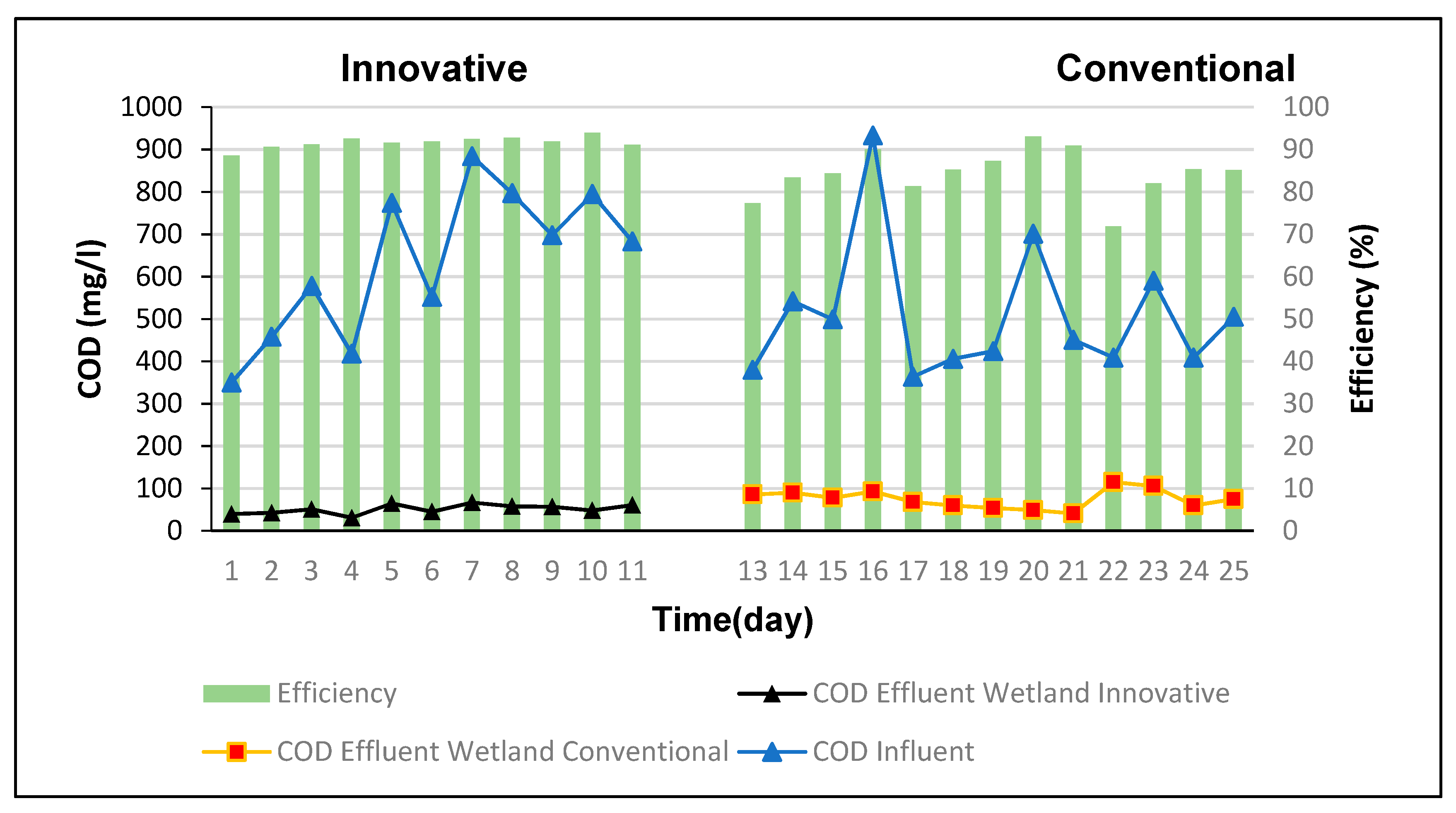

3.2. COD Concentration of the Artificial Wetland

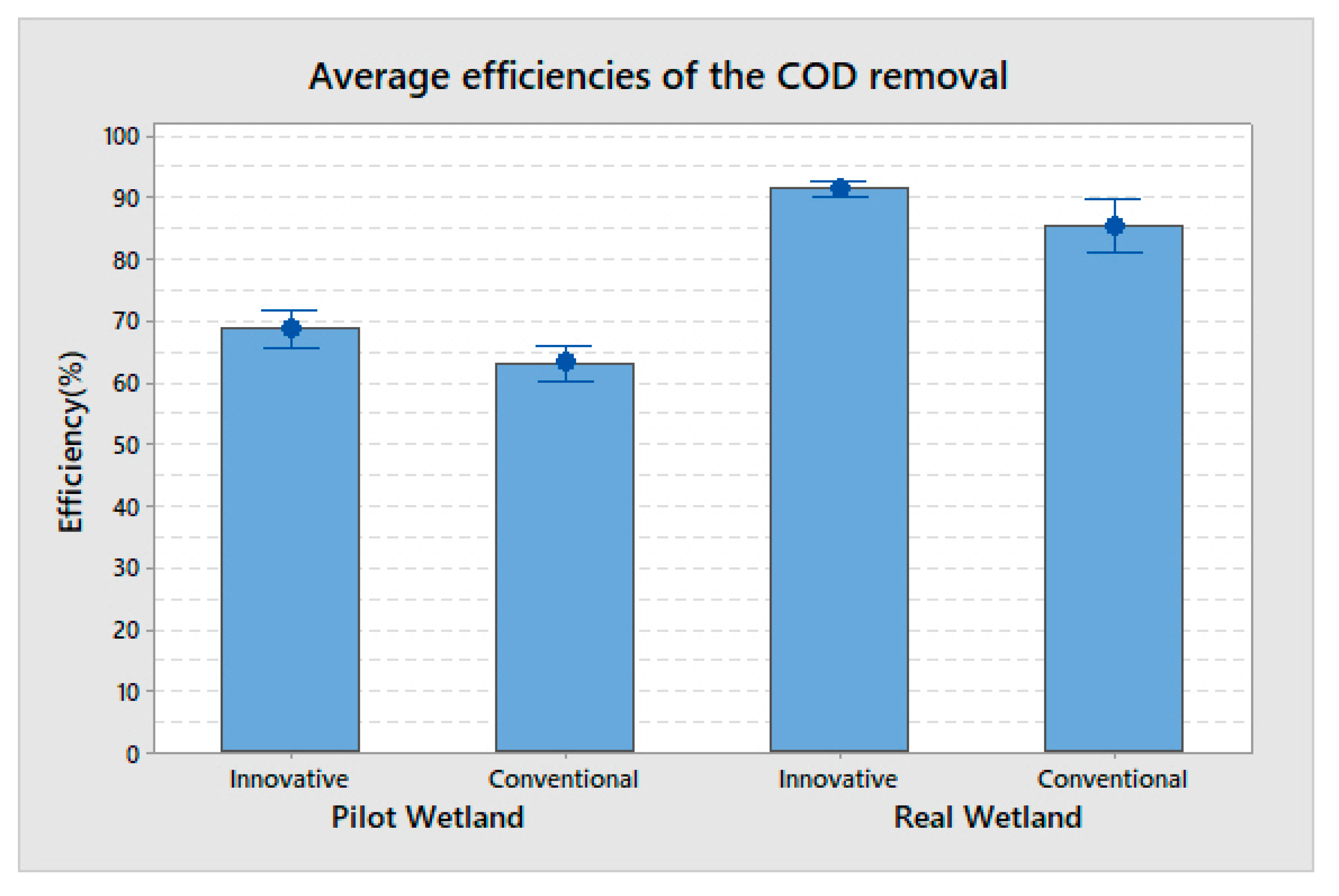

3.3. Average Efficiencies of the Removal of COD in the Wetland with Both Devices.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rodríguez-Monroy, J.Y.; Durán de Bazúa, C. Remoción de nitrógeno en un sistema de tratamiento de aguas residuales usando humedales artificiales de flujo vertical a escala de banco. Tecnol. Cienc. Educ. 2006, 21, 25–33. [Google Scholar]

- Ramalho, R.S. Tratamiento de Aguas Residuales, 1st ed.; Editorial Reverte S.A.: Barcelona, Spain, 2003. [Google Scholar]

- Saeed, T.; Sun, G. A review on nitrogen and organics removal mechanisms in subsurface flow constructed wetlands: Dependency on environmental parameters, operating conditions and supporting media. J. Environ. Manag. 2012, 112, 429–448. [Google Scholar] [CrossRef] [PubMed]

- Seoánez Calvo, M. Tratado de Gestión del Medio Ambiente Urbano: Colección Ingeniería del Medio Ambiente; Editorial Mundi-Prensa Libros: Madrid, Spain, 2001; ISBN 9788471149596. [Google Scholar]

- Lamchaturapatr, J.; Yi, S.W.; Rhee, J.S. Nutrient removals by 21 aquatic plants for vertical free surface-flow (VFS) constructed wetland. Ecol. Eng. 2007, 29, 287–293. [Google Scholar] [CrossRef]

- Persson, J.; Somes, N.L.G.; Wong, T.H.F. Hydraulics Efficiency of constructed Wetlands and ponds. Water Sci. Technol. 1999, 40, 291–300. [Google Scholar] [CrossRef]

- Lara, J. Depuración de Aguas Residuales Municipales con Humedales Artificiales. Master’s Thesis, Master en Ingenieria y Gestion Ambiental, Universidad Politécnica, Instituto Catalán de Tecnología, Barcelona, Spain, 1999. [Google Scholar]

- García, J.; Morató, J. Depuración con Sistemas Naturales: Humedales Construidos. In IV Congreso Iberico de Planificacion y Gestion del Agua, Sección de Ingeniería Sanitaria y Ambiental; Departamento de Ingeniería, Marítima y Ambiental, Universidad Politécnica de Catalunya: Barcelona, Spain, 2004. [Google Scholar]

- Ardila, A.N. Remoción fotocatalítica de DQO, DBO5 y COT de efluentes de la industria farmacéutica. Rev. Politéc. 2012, 15, 9–17. [Google Scholar]

- Vymazal, J. Horizontal sub-surface flow and hybrid constructed wetlands systems for wastewater treatment. Ecol. Eng. 2005, 25, 478–490. [Google Scholar] [CrossRef]

- Brix, H. Macrophyte-mediated oxygen transfer in wetlands: Transport mechanisms and rates. In Constructed Wetlands for Water Quality Improvement; CRC Press: Boca Raton, FL, USA, 1993; pp. 391–398. [Google Scholar]

- Lahora, A. Depuración de Aguas Residuales Mediante Humedales Artificiales: La EDAR de los Gallardos (Almeria); Gestión de Aguas del Levante Almeriense: Almeria, Spain, 2001. [Google Scholar]

- Garcia, J.; Corzo, A. Guía Práctica de Diseño, Construcción, y Explotación de Sistemas de Humedales de Flujo Subsuperficial; Departamento de Ingenieria Hidraulica Maritima y Ambiental de la Universidad Politecnica de Catalunya: Catalunya, Spain, 2008. [Google Scholar]

- Pérez, M. Análisis del Establecimiento de Typha y Phragmites en Humedales Artificiales de Flujo Superficial y Subsuperficial; Title Project Agricultural Civil Engineering; Universidad de Concepción: Concepción, Chile, 2010. [Google Scholar]

- EPA. Constructed Wetlands Treatment of Municipal Wastewaters; Environmental Protection Agency EPA/625/R-99/010; United States Environmental Protection Agency: Washington, DC, USA, 2000. [Google Scholar]

- Delgadillo, O.; Camacho, A.; Pérez, L.; Andrade, M. Depuración de Aguas Residuales por Medio de Humedales Artificiales; Centro Andino Para la Gestión y Uso del Agua: Cochabamba Bolivia, 2010. [Google Scholar]

- Steiner, G.R.; Watson, J.T.; Choate, K.D. General design, construction, and. operation guidelines for small constructed wetlands wastewater treatment systems. In Constructed Wetlands for Water Quality Improvement; Moshiri, G.A., Ed.; Lewis: Boca Raton, FL, USA, 1993; pp. 203–217. [Google Scholar]

- Kadlec, R.H.; Knight, R.L. Treatment Wetlands; CRC Press: Boca Raton, FL, USA, 1996; 893p. [Google Scholar]

- Reed, S.C.; Crites, R.W.; Middlebrooks, E.J. Natural Systems for Waste Management and Treatment, 2nd ed.; McGraw-Hill: New York, NY, USA, 1995. [Google Scholar]

- Rodriguez, D.; Giácoman, G.; Champagne, P. Assessment of the plug flow and dead volume ratios in a sub-surface horizontal-flow packed-bed reactor as a representative model of a sub-surface horizontal constructed wetland. Ecol. Eng. 2012, 40, 18–26. [Google Scholar]

- Sulimana, F.; Frenchb, H.; Haugenc, L.; Søvikb, A. Change in flow and transport patterns in horizontal subsurface flow constructed wetlands as a result of biological growth. Ecol. Eng. 2006, 27, 124–133. [Google Scholar] [CrossRef]

- Birkigta, J.; Stumppb, C.; Małoszewskibc, P.; Nijenhuisa, I. Evaluation of the hydrological flow paths in a gravel bed filter modeling a horizontal subsurface flow wetland by using a multi-tracer experiment. Sci. Total Environ. 2018, 621, 265–272. [Google Scholar] [CrossRef] [PubMed]

- Okhravi, S.; Eslamian, S.; Fathianpou, N. Assessing the effects of flow distribution on the internal hydraulic behavior of a constructed horizontal subsurface flow wetland using a numerical model and a tracer study. Ecohydrol. Hydrobiol. 2017, 17, 264–273. [Google Scholar] [CrossRef]

- Suliman, F.; Futsaether, C.; Oxaal, U.; Hauge, L. Effect of the inlet–outlet positions on the hydraulic performance of horizontal subsurface-flow wetlands constructed with heterogeneous porous media. J. Contam. Hydrol. 2006, 87, 22–36. [Google Scholar] [CrossRef] [PubMed]

- Crespi, M.; Huertas, J. Determinación simplificada de la demanda química de oxígeno por el método del dicromato. Tecnol. Cienc. Agua 1984, 13, 35–40. [Google Scholar]

- Water Environment Federation. Design of Municipal Wastewater Treatment Plants. In Manual of Practice No.8 and ASCE Manual and Report on Engineering Practice No.76; Book Press, Inc.: Brattleboro, Vermont, 1992; Volume 2. [Google Scholar]

- National Institute of Industrial Property, INAPI, Chile. Available online: https://www.inapi.cl/ (accessed on 1 March 2018).

- Henze, M.; Harremoes, P.; Jansen, J.C.; Arvin, E. Wastewater Treatment, Biological and Chemical Processes; Springer: Berlin, Germany, 1995. [Google Scholar]

- Marecos do Monte, H.; Albuquerque, A. Analysis of constructed wetland performance for irrigation reuse. Water Sci. Technol. 2010, 61, 1699–1705. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fountoulakis, M.; Daskalakis, G.; Papadaki, A.; Kalogerakis, N.; Manios, T. Use of halophytes in pilot-scale horizontal flow constructed wetland treating domestic wastewater. Environ. Sci. Pollut. Res. 2017, 24, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Romero, M.; Colín, A.; Sánchez, E.; Ortiz, L. Wastewater treatment by an artificial wetlands pilot system: Evaluation of the organic charge removal. Rev. Int. Contam. Ambient. 2009, 25, 157–167. [Google Scholar]

- Hernández, D.; Ramos, N.; Castillo, J.; Orduña, J. Efficiency assessment of sub-surface flow wetlands using Stipa ichu for treatment of domestic wastewater. Ingenium 2015, 9, 47–59. [Google Scholar] [CrossRef]

- Kamble, S.; Chakravarthy, Y.; Singh, A.; Chubilleau, C.; Starkl, M.; Bawa, I. A soil biotechnology system for wastewater treatment: Technical, hygiene, environmental LCA and economic aspects. Environ. Sci. Pollut. Res. 2017, 24, 13315–13334. [Google Scholar] [CrossRef] [PubMed]

- Bakhshoodeh, R.; Alavi, N.; Majlesi, M.; Paydary, P. Compost leachate treatment by a pilot-scale subsurface horizontal flow constructed wetland. Ecol. Eng. 2017, 105, 7–14. [Google Scholar] [CrossRef]

- He, H.; Duan, Z.; Wang, Z.; Yue, B. The removal efficiency of constructed wetlands filled with the zeolite-slag hybrid substrate for the rural landfill leachate treatment. Environ. Sci. Pollut. Res. 2017, 24, 17547–17555. [Google Scholar] [CrossRef] [PubMed]

- Salazar, R.; Chinchilla, C.; Marín, J.; Pérez, J. Evaluación del funcionamiento de un sistema alternativo de humedales artificiales para el tratamiento de aguas residuales. Uniciencia 2013, 27, 332–340. [Google Scholar]

| Co | Concentration of BOD in influent, mg/L |

| Ce | Concentration of BOD in effluent, mg/L |

| HRT | Hydraulic residence time, day |

| AS | Surface area of the wetland, m2 |

| N | Porosity of the wetland |

| Y | Depth of water in the wetland, m |

| Q | Average flow rate of the wetland, m3/day |

| V | Volume of the wetland, m3 |

| Constant dependent on temperature, | |

| T | Day |

| Parameter | Symbol | Pilot Wetland Characteristics | Real Wetland Characteristics |

|---|---|---|---|

| Flow (m3/day) | Q | 0.2 | 48 |

| Length (m) | L | 2 | 45 |

| Width (m) | W | 0.6 | 13 |

| Length/width ratio | L/W | 3.33 | 3.46 |

| Depth (m) | Y | 0.55 | 0.6 |

| Porosity Dry gravel (%) | N | 0.42 | 0.38 |

| Slope (m/m) | S | 0.002 | 0.005 |

| Surface Area (m2) | As | 1.2 | 585 |

| Transverse Area (m2) | Ac | 0.033 | 7.8 |

| Temperature media (°C) Hydraulic Residence Time (day) | T HRT | 19 1.2 | 23 2.8 |

| Vegetation | Typha | Typha |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cisterna-Osorio, P.; Lazcano-Castro, V.; Silva-Vasquez, G.; Llanos-Baeza, M.; Fuentes-Ortega, I. Innovative Effluent Capture and Evacuation Device that Increases COD Removal Efficiency in Subsurface Flow Wetlands. Processes 2019, 7, 418. https://doi.org/10.3390/pr7070418

Cisterna-Osorio P, Lazcano-Castro V, Silva-Vasquez G, Llanos-Baeza M, Fuentes-Ortega I. Innovative Effluent Capture and Evacuation Device that Increases COD Removal Efficiency in Subsurface Flow Wetlands. Processes. 2019; 7(7):418. https://doi.org/10.3390/pr7070418

Chicago/Turabian StyleCisterna-Osorio, Pedro, Verónica Lazcano-Castro, Gisela Silva-Vasquez, Mauricio Llanos-Baeza, and Ignacio Fuentes-Ortega. 2019. "Innovative Effluent Capture and Evacuation Device that Increases COD Removal Efficiency in Subsurface Flow Wetlands" Processes 7, no. 7: 418. https://doi.org/10.3390/pr7070418

APA StyleCisterna-Osorio, P., Lazcano-Castro, V., Silva-Vasquez, G., Llanos-Baeza, M., & Fuentes-Ortega, I. (2019). Innovative Effluent Capture and Evacuation Device that Increases COD Removal Efficiency in Subsurface Flow Wetlands. Processes, 7(7), 418. https://doi.org/10.3390/pr7070418