Performance Evaluation of Asphalt Concrete Incorporating Polyethylene Terephthalate-Coated Steel Slag Using Marshall Stability, Indirect Tensile Strength, and Moisture Susceptibility Tests

Abstract

1. Introduction

- Examine the effects of adding PET-coated steel slag to asphalt concrete on its strength and moisture resistance, in particular;

- Determine which PET and slag combinations offer the optimum stability and moisture resistance balance;

- Utilize statistical analysis to comprehend the impact of every element and how they interact;

- Provide useful advice for creating high-performing and more environmentally friendly asphalt mixtures.

2. Materials and Experimental Procedures

2.1. Materials

2.1.1. Asphalt

2.1.2. PET

| Property | Specification | Ref. | Unit | Results | Requirements | |

|---|---|---|---|---|---|---|

| PET | Asphalt | |||||

| Chemical Formula | Charles E. Carraher Jr. (2017) | [34] | (C10H8O4)n | – | – | |

| Specific Gravity (25 °C) | ASTM D792 | [35] | g/cm3 | 1.31 | – | – |

| AASHTO T 228–93 | [36] | – | 1.02 | 1.02 to 1.06 | ||

| Water Absorption | ASTM D570 | [37] | % | 0.15 | – | – |

| Penetration Test (25 °C) | AASHTO T 49–93 | [38] | – | 65 | 60 to 70 | |

| Ductility Test (25 °C) | AASHTO T 51–93 | [39] | cm | <1.0 | >100 | >100 |

| Softening Point Test | AASHTO T 53–92 | [40] | °C | – | 52 | 46–54 |

| Flash and Fire Point Test | AASHTO T 48–91 | [41] | °C | 300–330 | 310–340 | >232 |

2.1.3. Steel Slag

2.1.4. Stone Aggregate

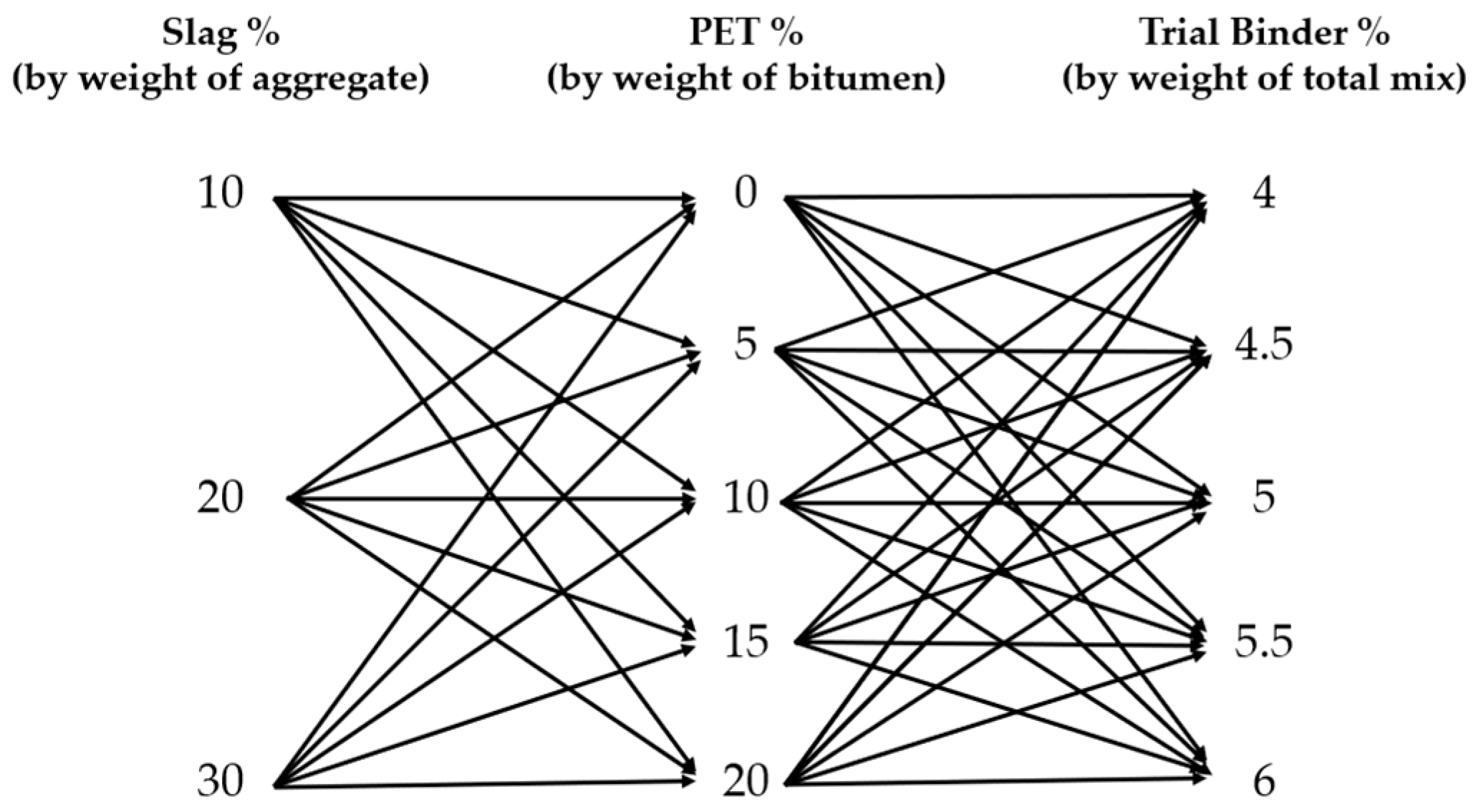

2.2. Mixing and Fabrication of Asphalt Concrete (AC)

2.3. Testing Program

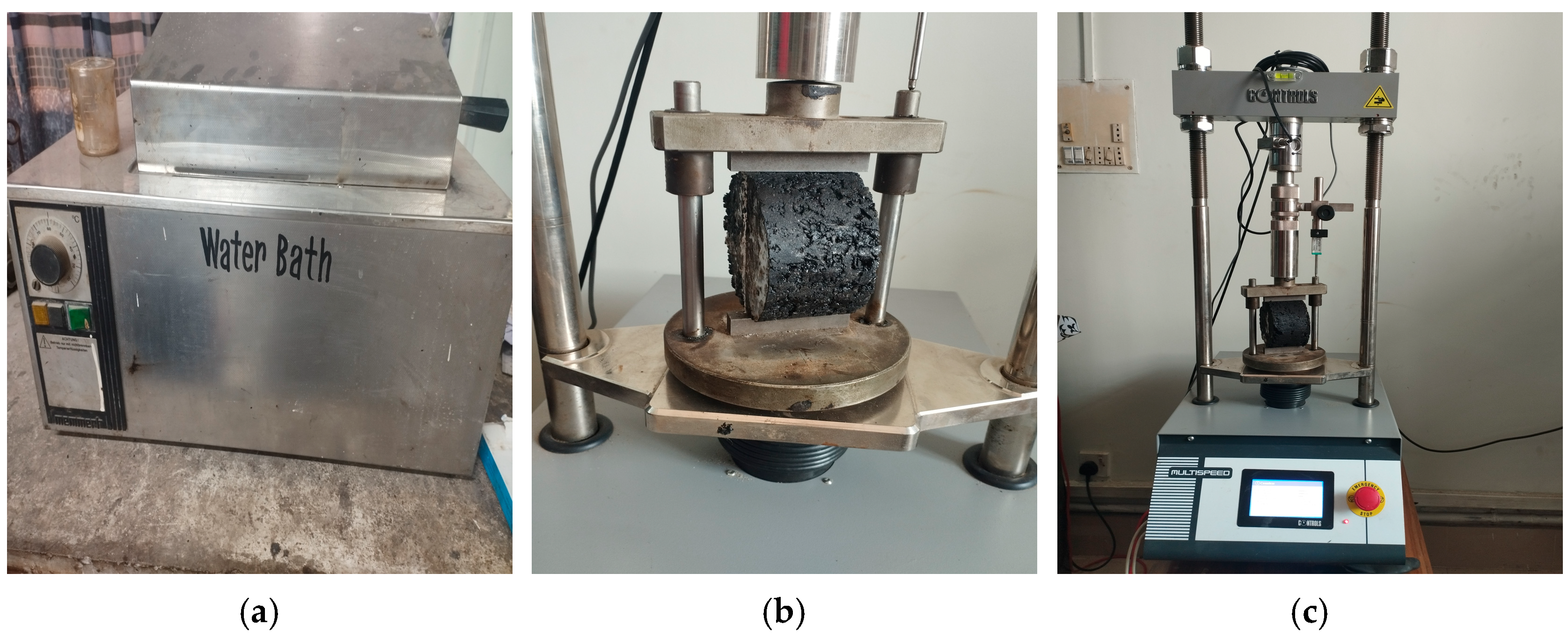

2.3.1. Marshall Mix Design

Marshall Stability and Flow

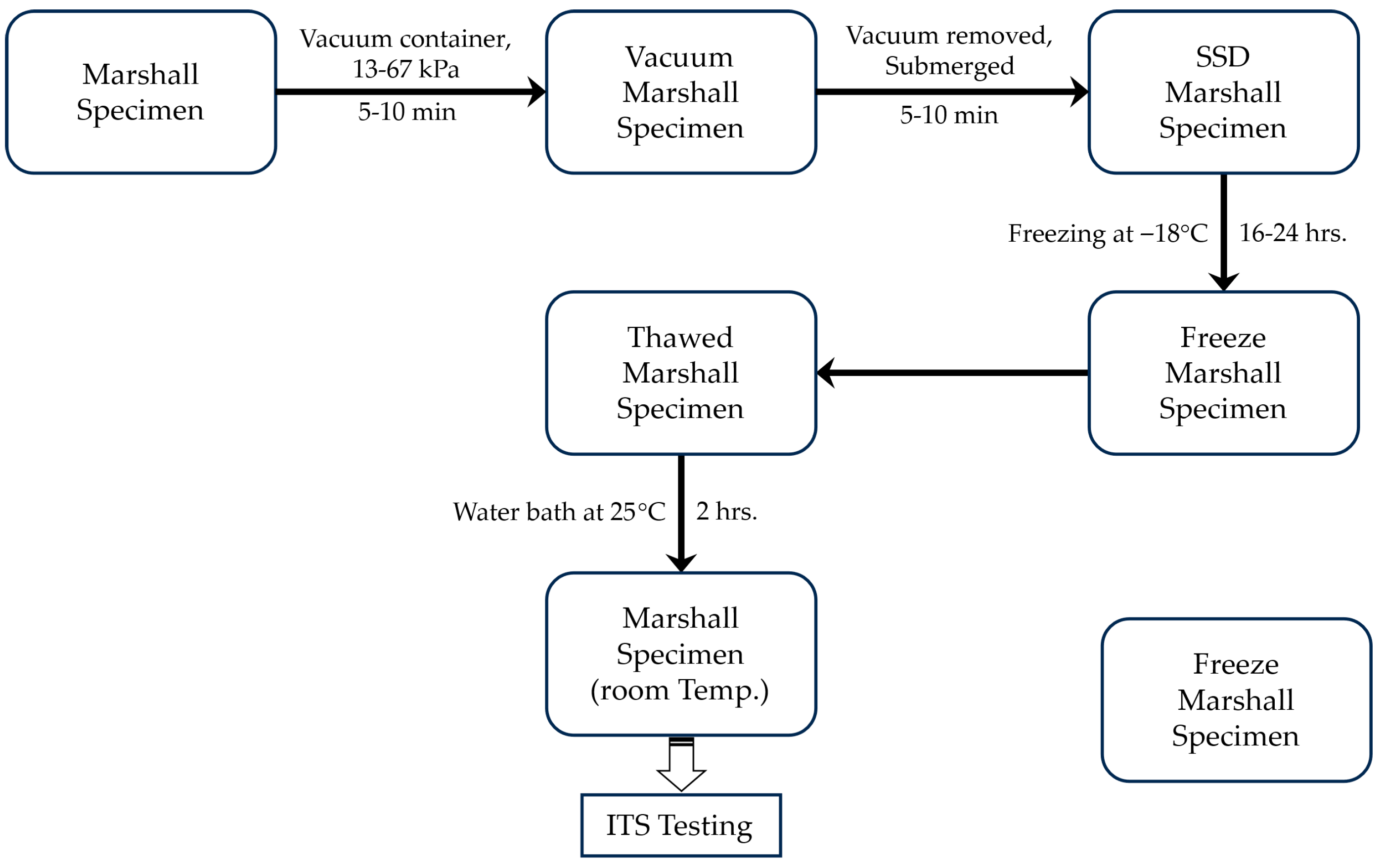

2.3.2. Moisture Susceptibility Tests

Indirect Tensile Strength Test (ITS)

Tensile Strength Ratio (TSR)

3. Results and Discussions

3.1. Marshall Test Results

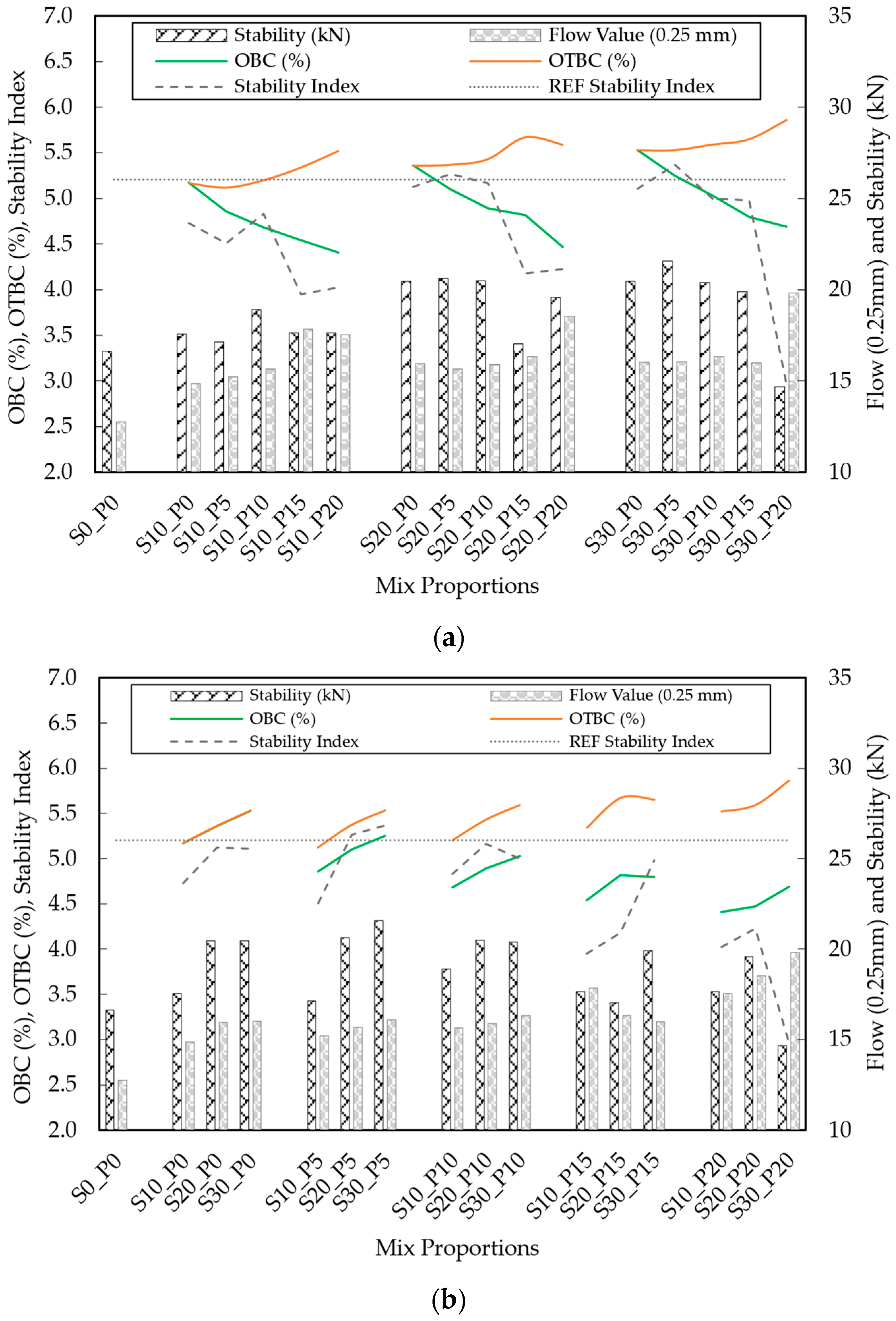

3.1.1. OBC and OTBC

3.1.2. Marshall Stability

3.1.3. Marshall Flow

3.1.4. Marshall Stability Index

3.2. Moisture Susceptibility

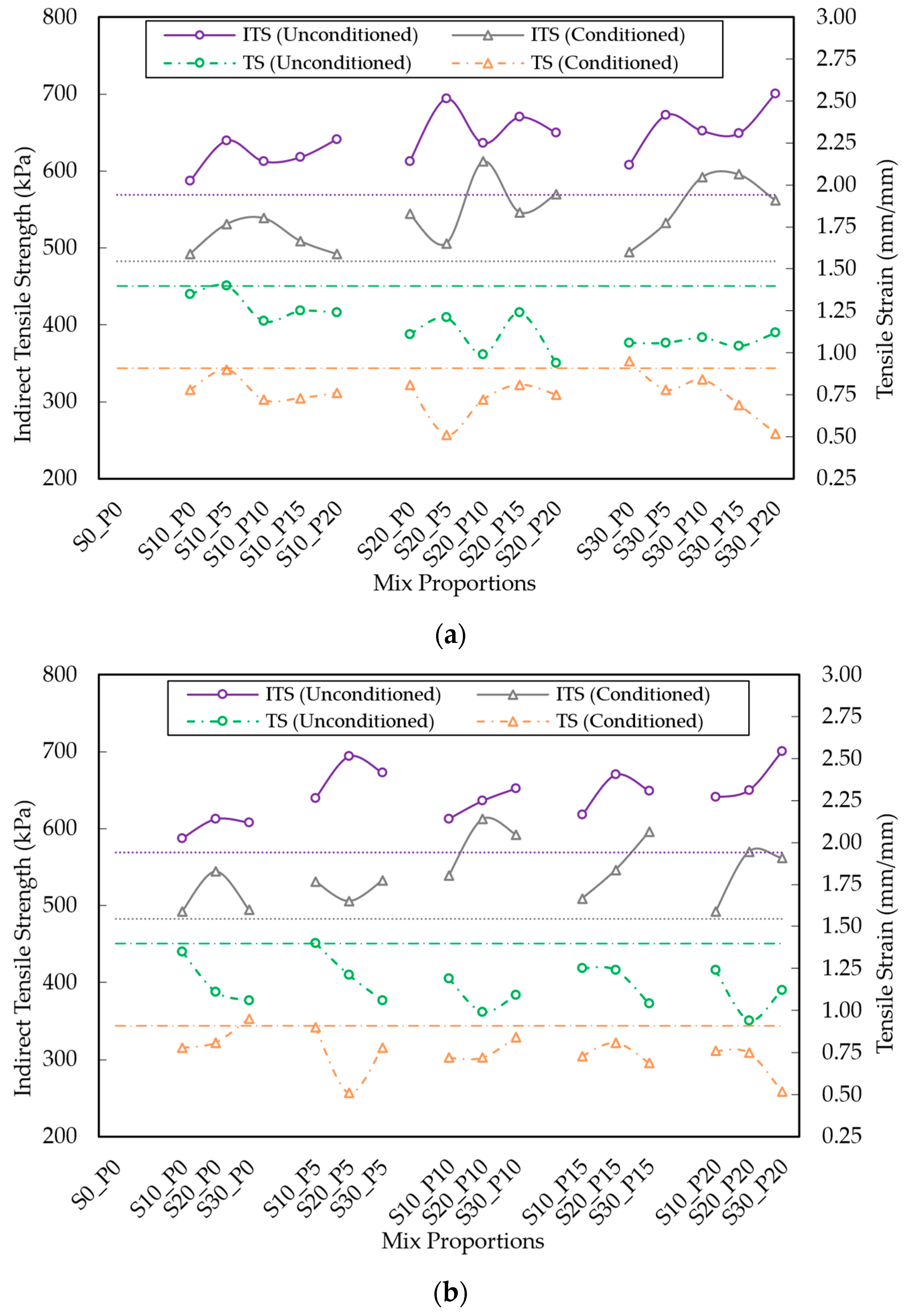

3.2.1. Indirect Tensile Strength (ITS)

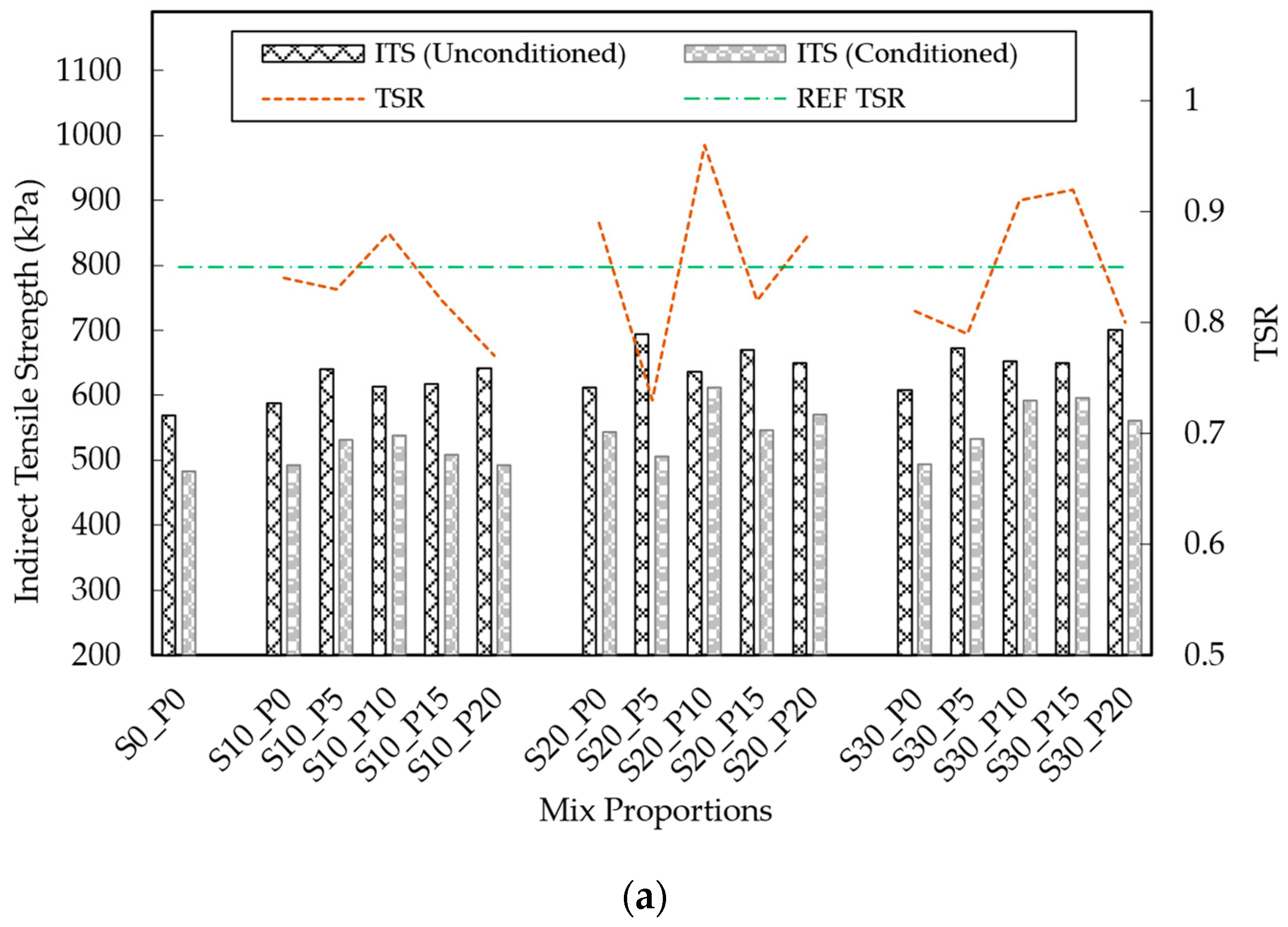

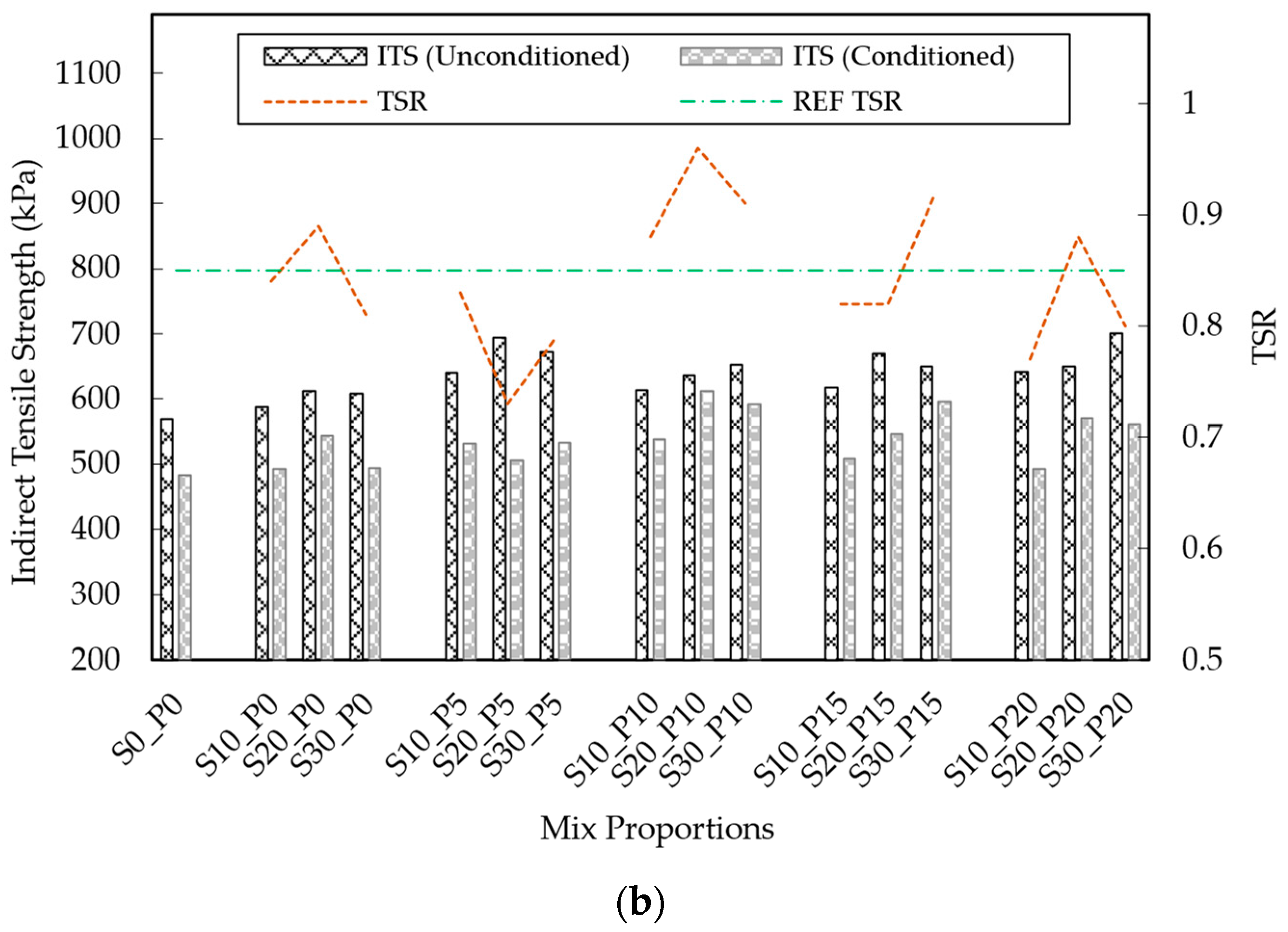

3.2.2. Tensile Strength Ratio (TSR)

4. Statistical Analysis

5. Limitations and Future Scope

6. Conclusions

- Higher slag content (10–30%) elevated both OTBC and OBC due to slag’s porous structure, requiring more binder. However, OBC for the specific AC mix containing 10% slag with 5% PET is below the virgin OBC.

- Stability values exceeded the virgin mix in all cases except for AC mix containing 30% slag with 20% PET. Increased slag content enhanced stability for fixed PET percentages, with peak values (21.57 kN and 20.62 kN for AC mixes containing 30% slag with 5% PET and 20% slag with 5% PET, respectively) indicating better performance at moderate PET and higher slag ratios.

- Both unconditioned and conditioned specimens of all mixes showed higher ITS than the virgin mix. The highest ITS (unconditioned) occurred in the AC mixes containing 30% slag with 20%, and 20% slag with 5%, indicating improved resistance to fatigue, thermal cracking, and rutting.

- The AC mixes containing 20% slag with 10% and 30% slag with 15 exhibited the highest tensile strength ratio (TSR) values of 0.96 and 0.92, respectively, indicating superior resistance to moisture-induced damage.

- Statistical analysis (MLRA) indicates that steel slag plays a dominant role in enhancing stability, with the combined effect of steel slag and OTBC also proving significant for the stability index; however, the influence of SS, PET, and OTBC on the TSR of AC mixes exhibits irregular or inconsistent behavior.

- Overall, the AC mix containing 20% slag with 10% is identified as the most suitable mix across all combinations due to its enhanced performance, reflected by the higher stability index, ITS, and TSR.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AC | Asphalt Concrete |

| AASHTO | American Association of State Highway and Transportation Officials |

| ACV | Aggregate Crushing Value |

| AIV | Aggregate Impact Value |

| ASTM | American Society for Testing and Materials |

| AV | Air Voids |

| BS | British Standard |

| CA | Coarse Aggregate |

| FA | Fine Aggregate |

| HDPE | High-Density Polyethylene |

| HMA | Hot Mix Asphalt |

| ITS | Indirect Tensile Strength |

| LDPE | Low-Density Polyethylene |

| MF | Mineral Filler |

| MLRA | Multiple linear regression analysis |

| MMD | Marshall Mix Design |

| OBC | Optimum Bitumen Content |

| OTBC | Optimum Total Binder Content |

| PET | Polyethylene Terephthalate |

| PP | Polypropylene |

| RHD | Roads and Highways Department (Bangladesh) |

| SS | Steel Slag |

| SSD | Saturated Surface-Dry |

| SSL | Specified Upper Limits |

| SUL | Specified Lower Limits |

| TS | Tensile Strain |

| TSR | Tensile Strength Ratio |

| VFA | Voids Filled with Asphalt |

| VMA | Voids in Mineral Aggregate |

References

- Plastic Pollution: When the Mermaids Cry—The Great Plastic Tide. Available online: https://coastalcare.org/2020/01/plastic-pollution-when-the-mermaids-cry-the-great-plastic-tide-by-claire-le-guern/ (accessed on 8 June 2025).

- Ziani, K.; Ioniță-Mîndrican, C.B.; Mititelu, M.; Neacșu, S.M.; Negrei, C.; Moroșan, E.; Drăgănescu, D.; Preda, O.T. Microplastics: A Real Global Threat for Environment and Food Safety: A State of the Art Review. Nutrients 2023, 15, 617. [Google Scholar] [CrossRef]

- Gameplan: It’s Time to Beat Plastic Pollution. Available online: https://www.unep.org/beatpollution/beat-plastic-pollution/gameplan-it-is-time-to-beat-plastic-pollution (accessed on 8 June 2025).

- Hester, R.E.; Harrison, R.M.; Harrison, R.; Hester, R. (Eds.) Marine Pollution and Human Health; The Royal Society of Chemistry: London, UK, 2011; Volume 33. [Google Scholar] [CrossRef][Green Version]

- How BSRM Turns Steel Waste into Eco-Friendly Construction Material. Available online: https://www.tbsnews.net/bangladesh/environment/how-bsrm-turns-steel-waste-eco-friendly-construction-material-644214 (accessed on 8 June 2025).[Green Version]

- Roadcap, G.S.; Kelly, W.R.; Bethke, C.M. Geochemistry of Extremely Alkaline (pH > 12) Ground Water in Slag-Fill Aquifers. Ground Water 2005, 43, 806–816. [Google Scholar] [CrossRef]

- Ettler, V.; Vítková, M. Slag Leaching Properties and Release of Contaminants. In Metallurgical Slags: Environmental Geochemistry and Resource Potential; Piatak, N.M., Ettler, V., Eds.; Royal Society of Chemistry: London, UK, 2021; pp. 151–173. [Google Scholar] [CrossRef]

- Ettler, V.; Kierczak, J. Environmental Impact of Slag Particulates. In Metallurgical Slags: Environmental Geochemistry and Resource Potential; Piatak, N.M., Ettler, V., Eds.; Royal Society of Chemistry: London, UK, 2021; pp. 174–193. [Google Scholar] [CrossRef]

- Huang, Y.; Bird, R.N.; Heidrich, O. A Review of the Use of Recycled Solid Waste Materials in Asphalt Pavements. Resour. Conserv. Recycl. 2007, 52, 58–73. [Google Scholar] [CrossRef]

- Asi, I.M.; Qasrawi, H.Y.; Shalabi, F.I. Use of Steel Slag Aggregate in Asphalt Concrete Mixes. Can. J. Civ. Eng. 2007, 34, 902–911. [Google Scholar] [CrossRef]

- Hunt, L.; Boyle, G.E. Steel Slag in Hot Mix Asphalt Concrete: Final Report; ROSA P: Washington, DC, USA, 2000. [CrossRef]

- Amuchi, M.; Abtahi, S.M.; Koosha, B.; Hejazi, S.M.; Sheikhzeinoddin, H. Reinforcement of Steel-Slag Asphalt Concrete Using Polypropylene Fibers. J. Ind. Text. 2015, 44, 526–541. [Google Scholar] [CrossRef]

- Zinnurain, M.; Dipto, S.B. Property Analysis of Induction Furnace Steel Slag for Use in Flexible Pavement. In Proceedings of the 6th International Conference on Civil Engineering for Sustainable Development (ICCESD 2022), Khulna, Bangladesh, 10–12 February 2022; ICCESD: Chittagong, Bangladesh, 2022; pp. 1–8. [Google Scholar]

- Ahmedzade, P.; Sengoz, B. Evaluation of Steel Slag Coarse Aggregate in Hot Mix Asphalt Concrete. J. Hazard. Mater. 2009, 165, 300–305. [Google Scholar] [CrossRef] [PubMed]

- Awwad, M.T.; Shbeeb, L. The Use of Polyethylene in Hot Asphalt Mixtures. Am. J. Appl. Sci. 2007, 4, 390–396. [Google Scholar] [CrossRef]

- Azarhoosh, A.; Koohmishi, M.; Hamedi, G.H. Rutting Resistance of Hot Mix Asphalt Containing Coarse Recycled Concrete Aggregates Coated with Waste Plastic Bottles. Adv. Civ. Eng. 2021, 2021, 1–11. [Google Scholar] [CrossRef]

- Mir, A.H. Use of Plastic Waste in Pavement Construction: An Example of Creative Waste Management. IOSR J. Eng. 2015, 5, 57–67. [Google Scholar] [CrossRef]

- Modak, S.; Belkhode, P. Construction of Pavement by Processing the Waste Plastic. Acad. J. Manuf. Eng. 2022, 20, 5–12. [Google Scholar]

- Sojobi, A.O.; Nwobodo, S.E.; Aladegboye, O.J. Recycling of Polyethylene Terephthalate (PET) Plastic Bottle Wastes in Bituminous Asphaltic Concrete. Cogent Eng. 2016, 3, 1133480. [Google Scholar] [CrossRef]

- Suaryana, N.; Nirwan, E.; Ronny, Y. Plastic Bag Waste on Hotmixture Asphalt as Modifier. Key Eng. Mater. 2018, 789, 20–25. [Google Scholar] [CrossRef]

- Moinuddin Sarker, M.M.R. Thermal Degradation of Poly(Ethylene Terephthalate) Waste Soft Drinks Bottles and Low Density Polyethylene Grocery Bags. Int. J. Sustain. Energy Environ. 2013, 1, 78–86. [Google Scholar]

- Zohoori, M.; Ghani, A. Municipal Solid Waste Management Challenges and Problems for Cities in Low-Income and Developing Countries. Int. J. Sci. Eng. Appl. 2017, 6, 39–48. [Google Scholar] [CrossRef]

- Martinho, F.C.G.; Picado-Santos, L.G.; Capitão, S.D. Feasibility Assessment of the Use of Recycled Aggregates for Asphalt Mixtures. Sustainability 2018, 10, 1737. [Google Scholar] [CrossRef]

- Fernandes, S.; Peralta, J.; Oliveira, J.R.M.; Williams, R.C.; Silva, H.M.R.D. Improving Asphalt Mixture Performance by Partially Replacing Bitumen with Waste Motor Oil and Elastomer Modifiers. Appl. Sci. 2017, 7, 794. [Google Scholar] [CrossRef]

- Fang, C.; Wu, C.; Yu, R.; Zhang, Z.; Zhang, M.; Zhou, S. Aging Properties and Mechanism of the Modified Asphalt by Packaging Waste Polyethylene and Waste Rubber Powder. Polym. Adv. Technol. 2013, 24, 51–55. [Google Scholar] [CrossRef]

- Leng, Z.; Padhan, R.K.; Sreeram, A. Production of a Sustainable Paving Material through Chemical Recycling of Waste PET into Crumb Rubber Modified Asphalt. J. Clean. Prod. 2018, 180, 682–688. [Google Scholar] [CrossRef]

- Abdel Bary, E.M.; Farag, R.K.; Ragab, A.A.; Abdel-monem, R.M.; Abo-shanab, Z.L.; Saleh, A.M.M. Green Asphalt Construction with Improved Stability and Dynamic Mechanical Properties. Polym. Bull. 2020, 77, 1729–1747. [Google Scholar] [CrossRef]

- Ahmadinia, E.; Zargar, M.; Karim, M.R.; Abdelaziz, M.; Ahmadinia, E. Performance Evaluation of Utilization of Waste Polyethylene Terephthalate (PET) in Stone Mastic Asphalt. Constr. Build. Mater. 2012, 36, 984–989. [Google Scholar] [CrossRef]

- Hasban, A.; Waje, A.; Vhatte, V.; Shinde, S.; Binayake, R.A. Study of Effective Utilization of Waste P.E.T (Plastic) and Steel Slag to Enhance the Performance of Bitumen Based Pavement. Int. J. Res. Appl. Sci. Eng. Technol. 2022, 10, 3172–3177. [Google Scholar] [CrossRef]

- Usman, N.; Masirin, M.I.M. Performance of Asphalt Concrete with Plastic Fibres; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- What Is PET?—NAPCOR. Available online: https://napcor.com/about-pet/ (accessed on 8 June 2025).

- Barber, N.A. (Ed.) Polymer Science and Technology Polyethylene Terephthalate: Uses, Properties, and Degradation; Nova Science Publishers: Hauppauge, NY, USA, 2017. [Google Scholar]

- File: Polyethylene-Terephthalate-3D-Spacefill.png. Available online: https://en.wikipedia.org/wiki/polyethylene_terephthalate#/media/file:polyethylene-terephthalate-3d-spacefill.png (accessed on 8 June 2025).

- Carraher, C.E., Jr. (Ed.) Introduction to Polymer Chemistry, 4th ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar] [CrossRef]

- ASTM D792; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- AASHTO T 228; Standard Method of Test for Specific Gravity of Semi-Solid Bituminous Material. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- ASTM D570; Standard Test Method for Water Absorption of Plastics. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- AASHTO T 49; Standard Method of Test for Penetration of Bituminous Materials. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022. Available online: https://store.transportation.org/item/publicationdetail?id=4762 (accessed on 12 May 2025).

- AASHTO T 51; Standard Method of Test for Ductility of Asphalt Materials. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022. Available online: https://store.transportation.org/item/publicationdetail?id=4764 (accessed on 12 May 2025).

- AASHTO T 53; Standard Method of Test for Softening Point of Bitumen (Ring-and-Ball Apparatus). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022. Available online: https://store.transportation.org/item/publicationdetail?id=4765 (accessed on 12 May 2025).

- AASHTO T 48; Standard Method of Test for Flash Point of Asphalt Binder by Cleveland Open Cup. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022. Available online: https://store.transportation.org/item/publicationdetail?id=4761 (accessed on 12 May 2025).

- Piatak, N.M.; Parsons, M.B.; Seal, R.R. Characteristics and Environmental Aspects of Slag: A Review. Appl. Geochem. 2015, 57, 236–266. [Google Scholar] [CrossRef]

- ASTM C127; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2024. [CrossRef]

- BS 812-112:1990; Testing Aggregates Method for Determination of Aggregate Impact Value (AIV). BSI: Bonn, Germany, 1990. Available online: https://www.en-standard.eu/bs-812-112-1990-testing-aggregates-method-for-determination-of-aggregate-impact-value-aiv/ (accessed on 22 July 2025).

- BS 812-110:1990; Testing Aggregates Methods for Determination of Aggregate Crushing Value (ACV). BSI: Bonn, Germany, 1990; 6p. Available online: https://www.en-standard.eu/bs-812-110-1990-testing-aggregates-methods-for-determination-of-aggregate-crushing-value-acv/ (accessed on 22 July 2025).

- ASTM C128; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- ASTM D854; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM International: West Conshohocken, PA, USA, 2002. [CrossRef]

- ASTM C136; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- Asphalt Institute. MS-4 The Asphalt Handbook, 7th ed.; Asphalt Institute: Lexington, KY, USA, 2007; Available online: https://my.asphaltinstitute.org/shop/product-details?productid=9e5a6840-361b-e811-80f2-000d3a011cec (accessed on 10 July 2025).

- Government of the People’s Republic of Bangladesh Ministry of Road Transport and Bridges Roads and Highways Department Bangladesh Road Research laboratory. Laboratory Technical Note on: Asphalt Mix Design for Heavily Trafficked. 2017. Available online: https://rhd.portal.gov.bd/sites/default/files/files/rhd.portal.gov.bd/page/5fe252bb_4e63_4d72_995f_7ddfb652e02a/asphalt%20mix%20design%20for%20heavily%20trafficked%20road.pdf (accessed on 10 July 2025).

- RHD Technical Specification Dense Bituminous Surfacing (Plant Method). 2001; Volume 3. Available online: https://www.rhd.gov.bd/documents/contractdocuments/technicalspecification/dense%20bituminous%20surfacing.pdf (accessed on 10 July 2025).

- Mitchell, T. Superpave Mixture Design Guide; U.S. Department of Transportation: Washington, DC, USA, 2001.

- Cominsky, R.J. Strategic Highway Research Program (SHRP-A-407). In The Superpave Mix Design Manual for New Construction and Overlays; Transportation Research Board: Washington, DC, USA, 1994. [Google Scholar]

- Nguyen, M.T.; Vu, B.T. Laboratory Investigation on Mixing Methods for Polymer Modified Asphalt Mixture. In Lecture Notes in Civil Engineering; Springer: Singapore, 2024; Volume 442, pp. 1780–1787. [Google Scholar] [CrossRef]

- AASHTO T166; Standard Method of Test for Bulk Specific Gravity of Compacted Asphalt Mixtures Using Saturated Surface-Dry Specimens. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2009.

- ASTM D2726; Standard Test Method for Bulk Specific Gravity and Density of Non-Absorptive Compacted Bituminous Mixtures. ASTM International: West Conshohocken, PA, USA, 2011. [CrossRef]

- AASHTO T209; Standard Method of Test for Theoretical Maximum Specific Gravity and Density of Bituminous Paving Mixtures. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2011.

- ASTM D6926; Standard Practice for Preparation of Asphalt Mixture Specimens Using Marshall Apparatus. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM D6927; Standard Test Method for Marshall Stability and Flow of Asphalt Mixtures. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- Ameri, M.; Hesami, S.; Goli, H. Laboratory Evaluation of Warm Mix Asphalt Mixtures Containing Electric Arc Furnace (EAF) Steel Slag. Constr. Build. Mater. 2013, 49, 611–617. [Google Scholar] [CrossRef]

- Zoorob, S.E.; Suparma, L.B. Laboratory Design and Investigation of the Properties of Continuously Graded Asphaltic Concrete Containing Recycled Plastics Aggregate Replacement (Plastiphalt). Cem. Concr. Compos. 2000, 22, 233–242. [Google Scholar] [CrossRef]

- AASHTO T 283; Standard Method of Test for Resistance of Compacted Hot Mix Asphalt to Moisture Induced Damage. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2011.

- AASHTO T 312; Standard Method of Test for Preparing and Determining the Density of Asphalt Mixture Specimens by Means of the Superpave Gyratory Compactor. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2011. Available online: https://store.transportation.org/item/publicationdetail?id=4865 (accessed on 15 June 2025).

- Usman, I.U.; Kunlin, M. Influence of Polyethylene Terephthalate (PET) Utilization on the Engineering Properties of Asphalt Mixtures: A Review. Constr. Build. Mater. 2024, 411, 134439. [Google Scholar] [CrossRef]

- Zinnurain, M.; Rahman, M.; Islam, S.; Hasan, H. Effect of Steel Slag on Moisture Susceptibility of Asphalt Concrete Based on Tensile Strength Ratio; Atlantis Press International: Dordrecht, The Netherlands, 2024. [Google Scholar] [CrossRef]

- Asphalt Institute. MS-2: Asphalt Mix Design Methods, 7th ed.; Abedali, A.H., Ed.; Asphalt Institute: Lexington, KY, USA, 1997. [Google Scholar]

- Taherkhani, H.; Arshadi, M.R. Investigating the Mechanical Properties of Asphalt Concrete Containing Waste Polyethylene Terephthalate. Road Mater. Pavement Des. 2019, 20, 381–398. [Google Scholar] [CrossRef]

- Aghayan, I.; Khafajeh, R. Recycling of PET in Asphalt Concrete. Use Recycl. Plast. Eco-Effic. Concr. 2019, 269–285. [Google Scholar] [CrossRef]

- Ahmadinia, E.; Zargar, M.; Karim, M.R.; Abdelaziz, M.; Shafigh, P. Using Waste Plastic Bottles as Additive for Stone Mastic Asphalt. Mater. Des. 2011, 32, 4844–4849. [Google Scholar] [CrossRef]

- Moghaddam, T.B.; Karim, M.R.; Soltani, M. Utilization of Waste Plastic Bottles in Asphalt Mixture. J. Eng. Sci. Technol. 2013, 8, 264–271. [Google Scholar]

- Yildirim, I.Z.; Prezzi, M. Use of Steel Slag in Subgrade Applications; Purdue University Press: West Lafayette, IN, USA, 2009. [Google Scholar] [CrossRef]

- Mukheed, M.; Khan, A. Plastic Pollution in Pakistan: Environmental and Health Implications. J. Pollut. Eff. Control 2020, 8, 251. [Google Scholar] [CrossRef]

- Luan, Y.; Zhang, W.; Zhao, Y.; Pan, Z.; Niu, Z.; Zeng, K.; Chen, X.; Mohammad, L.N. Mechanical Property Evaluation for Steel Slag in Asphalt Mixture with Different Skeleton Structures Using Modified Marshall Mix Design Methodology. J. Mater. Civ. Eng. 2022, 34, 04021382. [Google Scholar] [CrossRef]

- Venkatachalam, S.; Nayak, S.G.; Labde, J.V.; Gharal, P.R.; Rao, K.; Kelkar, A.K.; Venkatachalam, S.; Nayak, S.G.; Labde, J.V.; Gharal, P.R.; et al. Degradation and Recyclability of Poly (Ethylene Terephthalate). In Polyester; Saleh, H., Ed.; IntechOpen: London, UK, 2012. [Google Scholar] [CrossRef]

- Di Lorenzo, M.L. Crystallization of Poly(Ethylene Terephthalate): A Review. Polymers 2024, 16, 1975. [Google Scholar] [CrossRef] [PubMed]

- Ali, T.; Iqbal, N.; Ali, M. Sustainability Assessment of Bitumen with Polyethylene as Polymer. IOSR J. Mech. Civ. Eng. 2013, 10, 1–6. [Google Scholar] [CrossRef]

- Kalantar, Z.N.; Karim, M.R.; Mahrez, A. A Review of Using Waste and Virgin Polymer in Pavement. Constr. Build. Mater. 2012, 33, 55–62. [Google Scholar] [CrossRef]

- Al-Haydari, I.S.; Al-Haidari, H.S. Mechanical Properties of Polyethylene Terephthalate-Modified Pavement Mixture. IOP Conf. Ser. Mater. Sci. Eng. 2020, 870, 012073. [Google Scholar] [CrossRef]

- Wu, H.; Ji, X.; Song, W.; Deng, Z.; Zhan, Y.; Zou, X.; Li, Q.; He, F. Multi-Scale Analysis on Fracture Behaviors of Asphalt Mixture Considering Moisture Damage. Constr. Build. Mater. 2024, 416, 135234. [Google Scholar] [CrossRef]

- Kim, S.; Coree, B.J. Evaluation of Hot Mix Asphalt Moisture Sensitivity Using the Nottingham Asphalt Test Equipment; Iowa State University, Center for Transportation Research and Education: Ames, IA, USA, 2005. [Google Scholar]

- Júnior, J.L.O.L.; De Albuquerque Lima Babadopulos, L.F.; Soares, J.B. Influence of Aggregate–Binder Adhesion on Fatigue Life of Asphalt Mixtures. J. Test. Eval. 2020, 48, 150–160. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, Z.; Wang, R. Performance Evaluation of Asphalt Concrete Incorporating Steel Slag Powder as Filler under the Combined Damage of Temperature and Moisture. Sustainability 2023, 15, 14653. [Google Scholar] [CrossRef]

- Xiao, R.; Shen, Z.; Polaczyk, P.; Huang, B. Thermodynamic Properties of Aggregate Coated by Different Types of Waste Plastic: Adhesion and Moisture Resistance of Asphalt-Aggregate Systems. J. Mater. Civ. Eng. 2023, 35, 04023261. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, H.; Chen, J.; Cui, P. Adhesive and Cohesive Cracking Analysis of Asphalt Mastics in Contact with Steel Substrates Using an Energy-Based Crack Initiation Criterion. Sustainability 2023, 15, 4415. [Google Scholar] [CrossRef]

- Breakah, T.M.; Williams, R.C. Stochastic Finite Element Analysis of Moisture Damage in Hot Mix Asphalt. Mater. Struct. Constr. 2015, 48, 93–106. [Google Scholar] [CrossRef]

- Sun, L. Structural Behavior of Asphalt Pavements; ScienceDirect: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Movilla-Quesada, D.; Raposeiras, A.C.; Guíñez, E.; Frechilla-Alonso, A. A Comparative Study of the Effect of Moisture Susceptibility on Polyethylene Terephthalate-Modified Asphalt Mixes under Different Regulatory Procedures. Sustainability 2023, 15, 14519. [Google Scholar] [CrossRef]

- Agha, N.; Hussain, A.; Ali, A.S.; Qiu, Y. Performance Evaluation of Hot Mix Asphalt (HMA) Containing Polyethylene Terephthalate (PET) Using Wet and Dry Mixing Techniques. Polymers 2023, 15, 1211. [Google Scholar] [CrossRef] [PubMed]

| Property | Specification | Ref. | Unit | Result | Requirement | |

|---|---|---|---|---|---|---|

| Slag | Stone | |||||

| Coarse Aggregate: | ||||||

| Specific Gravity | ASTM C127 | [43] | g/cm3 | 2.66 | 2.62 | >2.5 |

| Water Absorption | ASTM C127 | [43] | % | 2.20 | 0.79 | <3 |

| Aggregate Impact Value (AIV) | BS 812–112 | [44] | % | 44 | 28 | <30 |

| Aggregated Crushing Value (ACV) | BS 812–110 | [45] | % | 46 | 20 | <30 |

| Fine Aggregate: | ||||||

| Specific Gravity | ASTM C128 | [46] | g/cm3 | 2.99 | 2.69 | >2.5 |

| Water Absorption | ASTM C128 | [46] | % | 0.89 | 1.53 | <2 |

| Mineral Finer: | ||||||

| Specific Gravity | ASTM D854 | [47] | g/cm3 | – | 2.75 | >2.5 |

| Water Absorption | ASTM D854 | [47] | % | – | 2.41 | – |

| Sieve Size | Opening | Gradation Adopted | p = 0.45 Power Gradation | RHD Specifications | |

|---|---|---|---|---|---|

| Lower Limit | Upper Limit | ||||

| mm | % Passing | % Passing | % Passing | % Passing | |

| 1″ | 25.0 | 100 | 100 | 100 | 100 |

| 3/4″ | 19.0 | 96 | 90 | 90 | 100 |

| 1/2″ | 12.5 | 85 | 73 | 65 | 90 |

| 3/8″ | 9.5 | 76 | 66 | 55 | 82 |

| #4 | 4.75 | 42 | 48 | 35 | 57 |

| #8 | 2.36 | 26 | 35 | 20 | 40 |

| #16 | 1.18 | 18 | 26 | 15 | 33 |

| #30 | 0.60 | 13 | 19 | 10 | 26 |

| #50 | 0.30 | 9.1 | 14 | 6 | 20 |

| #100 | 0.15 | 7 | 10 | 5 | 13 |

| #200 | 0.075 | 5 | 7 | 3 | 7 |

| Sample Designation | Sample Description | Unit | AIV BS-812 (1975) | ACV BS-812 (1975) |

|---|---|---|---|---|

| S0 | 100% Stone | % | 18 | 20 |

| S10 | 90% Stone + 10% Slag | % | 21 | 23 |

| S20 | 80% Stone + 20% Slag | % | 23 | 26 |

| S30 | 70% Stone + 30% Slag | % | 25 | 28 |

| S100 | 100% Slag | % | 44 | 46 |

| Designation | OTBC | OBC | Air Void | Stability | Flow | Stability Index | Comment [66] |

|---|---|---|---|---|---|---|---|

| (%) | (%) | (%) | (kN) | (0.25 mm) | |||

| S0_P0 | 4.93 | 4.93 | 6.85 | 16.62 | 12.77 | 5.21 | Okay |

| S10_P0 | 5.17 | 5.17 | 6.74 | 17.55 | 14.85 | 4.73 | Okay |

| S10_P5 | 5.12 | 4.86 | 7.11 | 17.13 | 15.21 | 4.50 | Okay |

| S10_P10 | 5.20 | 4.68 | 6.99 | 18.91 | 15.65 | 4.83 | Okay |

| S10_P15 | 5.34 | 4.54 | 7.28 | 17.63 | 17.85 | 3.95 | Flow Considered (MS-2) |

| S10_P20 | 5.52 | 4.41 | 7.43 | 17.64 | 17.53 | 4.03 | Flow Considered (MS-2) |

| S20_P0 | 5.36 | 5.36 | 7.43 | 20.45 | 15.96 | 5.13 | Okay |

| S20_P5 | 5.37 | 5.10 | 7.39 | 20.62 | 15.66 | 5.27 | Okay |

| S20_P10 | 5.43 | 4.89 | 6.87 | 20.50 | 15.88 | 5.16 | Okay |

| S20_P15 | 5.67 | 4.82 | 6.57 | 17.03 | 16.31 | 4.18 | Flow Considered (MS-2) |

| S20_P20 | 5.59 | 4.47 | 7.28 | 19.59 | 18.53 | 4.23 | Flow Considered (MS-2) |

| S30_P0 | 5.53 | 5.53 | 7.48 | 20.45 | 16.02 | 5.11 | Flow Considered (MS-2) |

| S30_P5 | 5.53 | 5.25 | 6.62 | 21.57 | 16.07 | 5.37 | Flow Considered (MS-2) |

| S30_P10 | 5.59 | 5.03 | 7.18 | 20.38 | 16.31 | 5.00 | Flow Considered (MS-2) |

| S30_P15 | 5.65 | 4.80 | 6.77 | 19.90 | 15.98 | 4.98 | Okay |

| S30_P20 | 5.86 | 4.69 | 7.34 | 14.67 | 19.81 | 2.96 | Flow Considered (MS-2) |

| Designation | ITS | Tensile Strain | TSR | Comment | ||

|---|---|---|---|---|---|---|

| Unconditioned | Conditioned | Unconditioned | Conditioned | |||

| (kN/m2) | (kN/m2) | (kN/m2) | (kN/m2) | |||

| S0_P0 | 568.97 | 482.68 | 1.40 | 0.91 | 0.85 | Accepted |

| S10_P0 | 587.52 | 492.29 | 1.35 | 0.78 | 0.84 | Accepted |

| S10_P5 | 639.82 | 531.07 | 1.40 | 0.90 | 0.83 | Accepted |

| S10_P10 | 612.89 | 538.79 | 1.19 | 0.72 | 0.88 | Accepted |

| S10_P15 | 617.81 | 509.07 | 1.25 | 0.73 | 0.82 | Accepted |

| S10_P20 | 641.21 | 491.88 | 1.24 | 0.76 | 0.77 | Accepted |

| S20_P0 | 612.69 | 544.20 | 1.11 | 0.81 | 0.89 | Accepted |

| S20_P5 | 694.09 | 505.55 | 1.21 | 0.51 | 0.73 | Accepted |

| S20_P10 | 636.16 | 612.19 | 0.99 | 0.72 | 0.96 | Accepted |

| S20_P15 | 670.21 | 546.24 | 1.24 | 0.81 | 0.82 | Accepted |

| S20_P20 | 649.99 | 569.95 | 0.94 | 0.75 | 0.88 | Accepted |

| S30_P0 | 607.89 | 494.13 | 1.06 | 0.95 | 0.81 | Accepted |

| S30_P5 | 672.77 | 532.21 | 1.06 | 0.78 | 0.79 | Accepted |

| S30_P10 | 652.17 | 592.25 | 1.09 | 0.84 | 0.91 | Accepted |

| S30_P15 | 649.13 | 595.51 | 1.04 | 0.69 | 0.92 | Accepted |

| S30_P20 | 700.80 | 561.57 | 1.12 | 0.52 | 0.80 | Accepted |

| Coefficient of p-Value and Standard Error | ||||||||

|---|---|---|---|---|---|---|---|---|

| SS | PET | OTBC | Constant | SE | R2 | RMSE | MAPE | MAE |

| Stability, S = 0.292SS + 0.066P − 10.3TB + 68.61 | (4) | |||||||

| 0.0378 | 0.5908 | 0.1369 | 0.0525 | 1.566 | 0.47 | 0.687 | 7.49% | 1.425 |

| 0.1250 | 0.1200 | 6.4610 | 31.8930 | |||||

| Stability Index, SI = 0.073SS − 0.009P − 3.41TB + 21.89 | (5) | |||||||

| 0.0516 | 0.7813 | 0.0745 | 0.0259 | 0.432 | 0.66 | 0.812 | 15.85% | 0.672 |

| 0.0338 | 0.0323 | 1.7456 | 8.6165 | |||||

| TSR = 0.008SS + 0.006P − 0.387TB + 2.75 | (6) | |||||||

| 0.1454 | 0.1991 | 0.1509 | 0.0479 | 0.061 | 0.17 | 0.413 | 7.64% | 0.064 |

| 0.0049 | 0.0047 | 0.2525 | 1.2462 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zinnurain, M.; Kawsar, M.K.H.; Rahman, M.M.; Islam, M.K.; Arifuzzaman, M.; Parvez, M.A. Performance Evaluation of Asphalt Concrete Incorporating Polyethylene Terephthalate-Coated Steel Slag Using Marshall Stability, Indirect Tensile Strength, and Moisture Susceptibility Tests. Processes 2025, 13, 2862. https://doi.org/10.3390/pr13092862

Zinnurain M, Kawsar MKH, Rahman MM, Islam MK, Arifuzzaman M, Parvez MA. Performance Evaluation of Asphalt Concrete Incorporating Polyethylene Terephthalate-Coated Steel Slag Using Marshall Stability, Indirect Tensile Strength, and Moisture Susceptibility Tests. Processes. 2025; 13(9):2862. https://doi.org/10.3390/pr13092862

Chicago/Turabian StyleZinnurain, Mahiman, Md. Kamrul Hasan Kawsar, Md. Mizanur Rahman, Md. Kamrul Islam, Md. Arifuzzaman, and Mohammad Anwar Parvez. 2025. "Performance Evaluation of Asphalt Concrete Incorporating Polyethylene Terephthalate-Coated Steel Slag Using Marshall Stability, Indirect Tensile Strength, and Moisture Susceptibility Tests" Processes 13, no. 9: 2862. https://doi.org/10.3390/pr13092862

APA StyleZinnurain, M., Kawsar, M. K. H., Rahman, M. M., Islam, M. K., Arifuzzaman, M., & Parvez, M. A. (2025). Performance Evaluation of Asphalt Concrete Incorporating Polyethylene Terephthalate-Coated Steel Slag Using Marshall Stability, Indirect Tensile Strength, and Moisture Susceptibility Tests. Processes, 13(9), 2862. https://doi.org/10.3390/pr13092862