A Review on the Dissection of Quenched Blast Furnaces—Spanning from the Early 1950s to the 1970s

Abstract

:1. The Dissection of Quenched Blast Furnaces

2. U.S. Bureau of Mines Case (1959)

2.1. Background Information

2.2. Quenching Procedure

2.3. Details of the Findings

3. The Iron and Steel Institute of Japan (ISIJ) Studies (1970)

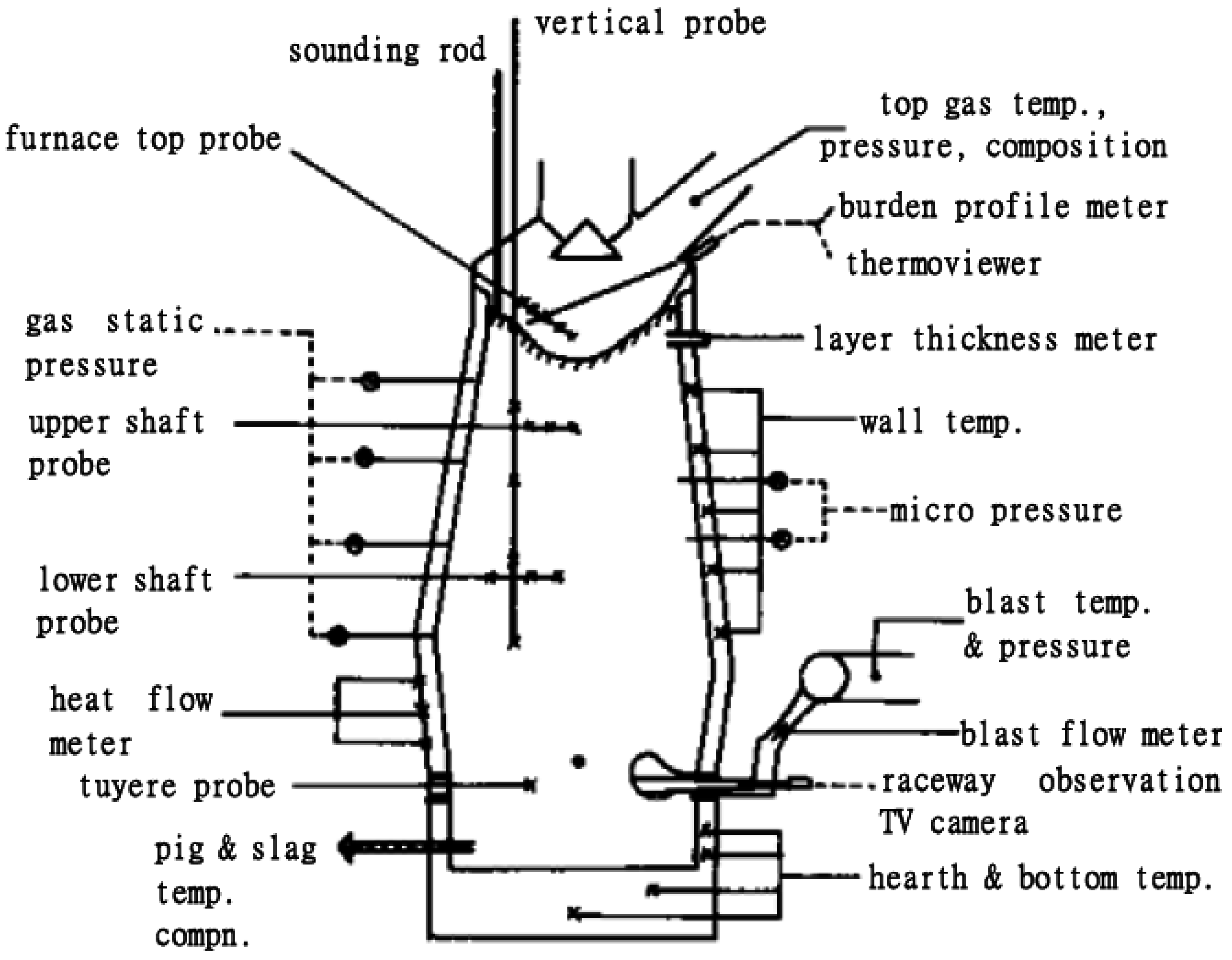

3.1. Background Information

3.2. Details of the Findings

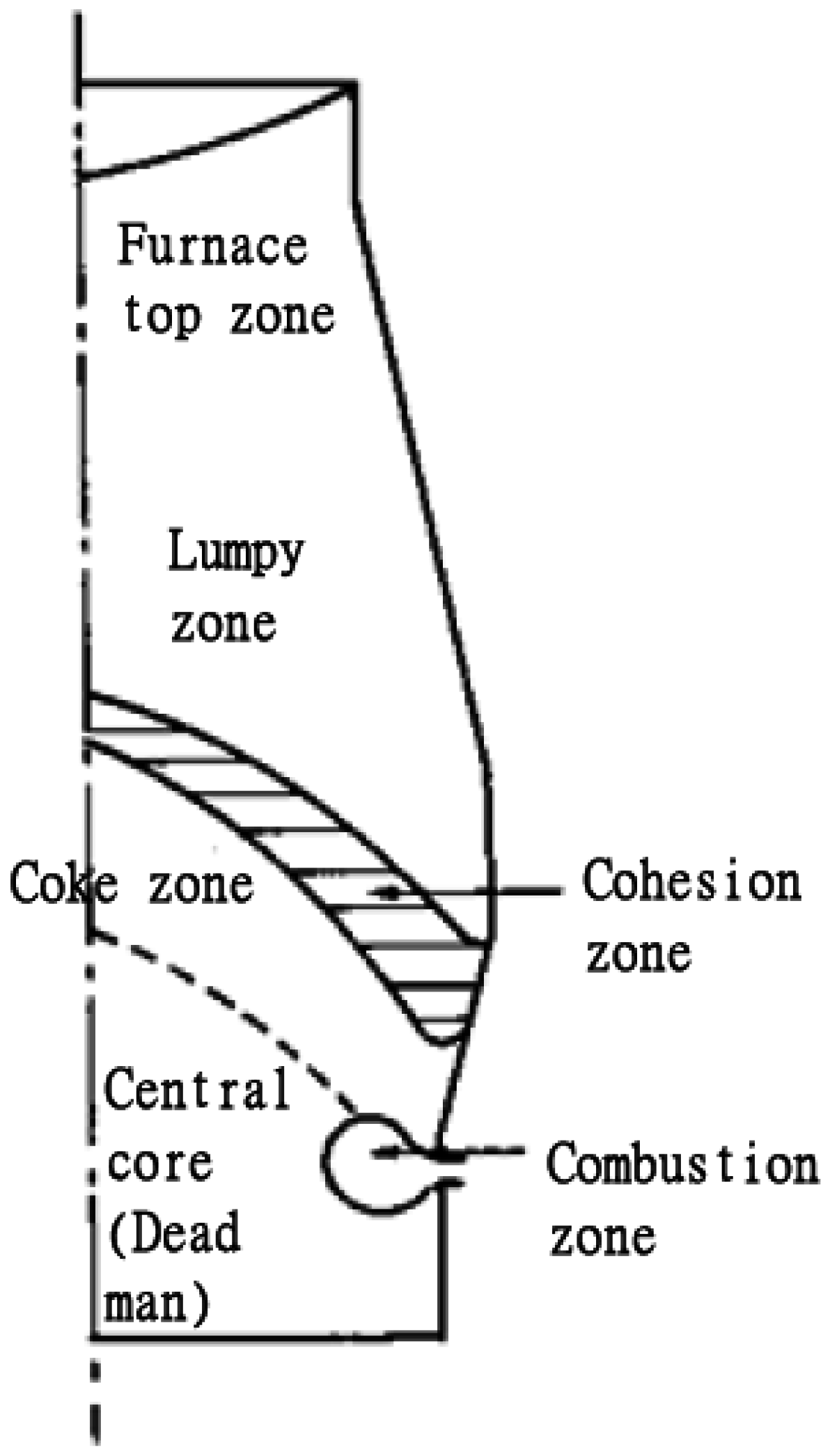

- The top part with the layered ore and coke as charged.

- The lumpy zone (stack zone) where coke and ore particles make a stratified descent down the furnace.

- The cohesion zone where ore is softened, fused, and melted in accordance with the state of gas flow from the tuyeres.

- The active coke zone which is situated below the cohesion zone where droplets of iron ore and slag interact with the coke as they percolate down to the hearth.

- The stagnant coke zone (dead man) is right below the active coke zone between the tuyeres where the reaction does not occur. This conical mass acts to support the burden of the furnace and as a path for the droplets of metal and slag to trickle down to the hearth. The Japanese refer to this zone as the core.

- The combustion zone which is a zone where hot blasts from the tuyeres react with coke to generate the heat needed to melt the iron. The air blasts form cavities as a result of the swirling motion of the coke particles, producing raceways.

- The hearth which is composed of the slag layer on top of the metal layer, both filled with coke, which is coagulated near the bottom.

4. Conclusions

Conflicts of Interest

References

- McCutcheon, K.C.; Marshall, W.E. Barnes: Procedure Used in Quenching and Digging Out a Blast Furnace and Some Results. In Proceedings of the AIME Blast Furnace, Coke Oven and Raw Materials Conference, Pittsburgh, PA, USA, 2–4 April 1951; pp. 217–221.

- Bosley, J.J.; Melcher, N.B.; Harris, M.M. Method for producing high-temperature cement in the blast furnace. J. Met. 1959, 11, 610–615. [Google Scholar]

- Muravev, V.M.; Mischenko, M.I. Physical chemistry of steelmaking. Stal. Eng. 1970, 7, 591. [Google Scholar]

- Omori, K. Blast Furnace Phenomena and Modeling; Elsevier Applied Science: London, UK, 1987; pp. 3–63. [Google Scholar]

- Sasaki, M.; Lino, K.; Suzuki, A.; Okuno, Y.; Oshizawa, K.Y. Formation and Melt-Down of Softening-Melting Zone in Blast Furnace: Report on the Dissection of Blast Furnaces 3. Tetsu Hagane 1976, 62, 559–569. [Google Scholar]

- Kuwabara, M.; Ma, Z. Further Insights into Blast Furnace Phenomena and Modeling for Researchers and Operators. In Proceedings of the Advances in Theory of Ironmaking and Steeimaking, Banga, India, 9–11 December 2009; pp. 184–191.

- Shimomura, Y.; Nishikawa, K.; Arino, S.; Katayama, T.; Hida, Y. On the Inside State of the Lumpy Zone of Blast Furnace: Report on the Dissection of Blast Furnaces 2. Tetsu Hagane 1976, 62, 547–558. [Google Scholar]

- Burgess, J.M. Fuel Combustion in the Blast Furnace Raceway Zone. Prog. Energy Combust. Sci. 1998, 11, 61–82. [Google Scholar] [CrossRef]

- Ondrey, G.; Parkinson, G.; Moore, S. Blast Furnaces Make Way for New Steel Technology. Chem. Eng. 1995, 102, 37–41. [Google Scholar]

- Patankar, S. Numerical Heat Transfer and Fluid Flow; McGREW-Hill: New York, NY, USA, 1980; pp. 27–51. [Google Scholar]

- Yagi, J. Mathematical Modeling of the Flow of Four Fluids in a Packed Bed. ISIJ Int. 1993, 33, 619–639. [Google Scholar] [CrossRef]

- Hattori, M.; lino, B.; Shimomura, A.; Tsukiji, H.; Ariyama, T. Development of Burden Distribution Simulation Model for Bell-jess Top in a Large Blast Furnace and Its Application. ISIJ Int. 1993, 33, 1070–1077. [Google Scholar] [CrossRef]

- Childs, K. A Comparison of Operational and Economic Factors of Arc and Induction Furnaces. In Proceedings of the BCIRA Conference on Electric Melting and Holding Furnaces in the Ironfounding Industry, Loughborough, UK, 20–22 September 1967; p. 463.

- Orechkin, L.M. On the Design of the Blast-furnace Well (Contribution to the Discussion on the Design and Durability of the Hearth and Well of the Blast-furnace). Metallurgist 1963, 7, 526. [Google Scholar] [CrossRef]

- Chirikhin, V.F.; Gal’perin, G.S.; Milyuts, V.G.; Bocharnikov, A.F.; Vostrikov, V.G. Treatment of low-alloy steel with argon outside the furnace. Metallurgist 1987, 31, 245–247. [Google Scholar] [CrossRef]

- Tsimbal, V.P.; Kustov, B.A.; Aizatulov, R.S.; Mochalov, S.P.; Shapirov, K.M. A new continuous metallurgical process based on principles of self-organization. Metallurgist 1995, 39, 212. [Google Scholar] [CrossRef]

- Ovcharenko, N.L. On the Durability of the Hearth and Well of the Blast-furnace (Contribution to the Discussion on the Construction and Durability of the Hearth and Well of the Blast-furnace). Metallurgist 1962, 6, 466–467. [Google Scholar] [CrossRef]

- Arzamastsev, E.I.; Baryshnikov, V.G.; Baryshnikov, G.I.; Vdovin, S.V.; Rempel, A.N.; Gudov, V.I. Treatment of Ball-bearing Steel Outside the Furnace with Synthetic Slag after Removal of the Furnace Slag. Metallurgist 1981, 25, 14–16. [Google Scholar] [CrossRef]

© 2016 by the author; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W. A Review on the Dissection of Quenched Blast Furnaces—Spanning from the Early 1950s to the 1970s. Processes 2016, 4, 36. https://doi.org/10.3390/pr4040036

Zhang W. A Review on the Dissection of Quenched Blast Furnaces—Spanning from the Early 1950s to the 1970s. Processes. 2016; 4(4):36. https://doi.org/10.3390/pr4040036

Chicago/Turabian StyleZhang, Wei. 2016. "A Review on the Dissection of Quenched Blast Furnaces—Spanning from the Early 1950s to the 1970s" Processes 4, no. 4: 36. https://doi.org/10.3390/pr4040036

APA StyleZhang, W. (2016). A Review on the Dissection of Quenched Blast Furnaces—Spanning from the Early 1950s to the 1970s. Processes, 4(4), 36. https://doi.org/10.3390/pr4040036