Analysis of Sealing Characteristics of Hydraulic Clamping Flange Connection Mechanism

Abstract

1. Introduction

2. Establishment of the Finite Element Analysis Model

2.1. Geometric Model of Hydraulically Clamped Flange Connecting Mechanism

2.2. Material Properties

2.3. Finite Element Mesh Model

2.4. Assembly Constraint Settings

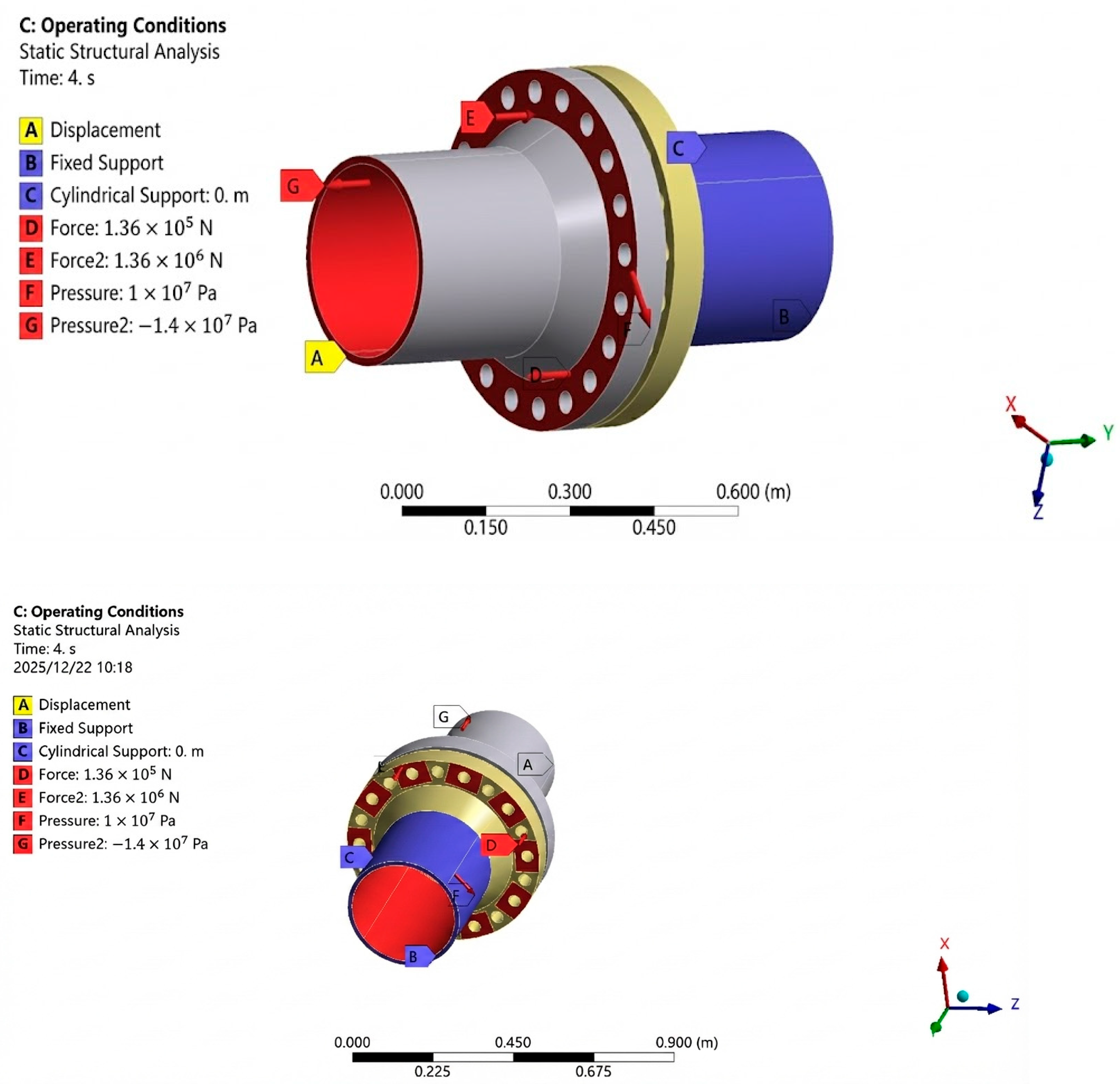

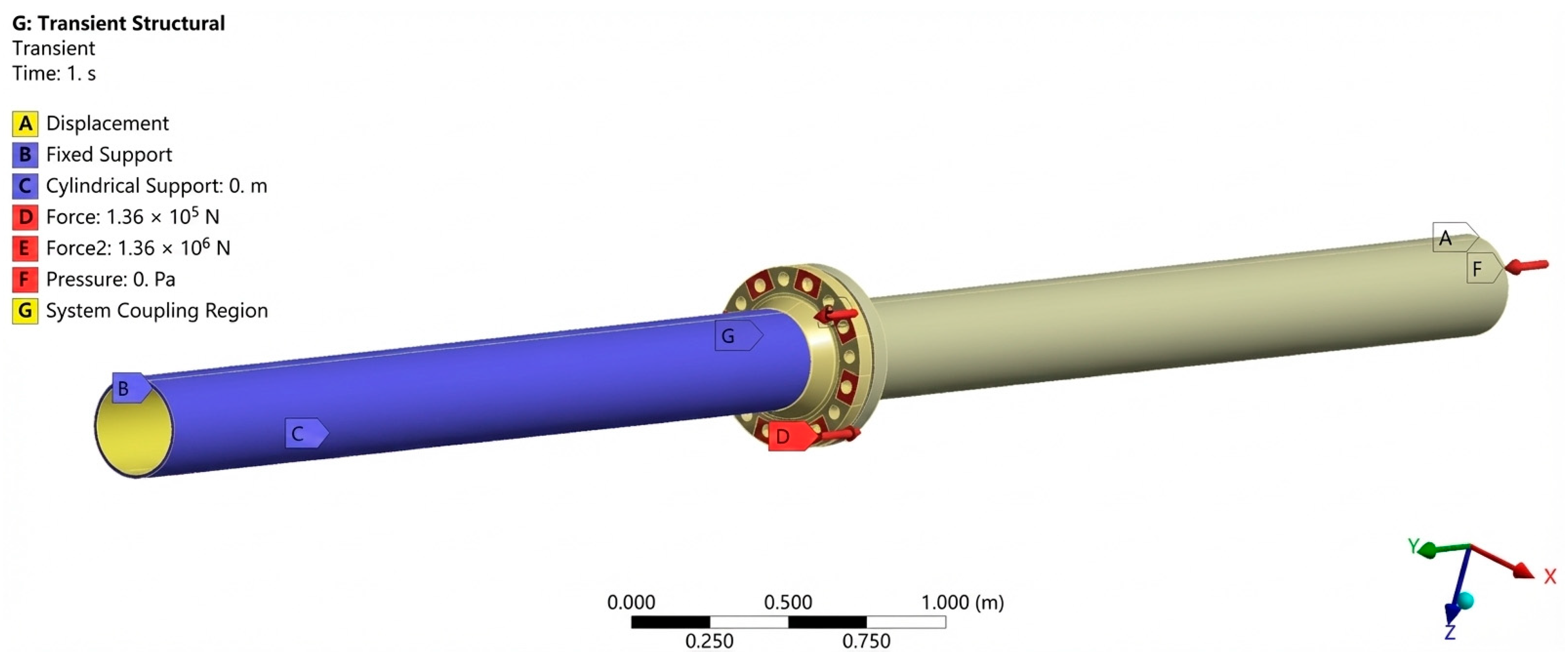

2.5. Constraints and Loads

- (1)

- Boundary Conditions: (1) Apply a displacement constraint on the end face of the gas pipeline tail: fixed in the axial direction (X-axis), while free in the circumferential and radial directions (Y-axis and Z-axis directions). (2) Apply a fixed constraint on the end face of the flowmeter tail. (3) Simulate the constraint provided by the self-centering support frame on the flowmeter and gas pipeline by applying cylindrical supports to the outer surfaces of the flowmeter and gas pipeline, with freedom in the axial direction and fixed constraints in both the radial and tangential directions.

- (2)

- Loading Conditions: Taking the DN300, PN100 flange as the research object, the required bolt preload force for sealing is consistent with the hydraulic clamping force. Two operating conditions, preload and pressurization, are simulated and applied in two steps (total duration of 2 s): Step 1 (0–1 s) involves loading the clamping force to 1,360,000 N; Step 2 (1–2 s) involves increasing the internal pressure to 10 MPa, while simultaneously applying an equivalent axial force to the pipeline end face. The internal pressure acts on all the inner surfaces in contact with the medium [28].

3. Analysis of the Impact of Different Factors on the Sealing Performance of Flanged Connections

3.1. Sealing Performance Evaluation Criteria for Flanged Connections

- (1)

- Allowable Stress of Components: The flanges, gaskets, and other metal components must be subjected to forces less than the material’s allowable stress under conditions such as pressurization and water hammer impact, in order to avoid insufficient strength that could lead to sealing failure.

- (2)

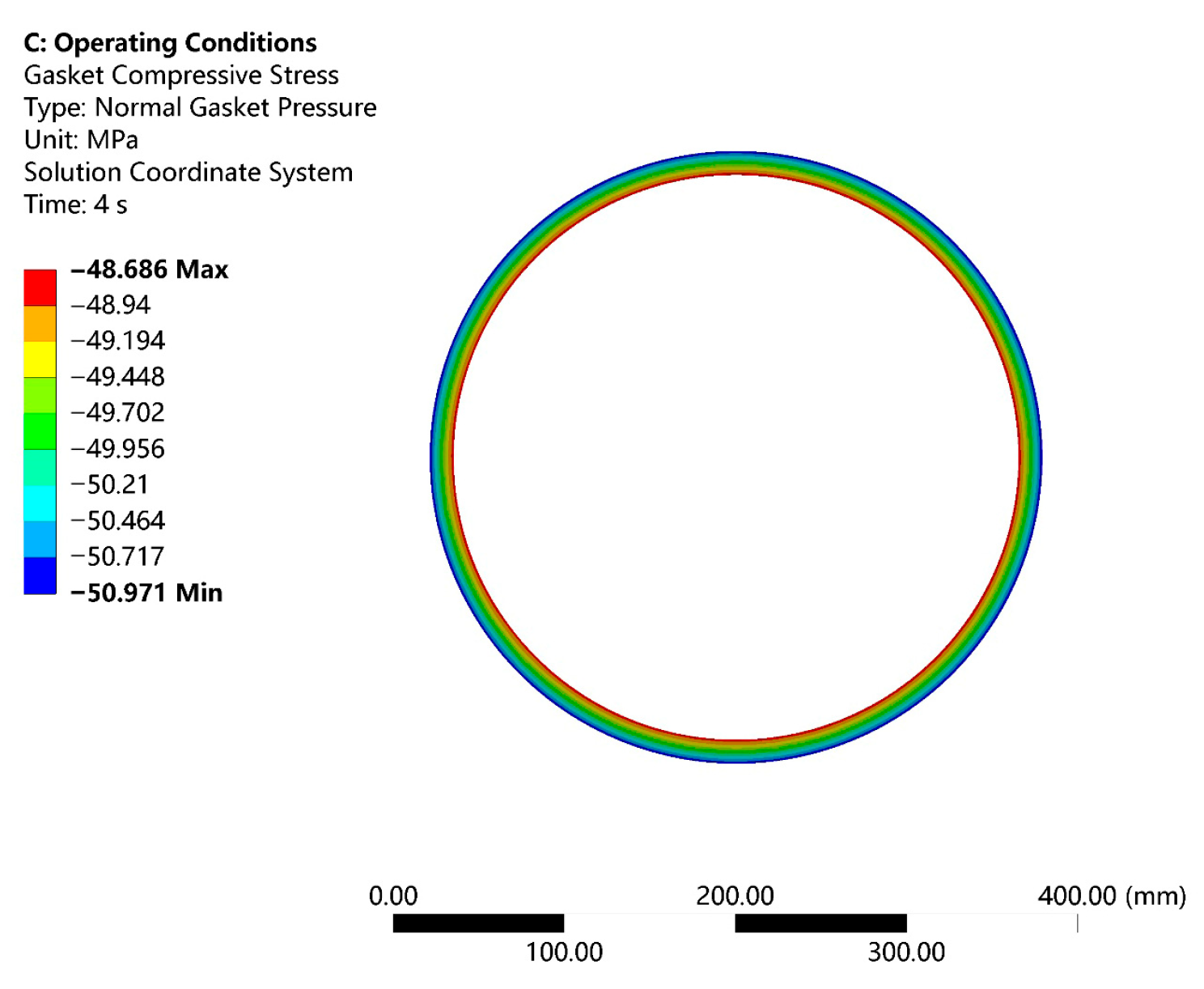

- Gasket Compressive Stress: According to GB150 [22] and ASME VIII-1 [31] standards, the gasket compressive stress should satisfy (where m is the gasket factor and p is the internal pressure) to meet the sealing requirements. Moreover, the larger the effective sealing area and the more uniform the stress distribution, the better the sealing performance [32].

- (3)

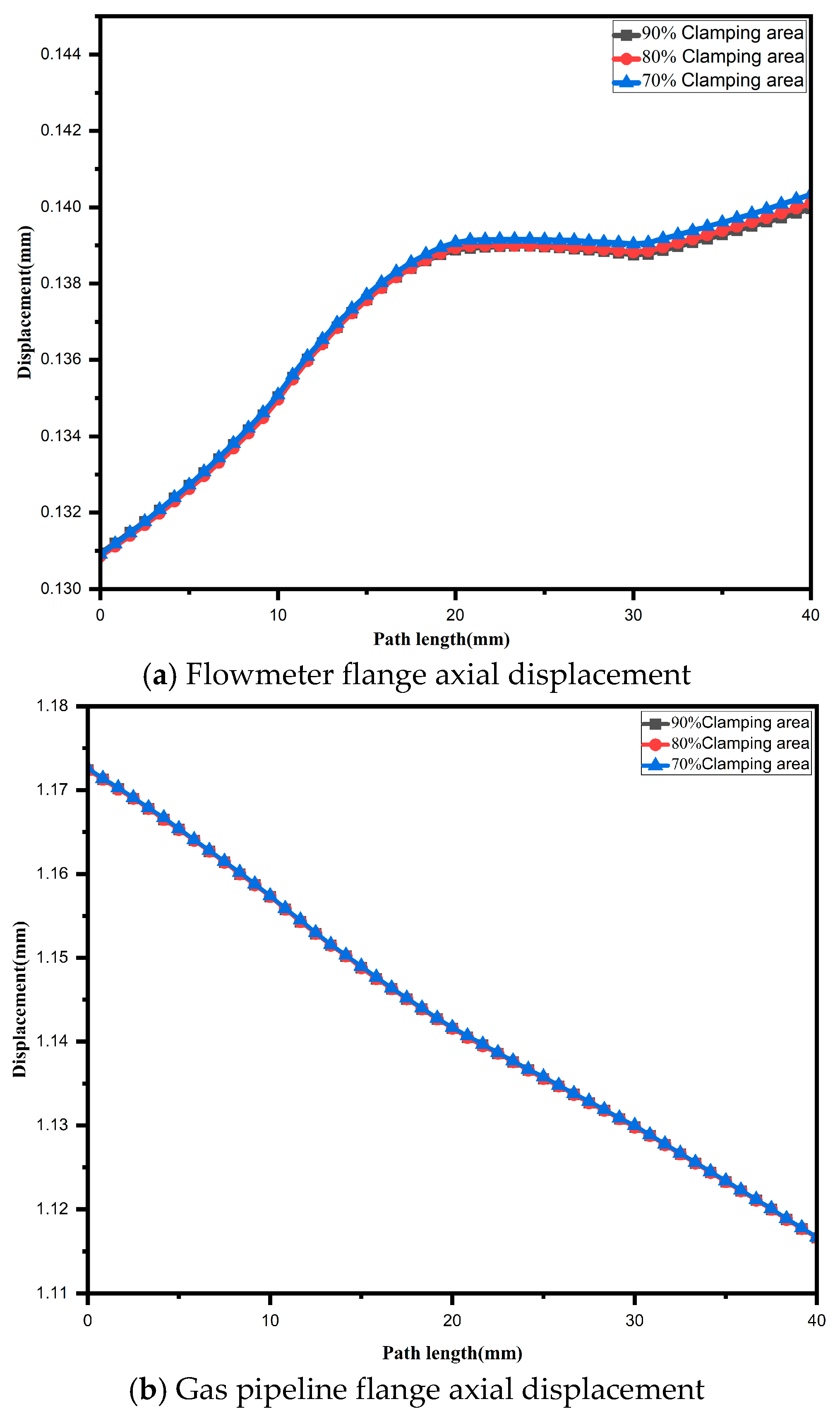

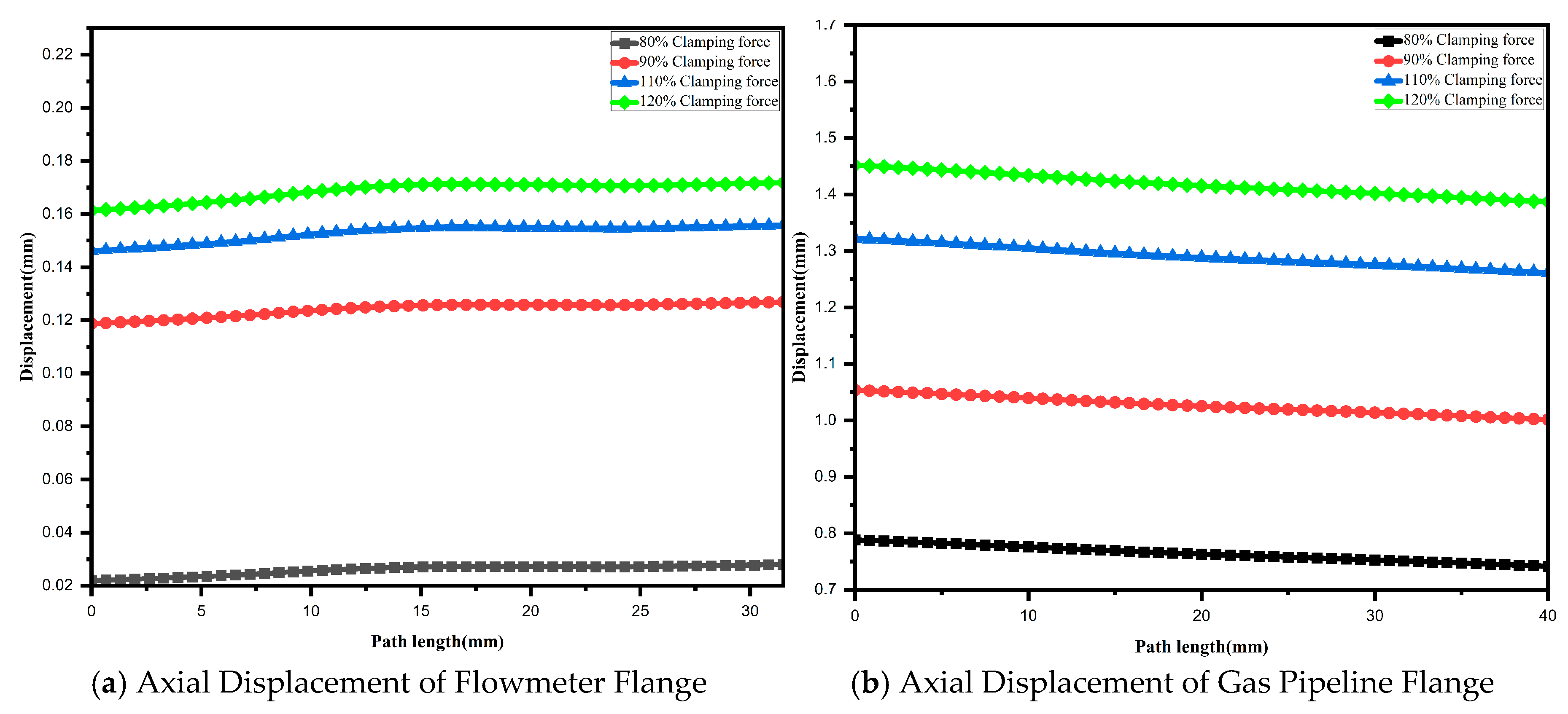

- Flange Angular Deformation: The combined effect of medium pressure and external bending moments can cause the flange to undergo circumferential deflection. According to the ASME VIII-1 standard, the flange angular deformation should be ≤1°. Studies show that the larger the angular deformation, the more uneven the distribution of the gasket compressive stress, so the deflection angle must be assessed. The calculation method is as follows: Measure the axial displacement of corresponding points on the inner and outer diameters of the flange plate, calculate the displacement difference, and divide by the flange plate width. If the resulting angular deformation is ≤1°, the flange connection stiffness meets the standards, and the sealing performance is good.The calculation formula for the deflection angle iswhere represents the difference in axial displacement between the outer and inner sides of the flange (mm), and V represents the radial width of the flange (mm).

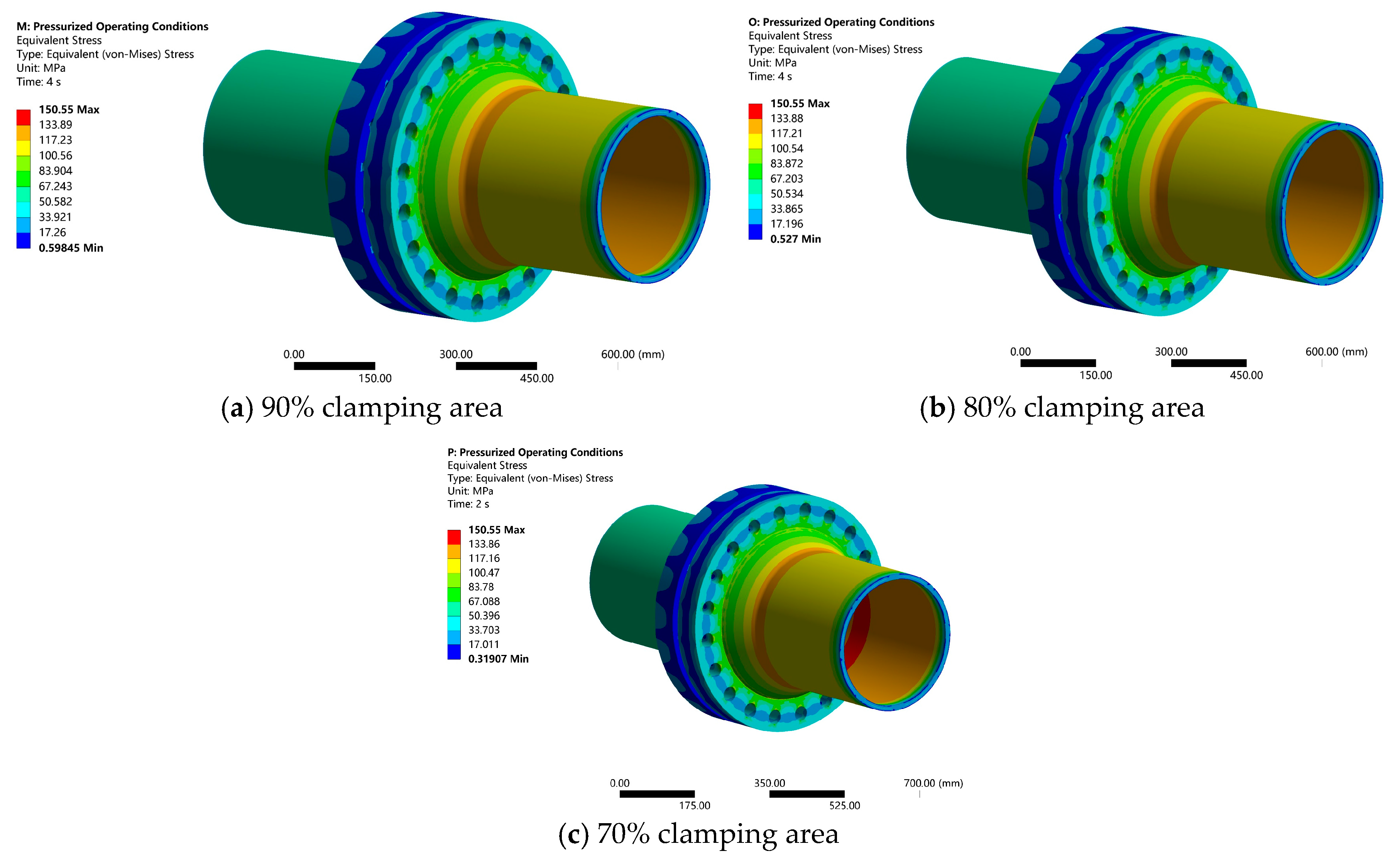

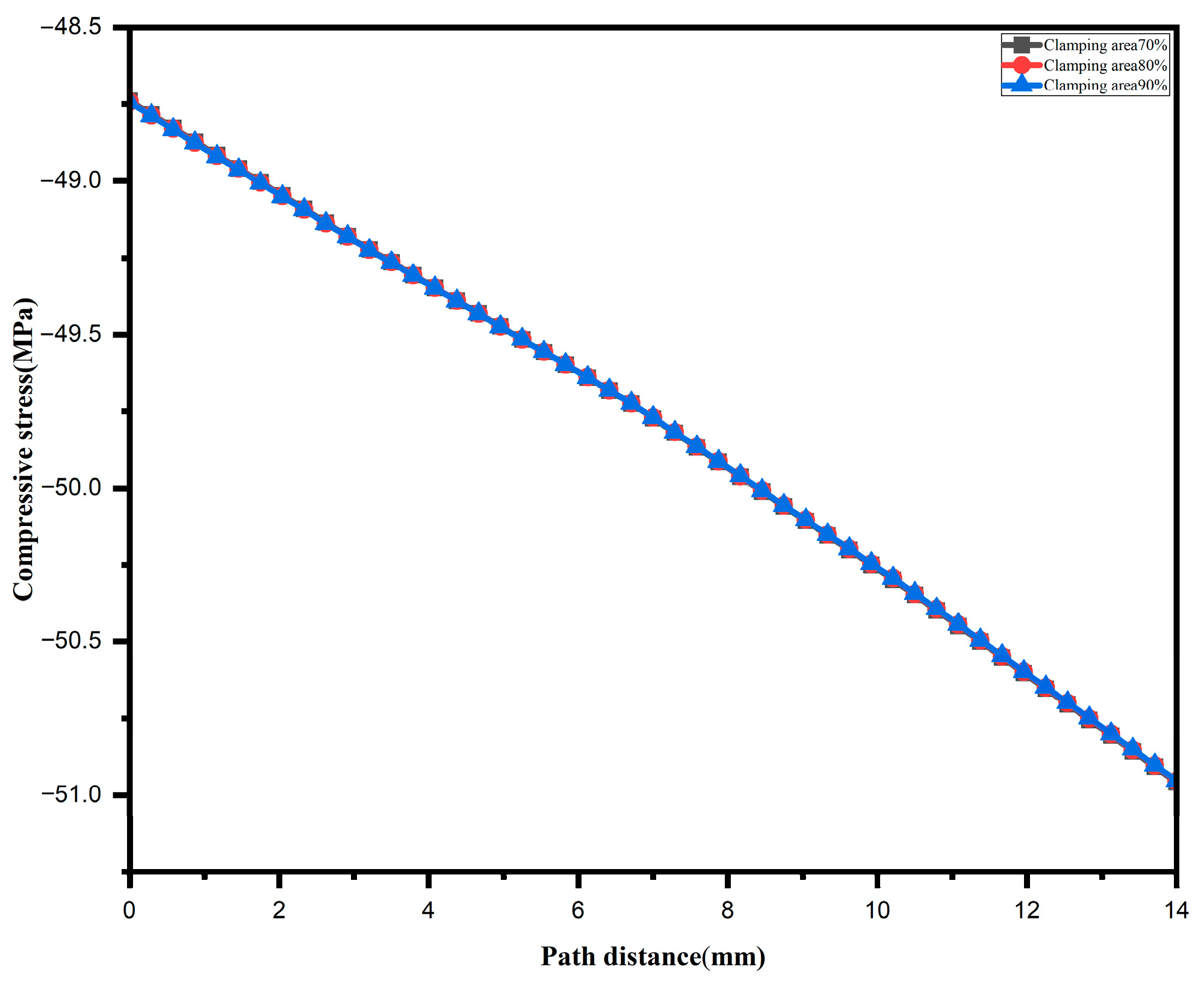

3.2. The Effect of Clamping Area Size on Sealing Performance

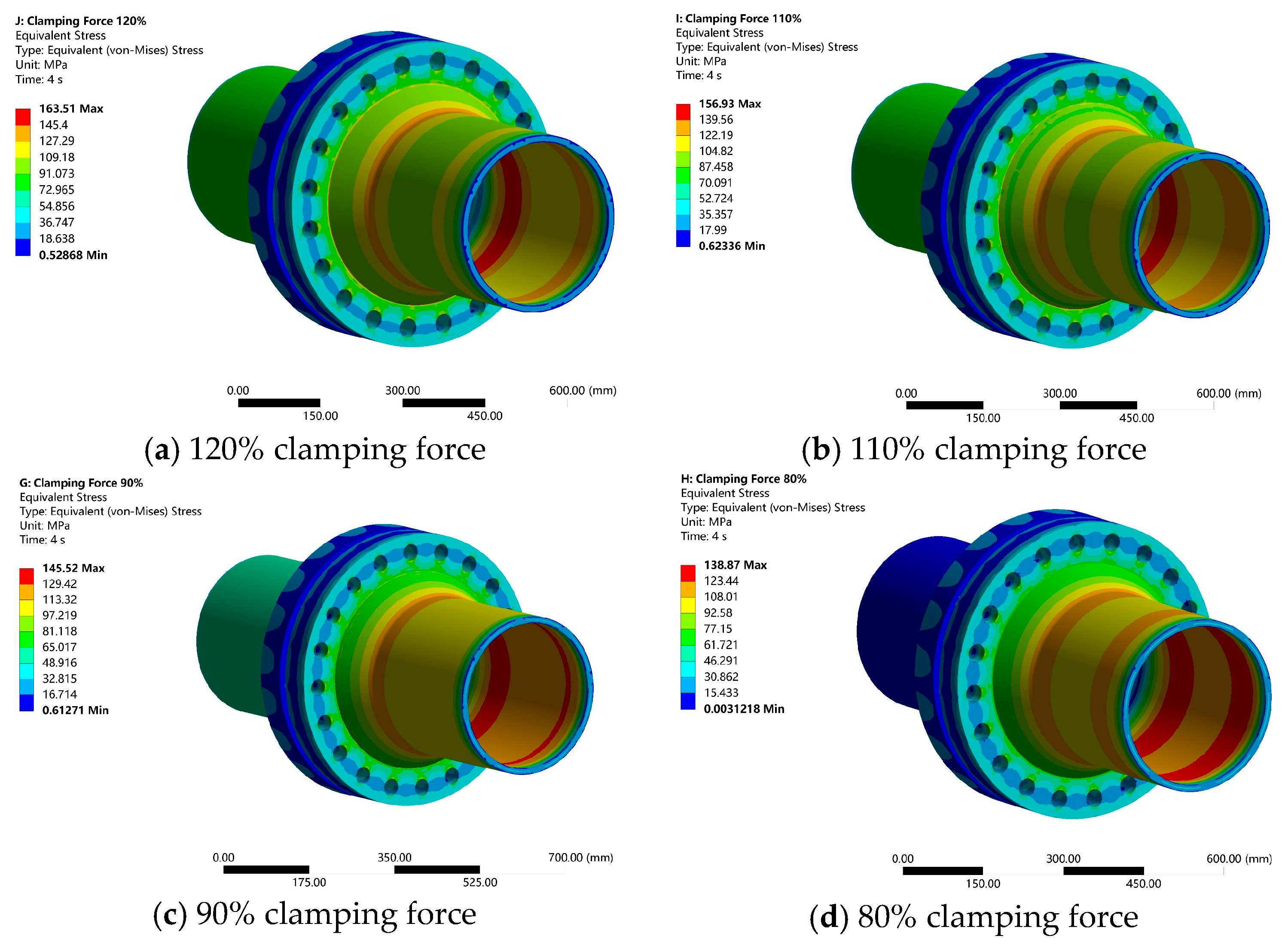

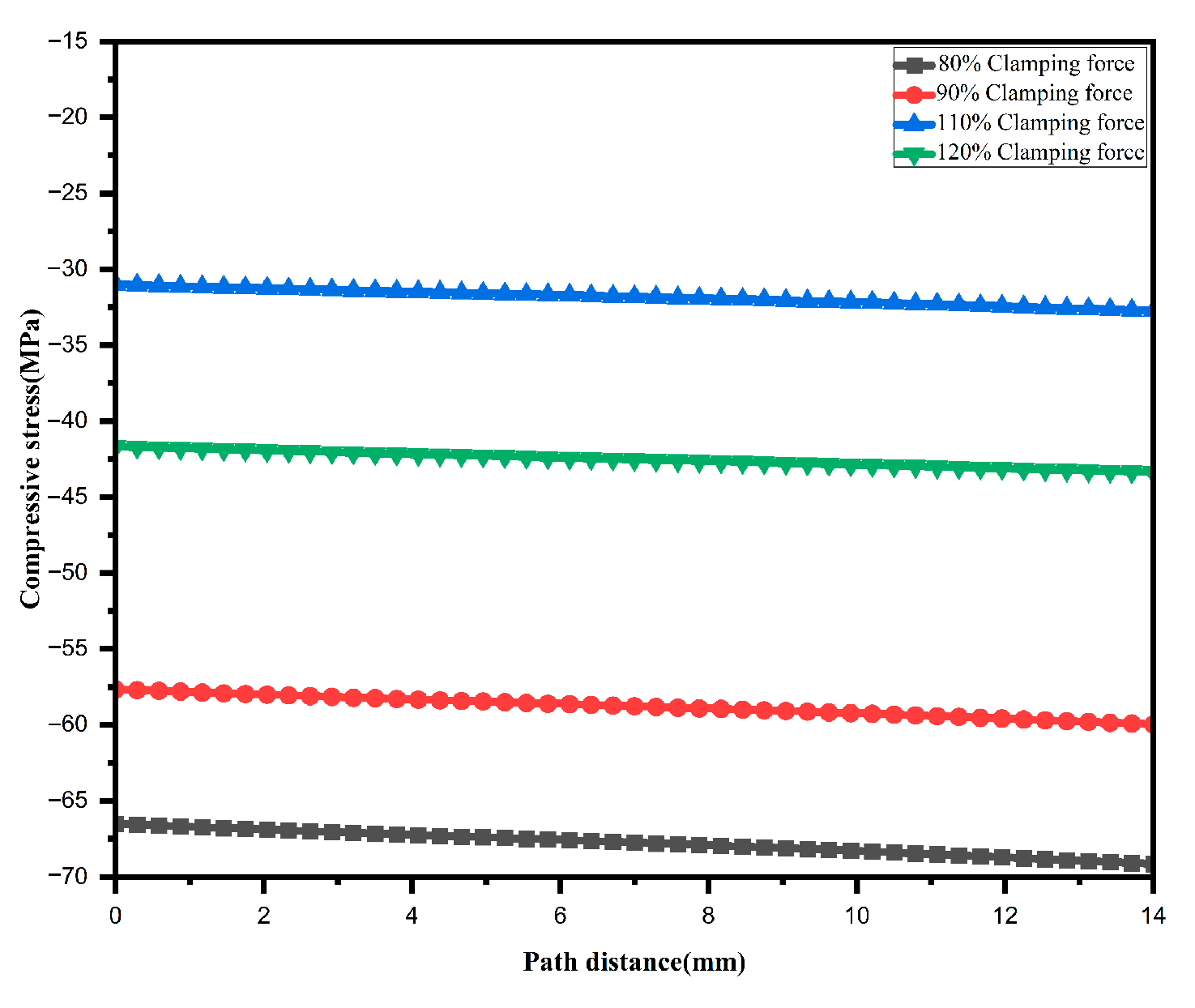

3.3. The Impact of Clamping Force on Sealing Performance

4. Sealing Analysis of Flange Connections Under Multiple Operating Conditions

4.1. Analysis of Operating Conditions

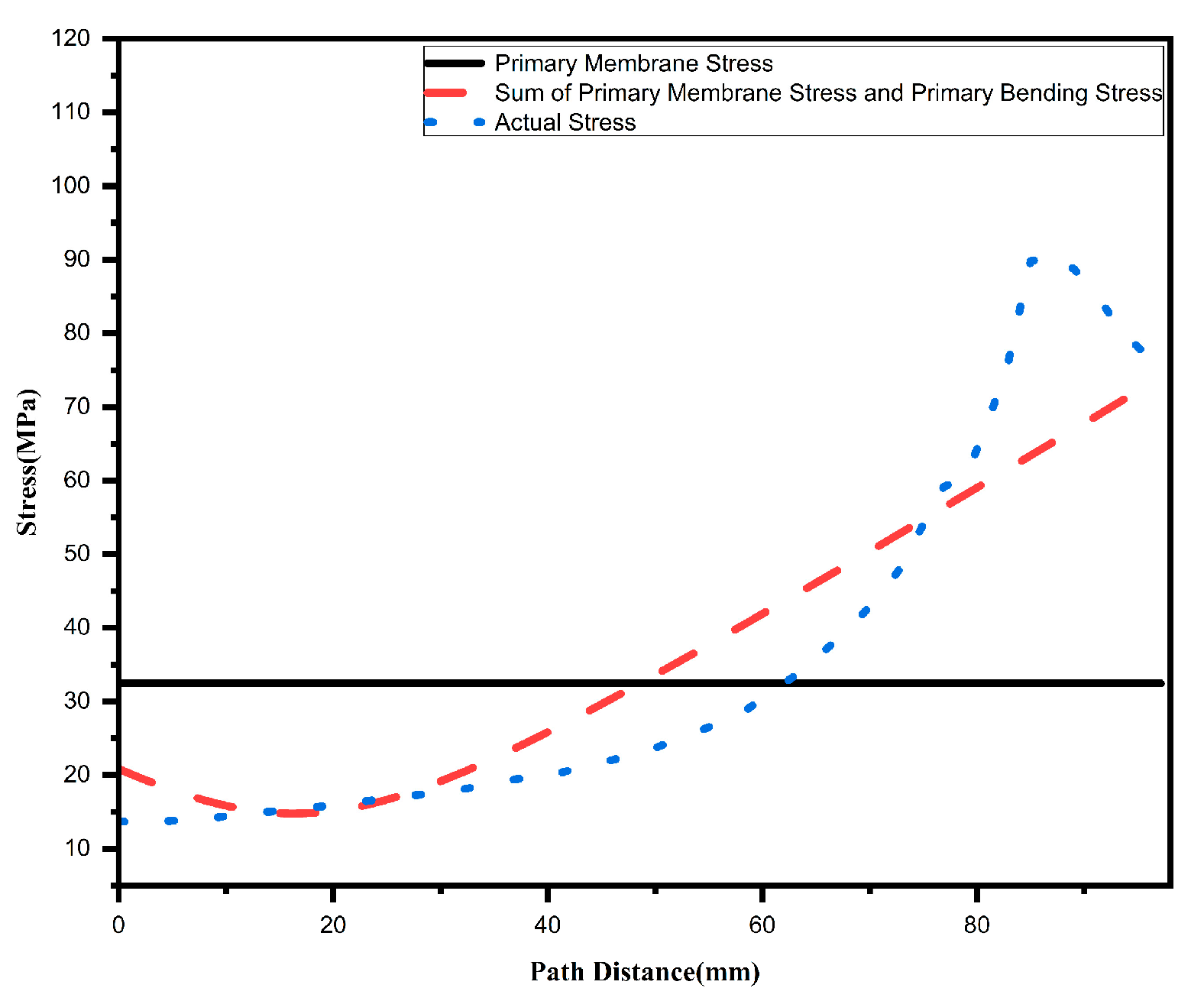

- (1)

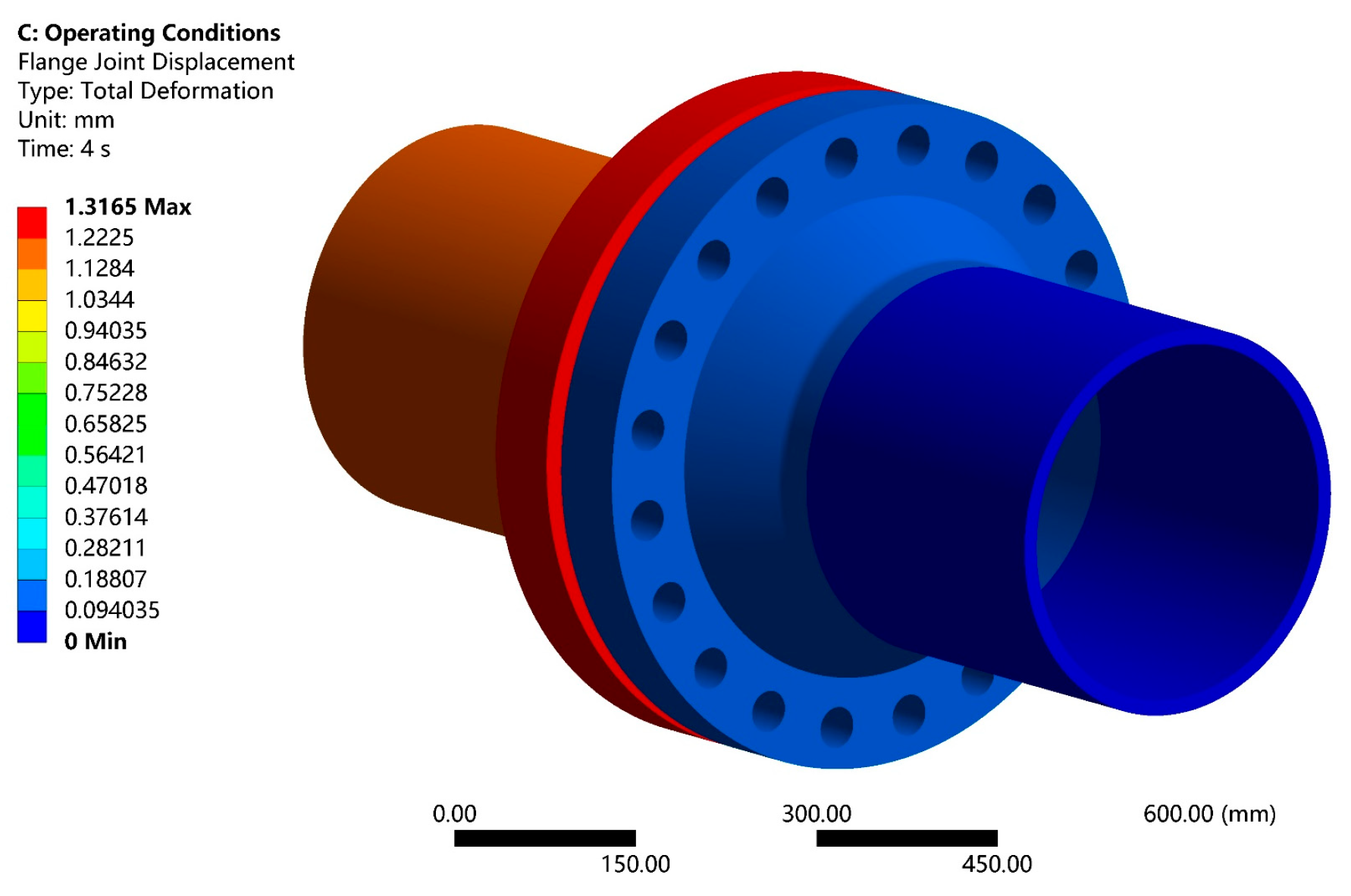

- Flange Stress Analysis and Strength Evaluation

- (2)

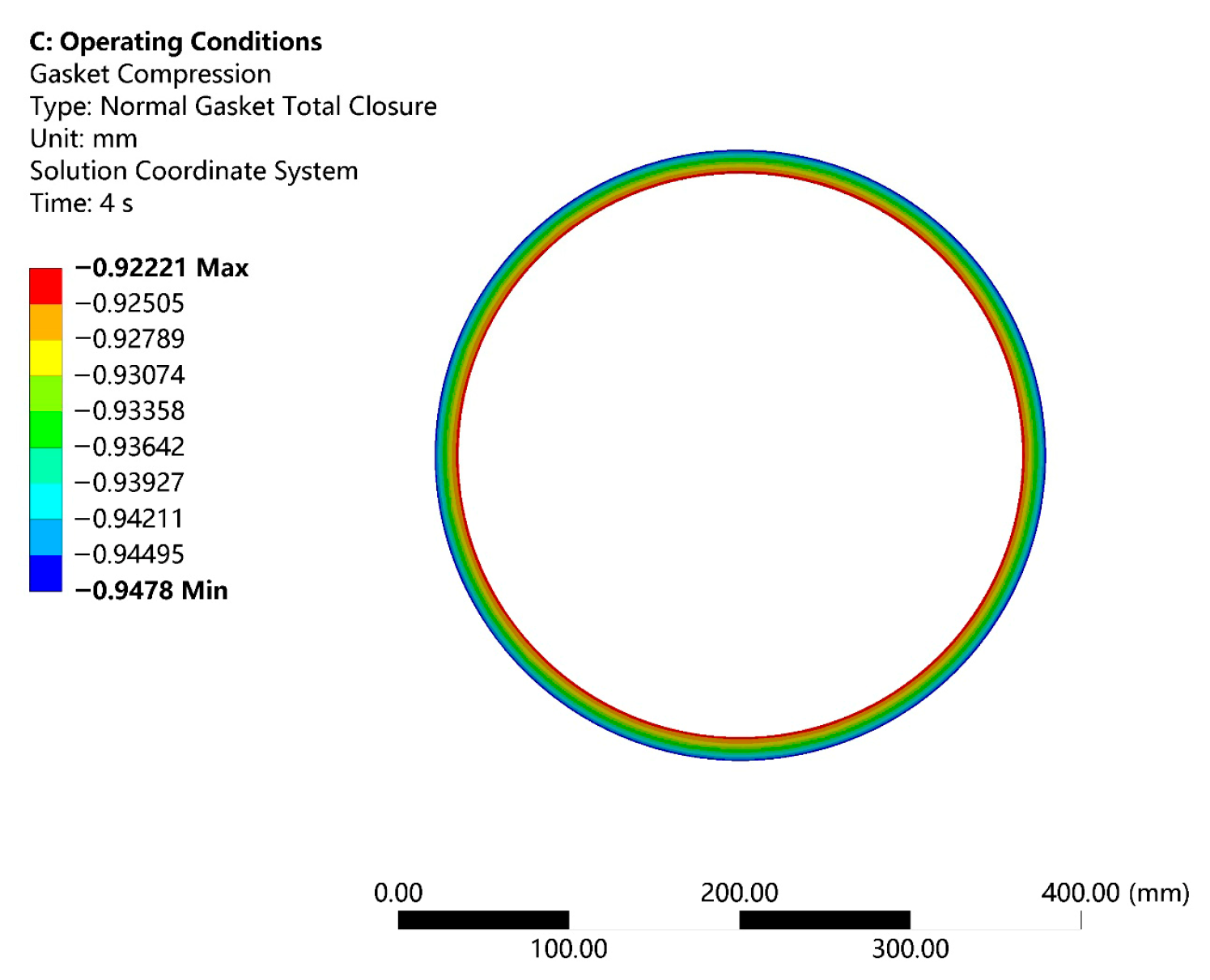

- Gasket Stress Analysis

- (3)

- Flange Displacement and Deflection Angle

4.2. Water Hammer Impact Condition Analysis

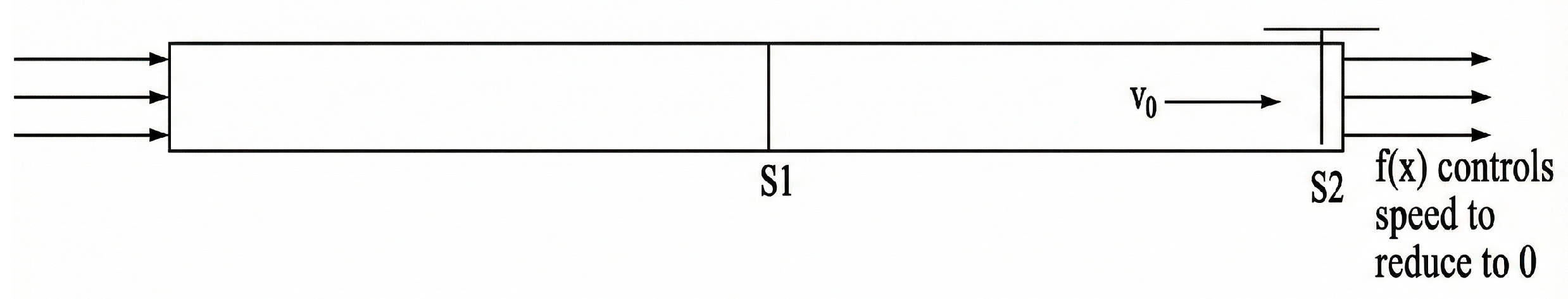

4.2.1. Numerical Model and Simulation Conditions

- (1)

- Governing Equations

- (2)

- Model Setup and Preprocessing

- (3)

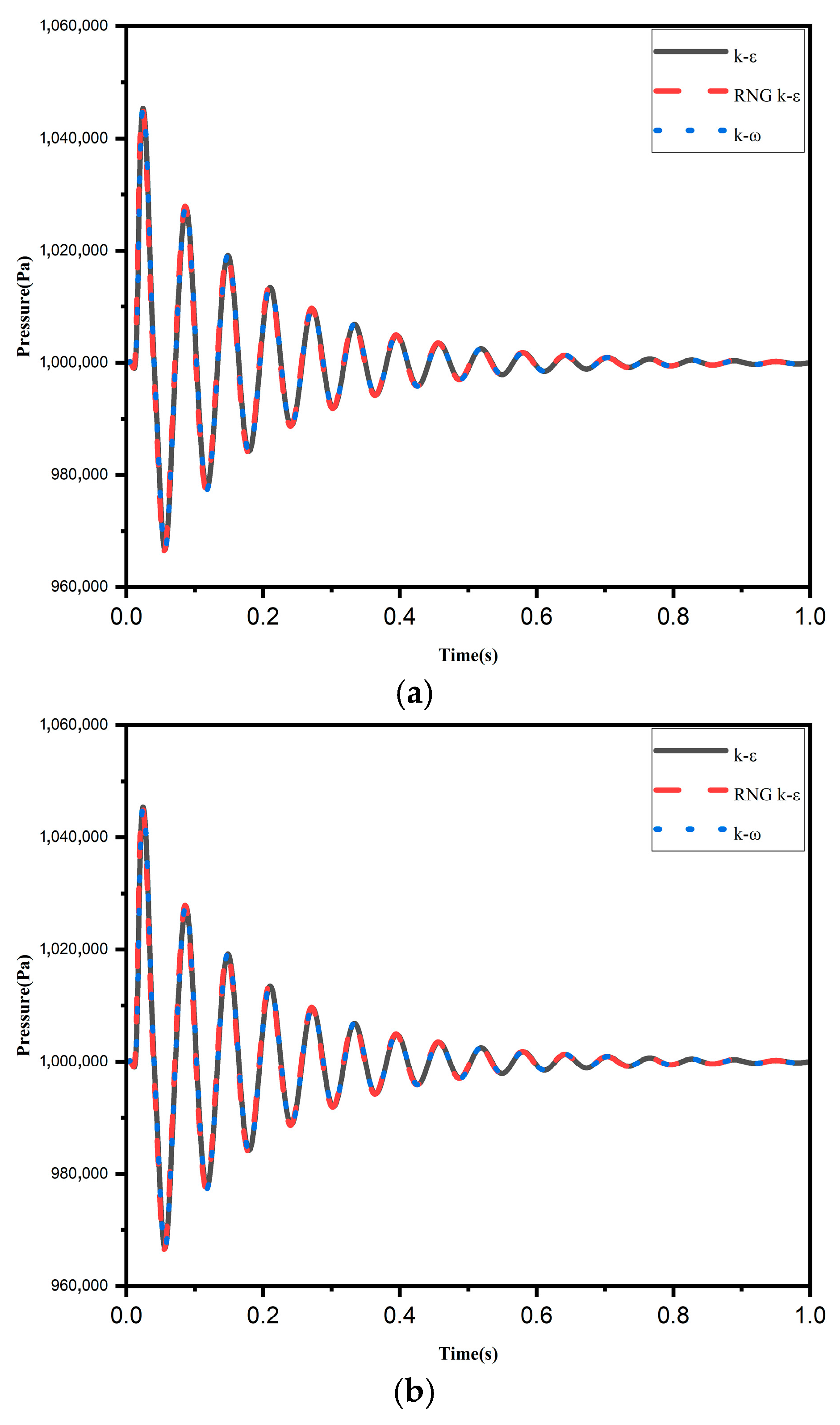

- Validation of Turbulence Models

4.2.2. Simulation Results and Sealing Performance Analysis

- (1)

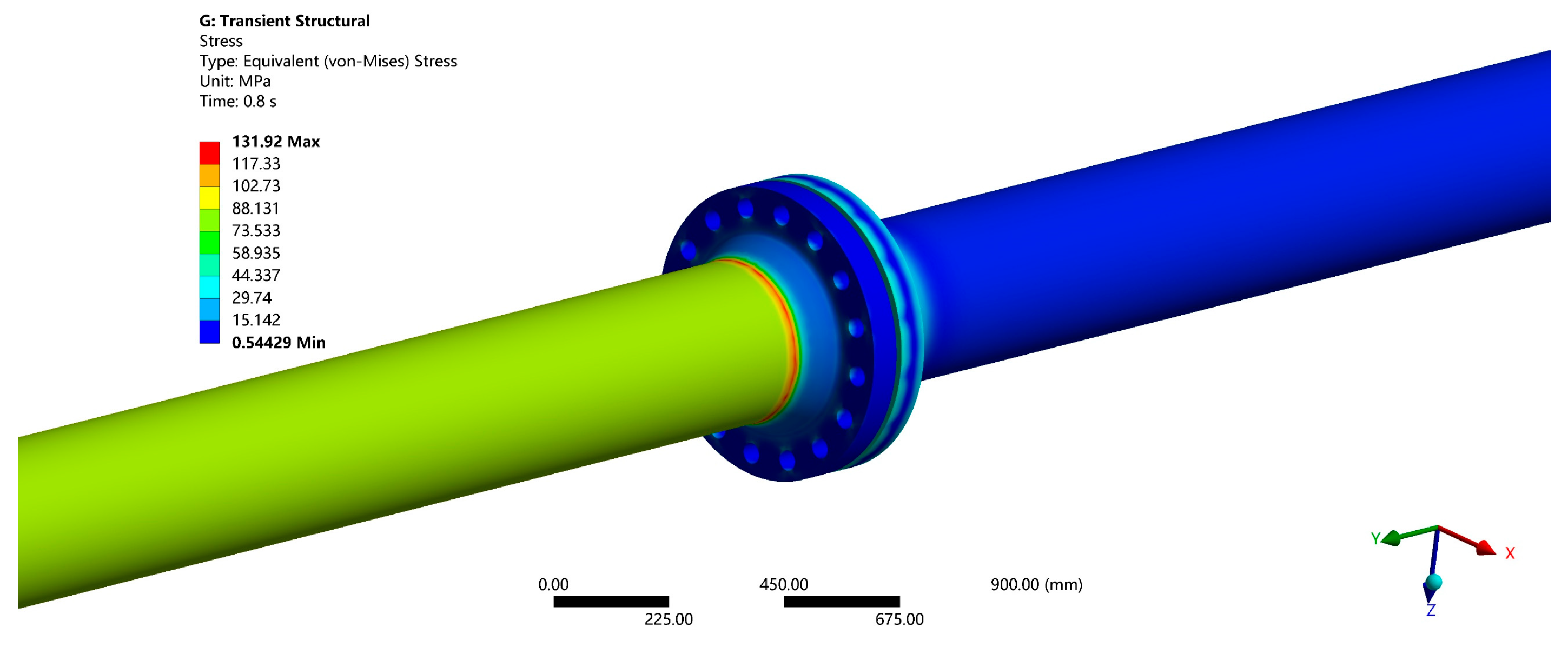

- Flange Stress and Strength Evaluation

- (2)

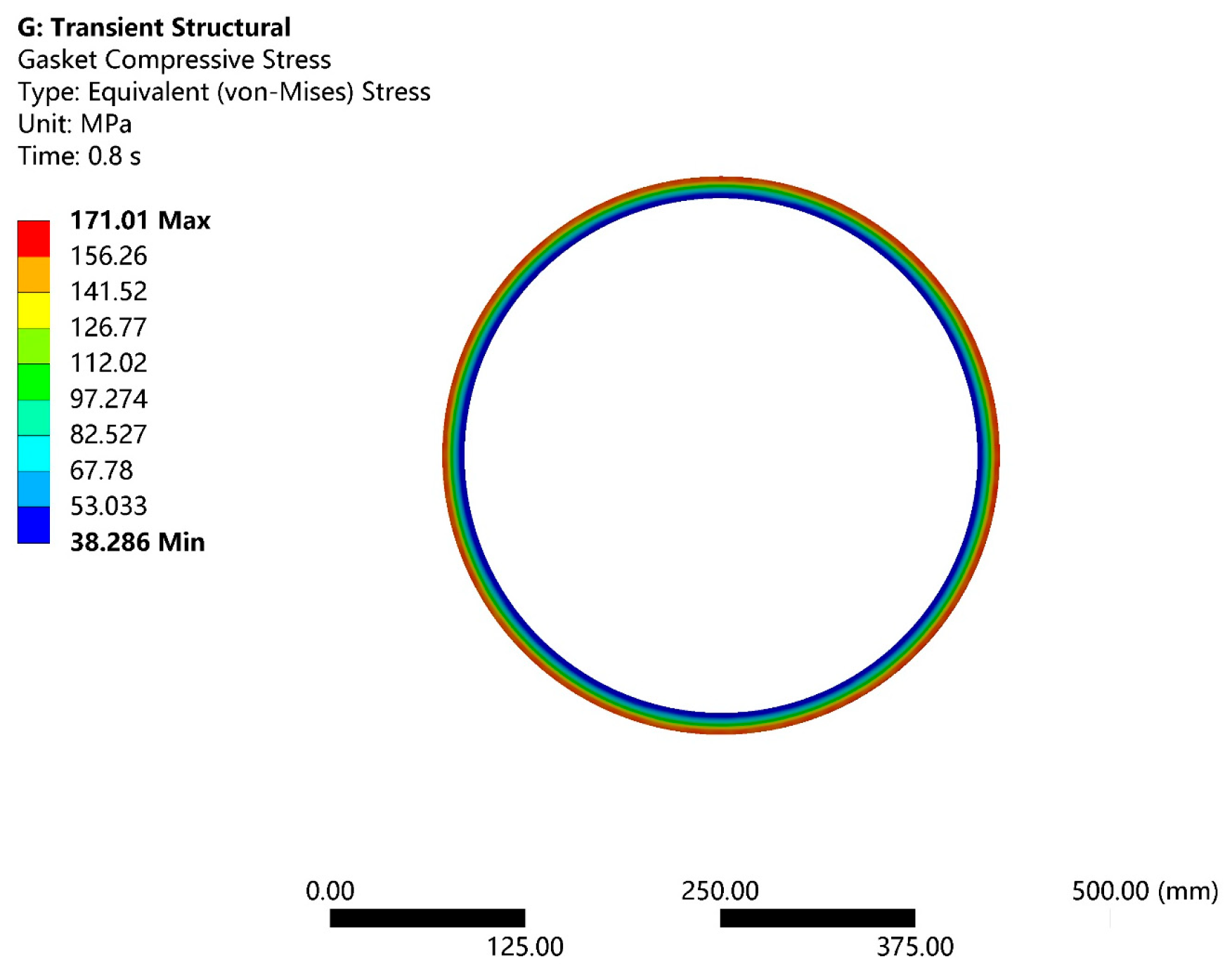

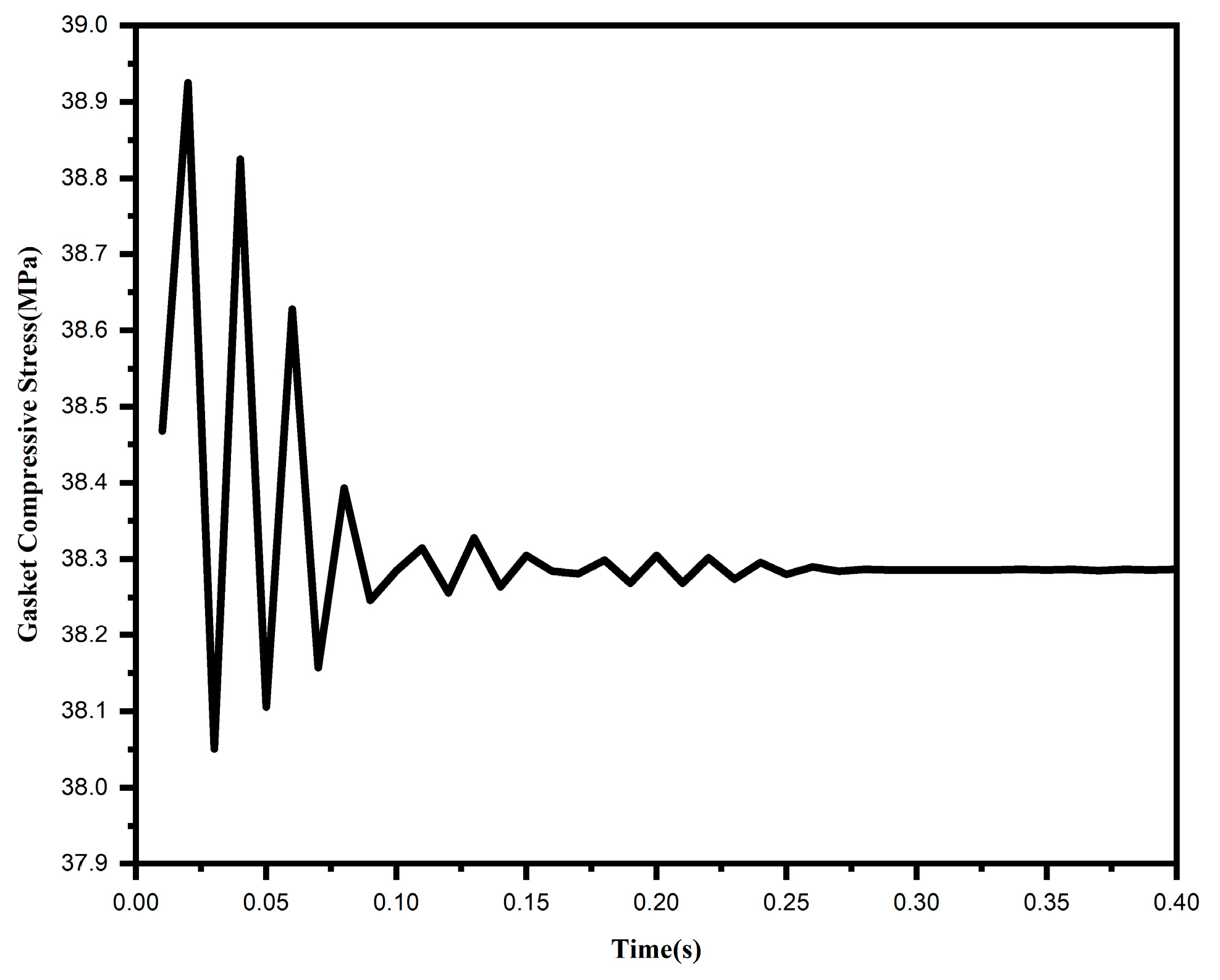

- Gasket Stress Analysis

5. Hydraulic Clamping Flange Connection Sealing Test

5.1. Introduction to the Test Bench

5.2. Test and Analysis

6. Conclusions

- (1)

- Simulation results demonstrate that both the clamping area and clamping force significantly influence sealing performance. When the clamping area is reduced below 80% of the design value, stress concentration causes the maximum stress in the flowmeter flange to rise to 136.73 MPa, leading to a marked degradation in sealing performance. Similarly, reducing the clamping force to 80% of the design value lowers the minimum compressive stress in the gasket to approximately 31 MPa, bringing the seal to the brink of failure. Although increasing the clamping force to 120% enhances sealing redundancy, it diminishes the strength margin of components such as the flange. Therefore, during operation and maintenance, it is recommended to maintain the clamping force within 90–110% of the design value while ensuring an effective clamping area of at least 80%. This approach optimally balances sealing reliability with structural strength and safety.

- (2)

- The instantaneous pressure fluctuations induced by water hammer result in periodic oscillations in both flange stress and gasket compressive stress, with the minimum gasket compressive stress decreasing to approximately 38 MPa. Although this does not cause immediate sealing failure, it exacerbates the “inner loose, outer tight” stress distribution pattern, substantially elevating the risk of gasket fatigue damage. To mitigate these effects, energy-dissipating devices can be installed at the pipeline terminus, or slow-closing valves can be employed to attenuate water hammer pressure peaks. Furthermore, regular monitoring of variations in gasket compressive stress is advised; if significant fluctuations are detected, the maintenance interval should be shortened to preempt potential fatigue-induced failure.

- (3)

- Experimental sealing tests confirm that the hydraulic clamping mechanism delivers stable and reliable sealing performance under a gas pressure of 10 MPa. These results validate that the hydraulic clamping force can effectively substitute for traditional bolt preload.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, Y.; Song, C.; Liu, Z.; Gu, J.; Liu, Y.; Jin, Z. Intelligent Quality Control Technology Practice in the Calibration Process of Natural Gas Flow Meters. Oil Gas Storage Transp. 2021, 40, 637–642. [Google Scholar] [CrossRef]

- Yang, H.; Xu, Y.; Liu, T.; Liu, T.; Huang, Z.; Xie, D. Research on ultra-clean micro gas flow calibration technology of passive piston type with sealing. Flow Meas. Instrum. 2024, 100, 102735. [Google Scholar] [CrossRef]

- Zhang, L.; Ding, X.; Wang, S.; Zhang, S.; Ding, J. Research Progress on the Dynamic Stability of Dry Gas Seals. Processes 2024, 12, 575. [Google Scholar] [CrossRef]

- Han, W.; Chen, X.; Zheng, C.; Han, J.; Hou, J. Preliminary Exploration of the Application of Intelligent Flow Meter Calibration System. Ind. Metrol. 2018, 28, 80–83. [Google Scholar] [CrossRef]

- Urse, G.; Olaru, N.; Urse, L. Some research results on the tightness and strength of flange joints. J. Eng. Sci. Innov. 2018, 3, 149–158. [Google Scholar] [CrossRef]

- Wang, H.; Lu, J.; Guan, K.; Wang, Z.W. Finite Element Analysis of Strength and Sealing for Flanges with Pipe Coupling. Press. Vessel. 2012, 29, 22–29. [Google Scholar] [CrossRef]

- Lei, J. A Brief Analysis of Sealing and Leakage in Pressure Pipeline Flanges. Petrochem. Technol. Econ. 2012, 28, 26–30. [Google Scholar] [CrossRef]

- Bouzid, A.-H.; Nechache, A. An Analytical Solution for Evaluating Gasket Stress Change in Bolted Flange Connections Subjected to High Temperature Loading. Asme J. Press. Vessel Technol. 2005, 127, 414–422. [Google Scholar] [CrossRef]

- Bouzid, A.-H.; Nechache, A. Thermally Induced Deflections in Bolted FlangedConnections. J. Press. Vessel Technol. 2005, 127, 394–401. [Google Scholar] [CrossRef]

- Liu, L.; Gu, B.; Li, C. The Influence of Maximum Stress at the Outer Edge of Gasket on the Leakage Rate of Bolt-Flange Connection Structure. Mech. Des. Manuf. 2012, 5, 196–198. [Google Scholar] [CrossRef]

- Larson, R.A.; Bibel, G. Experimental and analytical evaluation of buckling forces of a spiral wound flexible gasket. In Proceedings of the ASME 2005 Pressure Vessels and Piping Conference, Denver, CO, USA, 17–21 July 2005; Computer Technology; Volume 2, pp. 97–104. [Google Scholar]

- Nash, D.H.; Abid, M. Combined external load tests forstandard and compact flanges. Int. J. Press. Vessel. Pip. 2000, 77, 799–806. [Google Scholar] [CrossRef]

- Wu, P. Study on the Sealing Performance of Bolt-Flange Joints Under Dynamic Loading; East China University of Science and Technology: Shanghai, China, 2016. [Google Scholar] [CrossRef]

- Bortz, M.; Wink, R. Leakage Analysis of a High Pressure Flange Connection Under Bending Moments: An Analytic Procedure. In Proceedings of the Asme Pressure Vessels & Piping Conference, Anaheim, CA, USA, 20–24 July 2014. [Google Scholar] [CrossRef]

- Zhang, Z. Study on the Micromotion Wear Characteristics and Tightness Evaluation of Flange Sealing Connections in Gas Stations; China University of Petroleum: Beijing, China, 2022. [Google Scholar]

- Li, Y.; Zhong, X.; Chen, Y.; Chen, H.; Liu, J.; Qiu, T.; Yang, Y.; Cheng, L. The Effect of Pressure Fluctuations in Gas Stations on the Sealing Performance of Bolt-Flange Connection Systems. Lubr. Eng. 2023, 48, 118–124. [Google Scholar]

- Krishna, M.M.; Shunmugam, M.; Prasad, S.N. A study on the sealing performance of bolted flange joints with gaskets using finite element analysis. Int. J. Press. Vessel. Pip. 2007, 84, 349–357. [Google Scholar] [CrossRef]

- Wang, W.; Li, C.; Zhao, W. Analysis of the Tightness of Flange Joints Based on Workbench. New Technol. New Process. 2023, 7, 52–55. [Google Scholar] [CrossRef]

- Zhang, Q. Numerical Simulation and Experimental Study on the Sealing Performance of Flanged Connections in Pressure Pipelines; Wuhan University of Engineering: Wuhan, China, 2024. [Google Scholar]

- Cavalheiro, F.N.; Cabaleiro, M.; Conde, B.; Bouzas, Ó. Clamp-based steel connections for structural reusability: Experimental and finite element analysis in the elastic range. Structures 2025, 75, 108767. [Google Scholar] [CrossRef]

- GB/T 4622.1~2-2022; Spiral Wound Gaskets for Pipe Flanges. Standards Press of China: Beijing, China, 2022.

- GB 150.1~150.4-2011; Pressure Vessels. Standards Press of China: Beijing, China, 2011.

- GB/T 150.3-2011; Pressure Vessels—Part 3: Design. AQSIQ: Beijing, China; SAC: Beijing, China, 2011.

- API Specification 6A; Specification for Wellhead and Tree Equipment. American Petroleum Institute: Washington, DC, USA, 2018.

- Wang, L.; Xue, J. Numerical Simulation Analysis of the Gasket Stress Field in the Flange Joint Pre-tightening Process. Pipeline Technol. Equip. 2018, 6, 52–56. [Google Scholar] [CrossRef]

- Li, F.; Zhang, L.B.; Dong, S.H.; Wu, W. Numerical Analysis and Research on Sealing Performance of Flange Connection System in Gas Station. In Proceedings of the ASME 2023 Pressure Vessels and Piping Conference (PVP2023), Atlanta, Georgia, 16–21 July 2023; ASME: New York, NY, USA, 2023; Volume 2. [Google Scholar]

- Li, Y. Study on the Compression and Resilience Performance of Metal Wound Gaskets in Bolt-Flange Connection Systems; Lanzhou University of Technology: Lanzhou, China, 2018. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhan, J.; Liao, Y.; Ding, W.; Tan, S.; Liu, Y. Experimental and numerical studies on hybrid bolted connection of steel box girders: Bending mechanism. Eng. Struct. 2024, 321, 118986. [Google Scholar] [CrossRef]

- Lu, L. Study on the Performance of Metal Wound Gaskets Based on Leakage Rate; Zhejiang University of Technology: Zhejiang, China, 2016. [Google Scholar]

- Han, J. Study on the Seal Failure and Protection of Bolt-Flange Joints in Mobile Tanker Trucks; China University of Mining and Technology: Xuzhou, China, 2017. [Google Scholar]

- ASME Boiler and Pressure Vessel Code Section VIII, Division 1: Rules for Construction of Pressure Vessels; American Society of Mechanical Engineers: New York, NY, USA, 2023.

- Li, Y. Finite Element Simulation of the Influence of Complex Variable Operating Conditions on Flanged Connection Strength and Sealing; East China University of Science and Technology: Shanghai, China, 2020. [Google Scholar] [CrossRef]

- Ahmadi, N. Revolutionizing heat exchanger design: Helical groove turbulators for superior thermal-hydraulic and exergy performance. Results Eng. 2025, 28, 107207. [Google Scholar] [CrossRef]

- Lin, J. Study on the Nonlinear Vibration Characteristics of Hydraulic Pipe-Clamp Systems in Aircraft Engines; Northeastern University: Boston, MA, USA, 2018. [Google Scholar] [CrossRef]

- GB 50028-2006; Code for Design of City Gas Engineering. China Architecture & Building Press: Beijing, China, 2006.

- Wang, G.; Huo, Y.; Zhang, B.; Li, X.; Yu, Z. Application and Evaluation of Turbulence Models in the Performance Prediction of Axial Flow Pumps. J. Beijing Inst. Technol. 2009, 29, 309–313. [Google Scholar] [CrossRef]

- Zhang, D.; Wu, S.; Shi, W.; Pan, D.; Yao, J.; Zhang, J. Application and Experiment of Different Turbulence Models for Simulating Tip Leakage Vortex in Axial Flow Pump. Trans. Chin. Soc. Agric. Eng. 2013, 29, 46–53. [Google Scholar] [CrossRef]

- Wang, Z. Study on the Influence of Turbulence Models on the Simulation Results of Internal Flow Performance in Impeller Machinery; Tianjin University: Tianjin, China, 2009. [Google Scholar]

- He, B.; Jiao, B.; Wan, Q.; Nie, R.; Yang, J. Strength and tightness evaluation method for pipe flange connections considering thermal effects. J. Loss Prev. Process Ind. 2023, 83, 105053. [Google Scholar] [CrossRef]

| Component Name | Material | Elastic Modulus (GPA) | Poisson’s Ratio () | Density (kg/m3) | Yield Strength (MPA) | Tangential Modulus (MPA) | Allowable Stress (MPA) |

|---|---|---|---|---|---|---|---|

| Gas Pipeline | 16MnR | 211 | 0.3 | 7.87 × 103 | 450 | 150 | 170 |

| Flowmeter | 16MnR | 211 | 0.3 | 7.87 × 103 | 450 | 150 | 170 |

| Graphite Metal Spiral Wound Gasket | Flexible Graphite | 186 | 0.3 | 1.20 × 103 | — | — | — |

| Part | Mesh Generation Method | Mesh Size (mm) | Mesh Type |

|---|---|---|---|

| Flowmeter, Gas Pipeline | Patch Conforming Method | 10 mm | Tetrahedral |

| Graphite Wound Gasket | Sweeping Method | 1.5 mm | Hexahedral |

| Contact Body 1 | Contact Body 2 | Contact Type | Friction Coefficient |

|---|---|---|---|

| Gasket | Flowmeter | Frictional | 0.2 |

| Gasket | Gas Pipeline | Frictional | 0.2 |

| Evaluation Metric | Gas Pipeline Flange (°) | Flowmeter Flange (°) | Allowable Value (°) | Evaluation Result |

|---|---|---|---|---|

| Flange Rotation Angle | 0.082° | 0.0104° | 1° | Satisfied |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Liu, X.; Bu, Q.; Luan, S.; Cao, X.; Zhang, Y.; Mu, C.; Lin, J.; Shi, Y. Analysis of Sealing Characteristics of Hydraulic Clamping Flange Connection Mechanism. Processes 2026, 14, 72. https://doi.org/10.3390/pr14010072

Liu X, Bu Q, Luan S, Cao X, Zhang Y, Mu C, Lin J, Shi Y. Analysis of Sealing Characteristics of Hydraulic Clamping Flange Connection Mechanism. Processes. 2026; 14(1):72. https://doi.org/10.3390/pr14010072

Chicago/Turabian StyleLiu, Xiaofeng, Qingchao Bu, Sitong Luan, Xuelian Cao, Yu Zhang, Chaoyi Mu, Junzhe Lin, and Yafei Shi. 2026. "Analysis of Sealing Characteristics of Hydraulic Clamping Flange Connection Mechanism" Processes 14, no. 1: 72. https://doi.org/10.3390/pr14010072

APA StyleLiu, X., Bu, Q., Luan, S., Cao, X., Zhang, Y., Mu, C., Lin, J., & Shi, Y. (2026). Analysis of Sealing Characteristics of Hydraulic Clamping Flange Connection Mechanism. Processes, 14(1), 72. https://doi.org/10.3390/pr14010072