CFD Simulation of Aerosol and Odor Gas Transport Dynamics in Shipboard Underwater Lavatories

Abstract

1. Introduction

2. Materials and Methods

2.1. Lavatory Model

2.2. Numerical Strategies

2.3. Case Setting of Air-Exhaust Volumes and Ventilation Layouts

2.4. Validation of the Simulation Program

3. Results

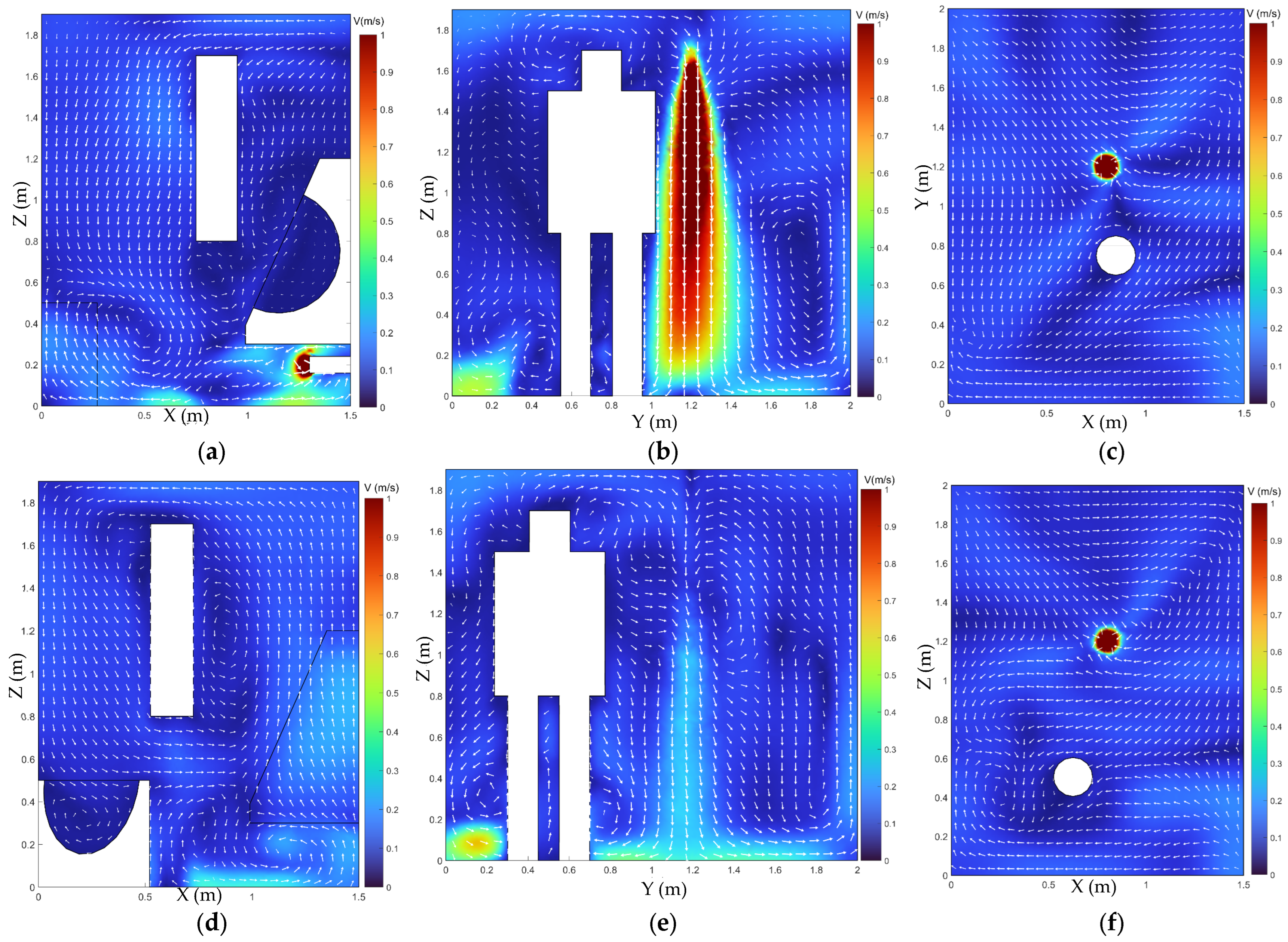

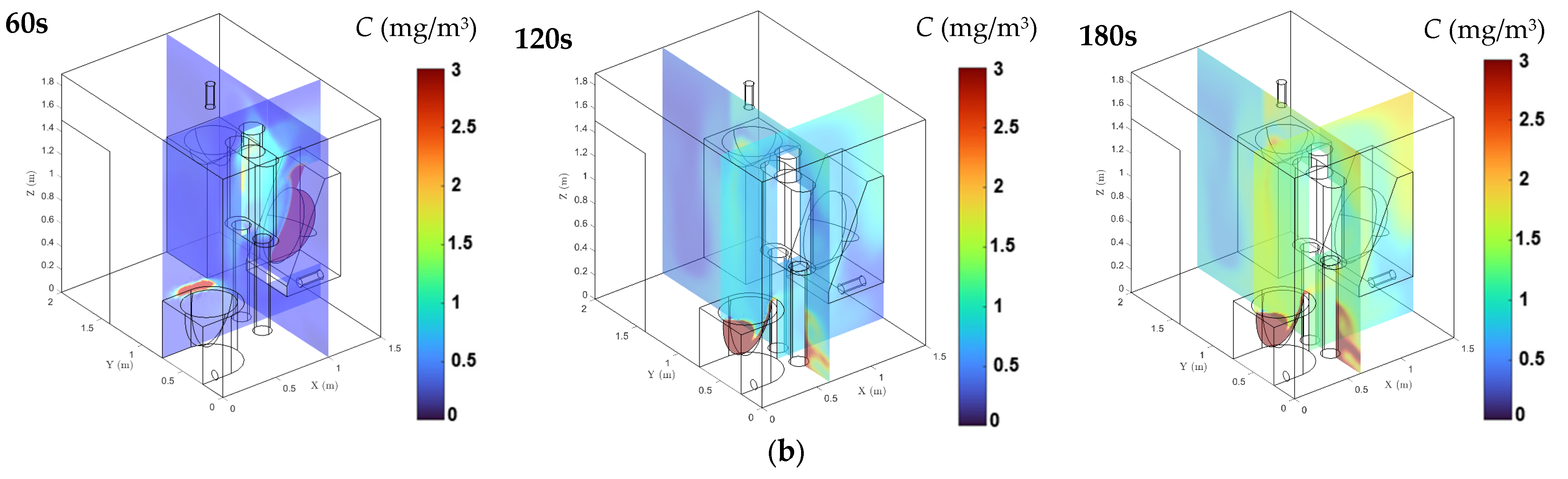

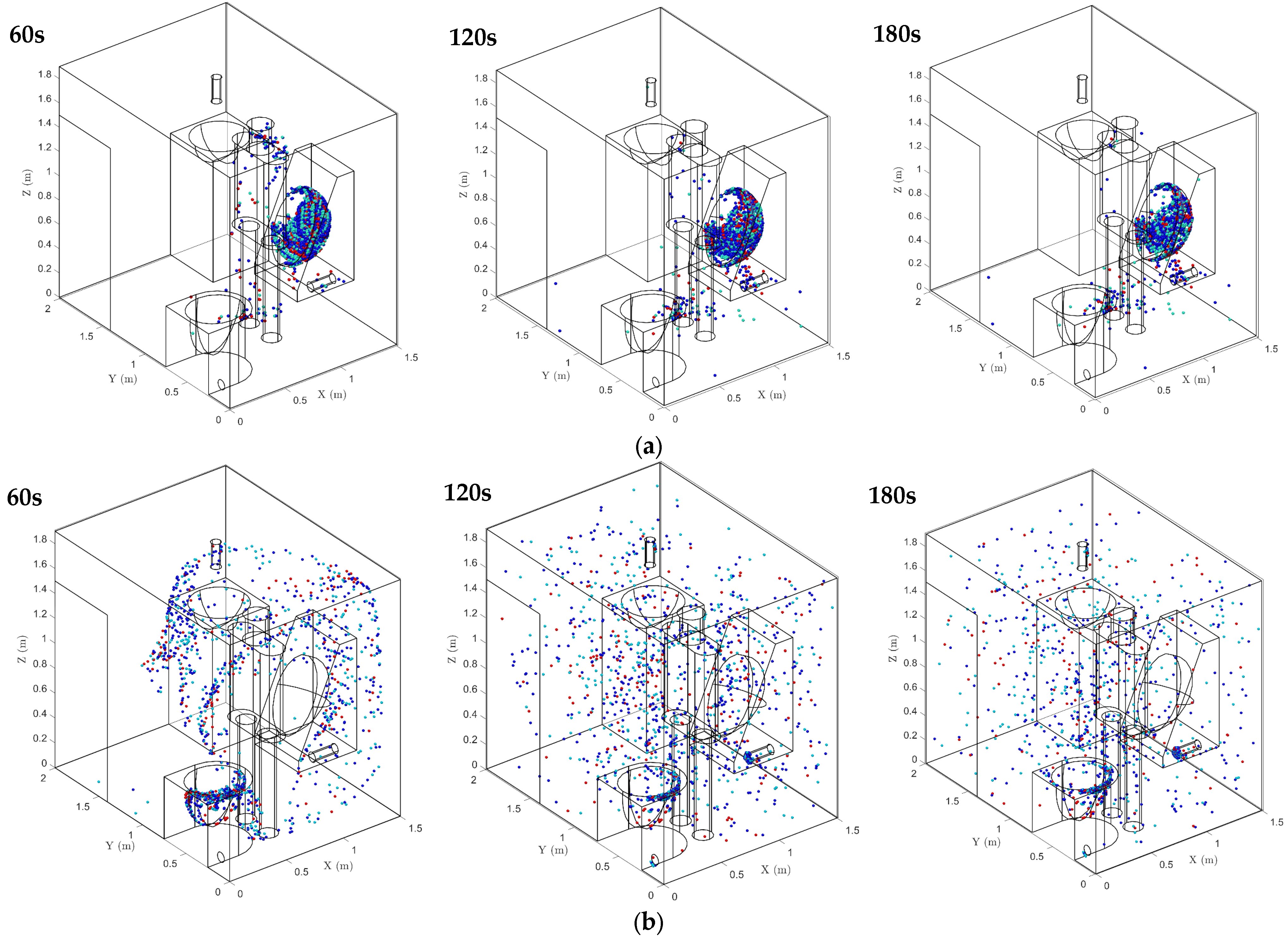

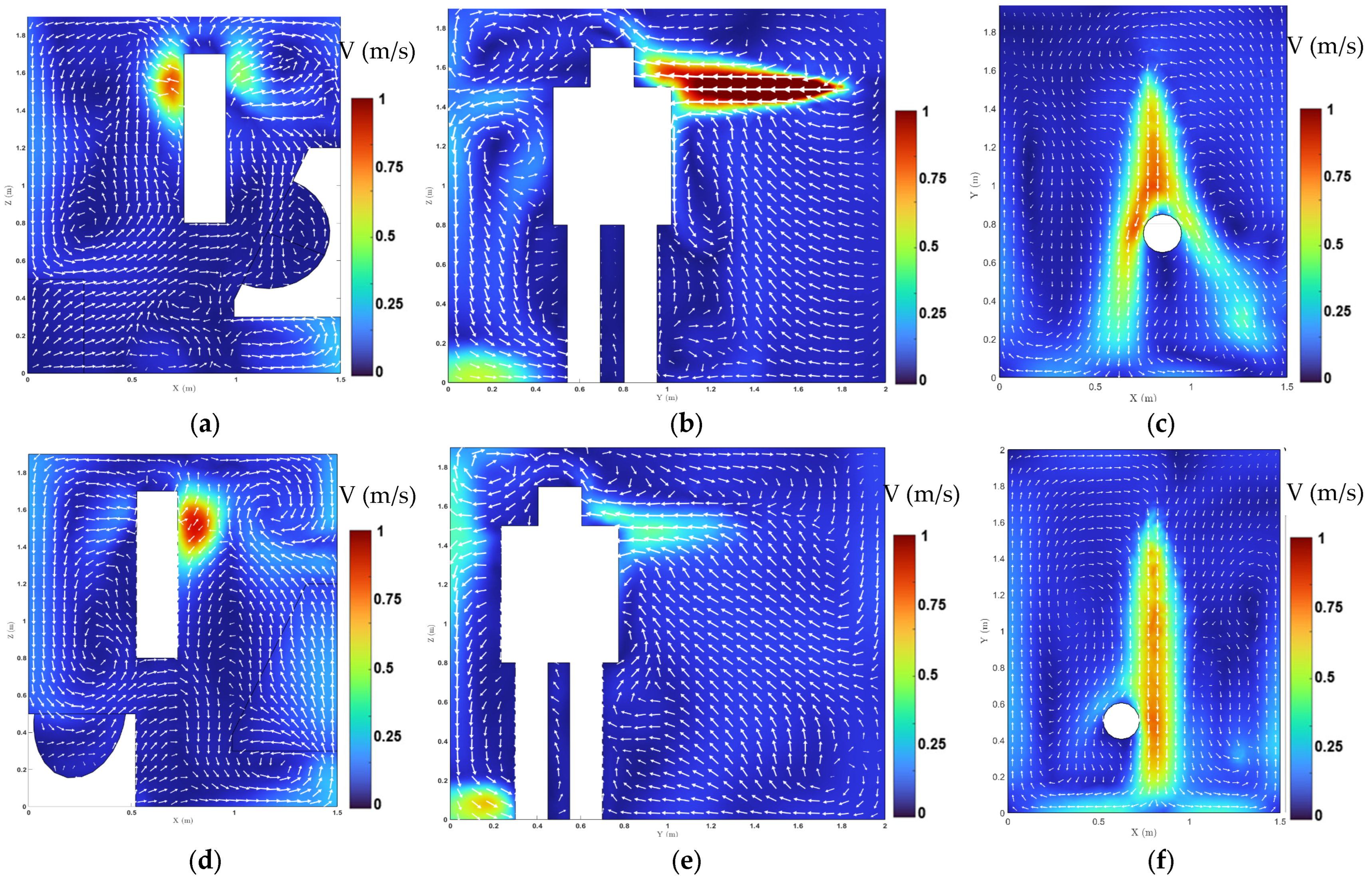

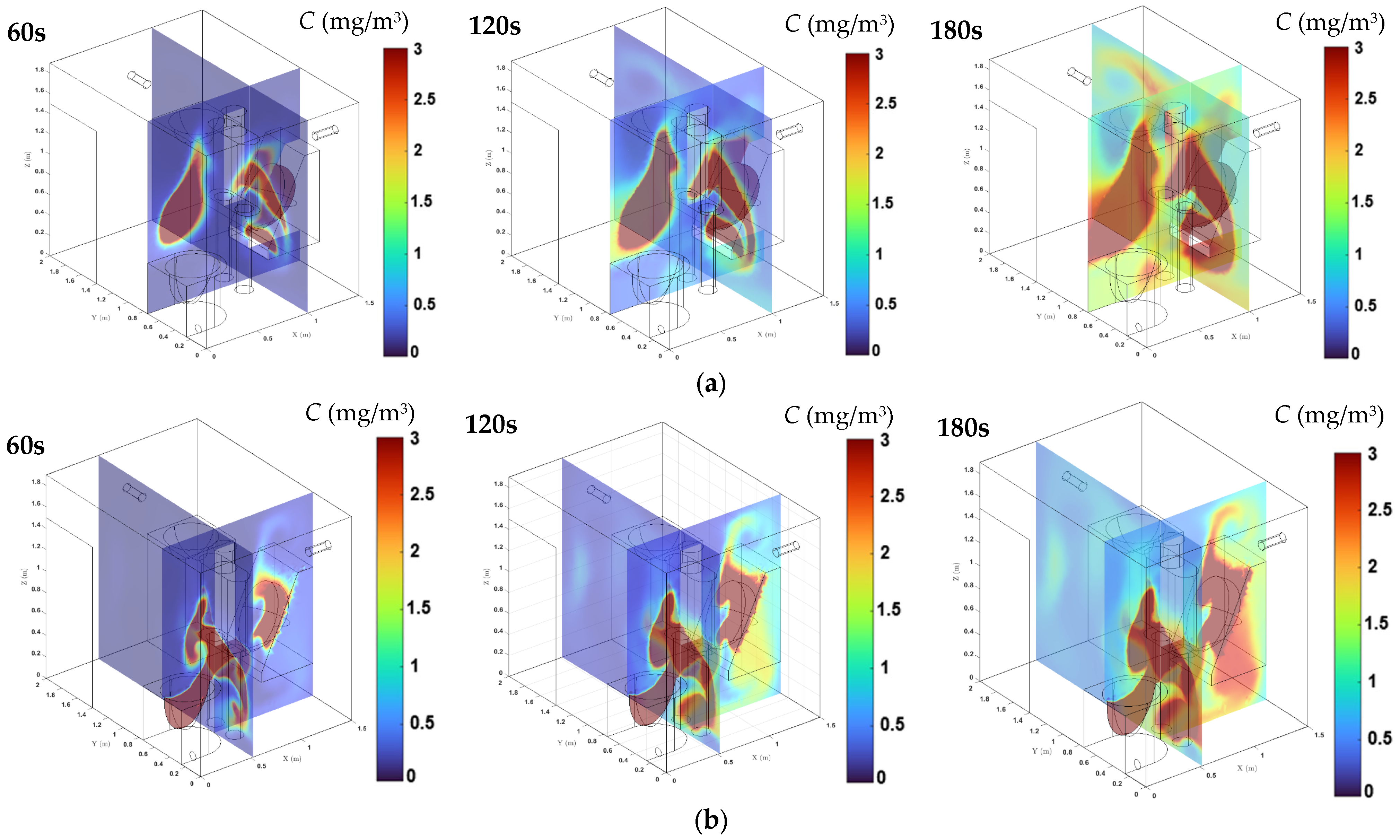

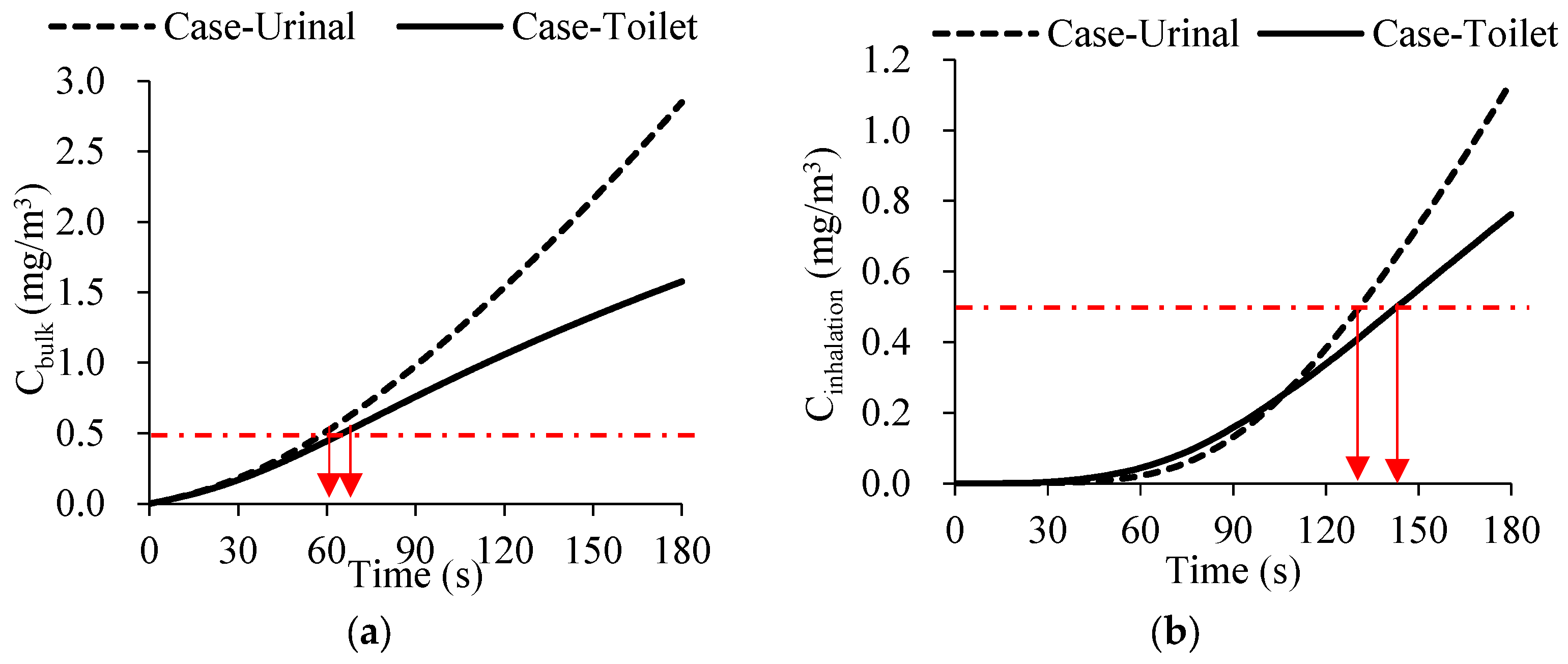

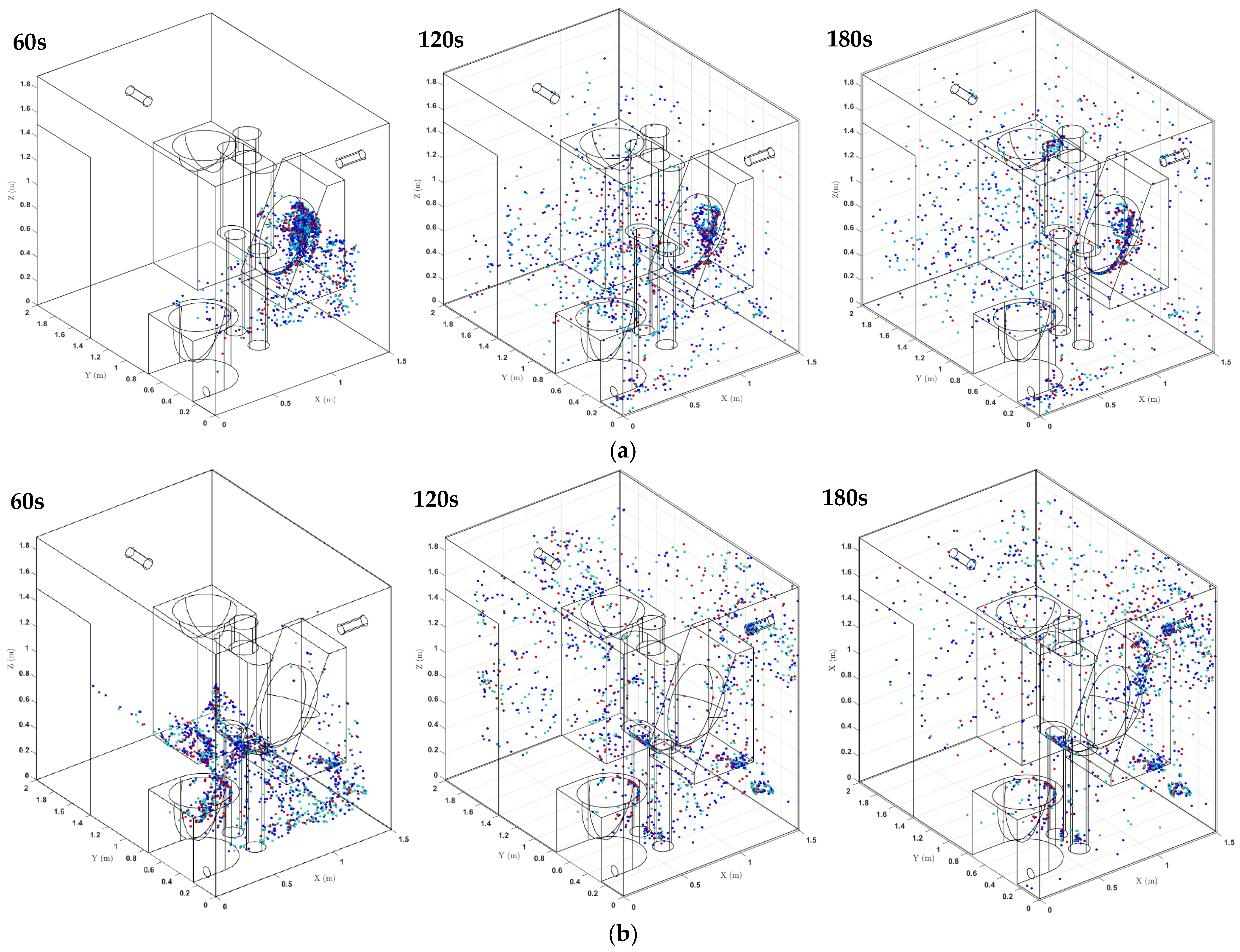

3.1. Flow Field, Odor Gas, and Particle Transport of Underwater Lavatory in Original Case

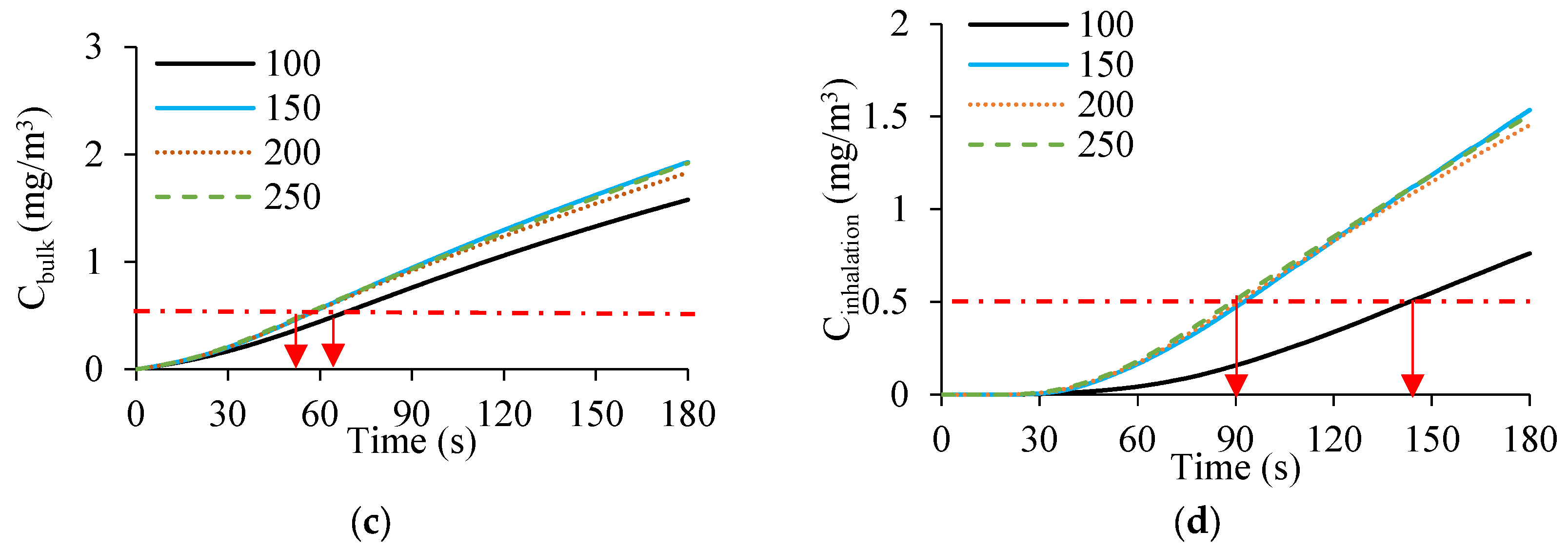

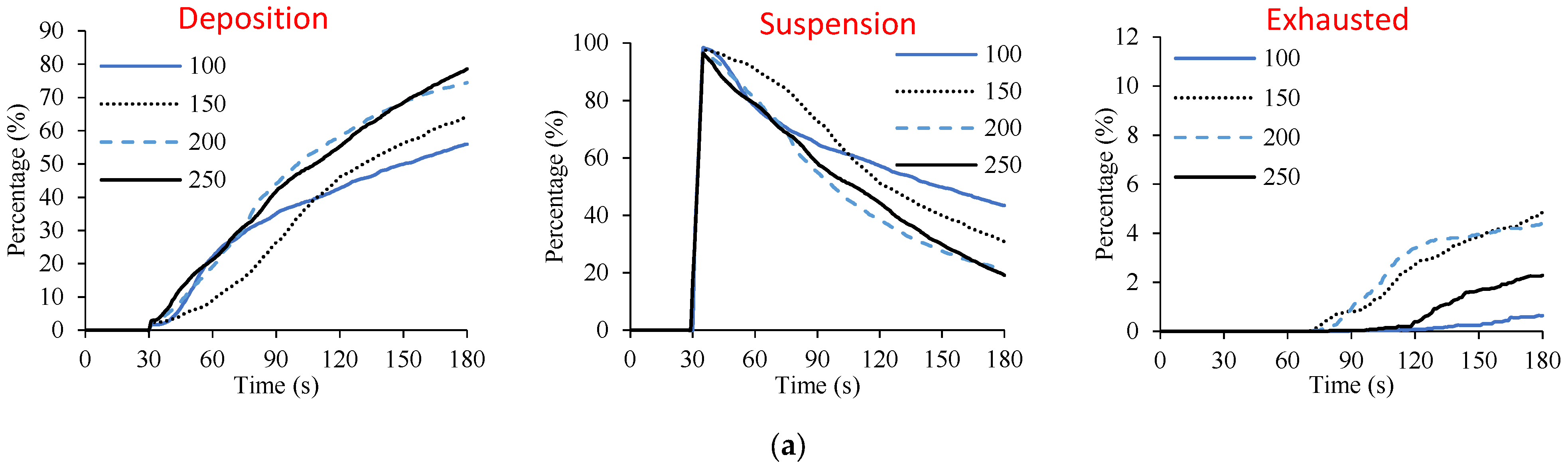

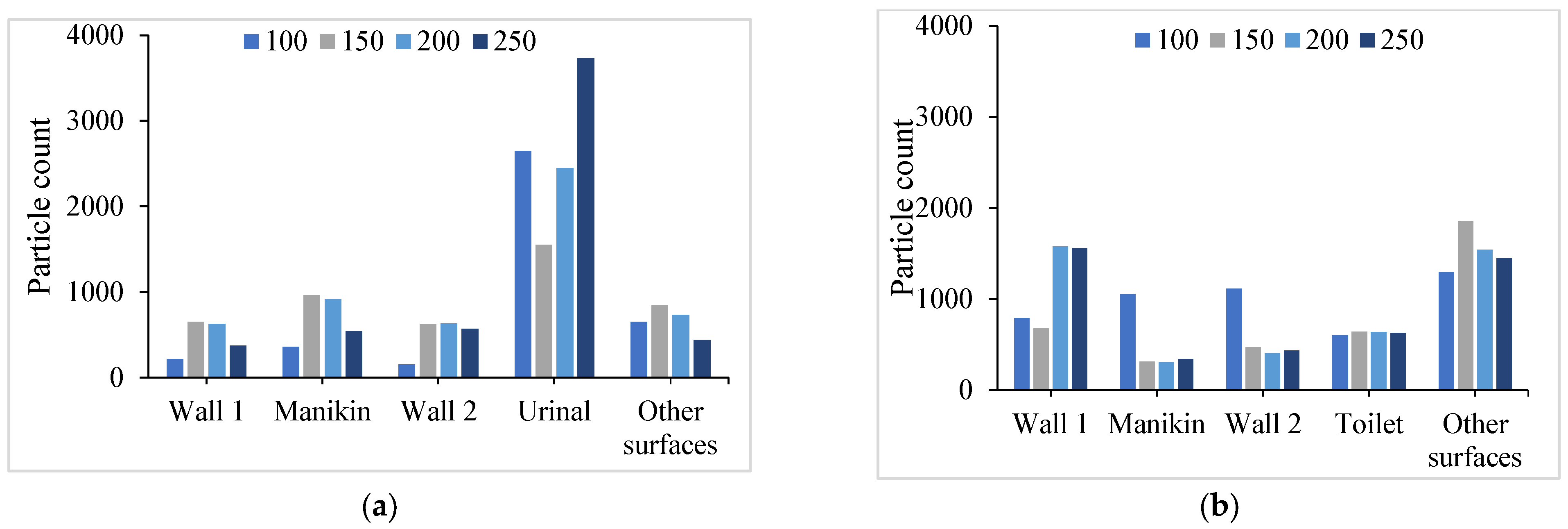

3.2. Influence of Air-Exhaust Volume on Odor Gas Concentration and Particle Fates

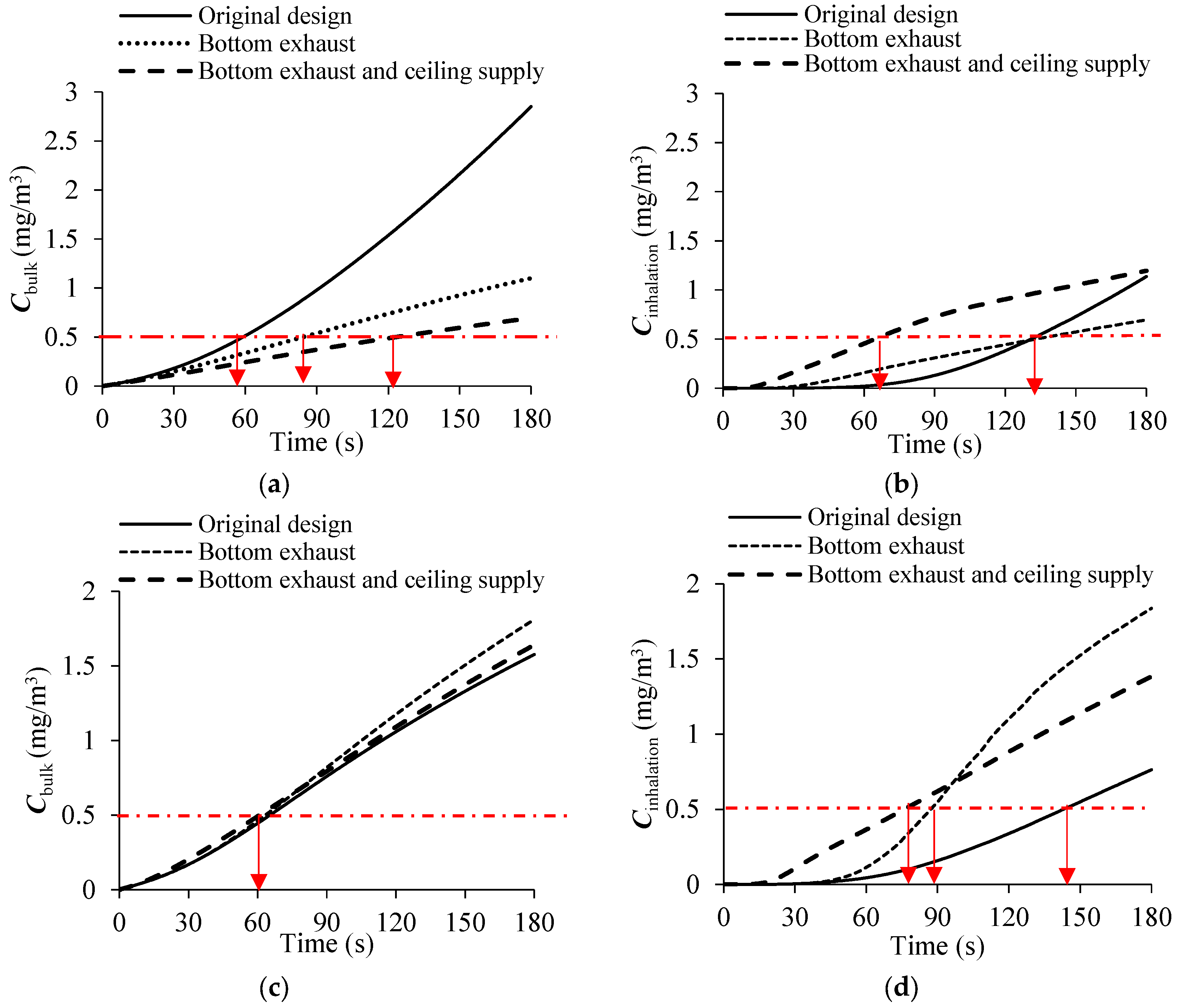

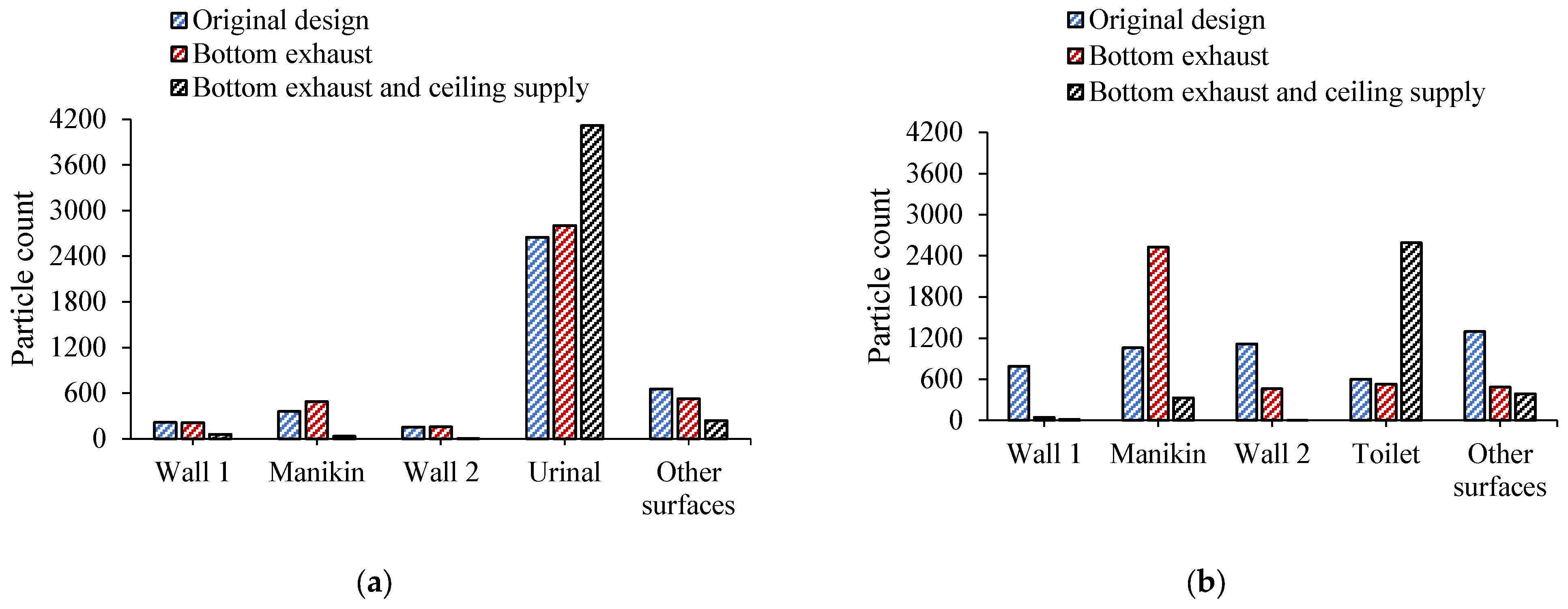

3.3. Influence of Ventilation Layouts on Odor Gas Concentration and Particle Fate

4. Discussion

5. Conclusions

- (1)

- The shipboard lavatory is equipped with both a urinal and a toilet, and the ventilation airflow differs due to the position of the user. In contrast to the case of using the urinal, the ammonia concentration levels during the toilet usage were consistently lower. For 1 min after using the lavatory, people will not experience an odor smell.

- (2)

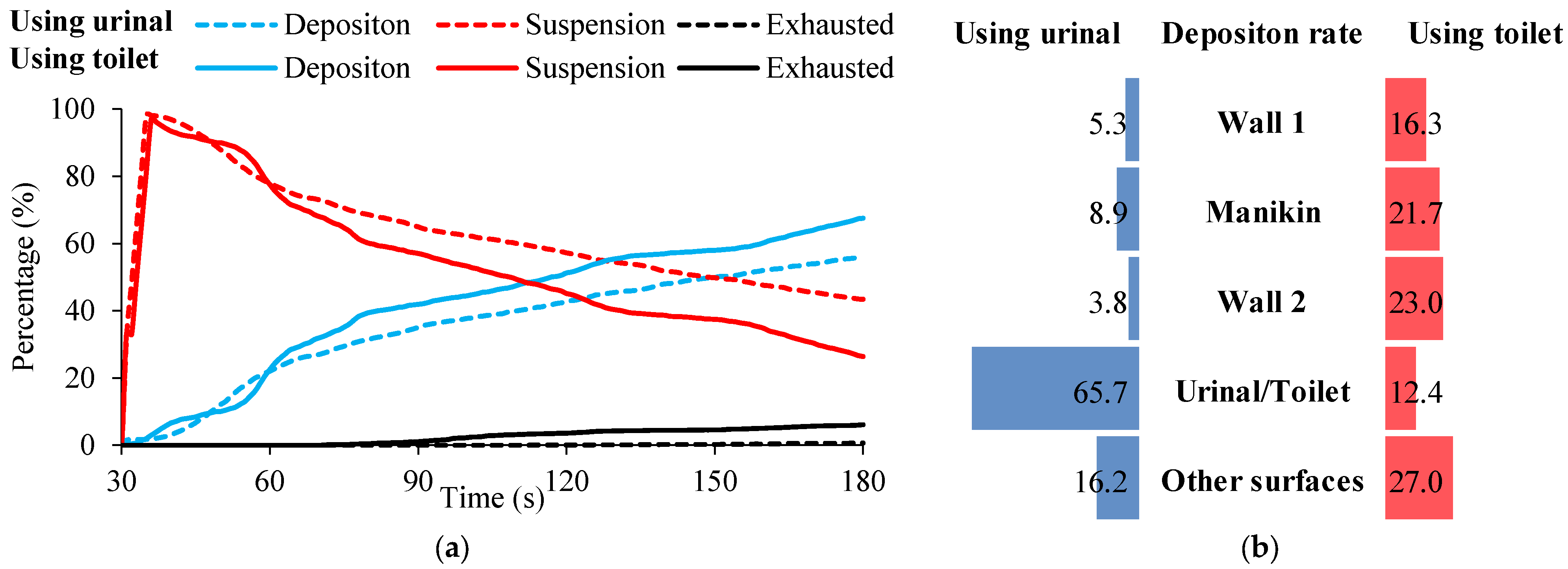

- The original design indicated that the case of using the urinal presented a significantly lower risk of human contact compared to using the toilet, with 65.7% of the deposited particles found on urinal surfaces, in contrast to only 8.9% on the manikin surfaces. Only 12.4% of the deposited particles were on the toilet surface, while 21.7% were found on the manikin surface, indicating a nearly uniform deposition of particles across all lavatory surfaces.

- (3)

- Increasing exhaust airflow in the urinal use-case accelerated the reduction of odor gas concentrations, but marginally enhanced odor perception in toilet use scenarios. In the case of toilet use, an airflow of 250 m3/h resulted in a reduction of approximately 70% in the ratio of particles deposited on the manikin surface, while increasing the deposited ratio in the urinal by 40%. Increasing the exhaust airflow after lavatory use is recommended to improve odor perception in the case of using the urinal and minimize the risk of particle exposure during both toilet and urinal use.

- (4)

- The layout of an aircraft-style design with a ceiling air supply and bottom exhaust effectively enhanced the removal of odorous gases while maintaining airflow during urinal use. This ventilation design concentrates most of the deposited particles on the surface of the urinal and toilet, while significantly reducing the risk of aerosol exposure for users. It is worth noting that this ventilation design does not seem to improve the odor control in the case of using the toilet, but rather slightly increases the odor sensation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Grid | Coarse | Medium | Fine |

|---|---|---|---|

| Total grid cell number | 139,622 | 257,472 | 673,072 |

| Minimum grid cell size | 0.03 m | 0.01 m | 0.006 m |

| Maximum grid cell size | 0.11 m | 0.08 m | 0.06 m |

| Growth rate | 1.15 | 1.13 | 1.1 |

References

- Byrnes, T.A.; Dunn, R.J. Boating-and shipping-related environmental impacts and example management measures: A review. Mar. Sci. Eng. 2020, 8, 908. [Google Scholar] [CrossRef]

- Widdowson, M.-A.; Glass, R.; Monroe, S.; Beard, R.S.; Bateman, J.W.; Lurie, P.; Johnson, C. Probable transmission of norovirus on an airplane. J. Am. Med. Assoc. 2005, 293, 1855–1860. [Google Scholar] [CrossRef]

- Shinohara, N.; Ogata, M.; Kim, H.; Kagi, N.; Tatsu, K.; Inui, F.; Naito, W. Evaluation of shields and ventilation as a countermeasure to protect bus drivers from infection. Environ. Res. 2023, 216, 114603. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Han, T.; Yoo, K.H.; Capecelatro, J.; Boehman, A.L.; Maki, K. Disease transmission through expiratory aerosols on an urban bus. Phys. Fluids 2021, 33, 015116. [Google Scholar] [CrossRef]

- Yamahata, Y.; Shibata, A. Preparation for quarantine on the cruise ship Diamond Princess in Japan due to COVID-19. JMIR Public Health Surveill. 2020, 6, e18821. [Google Scholar] [CrossRef]

- Dong, X.; Chen, Z.; Luo, Y.; Wang, Z.; Lin, Y.; Su, J. Numerical investigation and dynamics of pollutant dispersion in underground restroom ventilation. Build. Eng. 2024, 88, 109132. [Google Scholar] [CrossRef]

- Li, P.; Zhang, T.T.; Zhang, Y. Measuring the flushing-generated flow and aerosols in lavatory of commercial aircraft. Build. Environ. 2022, 214, 108948. [Google Scholar] [CrossRef]

- Li, Z.; Guan, J.; Yang, X.; Lin, C.-H. Source apportionment of airborne particles in commercial aircraft cabin environment: Contributions from outside and inside of cabin. Atmos. Environ. 2014, 89, 119–128. [Google Scholar] [CrossRef]

- Lin, Y.-P. Natural ventilation of toilet units in K–12 school restrooms using CFD. Energies 2021, 14, 4792. [Google Scholar] [CrossRef]

- Ding, B.; Liu, W.; Yang, M.; Liu, K.; Liu, T. Diffusion of aerosol pollution in residential bathroom under different air distribution. E3S Web Conf. 2022, 356, 05051. [Google Scholar] [CrossRef]

- Mihai, V.; Rusu, L. An overview of the ship ventilation systems and measures to avoid the spread of diseases. Inventions 2021, 6, 55. [Google Scholar] [CrossRef]

- MacNeil, A.; Ghosh, S. Gender Imbalance in the Maritime Industry: Impediments, Initiatives and Recommendations. Aust. J. Marit. Ocean Aff. 2017, 9, 42–55. [Google Scholar] [CrossRef]

- Xiang-yan, L.; Kai-bao, W.; Li-li, Y.; Bao-xin, W. Design and Study of the Environmental Protection and Energy Saving Toilet for the Long-Distance Train. In Proceedings of the International Conference on Mechatronic Science, Electric Engineering and Computer (MEC), Jilin, China, 19–22 August 2011; pp. 771–774. [Google Scholar] [CrossRef]

- Essa, A.; Yamanaka, T.; Kobayashi, T.; Choi, N. Effect of source location on contaminant dispersion pattern and occupants inhaled air quality in lecture room under displacement ventilation. Jpn. Archit. Rev. 2023, 6, e12313. [Google Scholar] [CrossRef]

- Zhang, Z.; Zeng, L.; Shi, H.; Liu, H.; Yin, W.; Shen, H.; Yang, L.; Gao, J.; Wang, L.; Zhang, Y. CFD study on the ventilation effectiveness in a public toilet under three ventilation methods. Energies 2021, 14, 8379. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, H.; Dai, Y.; Hu, Y. Prompt location of indoor instantaneous air contaminant source through multi-zone model-based probability method by utilizing airflow data from coarse-grid CFD model. Indoor Built Environ. 2022, 31, 944–954. [Google Scholar] [CrossRef]

- Wan, J.; Wei, J.; Lin, Y.; Zhang, T. Numerical investigation of bioaerosol transport in a compact lavatory. Buildings 2021, 11, 526. [Google Scholar] [CrossRef]

- Wilson, G.M.; Jackson, V.B.; Boyken, L.D.; Schweizer, M.L.; Perencevich, E.N. Bioaerosols generated from toilet flushing in rooms of patients with Clostridioides difficile infection. Infect. Control Hosp. Epidemiol. 2020, 41, 517–521. [Google Scholar] [CrossRef]

- Zhang, Z.; Zeng, L.; Shi, H.; Liu, H.; Yin, W.; Gao, J.; Wang, L.; Zhang, Y.; Zhou, X. CFD studies on the spread of ammonia and hydrogen sulfide pollutants in a public toilet under personalized ventilation. Build. Eng. 2022, 46, 103728. [Google Scholar] [CrossRef]

- Zhang, Z.; Zeng, L.; Shi, H.; Yang, G.; Yu, Z.; Yin, W.; Gao, J.; Wang, L.; Zhang, Y.; Zhou, X. Dynamics and numerical simulation of contaminant diffusion for a non-flushing ecological toilet. Energies 2021, 14, 7570. [Google Scholar] [CrossRef]

- Tung, Y.-C.; Hu, S.-C.; Tsai, T.-Y. Influence of bathroom ventilation rates and toilet location on odor removal. Build. Environ. 2009, 44, 1810–1817. [Google Scholar] [CrossRef]

- Tung, Y.-C.; Shih, Y.-C.; Hu, S.-C.; Chang, Y.-L. Experimental performance investigation of ventilation schemes in a private bathroom. Build. Environ. 2010, 45, 243–251. [Google Scholar] [CrossRef]

- Johnson, D.L.; Mead, K.R.; Lynch, R.A.; Hirst, D.V. Lifting the lid on toilet plume aerosol: A literature review with suggestions for future research. Am. J. Infect. Control 2013, 41, 254–258. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Yao, L.; Gao, Z.; Wang, F. Particle exposure risk to a lavatory user after flushing a squat toilet. Sci. Rep. 2022, 12, 21088. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Yang, X.; Xu, T.; Sun, L.; Gong, W. Optimization of bathroom ventilation design for an ISO Class 5 clean ward. Build. Simul. 2009, 2, 133–142. [Google Scholar] [CrossRef]

- Mui, K.W.; Wong, L.T.; Yu, H.; Cheung, C.; Li, N. Exhaust ventilation performance in residential washrooms for bioaerosol particle removal after water closet flushing. Build. Serv. Eng. Res. Technol. 2017, 38, 32–46. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhu, L.; Huang, Q.; Wang, Y.; Sun, Y.; Bi, D. Optimization of toilet bowl ventilation technology for odor control and energy efficiency enhancement in public toilet. Sci. Rep. 2025, 15, 4941. [Google Scholar] [CrossRef]

- Tu, R.; Shang, Y.; Li, X.; He, F.; Tu, J. Optimizing cabin air inlet velocities and personal risk assessment: Introducing the Personal Contamination Ratio (PCR) method for enhanced aircraft cabin infection risk evaluation. PLoS ONE 2024, 19, e0309730. [Google Scholar] [CrossRef]

- Chung, S.-C.; Lin, Y.-P.; Yang, C.; Lai, C.-M. Natural ventilation effectiveness of awning windows in restrooms in K-12 public schools. Energies 2019, 12, 2414. [Google Scholar] [CrossRef]

- Yu, J.; Qian, C.; Zhao, J.; Tao, J.; Leng, K.; Xu, X. Indoor air quality improvement in public toilets at railway stations in China: A field and numerical study. Sustainability 2023, 15, 8720. [Google Scholar] [CrossRef]

- Li, P.; Liu, W.; Zhang, T.T. CFD modeling of dynamic airflow and particle transmission in an aircraft lavatory. Build. Simul. 2023, 16, 1375–1390. [Google Scholar] [CrossRef]

- Dominique, M.; Guitton, P. Validation of Displacement Ventilation Simplified Models. Proc. Build. Simul. 1997, 1, 233–239. [Google Scholar]

- Schreck, J.H.; Lashaki, M.J.; Hashemi, J.; Dhanak, M.; Verma, S. Aerosol generation in public restrooms. Phys. Fluids 2021, 33, 033320. [Google Scholar] [CrossRef] [PubMed]

| Items | Boundary Settings |

|---|---|

| Air inlet | Flow rate inlet, 50 m3/h, 22 °C |

| Exhaust air vent | Flow rate outlet, 100 m3/h |

| Supply air vent | Pressure inlet, Atmospheric, 22 °C |

| Manikin surface | 31 °C |

| The rest of the wall surface | Adiabatic |

| Flushing-generated aerosol Releasing time: 31–35 s | 0.5 μm, 3600 |

| 1 μm, 2400 | |

| 5 μm, 1200 | |

| Continuous ammonia leakage from the walls of the commode | 5 × 10−6 m3/s [29,30] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Chen, Y.; Wang, S.; Ma, Y. CFD Simulation of Aerosol and Odor Gas Transport Dynamics in Shipboard Underwater Lavatories. Processes 2025, 13, 2706. https://doi.org/10.3390/pr13092706

Li P, Chen Y, Wang S, Ma Y. CFD Simulation of Aerosol and Odor Gas Transport Dynamics in Shipboard Underwater Lavatories. Processes. 2025; 13(9):2706. https://doi.org/10.3390/pr13092706

Chicago/Turabian StyleLi, Pin, Yongxing Chen, Shanran Wang, and Yuanjin Ma. 2025. "CFD Simulation of Aerosol and Odor Gas Transport Dynamics in Shipboard Underwater Lavatories" Processes 13, no. 9: 2706. https://doi.org/10.3390/pr13092706

APA StyleLi, P., Chen, Y., Wang, S., & Ma, Y. (2025). CFD Simulation of Aerosol and Odor Gas Transport Dynamics in Shipboard Underwater Lavatories. Processes, 13(9), 2706. https://doi.org/10.3390/pr13092706