Abstract

Intelligent data analytics-based cloud computing is a leading trend for managing a large-scale network in contemporary manufacturing environments. The data and information are shared using the cloud environments and valuable knowledge is driven using the embedded intelligence analytics. This research applied this trend to the control of a key supplier’s real-time production planning for solving joint production goals with downstream producers. As a key supplier has several downstream producers in general, several uncertainties are embedded on the supply chain network such as the quality issue in the supplier and the occurrence of unexpected orders from the downstream industries. While the control of a supply plan is difficult considering these dynamics in traditional frameworks, the proposed framework detects the dynamic changes accurately using the constructed cloud system. Moreover, the real-time control considering uncertain scenarios as well as the extracted knowledge is achieved using the provided Industrial Internet of Things (IIoT) and simulation-based control model using stochastic network. To show the effective of the suggested framework, real manufacturing cases and their numerical analyses are provided.

1. Introduction

The development of Information and Communication Technologies (ICT) has changed many aspects of production and supply chain environments. Cloud system and intelligent data analytics are the leading technologies among them [1]. Many globalized companies and organizations equip these technologies and the relevant systems to maximize the advantages of the environments. This tendency is resulted from the fact that more valuable knowledge can be extracted from the collected data in a cloud sever. Many researchers, e.g. Chen et al. [2], Hu et al. [3] and Abdollahi et al. [4], provided in-depth reviews of the cloud environment and the relevant big data analytics.

This research focused on the dynamic control of a key supplier in a large-scale supply chain network. While a key supplier has the following downstream producers in general, the module manufacturer has a responsibility of satisfying the requirements of the following producers. However, the real-time quality issues from the supplier and the occurrences of unexpected orders from the downstream producers might cause the failures of manufacturing objectives. To manage several dynamic situations effectively, reliable business and manufacturing partners have introduced cloud systems where predefined processing information and data are collected and shared using the relevant Industrial Internet of Things (IIoT). This paper suggests a new and effective dynamic control strategy of a key supplier using IIoT and the constructed cloud system. To connect to the cloud system, an Industrial Internet of Things device is developed. While the processing and quality data are collected using the IIoT device and the cloud environment, the relationship between the processing data as input data and the quality index as output data is reasoned using the embedded data analytics. Moreover, the reasoned rule and several manufacturing scenarios are incorporated into a stochastic network-based control model.

This research provides an effective dynamic control strategy of the key supplier using the proposed stochastic control model and intelligent data analytics-based cloud environment. While other research studies focus on the importance between supplier and producers with conceptual or theoretical frameworks, this research focused on a role of a key supplier with the advancements of information technologies for solving overall production issues jointly.

Section 2 reviews the relevant background and literature. Section 3 provides a cloud computing network architecture with a key supplier and several downstream manufacturers using a real manufacturing example. Section 4 explains the development of the cloud systems and intelligent data analytics for the provided applications. Section 5 elaborates the dynamic process control using the developed cloud system and the simulation-based control model.

2. Background and Literature Reviews

This section elaborates the importance of a key supplier in various manufacturing areas and reviews the relevant extant research studies. Then, to enhance the relationship between a key supplier and manufacturers in downstream, a strategic alliance using cloud environments is introduced.

Several extant researchers including Teller et al. [5] investigated the importance of key supplier relationship for successful supply chain managements. Most including Nair et al. [6] conducted surveys in terms of producers in downstream industries. These trends indicate that the viewpoints and strategies of a key supplier are investigated comparatively less. While joint problem solving and joint planning are some of the effective strategies for enhancing the supplying relationships [7], most executing subjects are not suppliers, but downstream producers. In addition, extant studies investigate the relationship or joint efforts with conceptual scenarios. This research focused on the role of a key supplier for solving joint production issues with real production planning and execution cases.

The extended capabilities and cooperation of a key supplier for joint problem solving result from the developments of the cloud environment and the relevant big data analytics with respect to a supply chain and globalized manufacturing network. The advancements of disruptive technologies leading to the fourth industrial revolution have accelerated innovations in supply chain management (SCM) fields. Aryal et al. [8] showed how IIoT and the relevant big data analytics have contributed to SCM innovations systematically. Muller et al. [9] provided requirements and strategies in supplier integration fields using these technologies. Hofmann and Rusch [10] analyzed the impacts of Industry 4.0 technologies for SCM sequences such as production planning, production order, disposition/production and delivery. In particular, they showed that using cloud computing makes it possible to integrate the relevant data and system.

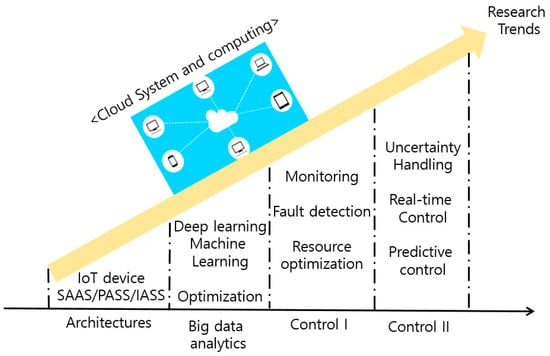

Figure 1 shows contemporary research trends in cloud computing and systems. While the existing cloud systems have been used for sharing data among the associated organizations, their main issues are in how the sharing data can be used for achieving several objectives. The initial relevant research studies examine the issues with the detailed architectures and their implementations. Then, cloud environments combine several analytics tools and intelligent methods. These tendencies indicate that the reasoning process and knowledge extraction are important prerequisite tasks for successful utilization of the constructed cloud system. Ikram et al. [11] used a neural network for analyzing big data on a cloud platform. Many machine learning-based analytical methods including Support Vector Machine (SVM) [12] and several heuristic algorithms [13,14,15] are applied for reasoning knowledge as well as for managing domain-specific tasks for cloud systems. Then, the contemporary cloud system has been evolved with the integration with deep learning methods. Zhang et al. [16] used a Canonical Polyadic Decomposition (CPD)-based deep learning model for predicting workloads in a cloud system. Roopaei et al. [17] applied deep learning methods for managing large-scale cloud systems. These analytics are considered as big data analytics, as the data size in the cloud system is huge and its operational time is endless.

Figure 1.

Research trends in the areas of cloud computing and systems.

The extracted knowledge from the cloud system are used for various applications. One of the popular applications is the fault detection in a large-scale manufacturing environments. Gao and Zhu [18] applied cloud computing to detect faults in data transmissions and Lee [1] used a cloud system for clarifying manufacturing faults in multi-sites production environments. They considered a large-scale manufacturing network with several dynamic changes. For instance, the functional breakdown of a node or the changes of linking information among nodes belong to the dynamic changes. The cloud system makes it possible to gather data from the network components and the accurate and fast detections are achieved using several big data analytics. Many researchers including Kasemsap and Sunandha [19] provided similar works where cloud system and analytics are applied to the management of global supply chains. However, these research studies are limited in the fact that the controls, considering various uncertainties embedding in a large-scale supply chain network, are examined comparatively less. To overcome this issue, this paper proposes the cloud system with big data analytics and simulation-based control strategies. While the adopted big data analytics have roles of analyzing hidden knowledge and enhancing its functionalities, the simulation-based control makes it possible to check various possible production scenarios. These checks contribute to the more reasonable decision making with the consideration of the big data in the cloud system.

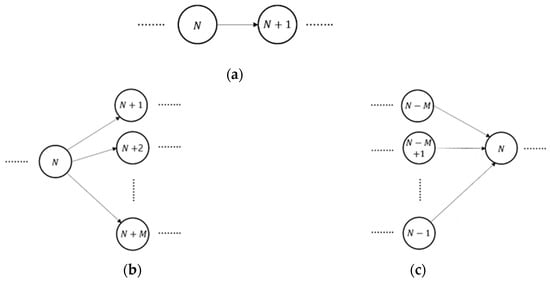

This study belongs to the Control Stage II shown in Figure 1. To manage and control a large-scale supply chain network, this paper uses a stochastic network-based analysis approach. As shown in Figure 2, a large-scaled network is classified into several parts with respect to the connection type: serial linking, split linking and merging linking.

Figure 2.

Several connection patterns among adjacent supply chain nodes: (a) serial linking; (b) split linking; and (c) merging linking.

Each node in a large-scaled network is considered as a supplier, a manufacturer or a logistics with supply chain/manufacturing/procurement concepts. The data transmission and information sharing are achieved using a cloud system. Then, domain-specific knowledge is extracted using the installed big data analyzers. Finally, an efficient network control is achieved using the reasoned knowledge considering uncertainties with a simulation-based optimization methods. The detailed frameworks and applications are provided in the following sections.

To show the effectiveness of the proposed framework, several process Key Performance Indices (KPIs) such as cycle time (CT), Work-in Process (WIP), and throughput (TH) are introduced and measured. Curry and Feldman [20] analyzed several key performance indices (e.g., cycle time, throughput and work-in-progress) using stochastic network approaches. Lee [1] applied this analytical method to the analyses of manufacturing processes that are connected to cloud environments. This research used these KPIs for measuring the performances of the proposed framework.

3. Cloud Network with a Key Supplier in Automotive Industry

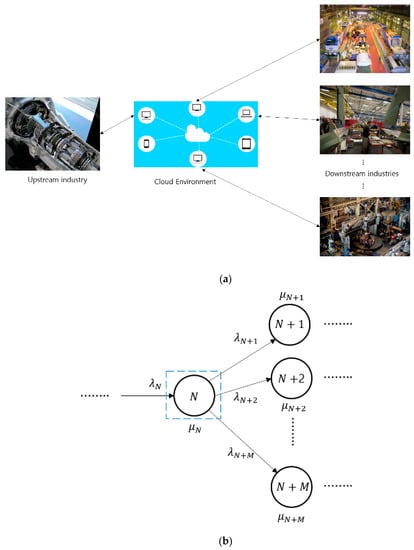

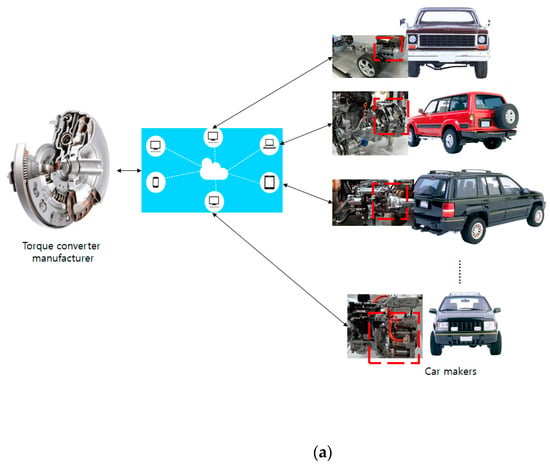

This section elaborates on a new and efficient framework covering overall supply chains. According to Zhou, Li and Weijnen [21], contemporary manufacturing environments and their processes can be represented as a large-scale network with various type of uncertainties. For this reason, their real-time monitoring and the relevant analyses have received considerable emphases. These trends are reflected on an inevitable usages of cloud systems. Many research studies [2,3,4,5,6,22] have collected manufacturing data in real time using a cloud system and several related supporting frameworks (e.g., IoT device, communication protocols and other embedded system framework). The gathered production data are analyzed for the better production controls. However, their analyses and controls are executed under the assumption that the nodes in the large-scale network belong to a single global/multinational company or can be guided comparatively easily with unified objectives. Researchers including Lee [1] assumed similar situations. While using cloud environments helps the efficient control of overall network, they are difficult to use in a network consisting of nodes under different ownerships and authentications. This paper provides a new and efficient control strategy of a cloud computing environment which consists of different users, ownerships and authentications. Figure 3a shows a part of a network topology connection using of a cloud environment. As shown in Figure 3a, the first node can be interpreted as an upstream industry (a key supplier) in terms of globalized supply chains. Then, the other nodes indicate several downstream industries. When the efficienct control of this network is attempted, traditional control approaches focus on the latter nodes. This results mainly because a general supply chain is operated for customers who are close to the downstream industries. In addition, it is assumed that the upstream industry can be guided comparatively easily.

Figure 3.

A cloud topology and information flow of an upstream supplier with multiple downstream industries: (a) cloud topology of an upstream industry with multiple producers; and (b) input and service flow in the topology.

However, this research aimed at the control of a large-scale network where each node has different ownership and authentications. Several researchers including Chunha et al. [23] stated that cloud computing and its environments enhance the independence of network elements due to the transparency of the information and relevant data. This paper focuses on the control of an independent node (a key supplier) using cloud computing. As shown in Figure 3a, each node has an objective and the relevant strategies. Thus, it is difficult to control all nodes with a unified objective. This issue occurs more frequently in a cloud environment connecting multiple sites and different companies. To overcome this issue, this paper proposes a new and effective control strategy of a node. The node attempts to achieve its objectives as well as to consider the requirements of the following downstream industries. As shown in Figure 3b, node N is considered a key supplier with its strategy. It is connected to a cloud environment where a predefined type of information and data are shared among the network elements. Then, its desirable strategy is proposed considering the dynamic requirements of the other nodes.

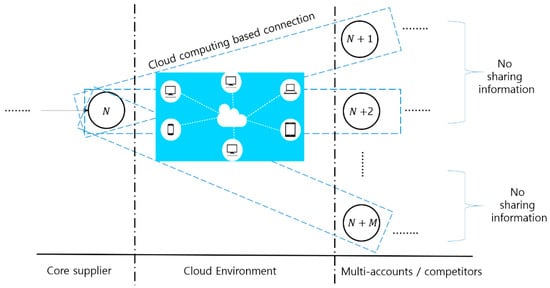

While this pattern might appear in many applications, this research considers a manufacturer (Node N in Figure 3b) which produces a key component and supplies it to the following accounts (e.g., Node N+1, N+2, …, N+M). Each producer is considered a competitor with each other producer. It implies that each producer is only connected with node N using the cloud environment. Figure 4 shows the connection relations among these nodes.

Figure 4.

The connection relations among an upstream industry and its producers.

The supplier/manufacturer’s (Node N in Figure 4) responsibility is to produce the core components and to supply it to the following producers. Table 1 provides the sharing information using the constructed cloud sever between a core supplier and each account. In general, a downstream producer knows the detailed processes and capabilities of a key supplier. As a seamless and stable supply is required for the successful production in the following account, the producer investigates candidate suppliers for selecting a best partner. The information provided in Table 1 can be shared with this relationship.

Table 1.

Connection information in a cloud computing environment.

Data sharing is achieved only with a mutual contract between a core supplier and each downstream producer. The range and the items of sharing data might be different with the cooperation level and supply priorities between both the supplier and manufacturers.

To provide an explicit example with the mentioned architecture, a part of supply chain network producing a key component in automotive manufacturing industries is supposed. A general vehicle is manufactured using several key components. A torque converter [13] is one of main components in a car. A torque converter is a key module of a powertrain system in a car. While a powertrain has roles of delivering torque of engine to the four driving wheels, a torque converter controls torque power precisely using fluid coupling mechanisms. The manufacturing of high-quality torque converter and its supplies influence heavily on the accurate car control. While most car makers produce several powertrain modules and their vehicles in their own manufacturing facilities, the torque converter modules are supplied in general. The mold-based processes and irregular specifications result in the supply of the torque converter modules. As the qualities of the module is important for accurate vehicle controls, the fine torque converter manufacturer is considered as an important manufacturing partner for a successful vehicle industry. For this reason, several car producers have contracted with the best torque converter manufacturer. Then, the cloud computing and its environment is constructed for managing a real-time processes and qualities.

Figure 5a shows a cloud computing environment among a torque converter manufacturer and vehicle producers.

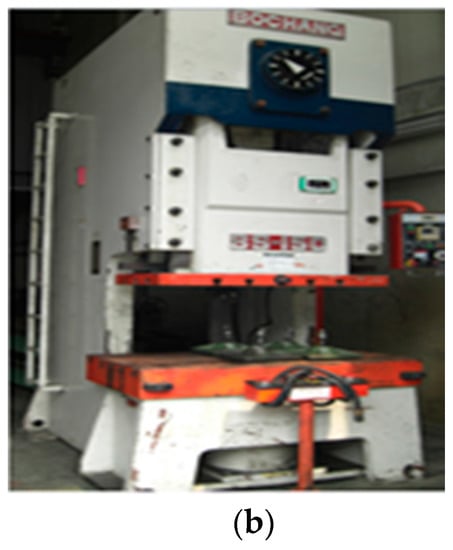

Figure 5.

A part of supply chain for torque converter modules and a manufacturing machine: (a) cloud environment among a supplier and car manufacturers; and (b) a torque converter manufacturing machine.

In general, the producer (downstream manufacturer) takes charge in the overall quality of the final product. However, the quality related analysis data for supplied parts are scarce from the remoted site information. Thus, a producer has a key alliance and partnership with a key supplier for sharing quality-based data and processing data in a predefined specific workstation. To share processes and quality data under a certain cooperative contract, several IoT devices are developed and installed on several manufacturing machines. Figure 5b shows a machine for producing a pump impeller which is a part of a torque converter. As several torque converter modules have different specifications for different vehicles and these have irregular patterns from the characteristics of fluid mechanism, the manufacturing processes might cause several quality issues, such as dimensional tolerance errors, outside/inside cracks or the module breakages. Even though a torque converter manufacturer checks these issues carefully, several defects are transferred to the following car manufacturers. As the vehicle assembler checks the quality of module comparatively less, the detection of defects might be ignored, thus this issue leads to the production of a vehicle with bad quality. The supplier analyzed those quality issues and found that most of the issues are resulted from the inappropriate posture of the mold and the wear of the machine parts.

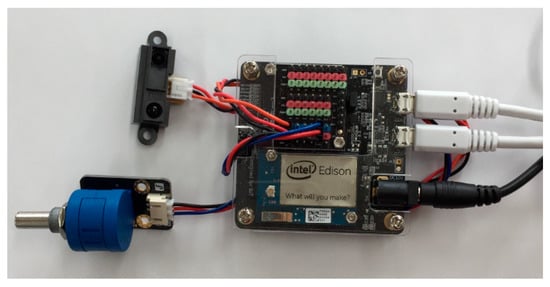

To detect those issues and prevent this situation, an IoT device was developed. In addition, the process monitoring and the relevant information sharing were achieved using the developed IoT device and the cloud environment. Figure 6 shows a developed IoT device.

Figure 6.

The developed IoT device for gathering process and quality data.

Table 2 provides the detailed specifications of the developed IoT device. The dimensional tolerances are detected using the embedded proximity sensors and it is attached on the processing machine shown in Figure 5b.

Table 2.

Embedded system architecture of the developed IoT device.

The IoT device detects the manufacturing status and sends it to the cloud environment. In addition, the synchronized process data are extracted from the manufacturing execution system (MES) in the factory and transmitted to the server. The following producer, a car assembler, shares these data and uses them to establish the process plan in real-time. Moreover, the constructed cloud system makes it possible not only to communicate from the supplier to a car maker, but also to communicate from the following car manufacturer to the module producer. For instance, it is difficult to catch unexpected orders in the module manufacturer using traditional systems. The delayed dissemination may disturb operating the production more quickly and result in the ineffective performance in terms of overall supply chain network. The cloud environment and its computing prevent these issues and contribute to effective and predictive control of the overall supply chain network. The following section elaborates on the cloud computing and its big data analytics.

4. Development of Intelligent Data Analytics-Based Cloud Computing System

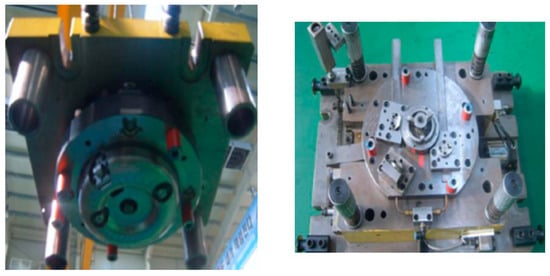

As provided in the previous section, the main quality issues result from the problems in the press injection machine. Figure 7 shows an upper part and a lower part of the press injection mold module in the machine. Its wear, wrong setup and oscillations cause the main defects of the torque converter module.

Figure 7.

The upper and lower parts in the press injection module.

To check its processing status in real-time, the IoT device shown in Figure 6 is embedded on the machine. As provided in Table 2, it has a Wi-Fi chip supporting IEEE 802.11n-based MQTT protocol [24]. The real-time sensor signals are transmitted to the constructed cloud sever. This research used Ubidots © platform [25] as a cloud sever. Several research studies [26,27] use the platform for sharing data using a cloud environment. Table 3 shows the collected and shared data using the cloud system.

Table 3.

Shared data specification in a cloud server.

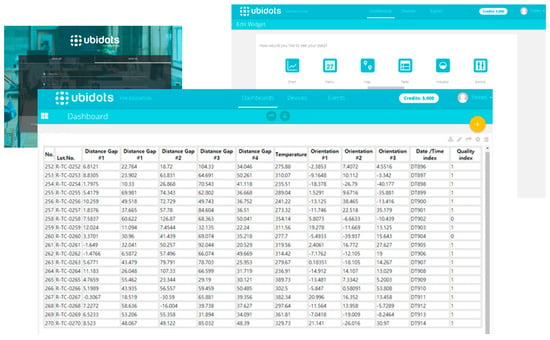

Figure 8 shows the collected data in the customized Ubidots© severs.

Figure 8.

The collected and shared data using the cloud sever.

Then, the data are analyzed using ECMiner © [28]—a commercial big data analytics engine. The data in the cloud server are transmitted to an analytical sever with a fixed planning time horizon. Then, the data are analyzed using various embedded statistical inference and intelligence engines.

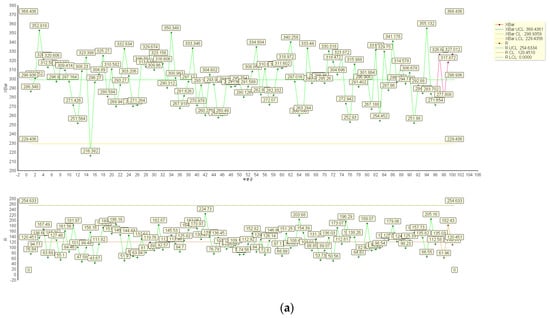

Figure 9a shows a generated control chart (-R control chart) of mold temperature data obtained using the installed temperature sensor. Figure 9b shows a matrix chart for depicting three mold setup orientations and the quality index where “1” indicates the product with accepted quality and “0” the module below the controlled quality. These data analyses are used for clarifying the correlations and dependencies among each signal type.

Figure 9.

Control charts and Data classification using big data analytics: (a) control charts; and (b) data classification using Matrix chart.

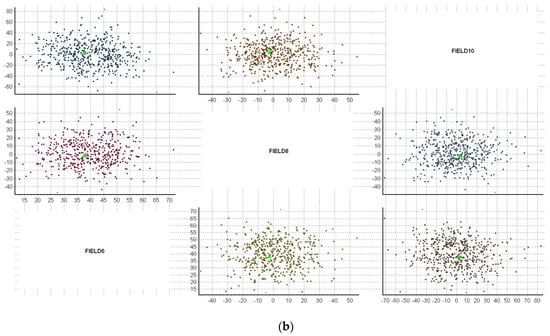

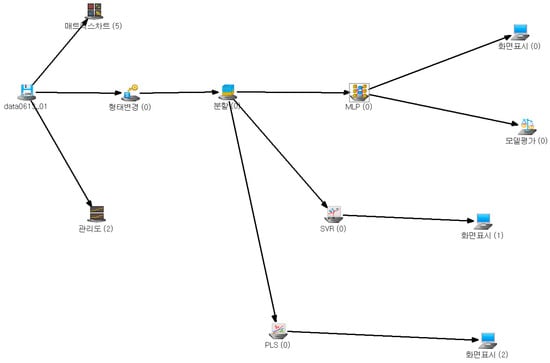

After reasoning the relationships among each input data, the mapping between gathered processes data and quality indices is analyzed. Figure 10 shows an ECMiner© model accomplishing the reasoning process between the input variables (ten types of data) and the output data (the quality index).

Figure 10.

Reasoning model between process data and quality indices using big data analytics.

This research applied three methods for analyzing the reasoning and for comparing those results: Multi-Layer Perceptron (MLP)-based Deep learning model (MLP-DL), Support Vector Regression model (SVR) and Partial Least Square method (PLS). PLM method projects the input and output data into the less dimensional space using Equation (1)

where and

As provided in Equation (1), X is the input data matrix and Y indicates the quality index data where the data sizes were “11 × the number of analyzing dataset (= N)” and “1 × N” in this research. Then, the data dimension is reduced to the latent variable space using P and Q. The detailed parameters are provided in Table 4. SVR combines Support Vector Machine (SVM) and regression analyses. This research used ϵ-SVR model [29] among various SVR models. The detailed parameters in this research are provided in Table 4.

Table 4.

Parameters of three data analytics.

Then, these two methods (SOM and PLS) were compared with a deep learning model: MLP-DL model. The detailed architecture and parameters are given in Table 4. To compare these methods, 70% of data were extracted and used as a training dataset and the remaining data were used for the test dataset. Table 5 shows the prediction accuracy of each model. As shown in Table 5, the MLP-DL model showed the best prediction performance among three predictive models. This result indicates that the trained mechanism using the cloud sever and big data analytics contributes to predict the quality of the key module in real-time. This real-time prediction helped control the current process plan. The following section shows how the process was controlled effectively using the proposed simulation-based control model.

Table 5.

Prediction accuracy using the test data.

5. Dynamic Process Control Using Cloud Computing and Simulation-Based Analytics

The data in the constructed cloud server were shared and analyzed using the previous analytics methods. In particular, the usage of MLP-DL method helped the reasoning between the process data and the quality data. It indicates that it is possible to predict current quality level with the real-time processing data in a supplier. As the supplier is in charge of the production of the key module for the following producers, the information is critical for achieving the manufacturing objectives in the downstream industries. This section elaborates on how the shared data and reasoned knowledge can be utilized for executing overall process plans dynamically. As shown in Figure 3b, the supplier and each downstream industry are represented with the Node N and the Node N+i , respectively. Then, each node’s (e.g., Node N) input rate () and service rate () are shared using the cloud server under the mutual contract. is estimated with the consideration of the number () of servers in the node. The manufacturing utilization in Node N is calculated using Equation (2).

Then, the overall cycle time of Node N is estimated using G/G/C-based [13] stochastic queue analysis. Equation (3) shows the estimated cycle time () of the supplier in normal conditions.

where is the coefficient of variable of arrival process in Node N and is the coefficient of variable of service process in Node N.

Then, the relationship between and (the input flow of each car manufacture (Node N+i)) is driven with Equation (4).

The arrival coefficient of variance () in Node N+i is calculated using Equation (5) and cycle time () in Node n+i is driven with Equations (3) and (5).

When the overall manufacturing processes are working in a normal condition, it indicates that each is fixed under the predefined orders and the relevant contracts from each car maker. In this condition, overall cycle time (CT) from the supplier to the ith account is calculated with Equation (6).

However, the emergence of quality issues or an occurrence of emergency orders might influence the changes of the parameters in Equations (2), (3) and (5). Then, the changes may result in unexpected bottlenecks and prolonged cycle time. While it is difficult to detect the quality issues or other dynamic situations in traditional systems, the cloud system and its analytical methods overcome the issue, as provided in the previous sections.

When the dynamic changes are detected using the cloud computing analytics, the parameters are estimated using the simulation methods. For instance, the detection of quality issues using the proposed MLP-DL model leads to changes of service and inflow rates with Equations (7) and (8).

where E[MTTR] is the estimated mean time to repair

The newly changed service rate () influences the drop of throughput (), as represented in Equation (8).

These changes generate the delay of the original cycle time (CT). To preserve the overall cycle time in an allowable range, a new strategy controlling new , and is applied using the simulation-based optimization. Similarly, occurrences of emergency in a downstream industry manufacturer are notified to the supplier using the cloud system. To meet the unexpected orders, Equation (9) is required and it increases the level of to .

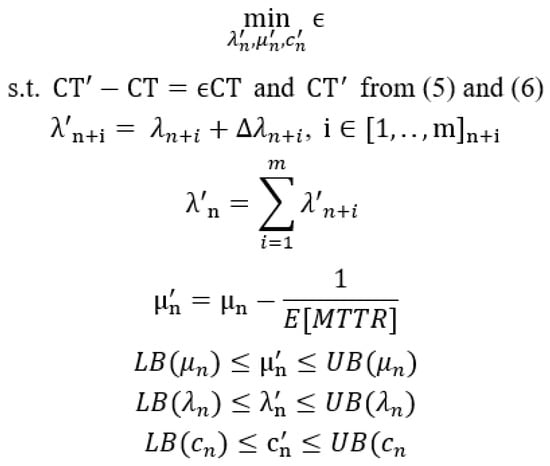

In terms of Node i, a new strategy considering the dynamic environments is driven using the proposed algorithm (Figure 11) where and are the lower bound and the upper bound of , respectively.

Figure 11.

Simulation-based optimization model using the cloud computing analytics.

As each and are formulated with the probabilities driven from the consideration of current status and historical data, the mathematical model belongs to stochastic programming model. To solve the model, L-shaped-based Monte Carlo method [31] is applied and the better control strategy is generated.

To prove the effectiveness of the provided framework, numerical studies were analyzed with various scenarios. Table 6 shows the assumed conditions and scenarios. Scenario 1 is the normally working case and Scenario 2 indicates that MLP-DL machine detects the abnormal status of the injection molding machine. Then, the cloud service gives the warning to the supplier and the subcontractor overhauls the machine with estimated E[MTTF].

Table 6.

Control scenarios and the relevant parameters.

Scenario 3 is the case with unexpected orders from the downstream manufacturers. These emergency orders are caught using the constructed cloud system. In each scenario, it was assumed that the service rates of the downstream manufacturers can be extended with the changes of the production environments. Table 7 shows the results, the comparison with Scenario 2 (the case without the cloud environment), and the comparison with Scenario 3 (the case with the cloud server and the proposed framework).

Table 7.

Comparisons between the cases with/without the cloud environment and the simulation-based optimization framework.

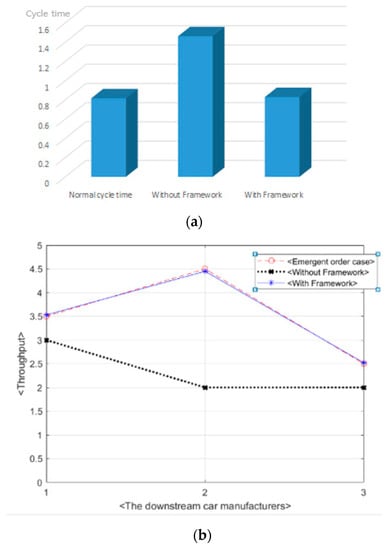

As shown in Table 7, the framework, consisting of the cloud environment, data analytics and the simulation-based control, had the better performance. Scenario 2 supposed that a quality issue occurred in the upstream supplier. However, it was difficult to detect the issue in real-time without the proposed framework. Thus, the machine broke down, resulting in the rise of the cycle time. However, the framework attempted to increase the number of resources () with the detection of the issue in real-time. Then, the cycle time was sustained with a controllable level (Figure 12a).

Figure 12.

The comparisons with Scenarios 2 and 3: (a) comparison of cycle time; and (b) comparison of throughput.

Scenario 3 supposed that the emergent orders are added from the customers. Then, these situations gave rise to the changes of (). The absence of the cloud system might cause difficulties with the information and the supplier tended to execute the existing process plan. As a result, it was difficult to meet the unexpected orders. However, the framework detected the changes and changed and to 10.45 and 12.6, respectively. Then, as shown in Figure 12b, the throughputs in the following downstream producers satisfied the emergent orders.

These numerical studies showed the effectiveness of the cloud systems and the embedded intelligent data analytics. In particular, the framework contributed to the effective dynamic control of a network consisting of a core supplier and several downstream producers.

6. Conclusions and Further Studies

Contemporary manufacturing and production environments have changed with the development of the ICT technologies. In particular, it is possible to control overall large-scale supply chains. Even though there are efficient control strategies for these large-scale supply chains, they are limited as most methods fail to integrate advanced ICT-based technologies and systems. Cloud systems and intelligent data analytics are considered main components among contemporary ICT-based methodologies. Even though the coverage of a supply chain network is huge, it is possible to share the processing data and status using the constructed cloud system in real time. The shared data are reasoned and the hidden control knowledge can be extracted using several big data analytics.

While relevant research studies have suggested several cloud system frameworks and big data analytics, this research applied simulation-based optimization method to the cloud-based data analytics. When production knowledge is extracted using the embedded data analytics, most existing studies focus on the control considering the real-time processing information. However, this research considers several future scenarios as well as real-time situations. These considerations generate a stochastic optimization model, which is driven from the big data analytics and contains several uncertainties. The real-time information and the future scenarios are obtained and reasoned from the constructed cloud system. Then, L-shaped-based Monte Carlo method is applied. The generated solution is considered the most efficient control strategy considering several dynamic changes in manufacturing environments. To clarify the proposed framework, a supply chain network with a key module supplier and several downstream car manufacturers was considered. The processing data and related information were transmitted using the developed IIoT device. The cloud system analyzed the collected data using the embedded big data analytics (MLP-DL, SVR or PLS) method. These methods found the nonlinear mapping between the processing data and the quality index. The reasoned model was used for predicting the quality of in-processing module in real-time. Moreover, the gathered data and the reasoned uncertain scenarios were integrated into a stochastic optimization model. Finally, the better dynamic control solution was generated using the provided framework.

As further studies, expansions of the framework are considered. Many uncertainties might be embedded in a large-scale network, which influence the solving complexities of the big data analytics. This issue disturbs the fast reasoning of shared data in the cloud system and requires prolonged solving time and more resources for a generated stochastic control model. Thus, several parallel processing algorithms and effective optimization methods are expected. In addition, joint efforts and cooperation between a key supplier and downstream producers are essential. The proposed framework is limited by trust and systematic cooperation between suppliers and producers being prerequisite conditions. Even though cloud system and the relevant analytics can enhance the production goals jointly, the strategic alliance in system level is required for the successful implementation of the provided framework.

The suggested framework is considered a new and efficient dynamic control framework of a key supplier using the cloud systems and the simulation-based data analytics. The framework can be applied to various applications such as supply chain management, manufacturing/productions, procurement and logistics controls areas. As many applications are introducing cloud frameworks, the suggested framework contributes to the dynamic control considering future scenarios as well as the real-time information.

Funding

This research was supported by The Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, S. Korea (grant number: NRF-2018R1D1A3B07047113).

Conflicts of Interest

The author declare no conflict of interest. The funders had no role in the design of the study; in the collection, analysis, or interpretation of data; in the writhing of the manuscripts, or in the decision to publish the results.

References

- Lee, H. Framework and development of fault detection classification using IoT device and cloud environment. J. Manuf. Syst. 2017, 43, 257–270. [Google Scholar] [CrossRef]

- Chen, F.; Deng, P.; Wan, J.; Zhang, D.; Vasilakos, A.V.; Rong, X. Data mining for the internet of things: literature review and challenges. Int. J. Distrib. Sens. N. 2015, 2015, 1–14. [Google Scholar] [CrossRef]

- Hu, T.; Chen, H.; Huang, L.; Zhu, X. A survey of mass data mining based on cloud-computing. Presented at the IEEE Anti-counterfeiting, Security and Identification, Taipei, Taiwan, 24–26 August 2012. [Google Scholar]

- Abdollahi, H.; Ghaemi, R.; Elham, D. A technical review on cloud computing in data mining. Presented at the CCSE2014, The 2nd National Conference on Computer Science and Engineering, Najafabad Branch, Iran, 21–22 October 2014. [Google Scholar]

- Teller, C.; Kotzab, H.; Grant, D.B.; Holweg, C. The importance of key supplier relationship management in supply chains. Int. J. Retail Distrib. Manag. 2016, 44, 1–16. [Google Scholar] [CrossRef]

- Nair, A.; Jayaram, J.; Das, A. Strategic purchasing participation, supplier selection, supplier evaluation and purchasing performance. Int. J. Prod. Res. 2015, 53, 1–16. [Google Scholar] [CrossRef]

- Matevz, R.; Maja, M.B. Buyer-supplier relationship and the resource-advantage perspective: an illustrative example of relational and transactional drivers of competitiveness. J. Compet. 2013, 5, 16–38. [Google Scholar]

- Aryal, A.; Liao, Y.; Nattuthurai, P.; Li, B. The emerging big data analytics and IoT in supply chain management: a systematic review. Supply Chain Manag. 2018. [Google Scholar] [CrossRef]

- Muller, J.M.; Veile, J.W.; Volgt, K. Supplier integration in industry 4.0-requirements and strategies. In Proceedings of the Hamburg International Conference of Logistics, Hamburg, Germany, 13–14 September 2018. [Google Scholar]

- Hofmann, E.; Rusch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Ikram, A.A.; Ibrahim, S.; Sardaraz, M.; Thhir, H.; Bajwa, H.; Bach, C. Neural network based cloud computing platform for bioinformatics. Presented at the 2013 IEEE Long Island Systems, Applications and Technology Conference (LISAT), Farmingdale, NY, USA, 3 May 2013. [Google Scholar]

- Shuhong, L. Improved SVM in cloud computing information mining. Int. J. Grid Distrib. Comput. 2015, 8, 33–40. [Google Scholar] [CrossRef]

- Lakra, A.V.; Yadav, D.K. Multi-objective tasks scheduling algorithm for cloud computing throughput optimization. Procedia Comput. Sci. 2015, 48, 107–113. [Google Scholar] [CrossRef]

- Enzai, N.; Tang, M. A heuristic algorithm for multi-site computation offloading in mobile cloud computing. Procedia Comput. Sci. 2016, 80, 1232–1241. [Google Scholar] [CrossRef]

- Sharma, N.; Tyagi, S.; Atri, S. A survey of heuristic approach for task scheduling in cloud computing. Int. J. Adv. Res. Comput. Sci. 2017, 8, 1089–1092. [Google Scholar]

- Zhang, Q.; Yang, L.; Yan, Z.; Chan, Z.; Li, P. An efficient deep learning model to predict cloud workload for industry informatics. IEEE T. Ind. Inform. 2018, 14. [Google Scholar] [CrossRef]

- Roopaei, M.; Rad, P.; Jamshidi, M. Deep learning control for complex and large scale cloud systems. Intell. Autom. Soft Co. 2017, 23, 389–391. [Google Scholar] [CrossRef]

- Gao, W.; Zhu, Y. A cloud computing fault detection method based on deep learning. J. Comput. Commun. 2017, 5, 24–34. [Google Scholar] [CrossRef]

- Kasemsap, K.; Sunandha, S. Adopting cloud computing in global supply chain: a literature review. Int. J. Soc. Organ. Dyn. IT 2015, 4, 49–62. [Google Scholar] [CrossRef]

- Curry, G.; Feldman, R.M. Manufacturing Systems Modeling and Analysis, 2nd ed.; Springer: Belrin, Germany, 2011. [Google Scholar]

- Zhou, M.; Li, H.; Weijnen, M. Contemporary Issues in Systems Science and Engineering, 1st ed.; Wiley-IEEE Press: New York, NY, USA, 2015. [Google Scholar]

- Ejiri, E.; Kubo, M. Performances analysis of automotive torque converter elements. J. Fluids Eng. 1999, 121, 266–275. [Google Scholar] [CrossRef]

- Chunha, C.R.; Morais, E.P.; Sousa, J.P.; Gomes, J.P. The role of cloud computing in the development of information systems for SMEs. J.Cloud Comput. 2017, 2017, 1–10. [Google Scholar]

- Lee, H. Embedded system framework and its implementation for device-to-device intelligent communication of Manufacturing IoT device considering smart factory. J. Korean Inst. Intell. Sys. 2017, 27, 459–465. [Google Scholar] [CrossRef]

- Ubidot, a Practical Guide to Smart Manufacturing. Available online: https://ubidots.com/blog/smart-manufacturing-examples/ (accessed on 15 November 2018).

- Saha, S.; Majumdar, A. Data centre temperature monitoring with ESP8266 based wireless sensor network and cloud based dashboard with real time alert system. Presented at the 2017 Devices for Integrated Circuit, DevIC, Kalyani, India, 23–24 March 2017. [Google Scholar]

- Kesavan, G.; Sanjeevi, P.; Viswanathan, P. A 24 h IoT framework for monitoring and managing home automation. Presented at the 2016 International Conference on Inventive Computation Technologies, (ICICT), Coimbatore, India, 26–27 August 2016. [Google Scholar]

- ECMiner, a User Manual of ECMiner. Available online: http://ecminer.com/?page_id=229 (accessed on 14 December 2017).

- Anandhi, V.; Chezian, R.M. Support vector regression to forecast the demand and supply of Pulpwood. Int. J. Future Comput. Commun. 2013, 2, 266–269. [Google Scholar] [CrossRef]

- Kanzow, C.; Yamashita, N.; Fukushima, M. Levenberg-Marquardt methods with strong local convergence properties for solving nonlinear equations with convex constraints. J. Comput. App. Math. 2004, 172, 375–397. [Google Scholar] [CrossRef]

- Birge, J.R.; Louveaux, F. Introduction to Stochastic Programming, 2nd ed.; Springer: New York, NY, USA, 2011. [Google Scholar]

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).