Optimization Analysis of Structural Parameters of Special Metal Sealing for 175 MPa Tube Hanger

Abstract

1. Introduction

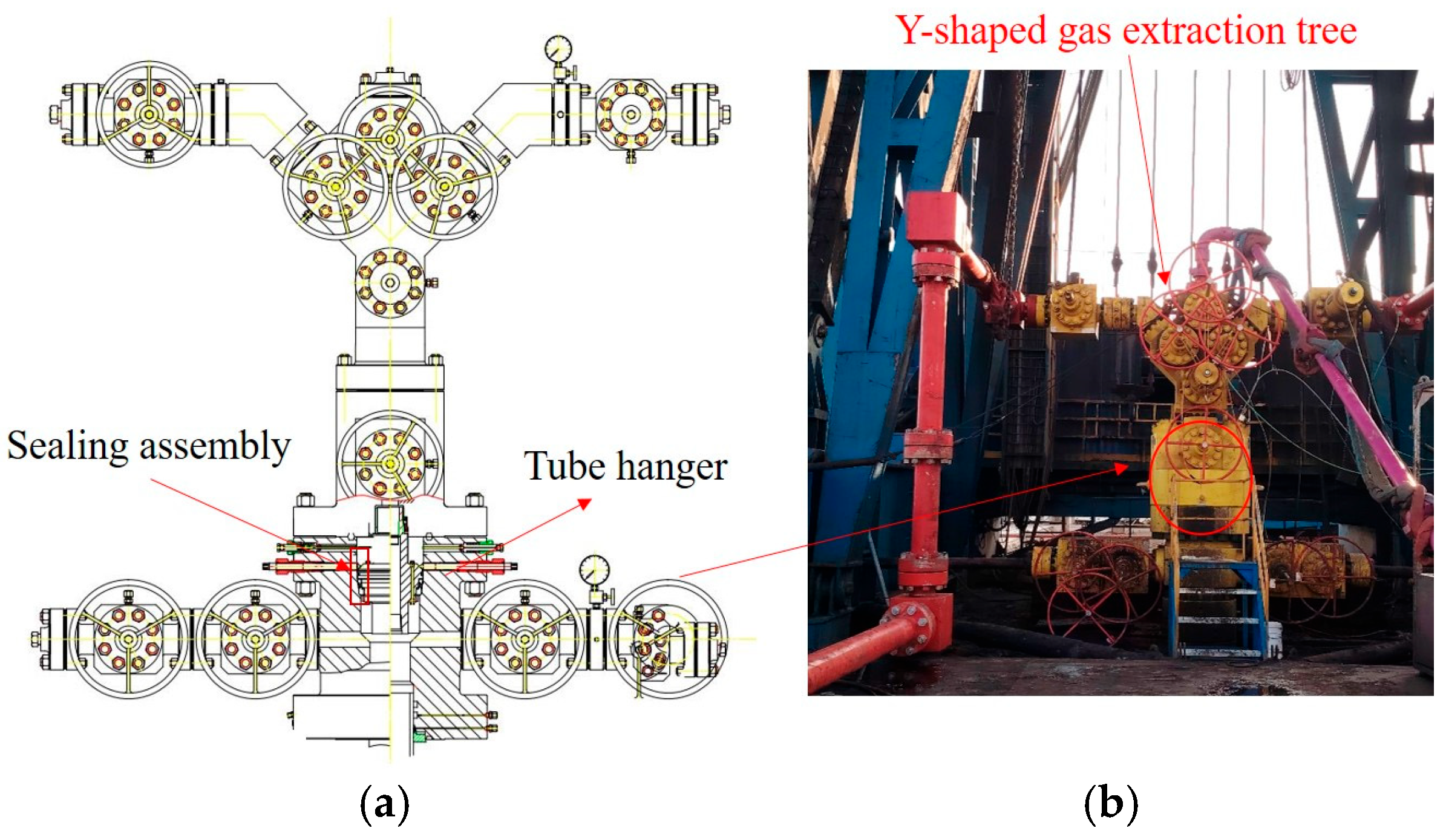

2. Structure and Failure Cases of Mandrel-Type Tube Hanger

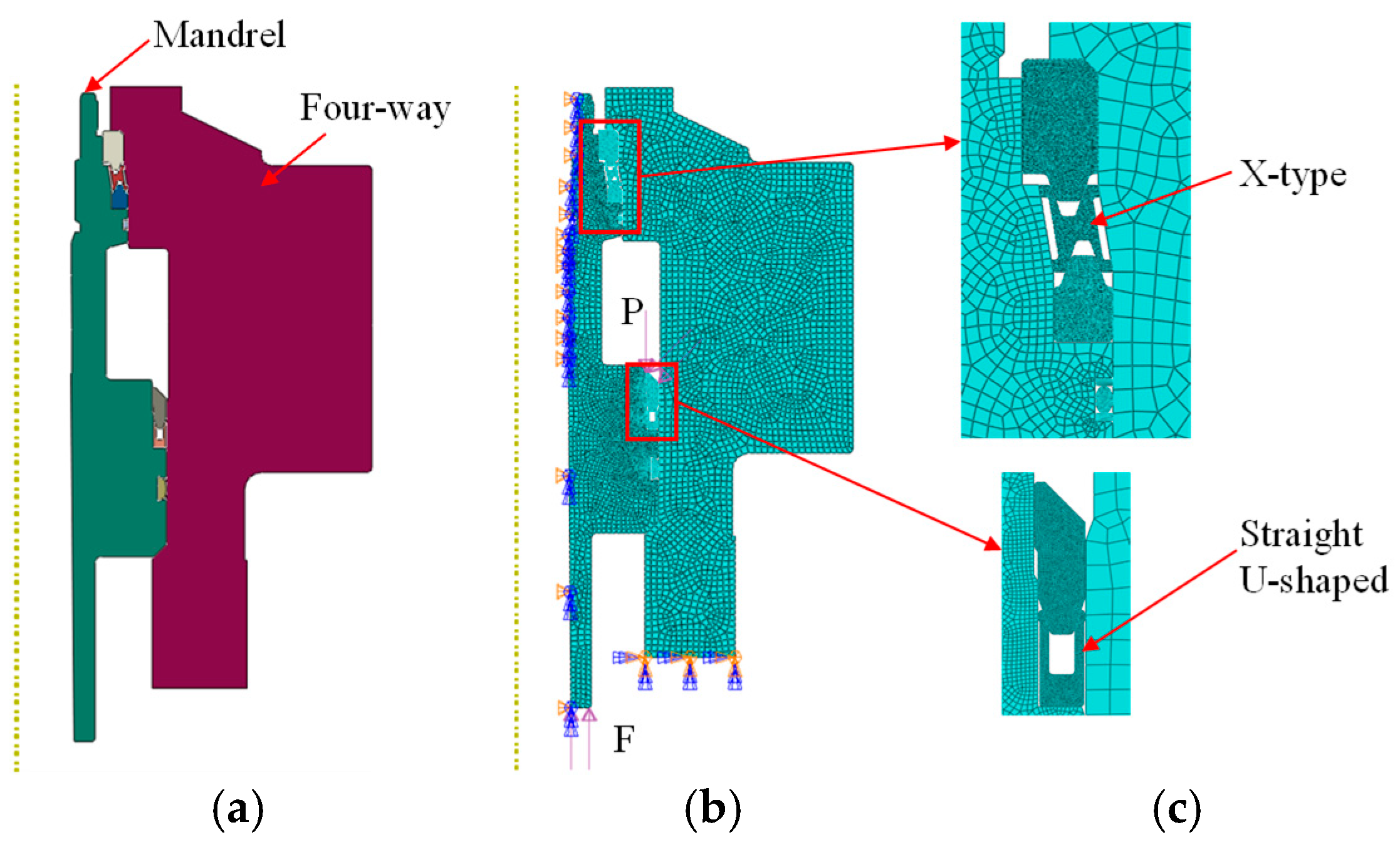

3. Research on the Performance of Special-Shaped Metal Sealing

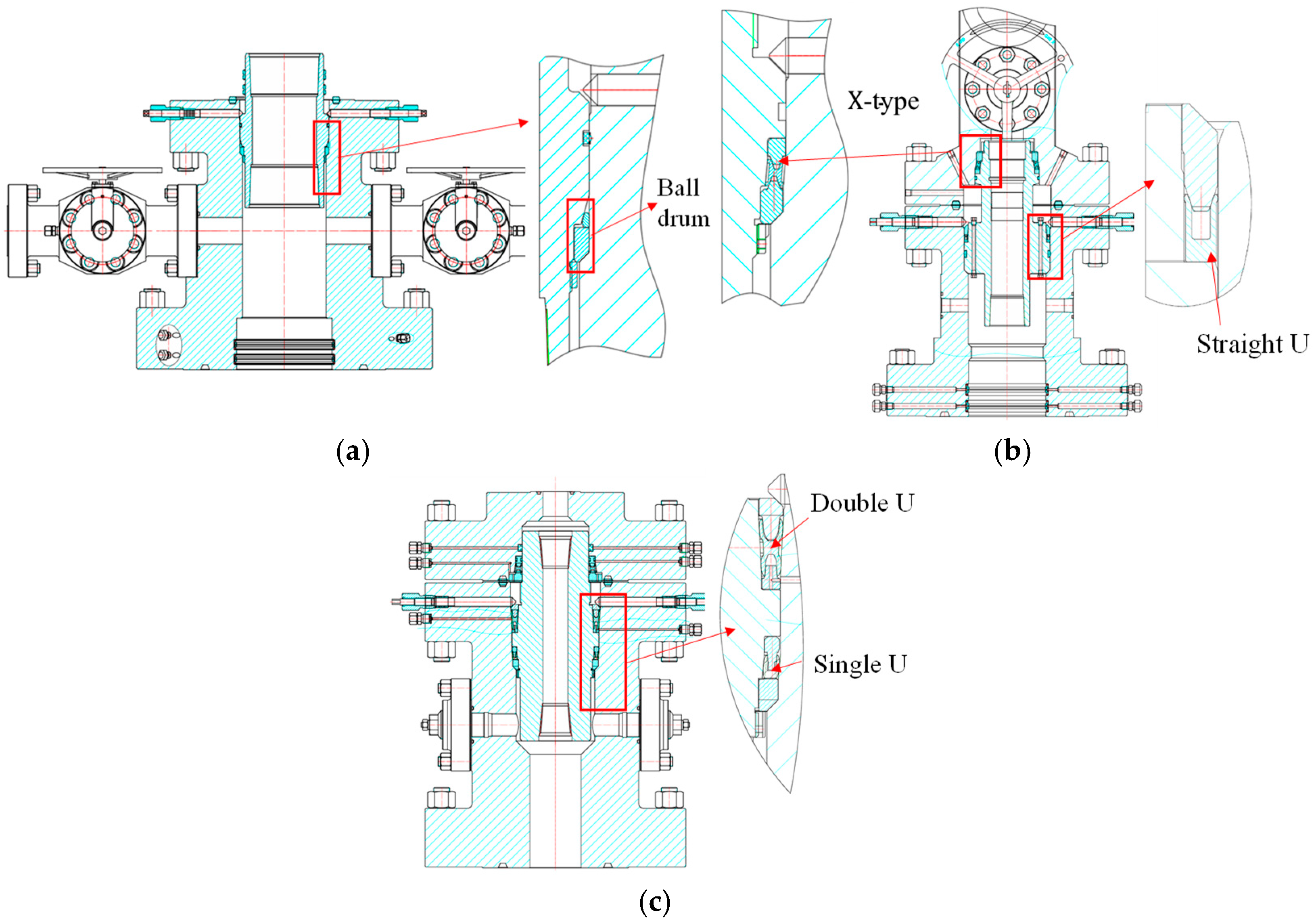

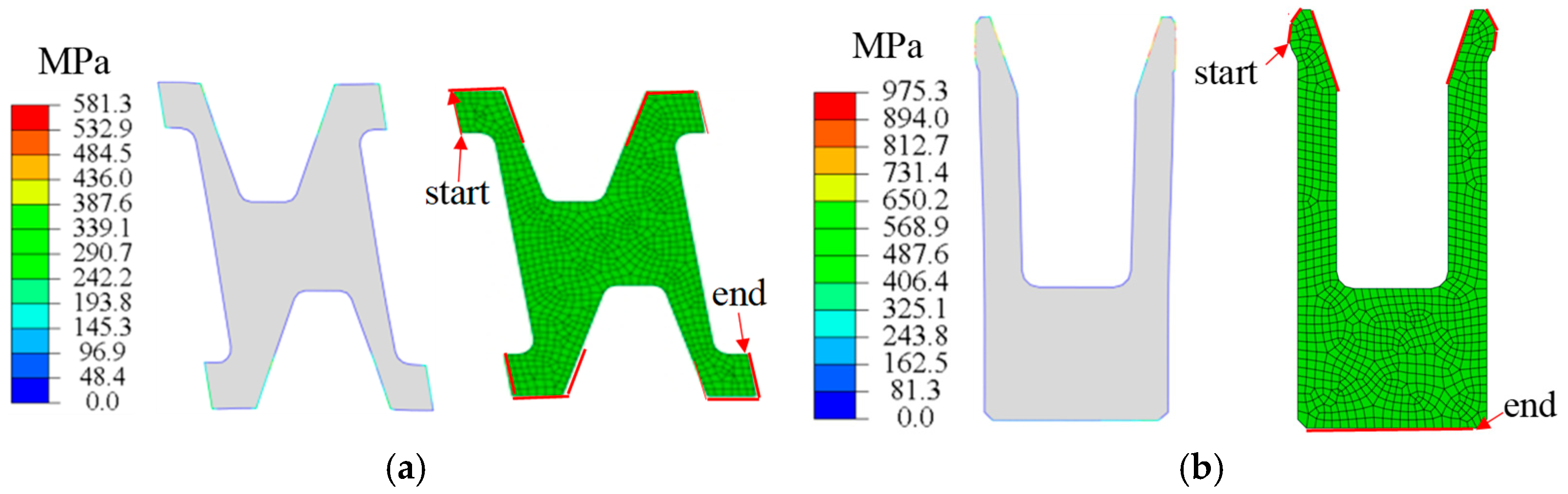

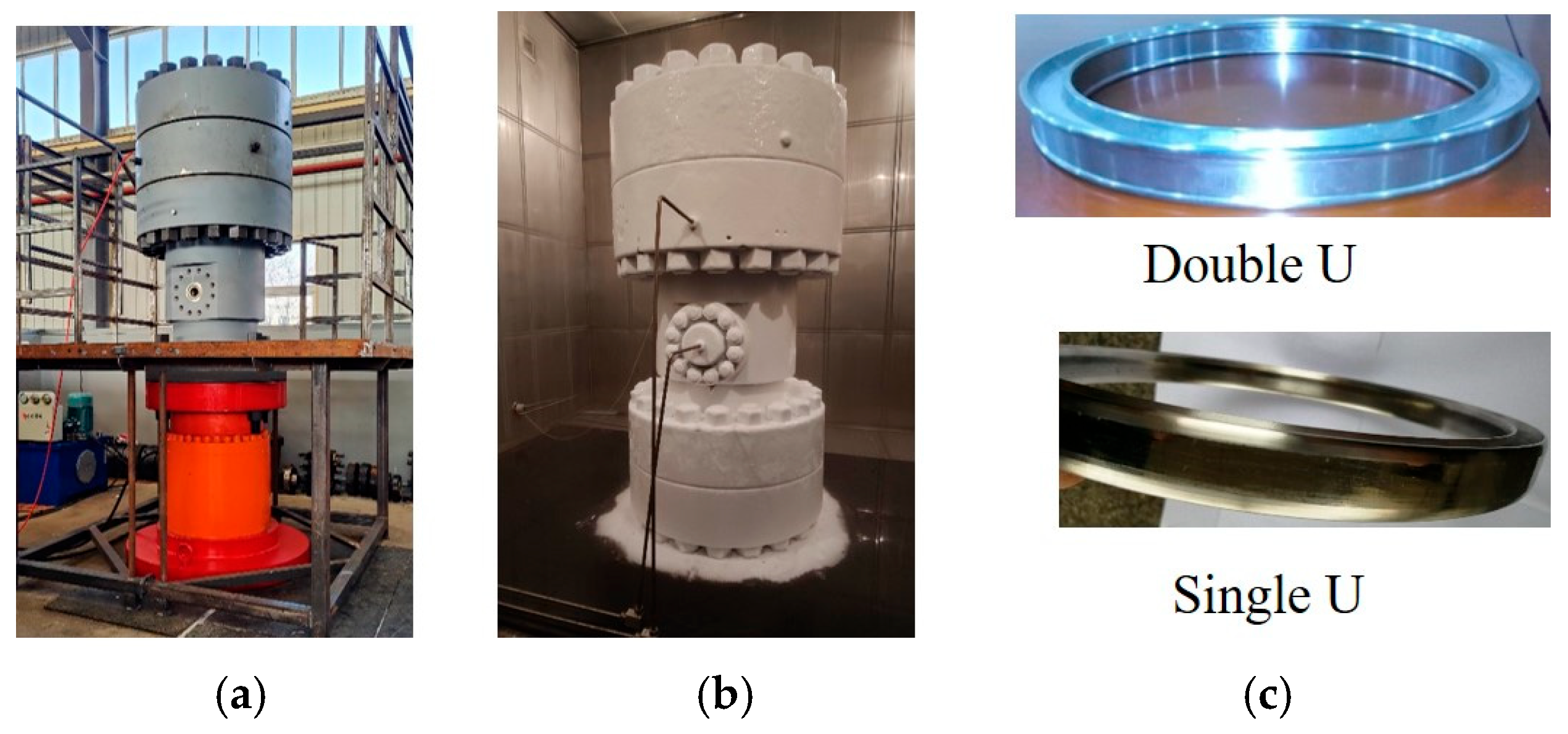

3.1. Analysis of the Ball-Drum Seal Structure

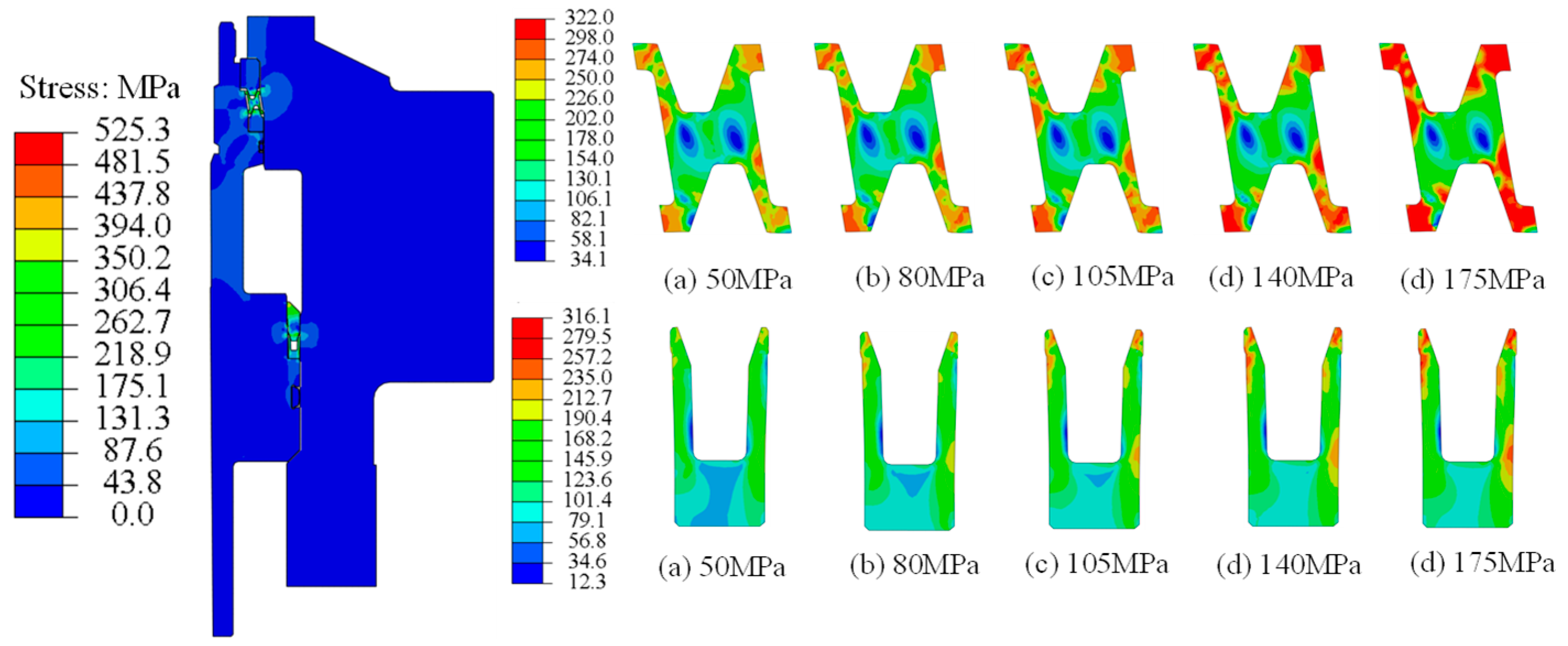

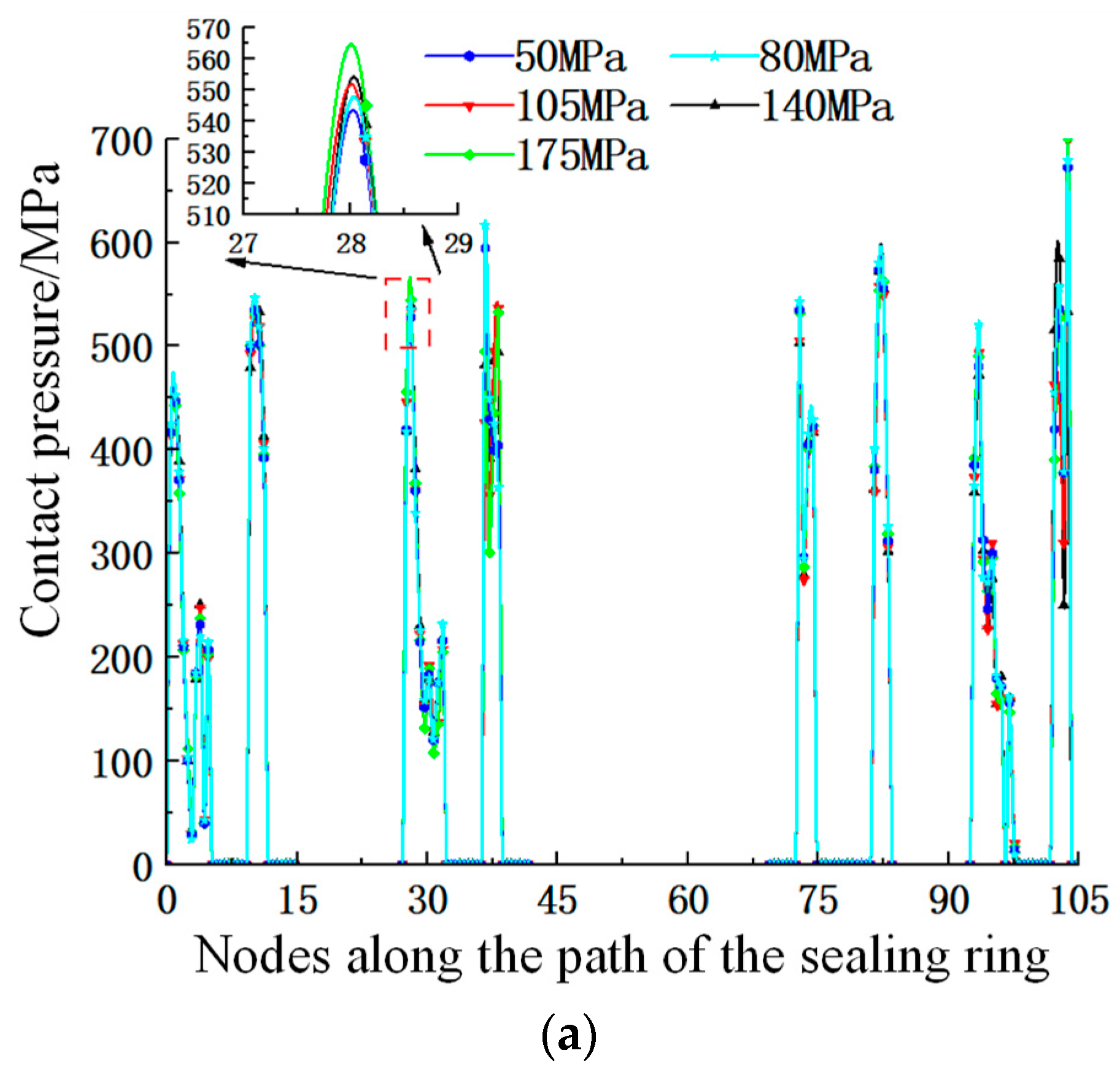

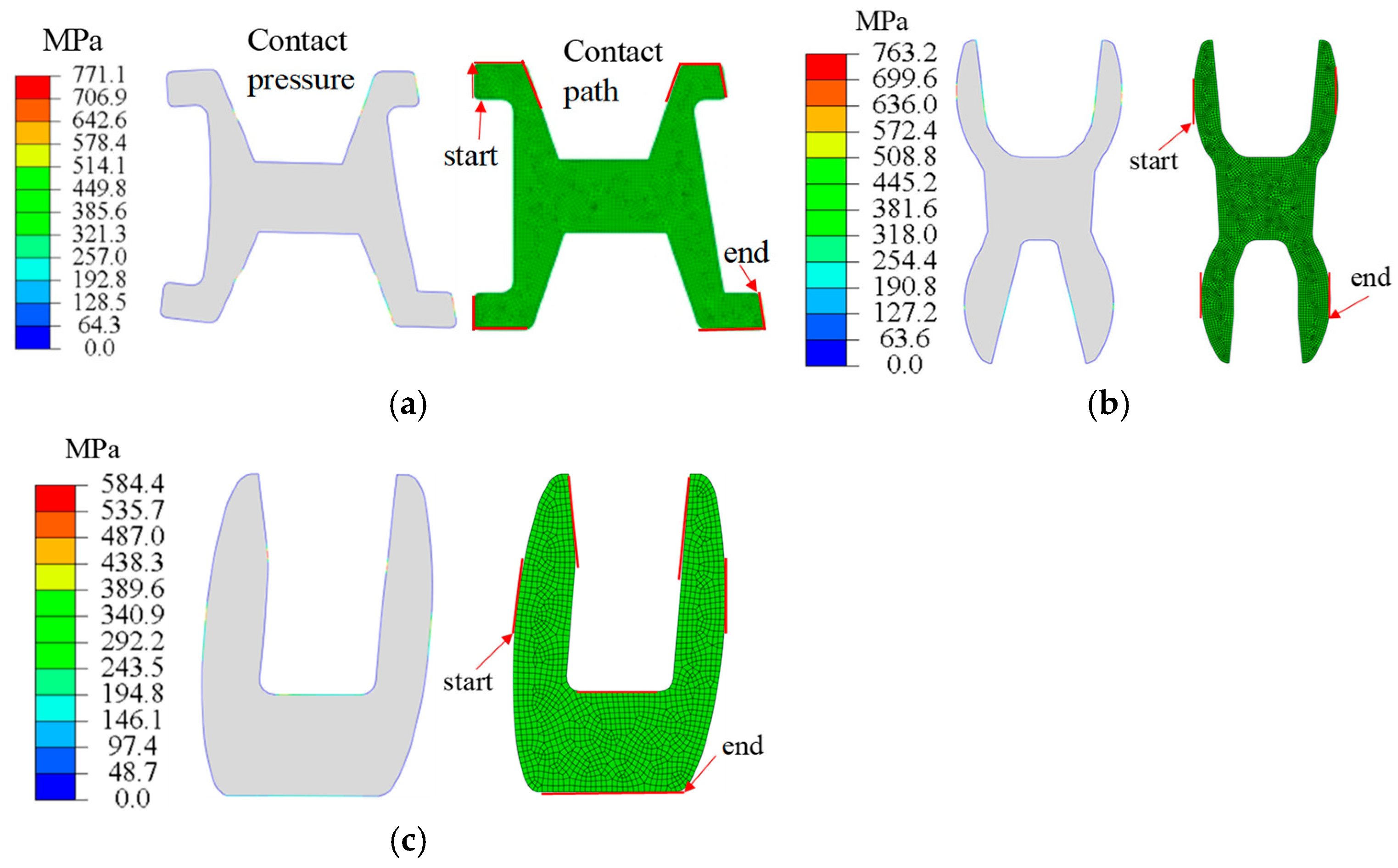

3.2. Analysis of Straight U-Shaped and X-Shaped Metal Seals

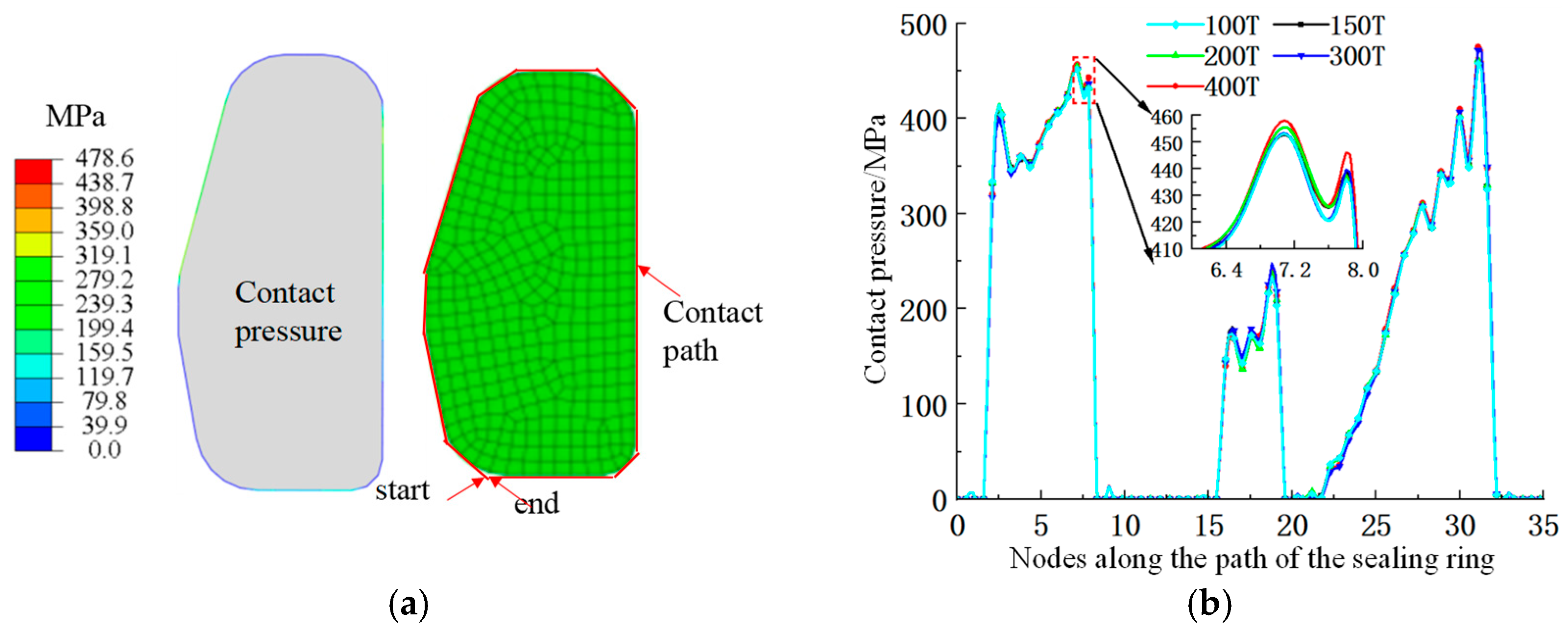

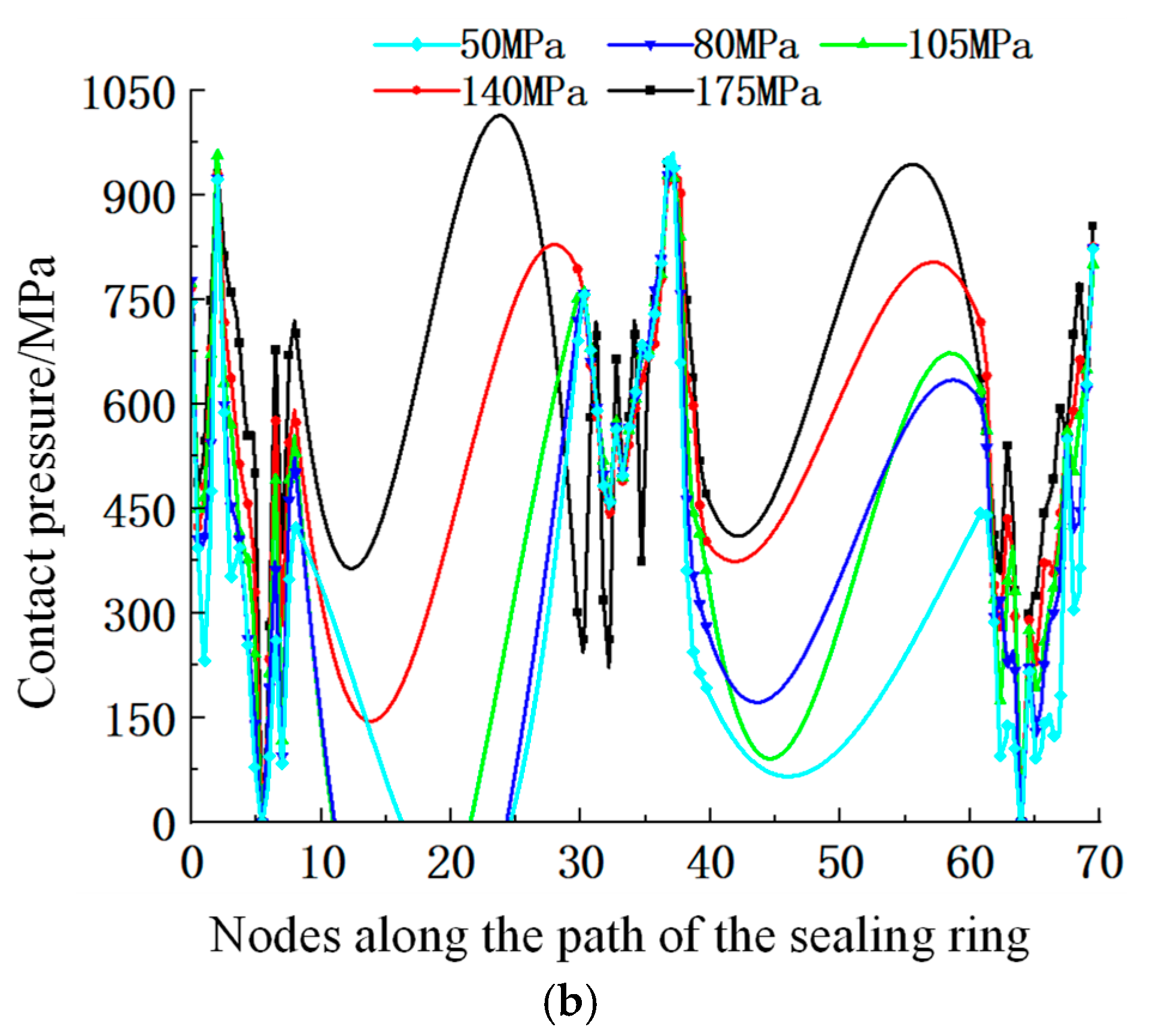

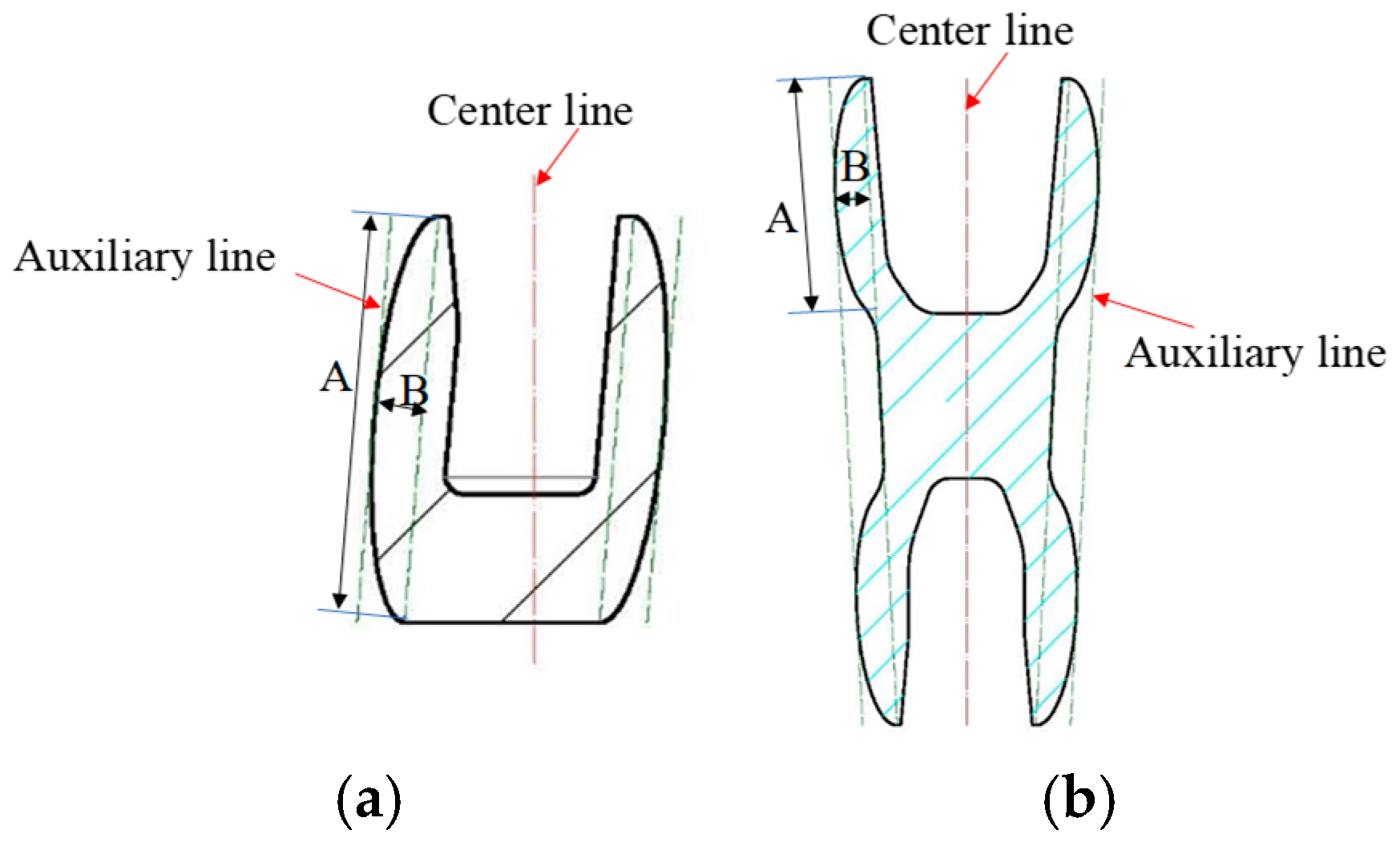

3.3. Analysis of Elliptical U-Shaped Metal Seal

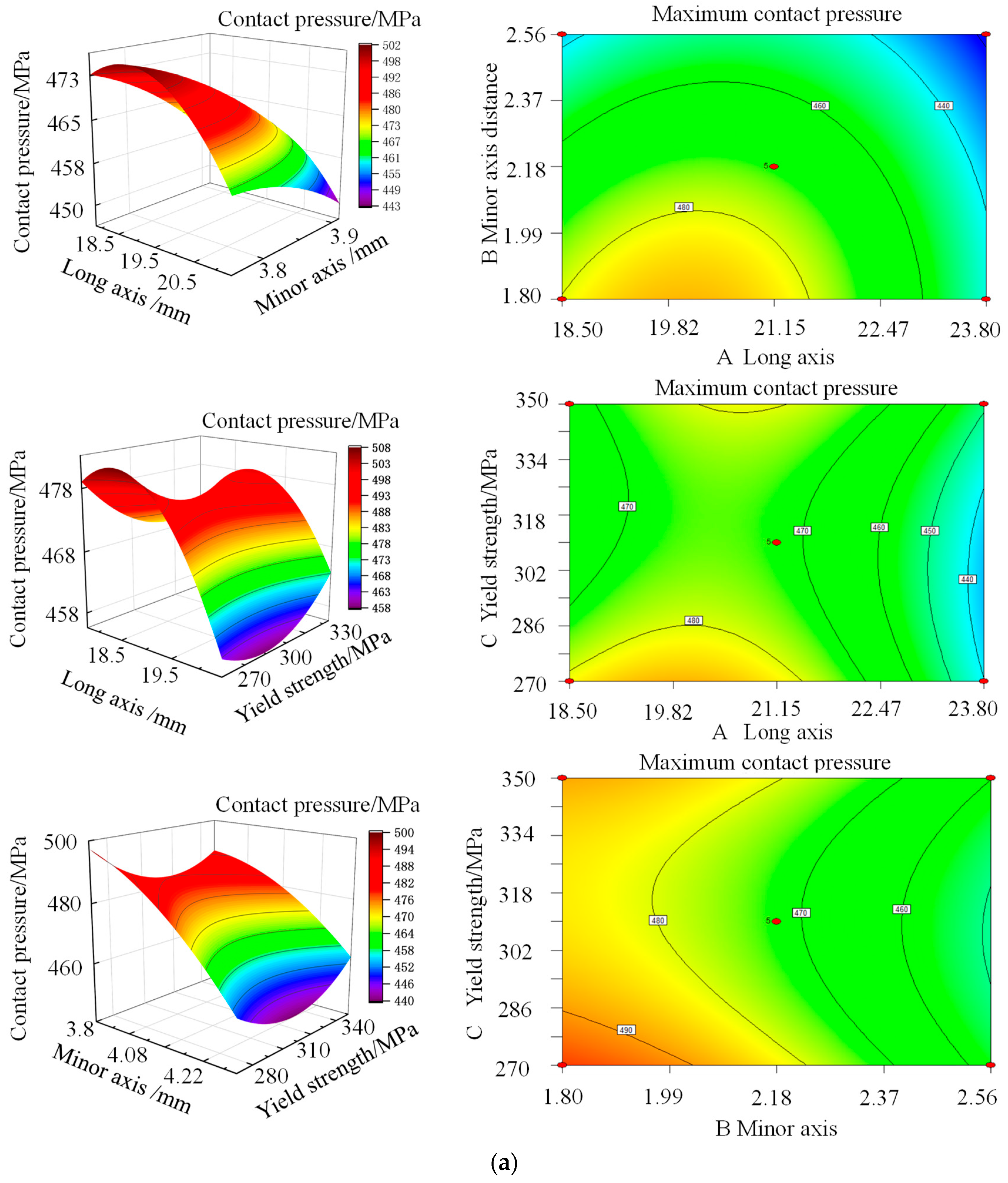

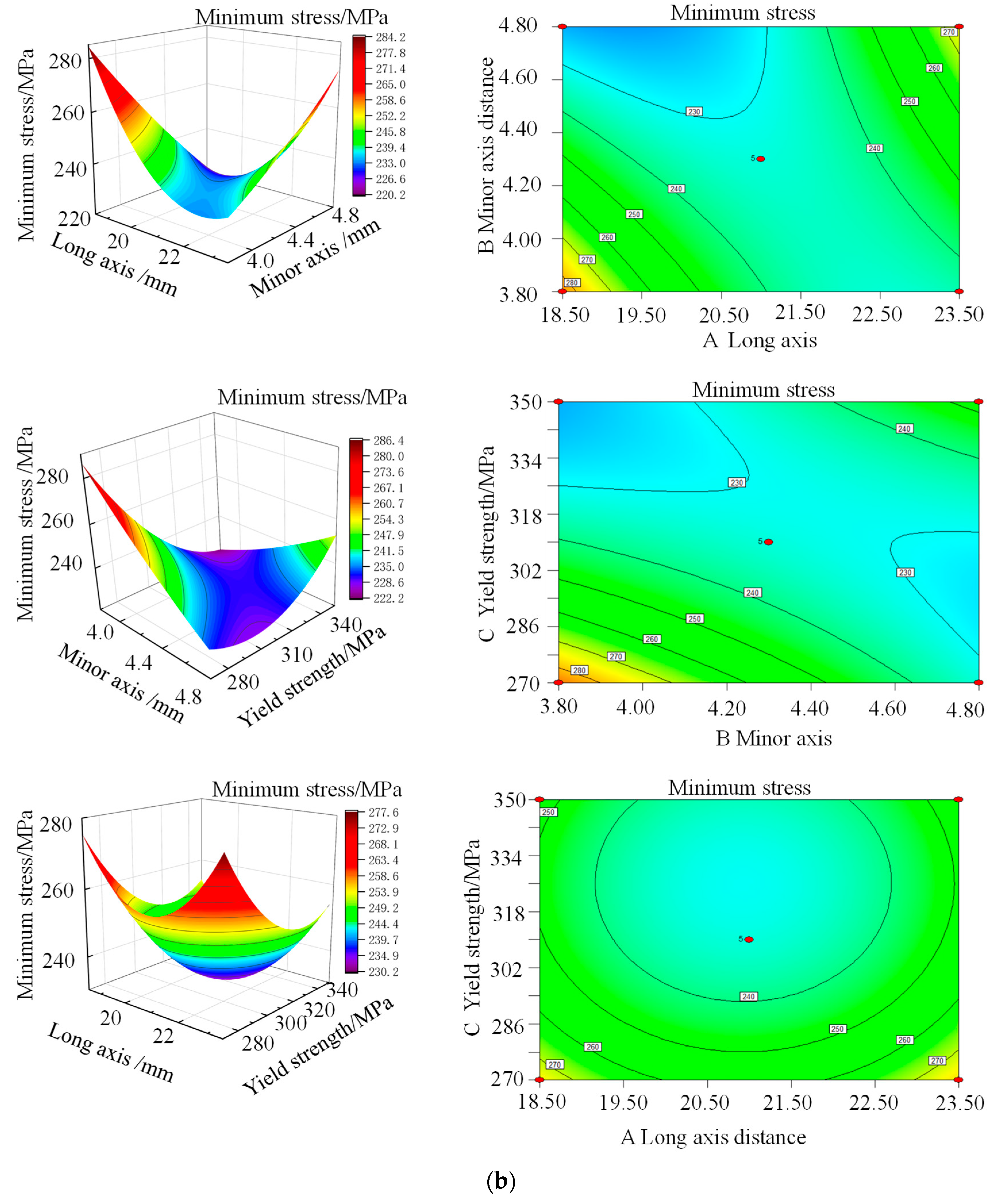

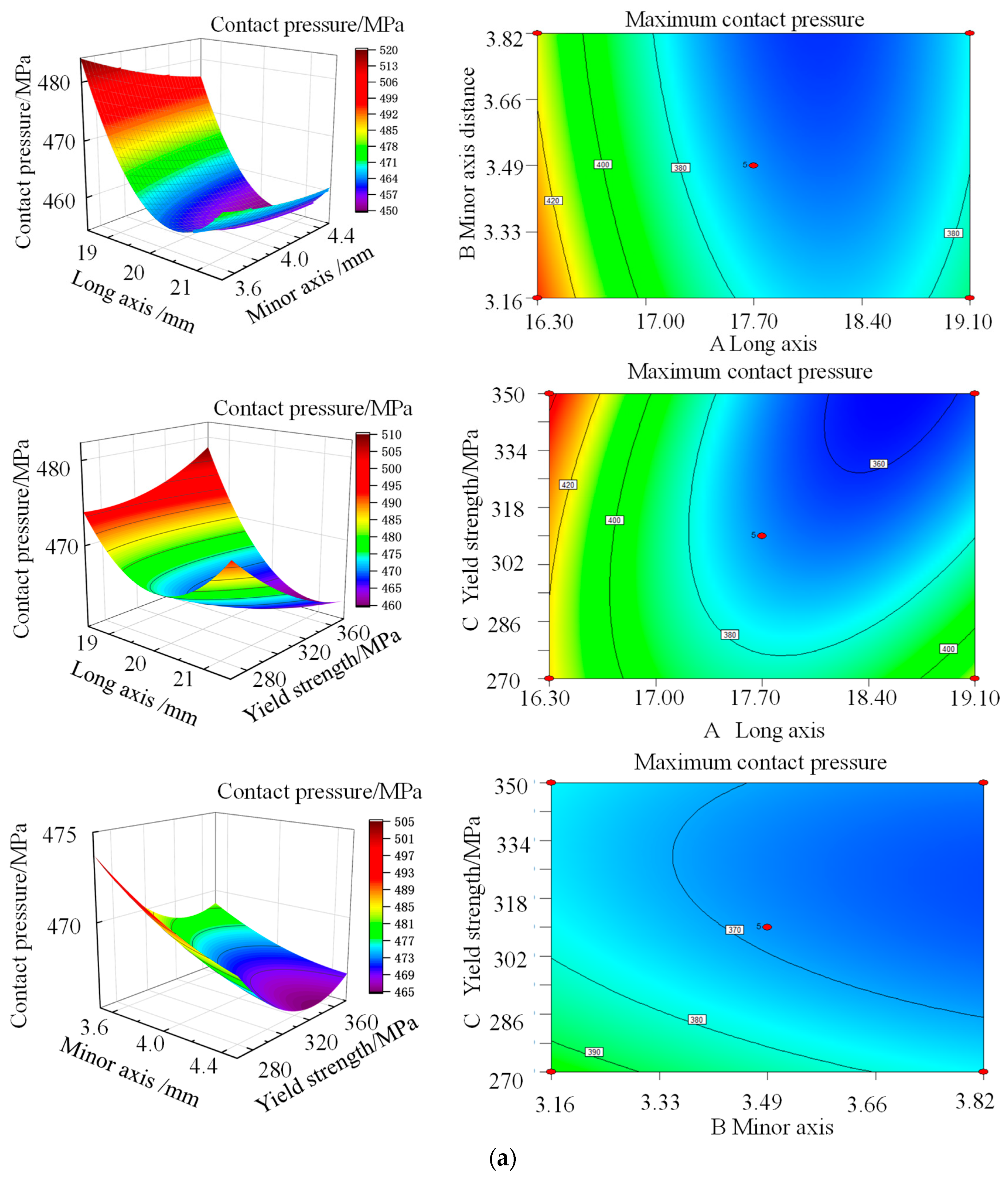

4. Research on Optimization of Seal Components of Hanger

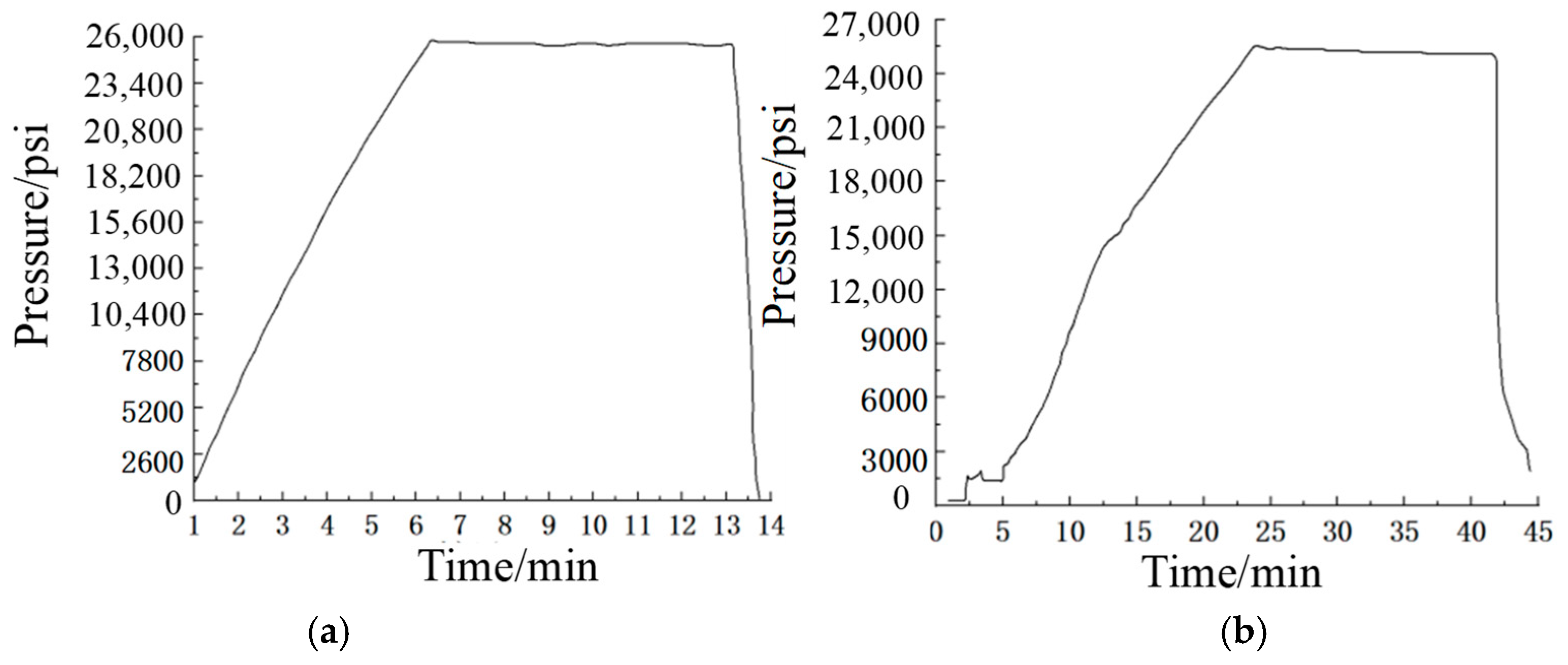

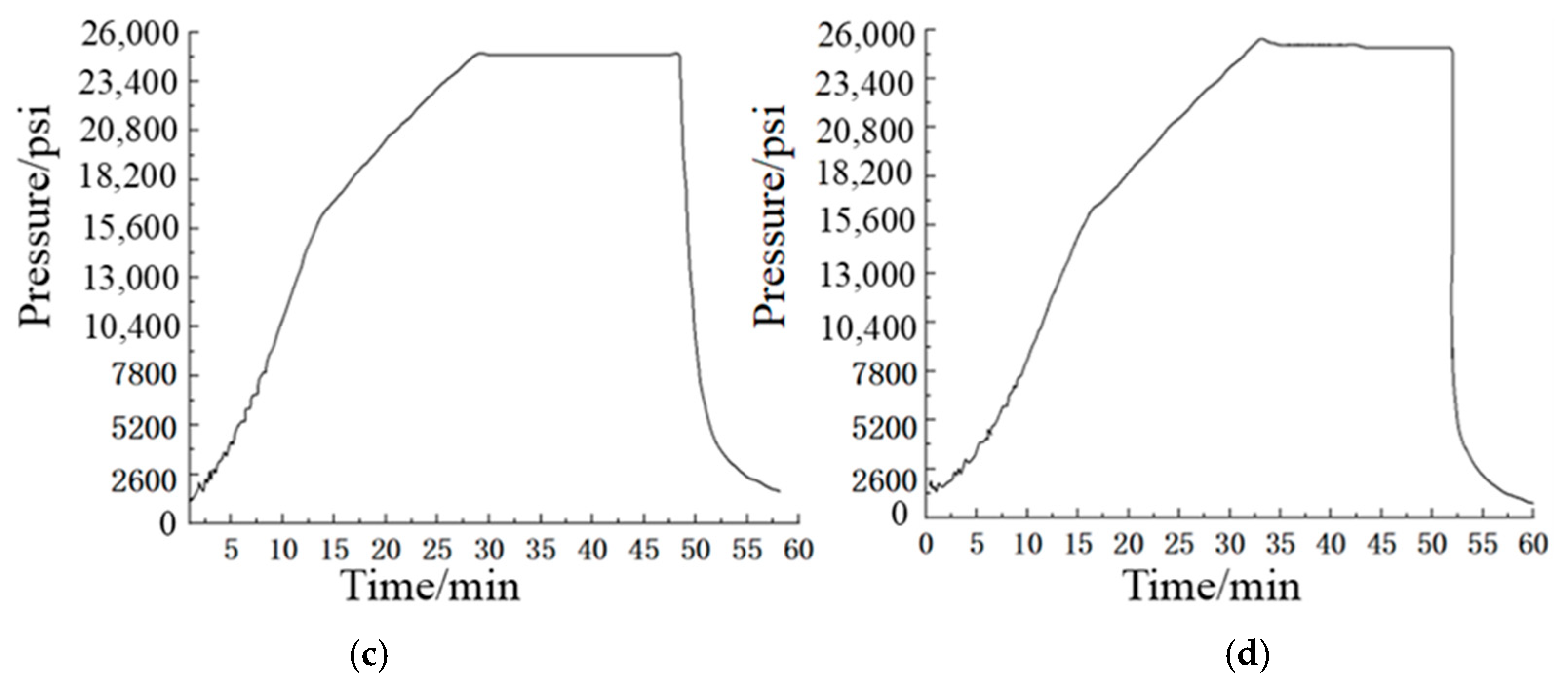

5. Experimental Study on the Sealing Structure of the Hanger

6. Conclusions

- (1)

- The peak contact pressure of the double U-shaped metal sealing ring is between 220 MPa and 275 MPa, and the peak contact pressure between the contact part of the right side and the four-way is between 400 MPa and 500 MPa, with a relatively large contact width. And it can effectively seal a gas pressure of 175 MPa.

- (2)

- It was found that the mechanical properties and contact pressure of X-shaped and straight U-shaped metal seals fluctuate greatly among the four types of special-shaped metal seals, and their sealing widths are relatively small. The mechanical properties and sealing performance of ball-drum metal seals and elliptical U-shaped seals are relatively stable, and their contact widths are relatively large.

- (3)

- The material’s ability to resist plastic deformation significantly improves when the yield strength further increases by 315.4 MPa, and thus the contact pressure rises accordingly. Within the range of parameters studied, the maximum contact pressure at the sealing interface reaches 512.6 MPa when the long axis distance is 20.56 mm and the short-axis distance is 3.94 mm. The analysis results show that this combination of structural parameters can enhance the sealing performance.

- (4)

- The contact pressure of the double U-shaped metal sealing ring first drops sharply and then rises slowly when the long axis distance increases. The contact pressure decreases slowly when the short-axis distance increases.

- (5)

- For the single U-shaped sealing structure, the optimization rates of the maximum contact pressure and the minimum equivalent stress reached 11.63% and 10.63%, respectively. For the double U-shaped structure, the optimization rates of both the maximum contact pressure and the minimum equivalent stress exceed 12%, demonstrating superior structural response characteristics.

- (6)

- During the four indoor tests, the pressure stabilization time was basically 15 min, and the average pressure drop was less than 1.5 MPa. The pressure was stable. The tests indicated that the metal sealing structure met the requirements of 175 MPa air pressure sealing.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lian, Z.; Wan, Z.; Wu, Y.; Shi, J.; Zhao, Z. Finite element analysis on mechanical strength of casing at slip hanger in ultra-deep wells. China Pet. Mach. 2023, 51, 1–8. [Google Scholar] [CrossRef]

- Zhang, Z.; Sang, P.; Sang, Z.; Hou, D.; Lv, Y.; Zheng, Y.; Zhang, C. Analyzing failure of casing head slip hanger. Eng. Fail. Anal. 2020, 108, 104301. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, L.; Liang, W. Casing safety evaluation for setting liner hanger. J. Nat. Gas Sci. Eng. 2014, 19, 58–61. [Google Scholar] [CrossRef]

- Liu, Y. Study on Design Mechanism and Test of Full-Metal Sealing Structure of Mandrel-Type Hanger of High Pressure Gas Well; Southwest Petroleum University: Chengdu, China, 2020. [Google Scholar] [CrossRef]

- Liu, Y.; She, Y.; Lian, Z.; Yi, X. Structural Design and Evaluation of High Strength Thread of Mandrel Hanger. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 2024, 46, 159–169. [Google Scholar] [CrossRef]

- Liu, Y.; Lian, Z.; Zhang, J.; Zhou, J.; Wang, F. Research on metal seal structure of large diameter mandrel hanger. Lubr. Eng. 2022, 47, 124–131. [Google Scholar] [CrossRef]

- Liu, Y.; Lian, Z.; Shi, T.; Sang, P. Fracture failure analysis and research on slip of casing head. Eng. Fail. Anal. 2019, 97, 589–604. [Google Scholar] [CrossRef]

- Liu, Y.; Lian, Z. Failure analysis on rubber sealing structure of mandrel hanger and improvement in extreme environments. Eng. Fail. Anal. 2021, 125, 105433. [Google Scholar] [CrossRef]

- Liu, Y.; She, Y.; Li, W. Research on Working Mechanism and Structural Optimization of High-Speed Bearing of Tricone Bits Based on Finite Difference Method. J. Tribol. 2025, 147, 044103-1. [Google Scholar] [CrossRef]

- Liu, Y.; Lian, Z.; Deng, C.; Zhang, Q.; Mu, Y. Design and experimental study on full-metal sealing structure of mandrel-type casing hanger. Adv. Mech. Eng. 2019, 11, 168781401984625. [Google Scholar] [CrossRef]

- Patel, H.; Salehi, S.; Teodoriu, C.; Ahmed, R. Performance evaluation and parametric study of elastomer seal in conventional hanger assembly. J. Pet. Sci. Eng. 2019, 175, 246–254. [Google Scholar] [CrossRef]

- Patel, H.; Salehi, S.; Ahmed, R.; Teodoriu, C. Review of elastomer seal assemblies in oil & gas wells: Performance evaluation, failure mechanisms, and gaps in industry standards. J. Pet. Sci. Eng. 2019, 179, 1046–1062. [Google Scholar] [CrossRef]

- Ahmed, S.; Salehi, S.; Ezeakacha, C. Review of gas migration and wellbore leakage in liner hanger dual barrier system: Challenges and implications for industry. J. Nat. Gas Sci. Eng. 2020, 78, 103284. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, H.; Zhao, Y.; Feng, D.; Tu, Y. Optimization Design for K-Shaped Metal Seal Structure Based on Response Surface Method. China Pet. Mach. 2022, 50, 80–85. [Google Scholar] [CrossRef]

- Tian, Y.; Ju, Y.; Pu, X.; Lv, H.; Zhao, Y.; Feng, D. Simulation Analysis of Sealing Characteristics of K-Shaped Metal Ring on Tube Hanger. China Pet. Mach. 2021, 49, 81–88. [Google Scholar] [CrossRef]

- Wang, Y.; Zou, S.; Liu, Y.; Wang, Y.; Fu, Z.; Chen, K.; Li, H. Research on seal structure design of marine casing hanger of high pressure. Valve 2023, 2, 133–135. [Google Scholar] [CrossRef]

- Wang, F.; Zheng, Z.; Liu, L.; Deng, Q.; Li, W.; Tian, F.; Zhou, J.; Li, R. Design and Performance Analysis of Mandrel Hanger Metal Sealings. Oil Field Equip. 2024, 53, 59–64. [Google Scholar] [CrossRef]

- Feng, C.; Li, A.; Chen, X.; Du, W.; Luo, X. Metal seal of tube hanger in ultra-high pressure gas wells. China Pet. Mach. 2025, 53, 102–108+131. [Google Scholar] [CrossRef]

- Cirimello, P.; Otegui, J.L.; Aguirre, A.; Carfi, G. Undetected non-conformities in material processing led to a service failure in a casing hanger during pre-fracture operation. Eng. Fail. Anal. 2019, 104, 203–215. [Google Scholar] [CrossRef]

- Peng, J.; Li, M.; Liu, F.; Guo, C.; Wei, C.; Li, Y. Analysis and optimization design of sealing performance of different linear flange surfaces of high pressure casing hanger. Lubr. Eng. 2024, 49, 141–149. [Google Scholar] [CrossRef]

- Ren, G.; Zhang, C.; Chen, C.; Wang, Y.; Zhang, H.; Feng, D. Research on the Sealing Performance of U-Shaped Metal Ring for Tube Hanger. Oil Field Equip. 2022, 51, 18–25. [Google Scholar] [CrossRef]

- Lian, Z.; Liu, Y.; Zhang, Y.; Yan, Y.; Wang, Y. Design and study on metal seal of casing mandrel hanger. Lubr. Eng. 2019, 44, 115–120. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, L.; Zou, J.; Xia, C.; Lian, Z. Study on failure mechanism and sealing performance optimization of compression packer. Eng. Fail. Anal. 2022, 136, 106176. [Google Scholar] [CrossRef]

- Huang, X.; Xu, T.; Liu, Y. Experimental and thermal-structure coupling analysis for oil and water-swellable packer. Energy Sci. Eng. 2023, 11, 3055–3069. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, L.; Xia, C.; Yi, X. Design and experimental study on a novel sealing structure of rotary control head for coalbed methane underbalanced drilling. Eng. Fail. Anal. 2022, 139, 106441. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, L.; Xia, C.; Yi, X.; Lian, Z. Failure Analysis of Ram Body and Sealing Performance of Semi-Sealed Blowout Preventer. J. Fail. Anal. Prev. 2022, 22, 1011–1030. [Google Scholar] [CrossRef]

- Liu, Y.; Li, W.; Xia, C. Research on sealing mechanism and structural improvement of metal sealing structures for high speed drill bits. Int. J. Press. Vessel. Pip. 2024, 207, 105104. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, L.; Xia, C.; Zou, J.; Lian, Z.; Yi, X. Failure analysis and structural optimization of rubber core and support rib of full-size spherical blowout preventer. Eng. Fail. Anal. 2023, 143, 106865. [Google Scholar] [CrossRef]

| Category | Original/MPa | Optimization/MPa | Error | Optimization Rate |

|---|---|---|---|---|

| max [Cp]/single U | 569.3 | 502.3 | 2.45% | 11.63% |

| max [Cp]/double U | 584.8 | 511.4 | 1.83% | 12.55% |

| min [σ]/single U | 297.6 | 265.6 | 4.69% | 10.63% |

| min [σ]/double U | 329.7 | 287.5 | 3.52% | 12.78% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Feng, S.; Wei, J.; Li, K.; Zhu, L.; Jia, Z.; Liu, F. Optimization Analysis of Structural Parameters of Special Metal Sealing for 175 MPa Tube Hanger. Processes 2025, 13, 2970. https://doi.org/10.3390/pr13092970

Wang J, Feng S, Wei J, Li K, Zhu L, Jia Z, Liu F. Optimization Analysis of Structural Parameters of Special Metal Sealing for 175 MPa Tube Hanger. Processes. 2025; 13(9):2970. https://doi.org/10.3390/pr13092970

Chicago/Turabian StyleWang, Jianfei, Shaobo Feng, Junhui Wei, Kun Li, Lijin Zhu, Zhenyu Jia, and Fudong Liu. 2025. "Optimization Analysis of Structural Parameters of Special Metal Sealing for 175 MPa Tube Hanger" Processes 13, no. 9: 2970. https://doi.org/10.3390/pr13092970

APA StyleWang, J., Feng, S., Wei, J., Li, K., Zhu, L., Jia, Z., & Liu, F. (2025). Optimization Analysis of Structural Parameters of Special Metal Sealing for 175 MPa Tube Hanger. Processes, 13(9), 2970. https://doi.org/10.3390/pr13092970