1. Introduction

With the continuous expansion of oil and gas resource exploration and development, the industry is gradually advancing into complex high-temperature formations such as onshore ultra-deep layers, deepwater subsea formations, geothermal reservoirs, and hot dry rocks [

1]. Formations with temperatures exceeding 150 °C are defined as high-temperature formations, while those exceeding 205 °C are classified as ultra-high-temperature formations [

2]. The successful completion of China’s first 10,000 m ultra-deep well, Well XX1, has inaugurated a new chapter in China’s 10,000 m oil and gas drilling. Furthermore, in areas like the Tarim Basin, where formation temperatures reach 200 °C, over 90% of operational complexities involve fluid influx and lost circulation. Conventional lost circulation materials struggle to meet the demands of ultra-high-temperature environments [

3,

4,

5]. The high-temperature conditions in complex formations pose severe challenges for bridge plugging, requiring enhanced performances in temperature resistance, compressive strength, settlement stability, and retention capability within loss zones.

Kang Yili et al. [

6] conducted high-temperature aging evaluation experiments using walnut shells and millimeter-sized calcium carbonate—common drilling materials—as research subjects. Their analysis emphasized the necessity of including high-temperature aging performance as a critical evaluation metric for lost circulation materials. Bao Dan et al. [

7] revealed the degradation mechanisms of high-temperature aging through technical indicators such as mass loss rate, particle size downgrading rate, compressive crushing rate, elastic deformation rate, friction coefficient variation rate, and fiber tensile strength retention rate. Based on the fundamental principles of dense pressure-bearing plugging via robust chain network structures, they optimized formulations for high-temperature-resistant, dense pressure-bearing plugging fluids tailored to different fracture apertures through the synergistic combination of various high-temperature-resistant materials. Current research highlights the need to establish evaluation methods for lost circulation material properties under ultra-high-temperature conditions to guide the development and selection of ultra-high-temperature lost circulation control materials.

Wang Jianli et al. [

8] synthesized a polymer particle resistant to 180 °C using styrene, acrylamide, and N, N′-methylenebisacrylamide via emulsion polymerization, with an average particle size of 21.36 μm, for application in drilling fluid loss prevention. Zhang Wei et al. [

9] developed a high-temperature-resistant (200 °C) pressure-bearing enhancer for drilling fluids using rigid particles, flexible particles, and water-absorbing polymer particles. Xiong Zhengqiang et al. [

10] formulated a 200 °C-resistant drilling fluid loss control agent composed of rigid particles, mineral fibers, deformable particles, fluid loss reducers, and high-temperature protective agents. Elastic graphite, formed by the high-temperature treatment of graphite into fine carbon particles, exhibits high-temperature resistance, elasticity, deformability, and chemical stability [

11,

12]. Mineral materials such as calcium carbonate, mica, vermiculite, and shell powder demonstrate excellent high-temperature resistance [

13]. Luo Ming et al. [

14] selected elastic plugging agent FLEX and composite plugging agent VANGUARD for high-temperature (200 °C) and high-pressure lost circulation scenarios in the Yinggehai Basin of the South China Sea. Duan Yongxian et al. [

15] employed rigid bridging particles with low density, high mechanical strength, and high-temperature resistance (>160 °C). Ai Zhengqing et al. [

16] introduced multi-faceted serrated aluminum alloy particles with oil-phase dispersibility, high rigidity, and acid solubility (density: 1.60 g/cm

3), demonstrating superior temperature resistance. Experts and scholars have conducted thermal resistance evaluations of fine packing particles, elastic particles, and flaky materials. Simultaneously, high-temperature-resistant inorganic and polymer composite materials were prepared. Under conditions of 220 °C and an acidic environment, a high-temperature- and high-pressure-resistant plugging agent can be formed through formulation optimization and particle gradation. The experiments simulated the plugging capability of the materials under different fracture widths, demonstrating the feasibility of an inorganic + thermally stable particle composite system for lost circulation control in high-temperature deep wells [

17,

18,

19].

As China advances toward drilling depths of 10,000 m, downhole temperatures are expected to commonly exceed 200 °C, though they have not yet reached 240 °C or above. Therefore, selecting 240 °C as the experimental threshold aims to simulate and address the extreme high-temperature environments that may be encountered in current and future ultra-deep drilling operations, demonstrating clear on-site relevance and representativeness. This paper investigates the high-temperature failure mechanisms of conventional bridge plugging materials through analyses of physico-chemical properties, mechanical performance, and structural degradation. A systematic selection of high-temperature-resistant (240 °C) rigid particles, elastic particles, and fibrous materials has been conducted, along with an optimization of drilling fluid loss prevention and static lost circulation system formulations. These advancements provide critical technical support for safe and efficient drilling in 10,000 m ultra-deep wells.

2. Materials, Apparatus, and Experimental Methods

2.1. Materials

Nut shells, calcium carbonate particles, elastic graphite, and mica were sourced from drilling sites in the Tarim Oilfield. The particle size of the lost circulation materials was adjusted according to experimental requirements. Polyimide and basalt fiber were obtained from Macklin Inc., Shanghai, China.

The water-based drilling fluid was a potassium-based polysulfonate system, and the oil-based drilling fluid was a water-in-oil emulsion system, both sourced from drilling sites in the Tarim Oilfield.

2.2. Experimental Apparatus

A high-temperature and high-pressure fracture-plugging experimental apparatus was independently developed by Chongqing University of Science and Technology. The PPA (Permeability Plugging Apparatus) was provided by Shandong Haitongda Instrument Co., Ltd., Qingdao, China. Scanning electron microscopy was performed using an instrument from Guoyi Company, Xiamen, China. A universal testing machine was supplied by Jinan Quanli Testing Instrument Co., Ltd., Jinan, China. High-temperature roller ovens, aging cells, and balances were provided by Shandong Haitongda Instrument Co., Ltd., Zibo, China.

2.3. Experimental Methods

Mass Loss Rate: Using the field drilling fluid system, a 500 mL test slurry was prepared with a mass fraction of 4% lost circulation material (6–40 mesh) uniformly mixed. The slurry was placed in a high-temperature roller oven and aged at 240 °C for 16 h or 48 h. After cooling to room temperature, the lost circulation material was sieved out, washed, dried, and weighed before and after aging. The mass loss rate was calculated as (m1 − m2)/m1, where m1 is the mass before aging and m2 is the mass after aging.

Compressive Strength Retention Rate: Following the rolling aging procedure described above, the compressive D90 size degradation rate was measured to evaluate the compressive strength of the lost circulation material. The D90 value of the material before compression was determined by sieving. After high-temperature aging, a pressure of 60 MPa was applied for 10 min, and the D90 value after compression was again determined by sieving. The particle size degradation rate SC was used as an evaluation index to characterize the compressive strength retention rate.

Plugging Performance Evaluation of the While-Drilling Leak Prevention System: A PPA (Permeability Plugging Apparatus) was used to measure the filtration loss under conditions of 240 °C and 7 MPa. The plugging condition of the sand disk was observed using scanning electron microscopy.

Plugging Performance Evaluation of the Pressure-Bearing Lost Circulation System: A high-temperature and high-pressure fracture-plugging experimental apparatus was employed to test the pressure-bearing capacity and leakage volume of the lost circulation formulations for different fracture widths, and to optimize the formulations. The prepared lost circulation working fluid was injected into an autoclave equipped with a fracture module of a specific width. At the set temperature (240 °C), a piston was driven at a constant rate to squeeze the lost circulation system into the fracture until the plugging layer failed and fluid breakthrough occurred. The maximum pressure before failure (i.e., the pressure-bearing capacity) and the leakage volume before breakthrough were recorded.

4. Optimization of Ultra-High-Temperature Leak Prevention and Plugging Materials

Bridging plugging materials are the most commonly used materials for field leak treatment, generally categorized as granular, flaky, and fibrous. Granular materials are further divided into bridging particles and filling particles. Bridging particles require a high compressive strength to the ensure successful formation of a plugging layer framework in fractures. Ultra-high-temperature bridging plugging materials for 10,000 m ultra-deep wells must maintain unchanged physical and mechanical properties after high-temperature aging, with aging temperature ≥200 °C. Organic plant-based materials such as walnut shells and fruit shells mainly consist of hemicellulose, cellulose, and lignin. High-temperature aging causes the removal of physical water and chemically adsorbed water [

20,

21], damaging the overall structure and causing inter cellular layer fractures with numerous pores, resulting in reduced compressive strength. These materials are prone to crushing instability in plugging layers and should not be used for ultra-high-temperature formation plugging operations [

22]. Organic materials like rubber particles and polypropylene fibers experience molecular chain scission at temperatures ≥200 °C, leading to melting or pyrolysis, making them unsuitable for ultra-high-temperature formation plugging operations.

Inorganic materials such as calcium carbonate, mica, resilient graphite, limestone, and quartz sand exhibit excellent high-temperature resistance. Several common ultra-high-temperature inorganic materials were preferentially selected for high-temperature aging performance evaluation. The above inorganic rigid materials with 6–40 mesh sizes underwent 240 °C/16 h rolling aging, followed by the observation of morphology and testing of mass loss rate and compressive strength retention rate. TLM-SCC, TLM-RGC, and TLM-MIC represent calcium carbonate particles, resilient graphite granules, and mica flakes, respectively. As shown in

Figure 3 and

Figure 4, all three materials demonstrated minimal mass loss rates, with almost no mass loss occurring under high-temperature aging. The compressive strength retention rates all exceeded 95%, proving that they maintain a high compressive strength after 240 °C aging, with no changes observed in surface morphology. Elastic graphite is a form of carbon with an extremely high melting point and excellent thermal stability, while mica is a layered silicate mineral that also demonstrates superior temperature resistance.

Inorganic materials (e.g., TLM-SCC, TLM-RGC, TLM-MIC, TLM-HTF) possess strong chemical bonds (ionic and covalent bonds) and high melting points, ensuring stable chemical structures without thermal decomposition at 240 °C. Consequently, mechanical properties such as hardness and strength are retained after aging. In contrast, organic materials like nut shells and polymer fibers, which are based on carbon chains and weaker bonds, are prone to chemical degradation, such as oxidation, chain scission, and carbonization under high-temperature conditions. This leads to poor mechanical and chemical stability, manifested as embrittlement, softening, and a loss of strength.

When handling fracture-induced lost circulation, high-strength bridging particles serve as one of the key factors in forming pressure-bearing sealing layers. Through the synergistic effects of filler particles, elastic particles, fibers, and flaky materials, dense pressure-bearing sealing layers can be formed. Small-sized calcium carbonate particles TLM-SCC, resilient graphite TLM-RGC, and mica flakes TLM-MIC maintain nearly unchanged mechanical properties after 240 °C aging, making them suitable for ultra-high-temperature formation lost circulation operations. However, when addressing large-aperture fracture losses in high-temperature formations, larger limestone particles exhibit strong brittleness, low compressive strength, high density (2.7 g/cm

3), and poor suspension stability under high temperatures, making them unsuitable as bridging particles [

23]. Additionally, plant-based fibers and organic fiber materials lack sufficient temperature resistance. Therefore, there is an urgent need to develop high-temperature-resistant rigid bridging particles and high-temperature-resistant fiber materials for lost circulation.

To meet the requirements of high-temperature formation lost circulation operations, sealing materials must maintain stable physical and mechanical properties during prolonged use at high temperatures (≥240 °C). Heat-resistant polymers are macro molecular materials capable of long-term service within 150–300 °C [

24]. Selection criteria for heat-resistant polymers include: (1) resistance to chemical changes under thermal or thermo-oxidative conditions, typically choosing elemental polymers (e.g., fluoro polymers, silicone polymers) and hetero cyclic polymers; (2) retention of certain physical and mechanical properties at service temperatures (excluding ablative materials), generally selecting materials with high molecular chain rigidity, high glass transition temperatures, or moderately cross-linked materials [

25,

26]. Recent advancements in heat-resistant polymer research provide technical references for developing new high-temperature lost circulation materials.

Polyimide is an aromatic hetero cyclic polymer compound whose molecular structure contains imide group chain segments. It can withstand high temperatures of 290 °C for extended periods and 490 °C for short durations. Additionally, it exhibits excellent mechanical properties, fatigue resistance, flame retardancy, dimensional stability, and wear resistance [

27,

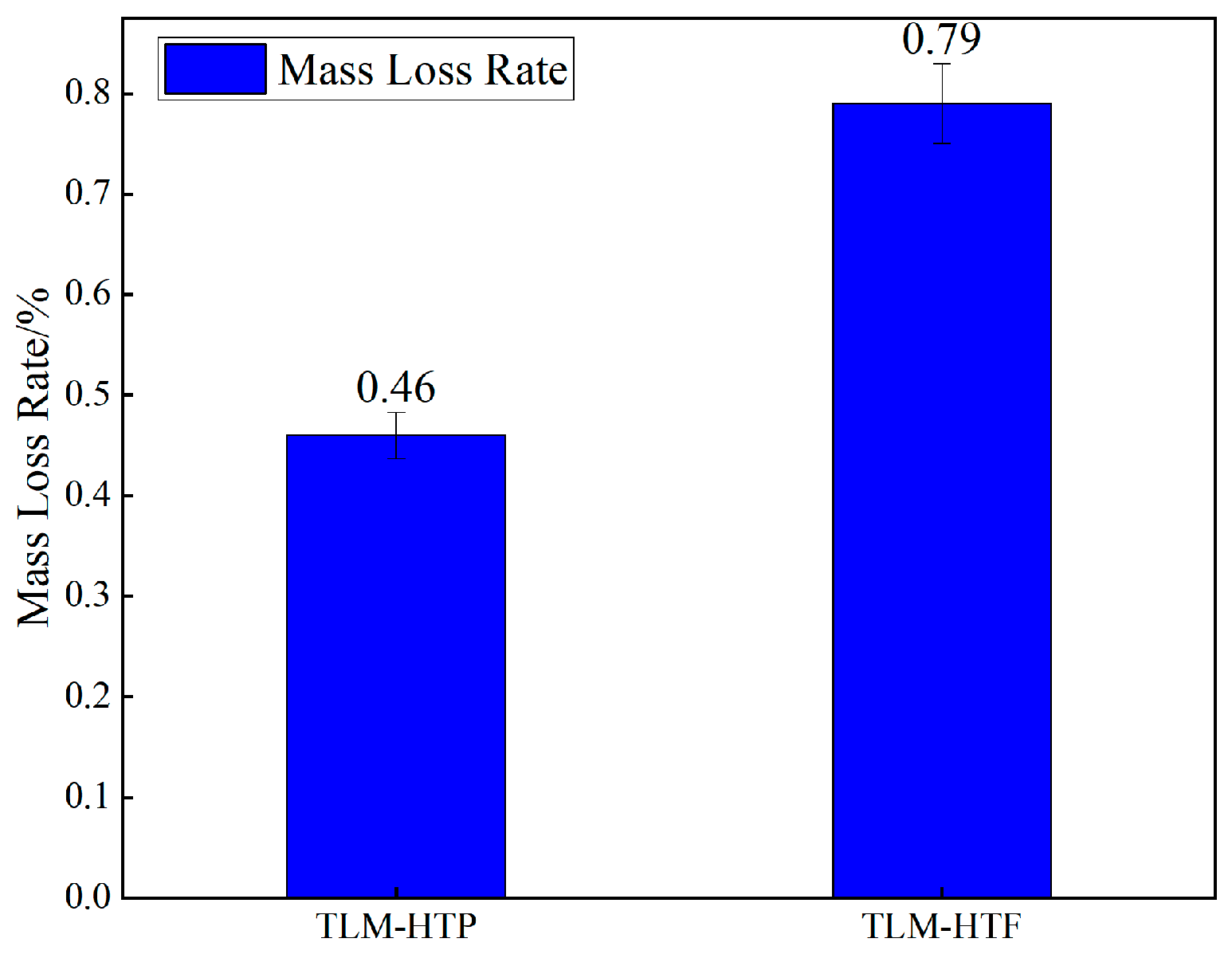

28]. When crushed into particles of different sizes, polyimide becomes an ultra-high-temperature leak prevention and bridging material TLM-HTP, which demonstrates better suspension in drilling fluids compared to high-density mineral particles. Inorganic leak plugging materials outperform plant fibers and polymer fibers in high-temperature resistance. Based on this, basalt fiber is selected as the ultra-high-temperature fiber leak plugging agent TLM-HTF, which can be processed into 3 mm, 6 mm, and 12 mm lengths for leak prevention. The mass loss rate and strength retention of TLM-HTP and TLM-HTF after 48 h of aging at 240 °C were tested. As shown in

Figure 5 and

Figure 6, these materials show almost no mass loss after ultra-high-temperature aging while maintaining high strength retention, proving their effectiveness in leak plugging under 240 °C ultra-high-temperature conditions. Polyimide is a stable high-molecular-weight polymer with excellent chemical stability and low susceptibility to decomposition, generally regarded as a low-toxicity or non-toxic material. As an inert lost circulation material, polyimide poses minimal risk of potential formation contamination. Furthermore, its applications in medical devices and the food industry demonstrate its biocompatibility and safety.

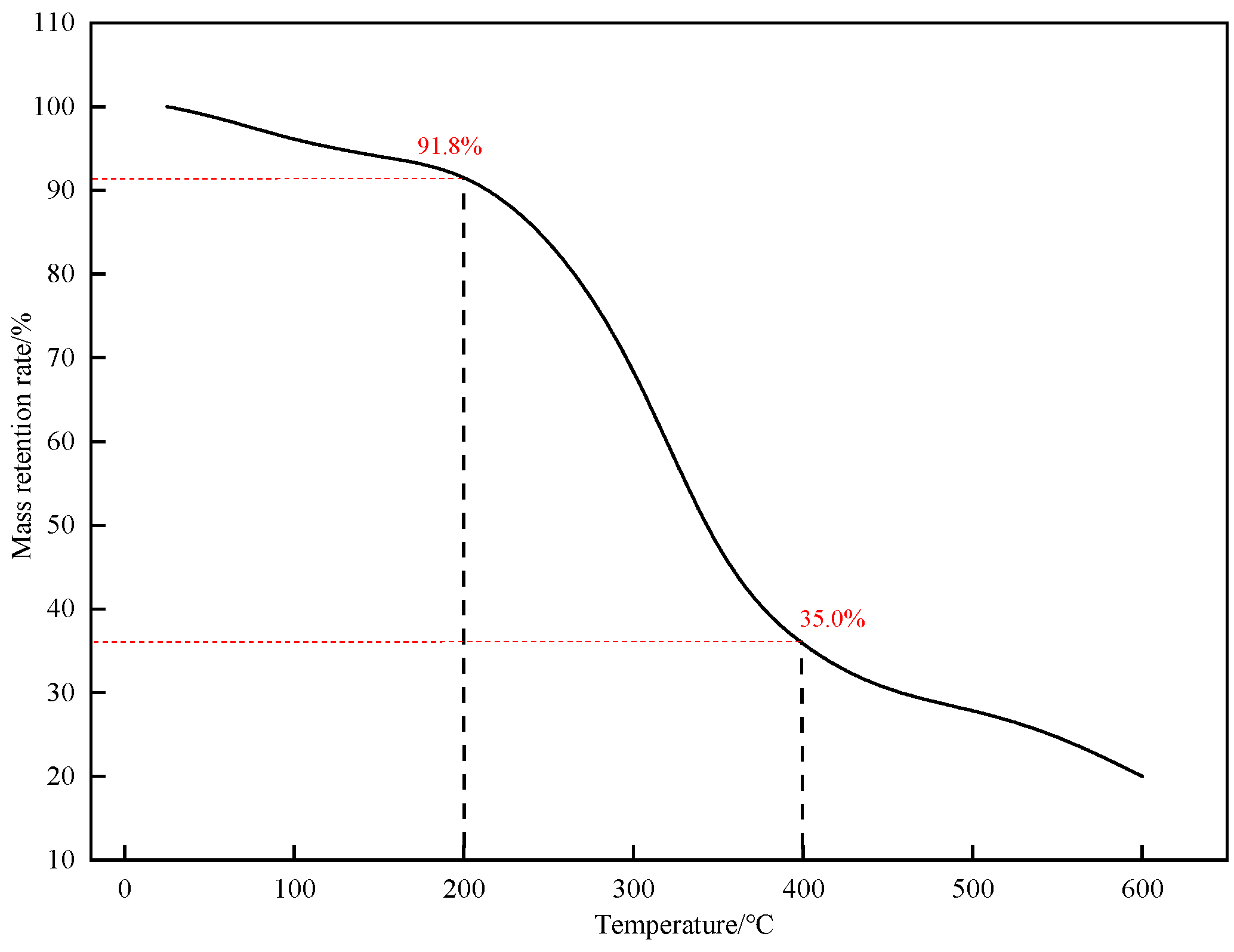

The thermal resistance of polyimide originates from its highly aromatic, rigid, and fully conjugated molecular chain structure. The molecular backbone of polyimide consists of alternating benzene rings (aromatic rings) and five- or six-membered imide rings (composed of carbonyl groups C=O and nitrogen atoms N). This structure is classified as an aromatic heterocyclic polymer. The π-electrons in the benzene and imide rings form an extensively delocalized conjugated system. The electron cloud is distributed across the entire molecular framework, lowering the molecular energy and conferring exceptional structural stability. Disrupting this structure requires extremely high energy (i.e., high temperatures). The benzene rings are planar and rigid, significantly restricting the rotation and flexibility of the molecular chains, thereby requiring very high temperatures for segmental motion to occur. As shown in

Figure 7, the thermogravimetric analysis data of polyimide particles (TLM-HTP) show that at 240 °C, the mass retention rate is as high as 99.8%, with a cumulative mass loss of only 0.2%. Its initial thermal decomposition temperature exceeds 550 °C, and the mass retention rate remains as high as 92.3% at 600 °C, far exceeding the temperature requirements of ultra-deep well drilling environments.

The high-temperature resistance of basalt fiber, on the other hand, stems from the network structure of its inorganic silicate glass. Basalt fiber is formed by melting basalt rock at high temperatures and drawing it into filaments, with silicon dioxide (SiO2) as its primary component. The fundamental structural unit of SiO2 is the [SiO4] tetrahedron, where each silicon atom is covalently bonded to four oxygen atoms. Covalent bonds are highly stable and resistant to high temperatures. In the molten state, these [SiO4] tetrahedra connect by sharing oxygen atoms, forming a continuous, disordered, yet dense three-dimensional network structure. Other metal oxides in basalt, such as Al2O3, CaO, MgO, and Fe2O3, integrate into this network. The Si-O bond is one of the most stable chemical bonds in nature, with a bond energy as high as 460 kJ/mol. The dense three-dimensional network formed by Si-O bonds exhibits an extremely high activation energy, making it highly stable in oxidative, acidic, or alkaline environments and exceptionally difficult to break under thermal excitation.

5. Experimental Study on Optimization of Ultra-High-Temperature Dense Pressure-Bearing Leak Prevention and Plugging Formulations

Field leak incidents are typically addressed through while-drilling leak prevention and pressure-bearing plugging. For cases with low leak rates, while-drilling leak prevention technology is employed. This uses smaller-sized plugging materials to achieve simultaneous drilling and plugging, effectively preventing drilling fluid loss while enhancing formation pressure-bearing capacity. For scenarios involving high leak rates or weak formations, pressure-bearing plugging technology is adopted. This generally utilizes larger-sized plugging materials that are compacted into the formation to improve pressure-bearing capacity. Ultra-high-temperature dense pressure-bearing means that under high-temperature formation conditions, a plugging layer can be formed. This layer exhibits a high pressure-bearing capacity, possesses an internally dense structure, and effectively prevents drilling fluid loss.

While-drilling leak prevention technology primarily targets micro-pore formations encountered during drilling. Sand disk permeability plugging experiments have become a crucial method for evaluating the sealing performance of drilling fluids in porous formations [

29]. By simulating downhole high-temperature (up to 260 °C) and high-pressure (up to 27 MPa) environments, and using sand disks with different permeability values (e.g., 20 μm

2, 10 μm

2, 2 μm

2, etc.) as filtration media to simulate formation pores, the fluid loss volume of drilling fluids is tested to assess their leak prevention and plugging capabilities in porous formations.

Based on the leakage-induced permeability and fracture apertures in porous and micro-fractured formations, sand disks with permeability of 10–20 μm

2 are selected as filtration media to simulate pore formations with 35–60 μm apertures. Fine limestone particles and elastic graphite particles are sieved into four size grades: 10–30 μm, 30–60 μm, 100–250 μm, and 300–500 μm. The particle size distribution of while-drilling leak control materials is shown in

Table 3.

Pressure-bearing plugging technology primarily targets formations with large-aperture fractures encountered during drilling. Using a high-temperature high-pressure fracture plugging simulation experimental apparatus, the sealing performance of ultra-high-temperature compact pressure-bearing plugging formulations on fractures with different apertures (1–5 mm, etc.) is evaluated (

Figure 8), with the aim of optimizing high pressure-bearing compact plugging formulations.

5.1. Evaluation of Sealing Performance for Ultra-High-Temperature While-Drilling Loss Prevention Formulations

Using high-temperature water-based drilling fluid from the high-temperature oil-based drilling fluid from the Tarim Basin as experimental base slurries, the formula for ultra-high-temperature while-drilling tight pressure-bearing leak prevention and plugging working fluid system was optimized. The optimized permeable while-drilling leak prevention formula is as follows: base slurry + 2% TLM-SCC60 + 1% TLM-SCC30 + 2% TLM-RGC30 + 0.5% TLM-HTF.

Sand disks with permeability of 20 μm

2 were selected as filtration media. The sealing performance of experimental base slurries and while-drilling leak prevention working fluid formulas was evaluated using a permeable sealing experimental device.

Figure 9 shows the sand disk sealing performance evaluation results of different drilling fluid systems. The total filtration loss of water-based drilling fluid was 24 mL, with instantaneous filtration loss and static filtration rate being 5.33 mL and 3.41 mL/min

1/2, respectively. After adding the while-drilling leak prevention formula, the total filtration loss decreased to 11 mL, with instantaneous filtration loss and static filtration rate reducing to 3.50 mL and 1.39 mL/min

1/

2, respectively. The total filtration loss, instantaneous filtration loss, and static filtration rate of oil-based drilling fluid also significantly decreased after adding the while-drilling leak prevention agent. Since the selected LCMs are all inert and compatible with both oil and water phases, the filtration loss of oil-based drilling fluids is lower than that of water-based drilling fluids. The primary differences may manifest in the dispersion stability of the materials, but this can be resolved by adjusting the wetting agents and emulsifiers in the oil-based drilling fluid.

Figure 10 shows SEM images of the water-based drilling fluid before and after sealing the sand disk. The unsealed sand disk exhibited numerous micropores, while the sealed structure became dense with effective plugging performance.

5.2. Evaluation of Sealing Performance of Ultra-High-Temperature Pressure-Bearing Loss-Off Sealing Formulations

Through the synergistic effect of optimized high-temperature-resistant and high-strength bridging particles TLM-HTP, high-temperature-resistant and high-strength leak-blocking fibers TLM-HTF, small-sized limestone filler particles, elastic graphite particles, mica flakes, and other different types of high-temperature-resistant leak-blocking materials, we experimentally optimized the high-temperature-resistant compact pressure-bearing leak-blocking working fluid formulas for different fracture widths by utilizing reasonable particle size gradation and concentration control. The experimental results are shown in

Table 4 and

Figure 11.

As shown in

Table 5, the optimized high-temperature-resistant dense pressure-bearing plugging work fluid formulation demonstrates a sealing layer pressure-bearing capacity up to 15 MPa. It can rapidly form a sealing layer with low leakage loss, meeting the special requirements for plugging operations in ultra-high-temperature (240 °C) formations or reservoirs. The pressure variation in the plugging zone was monitored via computer, as shown in

Figure 11. The pressure remained stable at 15 MPa for 10 min without breakthrough, indicating a pressure-bearing capacity of 15 MPa. Moreover, as the fracture aperture increased, the plugging time extended, requiring more materials to enter the fracture to achieve the high pressure-bearing performance.

Table 1 shows that the pressure-bearing capacity of walnut shell decreases to 0.5 MPa under high-temperature conditions at 240 °C, while limestone particles maintain a pressure-bearing capacity of 10 MPa. The optimized lost circulation formulation developed in this study achieves a pressure-bearing capacity of 15 MPa at 240 °C, clearly demonstrating a significant improvement in both the temperature resistance and plugging efficiency of the materials presented in this work.

Figure 12 shows that after ultra-high-temperature aging, the high-temperature sealing layer maintains an intact structure with excellent thermal resistance. Before aging, the plugging layer exhibits a dense structure, with different materials (particles, fibers, and flaky materials) tightly integrated and minimal porosity. After aging, the overall structure of the plugging layer remains intact, without large cracks or voids caused by material degradation. This demonstrates that the selected materials can maintain a stable microstructure even after aging at 240 °C, thereby ensuring their plugging performance.

The high-temperature-resistant lost circulation materials in this paper can maintain their original physical structure and mechanical properties under ultra-high-temperature conditions (240 °C). Through the synergistic effect of different types of lost circulation materials, they can form a dense pressure-bearing sealing layer with a reinforced force chain network structure in high-temperature environments. The novel high-temperature-resistant high-strength bridging particles TLM-HTP possess a high compressive strength, which helps establish the framework of the sealing layer. Fine limestone particles fill between the frameworks, increasing the average coordination number of particles and enhancing the number of strong force chains in the sealing layer. Elastic graphite, with its elastic deformation characteristics, fills between micro-pores to reduce the permeability of the sealing layer and increase the average coordination number of particles, thereby improving the probability of forming strong force chains through particle connections. The lost circulation fiber TLM-HTF can enhance the shear strength of the sealing layer, facilitate the formation of a strong force chain network structure, and improve the internal structural strength of the sealing layer [

30,

31,

32]. The experiment further optimized the particle size distribution of different types of granular materials, increased the average coordination number of particles, and reduced the permeability of the sealing layer [

33,

34].

As shown in

Table 5, based on the formula optimization results of the ultra-high-temperature dense pressure-bearing leak prevention and lost circulation working fluid system specifically designed for both drilling and non-drilling operations, the pilot-scale products of the high-temperature-resistant pressure-bearing lost circulation agent TLM-HTD series have been developed. These products exhibit a temperature resistance ≥ 240 °C and demonstrate high sealing and pressure-bearing capabilities. This new series of high-temperature leak prevention and lost circulation agents consists of inert materials, capable of treating lost circulation in both high-temperature water-based and oil-based drilling fluids. They can effectively implement leak prevention during drilling or prepare lost circulation working fluids for plugging operations through slug treatment, addressing different leakage scenarios (leakage rates).

This study systematically evaluated and revealed the failure mechanisms of traditional materials under ultra-high temperatures of 240 °C. It also selected and developed a novel high-temperature-resistant lost circulation material system capable of withstanding 240 °C, including polyimide rigid particles and basalt fibers. Furthermore, optimized formulations suitable for both while-drilling leak prevention and stop-drilling pressure-bearing plugging were developed, achieving a high pressure-bearing capacity of 15 MPa under ultra-high-temperature conditions. It provides critical material systems and formulation technical support for addressing drilling fluid loss challenges in high-temperature formations of 10,000 m ultra-deep wells, holding significant practical application value for ensuring the safe and efficient drilling of ultra-deep wells. In the future, we will identify suitable wells experiencing lost circulation and conduct on-site experiments for lost circulation prevention and control in high-temperature formations.

6. Conclusions

(1) Analyzed the causes and mechanisms of plugging instability and failure in traditional bridging plugging materials under ultra-high-temperature conditions. Organic plant-based plugging materials undergo dehydration and coking after high-temperature aging, resulting in reduced compressive strengths, making them unsuitable for ultra-high-temperature (≥240 °C) formation plugging operations. Inorganic plugging materials exhibit high decomposition temperatures and maintain good mechanical properties after high-temperature aging, making them suitable for ultra-high-temperature formation plugging operations in 10,000 m deep wells.

(2) Selected polyimide TLM-HTP as bridging particles, calcium carbonate particles TLM-SCC as filling and plugging particles, elastic graphite TLM-RGC as elastic particles, mica flakes TLM-MIC as flaky packing material, and basalt fiber TLM-HTF as fiber reinforcement material for the subsequent optimization of while-drilling leak prevention and pressure-bearing plugging formulations and systems. After high-temperature aging at 240 °C, the mass loss rate of the aforementioned materials is less than 1%, and the strength retention rate exceeds 95%.

(3) Experimentally optimized an ultra-high-temperature compact pressure-bearing leak prevention and plugging working fluid system formulation. Developed the high-temperature-resistant pressure-bearing plugging agent TLM-HTD series products, with temperature resistance reaching 240 °C, pressure-bearing capacity up to 15 MPa, loss volume of only 10–25 mL, excellent suspension stability, and is capable of treating high-temperature water-based and oil-based drilling fluid losses and suitable for solving ultra-high-temperature (240 °C) formation drilling plugging technical challenges.