Effect of Additive Manufacturing Parameters on PLA, ABS, and PETG Strength

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

- PLA (Polylactic Acid): Bio-based and biodegradable, popular for its ease of use and versatility. Supplied by NatureWorks LLC (Plymouth, MN, USA). PLA has a density of 1.25 g·cm−3, glass transition Tg of 137 °C, UTS of 53 MPa, and Young’s modulus of 3.5 GPa [29].

- ABS (Acrylonitrile Butadiene Styrene): Amorphous polymer with high impact resistance, widely used in industrial settings. Supplied by Stratasys Ltd. (Rehovot, Israel). ABS has a density of 1.04 g·cm−3, glass transition Tg of 107 °C, UTS of 40 MPa, and Young’s modulus of 2.1 GPa [29].

- PETG (Modified Polyethylene Terephthalate): Enhanced durability and mechanical strength, suitable for outdoor applications. Supplied by Prusa Research (Newark, DE, USA). PETG has a density of 1.27 g·cm−3, glass transition Tg of 71 °C, UTS of 50 MPa, and Young’s modulus of 2.0 GPa [29].

2.2. Samples Design and Processing Parameters

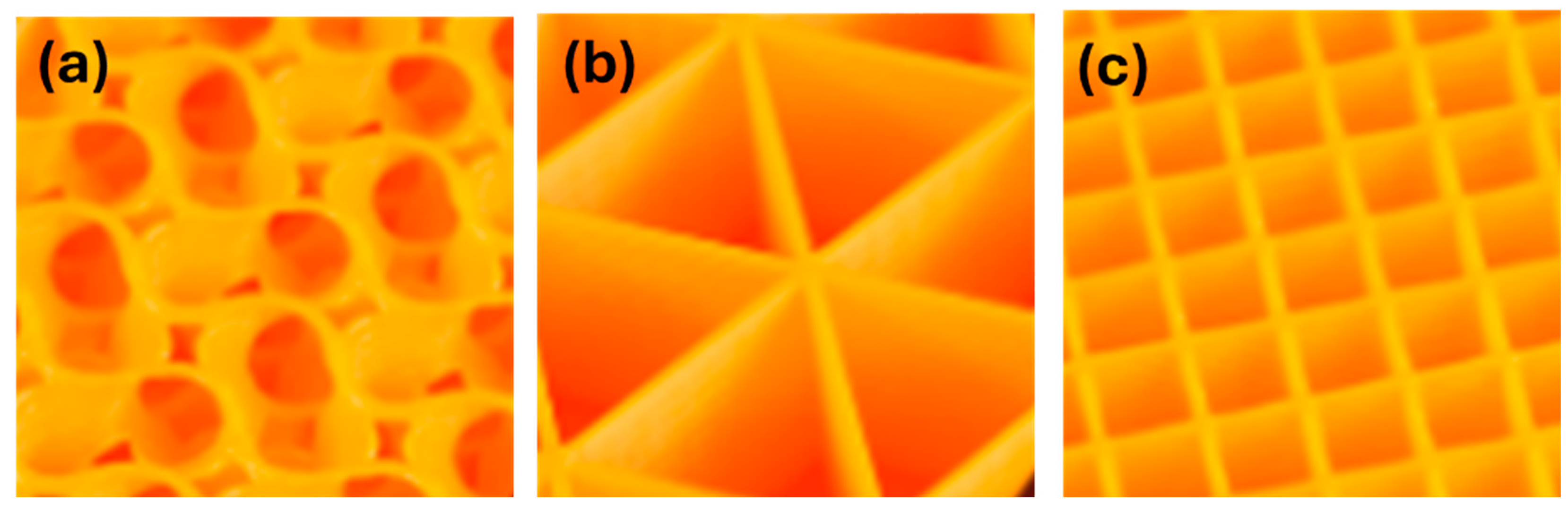

- Infill type

- Infill density

- Layer height

- Printing speed

- AM temperature

- Number of walls

2.3. Mechanical Strength Evaluation

3. Results

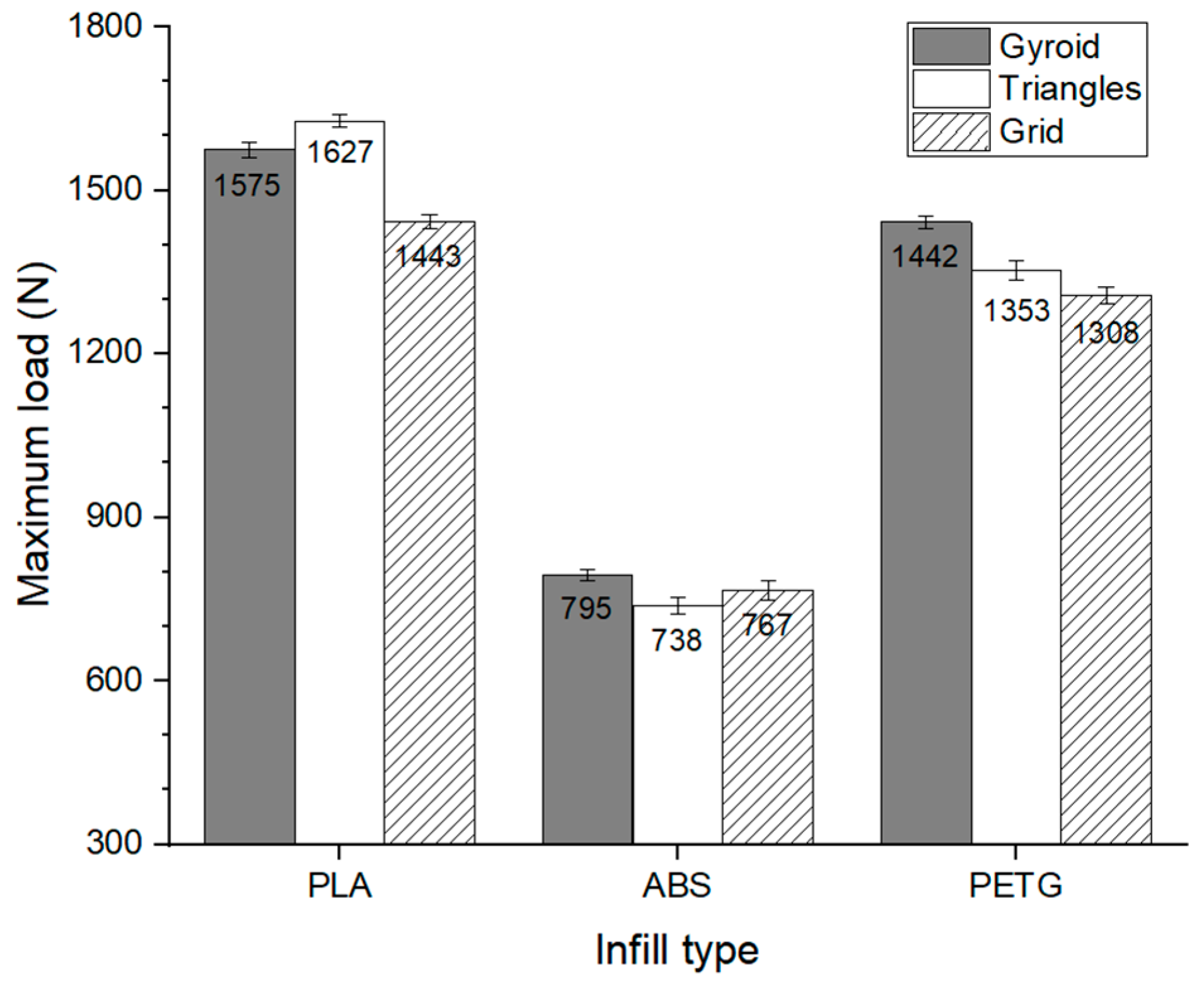

3.1. Effect of the Infill Type

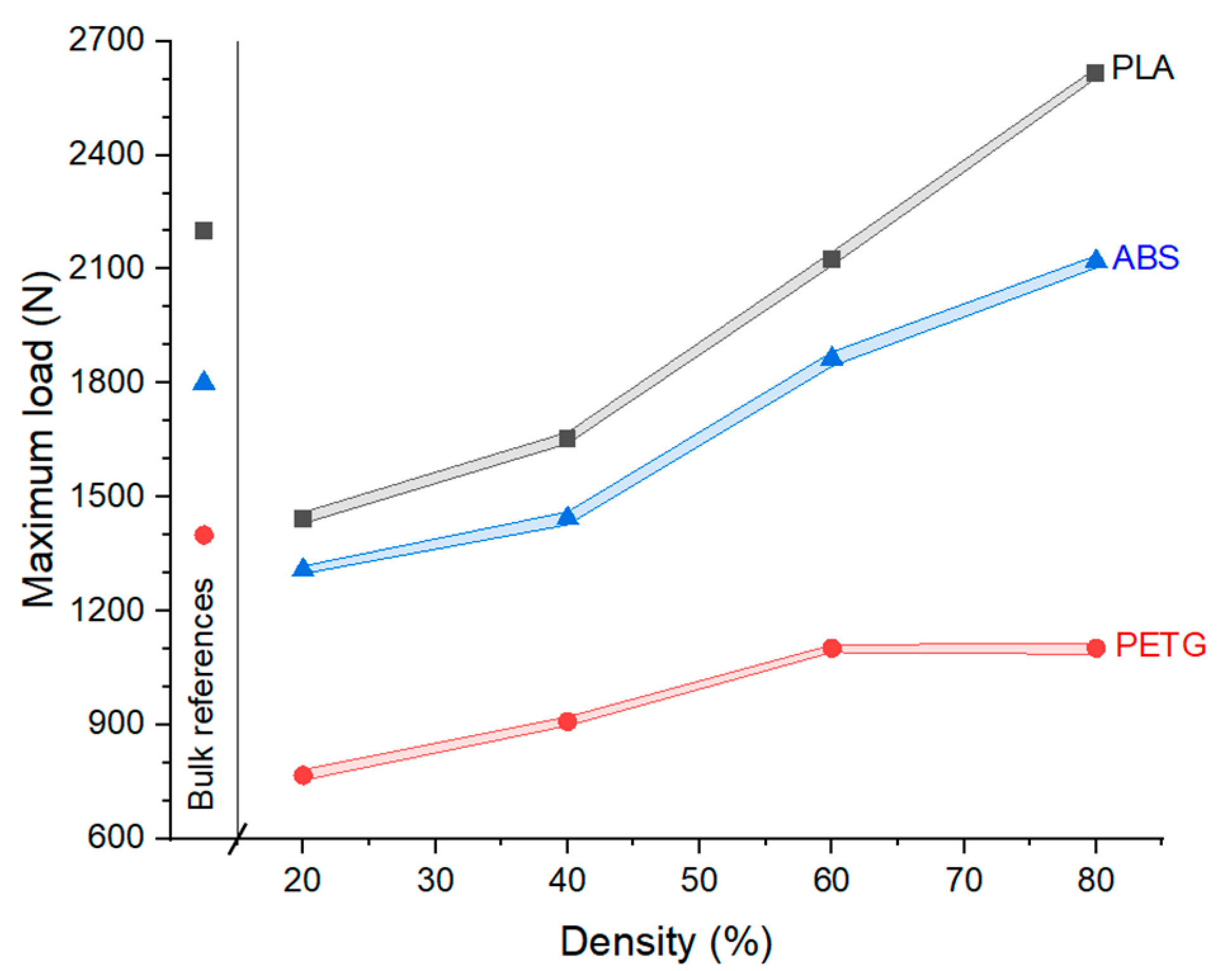

3.2. Effect of the Infill Density

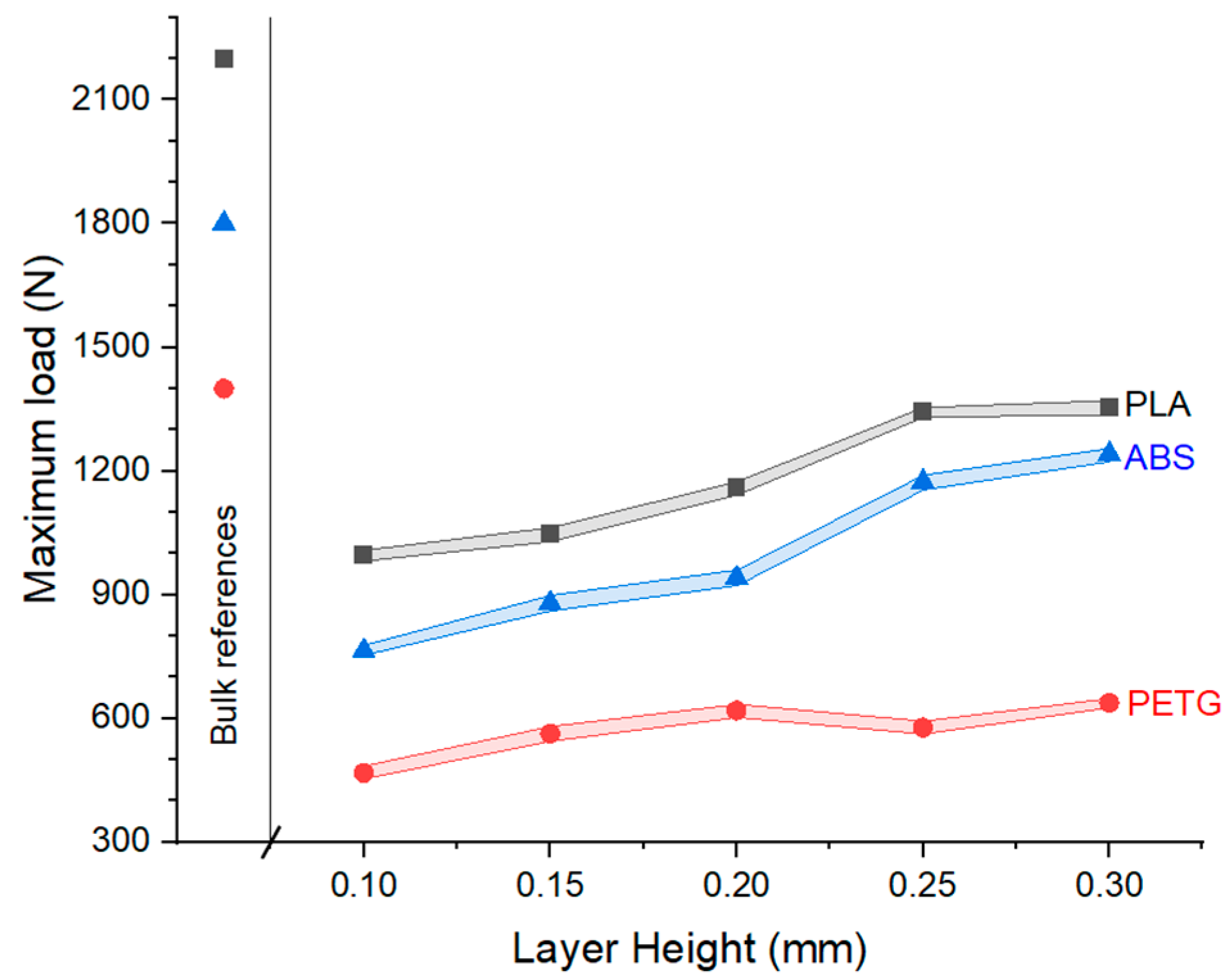

3.3. Effect of the Layer Height

3.4. Effect of the FFF Speed

3.5. Effect of the FFF Temperature

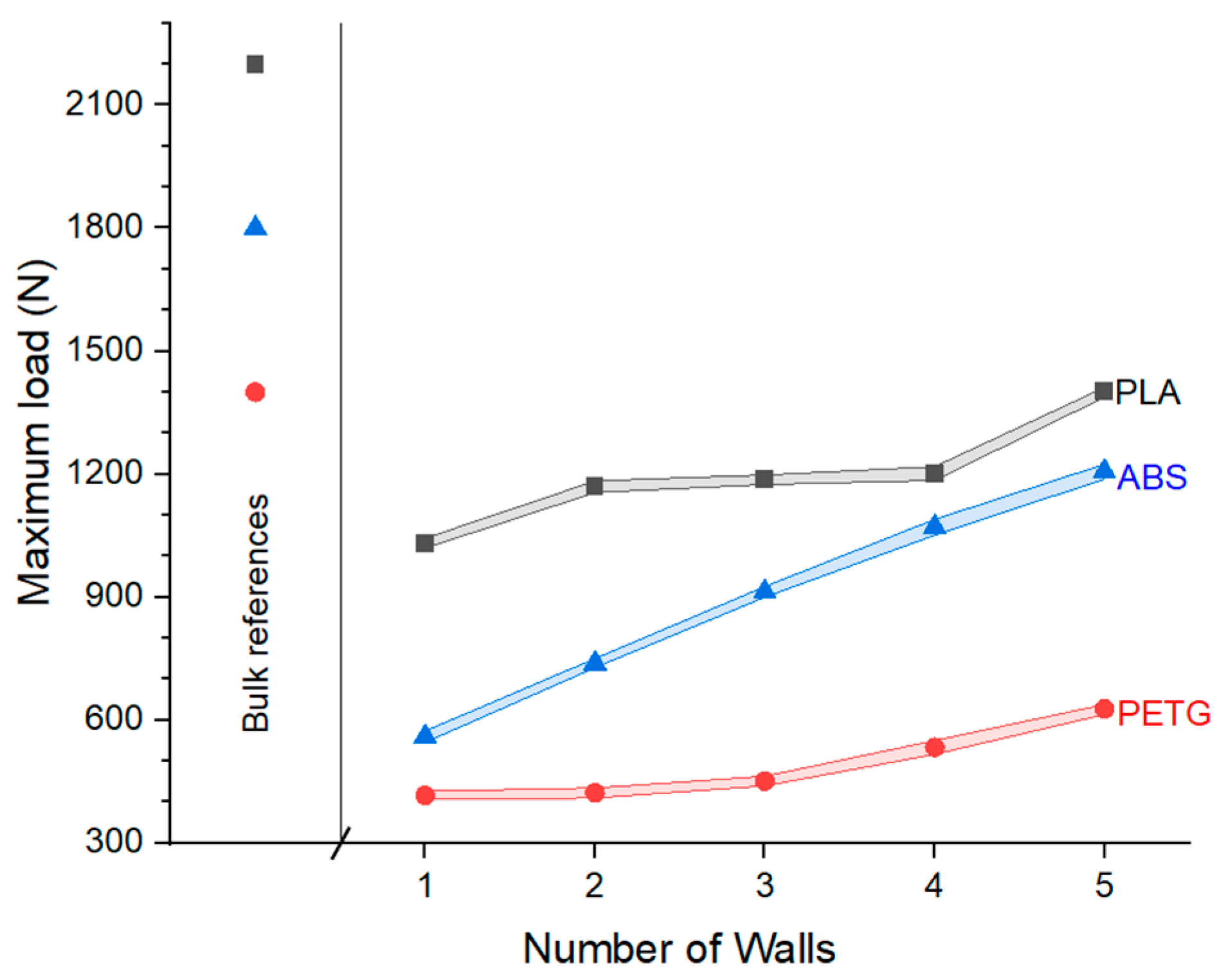

3.6. Effect of the Number of Walls

4. Conclusions

- The infill pattern significantly affects the tensile strength of FFF parts. Although the Grid pattern consistently yielded the lowest strength, the Gyroid and Triangular patterns improved performance for ABS and PETG, as well as PLA, respectively. However, material-dependent variability prevents a definitive selection of the most effective infill pattern.

- Increasing the infill density enhances the mechanical strength of printed parts. PLA exhibited the most substantial increase in tensile load with higher densities, while ABS showed a plateau beyond 60% density. PETG demonstrated an almost linear relationship between density and tensile performance.

- Increasing layer height generally improves tensile strength due to the reduction in weak interlayer interfaces. This effect is particularly notable in PLA and PETG specimens.

- Higher printing speeds tend to reduce mechanical resistance as they introduce extrusion instability. Each material presents an optimal processing speed, beyond which performance deteriorates due to suboptimal temperature–flow dynamics.

- Temperature had a limited and inconsistent influence on tensile strength. While PLA followed expected behavior, ABS and PETG exhibited less predictable responses, likely due to differences in polymer structure and thermal properties, such as glass transition temperature Tg.

- An increased number of perimetral walls leads to a consistent and nearly linear improvement in tensile strength across all materials. PETG, in particular, exhibited the clearest and most reliable response, with minimal variability among trials.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ABS | Acrylonitrile Butadiene Styrene |

| AM | Additive Manufacturing |

| BJ | Binder Jetting |

| CSAM | Cold Spray Additive Manufacturing |

| DLP | Digital Light Processing |

| FDM | Fused Deposition Modeling |

| FFF | Fused Filament Fabrication |

| MEX | Material Extrusion |

| PLA | Polylactic Acid |

| PETG | Modified Polyethylene Terephthalate |

| SLA | Stereolithography |

| SLM | Selective Laser Melting |

| SLS | Selective Laser Sintering |

| UTS | Ultimate Tensile Strength |

| WAAM | Wire Arc Additive Manufacturing |

References

- Skylar-Scott, M.A.; Mueller, J.; Visser, C.W.; Lewis, J.A. Voxelated Soft Matter via Multimaterial Multinozzle 3D Printing. Nature 2019, 575, 330–335. [Google Scholar] [CrossRef]

- Vraitch, R.; Prince, M.; Souppez, J.-B.R.G. Infill Density in Additive Manufacturing and Application to the DFMA of an Iron Man Helmet. In Proceedings of the 28th International Conference on Automation and Computing (ICAC), Birmingham, UK, 30 August–1 September 2023; IEEE: Birmingham, UK, 2023; pp. 1–6. [Google Scholar]

- Murr, L.E. Frontiers of 3D Printing/Additive Manufacturing: From Human Organs to Aircraft Fabrication. J. Mater. Sci. Technol. 2016, 32, 987–995. [Google Scholar] [CrossRef]

- Palo, M.; Holländer, J.; Suominen, J.; Yliruusi, J.; Sandler, N. 3D Printed Drug Delivery Devices: Perspectives and Technical Challenges. Expert Rev. Med. Devices 2017, 14, 685–696. [Google Scholar] [CrossRef]

- Vaz, R.; Garfias, A.; Albaladejo, V.; Sanchez, J.; Cano, I. A Review of Advances in Cold Spray Additive Manufacturing. Coatings 2023, 13, 267. [Google Scholar] [CrossRef]

- Leles da Silva, M.D.; Silva, L.F.; Toralles, B.M.; Cardoso, F.A.R.; Corso, M.; Soto Herek Rezende, L.C. Building a Sustainable Future: The Role of Additive Manufacturing in Civil Construction. Case Stud. Constr. Mater. 2024, 20, e02976. [Google Scholar] [CrossRef]

- Compton, B.G.; Lewis, J.A. 3D-printing of Lightweight Cellular Composites. Adv. Mater. 2014, 26, 5930–5935. [Google Scholar] [CrossRef] [PubMed]

- Ramaux, J.; Ziegler-Devin, I.; Besserer, A.; Nouvel, C. 3D Printing of Wood Composites: State of the Art and Opportunities. Polymers 2024, 16, 2827. [Google Scholar] [CrossRef]

- Karayel, E.; Bozkurt, Y. Additive Manufacturing Method and Different Welding Applications. J. Mater. Res. Technol. 2020, 9, 11424–11438. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Application of Directed Energy Deposition-Based Additive Manufacturing in Repair. Appl. Sci. 2019, 9, 3316. [Google Scholar] [CrossRef]

- Rasu, S. The Future of 3D Printing in Prototype Development: Minimizing Prototype Costs and Decreasing Validation Timelines. J. Eng. Appl. Sci. Technol. 2023, 5, 2–4. [Google Scholar] [CrossRef]

- Tan, K.; Markovych, S.; Hu, W.; Shorinov, O.; Wang, Y. Review of Manufacturing and Repair of Aircraft and Engine Parts Based on Cold Spraying Technology and Additive Manufacturing Technology. Aerosp. Tech. Technol. 2020, 3, 53–70. [Google Scholar] [CrossRef]

- Chaudhary, R.; Fabbri, P.; Leoni, E.; Mazzanti, F.; Akbari, R.; Antonini, C. Additive Manufacturing by Digital Light Processing: A Review. Prog. Addit. Manuf. 2023, 8, 331–351. [Google Scholar] [CrossRef]

- Ziaee, M.; Crane, N.B. Binder Jetting: A Review of Process, Materials, and Methods. Addit. Manuf. 2019, 28, 781–801. [Google Scholar] [CrossRef]

- Souza, J.; Großmann, A.; Mittelstedt, C. Micromechanical Analysis of the Effective Properties of Lattice Structures in Additive Manufacturing. Addit. Manuf. 2018, 23, 53–69. [Google Scholar] [CrossRef]

- Wang, S.; Ma, Y.; Deng, Z.; Zhang, K.; Dai, S. Implementation of an Elastoplastic Constitutive Model for 3D-Printed Materials Fabricated by Stereolithography. Addit. Manuf. 2020, 33, 101104. [Google Scholar] [CrossRef]

- Mohan, N.; Senthil, P.; Vinodh, S.; Jayanth, N. A Review on Composite Materials and Process Parameters Optimisation for the Fused Deposition Modelling Process. Virtual Phys. Prototyp. 2017, 12, 47–59. [Google Scholar] [CrossRef]

- Onwubolu, G.C.; Rayegani, F. Characterization and Optimization of Mechanical Properties of ABS Parts Manufactured by the Fused Deposition Modelling Process. Int. J. Manuf. Eng. 2014, 2014, 598531. [Google Scholar] [CrossRef]

- Ziemian, S.; Okwara, M.; Ziemian, C.W. Tensile and Fatigue Behavior of Layered Acrylonitrile Butadiene Styrene. Rapid Prototyp. J. 2015, 21, 270–278. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, M.; Li, S.; Si, L.; Peng, J.; Hu, Y. Mechanical Property Parametric Appraisal of Fused Deposition Modeling Parts Based on the Gray Taguchi Method. Int. J. Adv. Manuf. Technol. 2017, 89, 2387–2397. [Google Scholar] [CrossRef]

- Domingo-Espin, M.; Borros, S.; Agullo, N.; Garcia-Granada, A.-A.; Reyes, G. Influence of Building Parameters on the Dynamic Mechanical Properties of Polycarbonate Fused Deposition Modeling Parts. 3D Print. Addit. Manuf. 2014, 1, 70–77. [Google Scholar] [CrossRef]

- Almonti, D.; Salvi, D.; Ucciardello, N. Optimization of Printing Parameters for Polyethylene Terephthalate Glycol Thin Honeycomb Structures with Shape-Memory Behaviors. Int. J. Adv. Manuf. Technol. 2025, 136, 4455–4469. [Google Scholar] [CrossRef]

- Sri, L.S.V.; Karthick, A.; Dinesh, C. Evaluation of Mechanical Properties of 3D Printed PETG and Polyamide (6) Polymers. Chem. Phys. Impact 2024, 8, 100491. [Google Scholar] [CrossRef]

- Silva, C.; Pais, A.I.; Caldas, G.; Gouveia, B.P.P.A.; Alves, J.L.; Belinha, J. Study on 3D Printing of Gyroid-Based Structures for Superior Structural Behaviour. Prog. Addit. Manuf. 2021, 6, 689–703. [Google Scholar] [CrossRef]

- Hsueh, M.-H.; Lai, C.-J.; Wang, S.-H.; Zeng, Y.-S.; Hsieh, C.-H.; Pan, C.-Y.; Huang, W.-C. Effect of Printing Parameters on the Thermal and Mechanical Properties of 3D-Printed PLA and PETG, Using Fused Deposition Modeling. Polymers 2021, 13, 1758. [Google Scholar] [CrossRef]

- Wirawan, W.; Firmansyah, H.I.; Adiwidodo, S.; Mustapa, M.S. Impact of Print Speed and Nozzle Temperature on Tensile Strength of 3D Printed ABS for Permanent Magnet Turbine Systems. J. Mech. Eng. Sci. Technol. 2025, 9, 90. [Google Scholar] [CrossRef]

- Ulkir, O.; Ertugrul, I.; Ersoy, S.; Yağımlı, B. The Effects of Printing Temperature on the Mechanical Properties of 3D-Printed Acrylonitrile Butadiene Styrene. Appl. Sci. 2024, 14, 3376. [Google Scholar] [CrossRef]

- Almuallim, B.; Harun, W.S.W.; Al Rikabi, I.J.; Mohammed, H.A. Thermally Conductive Polymer Nanocomposites for Filament-Based Additive Manufacturing. J. Mater. Sci. 2022, 57, 3993–4019. [Google Scholar] [CrossRef]

- DeLassus, P.T.; Whiteman, N.F. Physical and Mechanical Properties of Some Important Polymers. In Polymer Handbook; Brandrup, J., Immergut, E.H., Grulke, E.A., Eds.; John Wiley & Sons: New York, NY, USA, 1999; pp. 881–891. [Google Scholar]

- UNE-EN-ISO 527-2; Test Conditions for Moulding and Extrusion Plastics. European Committee for Standardization: Brussels, Belgium, 2012; ISBN 978 0 580 70623 3.

- Dawoud, M.; Taha, I.; Ebeid, S.J. Mechanical Behaviour of ABS: An Experimental Study Using FDM and Injection Moulding Techniques. J. Manuf. Process. 2016, 21, 39–45. [Google Scholar] [CrossRef]

- Popescu, D.; Zapciu, A.; Amza, C.; Baciu, F.; Marinescu, R. FDM Process Parameters Influence over the Mechanical Properties of Polymer Specimens: A Review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Yao, T.; Deng, Z.; Zhang, K.; Li, S. A Method to Predict the Ultimate Tensile Strength of 3D Printing Polylactic Acid (PLA) Materials with Different Printing Orientations. Compos. Part B Eng. 2019, 163, 393–402. [Google Scholar] [CrossRef]

- Gordelier, T.J.; Thies, P.R.; Turner, L.; Johanning, L. Optimising the FDM Additive Manufacturing Process to Achieve Maximum Tensile Strength: A State-of-the-Art Review. Rapid Prototyp. J. 2019, 25, 953–971. [Google Scholar] [CrossRef]

- Es-Said, O.S.; Foyos, J.; Noorani, R.; Mendelson, M.; Marloth, R.; Pregger, B.A. Effect of Layer Orientation on Mechanical Properties of Rapid Prototyped Samples. Mater. Manuf. Process. 2000, 15, 107–122. [Google Scholar] [CrossRef]

- Wang, L.; Gardner, D.J. Effect of Fused Layer Modeling (FLM) Processing Parameters on Impact Strength of Cellular Polypropylene. Polymer 2017, 113, 74–80. [Google Scholar] [CrossRef]

- Álvarez, K.; Lagos, R.F.; Aizpun, M. Investigating the Influence of Infill Percentage on the Mechanical Properties of Fused Deposition Modeled ABS Parts. Ing. E Investig. 2016, 36, 110–116. [Google Scholar] [CrossRef]

- Hanon, M.M.; Zsidai, L.; Ma, Q. Accuracy Investigation of 3D Printed PLA with Various Process Parameters and Different Colors. Mater. Today Proc. 2021, 42, 3089–3096. [Google Scholar] [CrossRef]

- Zou, R.; Xia, Y.; Liu, S.; Hu, P.; Hou, W.; Hu, Q.; Shan, C. Isotropic and Anisotropic Elasticity and Yielding of 3D Printed Material. Compos. Part B Eng. 2016, 99, 506–513. [Google Scholar] [CrossRef]

- Croccolo, D.; De Agostinis, M.; Olmi, G. Experimental Characterization and Analytical Modelling of the Mechanical Behaviour of Fused Deposition Processed Parts Made of ABS-M30. Comput. Mater. Sci. 2013, 79, 506–518. [Google Scholar] [CrossRef]

- Jin, Z.; Tian, Y.; Wang, J. Chemistry and Thermodynamic Properties of Lactic Acid and Lactide and Solvent Miscibility. In Poly(Lactic Acid): Synthesis, Structures, Properties, Processing, and Applications; Auras, R., Lim, L.-T., Selke, S.E.M., Tsuji, H., Eds.; Wiley: Hoboken, NJ, USA, 2010; pp. 19–25. ISBN 9780470293669. [Google Scholar]

- Özen, A.; Abali, B.E.; Völlmecke, C.; Gerstel, J.; Auhl, D. Exploring the Role of Manufacturing Parameters on Microstructure and Mechanical Properties in Fused Deposition Modeling (FDM) Using PETG. Appl. Compos. Mater. 2021, 28, 1799–1828. [Google Scholar] [CrossRef]

| Temperature (°C) | PLA | ABS | PETG |

|---|---|---|---|

| 190 | x | ||

| 200 | x | ||

| 210 | x | x | x |

| 220 | x | x | x |

| 230 | x | x | x |

| 240 | x | x | |

| 250 | x | x | |

| 260 | x | x |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Menargues, S.; Navas, J.; Espinosa, I.; Baile, M.T.; Vaz, R.F.; Picas, J.A. Effect of Additive Manufacturing Parameters on PLA, ABS, and PETG Strength. Processes 2025, 13, 2733. https://doi.org/10.3390/pr13092733

Menargues S, Navas J, Espinosa I, Baile MT, Vaz RF, Picas JA. Effect of Additive Manufacturing Parameters on PLA, ABS, and PETG Strength. Processes. 2025; 13(9):2733. https://doi.org/10.3390/pr13092733

Chicago/Turabian StyleMenargues, Sergi, Javier Navas, Isabel Espinosa, Maria Teresa Baile, Rodolpho Fernando Vaz, and Josep Anton Picas. 2025. "Effect of Additive Manufacturing Parameters on PLA, ABS, and PETG Strength" Processes 13, no. 9: 2733. https://doi.org/10.3390/pr13092733

APA StyleMenargues, S., Navas, J., Espinosa, I., Baile, M. T., Vaz, R. F., & Picas, J. A. (2025). Effect of Additive Manufacturing Parameters on PLA, ABS, and PETG Strength. Processes, 13(9), 2733. https://doi.org/10.3390/pr13092733