Discrete Element Simulation of Vibration-Assisted Chute to Prevent Blockage of Viscous Materials

Abstract

1. Introduction

2. Numerical Modeling

2.1. Adhesion Force of Viscous Materials

2.2. Material Properties and DEM Parameters

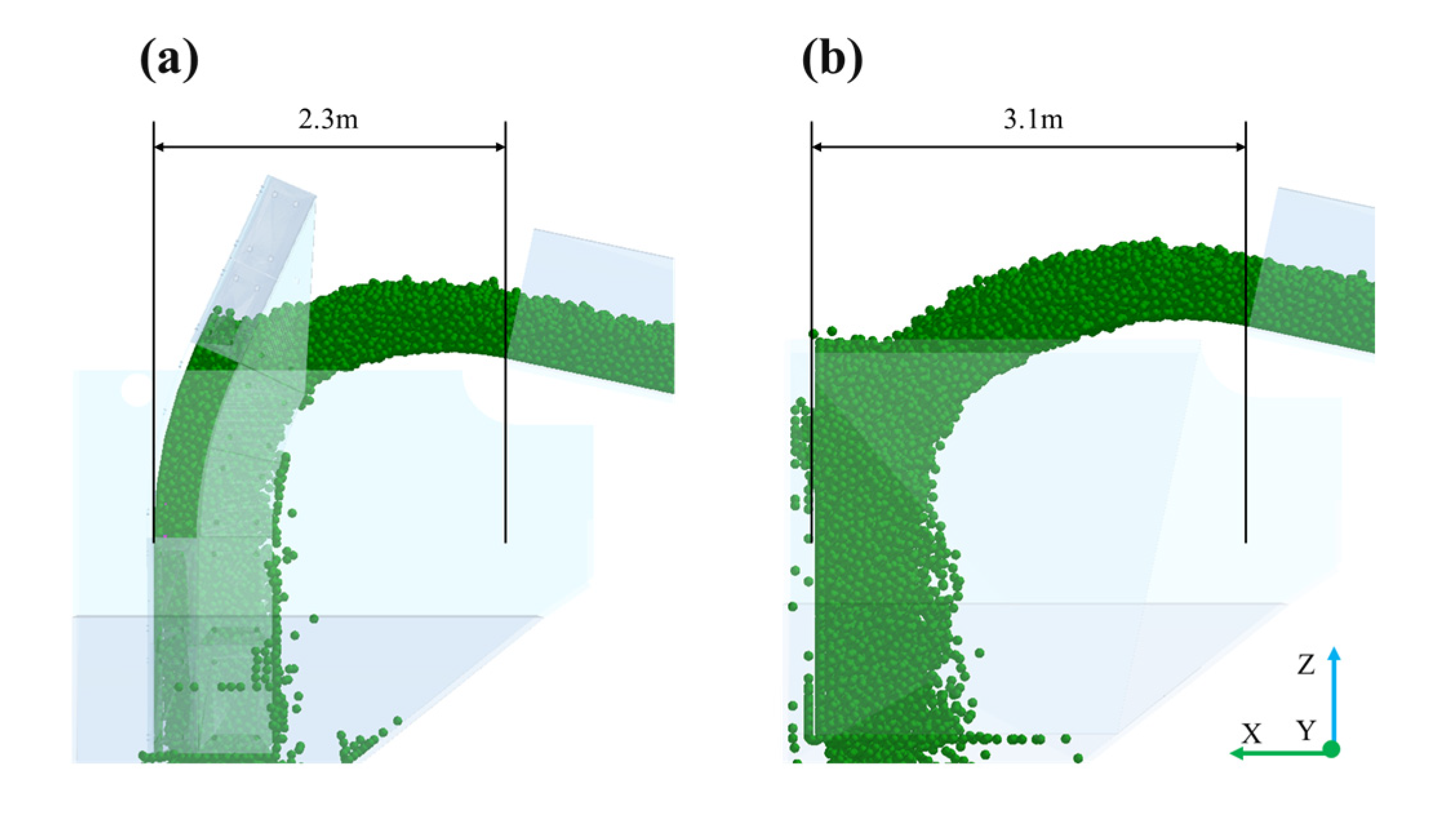

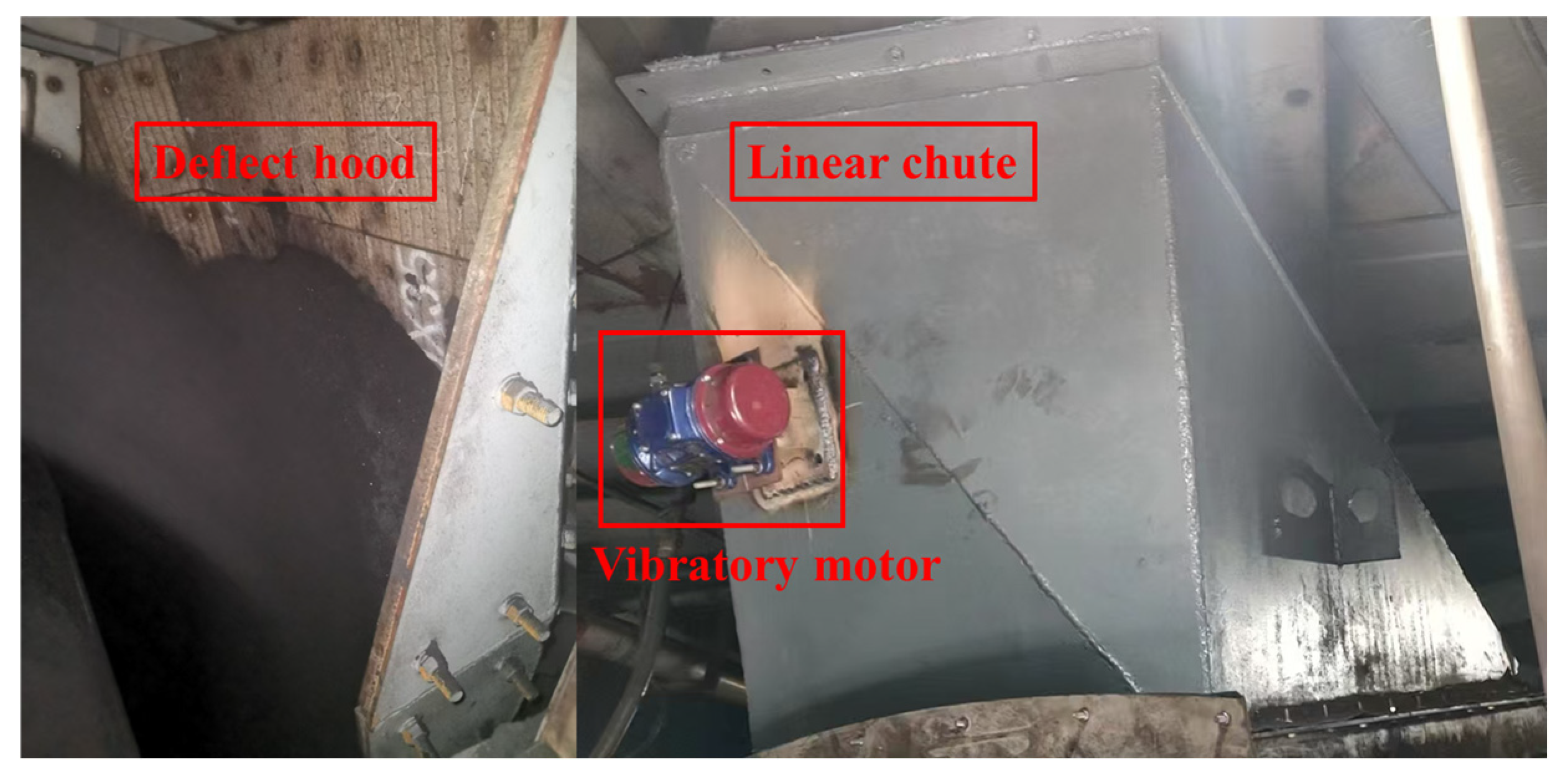

2.3. Transfer System Structures

2.4. Evaluation

3. Results and Discussion

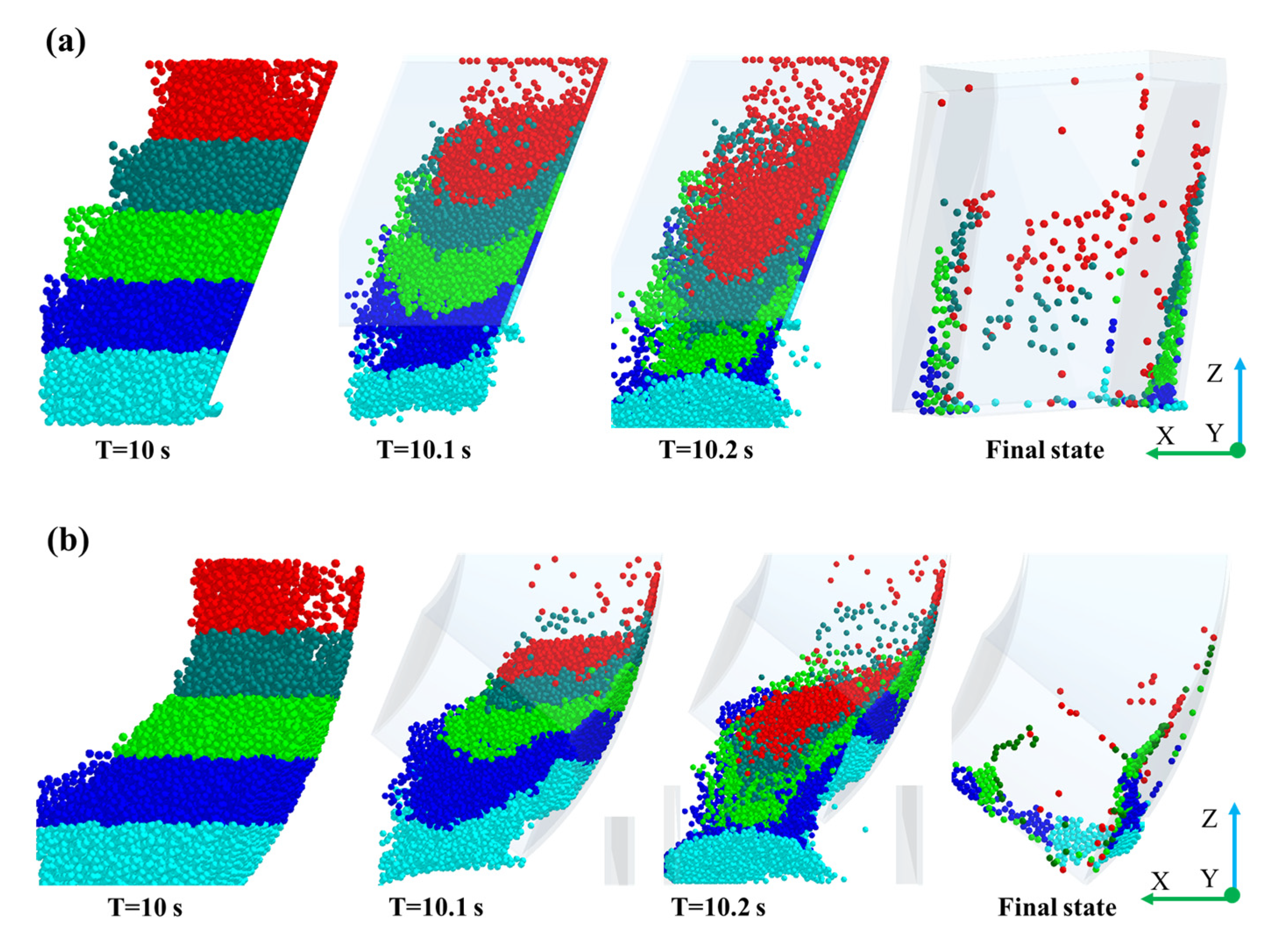

3.1. Influences of Various Structures

3.2. Influence of Vibration Parameters

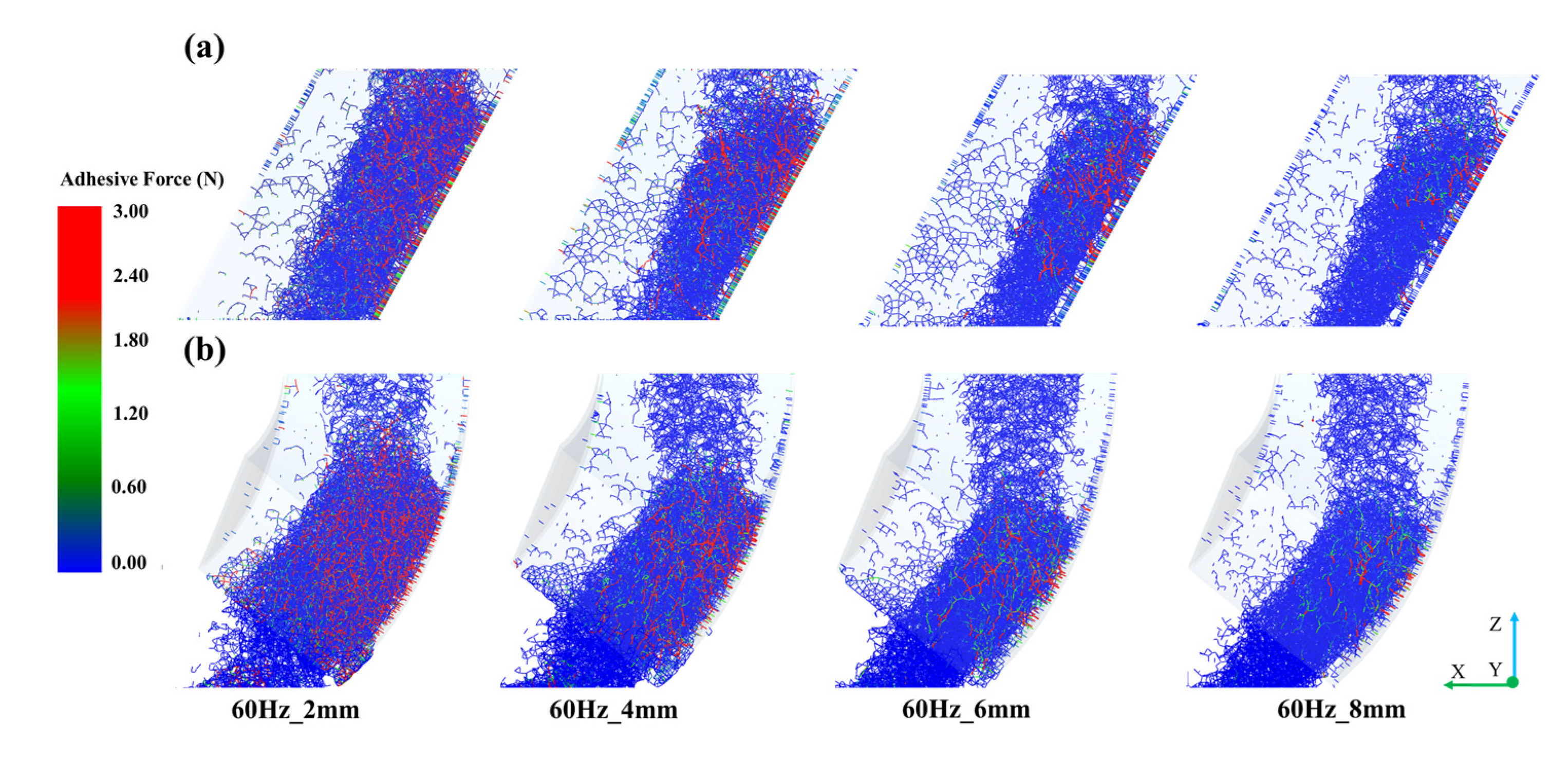

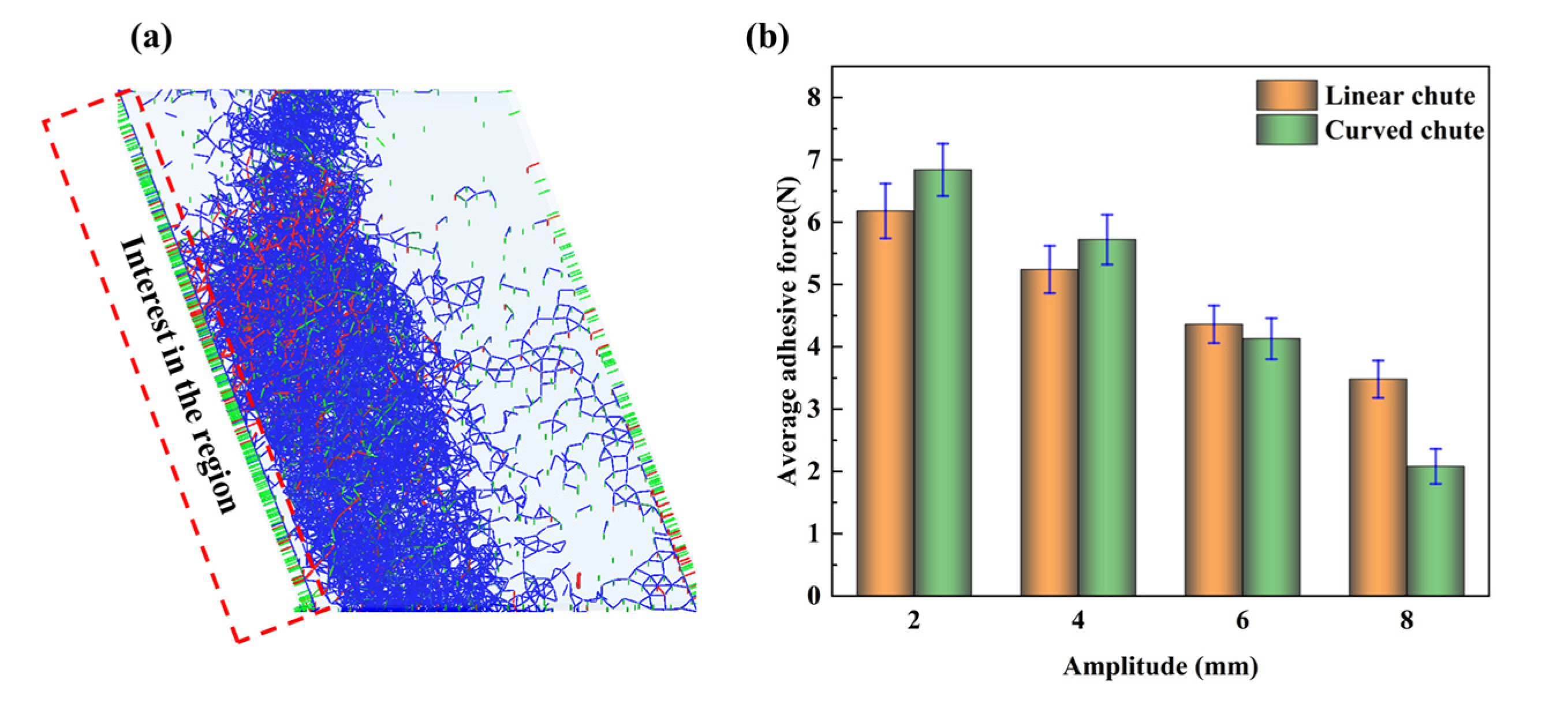

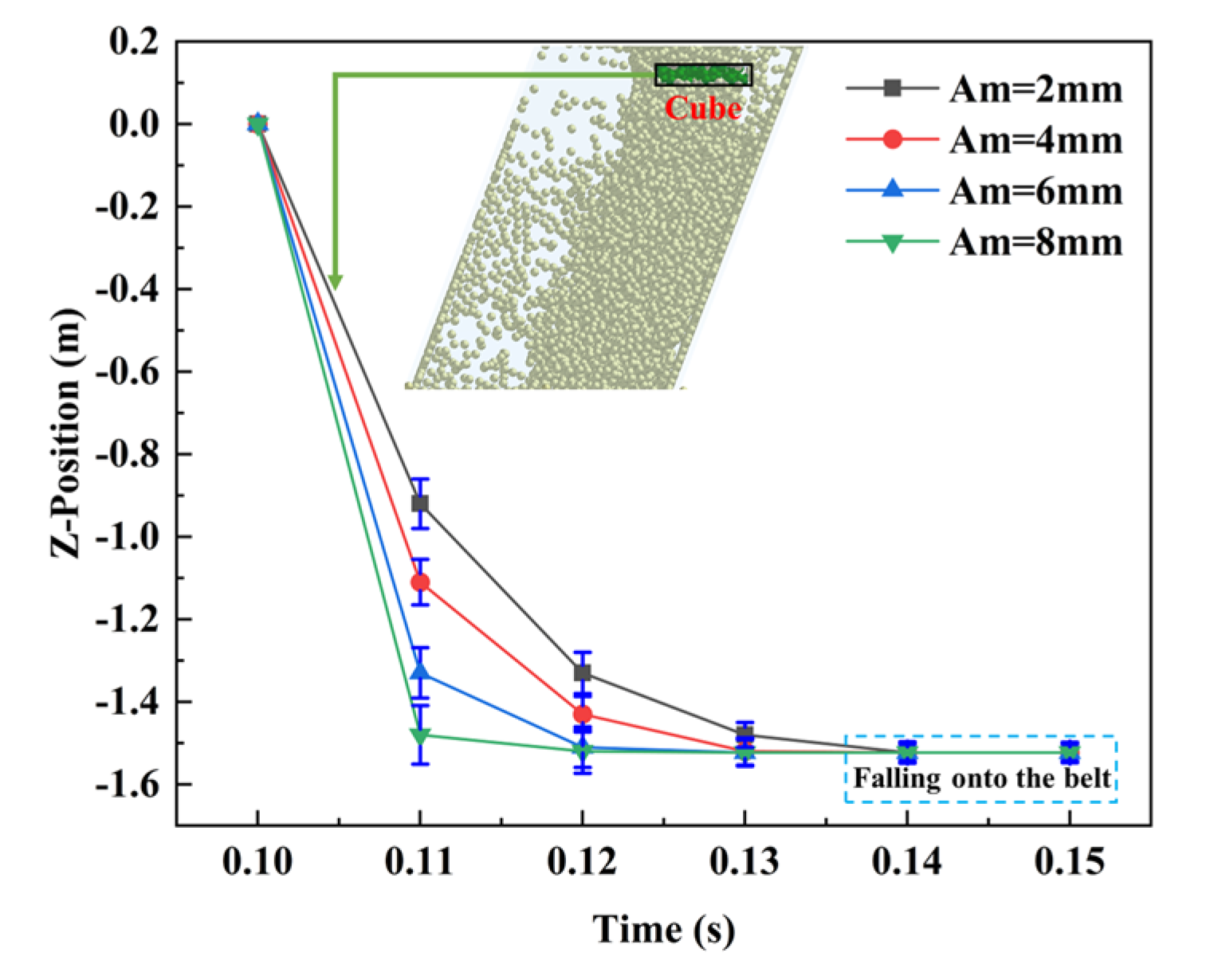

3.2.1. Influence of Vibration Amplitude

3.2.2. Influence of Vibration Frequency

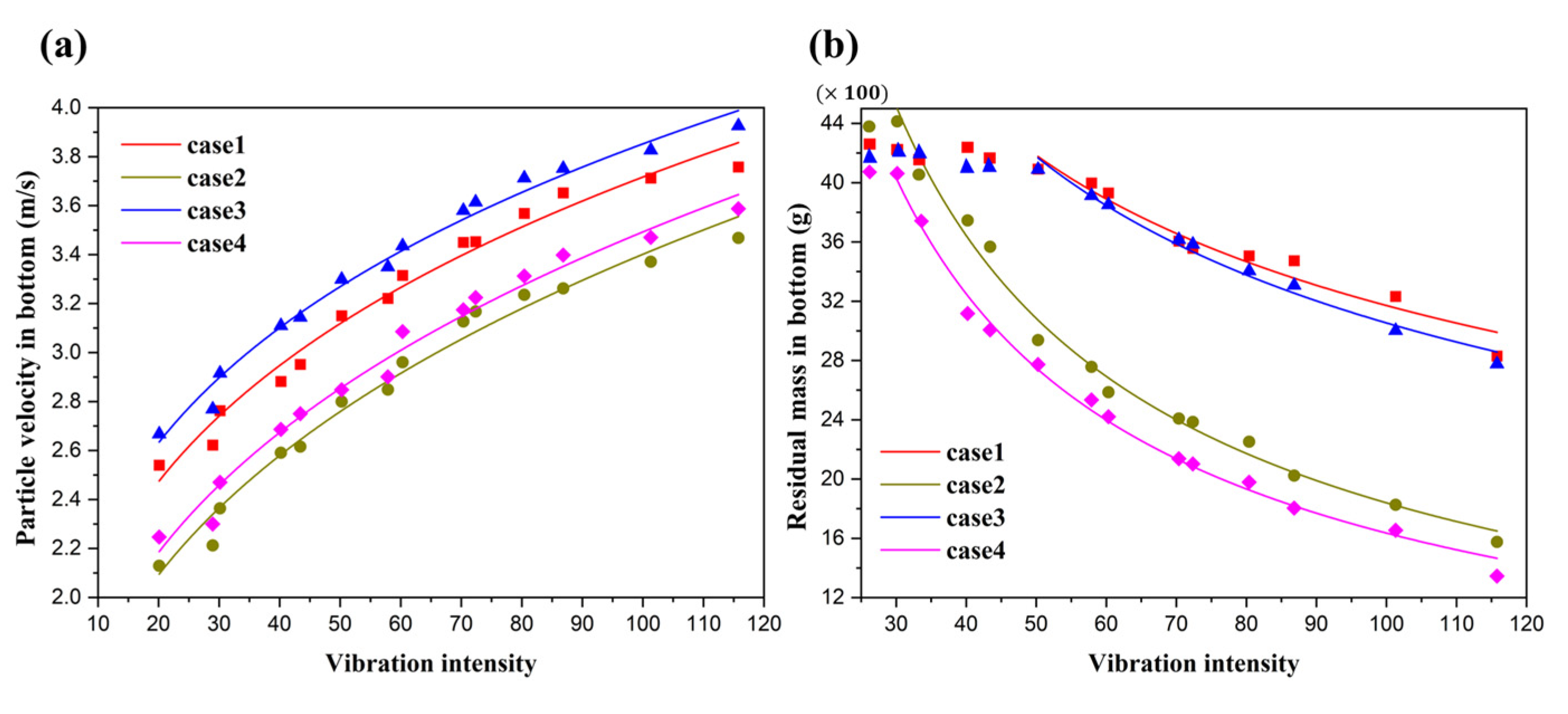

3.3. Optimization of Vibrations and Structures

4. Conclusions

- (1)

- The coals primarily adhered to the upper and chute areas of the transfer system. In the upper area, the adhesive coals tended to stick near the deflector or the surface of the impact plate. In the chute area, the coals primarily adhered to the impact point and the nearby chute wall.

- (2)

- The adhesive force and residual materials’ amount on the impact plate were all slightly lower than those on the deflect hood. The particles’ flowability on the impact plate was slightly superior than that on the deflect hood. For the chute, the particle velocity and amounts of adhered materials in the curved chute were lower than those in the linear chute because the curved chute was more sensitive to vibration.

- (3)

- Both the vibration frequency and amplitude could, to some extent, disrupt the adhesive bonds between the particles and the wall, thereby improving the flowability of the adhered bulk materials. Therefore, increasing the vibration parameters contributed to higher material flowability.

- (4)

- The average particle velocity inside the chute was directly proportional to the positive power of the vibration intensity, while the residual materials’ mass was inversely proportional to the negative power of the vibration intensity. Furthermore, for the curved chute, the flowability and adhered mass were more sensitive to the vibration intensity. The vibration intensity had a critical value; only when the applied vibration parameters exceeded this threshold could the vibration improve the adhesive bulk materials’ flowability. It was found that the critical vibration intensity from cases 1 to 4 was 55, 35, 52, and 30, respectively. Therefore, case 4, namely, “Impact plate & curved chute”, was the best structure. The critical intensity value can be used as a reference for engineers in terms of adhesive bulk materials conveyance.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bortnowski, P.; Kawalec, W.; Król, R.; Ozdoba, M. Types and causes of damage to the conveyor belt—Review, classification and mutual relations. Eng. Fail. Anal. 2022, 140, 106520. [Google Scholar] [CrossRef]

- Bortnowski, P.; Doroszuk, B.; Krol, R.; Marasova, D.; Moravic, M.; Ozdoba, M. Forecasting blockades of conveyor transfer points based on vibrodiagnostics. Measurement 2023, 216, 112884. [Google Scholar] [CrossRef]

- Roberts, A.W. Chute design considerations for feeding and transfer. In Proceedings of the BELTCON 11 International Materials Handling Conference, Randburg, South Africa, 31 July–2 August 2001; Available online: https://login.totalweblite.com/Clients/doublearrow/beltcon%202001/3.chute%20design%20considerations%20for%20feeding%20and%20transfer.pdf (accessed on 12 May 2023).

- Hann, D.; Strazisar, J. Influence of particle size distribution, moisture content, and particle shape on the flow properties of bulk solids. Instrum. Sci. Technol. 2007, 35, 571–584. [Google Scholar] [CrossRef]

- Grima, A.; Fraser, T.; Hastie, D.; Wypych, P. Discrete element modelling: Trouble-shooting and optimisation tool for chute design. In Proceedings of the Beltcon 16 Proceedings, Johannesburg, South Africa, 3–4 August 2011; Available online: https://hdl.handle.net/10779/uow.27694800.v1 (accessed on 10 May 2023).

- Aldrich, J.; Zhang, Y. Minimizing Belt Wear and Damage From Optimized Chute Design. In Proceedings of the SME Annual Meeting Conference, Salt Lake City, UT, USA, 23–26 February 2014; Available online: http://conveyor-dynamics.com/wp-content/uploads/2014/05/2014-SME-Minimizing-Belt-Wear-and-Damage-from-Optimized-Chute-Design-Aldrich-and-Zhang-Rev1-4.pdf (accessed on 10 May 2023).

- Kukreja, K.; Soni, M.K.; Nainegali, M.S.; Mohapatra, B. Development of transfer chute design through discrete element modelling for using refused derived fuel in Indian cement plants. Sustain. Energy Technol. Assess. 2022, 53, 102567. [Google Scholar] [CrossRef]

- Ji, C.Y. Discrete Element Simulation Study on the Flow Behavior of Coal Particles in Transfer Systems. Master’s Thesis, Huaqiao University, Quanzhou, China, 2022. [Google Scholar] [CrossRef]

- Yoshida, M.; Takatsuki, R.; Sakamoto, G.; Oshitani, J.; Gotoh, K. Dem simulation and analysis of the effects of adhesive forces and rotations of admixed particles on improving main particle flowability. Adv. Powder Technol. 2016, 27, 2084–2093. [Google Scholar] [CrossRef]

- Nguyen, D.; Rasmuson, A.; Thalberg, K.; Björn, I.N. The exchange of fines between carriers in adhesive particle mixing: A study using dem simulation. Powder Technol. 2016, 288, 266–278. [Google Scholar] [CrossRef]

- Komori, M.; Yoshida, M.; Shimosaka, A.; Shirakawa, Y. Dem simulation analysis of the improvement in particle discharge flowability using adhesive force distribution models based on admixed particle coating. Adv. Powder Technol. 2022, 33, 103355. [Google Scholar] [CrossRef]

- Li, J.; Wu, Y. Lubricants in pharmaceutical solid dosage forms. Lubricants 2014, 2, 21–43. [Google Scholar] [CrossRef]

- Persson, A.; Alderborn, G.; Frenning, G. Flowability of surface modified pharmaceutical granules: A comparative experimental and numerical study. Eur. J. Pharm. Sci. 2011, 42, 199–209. [Google Scholar] [CrossRef] [PubMed]

- Wassgren, C.R.; Hunt, M.L.; Freese, P.J.; Palamara, J.; Brennen, C.E. Effects of vertical vibration on hopper flows of granular material. Phys. Fluids 2002, 14, 3439–3448. [Google Scholar] [CrossRef]

- Zhou, S.; Ren, Z.; Zhang, Y.; Ju, J. Analysis of flow characteristics of granular material unloaded on nonlinear vibration inclined platform. Appl. Math. Model. 2020, 78, 57–74. [Google Scholar] [CrossRef]

- Zhao, L.; Duan, C.; Jiang, H.; Li, H.; Zhao, Y.; Zheng, Q. Dem simulation of size segregation of binary mixtures of cohesive particles under a horizontal swirling vibration. Powder Technol. 2022, 404, 117456. [Google Scholar] [CrossRef]

- Fartashvand, V.; Abdullah, A.; Vanini, S.A.S. Effects of high power ultrasonic vibration on the cold compaction of titanium. Ultrason. Sonochemistry 2017, 36, 155–161. [Google Scholar] [CrossRef] [PubMed]

- Zhu, G.; Luo, Y.; Chen, C.; Shen, K.; Zhang, Y. Effect of metakaolin on the microstructure of cement-based artificial marble slabs incorporating natural marble offcuts under vacuum vibration compaction method. Constr. Build. Mater. 2023, 369, 130478. [Google Scholar] [CrossRef]

- Zhang, J.; Tan, Y.; Bao, T.; Xu, Y.; Jiang, S. Discrete element simulation for effects of roller’s vibrations on powder spreading quality. China Mech. Eng. 2020, 31, 1717–1723. [Google Scholar] [CrossRef]

- Tahmasebi, P. A state-of-the-art review of experimental and computational studies of granular materials: Properties, advances, challenges, and future directions. Prog. Mater. Sci. 2023, 138, 101157. [Google Scholar] [CrossRef]

- Rycroft, C.H.; Kamrin, K.; Bazant, M.Z. Assessing continuum postulates in simulations of granular flow. J. Mech. Phys. Solids 2009, 57, 828–839. [Google Scholar] [CrossRef]

- Wu, K.; Francia, V.; Coppens, M. Dynamic viscoplastic granular flows: A persistent challenge in gas-solid fluidization. Powder Technol. 2020, 365, 172–185. [Google Scholar] [CrossRef]

- Zou, Y.; Zou, R.; Wu, Y. CFD-DEM study on agglomeration and spout-assisted fluidization of cohesive particles. Powder Technol. 2024, 436, 119512. [Google Scholar] [CrossRef]

- Nan, W.; Goh, W.P.; Rahman, M.T. Elasto-plastic and adhesive contact: An improved linear model and its application. Powder Technol. 2022, 407, 117634. [Google Scholar] [CrossRef]

- Zhang, J.; Tan, Y.; Xiao, X.; Jiang, S. Comparison of roller-spreading and blade-spreading processes in powder-bed additive manufacturing by dem simulations. Particuology 2022, 66, 48–58. [Google Scholar] [CrossRef]

- Zhao, L.; Li, Y.; Yang, X.; Jiao, Y.; Hou, Q. Dem study of size segregation of wet particles under vertical vibration. Adv. Powder Technol. 2019, 30, 1386–1399. [Google Scholar] [CrossRef]

- Bahramian, A.; Olazar, M. Influence of restitution and friction coefficients on the velocity field of polydisperse TiO2 ag-glomerates in a conical fluidized bed by the adhesive CFD-DEM simulation. Powder Technol. 2021, 386, 491–504. [Google Scholar] [CrossRef]

- Louati, H.; Bednarek, X.; Martin, S.; Ndiaye, A.; Bonnefoy, O. Qualitative and quantitative dem analysis of cohesive granular material behaviour in ft4 shear tester. Chem. Eng. Res. Des. 2019, 148, 155–163. [Google Scholar] [CrossRef]

- Zhong, W.; Zakhvatayeva, A.; Zhang, L.; Wu, C. Powder flow during linear and rotary die filling. Int. J. Pharm. 2021, 602, 120654. [Google Scholar] [CrossRef]

- Jiang, S.; Chen, X.; Cao, G.; Tan, Y.; Xiao, X.; Zhou, Y.; Liu, S.; Tong, Z.; Wu, Y. Optimization of fresh concrete pumping pressure loss with cfd-dem approach. Constr. Build. Mater. 2021, 276, 122204. [Google Scholar] [CrossRef]

- Wu, C. DEM simulations of die filling during pharmaceutical tabletting. Particuology 2008, 6, 412–418. [Google Scholar] [CrossRef]

- Chen, J.; Krengel, D.; Nishiura, D.; Furuichi, M.; Matuttis, H. A force–displacement relation based on the jkr theory for dem simulations of adhesive particles. Powder Technol. 2023, 427, 118742. [Google Scholar] [CrossRef]

- Hertz, H. Ueber die Berührung fester elastischer Körper. J. Reine Angew. Math. 2009, 1882, 156–171. [Google Scholar] [CrossRef]

- Bierwisch, C.; Kraft, T.; Riedel, H.; Moseler, M. Three-dimensional discrete element models for the granular statics and dynamics of powders in cavity filling. J. Mech. Phys. Solids 2009, 57, 10–31. [Google Scholar] [CrossRef]

- Chen, X.; Elliott, J.A. On the scaling law of JKR contact model for coarse-grained cohesive particles. Chem. Eng. Sci. 2020, 227, 115906. [Google Scholar] [CrossRef]

- Carr, M.J.; Roessler, T.; Robinson, P.W.; Otto, H.; Richter, C.; Katterfeld, A.; Wheeler, C.A. Calibration procedure of discrete element method (dem) parameters for wet and sticky bulk materials. Powder Technol. 2023, 429, 118919. [Google Scholar] [CrossRef]

- Mohajeri, M.J.; van Rhee, C.; Schott, D.L. Replicating cohesive and stress-history-dependent behavior of bulk solids: Feasibility and definiteness in DEM calibration procedure. Adv. Powder Technol. 2021, 32, 1532–1548. [Google Scholar] [CrossRef]

- Cao, G.; Bai, Y.; Shi, Y.; Li, Z.; Deng, D.; Jiang, S.; Xie, S.; Wang, H. Investigation of vibration on rheological behavior of fresh concrete using cfd-dem coupling method. Constr. Build. Mater. 2024, 425, 135908. [Google Scholar] [CrossRef]

- Li, Y.; Liu, D.; Cui, B.; Lin, Z.; Zheng, Y.; Ishnazarov, O. Studying particle transport characteristics in centrifugal pumps under external vibration using cfd-dem simulation. Ocean Eng. 2024, 301, 117538. [Google Scholar] [CrossRef]

- Zhao, L.; Zhao, Y.; Bao, C.; Hou, Q.; Yu, A. Laboratory-scale validation of a dem model of screening processes with circular vibration. Powder Technol. 2016, 303, 269–277. [Google Scholar] [CrossRef]

- Chen, M.; Liu, X.; Hu, P.; Zhai, X.; Han, Z.; Shi, Y.; Zhu, W.; Wang, D.; He, X.; Shang, S. Study on rotor vibration potato-soil separation device for potato harvester using dem-mbd coupling simulation. Comput. Electron. Agric. 2024, 218, 108638. [Google Scholar] [CrossRef]

- Nie, Z.; Chen, Y.; Qi, Q.; Zeng, J.; Lai, R. Investigating the effects of particle spatial evolutions on the vibration-induced compaction deformation of gap-graded mixtures via dem models. Powder Technol. 2023, 428, 118841. [Google Scholar] [CrossRef]

- Qi, Q.; Nie, Y.; Wang, X.; Liu, S. Exploring the effects of size ratio and fine content on vibration compaction behaviors of gap-graded granular mixtures via calibrated dem models. Powder Technol. 2023, 415, 118156. [Google Scholar] [CrossRef]

- Arifuzzaman, S.; Dong, K.; Zhu, H.; Zeng, Q. Dem study and machine learning model of particle percolation under vibration. Adv. Powder Technol. 2022, 33, 103551. [Google Scholar] [CrossRef]

- Jezerska, L.; Prokes, R.; Gelnar, D.; Zegzulka, J. Hard gelatine capsules: Dem supported experimental study of particle arrangement effect on properties and vibrational transport behaviour. Powder Technol. 2022, 405, 117525. [Google Scholar] [CrossRef]

| Material Properties | Value |

|---|---|

| Particle diameter (mm) | 1 |

| Solid density (kg/m3) | 1889 |

| Solid Poisson’s ratio | 0.25 |

| Solid Young’s modulus (MPa) | 155 |

| Wall density (kg/m3) | 7880 |

| Wall Poisson’s ratio | 0.3 |

| Wall Young’s modulus (GPa) | 100 |

| Belt density (kg/m3) | 1400 |

| Belt Young’s modulus (MPa) | 250 |

| Belt Poisson’s ratio | 0.3 |

| Friction coefficients (P-P) | 0.57 |

| Wall friction (P-W) | 0.7 |

| Belt friction (P-B) | 0.94 |

| Rolling resistance (P-P) | 0.3 |

| Rolling resistance (P-W) | 0.3 |

| Rolling resistance (P-B) | 0.7 |

| Restitution coefficients (P-P) | 0.12 |

| Restitution coefficients (P-W) | 0.12 |

| Restitution coefficients (P-B) | 0.108 |

| Surface energy (J/m2) (P-P) | 0.1 |

| Surface energy (J/m2) (P-W) | 1.96 |

| Structures | Frequency (Hz) | Amplitude (mm) | Number |

|---|---|---|---|

| Case 1 | 50, 52, 54, 56, 58, 60 | 2, 4, 6, 8 | 24 |

| Case 2 | 50, 52, 54, 56, 58, 60 | 2, 4, 6, 8 | 24 |

| Case 3 | 50, 52, 54, 56, 58, 60 | 2, 4, 6, 8 | 24 |

| Case 4 | 50, 52, 54, 56, 58, 60 | 2, 4, 6, 8 | 24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Tan, Y.; Zhou, S.; Yan, S.; Zhang, J. Discrete Element Simulation of Vibration-Assisted Chute to Prevent Blockage of Viscous Materials. Processes 2025, 13, 2819. https://doi.org/10.3390/pr13092819

Li J, Tan Y, Zhou S, Yan S, Zhang J. Discrete Element Simulation of Vibration-Assisted Chute to Prevent Blockage of Viscous Materials. Processes. 2025; 13(9):2819. https://doi.org/10.3390/pr13092819

Chicago/Turabian StyleLi, Jie, Yuanqiang Tan, Sunsheng Zhou, Shiyan Yan, and Jiangtao Zhang. 2025. "Discrete Element Simulation of Vibration-Assisted Chute to Prevent Blockage of Viscous Materials" Processes 13, no. 9: 2819. https://doi.org/10.3390/pr13092819

APA StyleLi, J., Tan, Y., Zhou, S., Yan, S., & Zhang, J. (2025). Discrete Element Simulation of Vibration-Assisted Chute to Prevent Blockage of Viscous Materials. Processes, 13(9), 2819. https://doi.org/10.3390/pr13092819