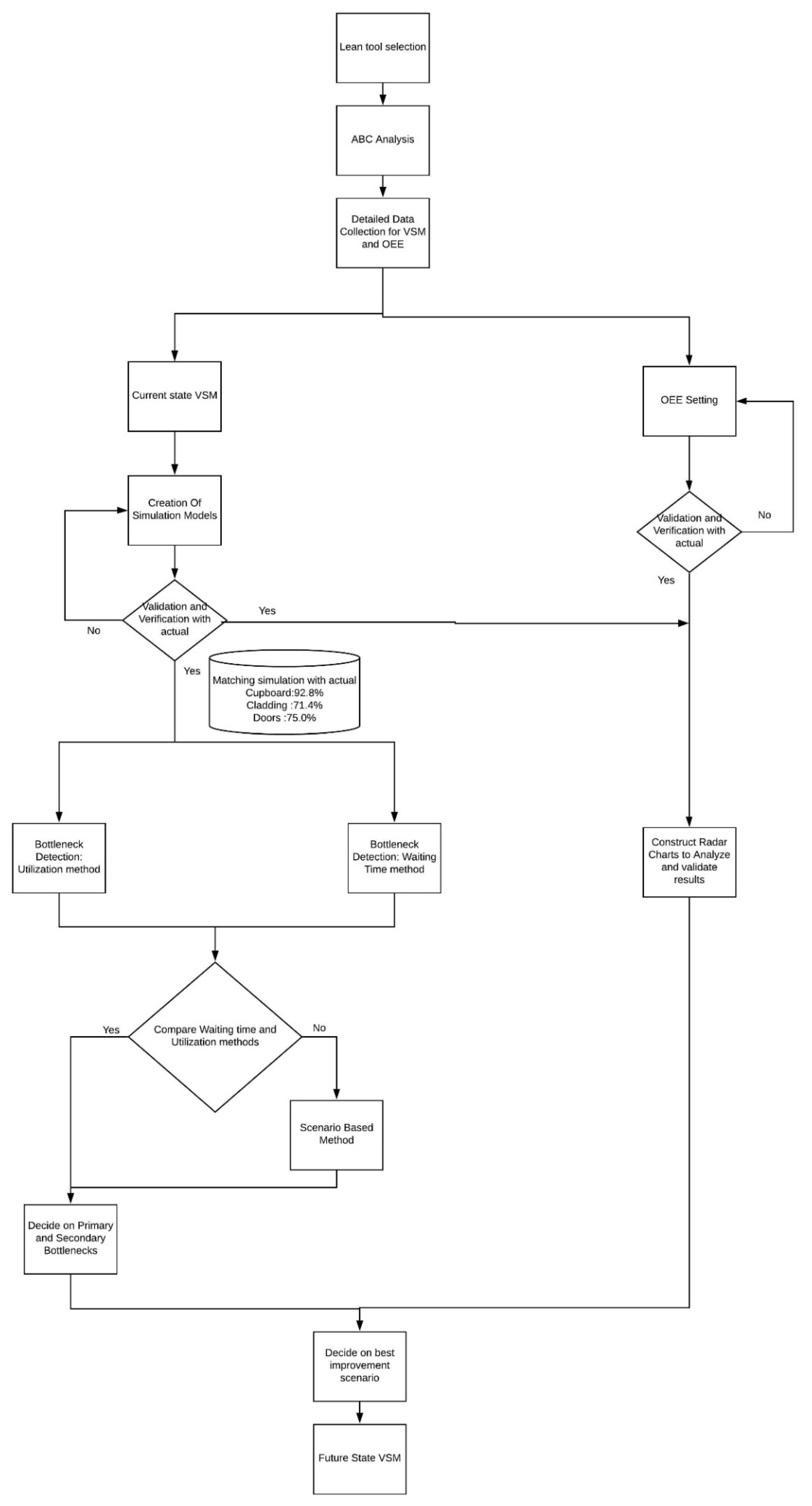

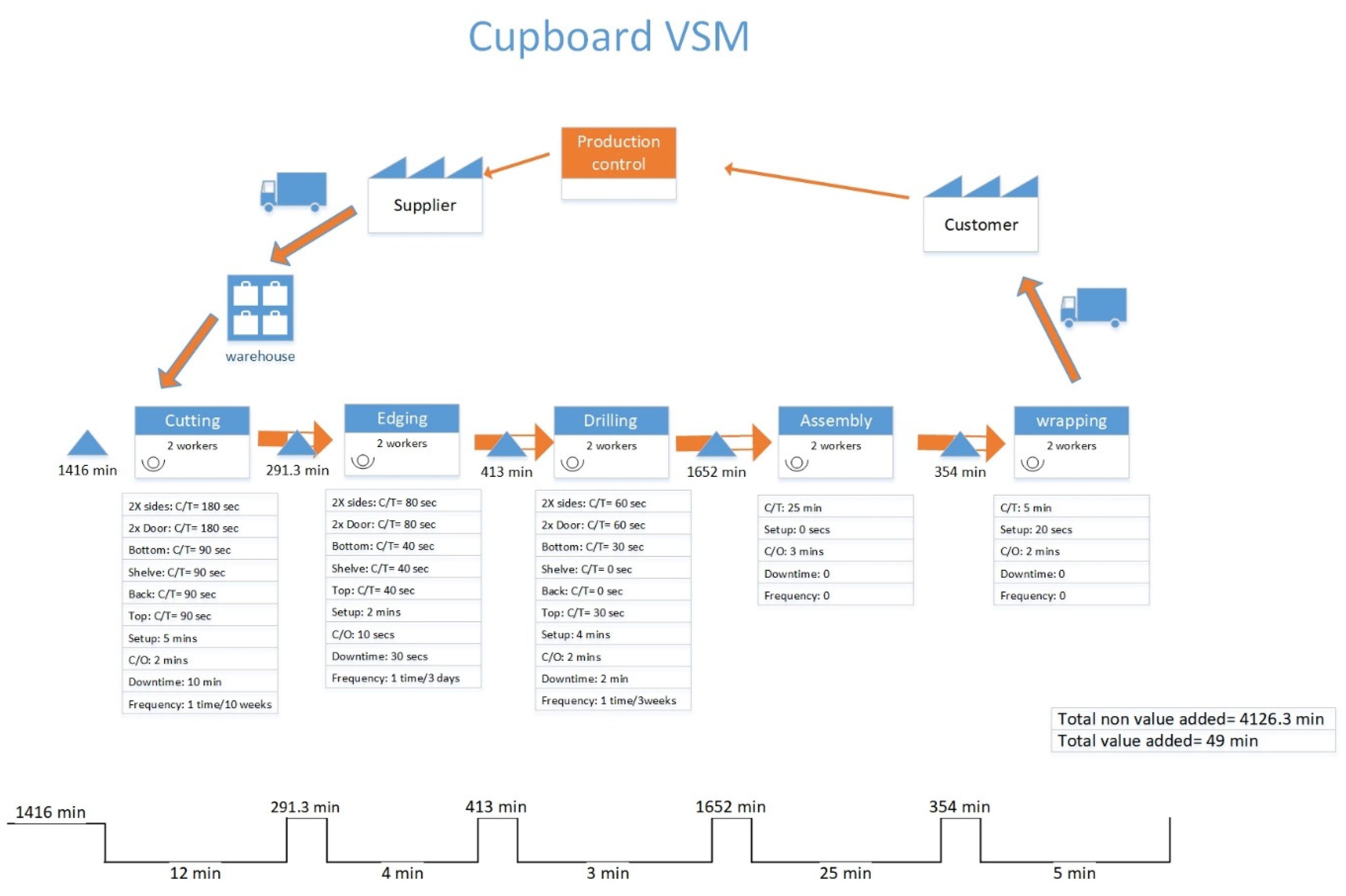

4.1. VSM: Current-State Map

The VSM visualizes process flow for a product or family of products as well as identify production status and any potential alerts (Andons) that might be causing problems to the production system. These Andons might include potential bottlenecks, cycle time problems, capacity limitations, inability to meet schedule, etc.

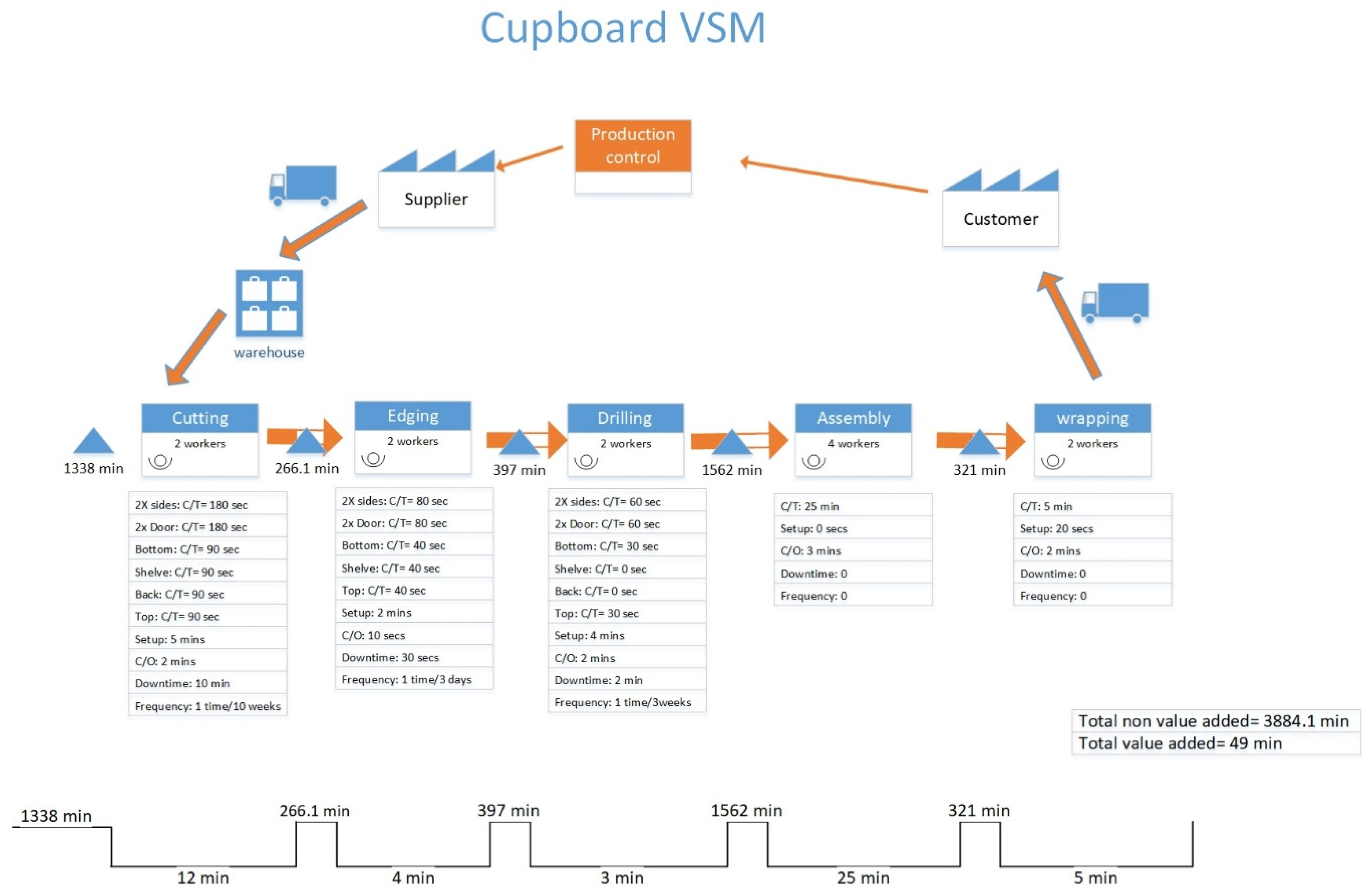

The structure and elements are divided into three parts. On the top, the information moving from right to left shows the customer’s requirements. In the middle, the steps of manufacturing processes are shown in boxes including the process name, the number of workers, the cycle time, setup time, change-over-time, in addition to the breakdowns. The processes are connected with a push arrow. WIP is shown in triangles between the processes. The bottom part of the VSM shows the time-line, which includes the value-added-time needed for each process at the bottom and non-value-added time such as queues and down-times at the top.

The cupboard is made from six main parts: Two sides, two doors, bottom, shelf, back, and top. As shown in the VSM below, the first process is cutting, followed by edging. After the pieces have been edged and sided, they are then moved to the next process. The third and final process is done using the computer numerical control (CNC) router machine, which is responsible for drilling parts. Once all pieces are completed, it is assembled to create the finished cupboards, finally, the finished products are wrapped to be shipped to the customer. From the VSM, it is noticed that the total value-added-time is 49 min and the total non-value-added time is 4126 min, indicating a major area for improvements (

Figure 2).

4.2. Simulation Model

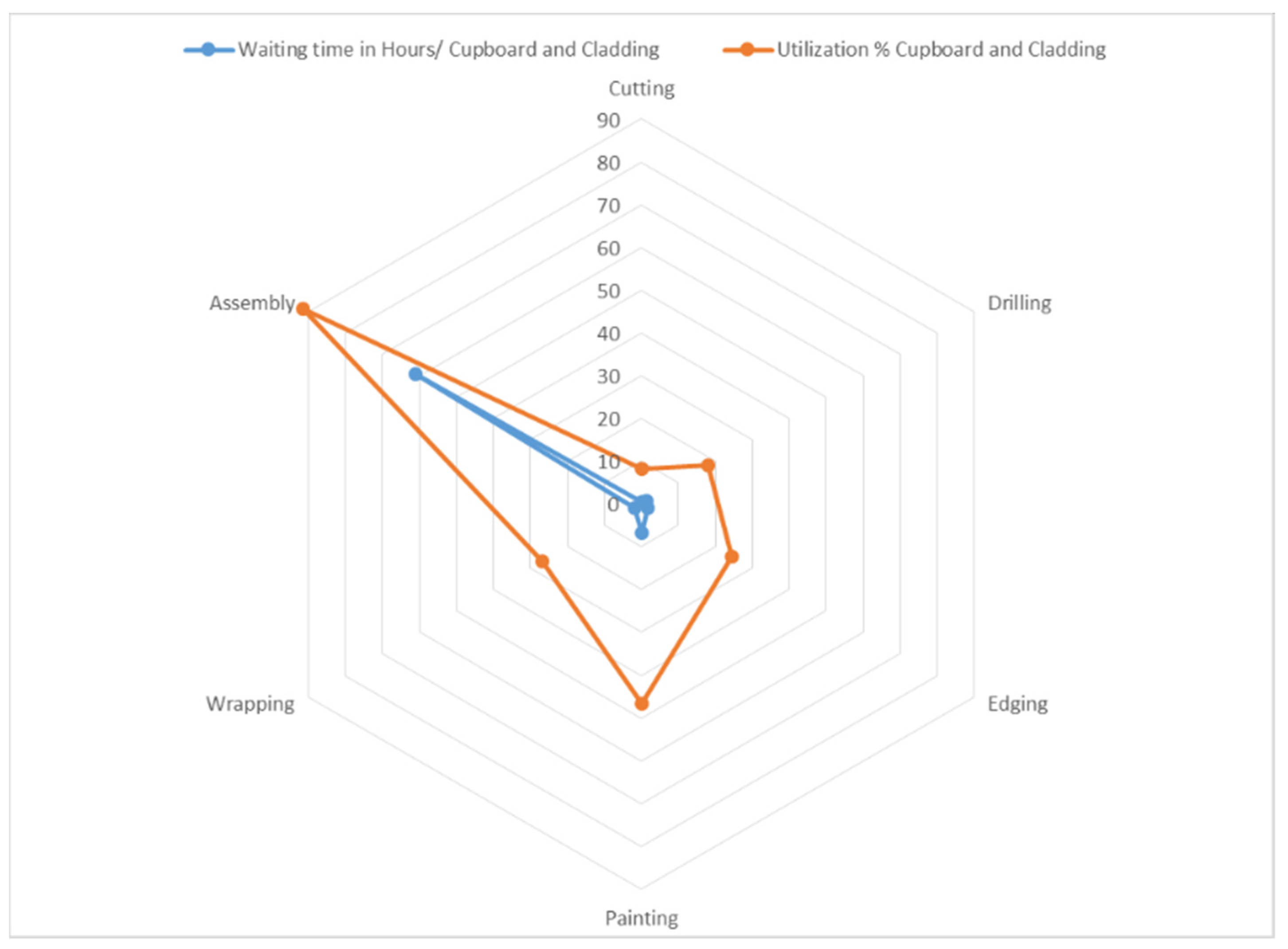

The simulation model provides an accurate estimation of the impact of Andons on the production system. In addition to the other performance measures, the simulation model will mainly evaluate bottlenecks in the production. Three bottleneck detection methods are used in this paper: utilization method, waiting time method, and scenario-based method. Based on the initial results obtained from the model, a number of scenarios will be tested. The algorithm starts with the resource that is maximally utilized and considers improving them by reducing process time and/or adding more resources. Then, the next highest utilization resource is considered, and new scenarios will be created accordingly. All resources identified as Andons in the VSM will be considered in a similar manner. Each scenario runs on the simulation model and then the overall system performance was evaluated. Performance measures including resource utilization, product cycle time, and the ability to meet deadline are used to evaluate system performance. Based on the results obtained, a proposed solution is provided to decision-makers. The last stage would be to examine the impact of the proposed solutions on the production facility, adding new resources to improved flow, and finally to create VSM future state.

The model was built using Rockwell’s Arena 14.7. It is a discrete-event system simulation, where events occur at discrete points of time on the simulation clock. For the simulation part of the analysis, two models were constructed for the analysis of production lines. The first model was concerned with modeling the production line of the doors, while the other model simulated the production lines of the cupboards and cladding, as both share the same resources in the factory. The simulation models were based on the VSMs drew in the previous stage and the data collected previously includes setup time, changeovers, and cycle time, which were recorded through observing workers for production runs and calculating the average of observations, the simulation model input data is shown in

Table 2.

Since the cupboard and cladding share the same production resources, one simulation model combining both products was created. Cladding is produced at first, then the entities needed to manufacture the cupboards are released, a separate model set to duplicate three pieces, the first piece is set to make the sides, second to make the doors, and the final piece to make the top, shelve and bottom.

A decision module works as follows: it divides the three entities into their own paths using the expression [(MOD, counter, 3) = 1, (MOD, counter, 3) = 2], this expression sends each entity to one of the three paths depending on the variable value each entity holds, if the module after dividing the variable by 3 is equal to 1, then the entity is sent to the first path, if its equal to 2, then its sent to the second path, and if its none of the above, then its sent to the third path.

A separate module duplicates the entity to 59 other entities that represent the raw materials that the workers load into the cutting machine when the processing starts. The sides are the first pieces to be worked out, they are batched into 3 to be loaded on the cutting machine, similar batching done with the cladding. After all 60 entities leave the cutting module, they pass into two separate modules, which were intended for loading the entities into the cutting machine while the other separate duplicated the entities in two as each board makes two sides.

Next, the entities pass through a signal module which releases the entity needed to produce the cupboard door, the entities pass through the exact steps as the sides passed through and when they’re done a signal is given for the release of the entity required to make the top, bottom and shelve. When all the pieces required to make the 60 cupboards are cut, the sides are released from the holding module so that they can enter the edging process. After all the sides finish with the edging module a signal is sent to release the door pieces and so on. After the top, bottom and shelving pieces are edged, the sides are released for drilling on the CNC machine. the pieces are worked on by fixed sequence, while one entity type is done by the operators at one of the three processes, the other entity types are being held in a hold waiting to be released by a signal.

After all the processing finish on all of the entity types, the cupboards are assembled, 2 batched sides enter a match module along with two batched doors, the output of this batching process is also matched and batched with a top, bottom and a shelve to complete a cupboard. After the cupboards are assembled they pass through a signal to initiate the production of the cladding again. Finally, the cupboards are wrapped so that they can be transported.

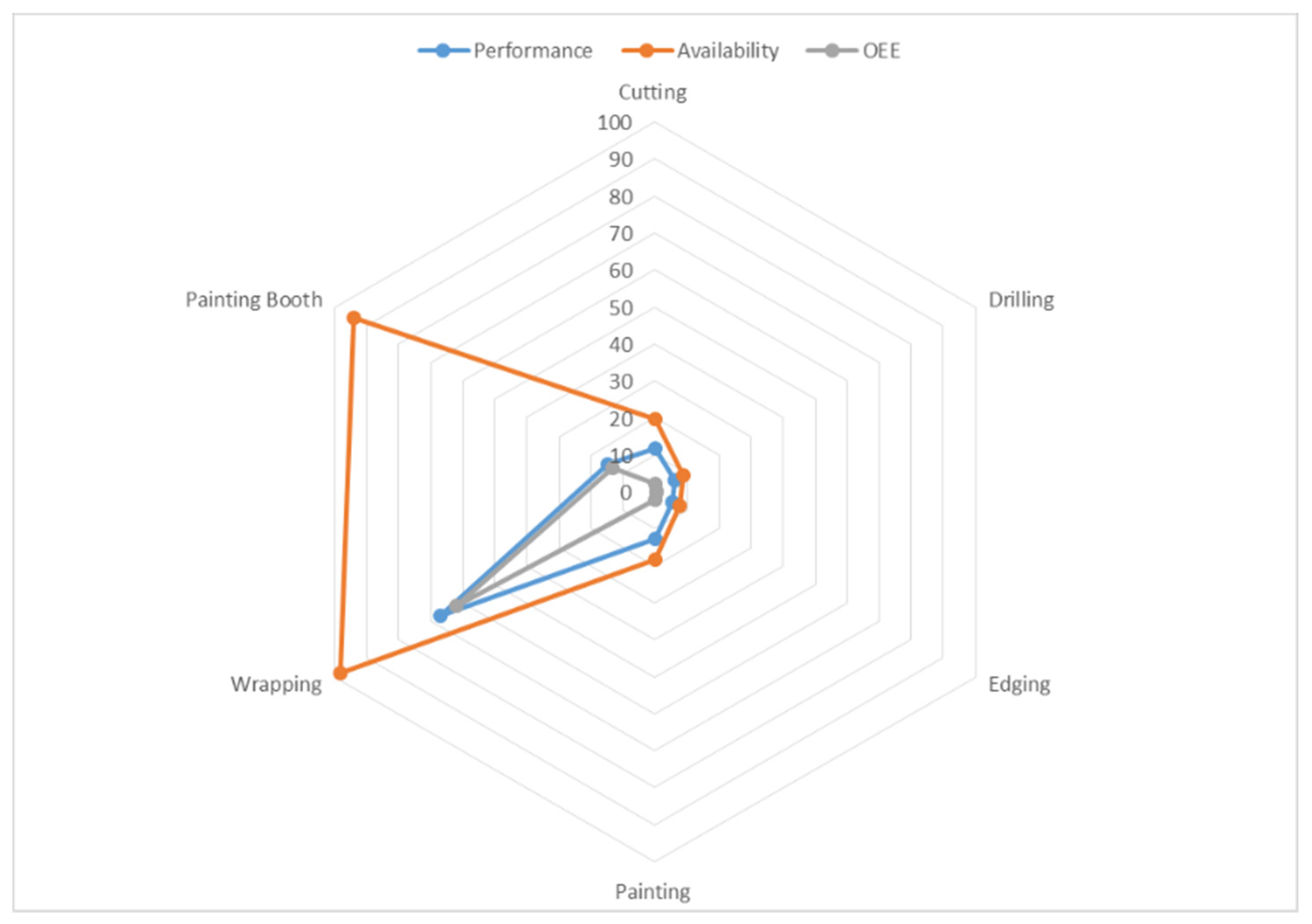

4.3. OEE Analysis

OEE analysis was conducted to study the effectiveness of the manufacturing processes as well as the subcomponents of those processes, to be able to compare it to the simulation results and validate it.

Both horizontal and vertical OEEs were calculated for both processes and machines. Total Available Time per shift was set as 570 min. Based on the information provided by the factory management, there is a one-hour break each shift, and there are on average 2 h wasted by employees for personal and minor technical problems, therefore, the planned production time was calculated as the total available time-breaks, and that is equal to 9.5 - 3 = 6.5 h (390 min). After collecting basic information about the shifts and times, the following equations for OEE were used [

33]:

To calculate the horizontal OEE for the cupboard, an input table was constructed for each process as shown in

Table 3, which are cutting, edging, drilling, assembly, and wrapping. The horizontal calculation results calculate the OEE of the whole manufacturing process. Three OEE values were calculated for the three processes based on the equations outlined above, as shown in

Table 4.

In the horizontal OEE Calculation, the OEE for manufacturing Cupboards turned about to be 54.1%. It is also noticeable that the highest factor affecting this factor is the performance of the processes, which could be considered as a potential improvement.

In the Vertical OEE calculation, OEE is calculated for machines that are used in the two or in all the three processes. Depending on our processes, the common machines between the processes are Cutting, Edging, Drilling, Wrapping, Painting as well as the Painting Booth. These processes are not necessarily used in all three processes, some are used in the production of only cupboards and claddings and not doors for example.

Table 5 shows the results for the vertical OEE.