Analysis of the Effectiveness Mechanism and Research on Key Influencing Factors of High-Pressure Water Injection in Low-Permeability Reservoirs

Abstract

1. Introduction

2. Effective Mechanism of High-Pressure Water Injection Development in Low-Permeability Reservoirs

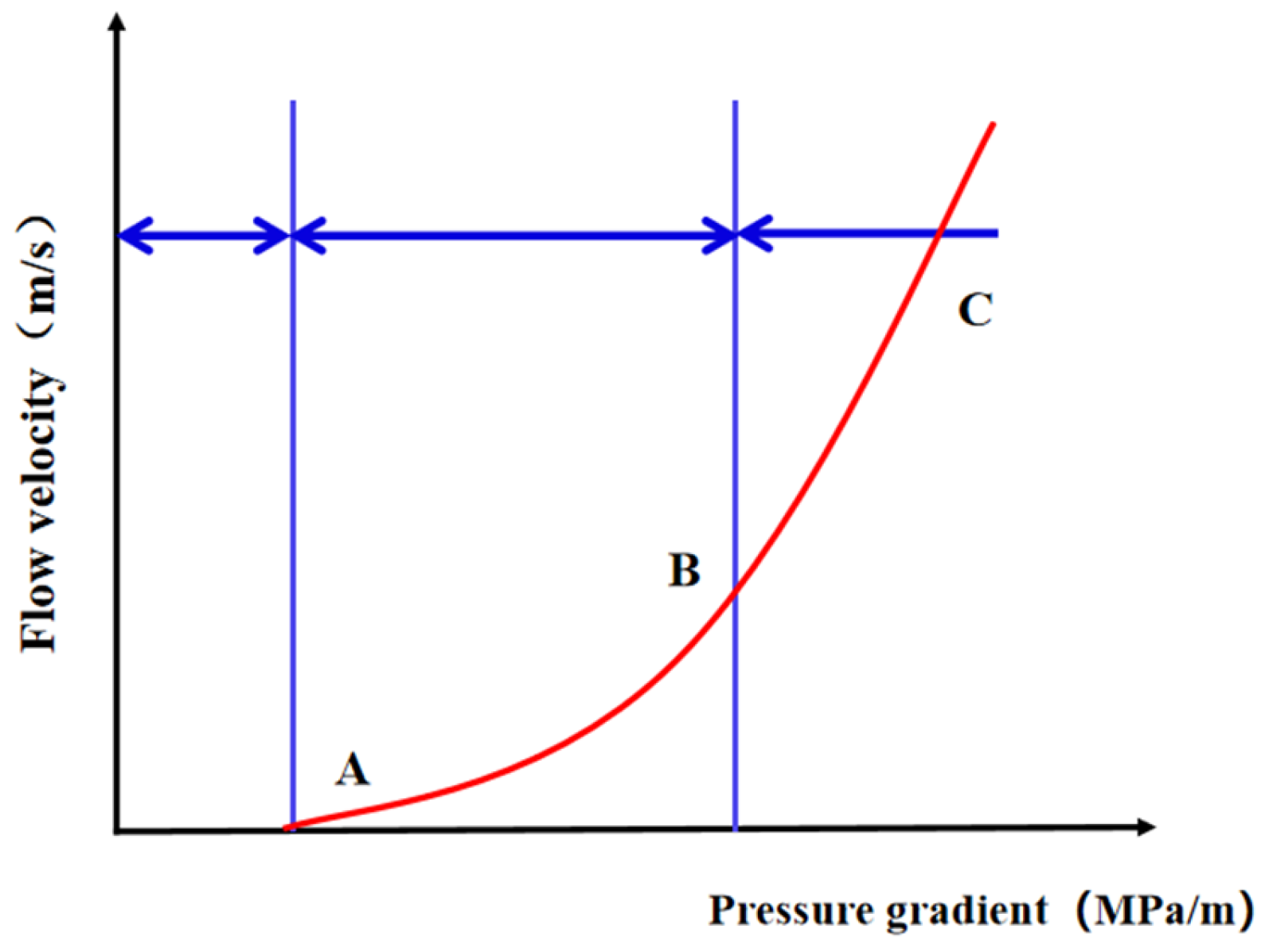

2.1. Seepage Characteristics of Low-Permeability Reservoirs

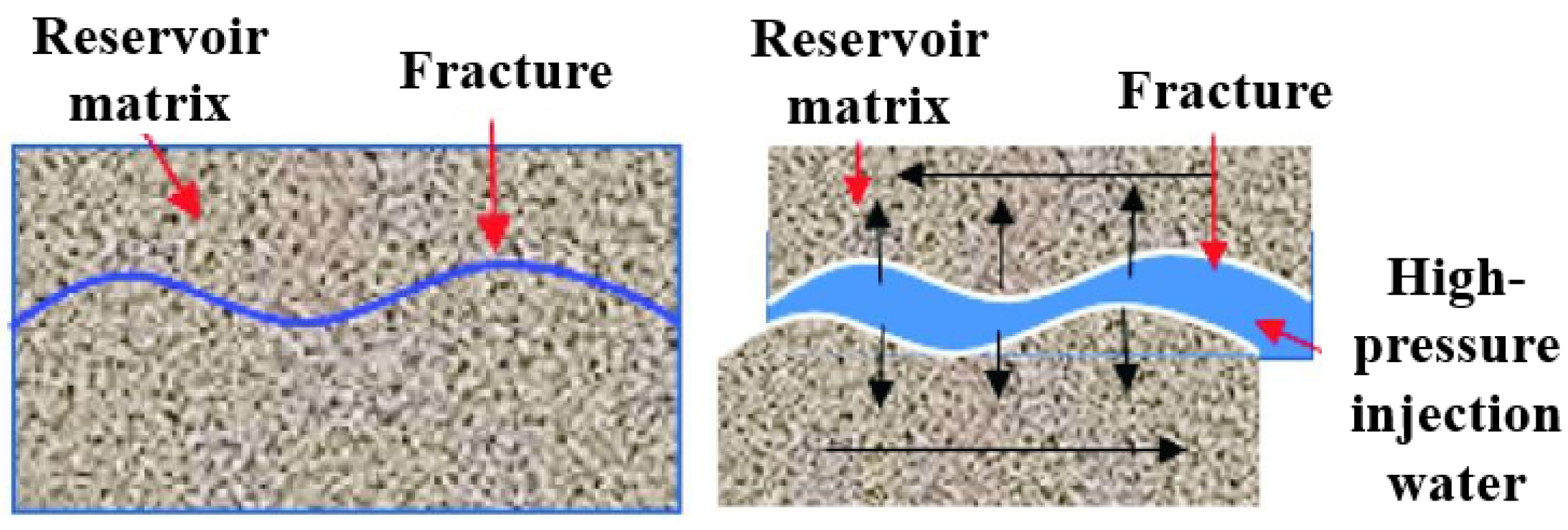

2.2. The Mechanism of High-Pressure Water Injection Expansion and Permeability Enhancement in Low-Permeability Rock Strata

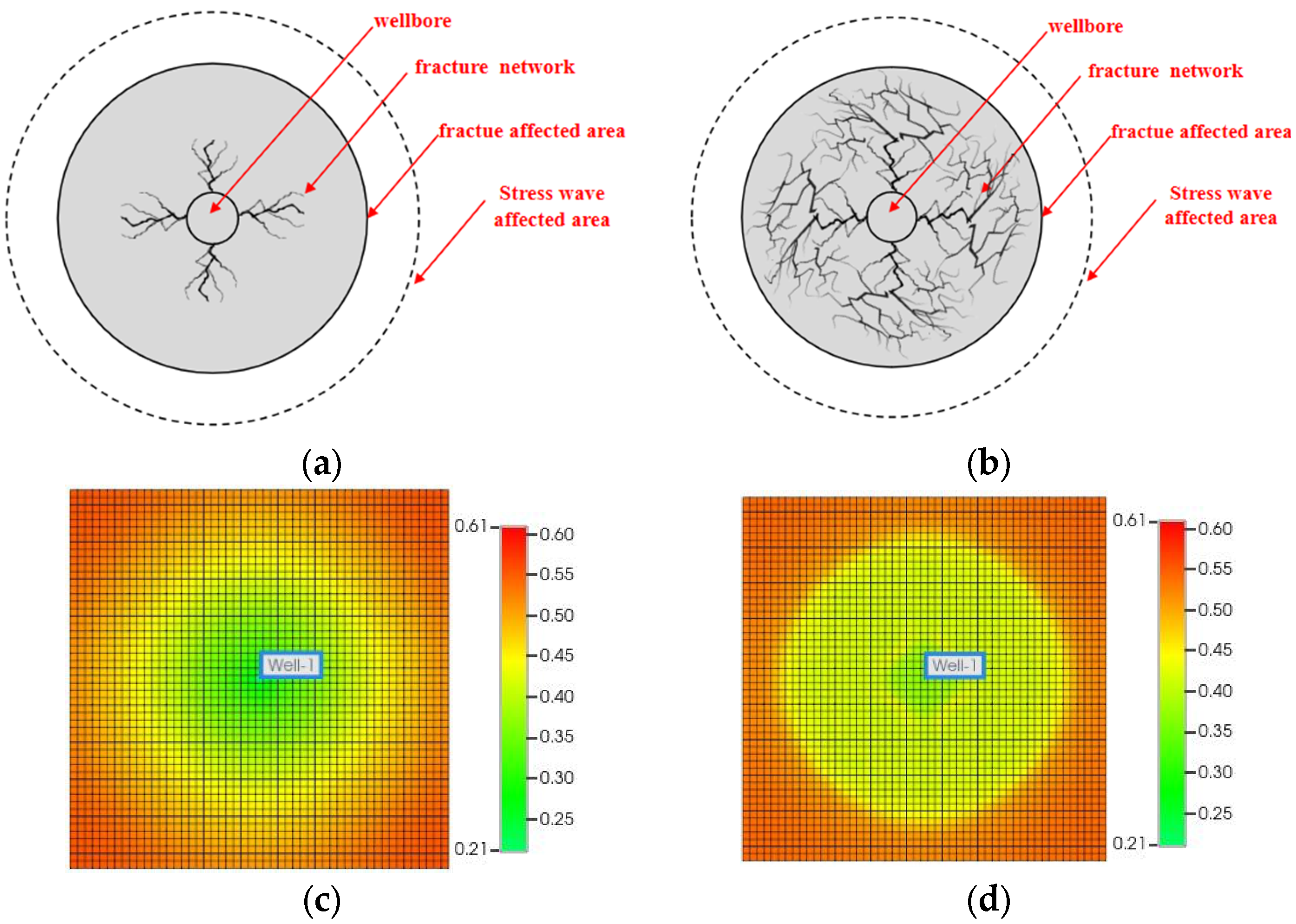

2.3. Dynamic Fracture Induction Mechanism

3. Analysis of the Reasons for High-Pressure Water Injection in Research Block

3.1. Geological Factors

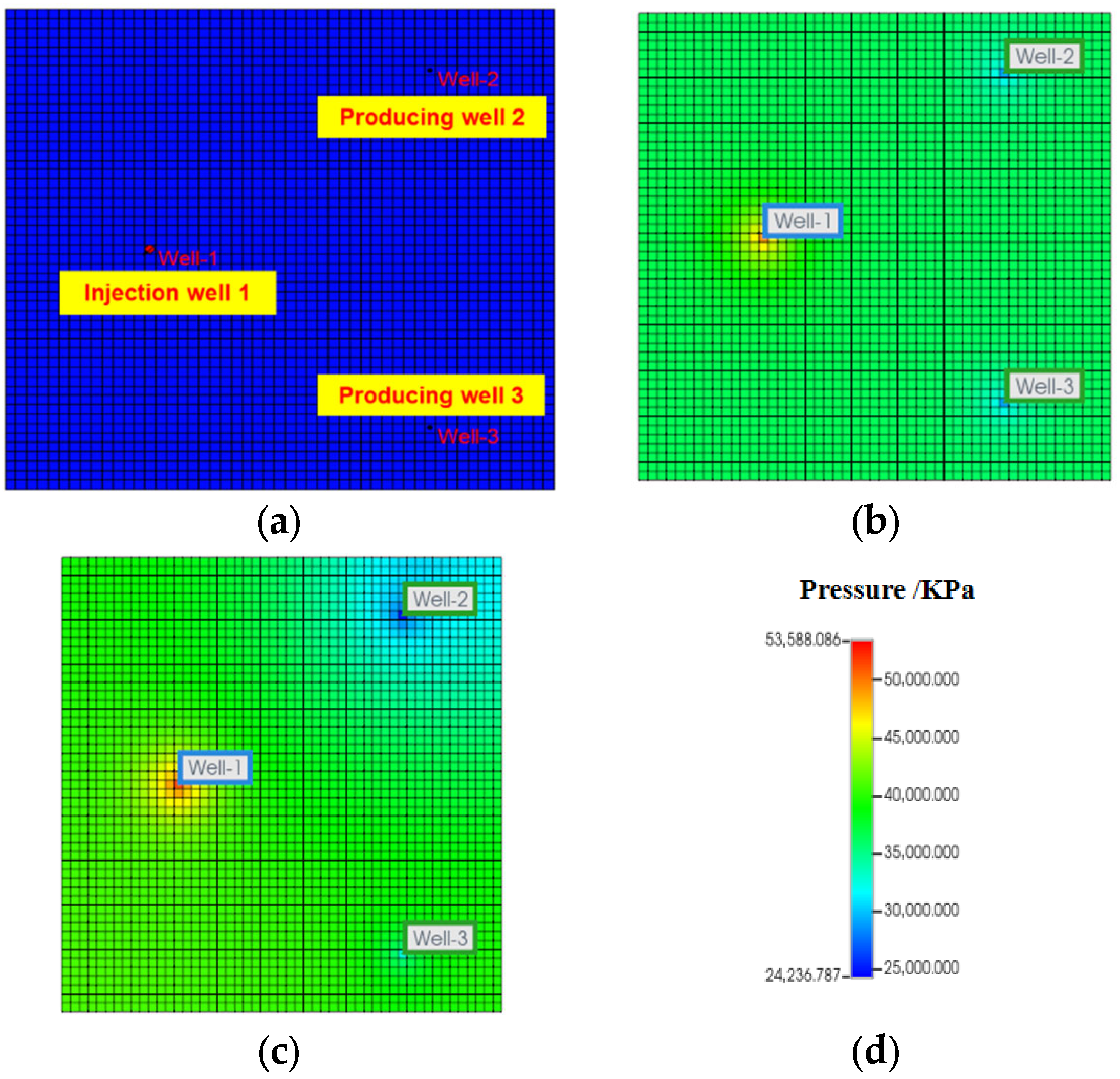

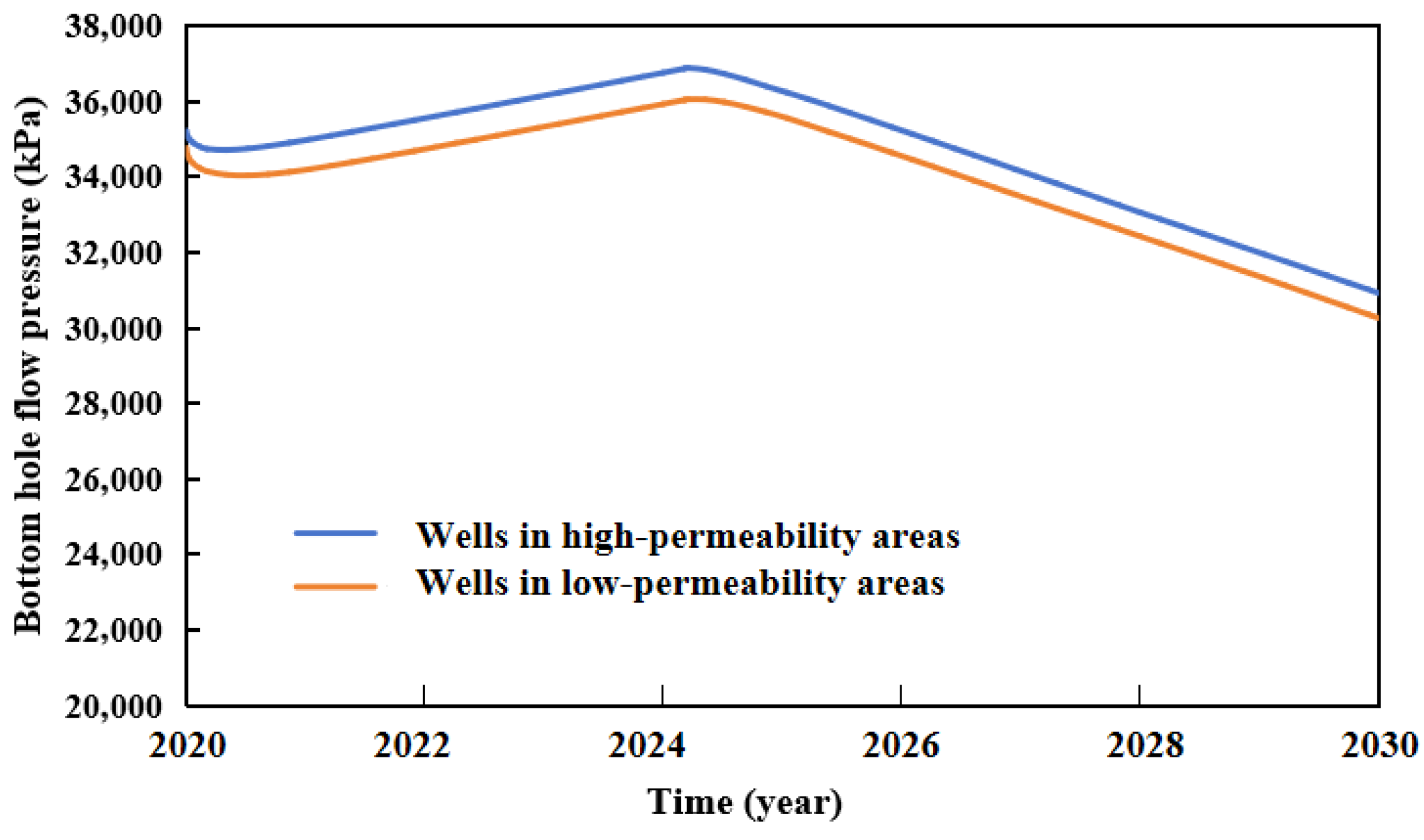

3.1.1. Formation Pressure Depletion

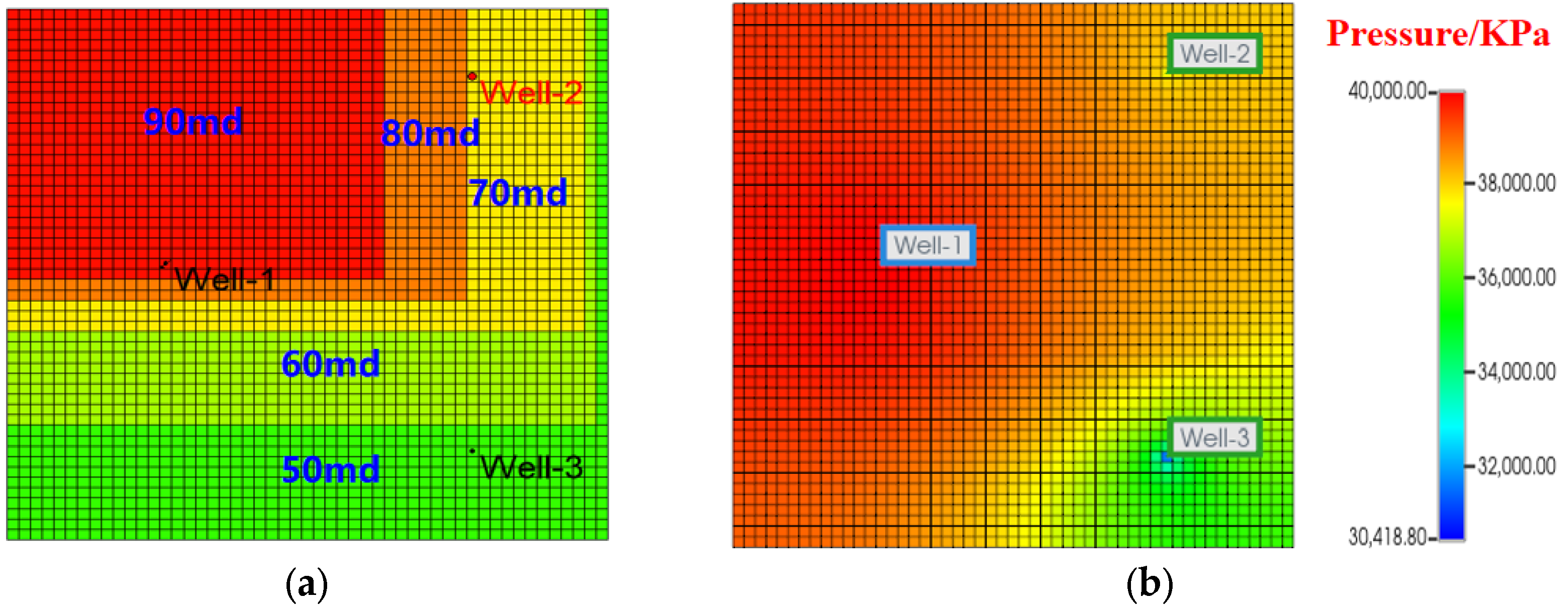

3.1.2. Reservoir Heterogeneity

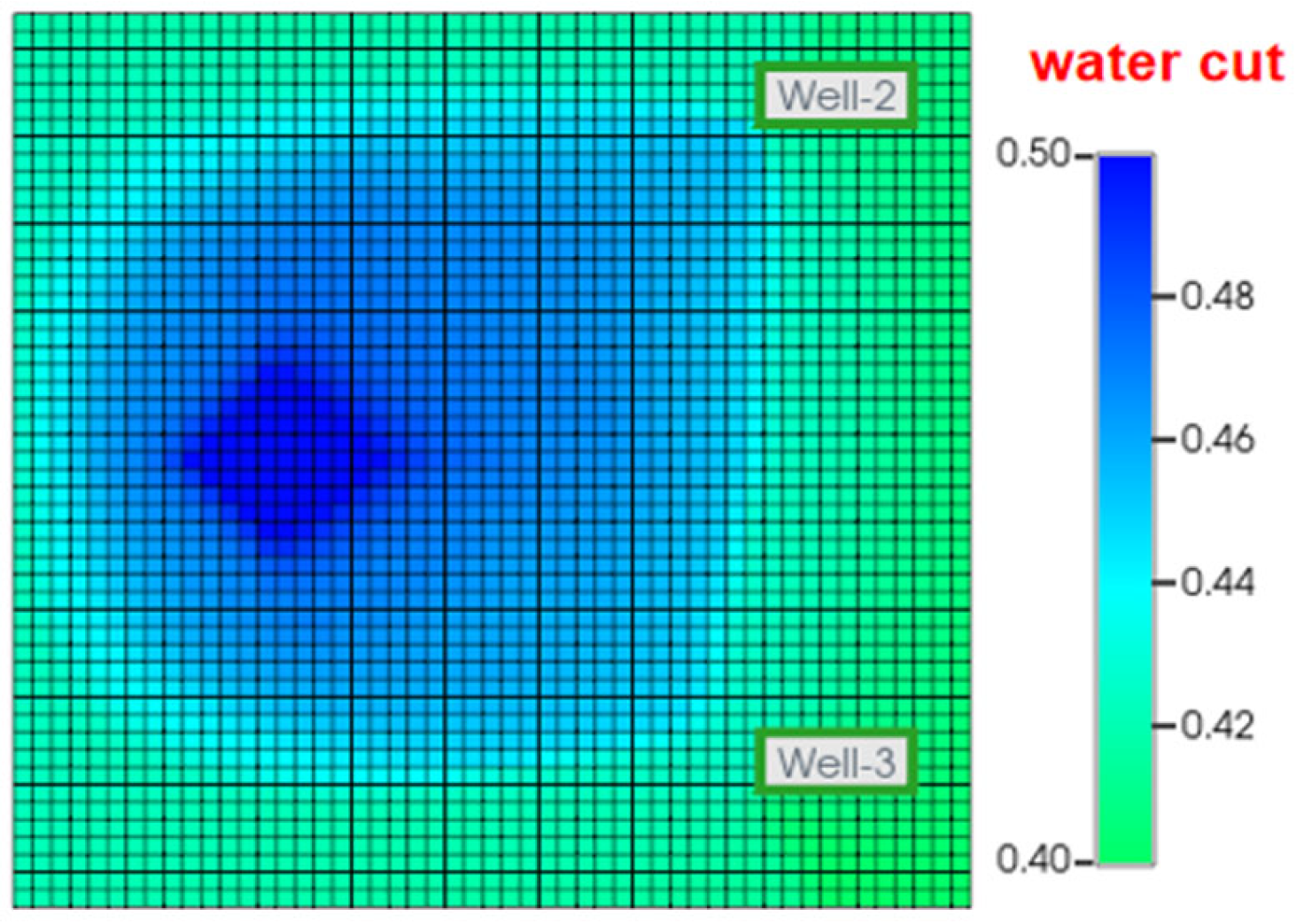

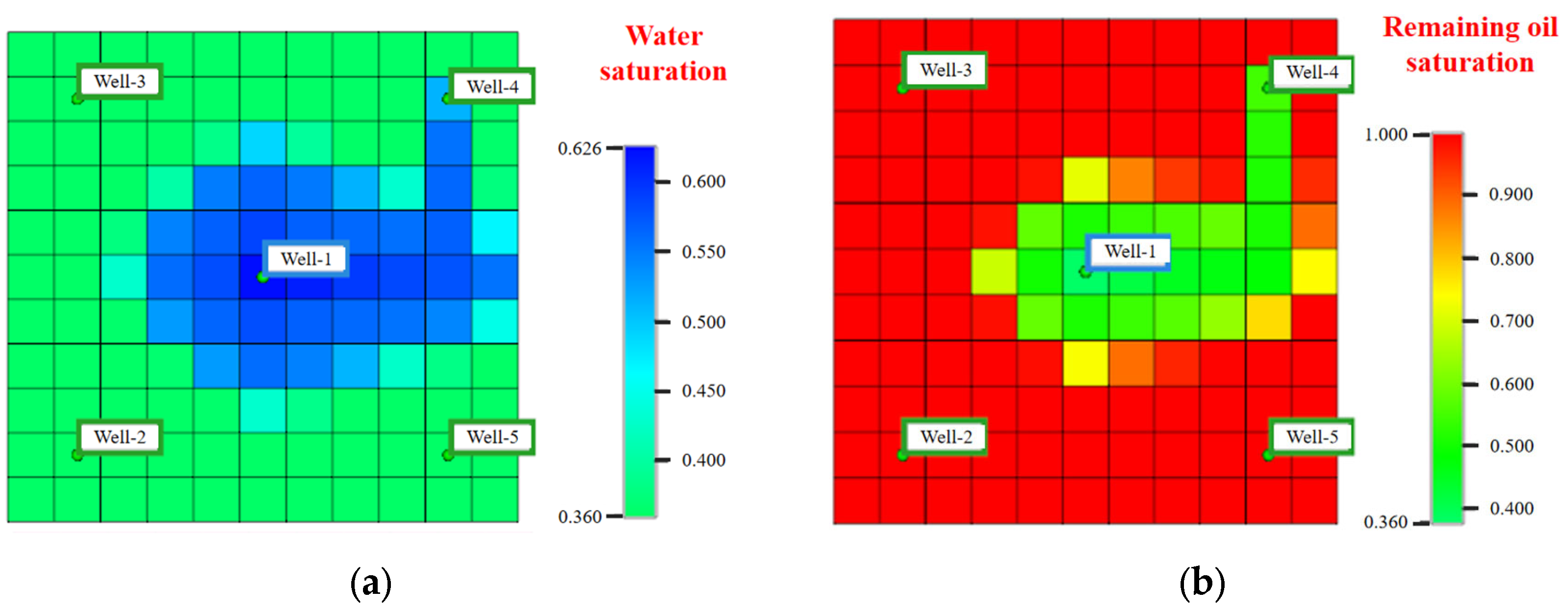

3.1.3. Water Flow Dominant Channel

3.2. Engineering Factors

3.2.1. Fracturing Stimulation Measures

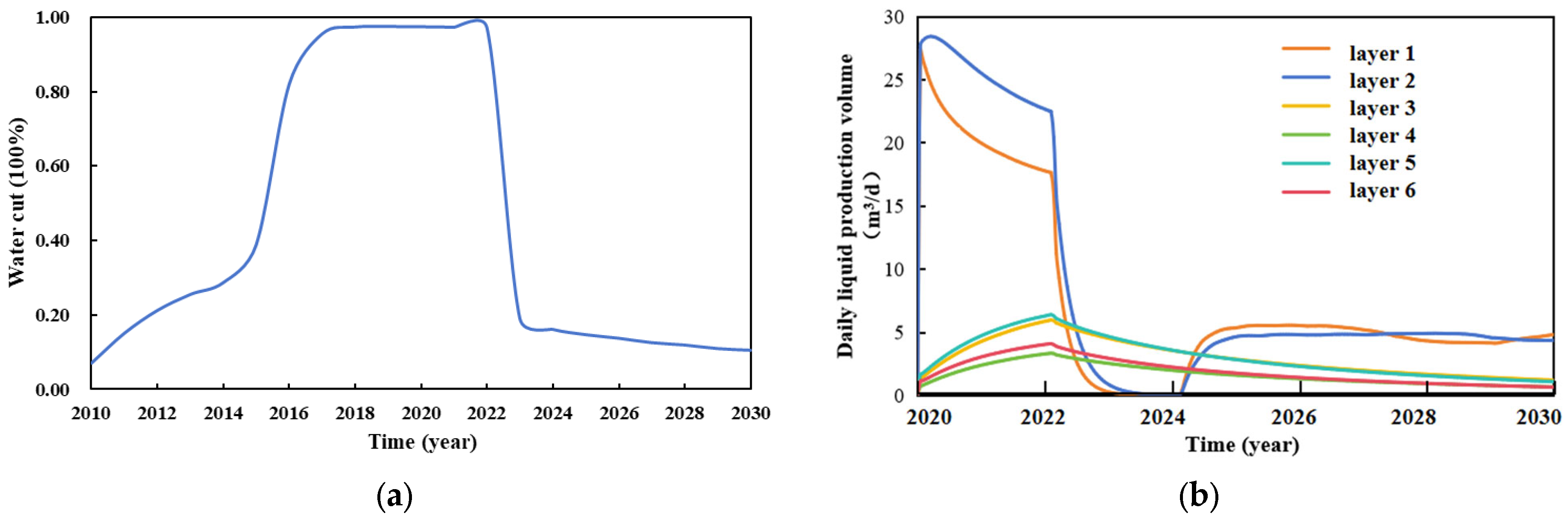

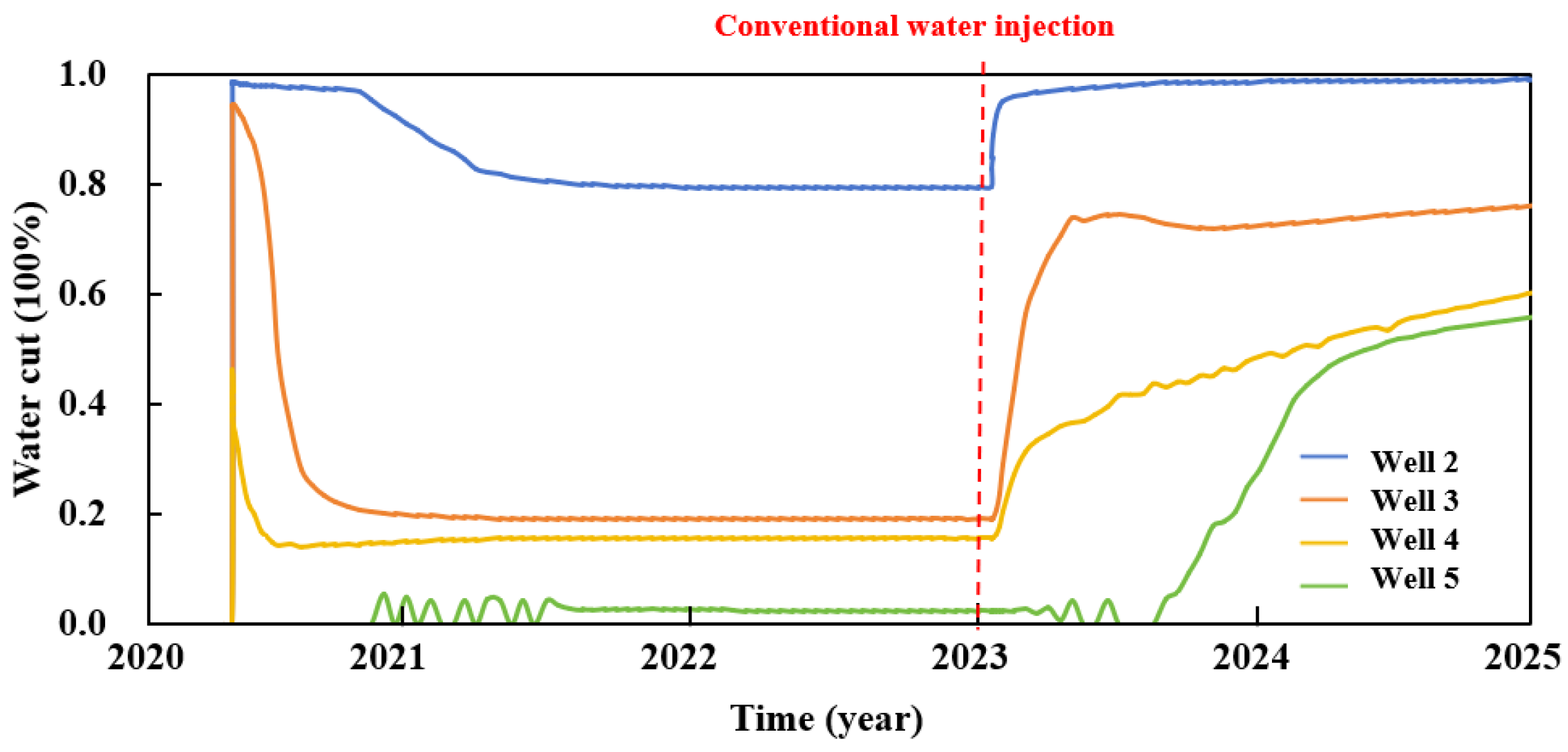

3.2.2. Water Injection Rate

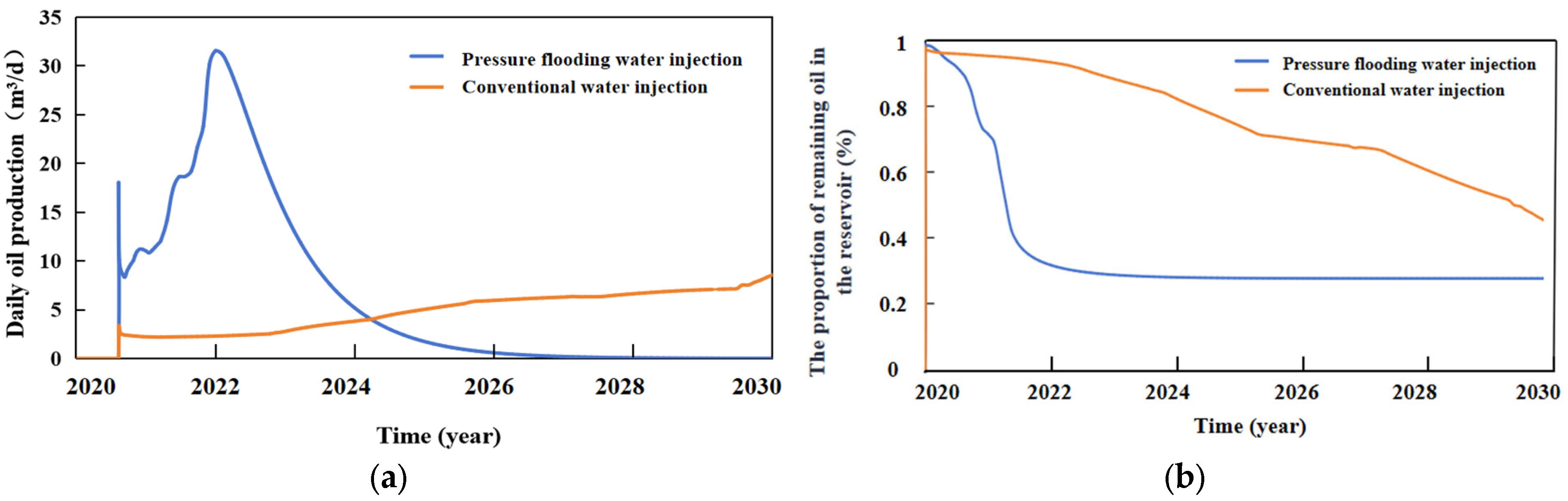

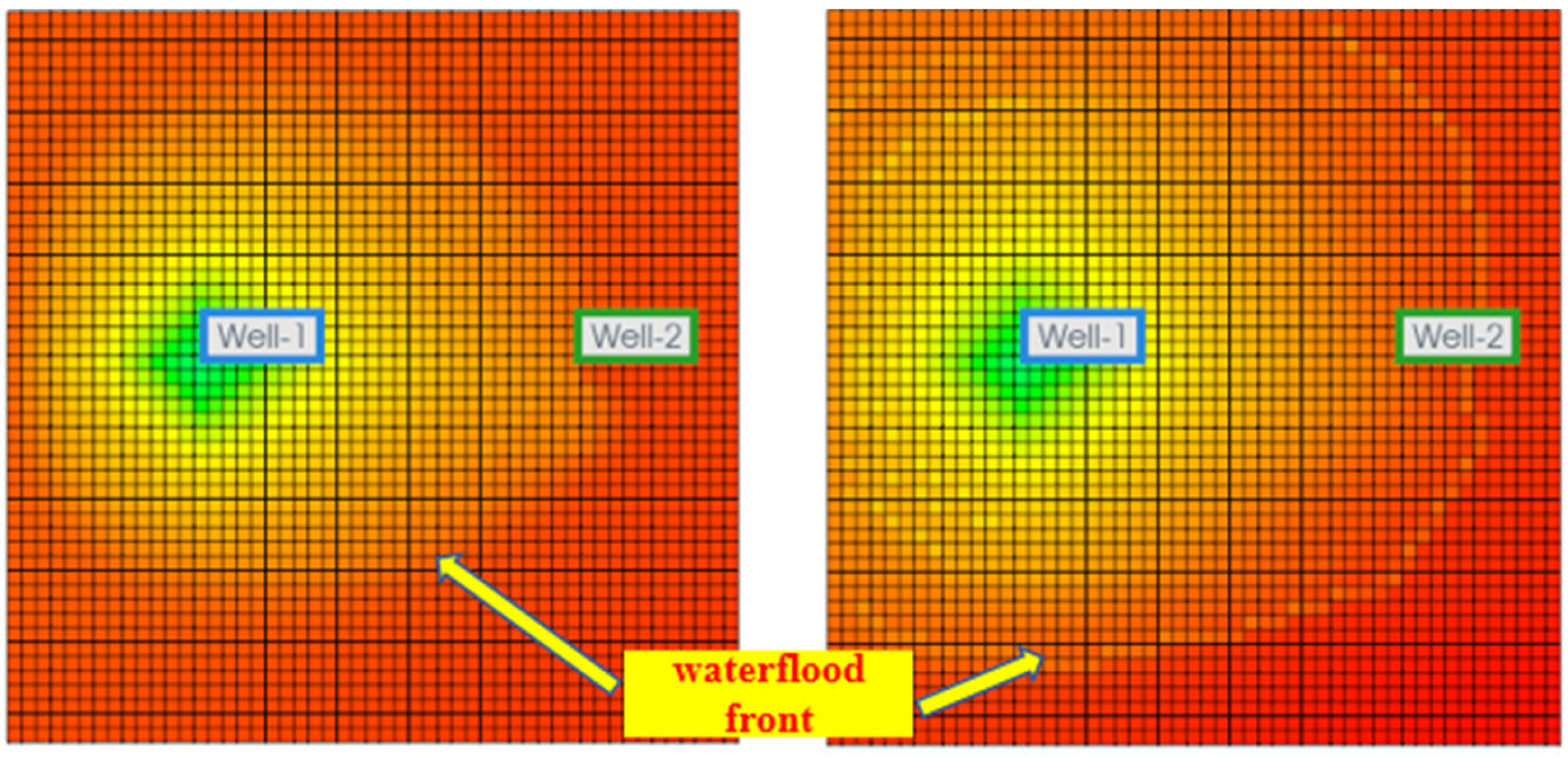

3.2.3. Microfracture Produced by High-Pressure Water Injection

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zeng, F.; Dong, C.; Lin, C.; Tian, S.; Wu, Y.; Lin, J.; Liu, B.; Zhang, X. Pore structure characteristics of reservoirs of Xihu Sag in East China Sea Shelf Basin based on dual resolution X-ray computed tomography and their influence on permeability. Energy. 2022, 239, 122386. [Google Scholar] [CrossRef]

- Xiao, W.; Ren, J.; Pu, W.; Yuan, C.; Meng, L.; Zeng, L.; Zhao, H.; Chen, Q. Laboratory tests and field pilot of foam-assisted deoxidized-air flooding in a low-permeability sandstone reservoir. Fuel 2023, 352, 129150. [Google Scholar] [CrossRef]

- Wang, Z.; Cao, G.; Bai, Y.; Wang, P.; Wang, X. Development Status and Prospect of EOR Technology in Low-Permeability Reservoirs. Spec. Oil Gas Reserv. 2023, 30, 1–13. [Google Scholar]

- Li, X.; Yang, Z.; Li, S.; Huang, W.; Zhan, J.; Lin, W. Reservoir characteristics and effective development technology in typical low-permeability to ultralow-permeability reservoirs of China National Petroleum Corporation. Energy Explor. Exploit. 2021, 39, 1713–1726. [Google Scholar] [CrossRef]

- Park, S.Y.; Ahn, K.I. Evaluation of an accident management strategy of emergency water injection using fire engines in a typical pressurized water reactor. Nucl. Eng. Technol. 2015, 47, 719–728. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, S.; Cao, X.; Lv, Q.; Wang, J.; Liu, H.; Yu, C.; Sun, H. Practice and understanding of pressure-driven development technology in Shengli Oilfield. Pet. Geol. Recovery Effic. 2023, 30, 61–71. [Google Scholar] [CrossRef]

- Chen, L.; Jia, C.; Zhang, R.; Yue, P.; Jiang, X.; Wang, J.; Su, Z.; Xiao, Y.; Lv, Y. High-pressure capacity expansion and water injection mechanism and indicator curve model for fractured-vuggy carbonate reservoirs. Petroleum 2024, 10, 511–519. [Google Scholar] [CrossRef]

- Worm, J.; Naber, J.; Duncan, J.; Barros, S.; Atkinson, W. Water injection as an enabler for increased efficiency at high-load in a direct injected, boosted, SI engine. SAE Int. J. Engines 2017, 10, 951–958. [Google Scholar] [CrossRef]

- Mahdavi, S.; James, L.A. High pressure and high-temperature study of CO2 saturated-water injection for improving oil displacement; mechanistic and application study. Fuel 2020, 262, 116442. [Google Scholar] [CrossRef]

- Tian, T.; Meng, Y.; Shi, S.; Wang, W. Development technologies and practice of undeveloped reserves in Shengli Oilfield. Pet. Geol. Recovery Effic. 2024, 31, 122–129. [Google Scholar] [CrossRef]

- Ma, X.; Bi, Y.; Jiang, M.; Li, D.; Gu, X. Characteristics of water phase permeability variation in medium-low permeability oil reservoirs during high multiple waterflooding. Pet. Reserv. Eval. Dev. 2025, 15, 103–109. [Google Scholar] [CrossRef]

- Wang, J.; Liu, L.; Wu, Y.; Liu, H.; Jia, Y. Progress and direction of water flooding development technologies in Shengli Oilfield. Pet. Geol. Recovery Effic. 2024, 31, 99–112. [Google Scholar] [CrossRef]

- Wang, Y.; Song, X.; Tian, C.; Shi, C.; Li, J. Dynamic fractures are an emerging new development geological attribute in water-flooding development of ultra-low-permeability reservoirs. Pet. Explor. Dev. 2015, 42, 222–228. [Google Scholar] [CrossRef]

- Zhao, X.; Zeng, L.; Ji, B.; Jiao, J.; Li, P.; Zhang, Y.; Chen, M. Discussion on optimal injection pressure of fractured low-permeability sandstone reservoirs—A case study from Wangyao block in Ansaioilfield, Ordos Basin. Oil Gas Geol. 2015, 36, 855–861. [Google Scholar]

- Zhao, X.; Lv, W.; Wang, C.; Zhu, S.; Fan, J. Major factors controlling waterflooding-induced fracture development in low-permeability reservoirs-A case study of Chang 6 reservoir in W block in Ansai oilfield, Ordos Basin. Oil Gas Geol. 2020, 41, 586–595. [Google Scholar]

- Wang, W.; Peng, Y.; Li, G.; Lei, Z.; Lv, W. Research on Water Flooding Dynamic Fractures to Optimize Infill Drilling Spacing in Ultra-low-permeability reservoirs, Changqing Oilfield. Pet. Drill. Tech. 2015, 43, 106–110. [Google Scholar] [CrossRef]

- Liang, W.; Dang, H.; Liu, B.; Zhang, T.; Wang, X.; Hou, B.; Cui, P.; Wang, Q.; Zhang, F. Experiment and numerical simulation of water injection induced dynamic fractures in ultra-low-permeability reservoirs. Pet. Geol. Exp. 2023, 45, 566–575. [Google Scholar]

- Wang, Y.; Song, X. Comprehensive characterization integrating static and dynamic data for dynamic fractures in ultra-low-permeability reservoirs: A case study of the Chang 6 reservoir of the Triassic Yanchang Formation in the Ordos Basin, China. Minerals 2022, 12, 1277. [Google Scholar] [CrossRef]

- Wang, J.; Zheng, X.; Wang, Z.; Li, B.; Li, Y. Integrated approach to identify and control the water-injection induced fractures in the low-permeability reservoir. In Proceedings of the SPE Annual Caspian Technical Conference and Exhibition, Astana, Kazakhstan, 31 October–2 November 2018. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, Y.; Sun, Z.; Yu, C.; Sun, Q.; Bei, J. Physical simulation of fracturing-flooding and quantitative characterization of fractures in low-permeability oil reservoirs. Pet. Geol. Recovery Effic. 2022, 29, 143–149. [Google Scholar] [CrossRef]

- Lv, Y.; Guo, Z.; Chen, X.; Liu, D.; Zhang, Y.; Wang, Z. Analysis of Key Geological Factors of High Pressure Water Injection in Fractured Reservoir. Adv. Geosci. 2019, 11, 1050–1055. [Google Scholar] [CrossRef]

- Souza, A.L.S.; Fernandes, P.D.; Mendes, R.A.; Rosa, A.J.; Furtado, C.J.A. The impact of injection with fracture propagation during waterflooding process. In Proceedings of the SPE Latin America and Caribbean Petroleum Engineering Conference. Rio de Janeiro, Brazil, 20–23 June 2005. [Google Scholar] [CrossRef]

- Ma, X.; Li, H.; Luo, H.; Nie, S.; Gao, S.; Zhang, Q.; Yuan, F.; Ai, W. Research on well selection method for high-pressure water injection in fractured-vuggy carbonate reservoirs in Tahe oilfield. J. Pet. Sci. Eng. 2022, 214, 110477. [Google Scholar] [CrossRef]

- Cui, C.; Li, H.; Wu, Z.; Zhang, C.; Li, H.; Zhang, Y.; Zheng, W. Analysis of pressures in water injection wells considering fracture influence induced by pressure-drive water injection. Pet. Reserv. Eval. Dev. 2023, 13, 686–694. [Google Scholar] [CrossRef]

- Zhu, W.; Gao, Y.; Wang, Y.; Liu, P.; Liu, Y. The injection capacity evaluation of high-pressure water injection in low permeability reservoir: Numerical and case study. Front. Earth Sci. 2024, 12, 1411451. [Google Scholar] [CrossRef]

- Zheng, S.; Yang, M.; Kang, Z.; Liu, Z.; Long, X.; Liu, K.; Li, X.; Zhang, S. Controlling factors of remaining oil distribution after water flooding and enhanced oil recovery methods for fracture-cavity carbonate reservoirs in Tahe Oilfield. Pet. Explor. Dev. 2019, 46, 786–795. [Google Scholar] [CrossRef]

- Wang, X.; Qiao, X.; Mi, N.; Wang, R. Technologies for the benefit development of low-permeability tight sandstone gas reservoirs in the Yan’an Gas Field, Ordos Basin. Nat. Gas Ind. B 2019, 6, 272–281. [Google Scholar] [CrossRef]

- Zeng, L.; Gao, C.; Qi, J.; Wang, Y.; Li, L.; Qu, X. The distribution rule and seepage effect of the fractures in the ultra-low permeability sandstone reservoir in east Gansu Province, Ordos Basin. Sci. China Ser. D Earth Sci. 2008, 51 (Suppl. SII), 44–52. [Google Scholar] [CrossRef]

- Prioul, R.; Jocker, J. Fracture characterization at multiple scales using borehole images, sonic logs, and walkaround vertical seismic profile. AAPG Bull. 2009, 93, 1503–1516. [Google Scholar] [CrossRef]

- Wanniarachchi, W.A.M.; Ranjith, P.G.; Perera, M.S.A.; Rathnaweera, T.D.; Zhang, D.C. Investigation of effects of fracturing fluid on hydraulic fracturing and fracture permeability of reservoir rocks: An experimental study using water and foam fracturing. Eng. Fract. Mech. 2018, 194, 117–135. [Google Scholar] [CrossRef]

- Hu, W.; Wei, Y.; Bao, J. Development of the theory and technology for low permeability reservoirs in China. Pet. Explor. Dev. 2018, 45, 685–697. [Google Scholar] [CrossRef]

- Di, S.; Zhao, Y.; Ma, S.; Wei, Y.; Chen, S.; Miu, L. Fracture-to-fracture stimulation method for horizontal wells in fractured tight reservoir. Pet. Geol. Oilfield Dev. Daqing 2025, 44, 168–174. [Google Scholar] [CrossRef]

- Wang, Y.; Song, X.; Meng, F.; Liang, Y.; Jiang, T. Dynamic fracture characteristics and controlling factors of ultra-low permeability reservoirs in Ordos Basin. Acta Pet. Sin. 2025, 46, 588–598. [Google Scholar]

- Yang, Y.; Wang, J.; Bu, Y.; Sun, D. Practice and understanding of pressure-driven development technology in Shengli Oilfield. Pet. Geol. Recovery Effic. 2023, 1–7. Available online: https://link.cnki.net/urlid/37.1359.TE.20230424.1050.002 (accessed on 18 August 2025).

- Gao, Y.; Li, D.; Chen, H.; Cao, Y.; Yu, J.; Wu, S.; Chen, X.; Yuan, H.; Chen, Z. Mechanism and application of rock dilation-induced injectivity enhancement in injection wells for offshore oil field. J. Northwest Univ. (Nat. Sci. Ed.) 2025, 55, 613–632. [Google Scholar] [CrossRef]

| Year | Experimental Group, Bottom Hole Flowing Pressure (kPa) | Control Group, Bottom Hole Flowing Pressure (kPa) | ||

|---|---|---|---|---|

| Well-2 (Deficit Well) | Well-3 (Newly Opened Well) | Well-2 (Deficit Well) | Well-3 (Newly Opened Well) | |

| 2020 | 26,471.96 | 26,471.96 | 26,401.14 | 36,430.00 |

| 2021 | 16,885.44 | 16,885.48 | 15,789.76 | 36,256.08 |

| 2022 | 17,040.81 | 17,040.79 | 12,907.02 | 35,563.70 |

| 2023 | 18,581.47 | 18,581.42 | 10,951.85 | 34,639.21 |

| 2024 | 21,986.09 | 21,986.06 | 9274.36 | 33,633.14 |

| 2025 | 25,274.68 | 25,274.66 | 7718.77 | 32,588.81 |

| 2026 | 25,274.60 | 27,878.65 | 6566.71 | 31,530.23 |

| 2027 | 27,878.66 | 29,624.72 | 5882.63 | 30,459.88 |

| 2028 | 29,624.71 | 31,624.32 | 4907.04 | 10,321.08 |

| 2029 | 31,624.30 | 34,015.21 | 7666.73 | 8006.76 |

| 2030 | 34,015.22 | 36,258.50 | 7999.32 | 7718.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Xu, H.; Fu, S.; Zhao, H.; Chen, Z.; Bai, X.; Li, J.; Xiu, C.; Zhang, L.; Wang, J. Analysis of the Effectiveness Mechanism and Research on Key Influencing Factors of High-Pressure Water Injection in Low-Permeability Reservoirs. Processes 2025, 13, 2664. https://doi.org/10.3390/pr13082664

Li Y, Xu H, Fu S, Zhao H, Chen Z, Bai X, Li J, Xiu C, Zhang L, Wang J. Analysis of the Effectiveness Mechanism and Research on Key Influencing Factors of High-Pressure Water Injection in Low-Permeability Reservoirs. Processes. 2025; 13(8):2664. https://doi.org/10.3390/pr13082664

Chicago/Turabian StyleLi, Yang, Hualei Xu, Shanshan Fu, Hongtao Zhao, Ziqi Chen, Xuejing Bai, Jianyu Li, Chunhong Xiu, Lianshe Zhang, and Jie Wang. 2025. "Analysis of the Effectiveness Mechanism and Research on Key Influencing Factors of High-Pressure Water Injection in Low-Permeability Reservoirs" Processes 13, no. 8: 2664. https://doi.org/10.3390/pr13082664

APA StyleLi, Y., Xu, H., Fu, S., Zhao, H., Chen, Z., Bai, X., Li, J., Xiu, C., Zhang, L., & Wang, J. (2025). Analysis of the Effectiveness Mechanism and Research on Key Influencing Factors of High-Pressure Water Injection in Low-Permeability Reservoirs. Processes, 13(8), 2664. https://doi.org/10.3390/pr13082664