Optimization of Low-Carbon Drilling Fluid Systems and Wellbore Stability Control for Shaximiao Formation in Sichuan Basin with a ‘Dual Carbon’ Background

Abstract

1. Introduction

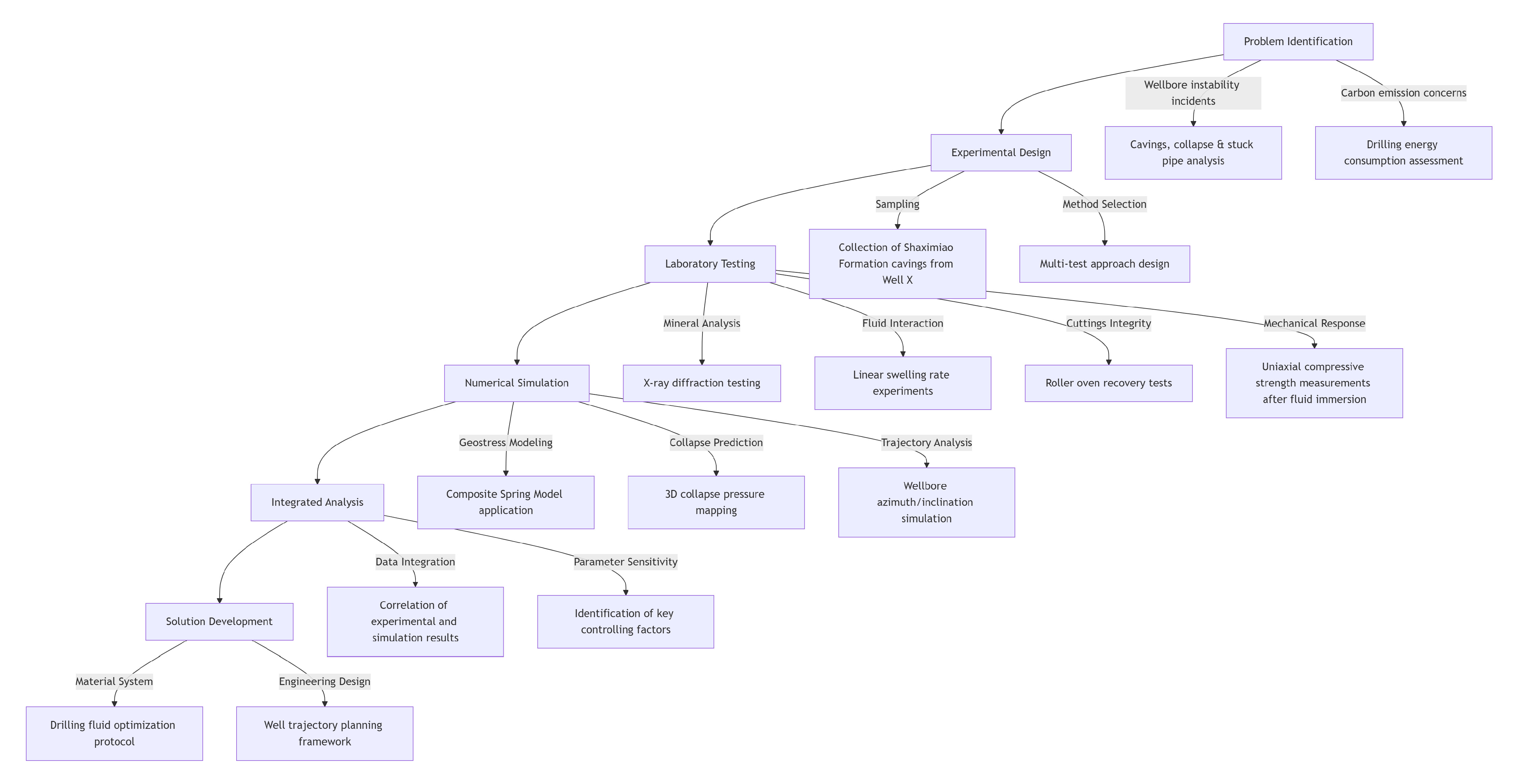

2. Methods and Research Procedure

3. Study on Water–Rock Interaction Mechanisms

3.1. Mineral Composition Analysis

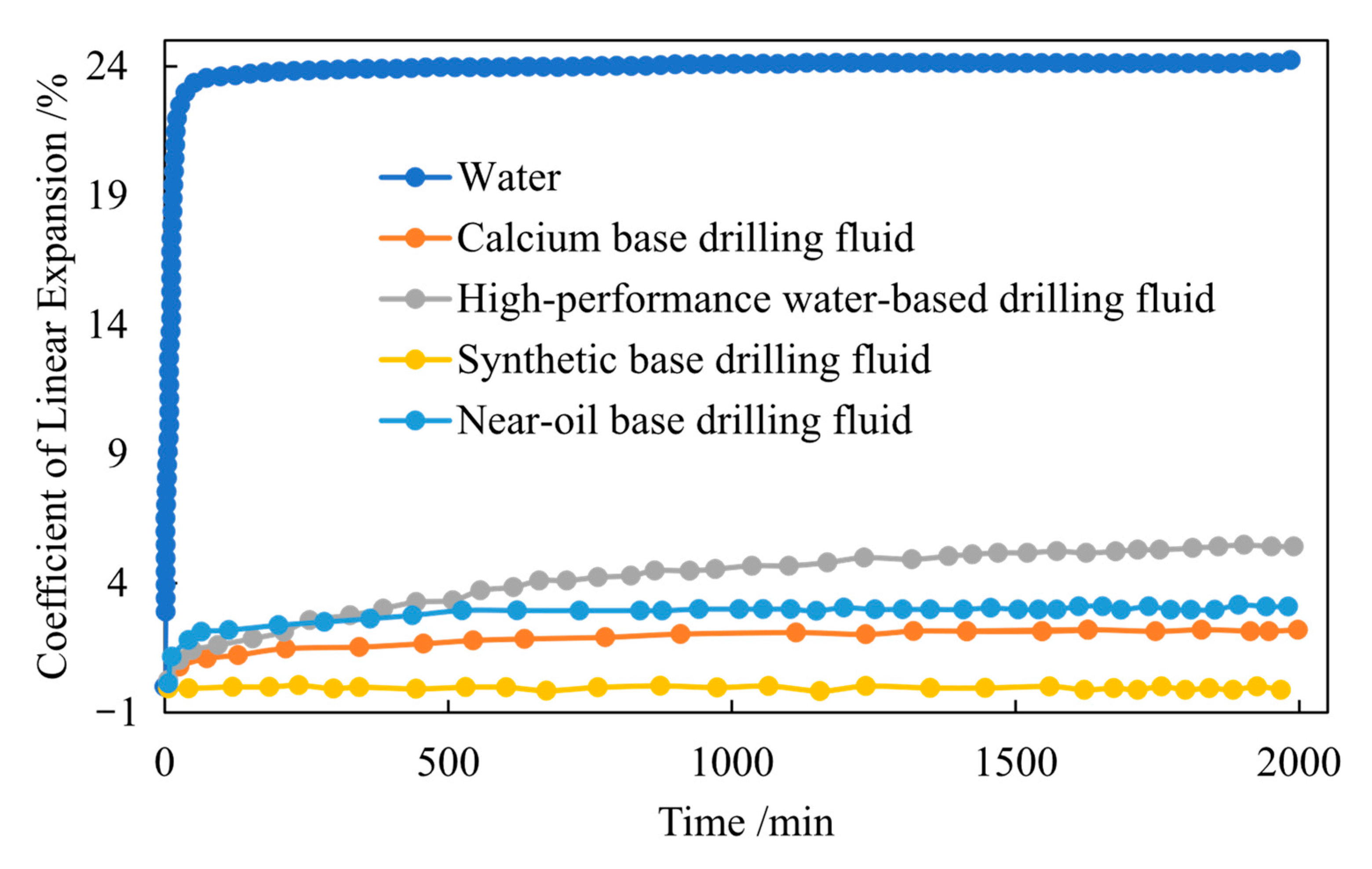

3.2. Linear Swelling Rate Test

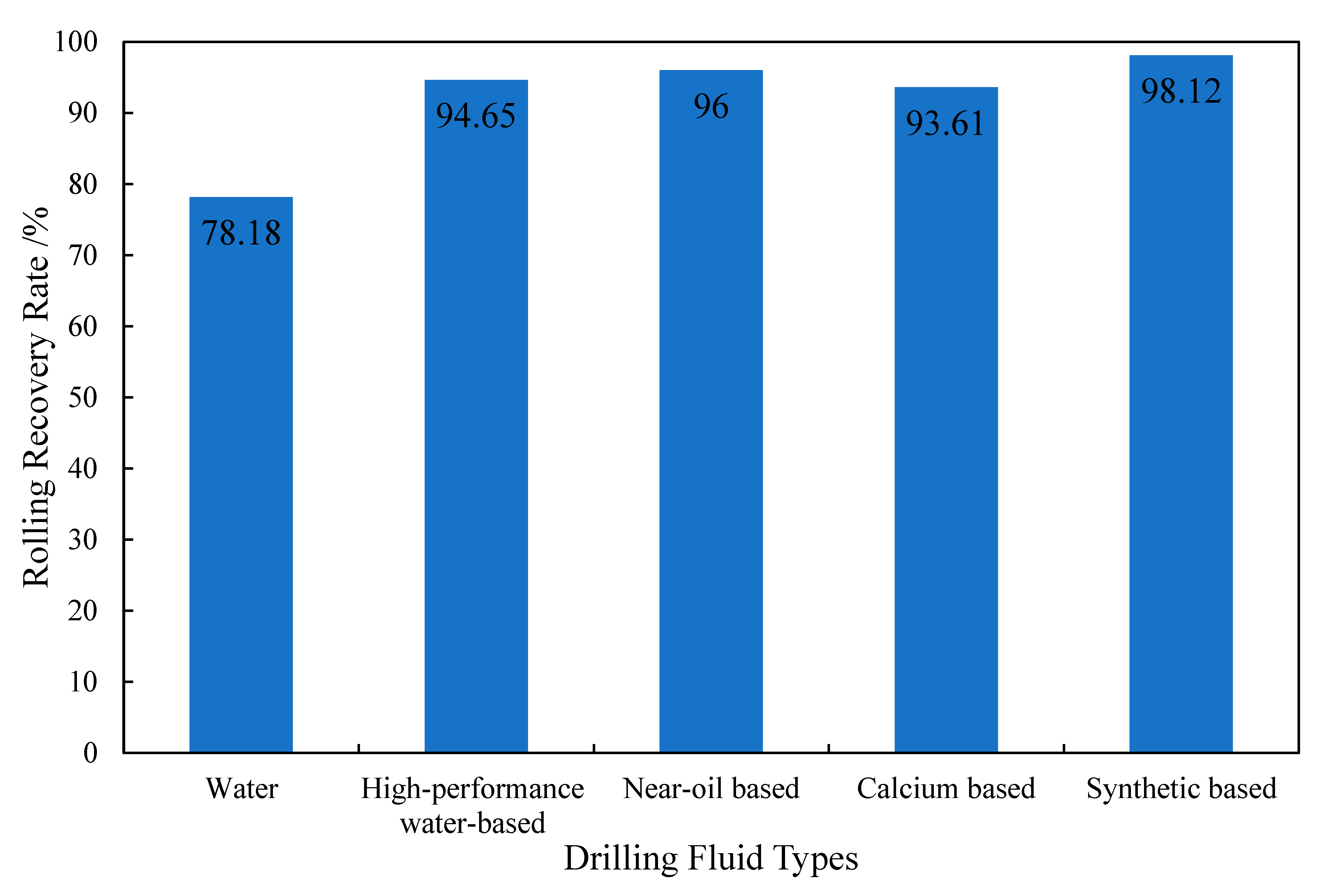

3.3. Roller Oven Recovery Test

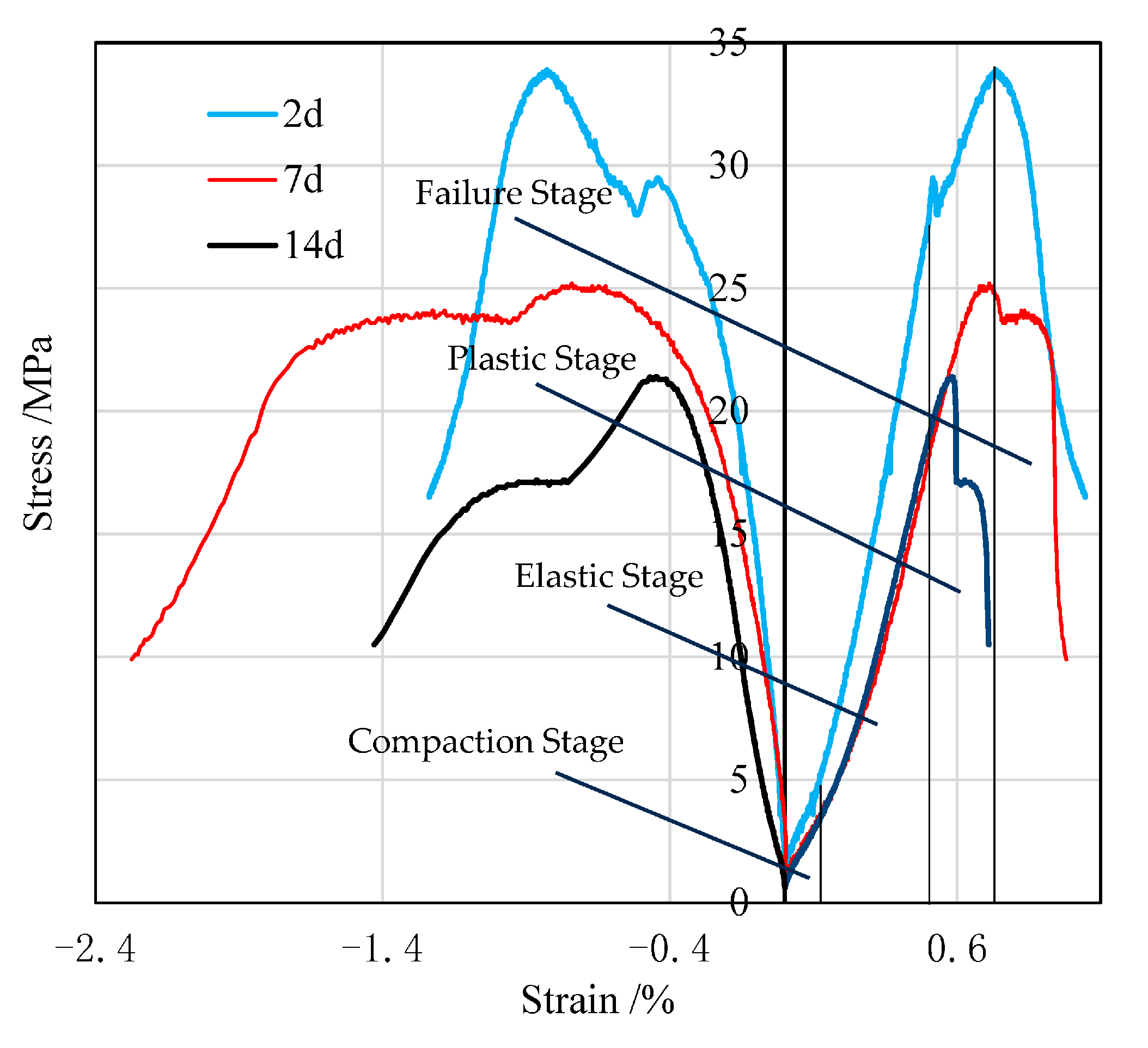

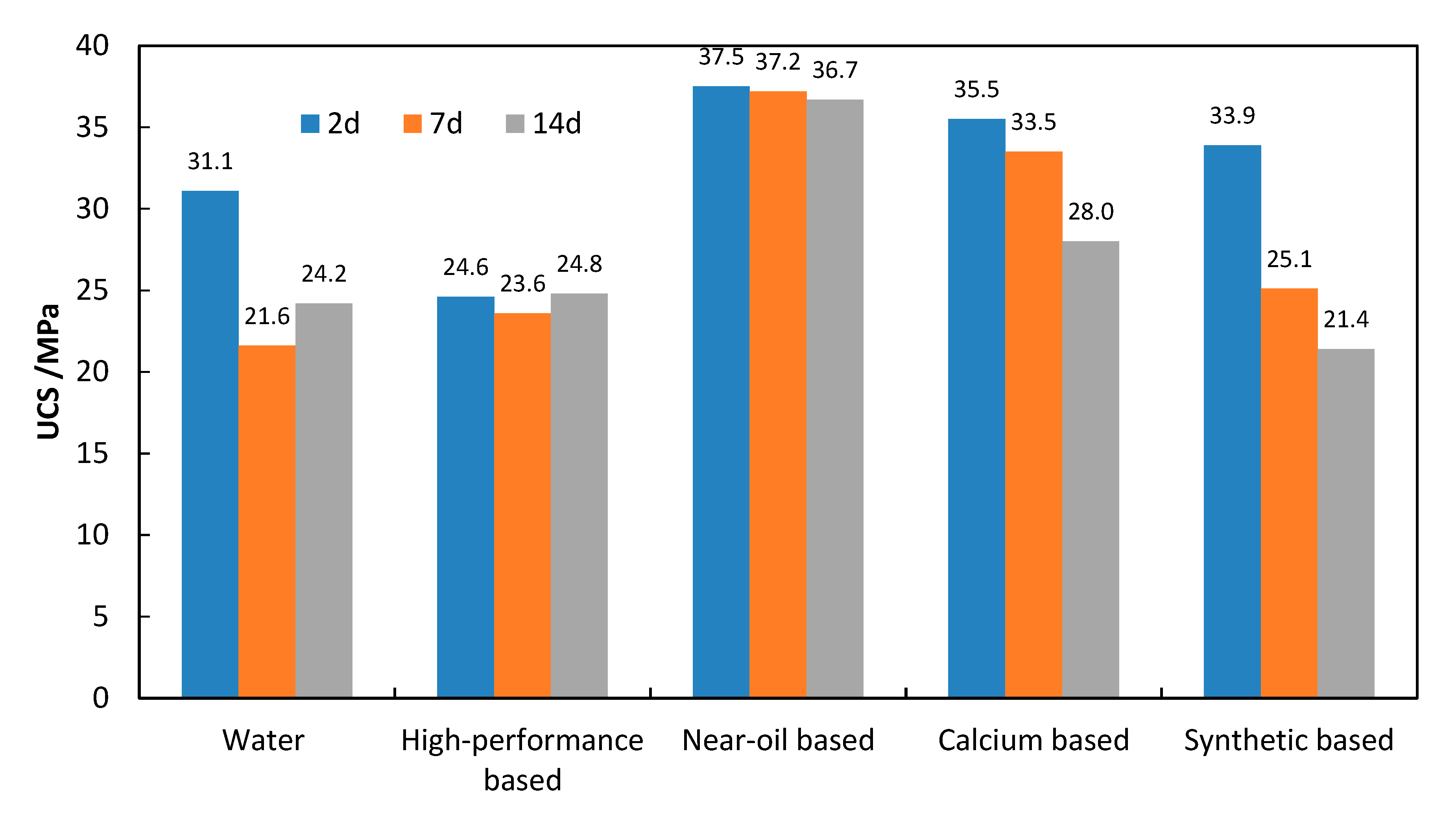

4. Strength Degradation Under Fluid–Rock Interactions

5. Wellbore Stability Study

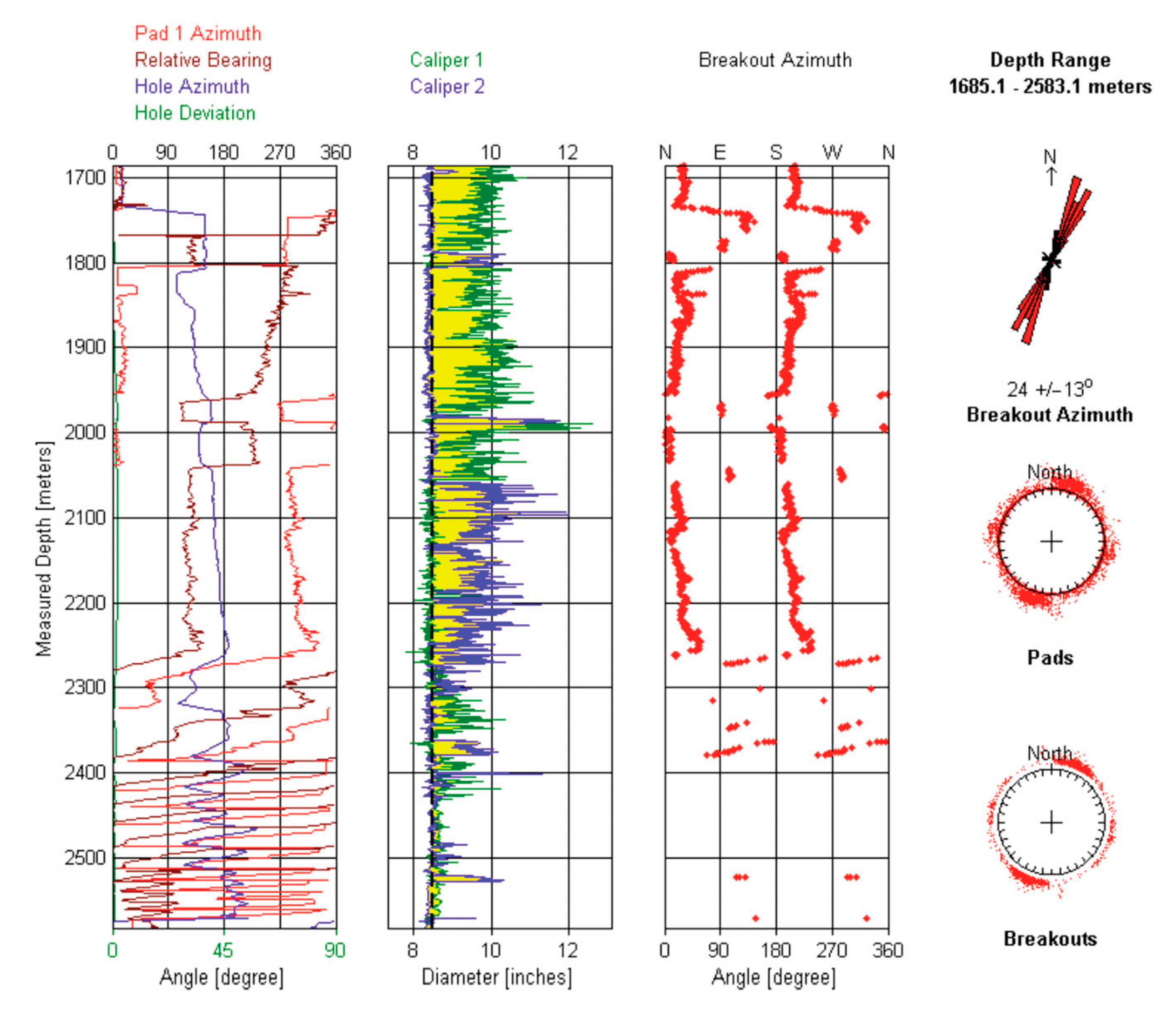

5.1. In Situ Stress Distribution

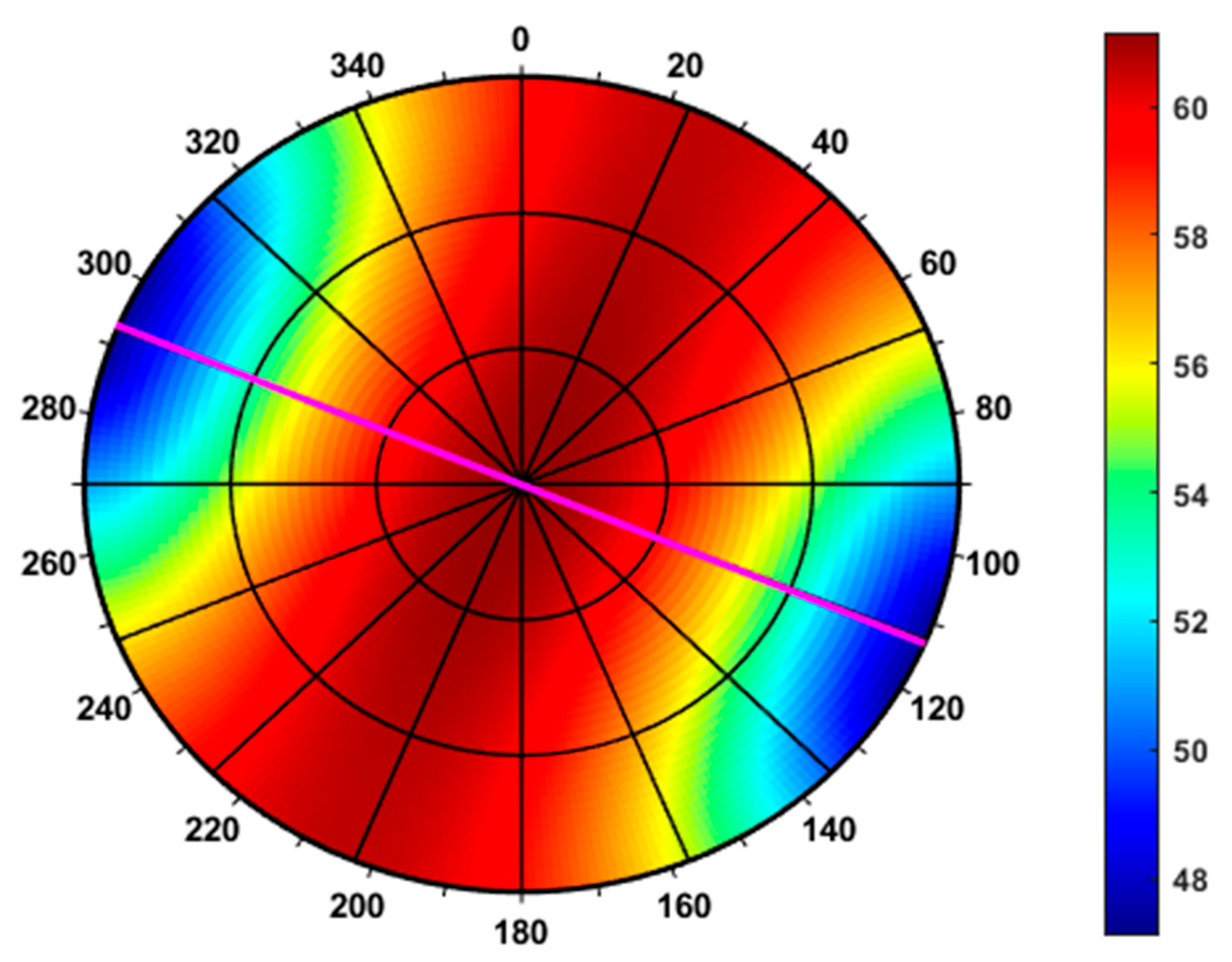

5.2. Collapse Pressure Distribution Characteristics

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Adham, A. Geomechanics Model for Wellbore Stability Analysis in Field X North Sumatra Basin. Master’s Thesis, Universiti Teknologi Malaysia, Johor Bahru, Malaysia, 2016. [Google Scholar]

- Al-Ajmi, A.M.; Al-Harthy, M.H. Probabilistic wellbore collapse analysis. J. Pet. Sci. Eng. 2010, 74, 171–177. [Google Scholar] [CrossRef]

- Bai, B.; Elgmati, M.; Zhang, H.; Wei, M. Rock characterization of Fayetteville shale gas plays. Fuel 2013, 105, 645–652. [Google Scholar] [CrossRef]

- Chen, F.; Gao, J.; Feng, Y.; Chen, Z.; Zhang, M.; Liu, Y.; Wang, H.; Li, X.; Zhao, P.; Sun, L. Optimizing the Wellbore Trajectory of Directional Wells Considering Wellbore Stability Subjected to the Non-Independence and Uncertainty of Geomechanical Parameters. In Proceedings of the SPE Asia Pacific Unconventional Resources Conference and Exhibition, Brisbane, Australia, 13–15 November 2023; SPE: Richardson, TX, USA, 2023; p. D021S010R003. [Google Scholar]

- Denney, D. Safe operating window: Wellbore stability is more than just fluid density. J. Pet. Technol. 2005, 57, 69–71. [Google Scholar] [CrossRef]

- Fan, Z.; Song, X.; Wang, D.; Ayasrah, M. Poroelastic solutions of a semi-permeable borehole under non-hydrostatic in situ stresses within transversely isotropic media. Int. J. Geomech. 2025, 25, 04024342. [Google Scholar] [CrossRef]

- Gao, R.; Bai, D.; Yu, B.; Tai, Y.; Meng, X.; Zhang, W. Ground fracturing of multi-strata for strong ground pressure control in extra-thick coal seams with hard roofs: Numerical simulation and case study. Eng. Fract. Mech. 2024, 303, 110129. [Google Scholar] [CrossRef]

- Gao, R.; Kuang, T.; Meng, X.; Huo, B. Effects of ground fracturing with horizontal fracture plane on rock breakage characteristics and mine pressure control. Rock Mech. Rock Eng. 2021, 54, 3229–3243. [Google Scholar] [CrossRef]

- Huang, L.; Yu, Y.; Ren, G.L.; Meng, W.B.; Zheng, W.P. Analysis of wellbore instability probability and parameter sensitivity of openhole testing. Oil Drill. Prod. Technol. 2023, 45, 143–150. (In Chinese) [Google Scholar]

- Jin, L.X.; Ding, Y.; Tian, S.C.; Wang, J.; Liu, F.; Zhang, S.; Ma, Y. A formation pressure prediction method for mudstone formations based on liquid-phase sensitivity and loading-unloading mechanism. China Offshore Oil Gas 2024, 36, 167–176. (In Chinese) [Google Scholar]

- Kadyrov, T.; Tutuncu, A.N. Integrated wellbore stability analysis for well trajectory optimization and field development in the West Kazakhstan Field. In Proceedings of the 46th US Rock Mechanics/Geomechanics Symposium, Chicago, IL, USA, 24–27 June 2012; American Rock Mechanics Association: Chicago, IL, USA, 2012; pp. 1–10. [Google Scholar]

- Li, J. Study on Main Controlling Factors and Prediction Model of Borehole Instability in Shunbei Carbonate Formation Based on Multiple Linear Regression Method. Master’s Thesis, China University of Petroleum, Beijing, China, 2022. (In Chinese). [Google Scholar] [CrossRef]

- Li, J.; Liu, C.; Liu, H.M.; Wang, S.; Zhang, Y.; Zhao, X. In-situ stress distribution and influencing factors in complex fault structure areas. J. China Univ. Min. Technol. 2021, 50, 123–137. (In Chinese) [Google Scholar] [CrossRef]

- Ling, X.Z.; Tang, L. Engineering Rock Mass Mechanics; Harbin Institute of Technology Press: Harbin, China, 2020. (In Chinese) [Google Scholar]

- Liu, S.; Ma, W.; Huang, W.; Zeng, X.; Zhang, C. Characteristics of the shale gas reservoir rocks in the Lower Silurian Longmaxi Formation, East Sichuan basin, China. Acta Petrol. Sin. 2011, 27, 2239–2252. [Google Scholar] [CrossRef]

- Long, Z.L.; Zhong, J.M.; Ding, J.; Chen, Y.; Liu, W.; Wang, K. Study on borehole stability of small borehole in deep shale gas horizontal well in South Yongchuan area. Nat. Gas Technol. Econ. 2023, 17, 22–29. (In Chinese) [Google Scholar] [CrossRef]

- Lu, Y.H.; Jin, Y.; Xia, Y.; Zhu, J.Y. Dynamic analysis model of borehole instability in ultra-deep hard rock formations: Effects of intrinsic frequency and high stress. Mech. Eng. 2023, 45, 1033–1043. (In Chinese) [Google Scholar]

- Ma, T.; Qiu, Y.; Zhang, Y.; Liu, Y. Numerical simulation of progressive sand production of open-hole completion borehole in heterogeneous igneous formation. Int. J. Rock Mech. Min. Sci. 2022, 150, 105030. [Google Scholar] [CrossRef]

- Ostadhassan, M.; Zeng, Z.; Jabbari, H. Using advanced acoustic to determine stress state around wellbore. In Proceedings of the 45th US Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 26–29 June 2011; OnePetro: San Francisco, CA, USA, 2011; pp. 1–10. [Google Scholar]

- Saeidi, O.; Dalkhani, A.R. Development of a Geomechanics Program for Wellbore Stability Analysis. Int. J. Geomech. 2023, 23, 04023118. [Google Scholar] [CrossRef]

- Song, X.Z.; Guo, Y.; Xiang, D.M.; Ju, P.F.; Tan, Q.; Liu, W. Multi-field coupling analysis of borehole instability mechanism of water-based drilling fluid in Hutubi Anticline. Xinjiang Oil Gas 2023, 19, 1–9. (In Chinese) [Google Scholar] [CrossRef]

- Udegbunam, J.E.; Fjelde, K.K.; Arild, Ø.; Ford, E.; Lohne, H.P. Uncertainty-Based Approach for Predicting the Operating Window in UBO Well Design. SPE Drill. Complet. 2013, 28, 326–337. [Google Scholar] [CrossRef]

- Wang, Y.P.; Liu, X.J.; Liang, L.X. Bedding effect on mechanical properties and brittleness prediction of shale. Lithol. Reserv. 2018, 30, 149–160. (In Chinese) [Google Scholar]

- Wang, Z.F.; Meng, J.C.; Zhang, Z.B. Application of acoustic interval transit time logging in rock drillability prediction. Petrol. Geol. Oilfield Dev. Daqing 2006, 25, 94–96. (In Chinese) [Google Scholar]

- Xie, H.; Lu, J.; Li, C.; Li, M.; Gao, M. Experimental study on the mechanical and failure behaviors of deep rock subjected to true triaxial stress: A review. Int. J. Min. Sci. Technol. 2022, 32, 1099–1113. [Google Scholar] [CrossRef]

- Yang, H.J.; Guo, S.S.; Gao, Y.D.; Li, J.; Wang, X.; Zhang, L.; Liu, Y.; Chen, Z.; Wu, Q.; Zhao, K. Reduce Drilling Risk in HPHT Gas Field Using Innovative Look-Ahead Technology—A Case Study from South China Sea. In Proceedings of the International Petroleum Technology Conference, Dhahran, Saudi Arabia, 13–15 January 2020; OnePetro: Dhahran, Saudi Arabia, 2020; pp. 1–15. [Google Scholar]

- Yang, Y.G.; Cai, W.J.; Xing, X.S.; Xing, X.J.; Lin, H. Borehole instability mechanism and countermeasures in fractured formations of Bozhong Block. Sci. Technol. Eng. 2023, 23, 9476–9483. (In Chinese) [Google Scholar]

- Zhang, L.; Xie, T.; Hou, X.X.; Li, Y.; Wang, C. Study on safe drilling cycle of soft mud stone of Minghuazhen Formation in an oilfield in Bohai Sea. Unconv. Oil Gas 2024, 11, 134–139. (In Chinese) [Google Scholar]

- Zhang, M.; Fan, X.; Zhang, Q.; Liu, J.; Li, D. Influence of multi-planes of weakness on unstable zones near wellbore wall in a fractured formation. J. Nat. Gas Sci. Eng. 2021, 93, 104026. [Google Scholar] [CrossRef]

- Zhang, M.; Fan, X.; Zhang, Q.; Liu, J.; Li, D. Parametric sensitivity study of wellbore stability in transversely isotropic medium based on poly-axial strength criteria. J. Pet. Sci. Eng. 2021, 197, 108078. [Google Scholar] [CrossRef]

- Zhang, M.; Li, D.; Liu, J.; Zhang, D.; Zhang, Y.; Cui, K. The modification of Mohr-Coulomb criteria based on shape function and determination method of undetermined parameters. Mech. Mater. 2023, 185, 104772. [Google Scholar] [CrossRef]

- Zhang, M.; Wen, J.; Xu, Z.; Li, D.; Liu, J. Study of borehole stability of volcanic rock formation with the influence of multiple factors. J. Pet. Explor. Prod. Technol. 2024, 14, 3367–3382. [Google Scholar] [CrossRef]

- Zhang, M.M.; Liang, L.X.; Liu, X.J. Analysis of the Influence of Different Rock Shear Failure Criteria Wellbore Collapse Pressure. Chin. J. Rock Mech. Eng. 2017, 36, 3485–3491. (In Chinese) [Google Scholar]

- Zhang, Y.Y.; Wang, T.H.; Gao, Z.L.; Liu, Y.; Chen, J. Study and application of borehole stability in sandstone formation of an offshore oilfield. Petrol. Ind. Technol. 2023, 30, 123–125. (In Chinese) [Google Scholar]

- Zhang, Z.W. Quantitative Risk Assessment of Borehole Instability in High Temperature and High Pressure Wells. Master’s Thesis, Xi’an Shiyou University, Xi’an, China, 2023. (In Chinese). [Google Scholar] [CrossRef]

- Zhi, H.W.; Li, H.J.; Quan, Z.H. Evaluation of borehole stability in horizontal wells of Qiongzhusi Formation shale reservoir in Jingyan area. Sino-Glob. Energy 2024, 29, 62–66. (In Chinese) [Google Scholar]

- Zhang, X.; Li, J. Advancements and challenges of high-speed active flow control: Plasma actuators. Int. J. Heat Mass Transf. 2025, 252, 127481. [Google Scholar] [CrossRef]

- Li, J.; Zhang, X. Active flow control for supersonic aircraft: A novel hybrid synthetic jet actuator. Sens. Actuators A Phys. 2019, 302, 111770. [Google Scholar] [CrossRef]

- Gangrade, R. Quantifying Spatial Geotechnical Uncertainty to Advance the Practice of Risk Assessment and Decision-Making for Tunnel Projects. Ph.D. Thesis, Colorado School of Mines, Golden, CO, USA, 2021. [Google Scholar]

- Yao, Z.; Zhu, Q.; Zhang, Y.; Huang, H.; Luo, M. Minimizing Long-Term Energy Consumption in RIS-Assisted AAV-Enabled MEC Network. IEEE Internet Things J. 2025, 12, 20942–20958. [Google Scholar] [CrossRef]

| Collapsed Depth (m) | Quartz (%) | K-Feldspar (%) | Plagioclase (%) | Calcite (%) | Dolomite (%) | Clay Minerals (%) |

|---|---|---|---|---|---|---|

| 2881.66 m | 42 | 0 | 40 | 0 | 0 | 18 |

| 2892.83 m | 32 | 11 | 40 | 0 | 0 | 13 |

| 2941.76 m | 33 | 0 | 56 | 0 | 0 | 11 |

| 3281.31 m | 30 | 7 | 15 | 0 | 0 | 48 |

| 3285.46 m | 36 | 4 | 13 | 4 | 0 | 43 |

| 3287.65 m | 35 | 4 | 13 | 0 | 14 | 34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, H.; Liu, L.; Zhang, M. Optimization of Low-Carbon Drilling Fluid Systems and Wellbore Stability Control for Shaximiao Formation in Sichuan Basin with a ‘Dual Carbon’ Background. Processes 2025, 13, 2859. https://doi.org/10.3390/pr13092859

Jin H, Liu L, Zhang M. Optimization of Low-Carbon Drilling Fluid Systems and Wellbore Stability Control for Shaximiao Formation in Sichuan Basin with a ‘Dual Carbon’ Background. Processes. 2025; 13(9):2859. https://doi.org/10.3390/pr13092859

Chicago/Turabian StyleJin, Haiyan, Lianwei Liu, and Mingming Zhang. 2025. "Optimization of Low-Carbon Drilling Fluid Systems and Wellbore Stability Control for Shaximiao Formation in Sichuan Basin with a ‘Dual Carbon’ Background" Processes 13, no. 9: 2859. https://doi.org/10.3390/pr13092859

APA StyleJin, H., Liu, L., & Zhang, M. (2025). Optimization of Low-Carbon Drilling Fluid Systems and Wellbore Stability Control for Shaximiao Formation in Sichuan Basin with a ‘Dual Carbon’ Background. Processes, 13(9), 2859. https://doi.org/10.3390/pr13092859