Recent Advances in Moderate Electric Field (MEF) Systems for Sustainable Food Processing

Abstract

1. Introduction

2. Moderate Electric Field (MEF) Systems and Current Applications

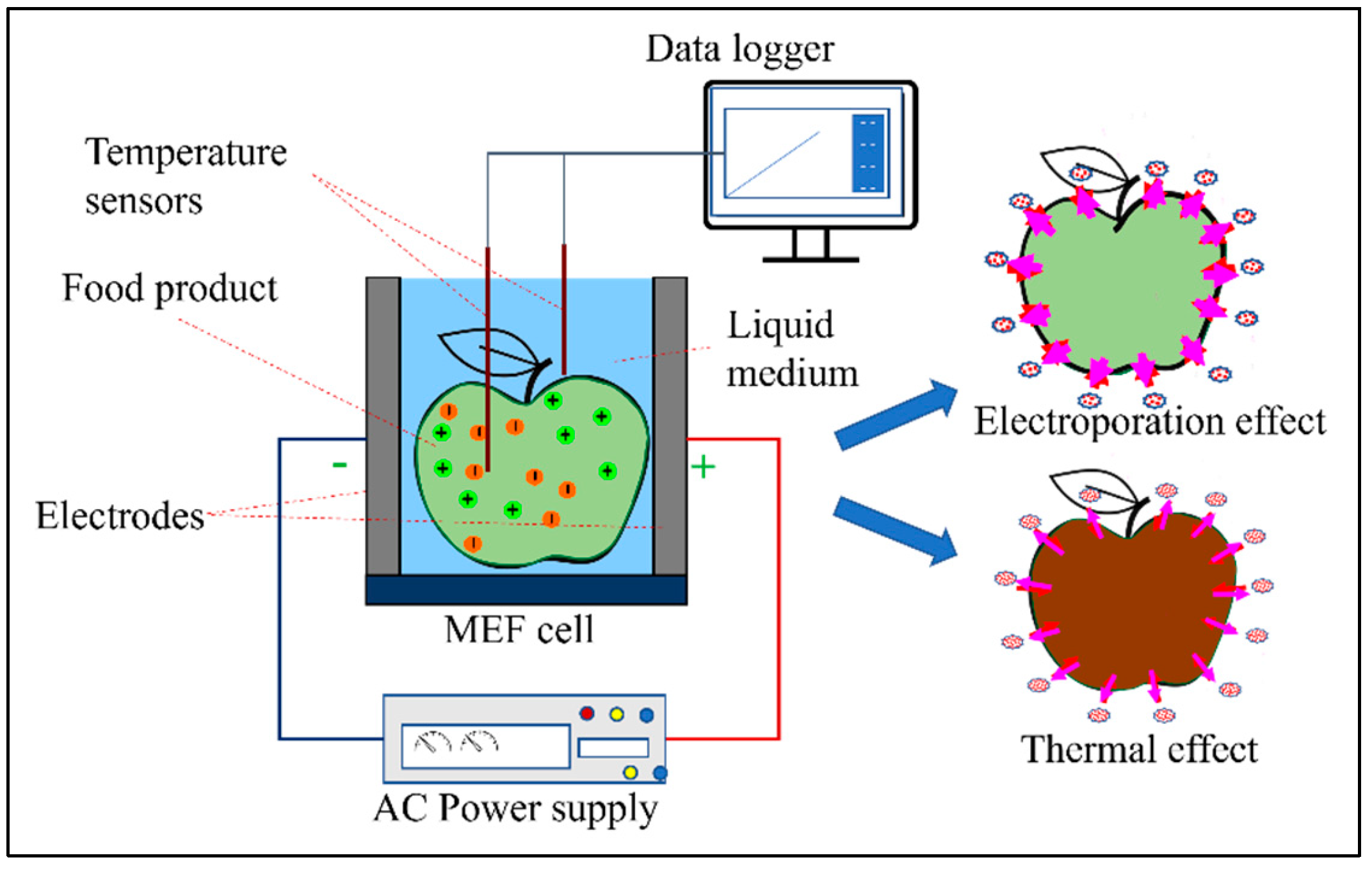

2.1. Basic Mechanism of MEF Technology

2.2. Advances in MEF Equipment Design

2.2.1. MEF Chamber and Electrode Materials

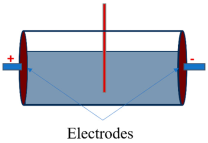

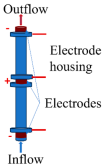

2.2.2. MEF System Design and Electrode Configurations

2.2.3. MEF Frequency and Waveforms

2.2.4. MEF Process Control

2.3. Electrical Conductivity of Foods

2.4. Electrical Conductivity of Foods—Prediction Equations

2.5. MEF Treatment in Electrically Conductive Packaging

3. The Role of Digital Tools in MEF Processing

4. Future Prospects of MEF Technology

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Priyadarshini, A.; Rajauria, G.; O’Donnell, C.P.; Tiwari, B.K. Emerging food processing technologies and factors impacting their industrial adoption. Crit. Rev. Food Sci. Nutr. 2019, 59, 3082–3101. [Google Scholar] [CrossRef] [PubMed]

- Chemat, F.; Rombaut, N.; Meullemiestre, A.; Turk, M.; Perino, S.; Fabiano-Tixier, A.S.; Abert-Vian, M. Review of Green Food Processing techniques. Preservation, transformation, and extraction. Innov. Food Sci. Emerg. Technol. 2017, 41, 357–377. [Google Scholar] [CrossRef]

- FAO. Renewable Energy and Agri-food Systems: Advancing Energy and Food Security towards Sustainable Development Goals; The International Renewable Energy Agency and The Food and Agriculture Organization of the United Nations: Rome, Italy, 2021. [Google Scholar] [CrossRef]

- Ramírez-Corona, N. Implementing process intensification principles for food processing by emerging technologies. Chem. Eng. Process.—Process Intensif. 2024, 205, 109981. [Google Scholar] [CrossRef]

- Gavahian, M.; Chaosuan, N.; Yusraini, E.; Sastry, S. Roles of ohmic heating to achieve sustainable development goals in the food industry: From reduced energy consumption and resource optimization to innovative production pathways with reduced carbon footprint. Trends Food Sci. Technol. 2025, 159, 2202–2211. [Google Scholar] [CrossRef]

- Gavahian, M.; Tiwari, B.K.; Chu, Y.H.; Ting, Y.W.; Farahnaky, A. Food texture as affected by ohmic heating: Mechanisms involved, recent findings, benefits, and limitations. Trends Food Sci. Technol. 2019, 86, 328–339. [Google Scholar] [CrossRef]

- Salari, S.; Jafari, S.M. The Influence of Ohmic Heating on Degradation of Food Bioactive Ingredients. Food Eng. Rev. 2020, 12, 191–208. [Google Scholar] [CrossRef]

- Makroo, H.A.; Rastogi, N.K.; Srivastava, B. Ohmic heating assisted inactivation of enzymes and microorganisms in foods: A review. Trends Food Sci. Technol. 2020, 97, 451–465. [Google Scholar] [CrossRef]

- Müller, W.A.; Ferreira Marczak, L.D.; Sarkis, J.R. Microbial inactivation by ohmic heating: Literature review and influence of different process variables. Trends Food Sci. Technol. 2020, 99, 650–659. [Google Scholar] [CrossRef]

- Jaeger, H.; Roth, A.; Toepfl, S.; Holzhauser, T.; Engel, K.H.; Knorr, D.; Vogel, R.F.; Bandick, N.; Kulling, S.; Heinz, V.; et al. Opinion on the use of ohmic heating for the treatment of foods. Trends Food Sci. Technol. 2016, 55, 84–97. [Google Scholar] [CrossRef]

- Turgay-İzzetoğlu, G.; Çokgezme, Ö.F.; Döner, D.; Ersoy, C.; Çabas, B.M.; İçier, F. Cooking the Chicken Meat with Moderate Electric Field: Rheological Properties and Image Processing of Microstructure. Food Bioprocess. Technol. 2022, 15, 1082–1100. [Google Scholar] [CrossRef]

- De Halleux, D.; Piette, G.; Buteau, M.; Dostie, M. Ohmic cooking of processed meats: Energy evaluation and food safety considerations. Can. Biosyst. Eng. 2005, 47, 341–347. [Google Scholar]

- Javed, T.; Oluwole-ojo, O.; Zhang, H.; Akmal, M.; Breikin, T.; O’Brien, A. System Design, Modelling, Energy Analysis, and Industrial Applications of Ohmic Heating Technology. Food Bioprocess Technol. 2024, 18, 2195–2217. [Google Scholar] [CrossRef]

- Darvishi, H.; Hosainpour, A.; Nargesi, F.; Fadavi, A. Exergy and energy analyses of liquid food in an Ohmic heating process: A case study of tomato production. Innov. Food Sci. Emerg. Technol. 2015, 31, 73–82. [Google Scholar] [CrossRef]

- Bedane, T.F.; Pedros-Garrido, S.; Quinn, G.; Lyng, J.G. The impact of emerging domestic and commercial electro-heating technologies on energy consumption and quality parameters of cooked beef. Meat Sci. 2021, 179, 108550. [Google Scholar] [CrossRef] [PubMed]

- Gavahian, M.; Tiwari, B.K. Moderate electric fields and ohmic heating as promising fermentation tools. Innov. Food Sci. Emerg. Technol. 2020, 64, 102422. [Google Scholar] [CrossRef]

- Astráin-Redín, L.; Ospina, S.; Cebrián, G.; Álvarez-Lanzarote, I. Ohmic Heating Technology for Food Applications, From Ohmic Systems to Moderate Electric Fields and Pulsed Electric Fields. Food Eng. Rev. 2024, 16, 225–251. [Google Scholar] [CrossRef]

- Lombergar, P.; Flisar, K.; Miklavčič, D.; Mahnič-Kalamiza, S. Time-dependent model of temperature distribution in continuous flow pulsed electric field treatment chambers. Innov. Food Sci. Emerg. Technol. 2024, 93, 103628. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, F.; Wang, J.; Yang, Z.; Huang, Z.; Xue, R. Digital twin for smart manufacturing equipment: Modeling and applications. Int. J. Adv. Manuf. Technol. 2025, 137, 4929–4946. [Google Scholar] [CrossRef]

- Geitner, C.; Iliev, O.; Matschuk, K.; Menne, A.; Nakos, P.; Osterroth, S.; Peters, M.; Steiner, K.; Zausch, J. Comparison of the Prediction of the Temperature Profile in an Ohmic Reactor on Different Modeling Scales. Chem. Ing. Tech. 2024, 96, 642–651. [Google Scholar] [CrossRef]

- Oluwole-ojo, O.; Javed, T.; Howarth, M.; Xu, X.; O’Brien, A.; Zhang, H. Model Validation and Real-Time Process Control of a Continuous Flow Ohmic Heater. Modelling 2024, 5, 752–775. [Google Scholar] [CrossRef]

- Tepnatim, W.; Daud, W.; Kamonpatana, P. Simulation of Thermal and Electric Field Distribution in Packaged Sausages Heated in a Stationary Versus a Rotating Microwave Oven. Foods 2021, 10, 1622. [Google Scholar] [CrossRef]

- Casaburi, O.; Petrosino, F.; Marra, F. Modeling Aspects in Simulation of MEF Processing of Solid Behaving Foods. Chemcical Eng. Trans. 2021, 87, 223–228. [Google Scholar] [CrossRef]

- Rivera, J.; Gratz, M.; Jaeger, H.; Schottroff, F. Computer-aided engineering: Quantification of the heating non-uniformity and distribution of the thermal load occurring during continuous ohmic and conventional thermal food sterilization. Innov. Food Sci. Emerg. Technol. 2024, 97, 103844. [Google Scholar] [CrossRef]

- Sastry, S. Ohmic Heating and Moderate Electric Field Processing. Food Sci. Technol. Int. 2008, 14, 419–422. [Google Scholar] [CrossRef]

- Samprovalaki, K.; Bakalis, S.; Fryer, P.J. Ohmic heating: Models and measurements. In Heat Transfer in Food Processing: Recent Developments and Applications; Yanniotis, S., Sunden, B., Eds.; Wit Press: Southampton, UK, 2007; Volume 21, pp. 159–186. [Google Scholar]

- Zell, M.; Lyng, J.G.; Cronin, D.A.; Morgan, D.J. Ohmic heating of meats: Electrical conductivities of whole meats and processed meat ingredients. Meat Sci. 2009, 83, 563–570. [Google Scholar] [CrossRef]

- Angel-Rendon, S.V.; Filomena-Ambrosio, A.; Hernandez-Carrion, M.; Llorca, E.; Hernando, I.; Quiles, A.; Sotelo-Diaz, I. Pork meat prepared by different cooking methods. A microstructural, sensorial and physicochemical approach. Meat Sci. 2020, 163, 108089. [Google Scholar] [CrossRef]

- Icier, F.; Sengun, I.Y.; Turp, G.Y.; Arserim, E.H. Effects of process variables on some quality properties of meatballs semi-cooked in a continuous type ohmic cooking system. Meat Sci. 2014, 96, 1345–1354. [Google Scholar] [CrossRef] [PubMed]

- Zell, M.; Lyng, J.G.; Cronin, D.A.; Morgan, D.J. Ohmic cooking of whole turkey meat—Effect of rapid ohmic heating on selected product parameters. Food Chem. 2010, 120, 724–729. [Google Scholar] [CrossRef]

- Zell, M.; Lyng, J.G.; Cronin, D.A.; Morgan, D.J. Ohmic cooking of whole beef muscle–evaluation of the impact of a novel rapid ohmic cooking method on product quality. Meat Sci. 2010, 86, 258–263. [Google Scholar] [CrossRef] [PubMed]

- Shirsat, N.; Brunton, N.P.; Lyng, J.G.; McKenna, B.; Scannell, A. Texture, colour and sensory evaluation of a conventionally and ohmically cooked meat emulsion batter. J. Sci. Food Agric. 2004, 84, 1861–1870. [Google Scholar] [CrossRef]

- Inmanee, P.; Kamonpatana, P.; Pirak, T. Ohmic heating effects on Listeria monocytogenes inactivation, and chemical, physical, and sensory characteristic alterations for vacuum packaged sausage during post pasteurization. LWT-Food Sci. Technol. 2019, 108, 183–189. [Google Scholar] [CrossRef]

- Negri Rodríguez, L.M.; Arias, R.; Soteras, T.; Sancho, A.; Pesquero, N.; Rossetti, L.; Tacca, H.; Aimaretti, N.; Rojas Cervantes, M.L.; Szerman, N. Comparison of the quality attributes of carrot juice pasteurized by ohmic heating and conventional heat treatment. LWT 2021, 145, 111255. [Google Scholar] [CrossRef]

- Doan, N.K.; Lai, Q.D.; Le, T.K.P.; Le, N.T. Influences of AC frequency and electric field strength on changes in bioactive compounds in Ohmic heating of pomelo juice. Innov. Food Sci. Emerg. Technol. 2021, 72, 102754. [Google Scholar] [CrossRef]

- Kim, S.S.; Park, S.H.; Kim, S.H.; Kang, D.H. Synergistic effect of ohmic heating and UV-C irradiation for inactivation of Escherichia coli O157:H7, Salmonella Typhimurium and Listeria monocytogenes in buffered peptone water and tomato juice. Food Control 2019, 102, 69–75. [Google Scholar] [CrossRef]

- Abedelmaksoud, T.G.; Mohsen, S.M.; Duedahl-Olesen, L.; Elnikeety, M.M.; Feyissa, A.H. Optimization of ohmic heating parameters for polyphenoloxidase inactivation in not-from-concentrate elstar apple juice using RSM. J. Food Sci. Technol. 2018, 55, 2420–2428. [Google Scholar] [CrossRef]

- Suebsiri, N.; Kokilakanistha, P.; Laojaruwat, T.; Tumpanuvatr, T.; Jittanit, W. The application of ohmic heating in lactose-free milk pasteurization in comparison with conventional heating, the metal contamination and the ice cream products. J. Food Eng. 2019, 262, 39–48. [Google Scholar] [CrossRef]

- Liu, L.; Llave, Y.; Jin, Y.; Zheng, D.-y.; Fukuoka, M.; Sakai, N. Electrical conductivity and ohmic thawing of frozen tuna at high frequencies. J. Food Eng. 2017, 197, 68–77. [Google Scholar] [CrossRef]

- Chen, Y.; Llave, Y.; Jiao, Y.; Okazaki, E.; Sakai, N.; Fukuoka, M. Ohmic tempering using a high frequency ohmic heating and model food of minced tuna based on Allaska pollock surimi—Evaluation of electrical conductivities. Innov. Food Sci. Emerg. Technol. 2022, 76, 102940. [Google Scholar] [CrossRef]

- Gally, T.; Rouaud, O.; Jury, V.; Le-Bail, A. Bread baking using ohmic heating technology; a comprehensive study based on experiments and modelling. J. Food Eng. 2016, 190, 176–184. [Google Scholar] [CrossRef]

- Waldert, K.; Bittermann, S.; Martinović, N.; Schottroff, F.; Jäger, H. Ohmic baking of wheat bread—Effect of process parameters on physico-chemical quality attributes. J. Food Eng. 2025, 392, 112493. [Google Scholar] [CrossRef]

- Panirani, P.N.; Darvishi, H.; Hosainpour, A.; Behroozi-Khazaei, N. Comparative study of different bread baking methods: Combined ohmic—Infrared, ohmic—Conventional, infrared—Conventional, infrared, and conventional heating. Innov. Food Sci. Emerg. Technol. 2023, 86, 103349. [Google Scholar] [CrossRef]

- Mattioli, N.G.; Olivera, D.F.; Salvadori, V.O.; Marra, F.; Goñi, S.M. Ohmic baking of gluten free sponge cake: Analysis of technological and quality characteristics. LWT 2024, 203, 116357. [Google Scholar] [CrossRef]

- Khodeir, M.; Rouaud, O.; Ogé, A.; Jury, V.; Le-Bail, P.; Le-Bail, A. Study of continuous cake pre-baking in a rectangular channel using ohmic heating. Innov. Food Sci. Emerg. Technol. 2021, 67, 102580. [Google Scholar] [CrossRef]

- Kristinawati, A.; Nikmatin, S.; Irmansyah; Setyaningsih, D. Extraction of citronella oil using an ohmic heating method. IOP Conf. Ser. Earth Environ. Sci. 2020, 460, 012014. [Google Scholar] [CrossRef]

- Moongngarm, A.; Loypimai, P.; Fitriati, A.; Moontree, T. Ohmic heating assisted extraction the concentrations of phytochemicals in rice bran oil and unsaponifiable matter. Int. Food Res. J. 2019, 26, 1389–1396. [Google Scholar]

- Gavahian, M.; Chu, Y.H.; Sastry, S. Extraction from Food and Natural Products by Moderate Electric Field: Mechanisms, Benefits, and Potential Industrial Applications. Compr. Rev. Food. Sci. Food Saf. 2018, 17, 1040–1052. [Google Scholar] [CrossRef] [PubMed]

- Guida, V.; Ferrari, G.; Pataro, G.; Chambery, A.; Di Maro, A.; Parente, A. The effects of ohmic and conventional blanching on the nutritional, bioactive compounds and quality parameters of artichoke heads. LWT-Food Sci. Technol. 2013, 53, 569–579. [Google Scholar] [CrossRef]

- Gomes, C.F.; Sarkis, J.R.; Marczak, L.D.F. Ohmic blanching of Tetsukabuto pumpkin: Effects on peroxidase inactivation kinetics and color changes. J. Food Eng. 2018, 233, 74–80. [Google Scholar] [CrossRef]

- Icier, F. Omhic blanching effects on drying of vegetable byproduct. J. Food Process Eng. 2010, 33, 661–683. [Google Scholar] [CrossRef]

- Wongsa-Ngasri, P.; Sastry, S.K. Tomato peeling by ohmic heating with lye-salt combinations: Effects of operational parameters on peeling time and skin diffusivity. J. Food Eng. 2016, 186, 10–16. [Google Scholar] [CrossRef]

- Wongsa-Ngasri, P.; Sastry, S.K. Effect of ohmic heating on tomato peeling. LWT-Food Sci. Technol. 2015, 61, 269–274. [Google Scholar] [CrossRef]

- Moreno-Vilet, L.; Hernandez-Hernandez, H.M.; Villanueva-Rodriguez, S.J. Current status of emerging food processing technologies in Latin America: Novel thermal processing. Innov. Food Sci. Emerg. Technol. 2018, 50, 196–206. [Google Scholar] [CrossRef]

- Moreno, J.; Espinoza, C.; Simpson, R.; Petzold, G.; Nunez, H.; Gianelli, M.P. Application of ohmic heating/vacuum impregnation treatments and air drying to develop an apple snack enriched in folic acid. Innov. Food Sci. Emerg. Technol. 2016, 33, 381–386. [Google Scholar] [CrossRef]

- Moreno, J.; Simpson, R.; Pizarro, N.; Pavez, C.; Dorvil, F.; Petzold, G.; Bugueno, G. Influence of ohmic heating/osmotic dehydration treatments on polyphenoloxidase inactivation, physical properties and microbial stability of apples (cv. Granny Smith). Innov. Food Sci. Emerg. Technol. 2013, 20, 198–207. [Google Scholar] [CrossRef]

- Sagita, D.; Darmajana, D.A.; Hidayat, D.D.; Novrinaldi; Sitorus, A. Design and performance of ohmic-based fermentor model for controlling fermentation process. Earth Environ. Sci. 2020, 542, 012033. [Google Scholar] [CrossRef]

- Singh, H.; Vatankhah, H.; Jassal, D.K.; Ramaswamy, H.S. Ohmic heating equipment for the food industry. In Emerging Thermal Processes in the Food Industry; Woodhead Publishing: Sawston, UK, 2023; pp. 245–260. [Google Scholar] [CrossRef]

- Maloney, N.; Harrison, M. Advanced Heating Technologies for Food Processing. In Innovation and Future Trends in Food Manufacturing and Supply Chain Technologies; Woodhead Publishing: Sawston, UK, 2016; pp. 203–256. [Google Scholar] [CrossRef]

- Lyng, J.G.; McKenna, B.M. Ohmic Heating of Foods. In Alternatives to Conventional Food Processing; Proctor, A., Ed.; Royal Society of Chemistry: Cambridge, UK, 2011; Volume 10, pp. 307–340. [Google Scholar]

- Zell, M.; Lyng, J.G.; Morgan, D.J.; Cronin, D.A. Minimising heat losses during batch ohmic heating of solid food. Food Bioprod. Process. 2011, 89, 128–134. [Google Scholar] [CrossRef]

- Samaranayake, C.P.; Sastry, S.K.; Zhang, H. Pulsed ohmic heating—A novel technique for minimization of electrochemical reactions during processing. J. Food Sci. 2005, 70, E460–E465. [Google Scholar] [CrossRef]

- Samaranayake, C.P.; Sastry, S.K. Electrode and pH effects on electrochemical reactions during ohmic heating. J. Electroanal. Chem. 2005, 577, 125–135. [Google Scholar] [CrossRef]

- Pataro, G.; Barca, G.M.J.; Pereira, R.N.; Vicente, A.A.; Teixeira, J.A.; Ferrari, G. Quantification of metal release from stainless steel electrodes during conventional and pulsed ohmic heating. Innov. Food Sci. Emerg. Technol. 2014, 21, 66–73. [Google Scholar] [CrossRef]

- Varghese, K.S.; Pandey, M.C.; Radhakrishna, K.; Bawa, A.S. Technology, applications and modelling of ohmic heating: A review. J. Food Sci. Technol. 2014, 51, 2304–2317. [Google Scholar] [CrossRef] [PubMed]

- Sakr, M.; Liu, S. A comprehensive review on applications of ohmic heating (OH). Renew. Sustain. Energy Rev. 2014, 39, 262–269. [Google Scholar] [CrossRef]

- Crattelet, J.; Ghnimi, S.; Debreyne, P.; Zaid, I.; Boukabache, A.; Esteve, D.; Auret, L.; Fillaudeau, L. On-line local thermal pulse analysis sensor to monitor fouling and cleaning: Application to dairy product pasteurisation with an ohmic cell jet heater. J. Food Eng. 2013, 119, 72–83. [Google Scholar] [CrossRef]

- Ryang, J.H.; Kim, N.H.; Lee, B.S.; Kim, C.T.; Lee, S.H.; Hwang, I.G.; Rhee, M.S. Inactivation of Bacillus cereus spores in a tsuyu sauce using continuous ohmic heating with five sequential elbow-type electrodes. J. Appl. Microbiol. 2016, 120, 175–184. [Google Scholar] [CrossRef]

- Shynkaryk, M.; Sastry, S.K. Simulation and optimization of the ohmic processing of highly viscous food product in chambers with sidewise parallel electrodes. J. Food Eng. 2012, 110, 448–456. [Google Scholar] [CrossRef]

- Park, S.H.; Balasubramaniam, V.M.; Sastry, S.K. Quality of shelf-stable low-acid vegetables processed using pressure-ohmic-thermal sterilization. LWT-Food Sci. Technol. 2014, 57, 243–252. [Google Scholar] [CrossRef]

- Kamonpatana, P.; Sastry, S.K. Electrical conductivity of foods and food components: The influence of formulation processes. J. Food Process Eng. 2022, 45, e13992. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, D.; Zhou, X.; Cui, Y.; Jiao, S.; Shi, X. Development of a pasteurization method based on radio frequency heating to ensure microbiological safety of liquid egg. Food Control 2021, 123, 107035. [Google Scholar] [CrossRef]

- Zareifard, M.R.; Ramaswamy, H.S.; Trigui, M.; Marcotte, M. Ohmic heating behaviour and electrical conductivity of two-phase food systems. Innov. Food Sci. Emerg. Technol. 2003, 4, 45–55. [Google Scholar] [CrossRef]

- Jittanit, W.; Khuenpet, K.; Kaewsri, P.; Dumrongpongpaiboon, N.; Hayamin, P.; Jantarangsri, K. Ohmic heating for cooking rice: Electrical conductivity measurements, textural quality determination and energy analysis. Innov. Food Sci. Emerg. Technol. 2017, 42, 16–24. [Google Scholar] [CrossRef]

- Kanjanapongkul, K. Rice cooking using ohmic heating: Determination of electrical conductivity, water diffusion and cooking energy. J. Food Eng. 2017, 192, 1–10. [Google Scholar] [CrossRef]

- Ding, X.; Liu, J.; Xiong, X.; Wang, S.; Li, X. Influence of ohmic heating on the electrical conductivity, volume, and rice quality of each component of the water–rice mixture. Innov. Food Sci. Emerg. Technol. 2021, 72, 102757. [Google Scholar] [CrossRef]

- Pedersen, S.J.; Feyissa, A.H.; Kavli, S.T.B.; Frosch, S. An investigation on the application of ohmic heating of cold water shrimp and brine mixtures. J. Food Eng. 2016, 179, 28–35. [Google Scholar] [CrossRef]

- Lascorz, D.; ToreIla, E.; Lyng, J.G.; Arroyo, C. The potential of ohmic heating as an alternative to steam for heat processing shrimps. Innov. Food Sci. Emerg. Technol. 2016, 37, 329–335. [Google Scholar] [CrossRef]

- Gratz, M.; Schottroff, F.; Gall, L.; Zejma, B.; Simon, F.; Jaeger, H. Advantages of ohmic cooking in the kilohertz-range—Part I: Impact of conductivity and frequency on the heating uniformity of potatoes. Innov. Food Sci. Emerg. Technol. 2021, 67, 102595. [Google Scholar] [CrossRef]

- Kim, S.S.; Lee, J.I.; Kang, D.H. Resistance of Escherichia coli O157:H7 ATCC 35150 to ohmic heating as influenced by growth temperature and sodium chloride concentration in salsa. Food Control 2019, 103, 119–125. [Google Scholar] [CrossRef]

- Wattanayon, W.; Udompijitkul, P.; Kamonpatana, P. Ohmic heating of a solid-liquid food mixture in an electrically conductive package. J. Food Eng. 2021, 289, 110180. [Google Scholar] [CrossRef]

- Jo, Y.J.; Park, S.H. Evaluation of energy efficacy and texture of ohmically cooked noodles. J. Food Eng. 2019, 248, 71–79. [Google Scholar] [CrossRef]

- Jantapirak, S.; Vangnai, K.; Tumpanuvatr, T.; Jittanit, W. Ohmic heating of chicken sausage: Electrical conductivities, heating characteristics, temperature prediction, and the comparison with conventional heating methods. Int. J. Food Eng. 2024, 20, 243–255. [Google Scholar] [CrossRef]

- Jantapirak, S.; Vangnai, K.; Tumpanuvatr, T.; Jittanit, W. Effects of heating method, temperature, initial nitrite level, and storage time on residual nitrite, pigments, and curing efficiency of chicken sausages. Int. J. Food Prop. 2023, 26, 2186–2200. [Google Scholar] [CrossRef]

- Kim, N.H.; Ryang, J.H.; Lee, B.S.; Kim, C.T.; Rhee, M.S. Continuous ohmic heating of commercially processed apple juice using five sequential electric fields results in rapid inactivation of Alicyclobacillus acidoterrestris spores. Int. J. Food Microbiol. 2017, 246, 80–84. [Google Scholar] [CrossRef] [PubMed]

- Cho, W.I.; Kim, E.J.; Hwang, H.J.; Cha, Y.H.; Cheon, H.S.; Choi, J.B.; Chung, M.S. Continuous ohmic heating system for the pasteurization of fermented red pepper paste. Innov. Food Sci. Emerg. Technol. 2017, 42, 190–196. [Google Scholar] [CrossRef]

- Kim, S.S.; Park, S.H.; Kang, D.H. Application of continuous-type pulsed ohmic heating system for inactivation of foodborne pathogens in buffered peptone water and tomato juice. LWT-Food Sci. Technol. 2018, 93, 316–322. [Google Scholar] [CrossRef]

- Loghavi, L.; Sastry, S.K.; Yousef, A.E. Effect of moderate electric field frequency on growth kinetics and metabolic activity of Lactobacillus acidophilus. Biotechnol. Prog. 2008, 24, 148–153. [Google Scholar] [CrossRef] [PubMed]

- Costello, S.R. Effect of Electric Field on Growth Kinetics of Yogurt Starter Cultures, Lactobacillus bulgaricus and Streptococcus thermophilus. Master’s Thesis, The Ohio State University, Columbus, OH, USA, 2012. [Google Scholar]

- Pesso, T.; Piva, S. Laminar forced convection in a cylindrical collinear ohmic sterilizer. Therm. Sci. 2017, 21, 2217–2226. [Google Scholar] [CrossRef]

- Ghnimi, S.; Delaplace, G.; Fillaudeau, L. Tubular and fluid jet units. In Ohmic Heating in Food Processing, Electro-Technologies for Food Processing Series; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Gavahian, M.; Lee, Y.T.; Chu, Y.H. Ohmic-assisted hydrodistillation of citronella oil from Taiwanese citronella grass: Impacts on the essential oil and extraction medium. Innov. Food Sci. Emerg. Technol. 2018, 48, 33–41. [Google Scholar] [CrossRef]

- Roohi, R.; Hashemi, S.M.B. Experimental and computational fluid dynamics modeling of Satureja khuzestanica essential oil extraction during ohmic-hydrodistillation. J. Food Process Eng. 2019, 42, 11. [Google Scholar] [CrossRef]

- Hashemi, S.M.B.; Nikmaram, N.; Esteghlal, S.; Khaneghah, A.M.; Niakousari, M.; Barba, F.J.; Roohinejad, S.; Koubaa, M. Efficiency of Ohmic assisted hydrodistillation for the extraction of essential oil from oregano (Origanum vulgare subsp viride) spices. Innov. Food Sci. Emerg. Technol. 2017, 41, 172–178. [Google Scholar] [CrossRef]

- Gavahian, M.; Farahnaky, A.; Sastry, S. Ohmic-assisted hydrodistillation: A novel method for ethanol distillation. Food Bioprod. Process. 2016, 98, 44–49. [Google Scholar] [CrossRef]

- Gavahian, M.; Farhoosh, R.; Javidnia, K.; Shahidi, F.; Farahnaky, A. Effect of applied voltage and frequency on extraction parameters and extracted essential oils from Mentha piperita by ohmic assisted hydrodistillation. Innov. Food Sci. Emerg. Technol. 2015, 29, 161–169. [Google Scholar] [CrossRef]

- Joeres, E.; Ristic, D.; Tomasevic, I.; Smetana, S.; Heinz, V.; Terjung, N. Structure, Microbiology and Sensorial Evaluation of Bologna-Style Sausages in a Kilohertz Ohmic Heating Process. Appl. Sci. 2024, 14, 5460. [Google Scholar] [CrossRef]

- Shynkaryk, M.V.; Ji, T.; Alvarez, V.B.; Sastry, S.K. Ohmic Heating of Peaches in the Wide Range of Frequencies (50 Hz to 1 MHz). J. Food Sci. 2010, 75, E493–E500. [Google Scholar] [CrossRef]

- Jun, S.; Sastry, S.; Samaranayake, C. Migration of electrode components during ohmic heating of foods in retort pouches. Innov. Food Sci. Emerg. Technol. 2007, 8, 237–243. [Google Scholar] [CrossRef]

- Wang, R.G.; Farid, M.M. Corrosion and health aspects in ohmic cooking of beef meat patties. J. Food Eng. 2015, 146, 17–22. [Google Scholar] [CrossRef]

- Llave, Y.; Udo, T.; Fukuoka, M.; Sakai, N. Ohmic heating of beef at 20 kHz and analysis of electrical conductivity at low and high frequencies. J. Food Eng. 2018, 228, 91–101. [Google Scholar] [CrossRef]

- Lee, S.Y.; Ryu, S.; Kang, D.H. Effect of frequency and waveform on inactivation of Escherichia coli O157:H7 and Salmonella enterica Serovar Typhimurium in salsa by ohmic heating. Appl. Environ. Microbiol. 2013, 79, 10–17. [Google Scholar] [CrossRef]

- Oluwole-ojo, O.; Zhang, H.; Howarth, M.; Xu, X. Model Based Design and Validation of a Batch Ohmic Heating System. Modelling 2021, 2, 641–658. [Google Scholar] [CrossRef]

- Wiroonsri, P.; Wattanachant, S. Electrical conductivity as a precise method for salt content estimation in raw and cooked tuna meat. J. Food Compos. Anal. 2025, 137, 106953. [Google Scholar] [CrossRef]

- Zhu, S.M.; Zareifard, M.R.; Chen, C.R.; Marcotte, M.; Grabowski, S. Electrical conductivity of particle-fluid mixtures in ohmic heating: Measurement and simulation. Food Res. Int. 2010, 43, 1666–1672. [Google Scholar] [CrossRef]

- Shirsat, N.; Lyng, J.G.; Brunton, N.P.; McKenna, B. Ohmic processing: Electrical conductivities of pork cuts. Meat Sci. 2004, 67, 507–514. [Google Scholar] [CrossRef]

- Tulsiyan, P.; Sarang, S.; Sastry, S.K. Electrical conductivity of multicomponent systems during ohmic heating. Int. J. Food Prop. 2008, 11, 233–241. [Google Scholar] [CrossRef]

- Sarang, S.; Sastry, S.K.; Knipe, L. Electrical conductivity of fruits and meats during ohmic heating. J. Food Eng. 2008, 87, 351–356. [Google Scholar] [CrossRef]

- Piette, G.; Buteau, M.L.; de Halleux, D.; Chiu, L.; Raymond, Y.; Ramaswamy, H.S.; Dostie, M. Ohmic cooking of processed meats and its effects on product quality. J. Food Sci. 2004, 69, E71–E78. [Google Scholar] [CrossRef]

- Palaniappan, S.; Sastry, S. Palaniappan and Sastry. 1991. Electrical Conductivites of selected solid foods during ohmic heating. J. Food Process Eng. 1991, 14, 221–236. [Google Scholar] [CrossRef]

- Shirsat, N.; Lyng, J.G.; Brunton, N.P.; McKenna, B.M. Conductivities and ohmic heating of meat emulsion batters. J. Muscle Foods 2004, 15, 121–137. [Google Scholar] [CrossRef]

- Engchuan, W.; Jittanit, W. Electrical and Thermo-Physical Properties of Meat Ball. Int. J. Food Prop. 2013, 16, 1676–1692. [Google Scholar] [CrossRef]

- Bozkurt, H.; Icier, F. Electrical conductivity changes of minced beef-fat blends during ohmic cooking. J. Food Eng. 2010, 96, 86–92. [Google Scholar] [CrossRef]

- Jin, Y.Z.; Cheng, Y.D.; Fukuoka, M.; Sakai, N. Electrical Conductivity of Yellowtail (Seriola quinqueradiata) Fillets During Ohmic Heating. Food Bioprocess Technol. 2015, 8, 1904–1913. [Google Scholar] [CrossRef]

- Guo, W.; Llave, Y.; Fukuoka, M. Electrical conductivity of salmon muscles—Analysis of the influence of muscle position and electrical current direction during ohmic heating. Int. J. Food Eng. 2023, 19, 445–455. [Google Scholar] [CrossRef]

- Zareifard, M.R.; Marcotte, M.; Ramaswamy, H.S.; Karimi, Y. Modeling of electrical conductivity in the context of ohmic heating. Ohmic Heat. Food Process. 2014, 67, 89–112. [Google Scholar]

- Alwis, A.A.P.D.; Fryer, P.J. A Finite Element Analysis of Heat Generation and Heat Transfer During Ohmic Heatin og Food. Chem. Eng. Sci. 1990, 45, 1547–1559. [Google Scholar] [CrossRef]

- van der Sman, R.G.M. Model for electrical conductivity of muscle meat during Ohmic heating. J. Food Eng. 2017, 208, 37–47. [Google Scholar] [CrossRef]

- Kanogchaipramot, K.; Tongkhao, K.; Sajjaanantakul, T.; Kamonpatana, P. Ohmic Heating of an Electrically Conductive Food Package. J. Food Sci. 2016, 81, E2966–E2976. [Google Scholar] [CrossRef] [PubMed]

- Jun, S.; Sastry, S.K. Modeling and Optimization of Ohmic heating of foods inside a flexible package. J. Food Process Eng. 2005, 28, 417–436. [Google Scholar] [CrossRef]

- Somavat, R.; Kamonpatana, P.; Mohamed, H.M.H.; Sastry, S.K. Ohmic sterilization inside a multi-layered laminate pouch for long-duration space missions. J. Food Eng. 2012, 112, 134–143. [Google Scholar] [CrossRef]

- da Trindade, E.S.; da Costa, C.A.; de Souza, V.C. Digital twin for product design collaboration: A systematic literature review. Int. J. Adv. Manuf. Technol. 2025, 136, 4751–4767. [Google Scholar] [CrossRef]

- Maheshwari, P.; Kamble, S.; Belhadi, A.; Mani, V.; Pundir, A. Digital twin implementation for performance improvement in process industries—A case study of food processing company. Int. J. Prod. Res. 2022, 61, 8343–8365. [Google Scholar] [CrossRef]

- Verboven, P.; Defraeye, T.; Datta, A.K.; Nicolai, B. Digital twins of food process operations: The next step for food process models? Curr. Opin. Food Sci. 2020, 35, 79–87. [Google Scholar] [CrossRef]

- Erdogdu, F.; Datta, A.; Vitrac, O.; Marra, F.; Verboven, P.; Sarghini, F.; Nicolai, B. Mathematical modeling—Computer-aided food engineering. In Food Engineering Innovations Across the Food Supply Chain; Academic Press: Cambridge, MA, USA, 2022; pp. 277–290. [Google Scholar] [CrossRef]

- Udugama, I.A.; Kelton, W.; Bayer, C. Digital twins in food processing: A conceptual approach to developing multi-layer digital models. Digit. Chem. Eng. 2023, 7, 100087. [Google Scholar] [CrossRef]

- Bottani, E.; Vignali, G.; Carlo Tancredi, G.P. A digital twin model of a pasteurization system for food beverages: Tools and architecture. In Proceedings of the 2020 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Cardiff, UK, 15–17 June 2020. [Google Scholar]

- Tancredi, G.; Bottani, E.; Vignali, G. Digital Twin Application for the Temperature and Steam Flow Monitoring of a Food Pasteurization Pilot Plant. In Advances in Production Management Systems. Artificial Intelligence for Sustainable and Resilient Production Systems; Springer: Cham, Switzerland, 2021; pp. 612–619. [Google Scholar] [CrossRef]

- Khan, T. An Intelligent Microwave Oven with Thermal Imaging and Temperature Recommendation Using Deep Learning. Appl. Syst. Innov. 2020, 3, 13. [Google Scholar] [CrossRef]

- Valero, M.R.; Hicks, B.J.; Nassehi, A. A Conceptual Framework of a Digital-Twin for a Circular Meat Supply Chain. In Flexible Automation and Intelligent Manufacturing: The Human-Data-Technology Nexus; Springer: Cham, Switzerland, 2023; pp. 188–196. [Google Scholar] [CrossRef]

- Kannapinn, M.; Pham, M.K.; Schäfer, M. Physics-based Digital Twins for Autonomous Thermal Food Processing: Efficient, Non-intrusive Reduced-order Modeling. Innov. Food Sci. Emerg. Technol. 2022, 81, 103143. [Google Scholar] [CrossRef]

- Zhao, S.; Jiao, T.; Adade, S.Y.-S.S.; Wang, Z.; Ouyang, Q.; Chen, Q. Digital twin for predicting and controlling food fermentation: A case study of kombucha fermentation. J. Food Eng. 2025, 393, 112467. [Google Scholar] [CrossRef]

- Koulouris, A.; Misailidis, N.; Petrides, D. Applications of process and digital twin models for production simulation and scheduling in the manufacturing of food ingredients and products. Food Bioprod. Process. 2021, 126, 317–333. [Google Scholar] [CrossRef]

- Cabeza-Gil, I.; Ríos-Ruiz, I.; Martínez, M.Á.; Calvo, B.; Grasa, J. Digital twins for monitoring and predicting the cooking of food products: A case study for a French crêpe. J. Food Eng. 2023, 359, 111697. [Google Scholar] [CrossRef]

- Melesse, T.Y.; Bollo, M.; Pasquale, V.D.; Centro, F.; Riemma, S. Machine learning-based digital twin for monitoring fruit quality evolution. Procedia Comput. Sci. 2022, 200, 13–20. [Google Scholar] [CrossRef]

- Defraeye, T.; Shrivastava, C.; Berry, T.; Verboven, P.; Onwude, D.; Schudel, S.; Bühlmann, A.; Cronje, P.; Rossi, R.M. Digital twins are coming: Will we need them in supply chains of fresh horticultural produce? Trends Food Sci. Technol. 2021, 109, 245–258. [Google Scholar] [CrossRef]

- Datta, A.; Nicolai, B.; Vitrac, O.; Verboven, P.; Erdogdu, F.; Marra, F.; Sarghini, F.; Koh, C. Computer-aided food engineering. Nat. Food 2022, 3, 894–904. [Google Scholar] [CrossRef] [PubMed]

| MEF Chamber Configuration | Food Processing Applications | References |

|---|---|---|

Parallel plate electrode–batch rectangular system | Ready–to–eat foods (solid–liquid mixtures) | [11,71,72,73] |

| Cooking rice | [74,75,76] | |

| Cooking shrimps in brine mixtures | [59,77,78] | |

| Potato cubes and whole potatoes in NaCl solution | [79] | |

| Jalapeno and serrano peppers (solid–liquid) | [80] | |

| Orange juice with alginate particles | [81] | |

| Cooking meat and meat products, chicken sausage | [82,83,84] | |

| Bread baking | [41,42,45] | |

Parallel plate electrode—cylindrical system | Apple juice (sequential electric fields) | [85] |

| Pasteurization of fermented red pepper paste | [86] | |

| Tomato juice (pulsed ohmic heating) | [87] | |

Cylindrical fermenters/reactors with parallel electrodes  | Fermentation of soya bean in NaCl solution | [57] |

| Fermentation–growth kinetics and metabolic activity of Lactobacillus acidophilus | [88] | |

| Fermentation–growth kinetics of yogurt starter cultures | [89] | |

Collinear MEF heater (cylindrical) | Sterilization of liquid food (mathematical model)–continuous system | [90] |

The Emmepiemme design | The Emmepiemme design for continuous operation (60–480 kW)–tubular systems applied for industrial applications | [91] |

Elbow electrodes (used five sequential elbow-type electrodes  | Continuous ohmic heating for microbial inactivation | [68,85] |

Sidewise parallel electrodes | Cooking high–viscosity food formulation (chicken chow Mein sauce) | [69] |

Electrodes in flask  | Ohmic-assisted hydro–distillation of citronella oil from Taiwanese citronella grass | [92] |

| Oil extraction during ohmic–hydro-distillation | [93,94] | |

| Ohmic assisted–hydro–distillation–ethanol distillation, essential oil | [95,96] | |

Movable electrodes | Pressure-assisted thermal treatment of carrot samples in NaCl solution | [70] |

Fluid jet heater system | Continuous flow heating using fluid jet–viscous foods. | [67,91] |

| Food Materials | Temperature Range | Voltage Gradient and Frequency | References |

|---|---|---|---|

| Beef (wagyu beef) | 5 to 65 °C | 16.67 V cm−1, 50 Hz to 20 kHz | [101] |

| Chicken (breast, tender, thigh, drumstick, and separable fat) | 25 to 140 °C | 19–25 V cm−1, 60 Hz | [108] |

| Chicken Chow Mein (multicomponent) | 25 to 140 °C | 15 to 20 V, 60 Hz | [107] |

| Frozen Tuna fish | −30 to 20 ° C | 100 V cm−1, 50 Hz and 20 Hz | [39] |

| Ham pastes and bologna emulsion | 10 to 80 °C | 64 to 103 V, 60 Hz | [109] |

| Lean beef and chicken | 25 to 120 °C | 60 V, 60 Hz | [110] |

| Meat emulsion batters (frankfurter and luncheon meats) | 15 to 80 °C | 4 V cm−1, 50 Hz | [111] |

| Meatball (lean pork) | 30–90 °C | 20.5 V cm−1, 50 Hz | [112] |

| Minced beef-fat blends (25.9% and 15% fat levels) | 20–80 °C | 20, 30, 40 V cm−1, 50 Hz | [113] |

| Pork cuts (leg lean, shoulder lean, belly lean, back fat and belly fat) | 20 °C | 3.6 V cm−1. 50 Hz | [106] |

| Whole meats and processed meat ingredients | 5 to 85 °C | 20 V cm−1, 50 Hz | [27] |

| Yellowtail muscle filets | 15–80 °C | 10 V cm−1, 50 Hz–20 kHz | [114] |

| Cubic particles (carrot, potato, radish, beef muscle, pork muscle and ham)/5% starch-water solution (0.15–1.5% w/w salt) | 25–125 °C | 60 Hz | [105] |

| Raw and cooked tuna | Room temperature | Measured with an electrical conductivity meter | [104] |

| Salmon muscles | 5–70 °C | 50 Hz–20 kHz | [115] |

| Orange juice containing alignate particles | 25–100 °C | 20 V, 50 Hz | [81] |

| Minced tuna and pollock surimi | −40–10 °C | 50 Hz–20 kHz | [40] |

| Whole potato tubers and potato cubes | 20–100 °C | 1.38 kHz–11.2 MHz | [79] |

| Food Product | Electrical Conductivity—Model Equation | Description | References |

|---|---|---|---|

| Chicken, beef, and vegetables (potato, carrot, yam) | σref is the σ of the product at the reference temperature Tref (25 °C), and m is the temperature compensation constant | [110] | |

| Cooked meatballs | X is the weight ratio of ingredients to meat, STPP is added tripolyphosphate and T is the temperature (°C) | [112] | |

| Fresh meatballs | X is the weight ratio of ingredients to meat, and T is the temperature (°C) | [112] | |

| Lamb | T is the temperature | [117] | |

| Minced beef meat | A (S m−1) σ of a sample at a reference temperature of 0 °C and B (S m−1 °C) is the temperature dependency constant which is determined by regression | [113] | |

| Minced beef-fat blend | A (S m−1) σ of sample at a reference temperature of 0 °C, B (S m−1 °C) is the temperature dependency constant which is determined by regression, and C (S m−1 per fat%) is σ constant. The N power term indicates the effect of initial fat level on σ | [113] | |

| Salt solution | c is the salt concentration (%) and Tref is the reference temperature (25 °C) | [118] | |

| Sausages | ω = 2πf, f is the frequency (Hz), ε0 is the permittivity of free space (~8.85 × 10−22 F/m), and ε″ is the dielectric loss factor through the frequency of applied field | [22] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bedane, T.; Marra, F.; Maloney, N.; Lyng, J. Recent Advances in Moderate Electric Field (MEF) Systems for Sustainable Food Processing. Processes 2025, 13, 2662. https://doi.org/10.3390/pr13082662

Bedane T, Marra F, Maloney N, Lyng J. Recent Advances in Moderate Electric Field (MEF) Systems for Sustainable Food Processing. Processes. 2025; 13(8):2662. https://doi.org/10.3390/pr13082662

Chicago/Turabian StyleBedane, Tesfaye, Francesco Marra, Norman Maloney, and James Lyng. 2025. "Recent Advances in Moderate Electric Field (MEF) Systems for Sustainable Food Processing" Processes 13, no. 8: 2662. https://doi.org/10.3390/pr13082662

APA StyleBedane, T., Marra, F., Maloney, N., & Lyng, J. (2025). Recent Advances in Moderate Electric Field (MEF) Systems for Sustainable Food Processing. Processes, 13(8), 2662. https://doi.org/10.3390/pr13082662