A Numerical Research on Vortex Street Flow Oscillation in the Double Flapper Nozzle Servo Valve

Abstract

:1. Introduction

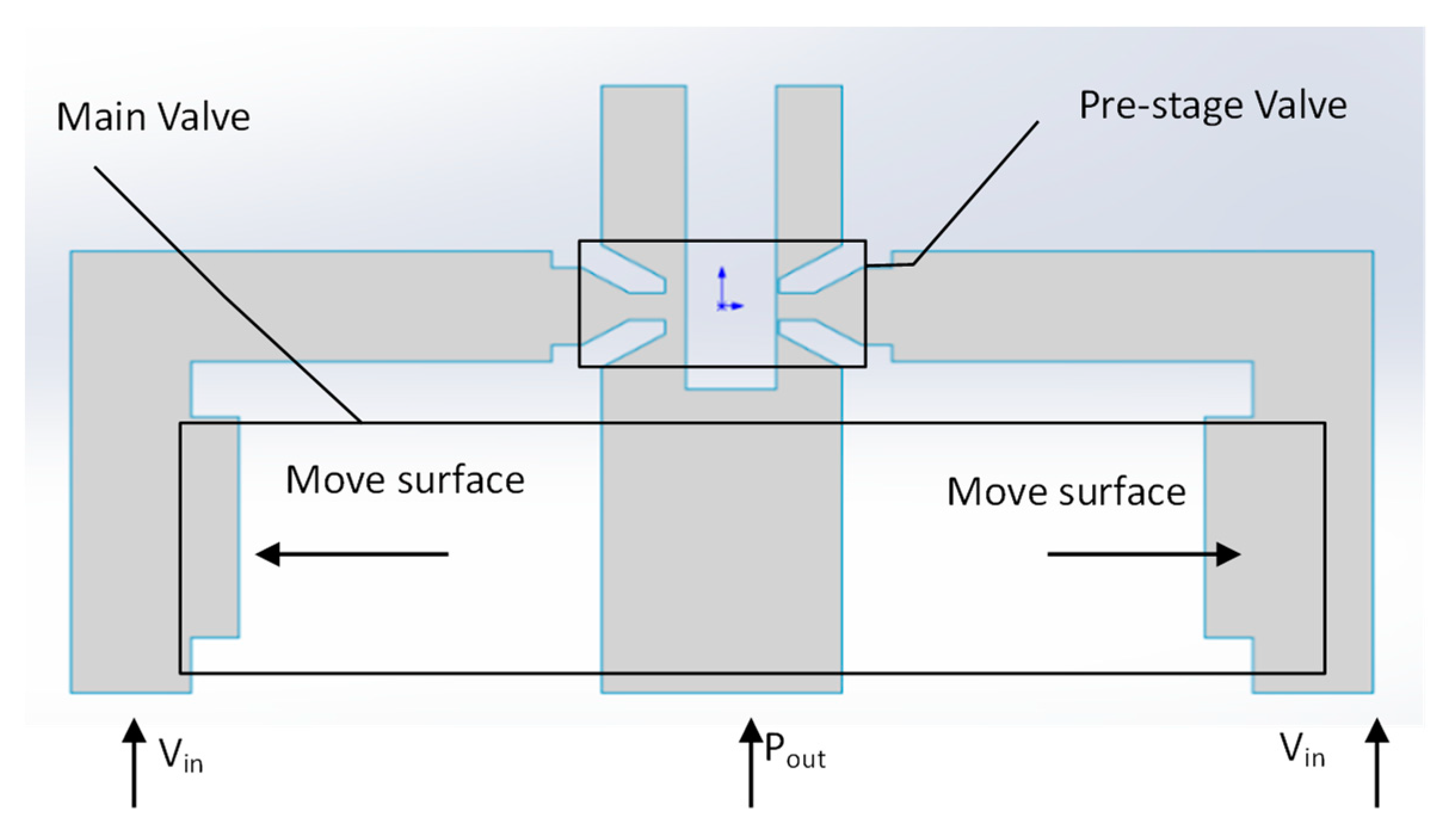

2. Flow Structure and Grid Independence Analysis

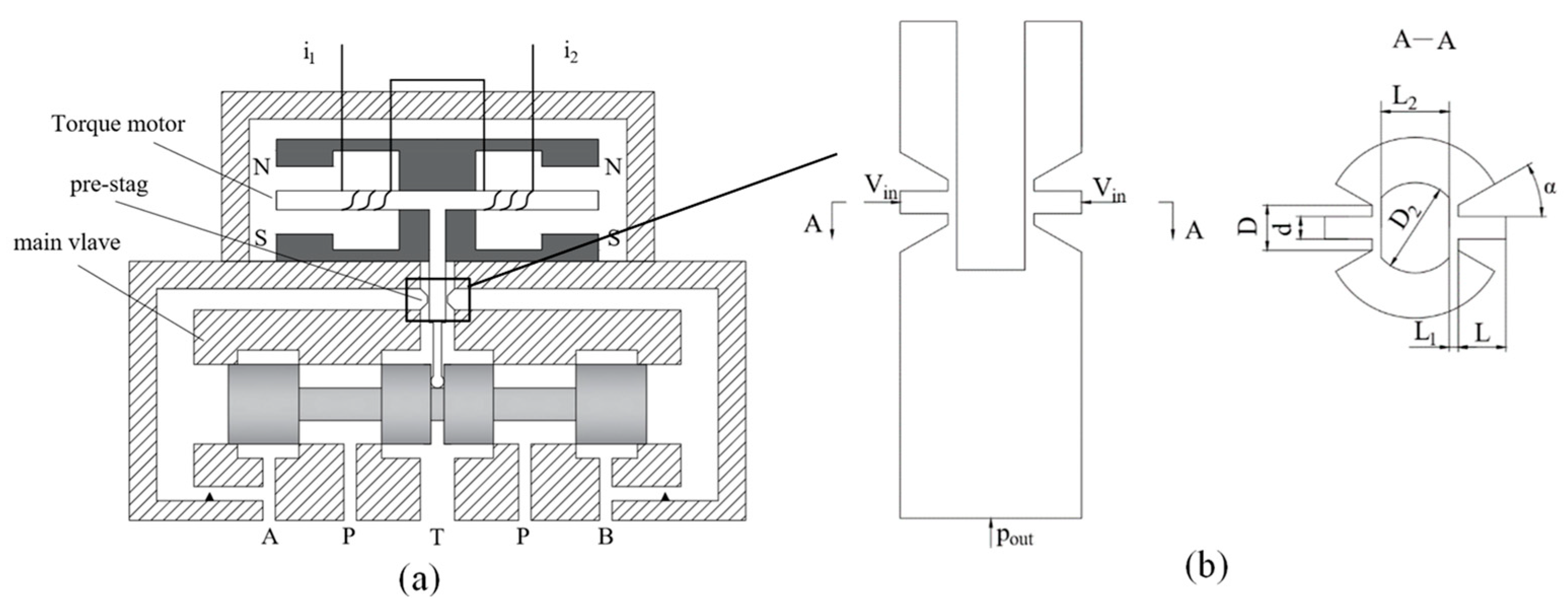

2.1. Operation Principle and Structural Parameters

2.2. Boundary Conditions and Simulation Settings

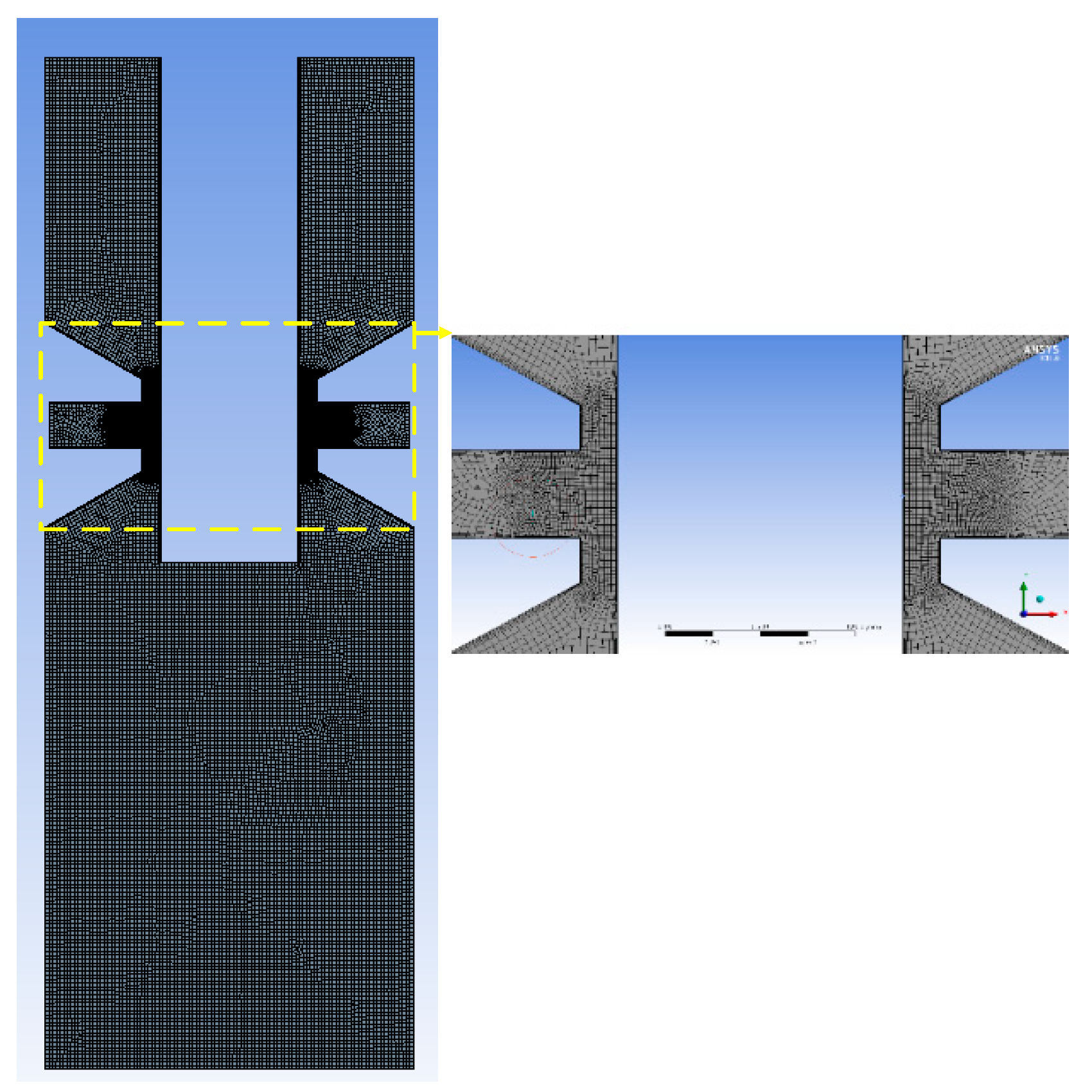

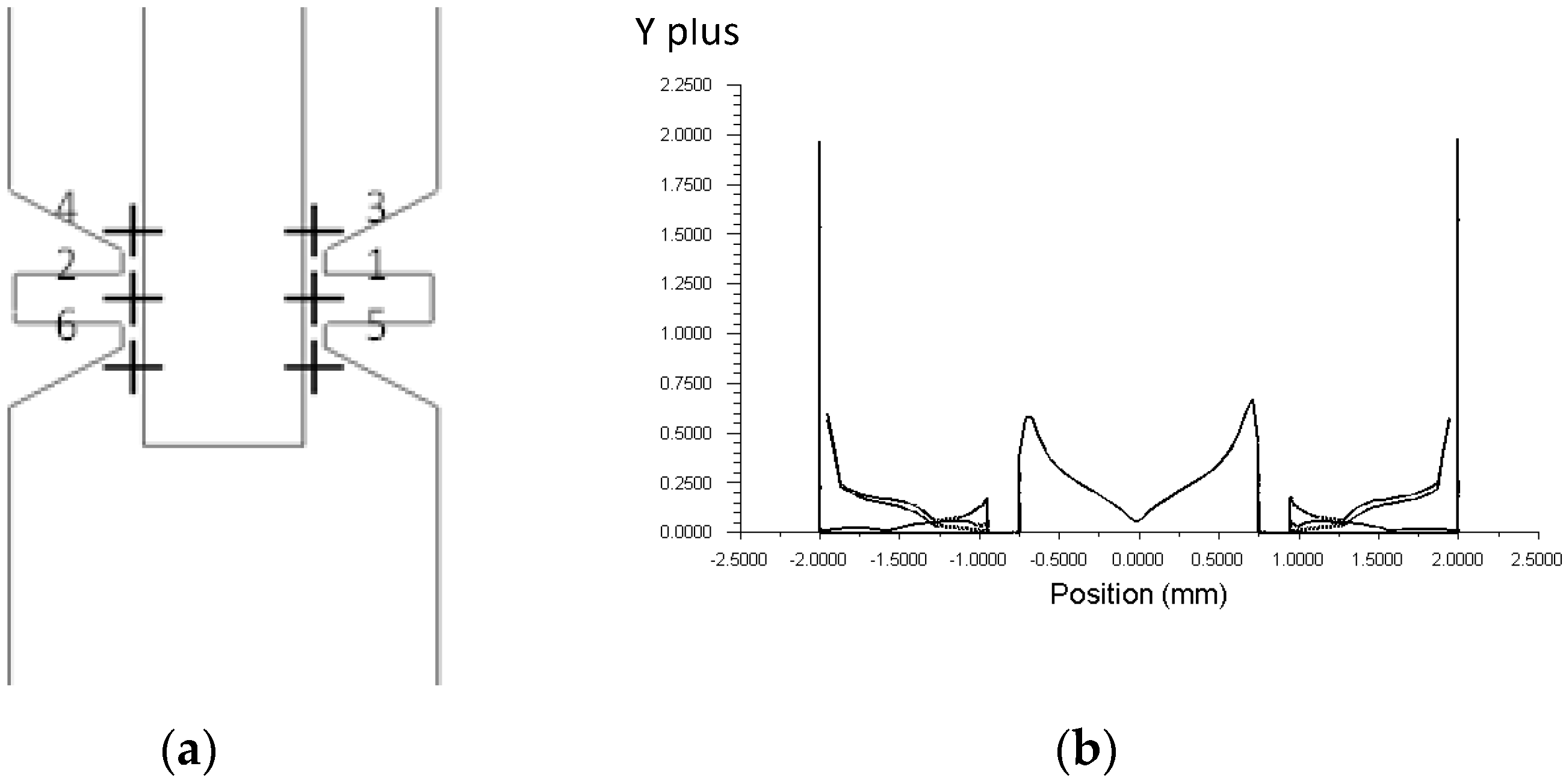

2.3. Grid Generation and Independence Analysis

3. Results and Discussion

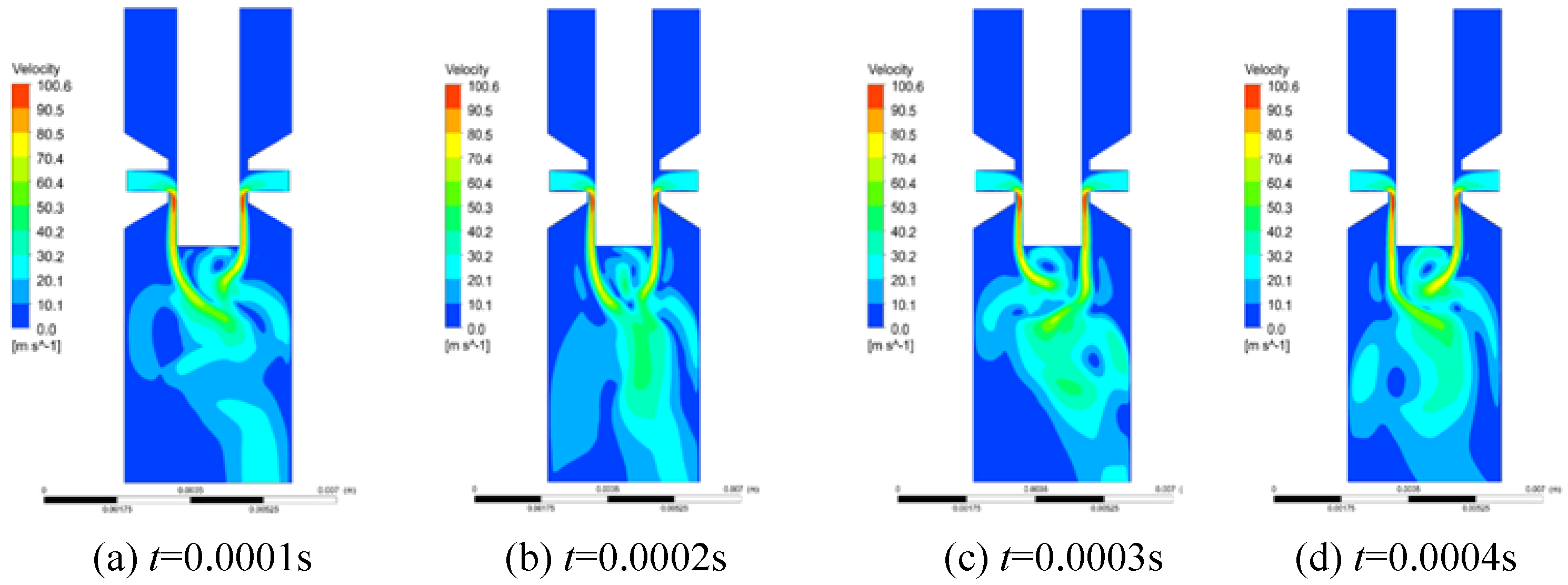

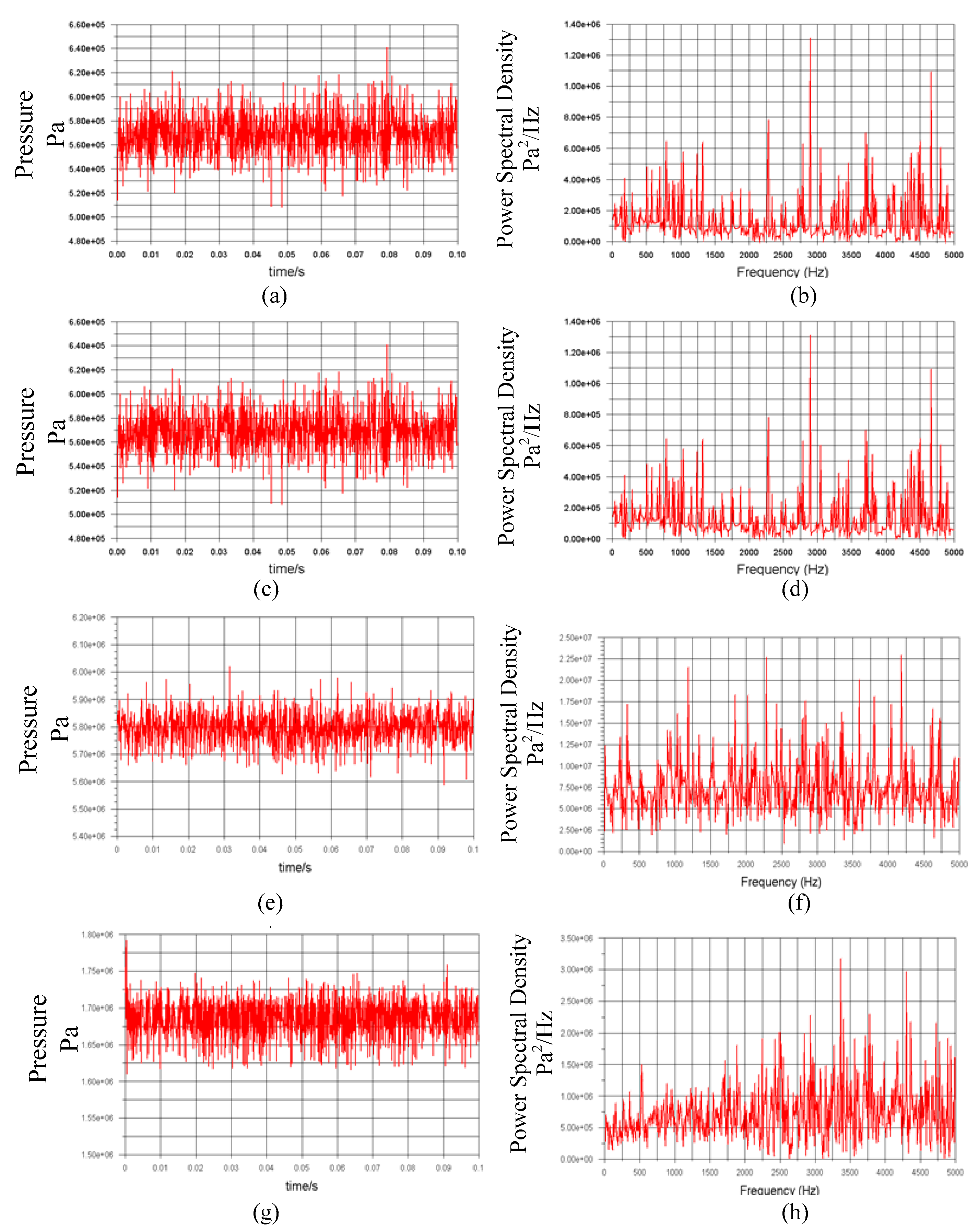

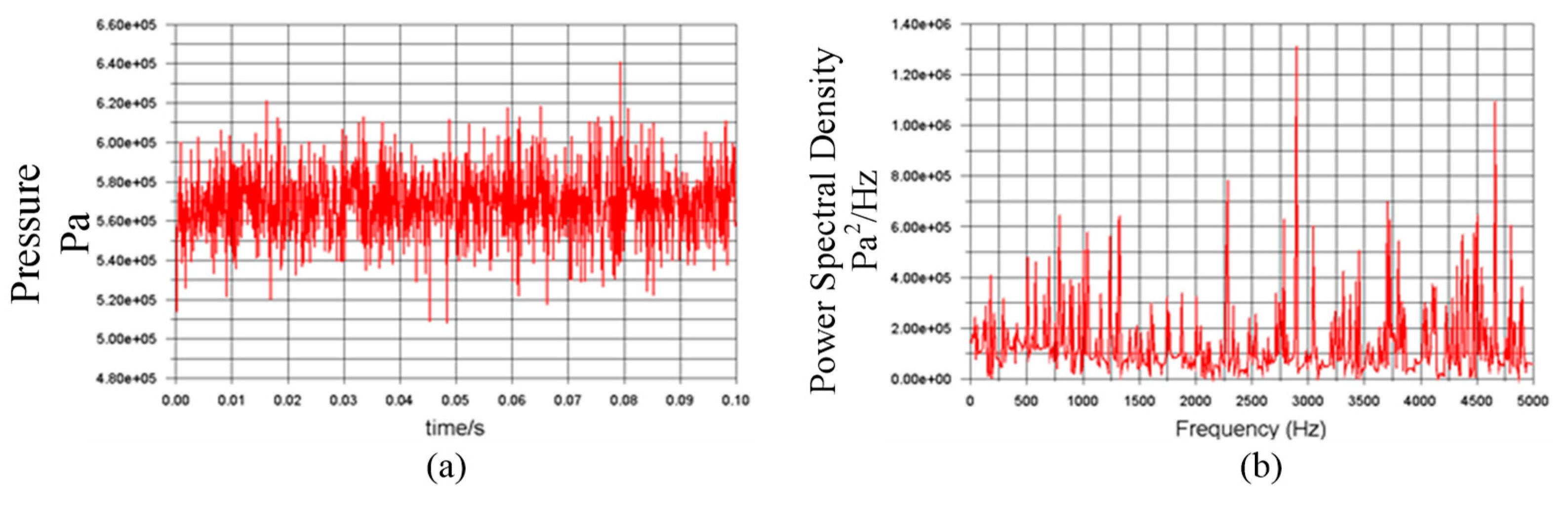

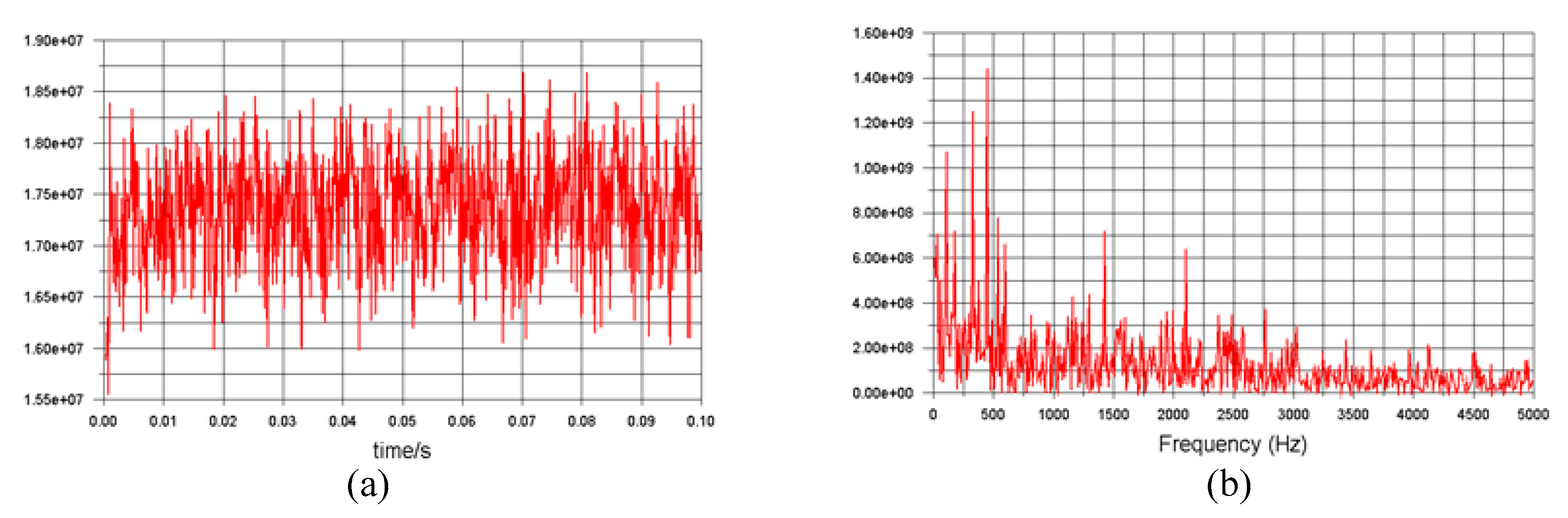

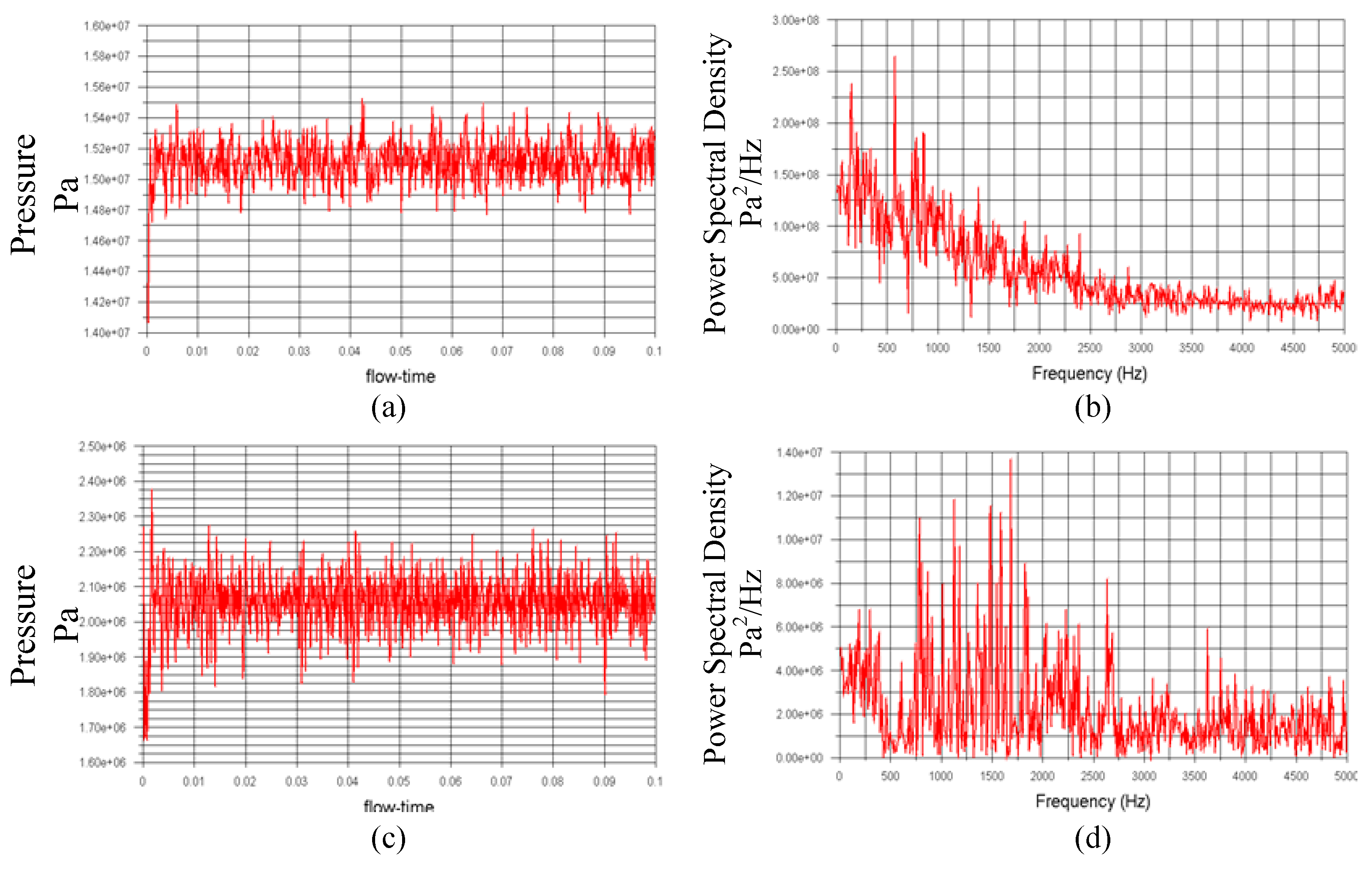

3.1. Flow Field Characteristics with Constant Velocity and Flapper Displacement

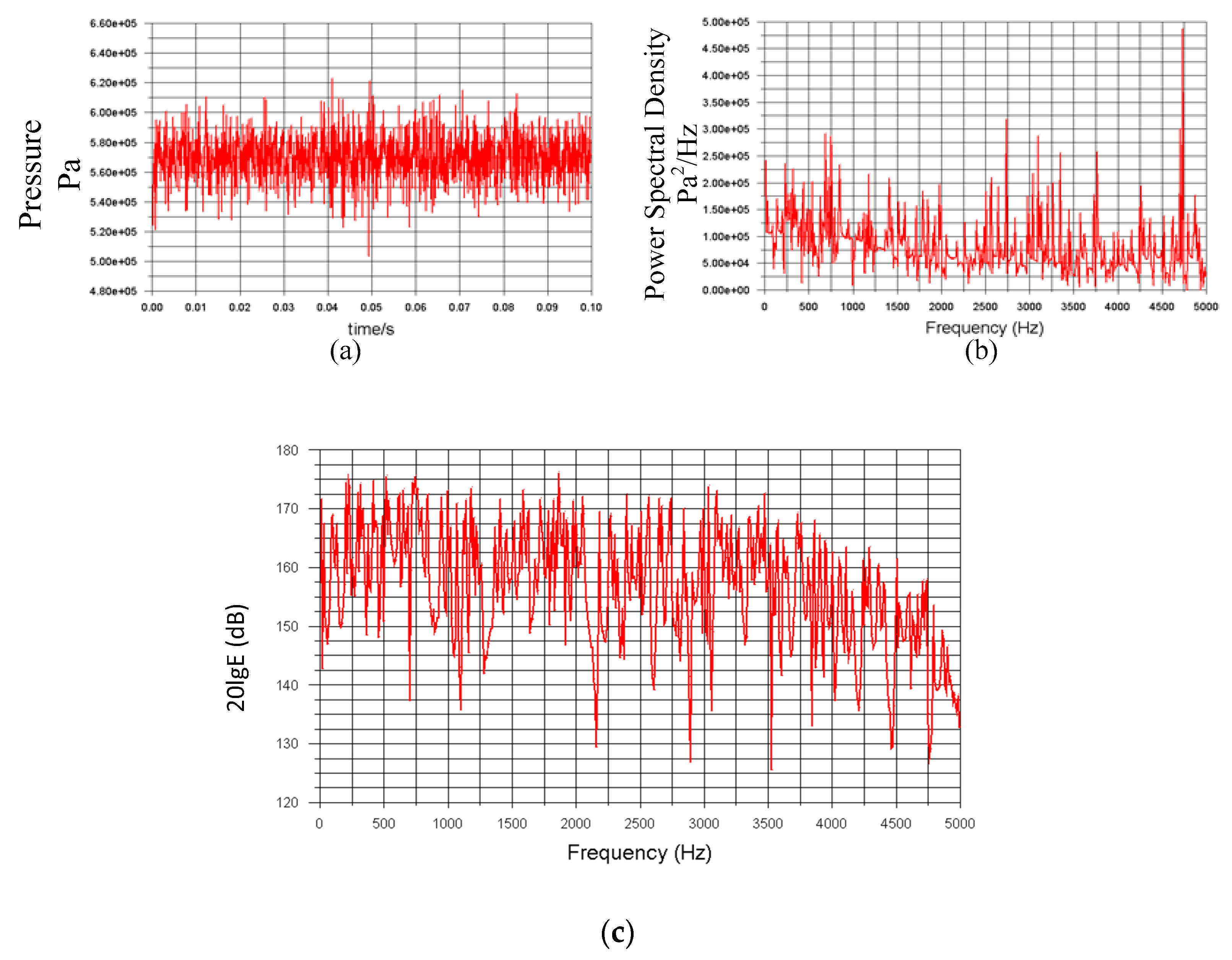

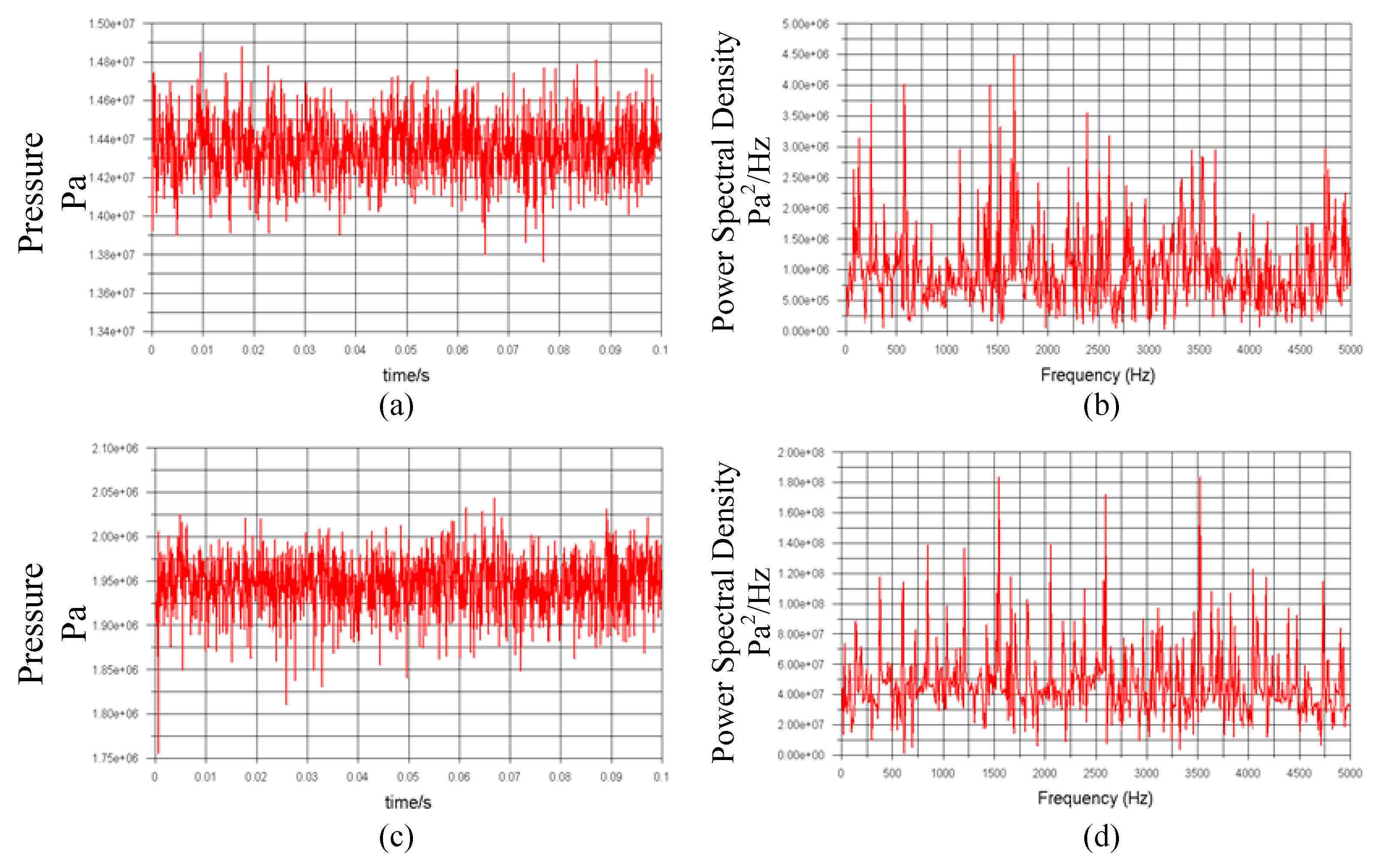

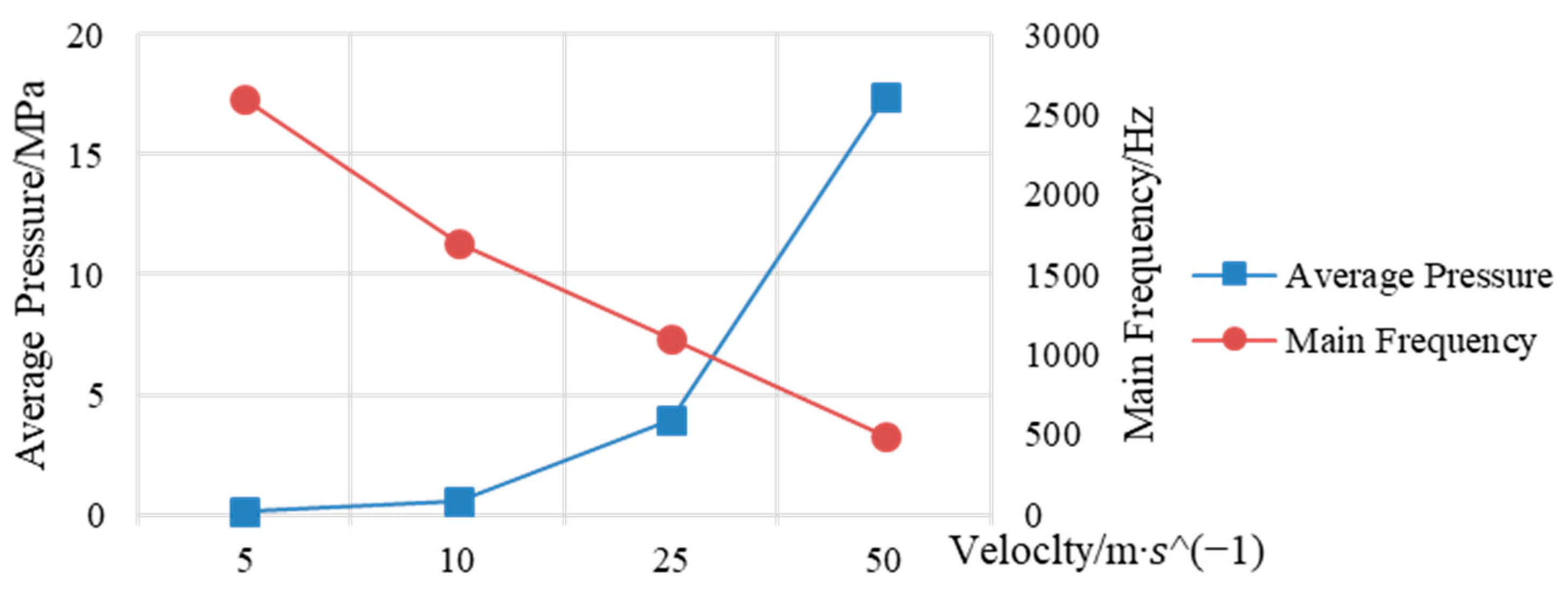

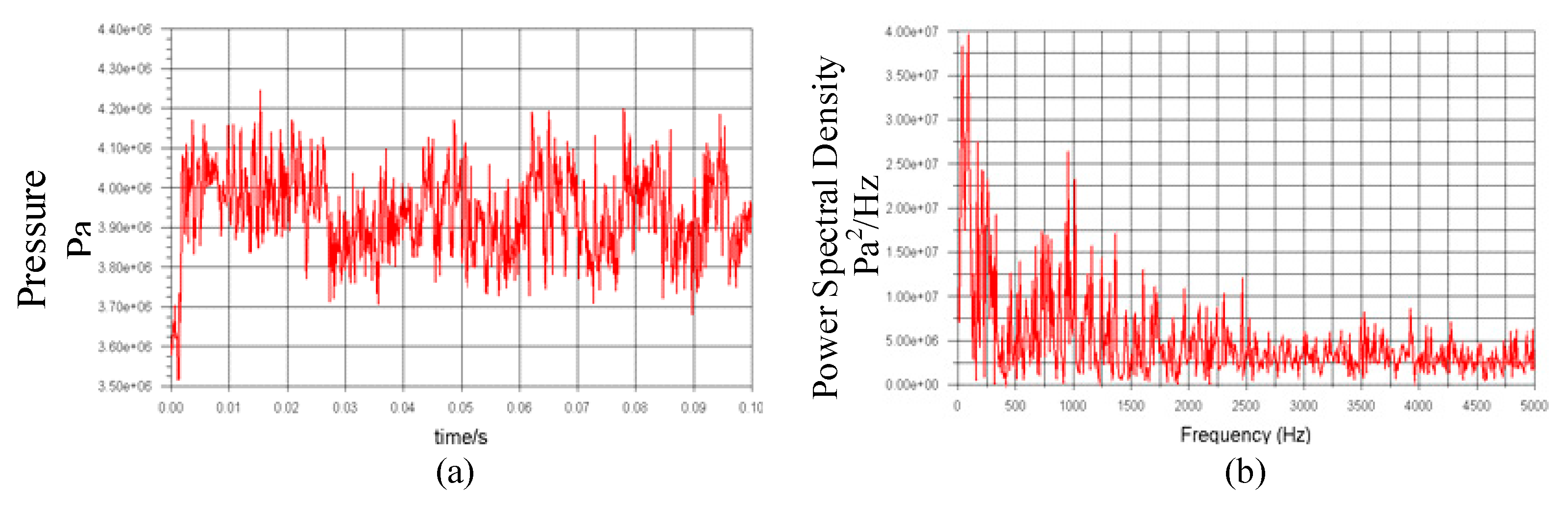

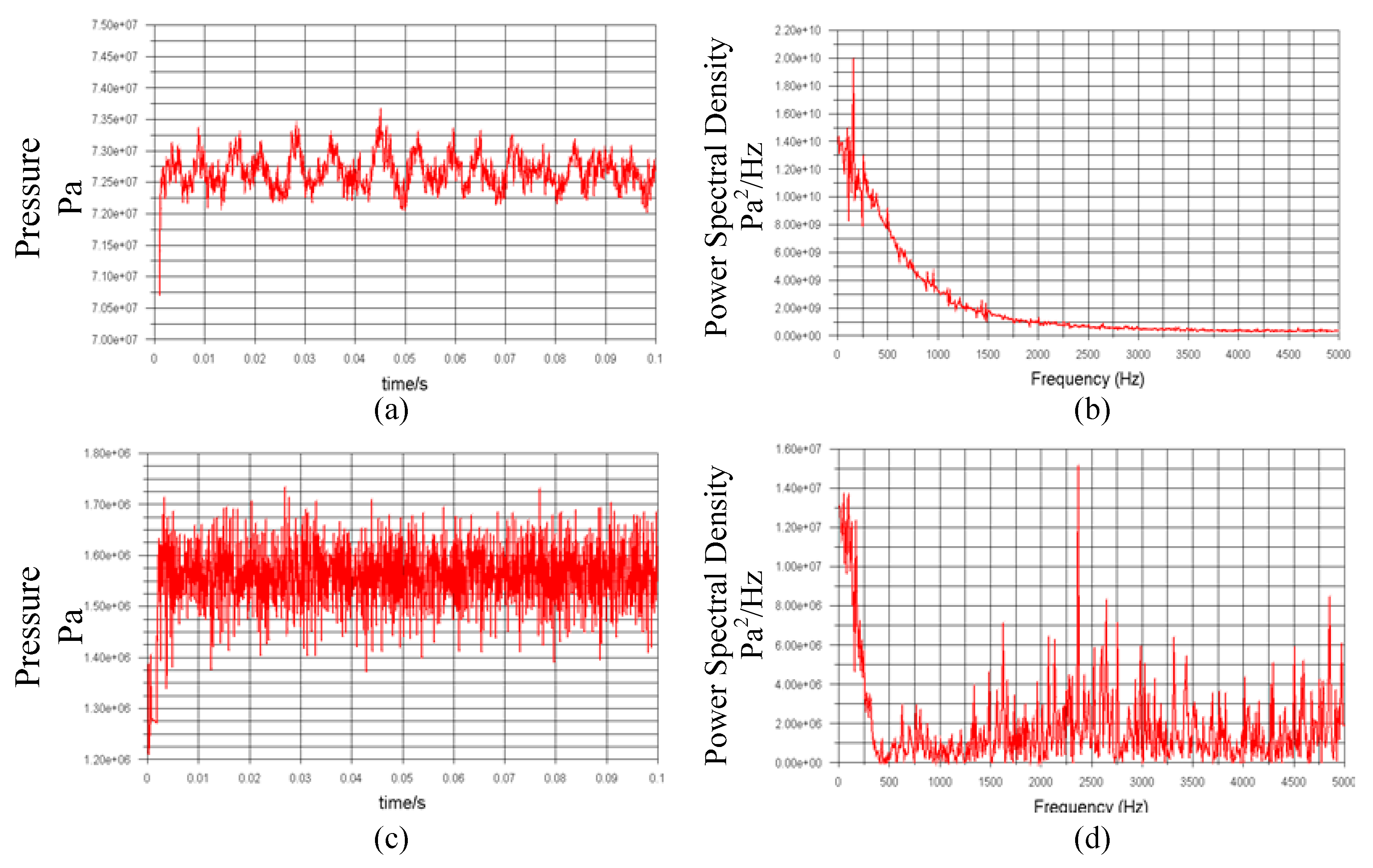

3.2. Variation of Main Frequency and Amplitude of Oscillation at Different Velocities

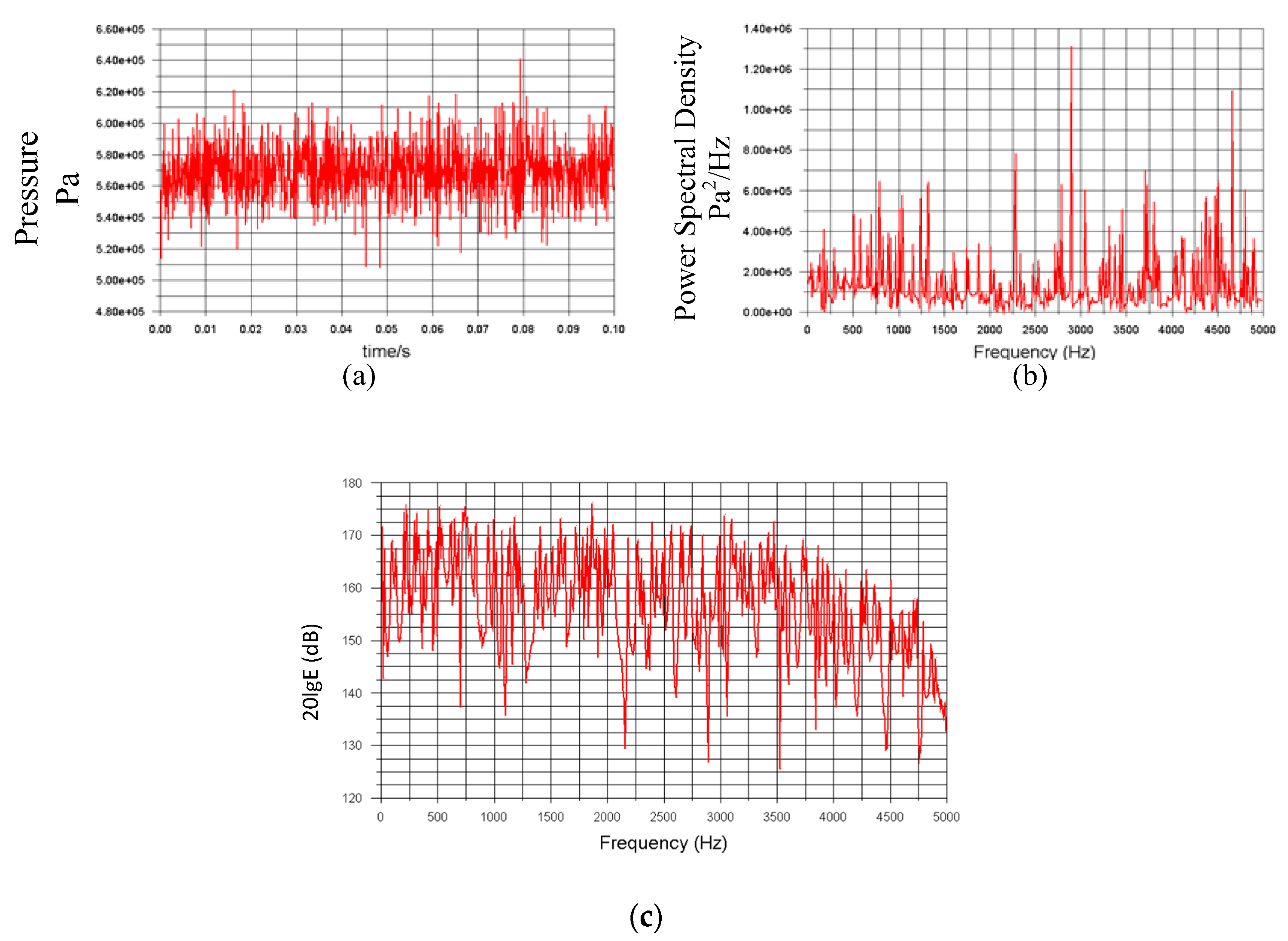

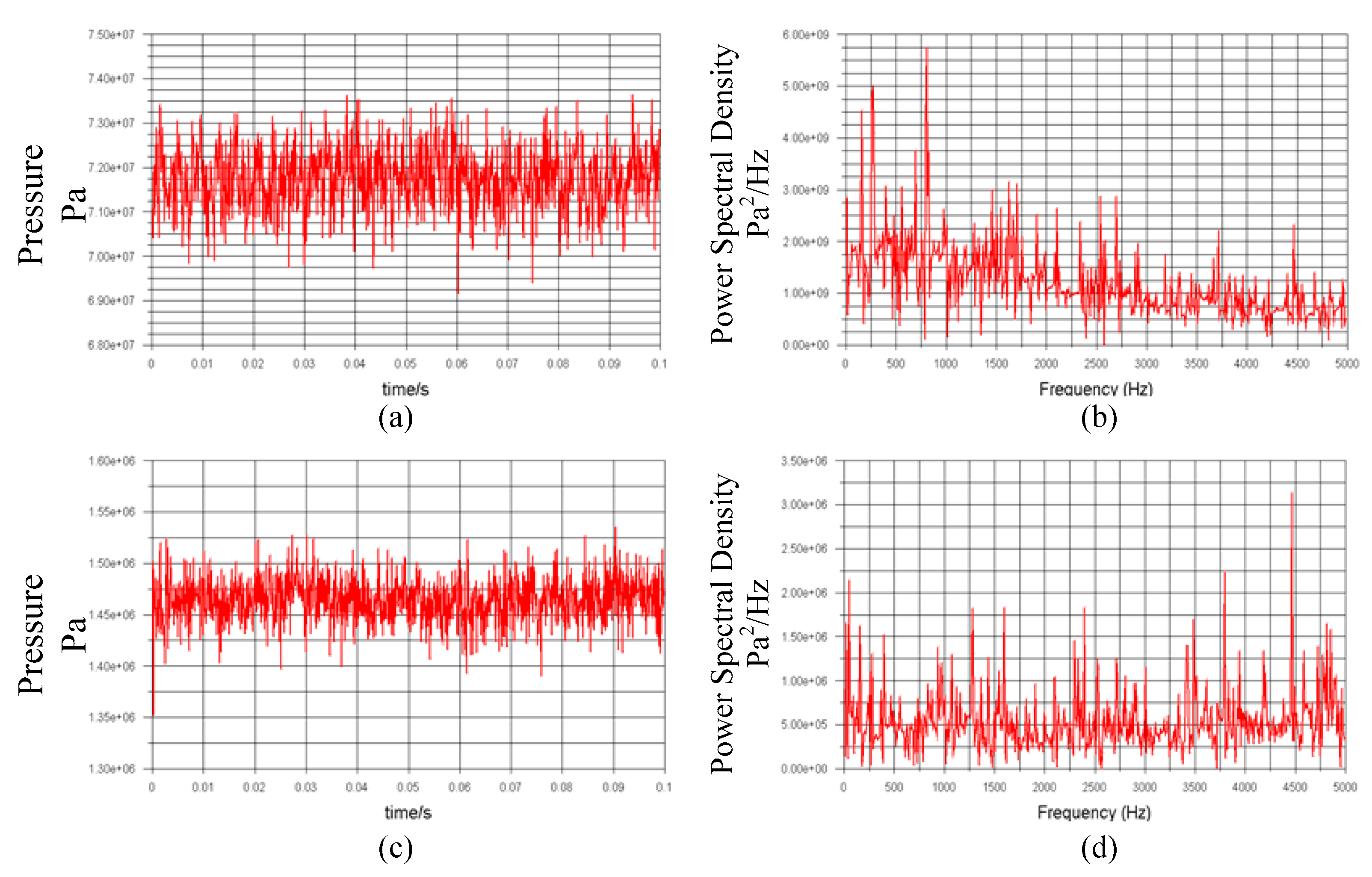

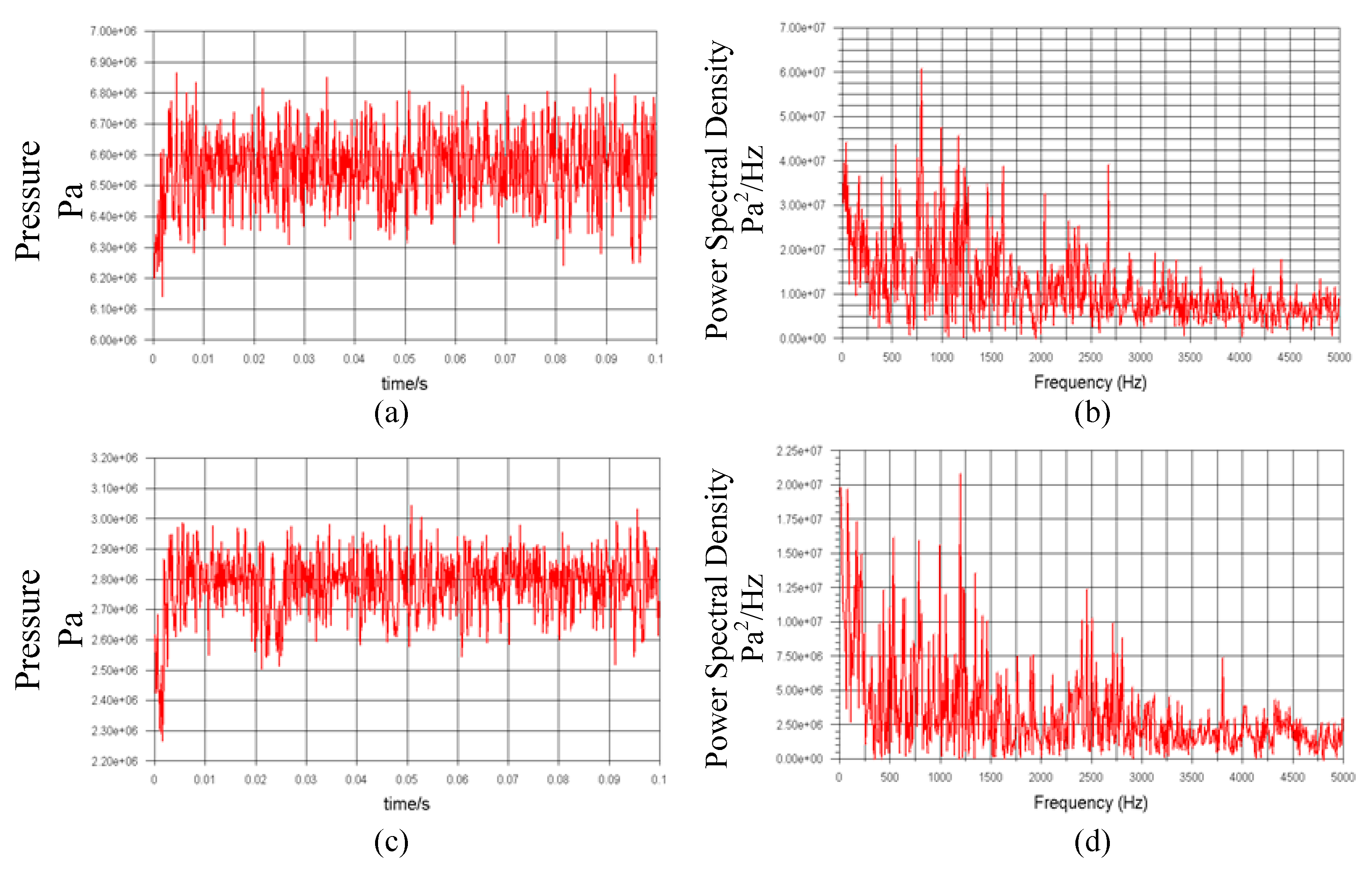

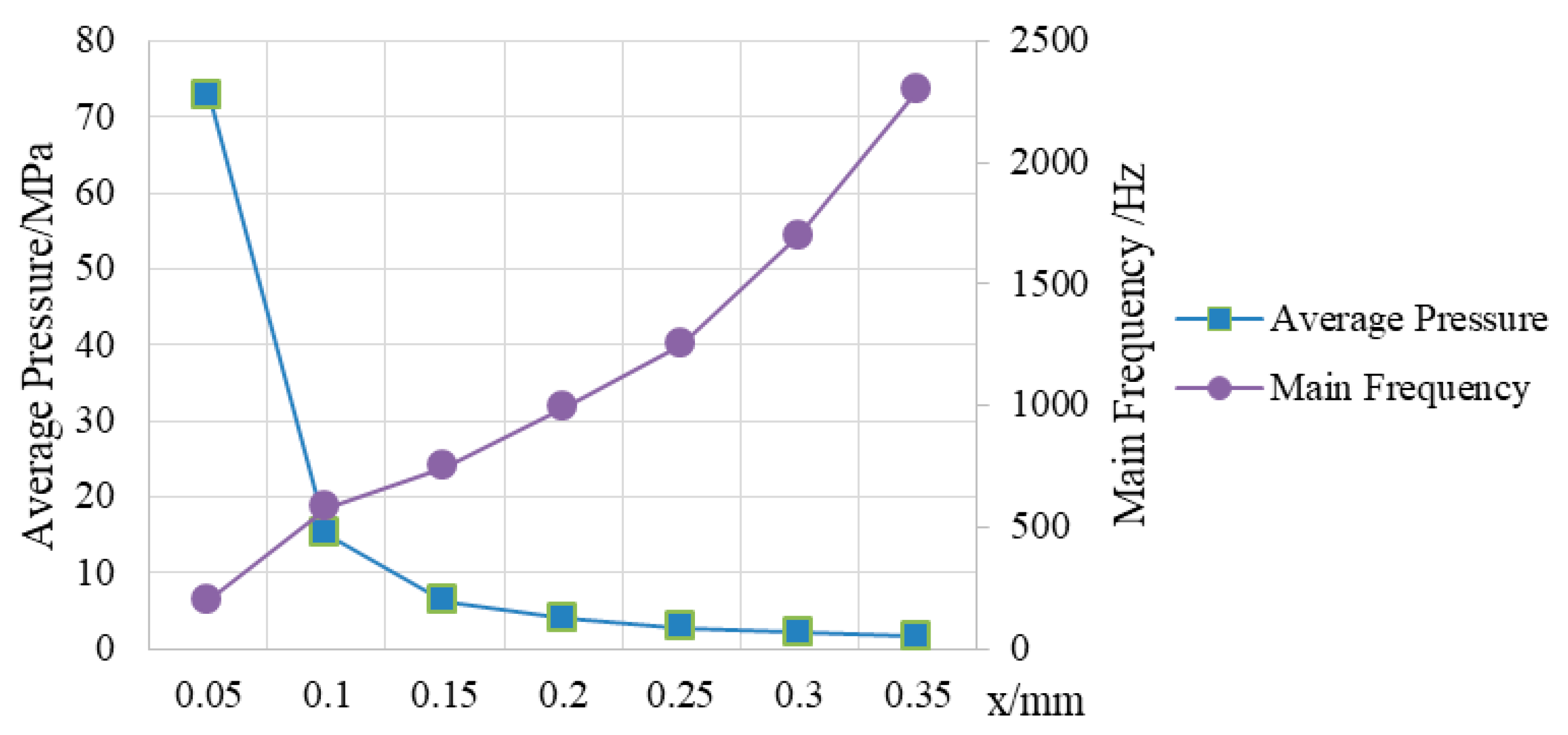

3.3. Variation of Main Frequency and Amplitude of Oscillation under Different Displacements

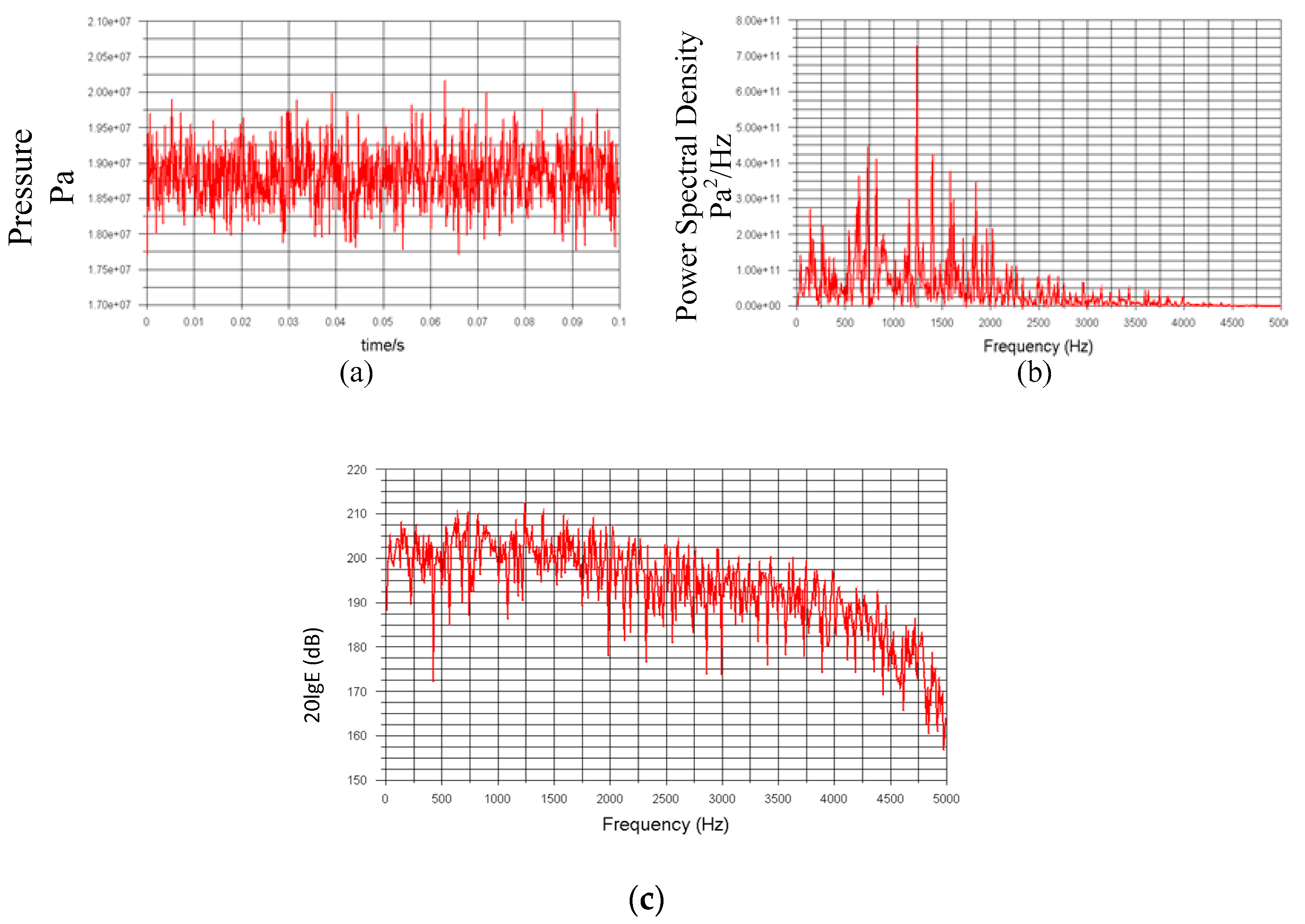

3.4. Oscillation Characteristics Considering Motion Coupling of the Main Valve

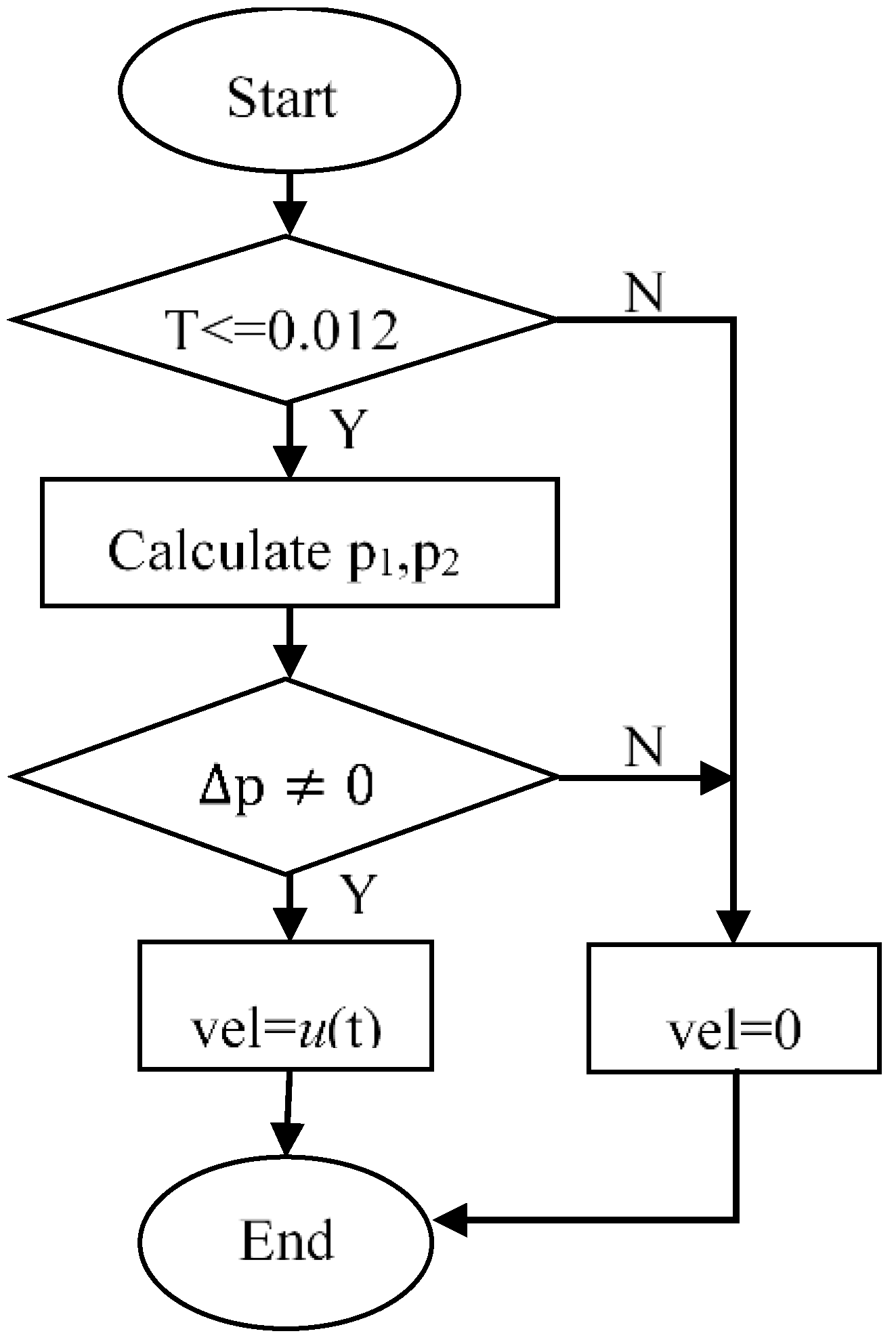

3.4.1. UDF Implementation Logic

3.4.2. Dynamic Grid Design and Simplification for Flapper Deflection

3.4.3. Principal Frequency and Amplitude Change Rule in the Coupling of Main Valve

- (1)

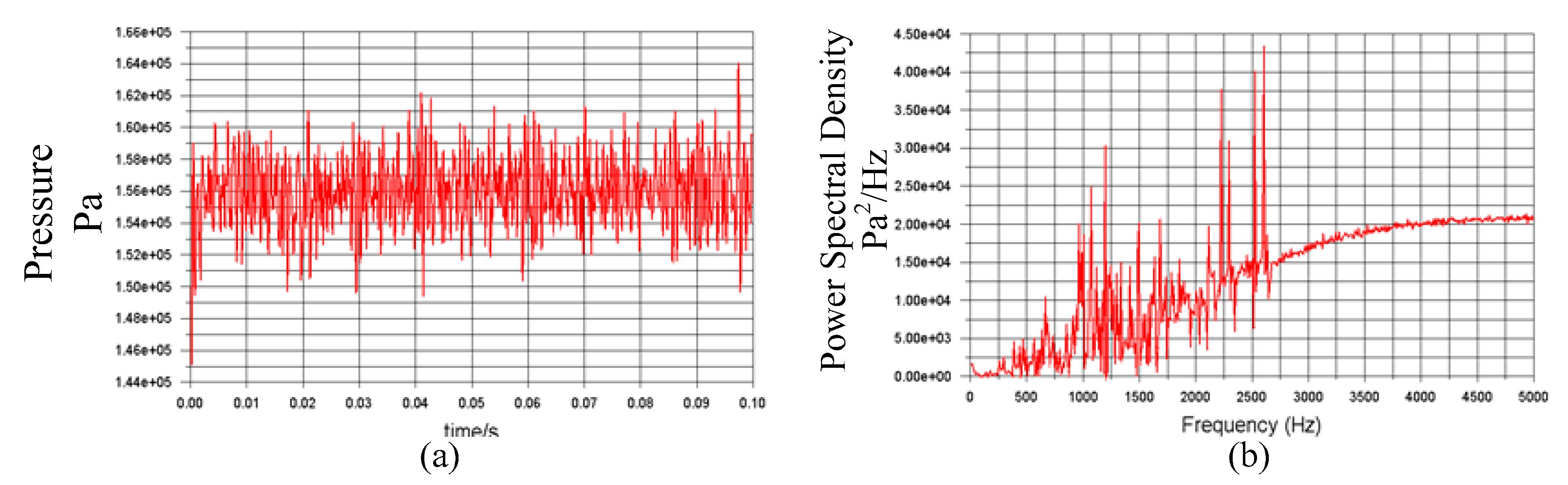

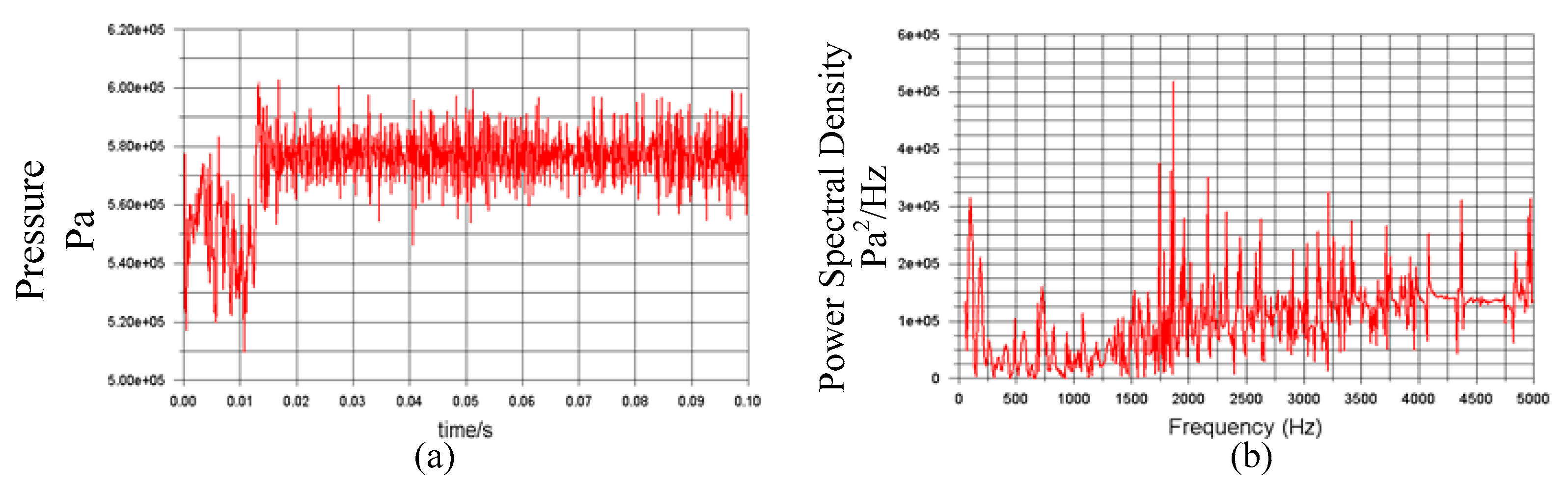

- Variation of flow field of servo valve with the change of inlet velocity

- (2)

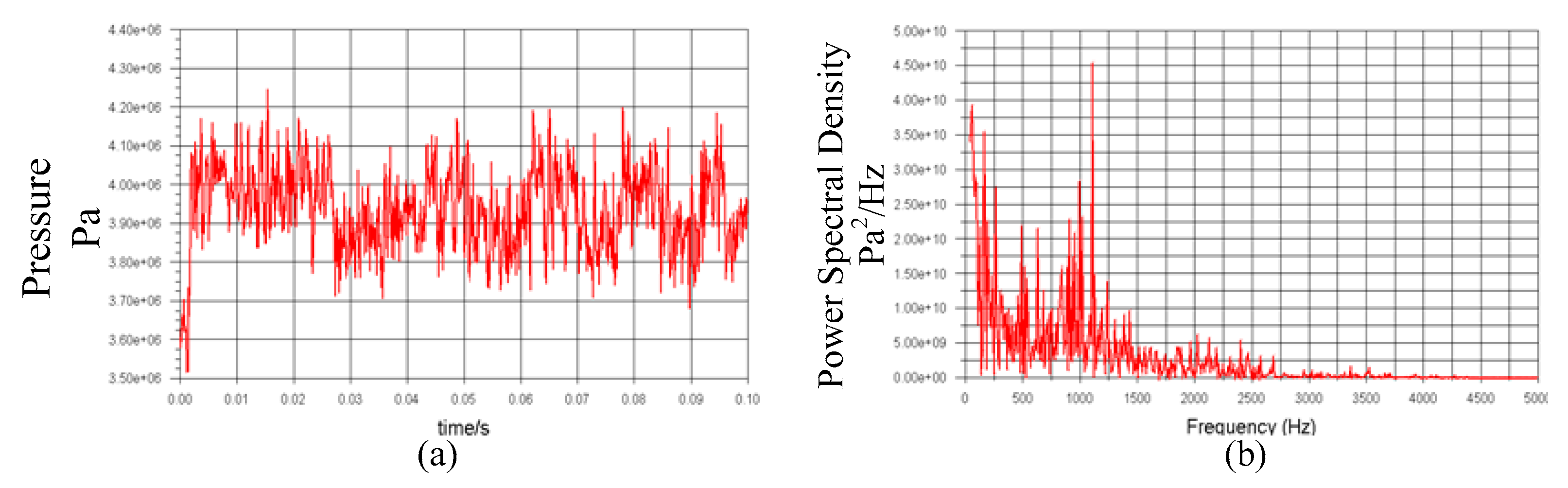

- Variation of flow field of the servo valve with the change of the flapper displacement

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| d | Internal diameter | D | External diameter |

| L1 | Spacing | α | Angle |

| L | Length | D1 | Diameter |

| L2 | Thickness | L3 | Import and Export Center Distance of Load |

| m | Spool mass | pv | Pressure difference between inlet and outlet of main valve |

| x | Spool displacement | Cv | Oil Flow Velocity Coefficient of Main Valve |

| Cf | Coefficient of viscous resistance | θ | Directional angle of jet-flow |

| A | Spool end area | r | Distance between nozzle hole axis and armature Center |

| p1, p2 | Pressure at both ends of spool | b | Axis pitch from core center to nozzle hole |

| ρ | Density of hydraulic oil | Kf | Stiffness of Feedback Bar |

| Cq1 | The Flow Coefficient of Main Valve | Q | Inlet flow |

| w | Area Gradient of Throttle Hole |

References

- Jones, J.C. Developments in Design of Electrohydraulic Control Valves; Moog Technical Paper; Moog: Melbourne, VIC, Australia, 1997. [Google Scholar]

- Moog, J.W.C. Electrohydraulic Servo Mechanism. U.S. Patent 2,625,136, 13 January 1953. [Google Scholar]

- Howard, C.T. Flow Control Servo Valve. U.S. Patent 2,790,427, 30 April 1957. [Google Scholar]

- Atchley, R.D. Valve. U.S. Patent 3,017,864, 23 January 1962. [Google Scholar]

- Vanderlaan, R.D.; Meulendyk, J.W. Direct Drive Valve-Ball Drive Mechanism. U.S. Patent 4,672,992, 16 June 1987. [Google Scholar]

- Laux, K. Motor-to-Spool Coupling for Rotary-to-Linear Direct Drive Valve. U.S. Patent 5,263,680, 23 November 1993. [Google Scholar]

- Samakwong, T.; Assawinchaichote, W. PID controller design for electro-hydraulic servo valve system with genetic algorithm. Procedia Comput. Sci. 2016, 86, 91–94. [Google Scholar] [CrossRef]

- Brito, A.G.; Leite, F.W.C.; Hemerly, E.M. Identification of a Hammerstein model for an aerospace electrohydraulic servovalve. IFAC Proc. Vol. 2013, 46, 459–463. [Google Scholar] [CrossRef]

- Khodaee, Z.; Zareinejad, M.; Ghidary, S.S. Modeling of a two-stage flapper-nozzle electrohydraulic servo valve exposed to acceleration. In Proceedings of the 2014 Second RSI/ISM International Conference on Robotics and Mechatronics (ICRoM) IEEE, Tehran, Iran, 15–17 October 2014; pp. 268–273. [Google Scholar]

- Ye, S.; Zhang, J.; Xu, B.; Zhu, S.; Xiang, J.; Tang, H. Theoretical investigation of the contributions of the excitation forces to the vibration of an axial piston pump. Mech. Syst. Signal Process. 2019, 129, 201–217. [Google Scholar] [CrossRef]

- Li, S.; Aung, N.Z.; Zhang, S.; Cao, J.; Xue, X. Experimental and numerical investigation of cavitation phenomenon in flapper–nozzle pilot stage of an electrohydraulic servo-valve. Comput. Fluids 2013, 88, 590–598. [Google Scholar] [CrossRef]

- Chen, M.; Aung, N.Z.; Li, S.; Zou, C. Effect of oil viscosity on self-excited noise production inside the pilot stage of a two-stage electrohydraulic servovalve. J. Fluids Eng. 2019, 141, 011106. [Google Scholar] [CrossRef]

- Qian, J.Y.; Chen, M.R.; Liu, X.L.; Jin, Z.J. A numerical investigation of the flow of nanofluids through a micro Tesla valve. J. Zhejiang Univ. Sci. A 2019, 20, 50–60. [Google Scholar] [CrossRef]

- Chao, Q.; Zhang, J.; Xu, B.; Huang, H.; Zhai, J. Effects of inclined cylinder ports on gaseous cavitation of high-speed electro-hydrostatic actuator pumps: A numerical study. Eng. Appl. Comput. Fluid Mech. 2019, 13, 245–253. [Google Scholar] [CrossRef]

- Qian, J.Y.; Gao, Z.X.; Liu, B.Z.; Jin, Z.J. Parametric study on fluid dynamics of pilot-control angle globe valve. J. Fluids Eng. 2018, 140, 111103. [Google Scholar] [CrossRef]

- Zhang, J.H.; Wang, D.; Xu, B.; Gan, M.Y.; Pan, M.; Yang, H.Y. Experimental and numerical investigation of flow forces in a seat valve using a damping sleeve with orifices. J. Zhejiang Univ. Sci. A 2018, 19, 417–430. [Google Scholar] [CrossRef]

- Yin, Y.B. Theory and Application of Advanced Hydraulic Component; Shanghai Scientific & Technical Publishers: Shanghai, China, 2017. [Google Scholar]

- Wang, F.J. Computational Fluid Dynamics Analysis; Tsinghua University Press: Beijing, China, 2004. [Google Scholar]

| Parameter | Numerical Value | |

|---|---|---|

| Reference pressure/MPa | 0.1 | |

| Density/kg∙m−3 | 889 | |

| Dynamic Viscosity/Pa·s | 0.04 | |

| Modulus of elasticity/MPa | 1000 | |

| Nozzle | Internal diameter/d | 0.5 |

| External diameter/D | 1 | |

| Spacing/L1 | 0.2 | |

| Length/L | 1.0 | |

| Angle/α | 30 | |

| Flapper | Diameter/D1 | 2.0 |

| Thickness/L2 | 1.5 | |

| Emulation Items | Emulation Settings |

|---|---|

| Fluid state | Single-phase turbulent transient |

| Pressure algorithm | SIMPLEC |

| Discrete scheme | Second-order upwind |

| Pressure correction algorithm | PRESTO! |

| Transient equation | Second-order implicit equation |

| Simulation step size | 0.0001s |

| Grid Size/mm | Nodes | Elements | Element Quality | Skewness | Skewness (max) | Orthogonal Quality | Orthogonal Quality (min) |

|---|---|---|---|---|---|---|---|

| 0.010 | 26,090 | 25,411 | 0.835 | 0.078 | 0.643 | 0.982 | 0.544 |

| 0.012 | 22,795 | 22,150 | 0.839 | 0.068 | 0.609 | 0.985 | 0.544 |

| 0.015 | 20,048 | 19,440 | 0.839 | 0.066 | 0.759 | 0.985 | 0.312 |

| 0.020 | 17,815 | 17,243 | 0.841 | 0.066 | 0.788 | 0.985 | 0.272 |

| Flapper Displacement x/mm | Nodes | Elements | Element Quality | Skewness | Skewness (max) | Orthogonal Quality |

|---|---|---|---|---|---|---|

| x = 0.00 | 22,795 | 22,150 | 0.839 | 0.068 | 0.609 | 0.985 |

| x = 0.05 | 20,922 | 20,291 | 0.899 | 0.071 | 0.669 | 0.986 |

| x = 0.10 | 22,953 | 22,292 | 0.836 | 0.069 | 0.747 | 0.983 |

| x = 0.15 | 20,967 | 20,321 | 0.909 | 0.061 | 0.676 | 0.989 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Spool mass m/kg | 0.01 | Import and Export Center Distance of Load L3/m | 1.34 × 10−2 |

| Spool displacement x/m | Pressure difference between inlet and outlet of main valve pv/MPa | 5 | |

| Coefficient of viscous resistance Cf/kg·s−1 | 17.4 | Oil Flow Velocity Coefficient of Main Valve Cv | 0.99 |

| Spool end area | 3.14 × 10−6 | Directional angle of jet-flow θ/° | 69 |

| Pressure at both ends of spool p1, p2 | Distance between nozzle hole axis and armature Center r/m | 2.0 × 10−3 | |

| Density of hydraulic oil ρ/kg·m−3 | 889 | Axis pitch from core center to nozzle hole b/m | 3.0 × 10−3 |

| The Flow coefficient of the main valve Cq1 | 0.8 | Stiffness of Feedback Bar kf/N·m−1 | 3.4 × 103 |

| Area gradient of the throttle hole w/m2 | 1.256 × 10−2 | Inlet flow Q/m3·s−1 | 8.3 × 10−5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, L.; Long, S.; Zhu, K. A Numerical Research on Vortex Street Flow Oscillation in the Double Flapper Nozzle Servo Valve. Processes 2019, 7, 721. https://doi.org/10.3390/pr7100721

Lu L, Long S, Zhu K. A Numerical Research on Vortex Street Flow Oscillation in the Double Flapper Nozzle Servo Valve. Processes. 2019; 7(10):721. https://doi.org/10.3390/pr7100721

Chicago/Turabian StyleLu, Liang, Shirang Long, and Kangwu Zhu. 2019. "A Numerical Research on Vortex Street Flow Oscillation in the Double Flapper Nozzle Servo Valve" Processes 7, no. 10: 721. https://doi.org/10.3390/pr7100721

APA StyleLu, L., Long, S., & Zhu, K. (2019). A Numerical Research on Vortex Street Flow Oscillation in the Double Flapper Nozzle Servo Valve. Processes, 7(10), 721. https://doi.org/10.3390/pr7100721