Numerical Simulation of the Effects of the Helical Angle on the Decaying Swirl Flow of the Hole Cleaning Device

Abstract

1. Introduction

2. Methodology

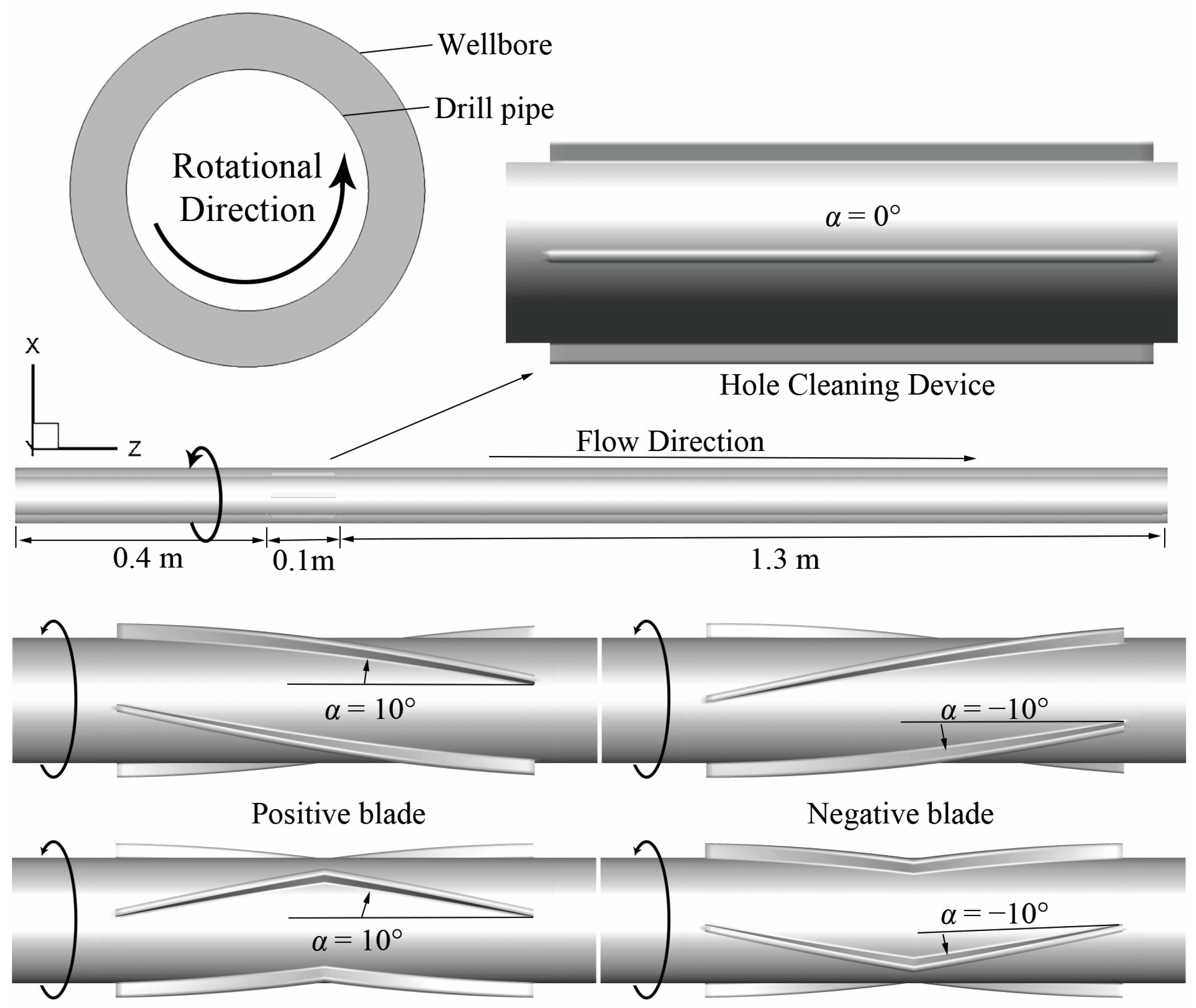

2.1. Numerical Model

2.2. Governing Equations

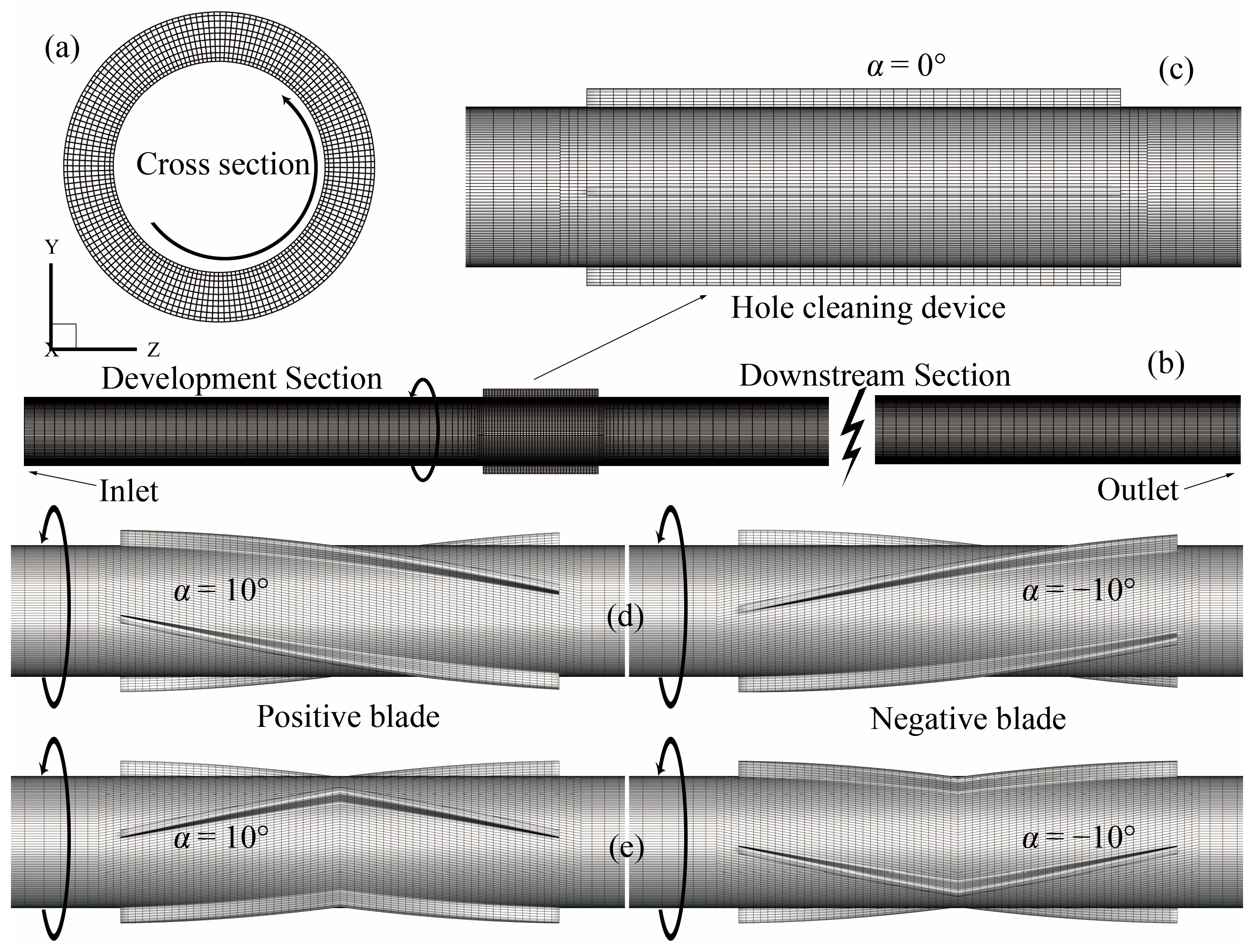

2.3. Mesh Model and Boundary Condition

2.4. Numerical Scheme

2.5. Grid Independence and Model Validation

3. Results

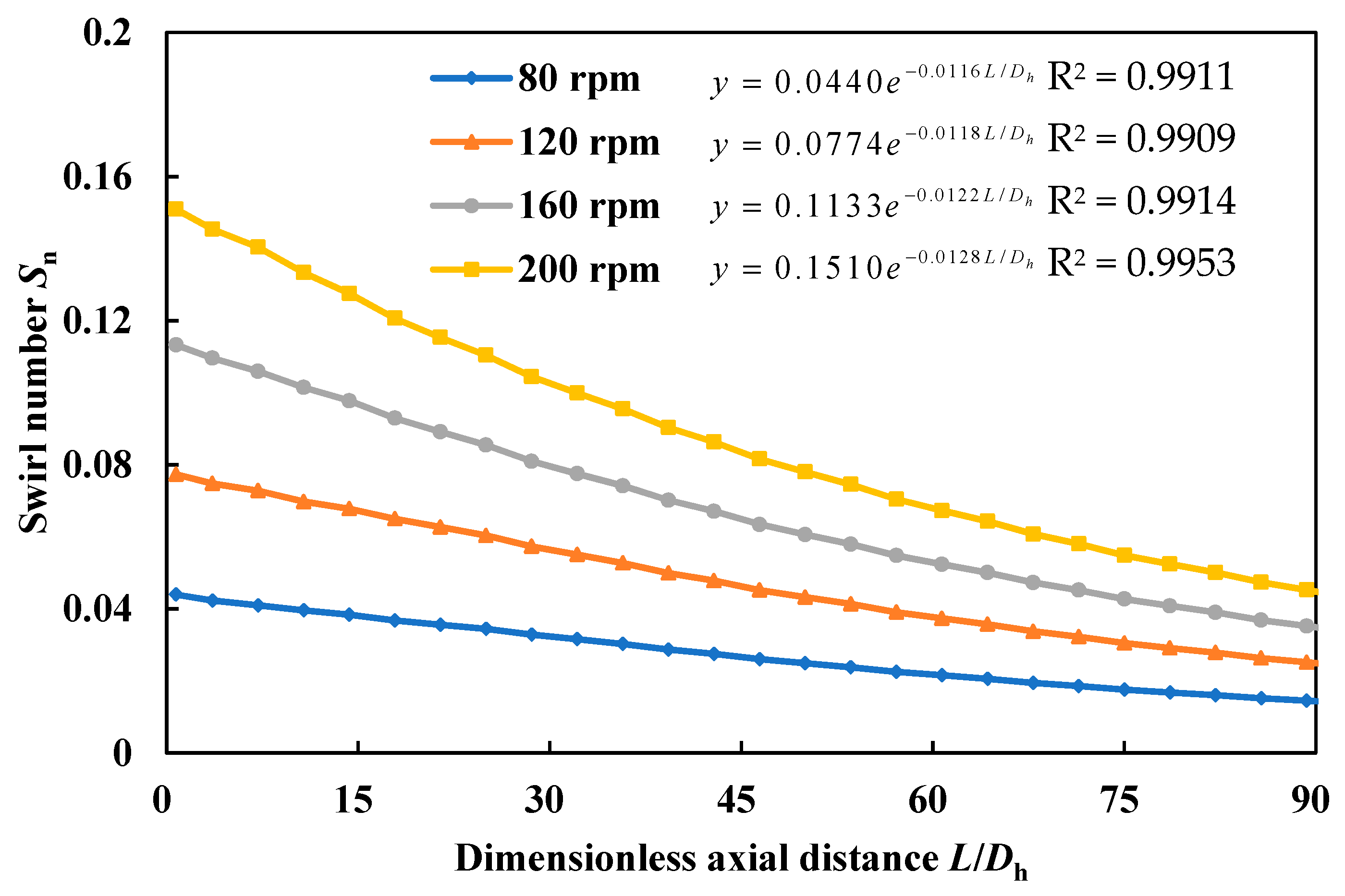

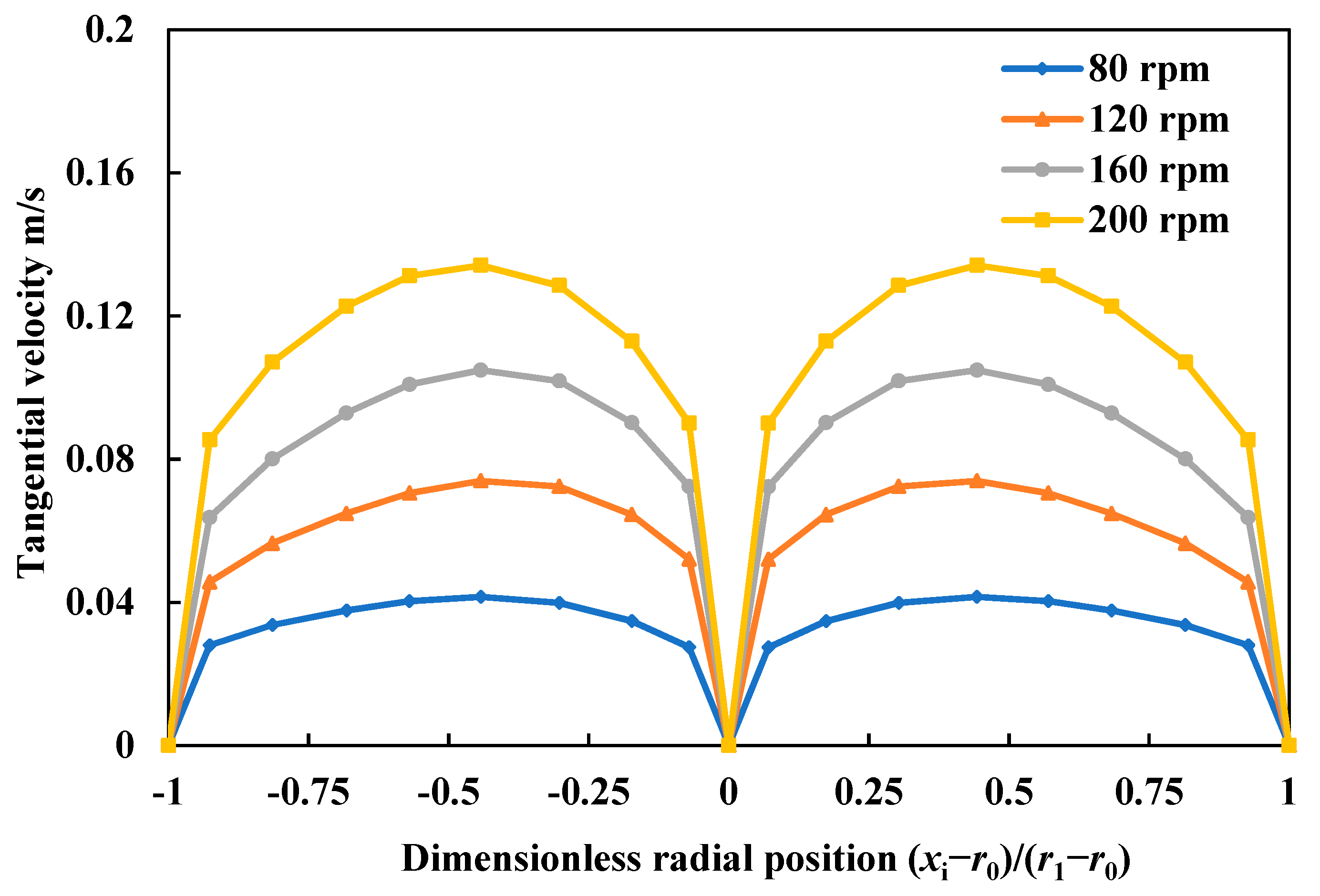

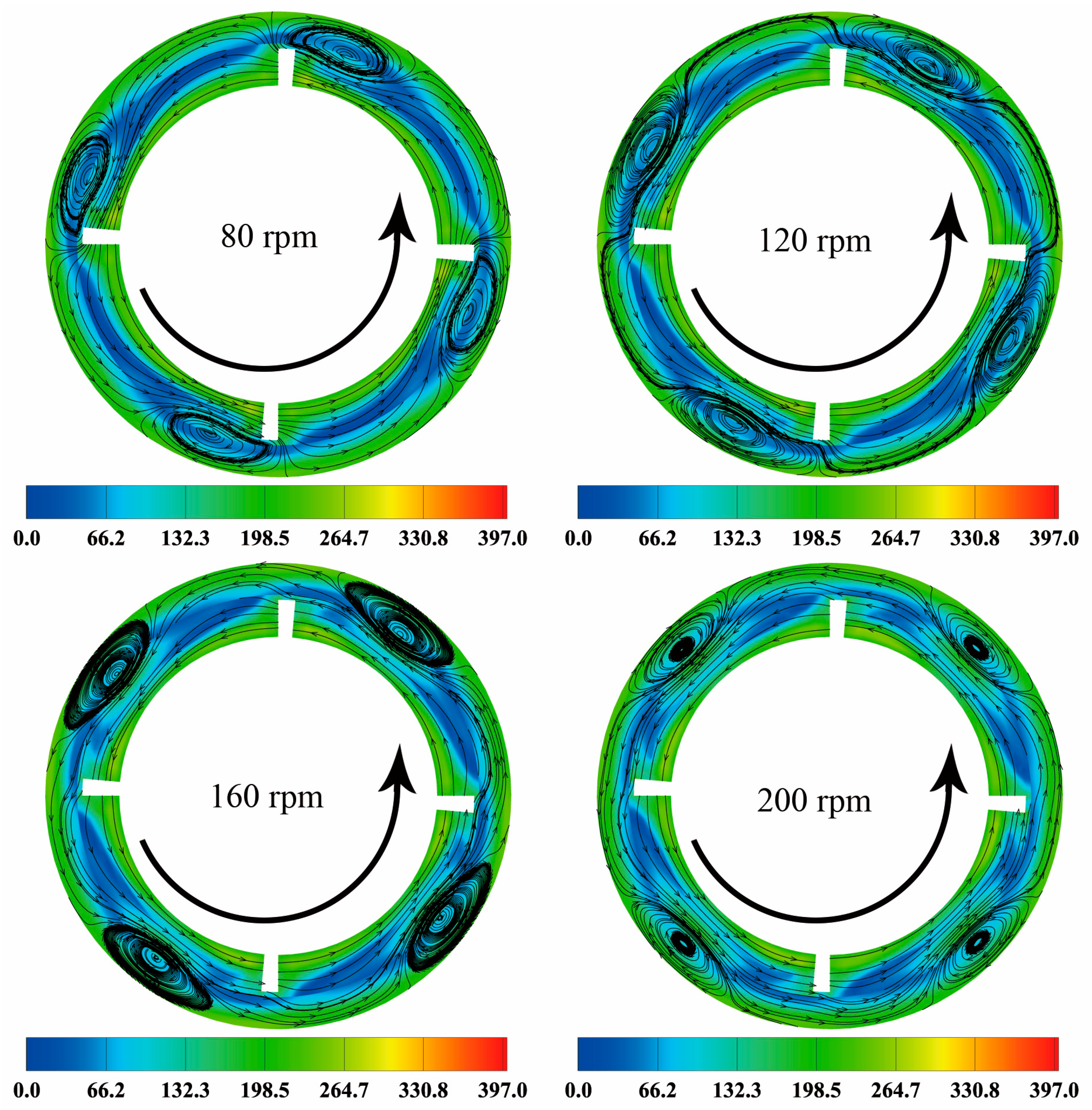

3.1. Analysis of the Effect of the Rotational Speed

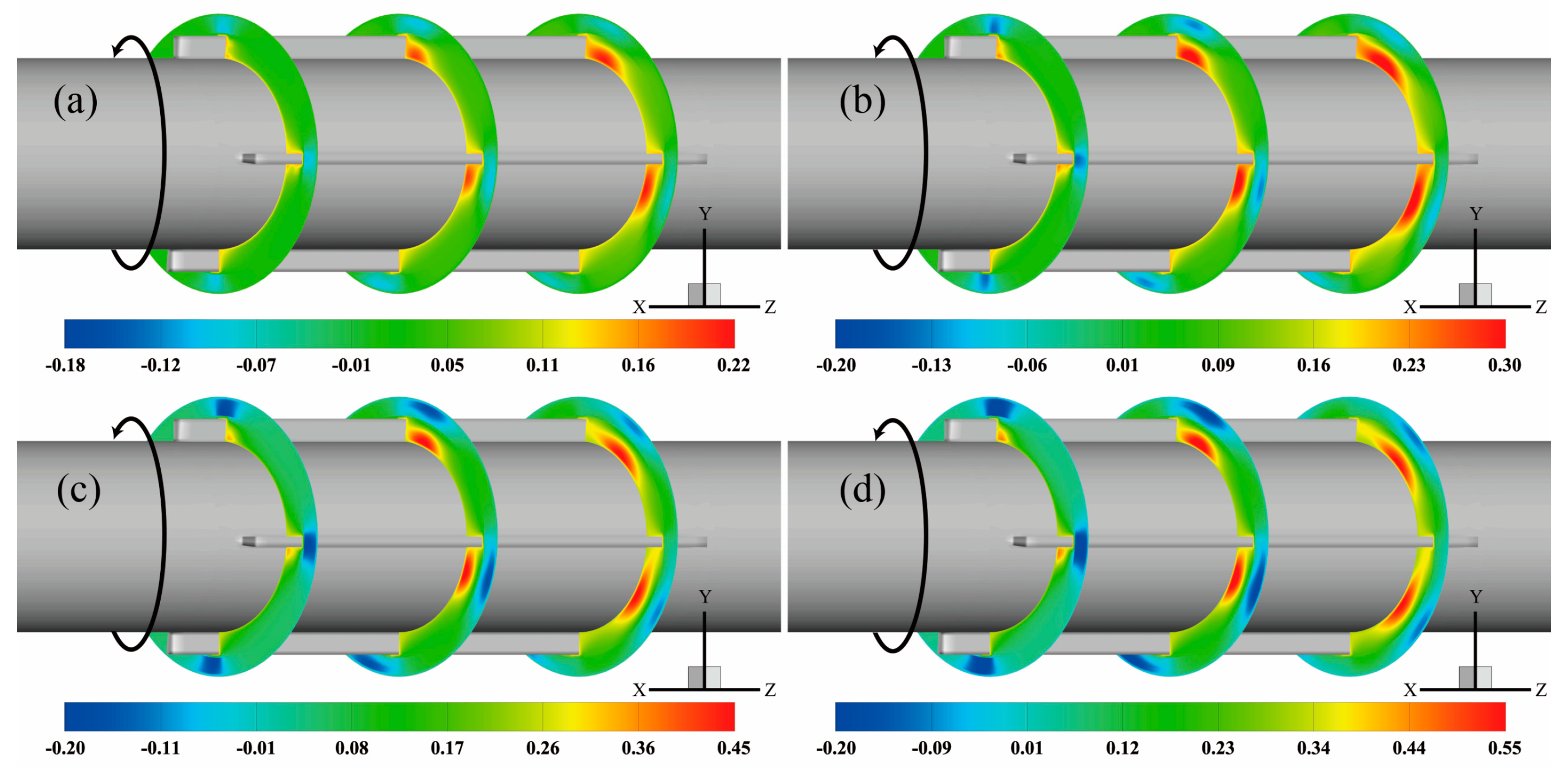

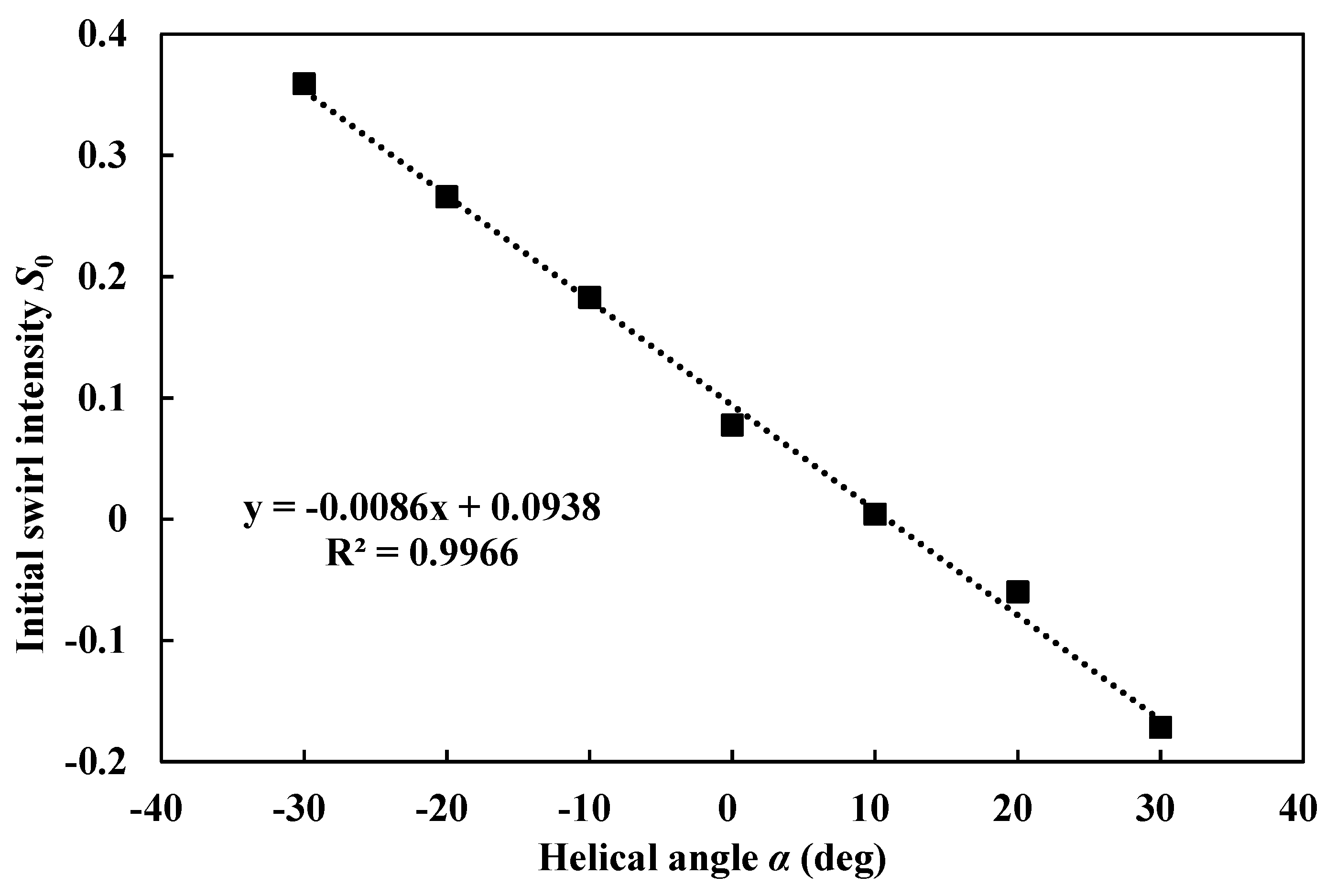

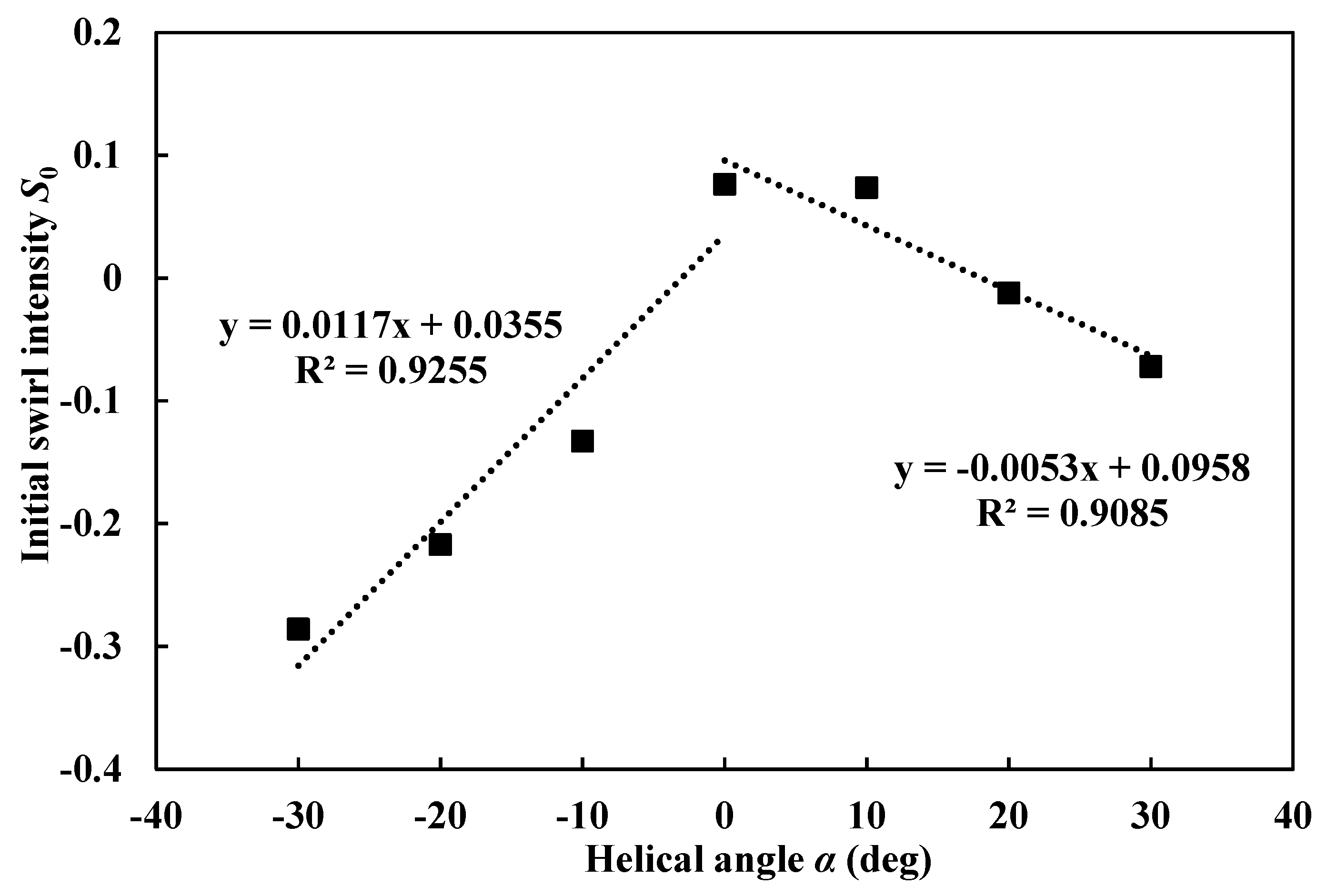

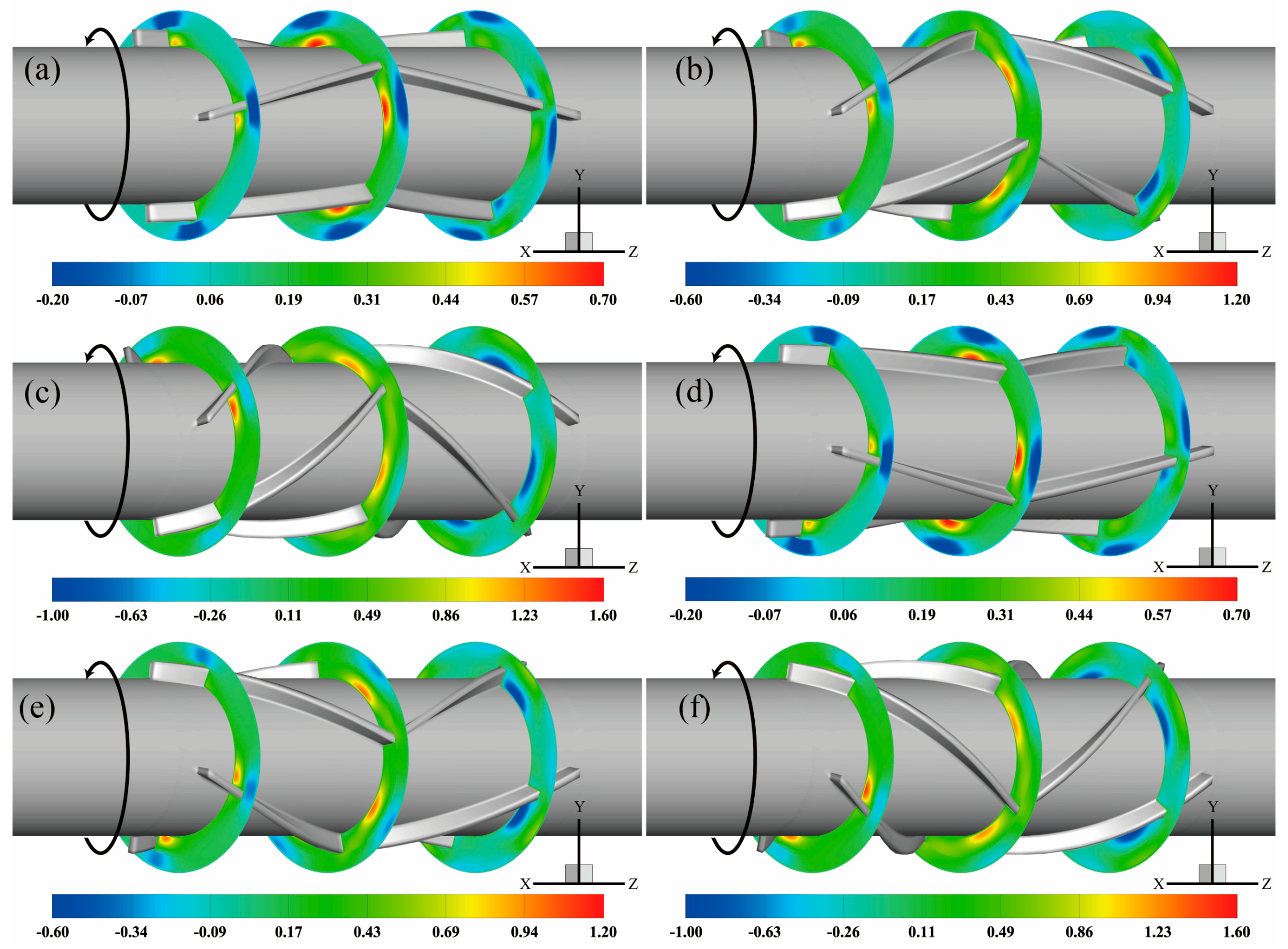

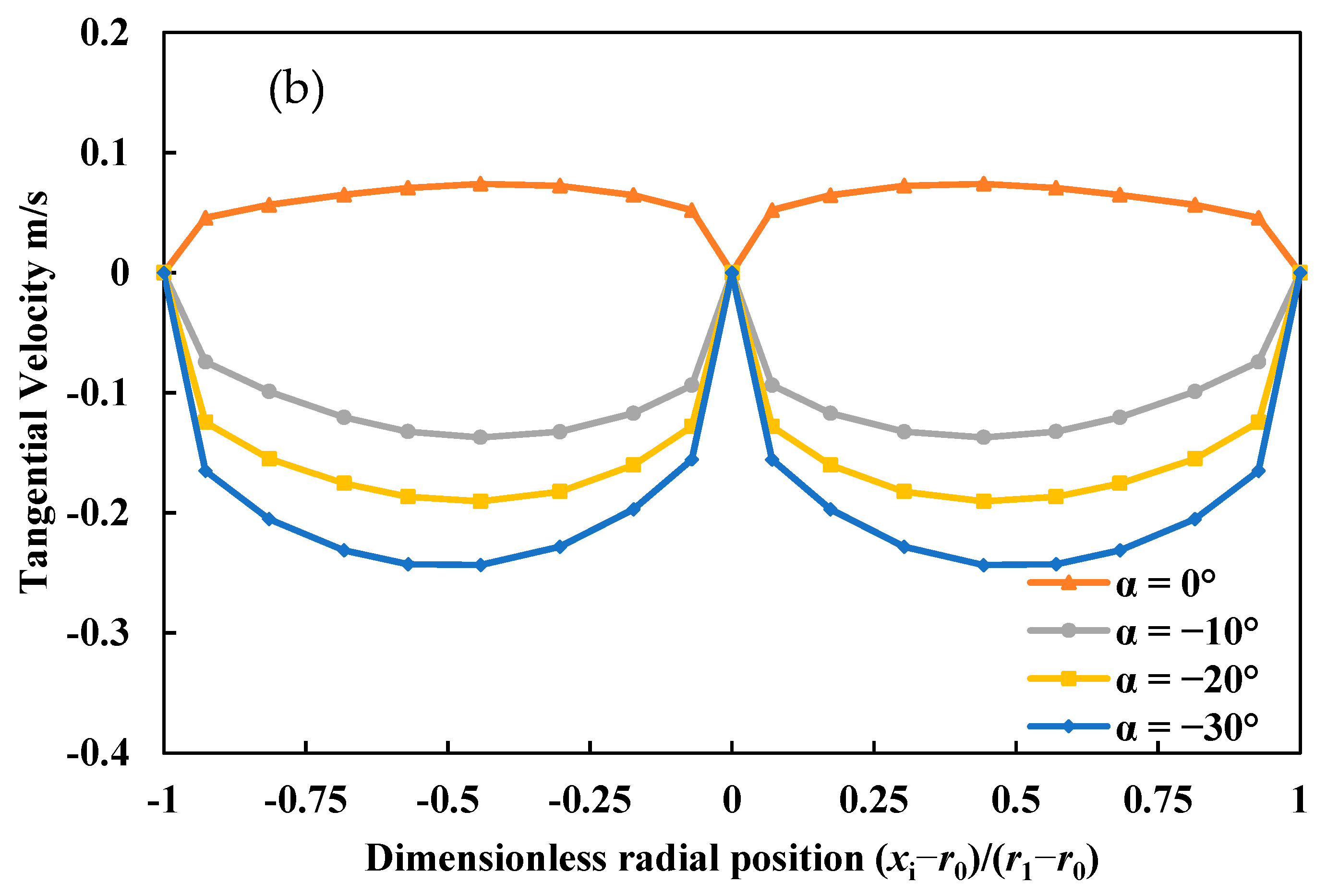

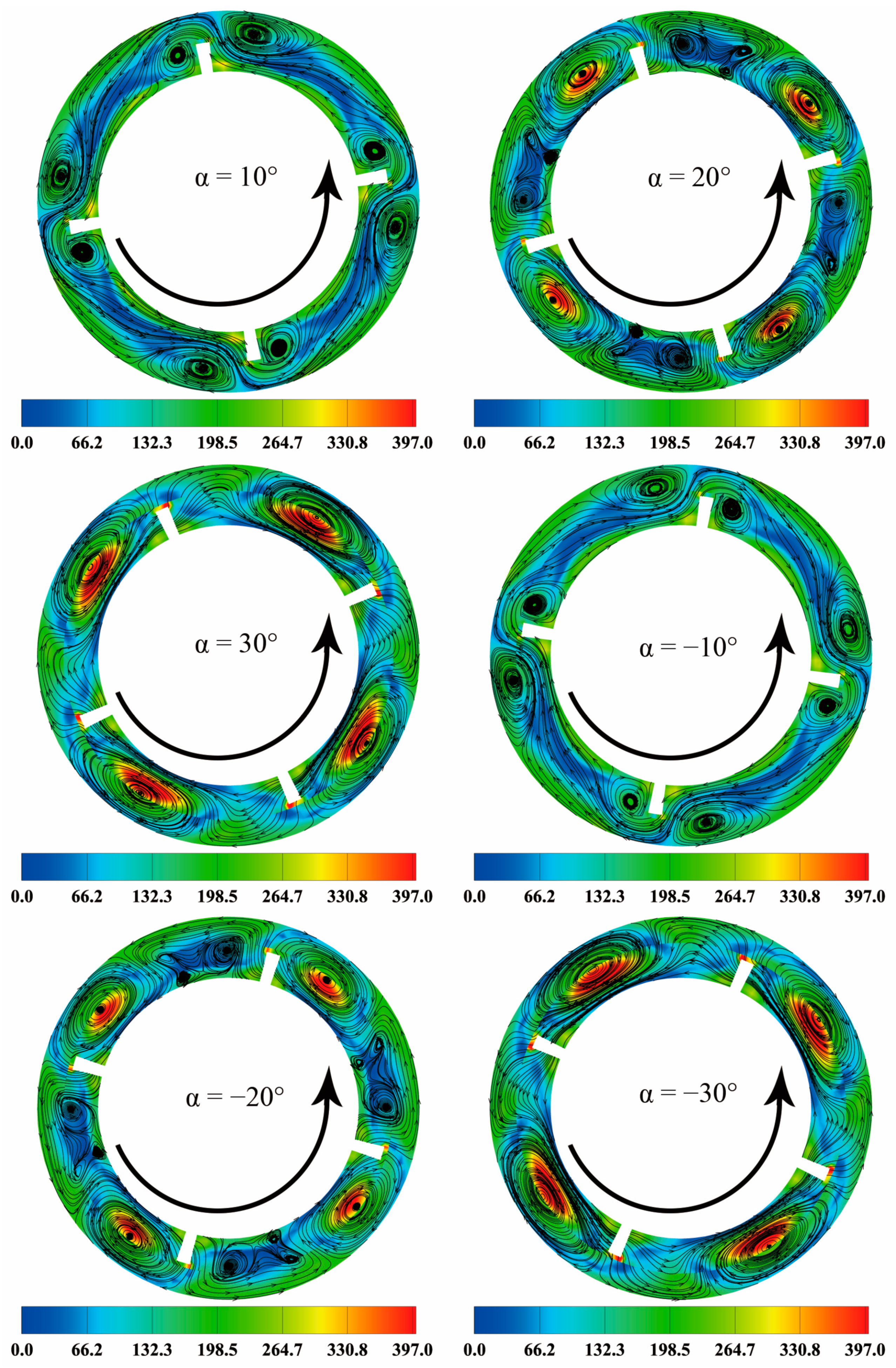

3.2. Analysis of the Effect of the Helical Angle

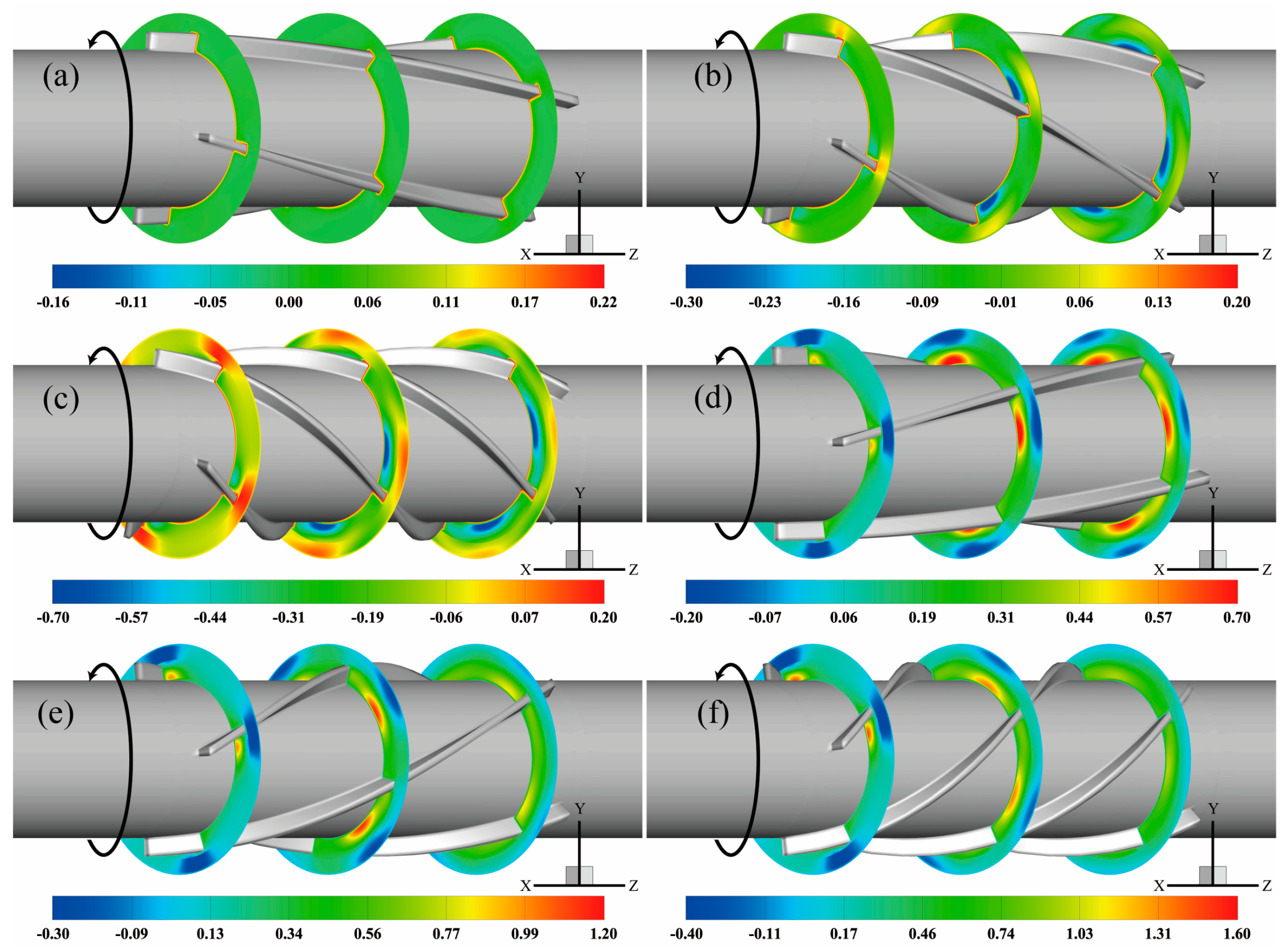

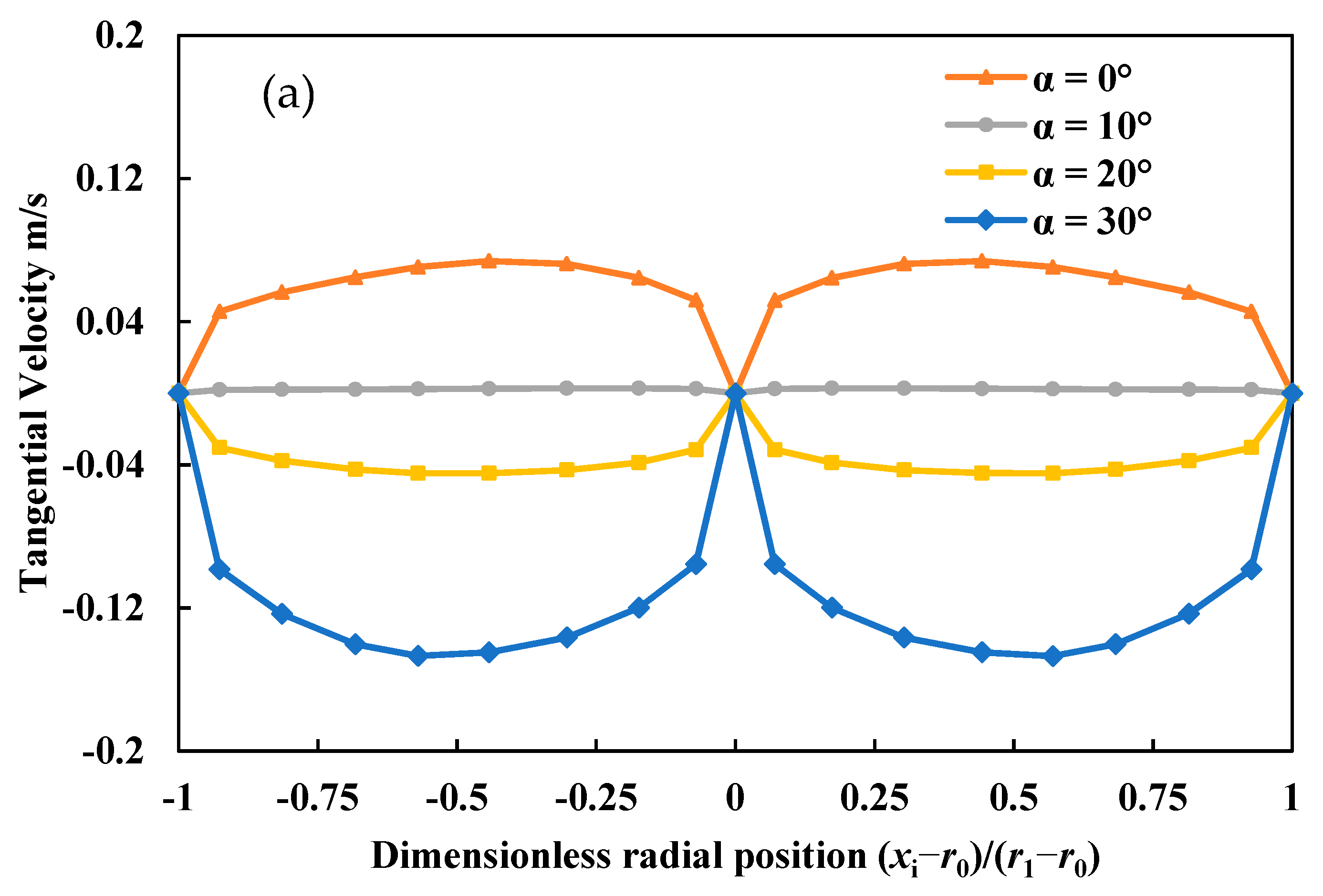

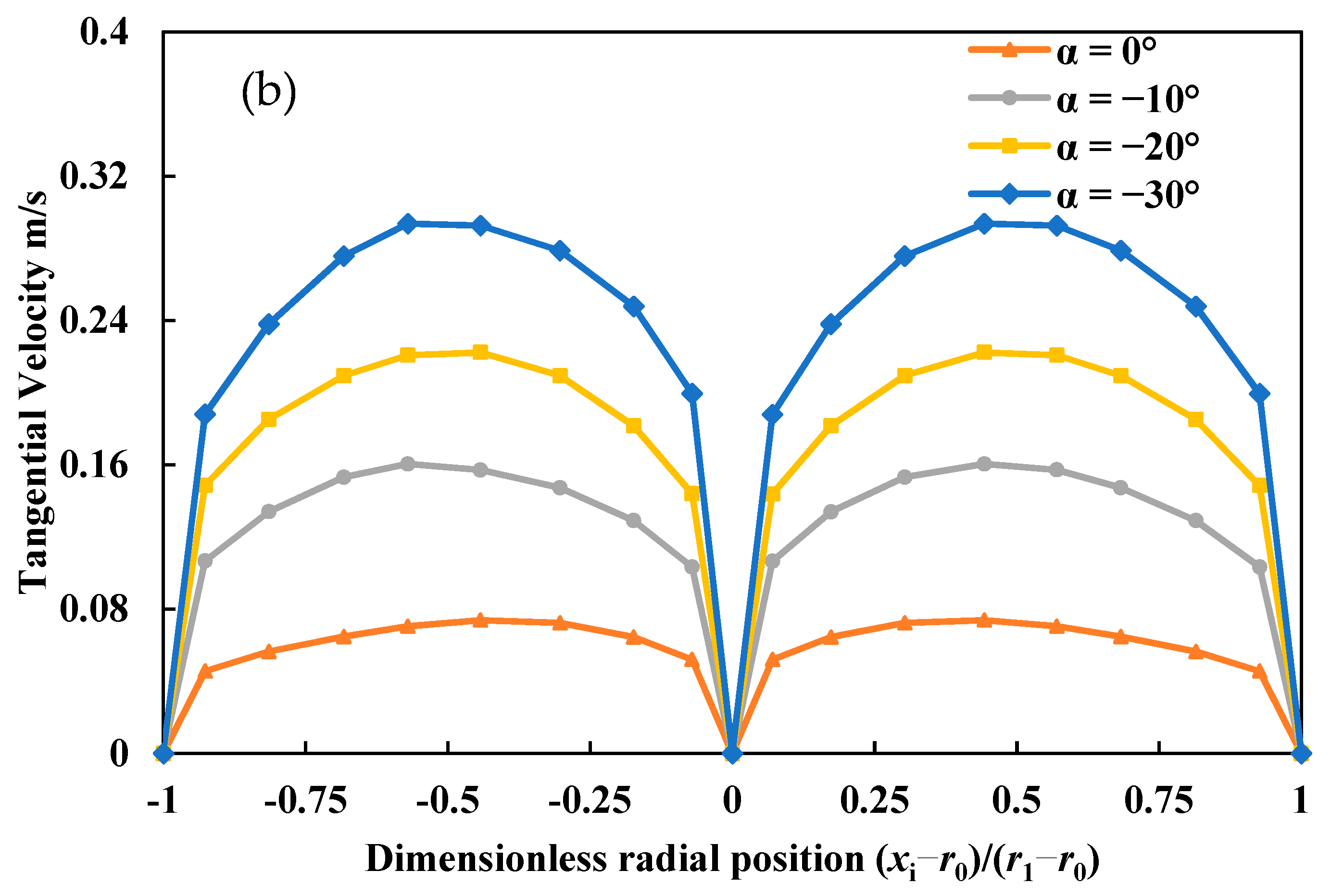

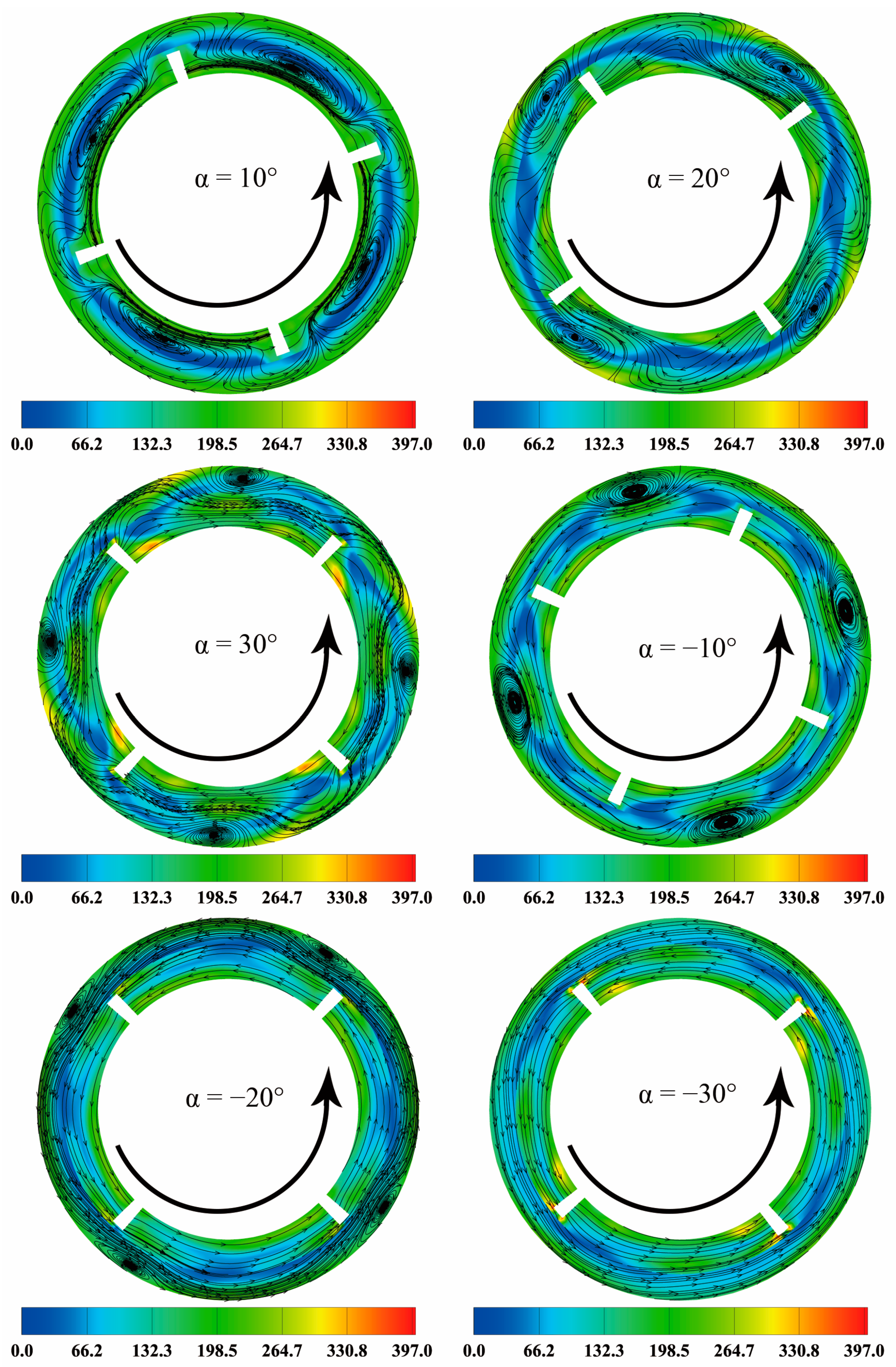

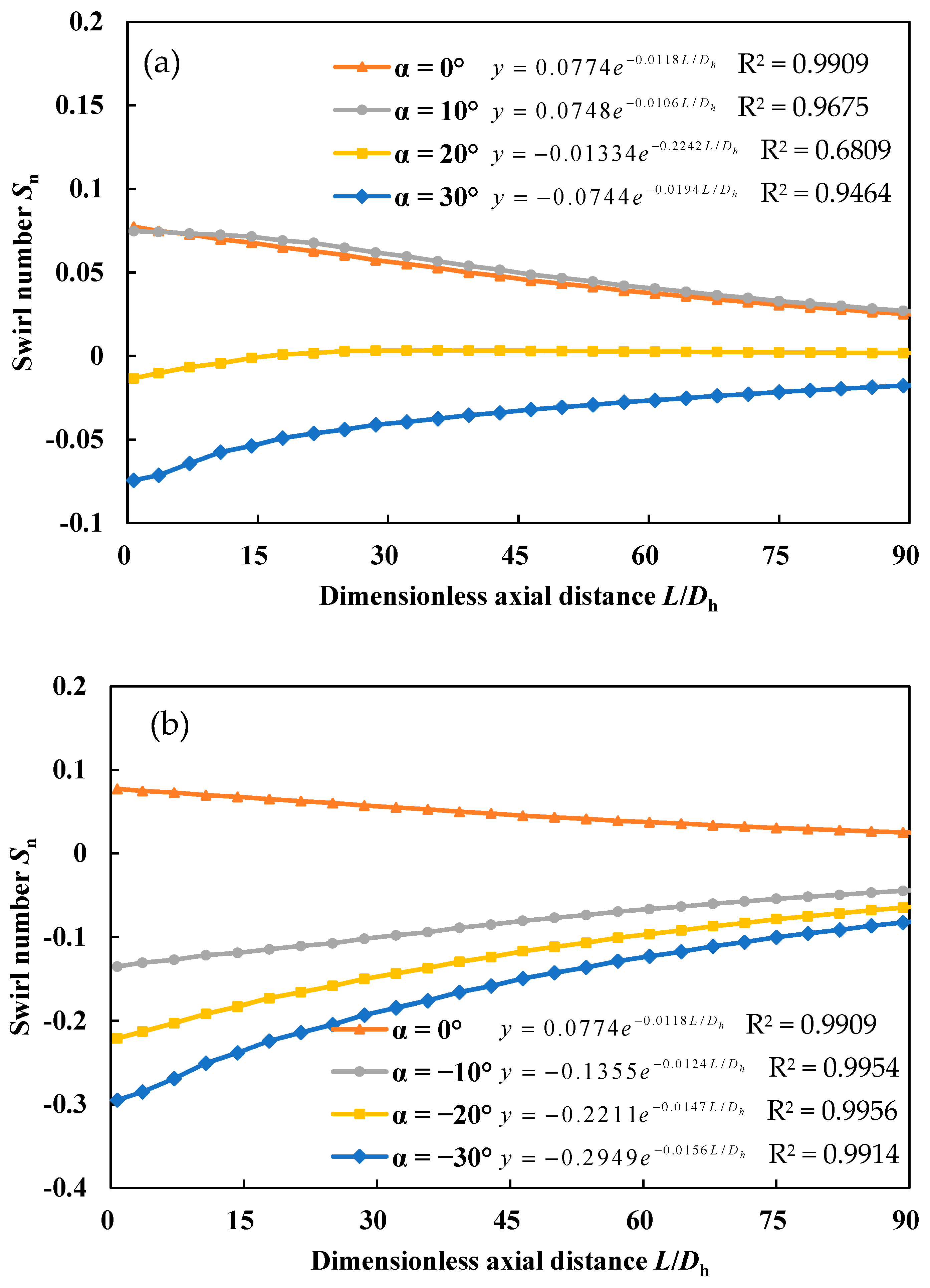

3.2.1. Influence of the Helical Angle of the Straight Blade

3.2.2. Influence of the Helical Angle of the V-Shaped Blade

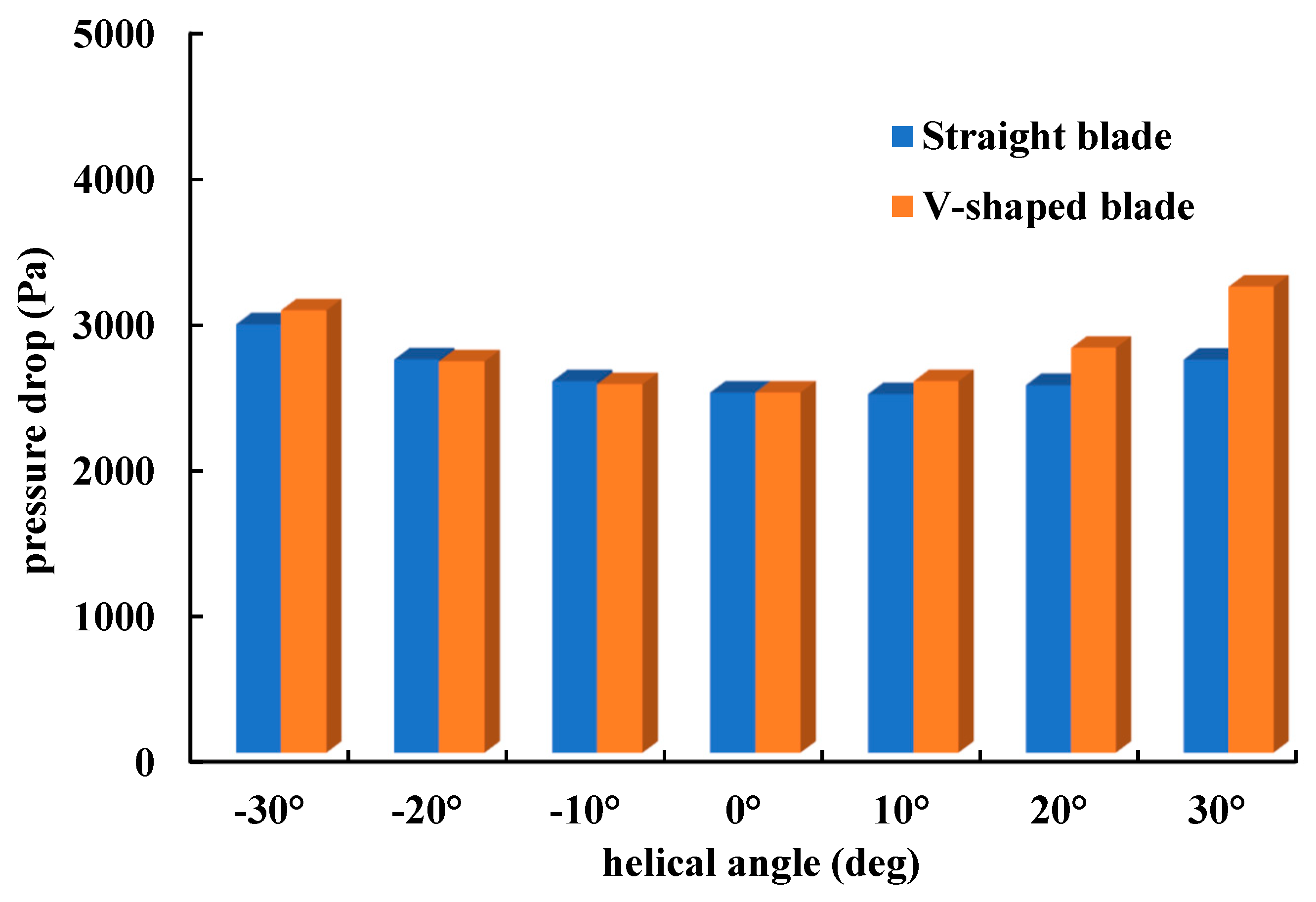

3.3. Analysis of the Effect of the Helical Angle on Pressure Drop

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Guan, Z.C.; Liu, Y.M.; Liu, Y.W.; Xu, Y.Q. Hole cleaning optimization of horizontal wells with the multi-dimensional ant colony algorithm. J. Nat. Gas Sci. Eng. 2016, 28, 347–355. [Google Scholar] [CrossRef]

- Ogunrinde, J.O.; Dosunmu, A. Hydraulics Optimization for Efficient Hole Cleaning in Deviated and Horizontal Wells. Niger. Annu. Int. Conf. Exhib. 2012, 16. [Google Scholar] [CrossRef]

- Massie, G.W.; Castlesmith, J.; Lee, J.W.; Ramsey, M.S. Amoco’s training initiative reduces wellsite drilling problems. Pet. Eng. Int. 1995, 67, 3029–3035. [Google Scholar]

- Hopkins, C.J.; Leicksenring, R.A. Reducing the risk of stuck pipe in the Netherlands. In Proceedings of the IADC/SPE Drilling Conference, Amsterdam, The Netherlands, 28 February–2 March 1995; pp. 757–766. [Google Scholar] [CrossRef]

- Oh, J.; Choi, S.; Kim, J. Numerical simulation of an internal flow field in a uniflow cyclone separator. Powder Technol. 2015, 274, 135–145. [Google Scholar] [CrossRef]

- Duangthongsuk, W.; Wongwises, S. An experimental investigation of the heat transfer and pressure drop characteristics of a circular tube fitted with rotating turbine-type swirl generators. Exp. Therm. Fluid Sci. 2013, 45, 8–15. [Google Scholar] [CrossRef]

- Varava, A.N.; Dedov, A.V.; Zakharov, E.M.; Malakhovskii, S.A.; Komov, A.T.; Yagov, V.V. Study of pressure drop and heat transfer in a swirl flow with one-sided heating in a range of heat flowrates below boiling crisis. Therm. Eng. 2009, 56, 953–962. [Google Scholar] [CrossRef]

- Lee, C.; Na, Y.; Lee, J.W.; Byun, Y.H. Effect of induced swirl flow on regression rate of hybrid rocket fuel by helical grain configuration. Aerosp. Sci. Technol. 2007, 11, 68–76. [Google Scholar] [CrossRef]

- Fokeer, S.; Lowndes, I.; Kingman, S. An experimental investigation of pneumatic swirl flow induced by a three lobed helical pipe. Int. J. Heat Fluid Flow 2009, 30, 369–379. [Google Scholar] [CrossRef]

- Derksen, J.J. Simulations of confined turbulent vortex flow. Comput. Fluids 2005, 34, 301–318. [Google Scholar] [CrossRef]

- Li, H.; Tomita, Y. Particle velocity and concentration characteristics in a horizontal dilute swirling flow pneumatic conveying. Powder Technol. 2000, 107, 144–152. [Google Scholar] [CrossRef]

- Bali, T.; Sarac, B.A. Experimental investigation of decaying swirl flow through a circular pipe for binary combination of vortex generators. Int. Commun. Heat Mass Transf. 2014, 53, 174–179. [Google Scholar] [CrossRef]

- Swietlik, G. Cutting Bed Impeller. U.S. Patent US5937957, 17 August 1999. [Google Scholar]

- Swietlik, G. Cutting Bed Impeller. U.S. Patent US6223840, 1 May 2001. [Google Scholar]

- Rodman, D.; Wong, T.; Chong, A.C. Steerable hole enlargement technology in complex 3d directional wells. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Jakarta, Indonesia, 9–11 September 2003. [Google Scholar]

- Puymbroeck, L.V.; Williams, H.; Drilling, V.A.M. Increasing Drilling Performance in ERD Wells with New Generation Drill Pipe. In Proceedings of the Unconventional Resources Technology Conference, Denver, CO, USA, 12–14 August 2013; pp. 1060–1070. [Google Scholar]

- Ahmed, R.; Sagheer, M.; Takach, N.; Majidi, R.; Yu, M.; Miska, S.; Rohart, C.; Boulet, J. Experimental Studies on the Effect of Mechanical Cleaning Devices on Annular Cuttings Concentration and Applications for Optimizing ERD Systems. In Proceedings of the SPE Annual Technical Conference and Exhibition, Florence, Italy, 19–22 September 2010. [Google Scholar] [CrossRef]

- Heitmann, N.; Chacinet, E.; Molero, R.; Graterol, W.; Servicios, P. Novel Integrated Hole-Cleaning Concept Reduces Well Construction by 3 Rig Days. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference, Bangkok, Thailand, 25–27 August 2014. [Google Scholar]

- Griffiths, W.D.; Boysan, F. Computational fluid dynamics (CFD) and empirical modelling of the performance of a number of cyclone samplers. J. Aerosol Sci. 1996, 27, 281–304. [Google Scholar] [CrossRef]

- Munson, B.R.; Young, D.F.; Okiishi, T.H. Fundamentals of Fluid Mechanics; John Wiley: New York, NY, USA, 1998. [Google Scholar]

- Araoye, A.A.; Badr, H.M.; Ahmed, W.H. Investigation of flow through multi-stage restricting orifices. Ann. Nucl. Energy 2017, 104, 75–90. [Google Scholar] [CrossRef]

- Beer, J.M.; Chigier, N.A. Combustion Aerodynamics; Applied Science Publishers LTD: London, UK, 1972. [Google Scholar]

- ANSYS Inc. Fluent User Guide and Fluent Theory Guide, Version 16.2. 2015. Available online: https://www.sharcnet.ca/Software/Ansys/16.2.3/en-us/help/flu_th/flu_th.html (accessed on 10 January 2019).

- Fokeer, S.; Lowndes, I.S.; Hargreaves, D.M. Numerical modelling of swirl flow induced by a three-lobed helical pipe. Chem. Eng. Process. Process Intensification 2010, 49, 536–546. [Google Scholar] [CrossRef]

- Li, G.; Miles, N.J.; Wu, T.; Hall, P. Large eddy simulation and Reynolds-averaged Navier–Stokes based modelling of geometrically induced swirl flows applied for the better understanding of Clean-In-Place procedures. Food Bioprod. Process. 2017, 104, 77–93. [Google Scholar] [CrossRef]

- Zhou, J.W.; Du, C.L.; Liu, S.Y.; Liu, Y. Comparison of three types of swirling generators in coarse particle pneumatic conveying using CFD-DEM simulation. Powder Technol. 2016, 301, 1309–1320. [Google Scholar] [CrossRef]

- Reader-Harris, M.J. The decay of swirl in a pipe. Int. J. Heat Fluid Flow. 1994, 15, 212–217. [Google Scholar] [CrossRef]

- Steenbergen, W.; Voskamp, J. The rate of decay of swirl in turbulent pipe flow. Flow Meas. Instrum. 1998, 9, 67–78. [Google Scholar] [CrossRef]

- Zhang, D.; Shi, W.; van Esch, B.P.M.; Shi, L.; Dubuisson, M. Numerical and experimental investigation of tip leakage vortex trajectory and dynamics in an axial flow pump. Comput. Fluids 2015, 112, 61–71. [Google Scholar] [CrossRef]

| Annulus Length, L (m) | 1.8 |

| Angle of inclination, θ (deg) | 90 |

| Pipe diameter, D0 (mm) | 30 |

| Hole diameter, D1 (mm) | 44 |

| Eccentricity e | 0 |

| Drill pipe rotational speed, n0 (rpm) | 80, 120, 160, 200 |

| Fluid inlet velocity, Uin (m/s) | 1.02 |

| Fluid density, ρl (kg/m3) | 998.5 |

| Power law exponent, n | 1 |

| Consistency factor, κ (Pa·sn) | 0.001 |

| Helical angle α (deg) | −30, −20, −10, 0, 10, 20, 30 |

| Blade height h/Dh | 0.25 |

| Grid Model | Pressure Drop (Pa/m) | Relative Error | Mean Tangential Velocity at Sampling Surface (m/s) | Relative Error |

|---|---|---|---|---|

| 313,228 | 1416.7 | - | 0.0192 | - |

| 380,228 | 1368.8 | 3.50% | 0.0185 | 3.78% |

| 437,828 | 1360.1 | 0.64% | 0.0183 | 1.09% |

| 553,028 | 1357.7 | 0.17% | 0.0184 | 0.54% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, J.; Yan, T.; Sun, X.; Li, Z.; Li, W. Numerical Simulation of the Effects of the Helical Angle on the Decaying Swirl Flow of the Hole Cleaning Device. Processes 2019, 7, 109. https://doi.org/10.3390/pr7020109

Qu J, Yan T, Sun X, Li Z, Li W. Numerical Simulation of the Effects of the Helical Angle on the Decaying Swirl Flow of the Hole Cleaning Device. Processes. 2019; 7(2):109. https://doi.org/10.3390/pr7020109

Chicago/Turabian StyleQu, Jingyu, Tie Yan, Xiaofeng Sun, Zijian Li, and Wei Li. 2019. "Numerical Simulation of the Effects of the Helical Angle on the Decaying Swirl Flow of the Hole Cleaning Device" Processes 7, no. 2: 109. https://doi.org/10.3390/pr7020109

APA StyleQu, J., Yan, T., Sun, X., Li, Z., & Li, W. (2019). Numerical Simulation of the Effects of the Helical Angle on the Decaying Swirl Flow of the Hole Cleaning Device. Processes, 7(2), 109. https://doi.org/10.3390/pr7020109