Experimental and Numerical Simulation Study on Co-Incineration of Solid and Liquid Wastes for Green Production of Pesticides

Abstract

:1. Introduction

2. Materials and Methods

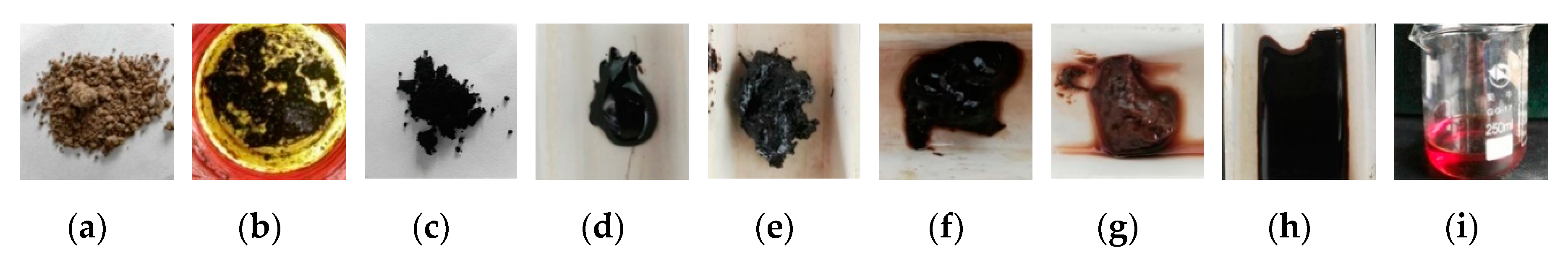

2.1. Material Characteristics

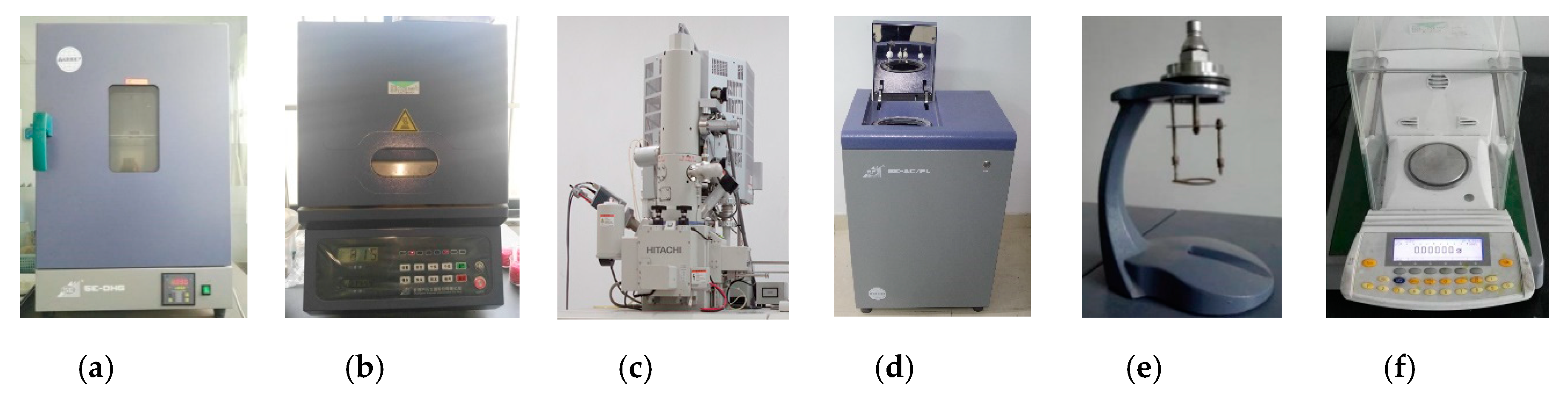

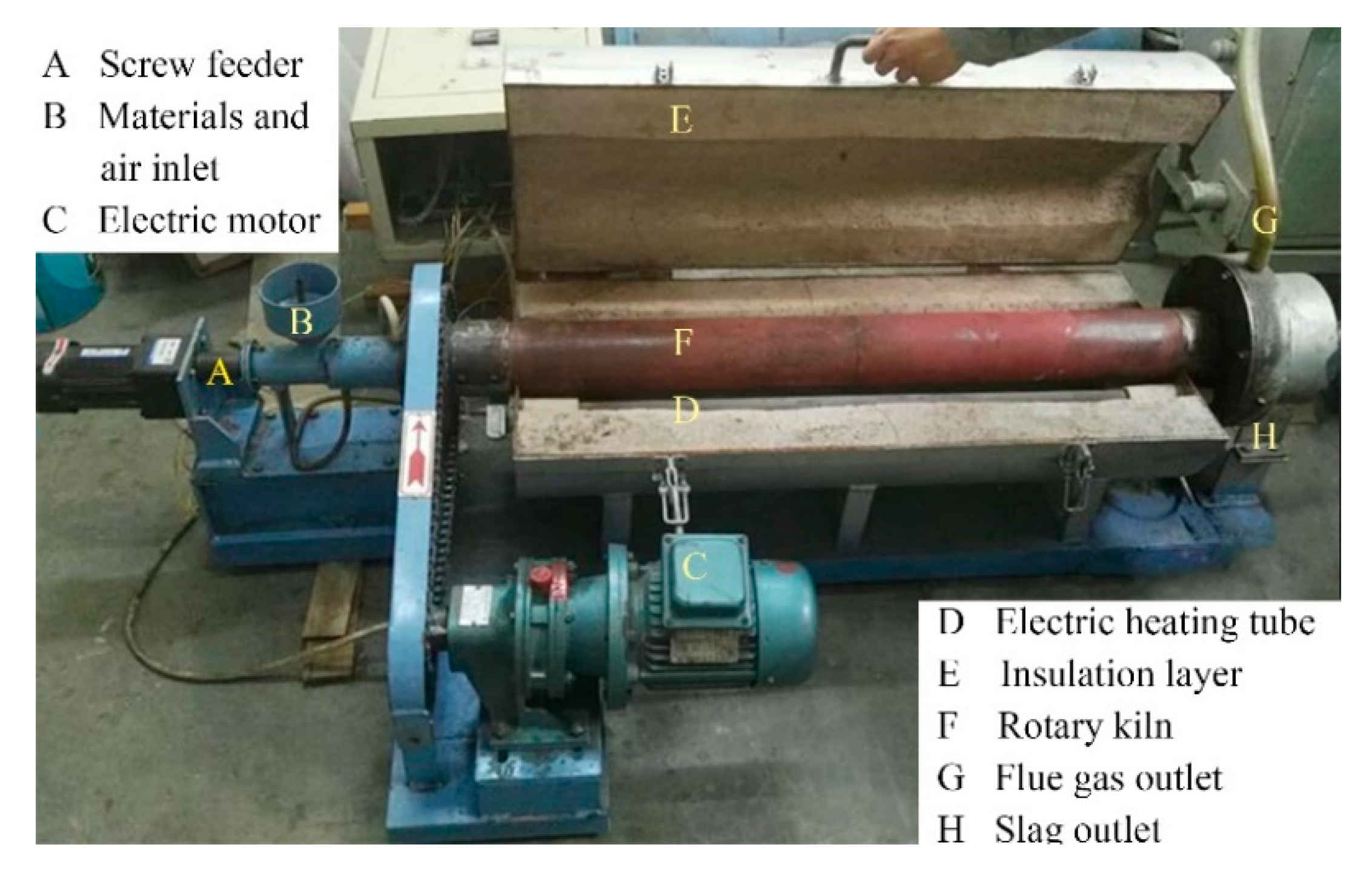

2.2. Co-Incineration Experiment in the Rotary Kiln

3. Numerical Method

3.1. Gas Phase

3.2. Particle Phase

3.3. Combustion Model

4. Numerical Simulation

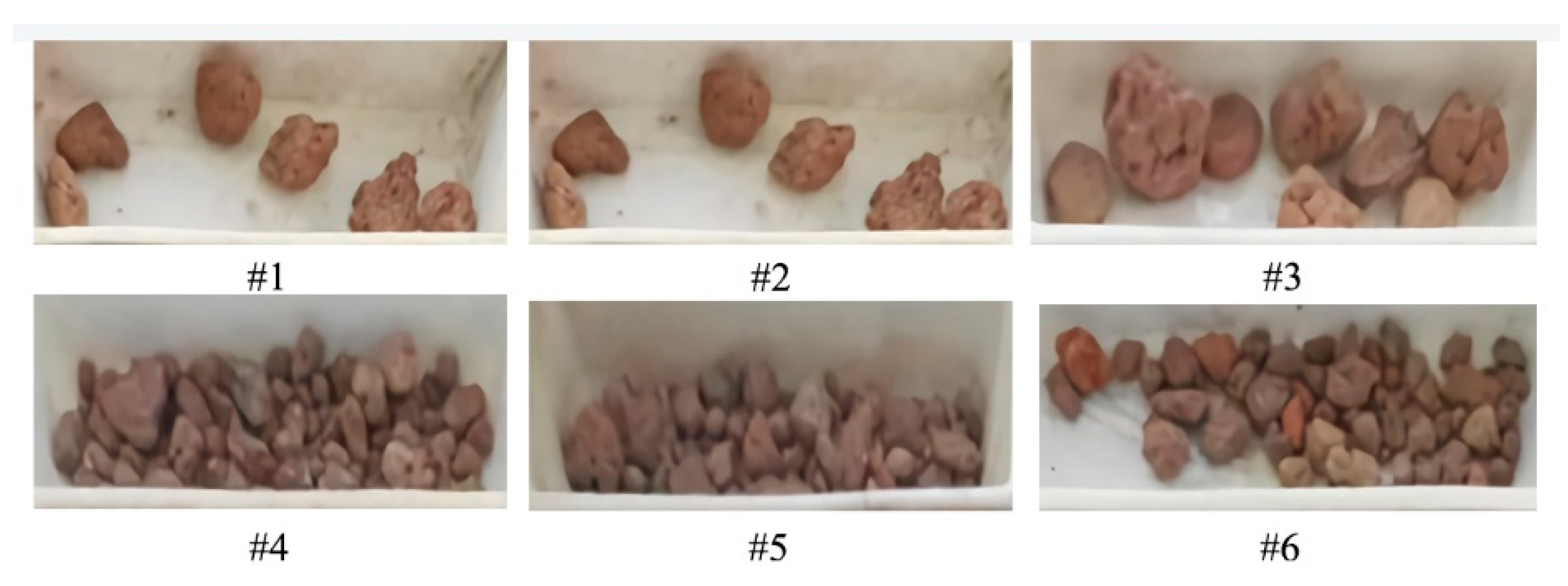

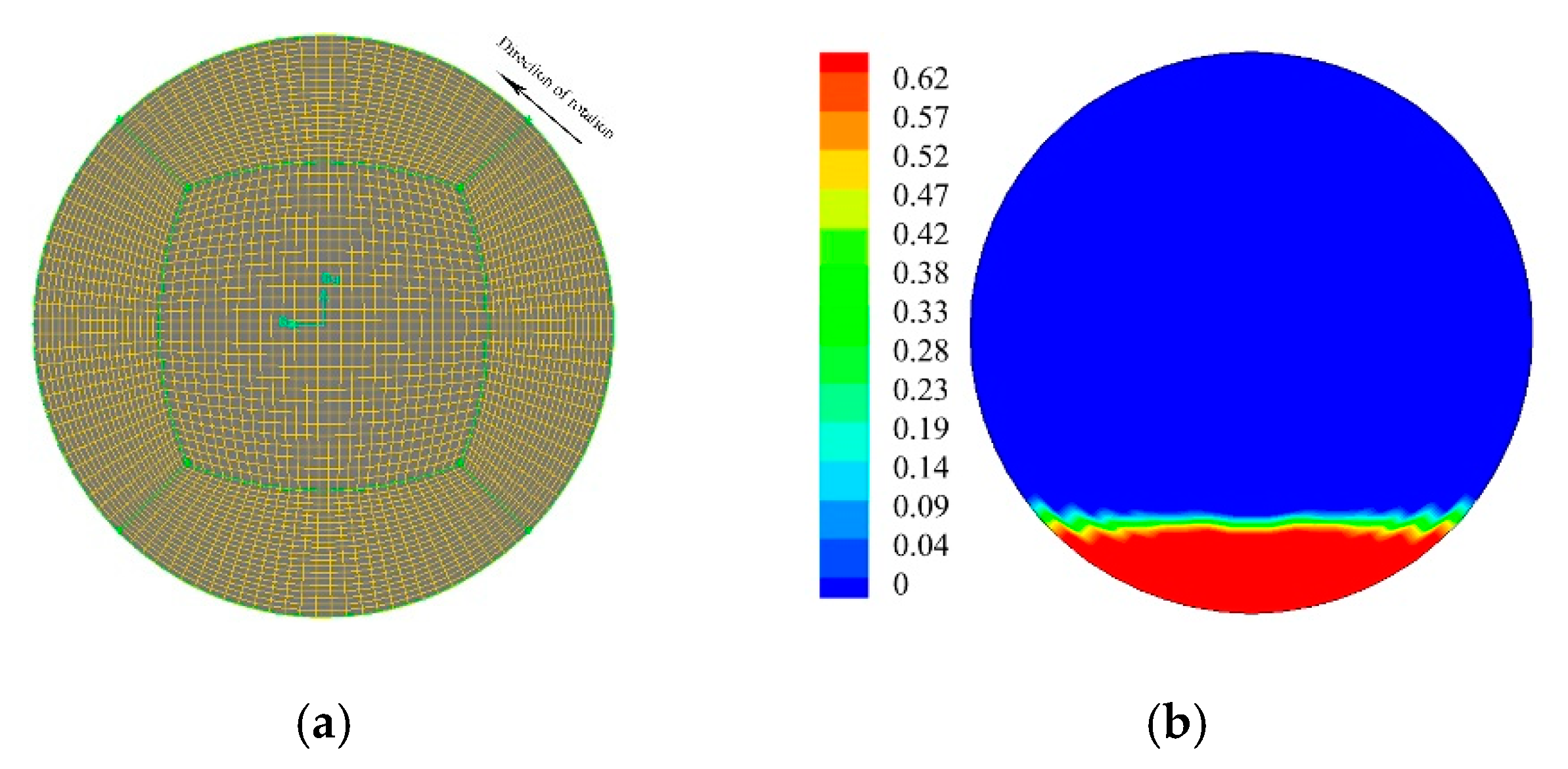

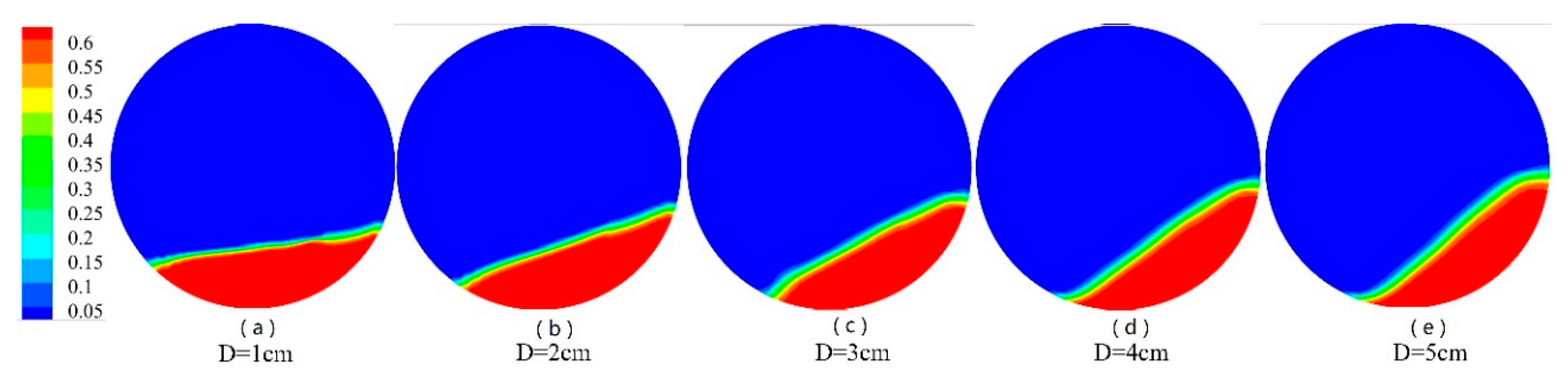

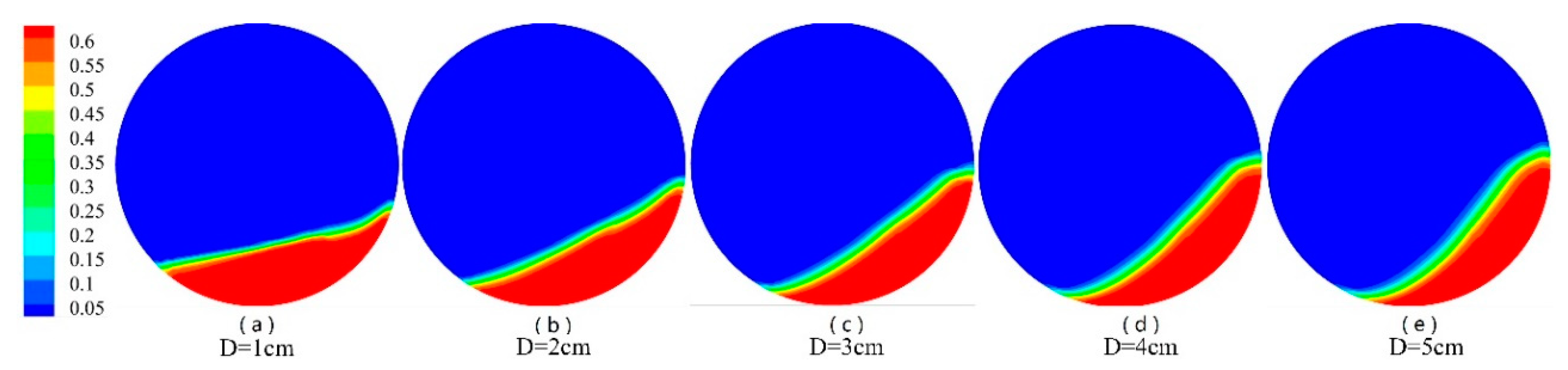

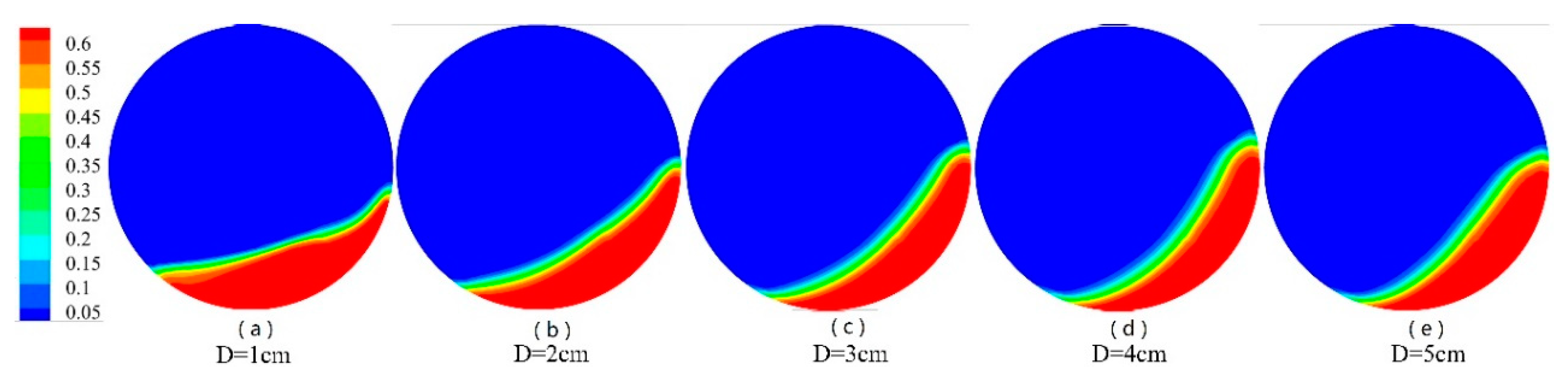

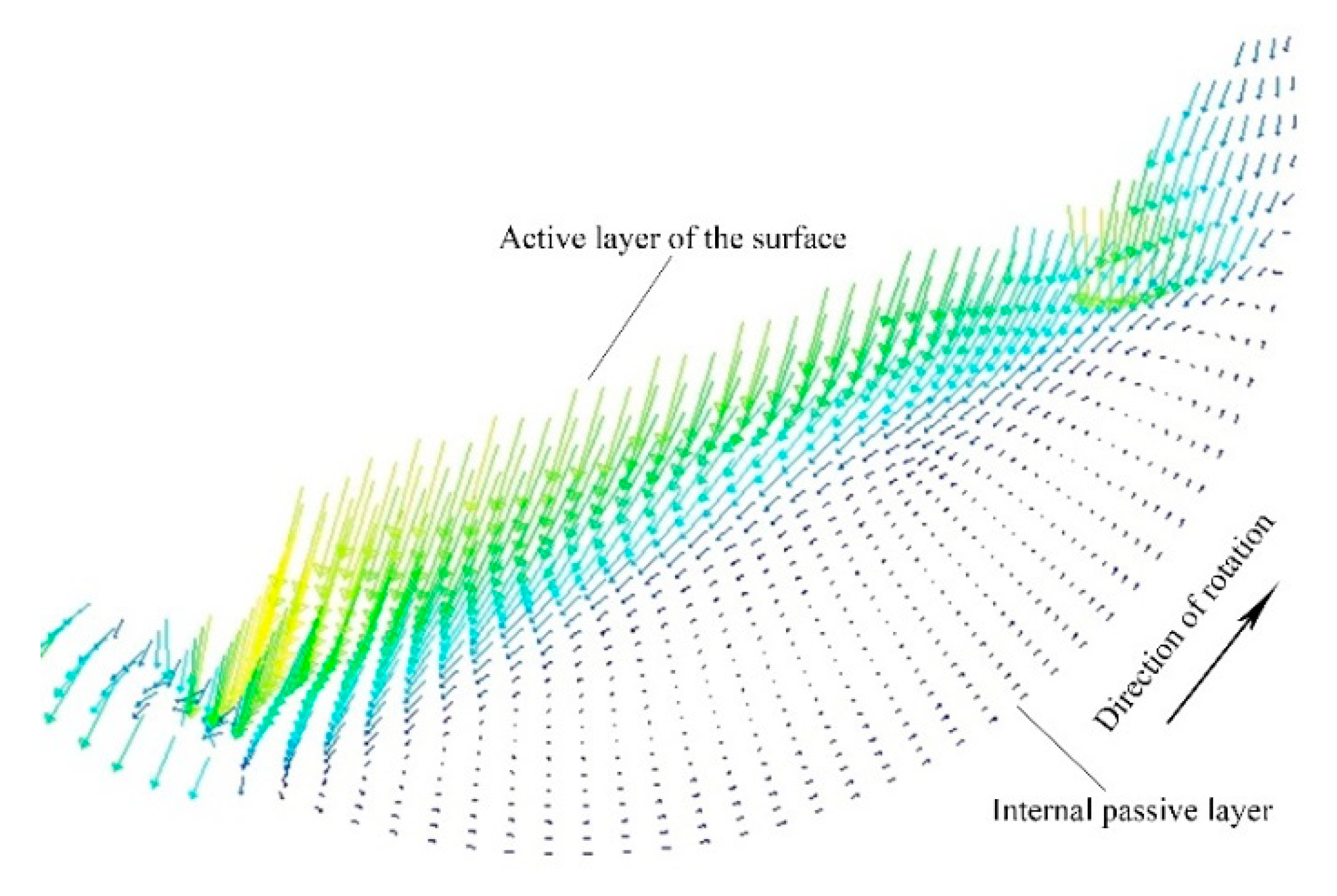

4.1. Numerical Simulation of Material Movement in Kiln

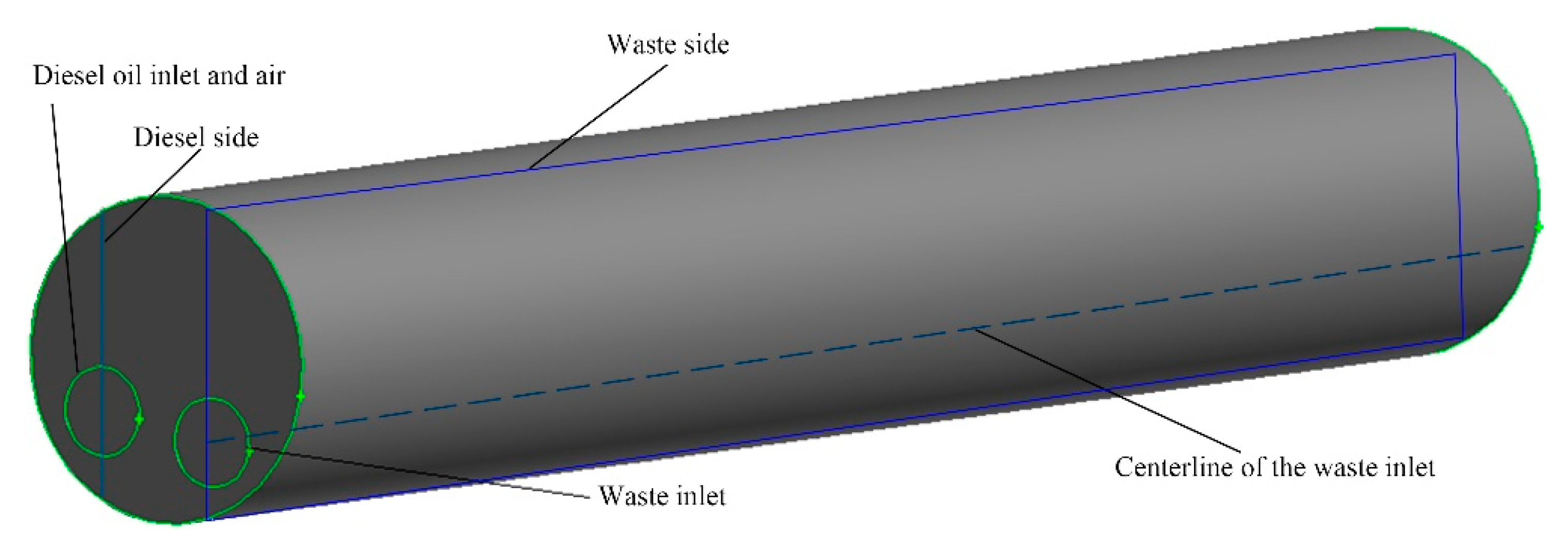

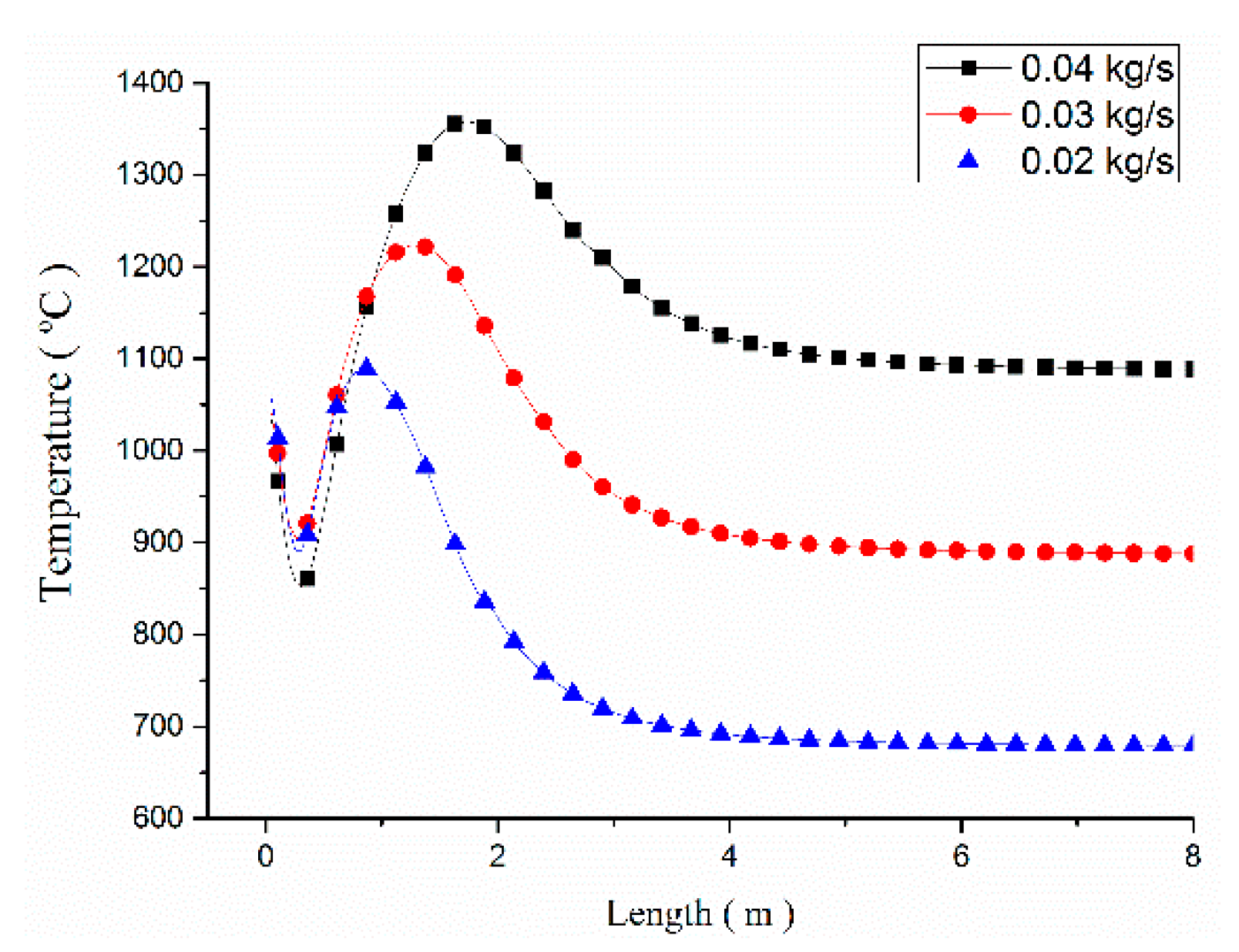

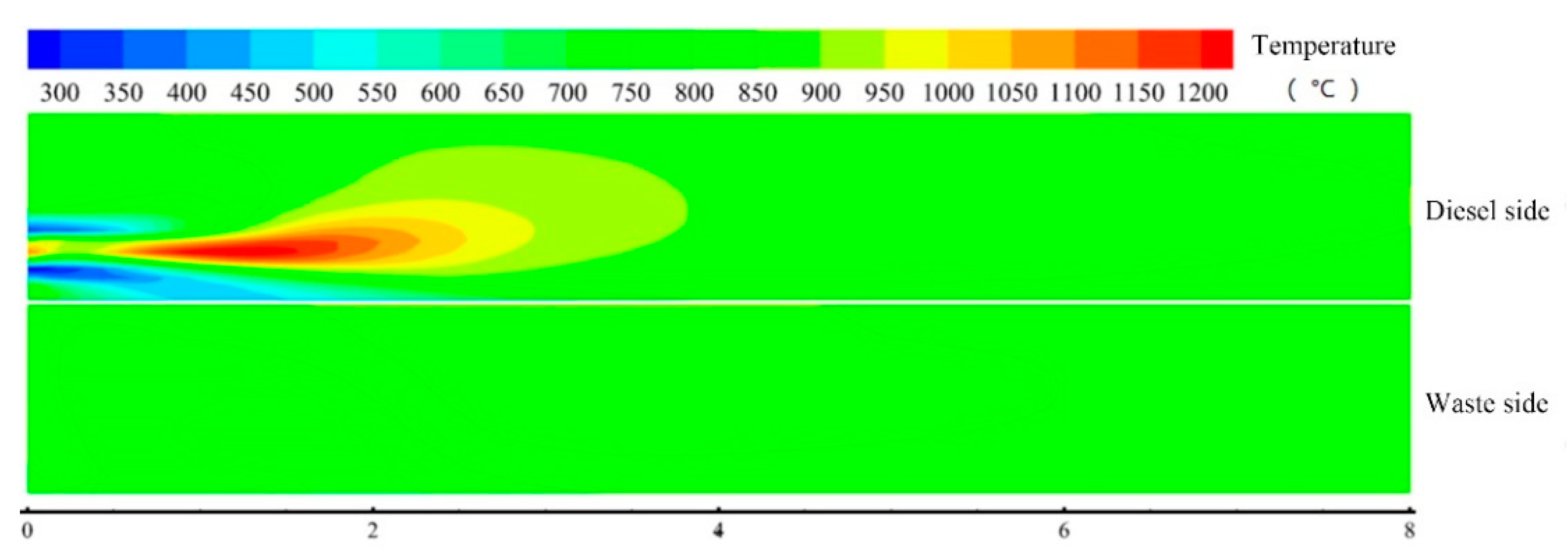

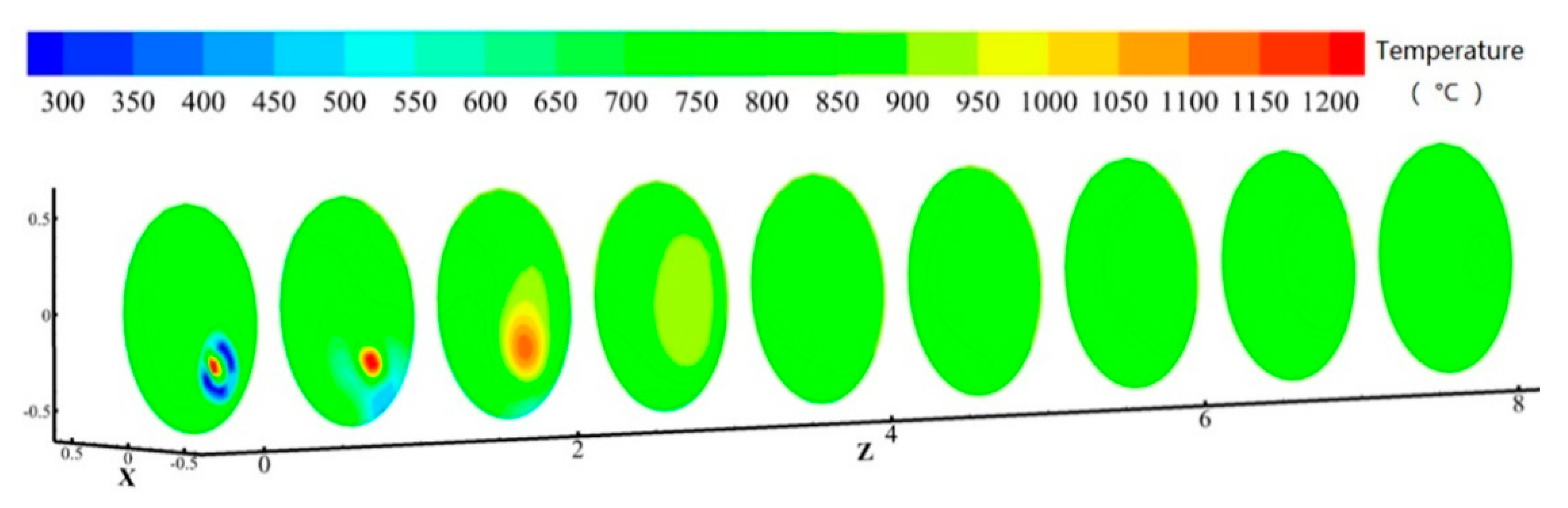

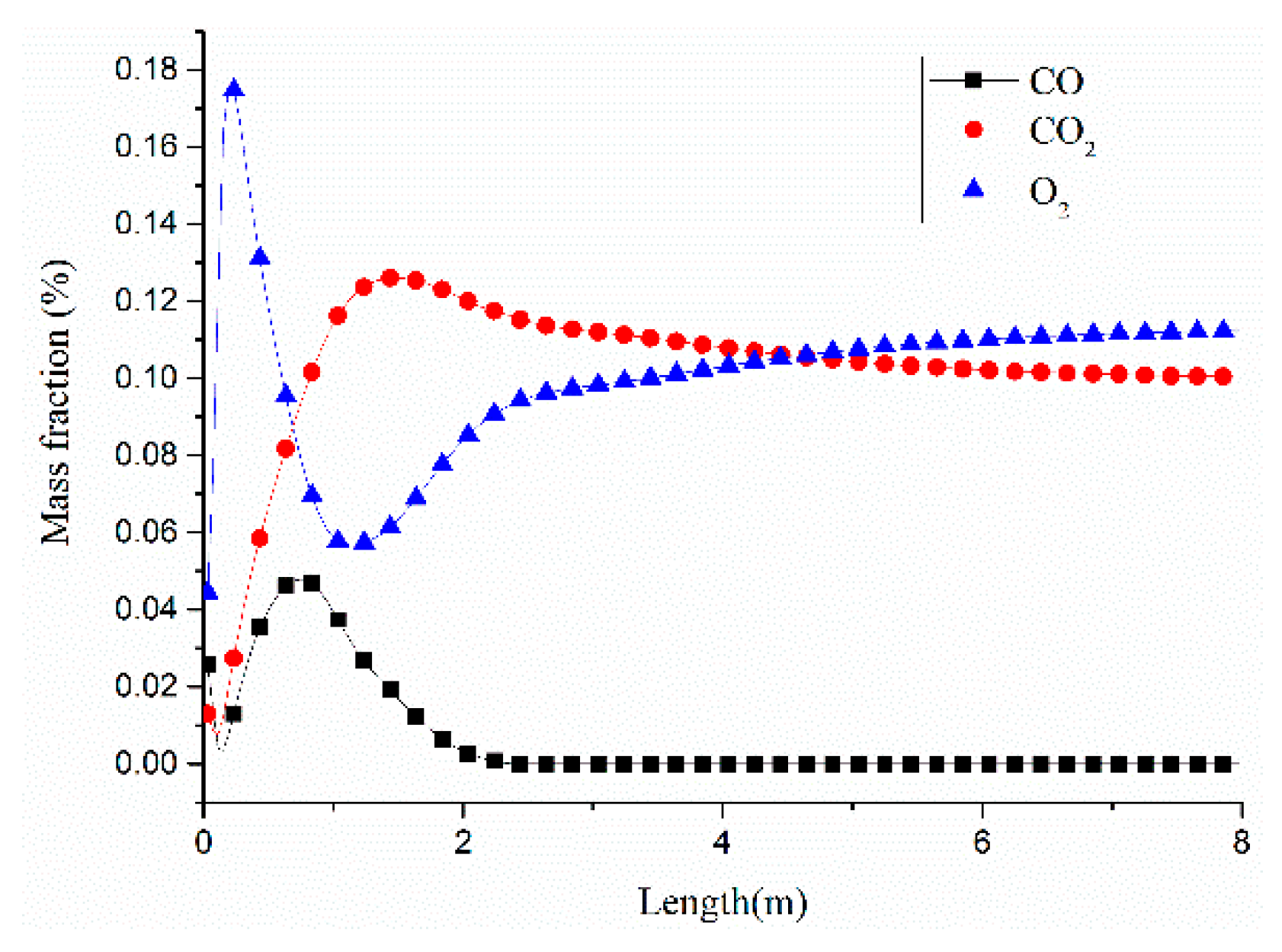

4.2. Numerical Simulation of Waste Rotary Incineration

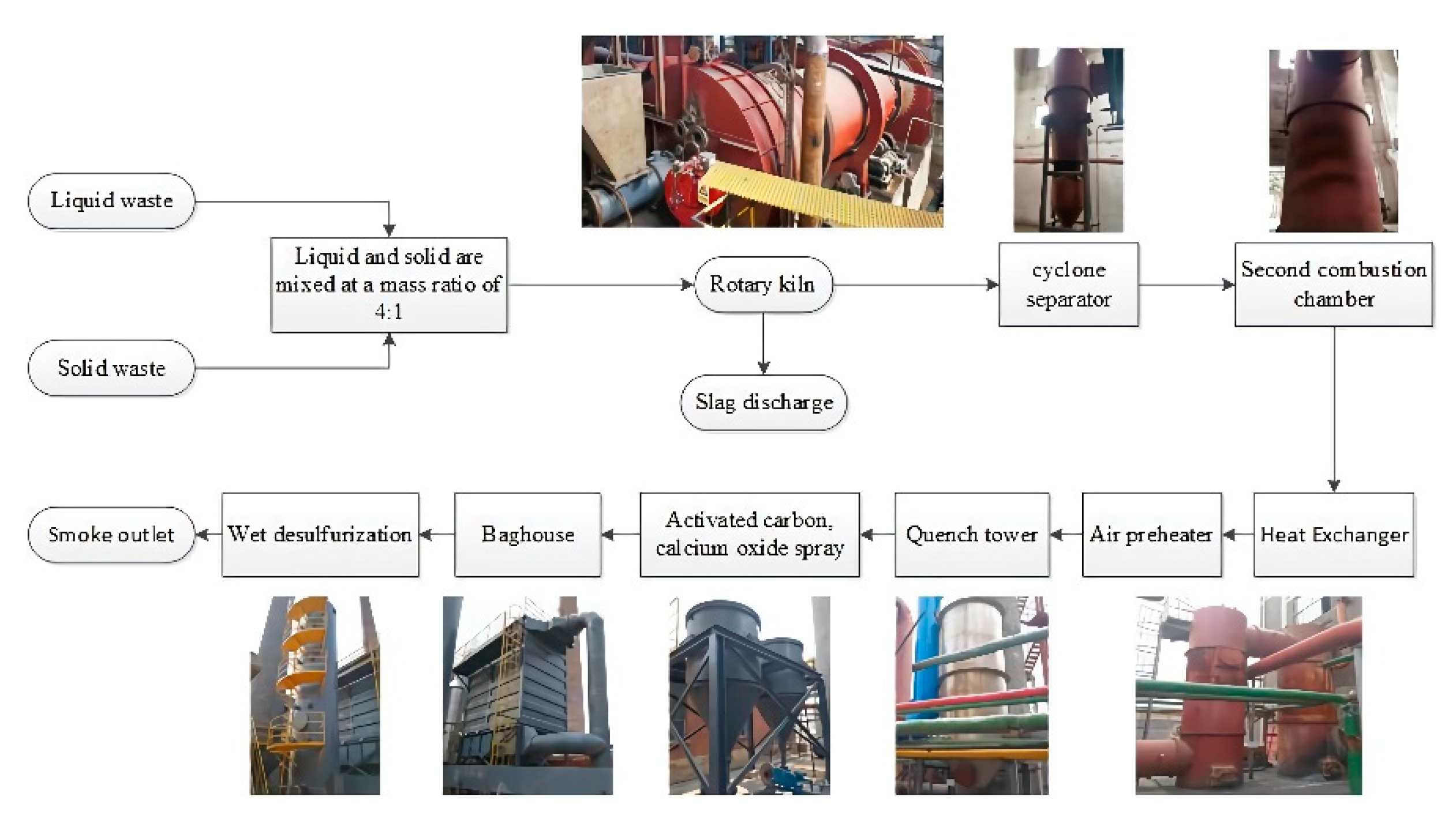

5. Engineering Application of Rotary Kiln

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Ash content of the mixed waste, % | Static pressure, Pa | ||

| Arrhenius type pre-exponential factor | Partial pressure of oxidant species in the gas, Pa | ||

| Surface area of the particle, m2 | Calorific value of mother liquor of methomyl | ||

| Arrhenius factor | Calorific value of solid composition, MJkg−1 | ||

| Carbon content in mixed waste, % | Calorific value of total solid wastes, MJkg−1 | ||

| Diffusion rate coefficient | Calorific value of total mixed waste, MJkg−1 | ||

| Internal energy, Jkg−1 | Particle velocities, ms−1 | ||

| Activation energy, Jmol−1 | Gas velocities, ms−1 | ||

| Fixed carbon of the mixed waste, % | Particle velocities, ms−1 | ||

| Additional forces, N | Mass source, kgs−1 | ||

| Mixing fraction | Temperature, K | ||

| Mixture fraction of the secondary stream diesel oil | Particle temperature, K | ||

| Mass fraction of evaporating material | Volatiles content of the wastes, % | ||

| Mass fraction of solid composition in the total solid wastes | Velocity vector in the x direction, ms−1 | ||

| Mass fraction of mother liquor in the total waste | Velocity vector in the y direction, ms−1 | ||

| Mixture fraction of oxidant | Velocity vector in the z direction, ms−1 | ||

| Mixture fraction of the waste fuel | Mass fraction for element | ||

| Mass fraction of total solid wastes in the total waste | Elemental mass fraction of fuel inlet | ||

| Mass fraction of the volatiles in the initial particle | Elemental mass fraction of oxidant inlet | ||

| Hydrogen content in wastes, % | Stress tensor, Pa | ||

| Kinetic rate, s−1 | Kinetic rate, s−1 | ||

| Moisture content of the wastes, % | Dynamic viscosity, Pas | ||

| Particle mass, kg | Kronecker symbol | ||

| Initial particle mass, kg | Gas phase density, kgm−3 | ||

| Nitrogen content in mixed waste, % | Thermal conductivity, Wm−1 K−1 | ||

| Oxygen content in mixed waste, % | Density of particle phase, kgm−3 | ||

| Gravitational body force, ms−2, Greek letters |

References

- Jin, F.; Wang, J.; Shao, H. Pesticide use and residue control in china. J. Pestic. Sci. 2010, 35, 138–142. [Google Scholar] [CrossRef]

- Chen, Z.L.; Dong, F.S.; Jun, X.U. Management of pesticide residues in China. J. Integr. Agric. 2015, 14, 2319–2327. [Google Scholar] [CrossRef]

- Xu, D.; Wang, S.; Zhang, J. Supercritical water oxidation of a pesticide wastewater. Chem. Eng. Res. Des. 2015, 94, 396–406. [Google Scholar] [CrossRef]

- Renou, S.; Givaudan, J.G.; Poulain, S. Landfill leachate treatment: review and opportunity. J. Hazard. Mater. 2008, 150, 468–493. [Google Scholar] [CrossRef] [PubMed]

- Gao, Q.; Wang, L.; Li, Z. Adsorptive Removal of Pyridine in Simulation Wastewater Using Coke Powder. Processes 2019, 7, 459. [Google Scholar] [CrossRef]

- Migliori, M.; Catizzone, E.; Giordano, G. Pilot Plant Data Assessment in Anaerobic Digestion of Organic Fraction of Municipal Waste Solids. Processes 2019, 7, 54. [Google Scholar] [CrossRef]

- Nie, Y. Development and prospects of municipal solid waste (MSW) incineration in China. Front. Environ. Sci. Eng. China 2008, 2, 1–7. [Google Scholar] [CrossRef]

- Jabłońska, B.; Kiełbasa, P.; Korenko, M.; Dróżdż, T. Physical and Chemical Properties of Waste from PET Bottles Washing as A Component of Solid Fuels. Energies 2019, 12, 2197. [Google Scholar] [CrossRef]

- Tabasová, A.; Kropáč, J.; Kermes, V. Waste-to-energy technologies: Impact on environment. Energy 2012, 44, 146–155. [Google Scholar] [CrossRef]

- Ghouleh, Z.; Shao, Y. Turning municipal solid waste incineration into a cleaner cement production. J. Clean. Prod. 2018, 195, 268–279. [Google Scholar] [CrossRef]

- Guo, Y.; Glad, T.; Zhong, Z. Environmental life-cycle assessment of municipal solid waste incineration stocks in Chinese industrial parks. Resour. Conserv. Recycl. 2018, 139, 387–395. [Google Scholar] [CrossRef]

- Chen, H.C.; Zhao, C.S.; Li, Y.W.; Lu, D.F. NOx emission from incineration of organic liquid waste in a circulating fluidized bed. Korean J. Chem. Eng. 2007, 24, 906–910. [Google Scholar] [CrossRef]

- Ma, J.; Liu, D.; Chen, Z.; Chen, X. Agglomeration characteristics during fluidized bed combustion of salty wastewater. Powder Technol. 2014, 253, 537–547. [Google Scholar] [CrossRef]

- Wang, N.Y.; Chun, H.S.; Peite, C. Environmental effects of sewage sludge carbonization and other treatment alternatives. Energies 2013, 6, 871–883. [Google Scholar] [CrossRef]

- Hu, S.; Ma, X.; Lin, Y. Thermogravimetric analysis of the co-combustion of paper mill sludge and municipal solid waste. Energy Convers. Manag. 2015, 99, 112–118. [Google Scholar] [CrossRef]

- Lin, H.; Ma, X. Simulation of co-incineration of sewage sludge with municipal solid waste in a grate furnace incinerator. Waste Manag. 2012, 32, 561–567. [Google Scholar] [CrossRef]

- Zhong, Q.; Zhang, J.; Yang, Y. Thermal Behavior of Coal Used in Rotary Kiln and Its Combustion Intensification. Energies 2018, 11, 1055. [Google Scholar] [CrossRef]

- Shi, H.; Si, W.; Li, X. The Concept, Design and Performance of a Novel Rotary Kiln Type Air-Staged Biomass Gasifier. Energies 2016, 9, 67. [Google Scholar] [CrossRef]

- Weinberg, A.V.; Varona, C.; Chaucherie, X. Extending refractory lifetime in rotary kilns for hazardous waste incineration. Ceram. Int. 2016, 42, 17626–17634. [Google Scholar] [CrossRef]

- Bai, Y.; Bao, Y.B.; Cai, X.L. Feasibility of disposing waste glyphosate neutralization liquor with cement rotary kiln. J. Hazard. Mater. 2014, 278, 500–505. [Google Scholar] [CrossRef]

- Huber, F.; Blasenbauer, D.; Mallow, O. Thermal co-treatment of combustible hazardous waste and waste incineration fly ash in a rotary kiln. Waste Manag. 2016, 58, 181–190. [Google Scholar] [CrossRef] [PubMed]

- Bujak, J. Thermal treatment of medical waste in a rotary kiln. J. Environ. Manag. 2015, 162, 139–147. [Google Scholar] [CrossRef] [PubMed]

- Bujak, J. Thermal utilization (treatment) of plastic waste. Energy 2015, 90, 1468–1477. [Google Scholar] [CrossRef]

- Mellmann, J. The transverse motion of solids in rotating cylinders—forms of motion and transition behavior. Powder Technol. 2001, 118, 251–270. [Google Scholar] [CrossRef]

- Wang, M.; Liao, B.; Liu, Y. Numerical simulation of oxy-coal combustion in a rotary cement kiln. Appl. Therm. Eng. 2016, 103, 491–500. [Google Scholar] [CrossRef]

- Badzioch, S.; Hawksley, P.G.W. Kinetics of Thermal Decomposition of Pulverized Coal Particles. Ind. Eng. Chem. Process Des. Dev. 1970, 9, 521–530. [Google Scholar] [CrossRef]

- Baum, M.M.; Street, P.J. Predicting the Combustion Behaviour of Coal Particles. Combust. Sci. Technol. 1971, 3, 231–243. [Google Scholar] [CrossRef]

- Ghenai, C.; Lin, C.X.; Ebadian, M.A. Numerical Investigation of Oxygen-Enriched Pulverized Coal Combustion. Heat Transf. 2003, 2. [Google Scholar] [CrossRef]

- Pham, M.T.N.; Anh, H.Q.; Nghiem, X.T. Characterization of PCDD/Fs and dioxin-like PCBs in flue gas from thermal industrial processes in Vietnam: A comprehensive investigation on emission profiles and levels. Chemosphere 2019, 225, 238–246. [Google Scholar] [CrossRef]

| Proximate Analysis (wt%) | Ultimate Analysis (wt%) | Qgr,ad (MJ/kg) | ||||||

|---|---|---|---|---|---|---|---|---|

| Mad | Aad | FCad | Vad | Cad | Had | Oad | Nad | |

| 23.6 | 20.4 | 20 | 36 | 56.74 | 2.20 | 36.20 | 4.86 | 4.05 |

| Material Name | Daily Production/kg | Mass Fraction/% | Calorific Value/(103 kJ/kg) |

|---|---|---|---|

| Aniline | 20 | 0.38 | 25.8 |

| Amyl amine | 10 | 0.19 | 36.6 |

| Kettle residue | 100 | 1.94 | 23.7 |

| Kettle substrate | 15 | 0.29 | 38.4 |

| Floccus | 70 | 1.36 | 42.0 |

| Pendimethalin | 100 | 1.94 | 25.2 |

| Activated carbon | 230 | 4.47 | 18.5 |

| Sludge | 600 | 11.66 | 4.5 |

| Solid wastes in total 1 | 1145 | 22.26 | 14.1 |

| Mother liquor of methomyl | 4000 | 77.74 | 1.2 |

| Wastes in total 2 | 5145 | 100 | 4.05 |

| Description | Value | ||||

|---|---|---|---|---|---|

| Rotating speed (rpm) | 2 | 3 | 4 | ||

| Particle diameter (cm) | 1 | 2 | 3 | 4 | 5 |

| Rotary kiln diameter (m) | 1.2 | ||||

| Solid density (kg/m3) | 1150 | ||||

| Air density (kg/m3) | 1.225 | ||||

| Air pressure (105 N/m2) | 1.01 | ||||

| Particle–wall restitution coefficient | 0.8 | ||||

| Particle–particle restitution coefficient | 0.9 | ||||

| Temperature (k) | Case (1) | Case (2) | Case (3) | Case (4) | |

|---|---|---|---|---|---|

| Mass Flow Rates (kg/s) | |||||

| Air | 300 | 1.5 | 1.5 | 1.5 | 1.5 |

| Diesel inlet | 500 | 0.02 | 0.03 | 0.04 | 0.03 |

| Waste inlet | 300 | 0 | 0 | 0 | 0.06 |

| Pollutants | Daily Average Concentration | Chinese Standard 18485–2014 |

|---|---|---|

| Dust/(mg/Nm3) | 15 | 20 |

| SOx/(mg/Nm3) | 40 | 80 |

| NOx/(mg/Nm3) | 120 | 250 |

| HCl/(mg/Nm3) | 25 | 50 |

| Dioxins/(ngTEQ/Nm3) | 0.015 | 0.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; He, J.; Hu, C.; Chen, W. Experimental and Numerical Simulation Study on Co-Incineration of Solid and Liquid Wastes for Green Production of Pesticides. Processes 2019, 7, 649. https://doi.org/10.3390/pr7100649

Zhang B, He J, Hu C, Chen W. Experimental and Numerical Simulation Study on Co-Incineration of Solid and Liquid Wastes for Green Production of Pesticides. Processes. 2019; 7(10):649. https://doi.org/10.3390/pr7100649

Chicago/Turabian StyleZhang, Bin, Jinjie He, Chengming Hu, and Wei Chen. 2019. "Experimental and Numerical Simulation Study on Co-Incineration of Solid and Liquid Wastes for Green Production of Pesticides" Processes 7, no. 10: 649. https://doi.org/10.3390/pr7100649

APA StyleZhang, B., He, J., Hu, C., & Chen, W. (2019). Experimental and Numerical Simulation Study on Co-Incineration of Solid and Liquid Wastes for Green Production of Pesticides. Processes, 7(10), 649. https://doi.org/10.3390/pr7100649