Mechanical Behavior and Stress Mechanism of Roof Cutting Gob-Side Entry Retaining in Medium-Thick Coal Seams

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Area

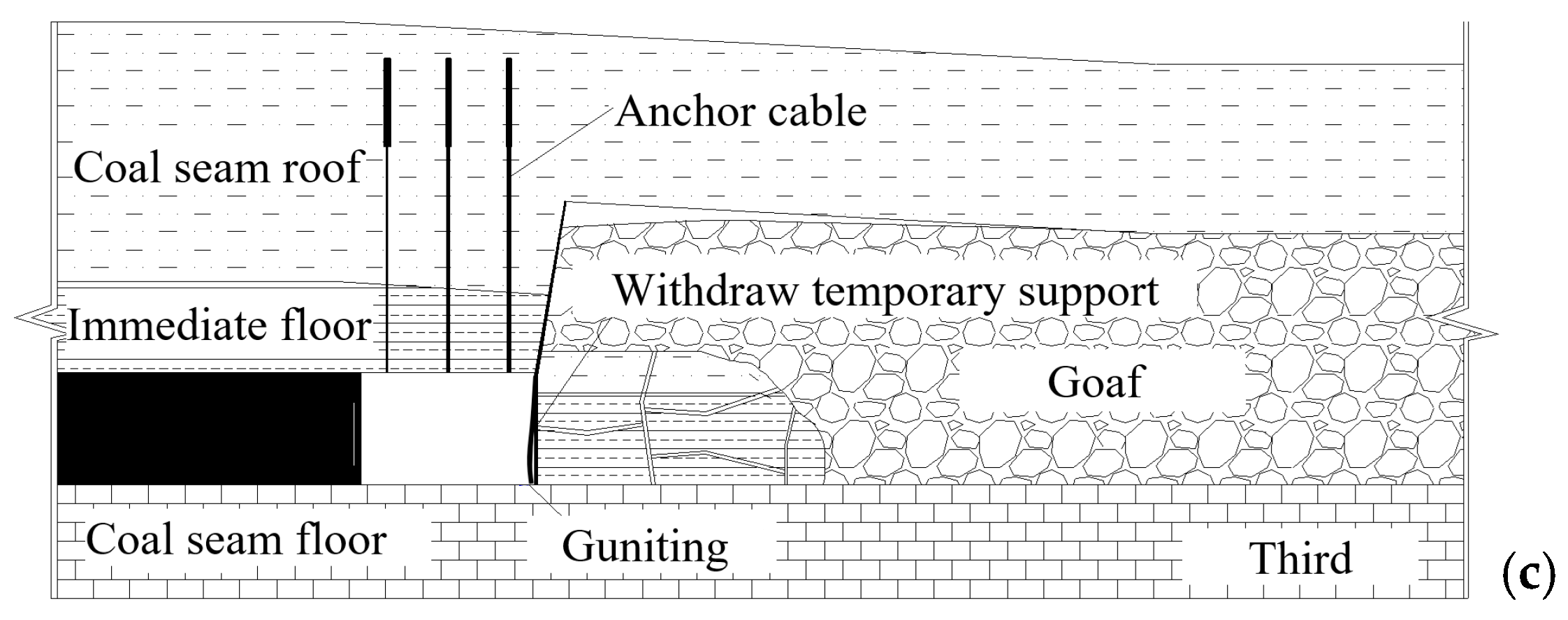

2.2. The Principle of the Gob-Side Entry Retaining by Roof Cutting

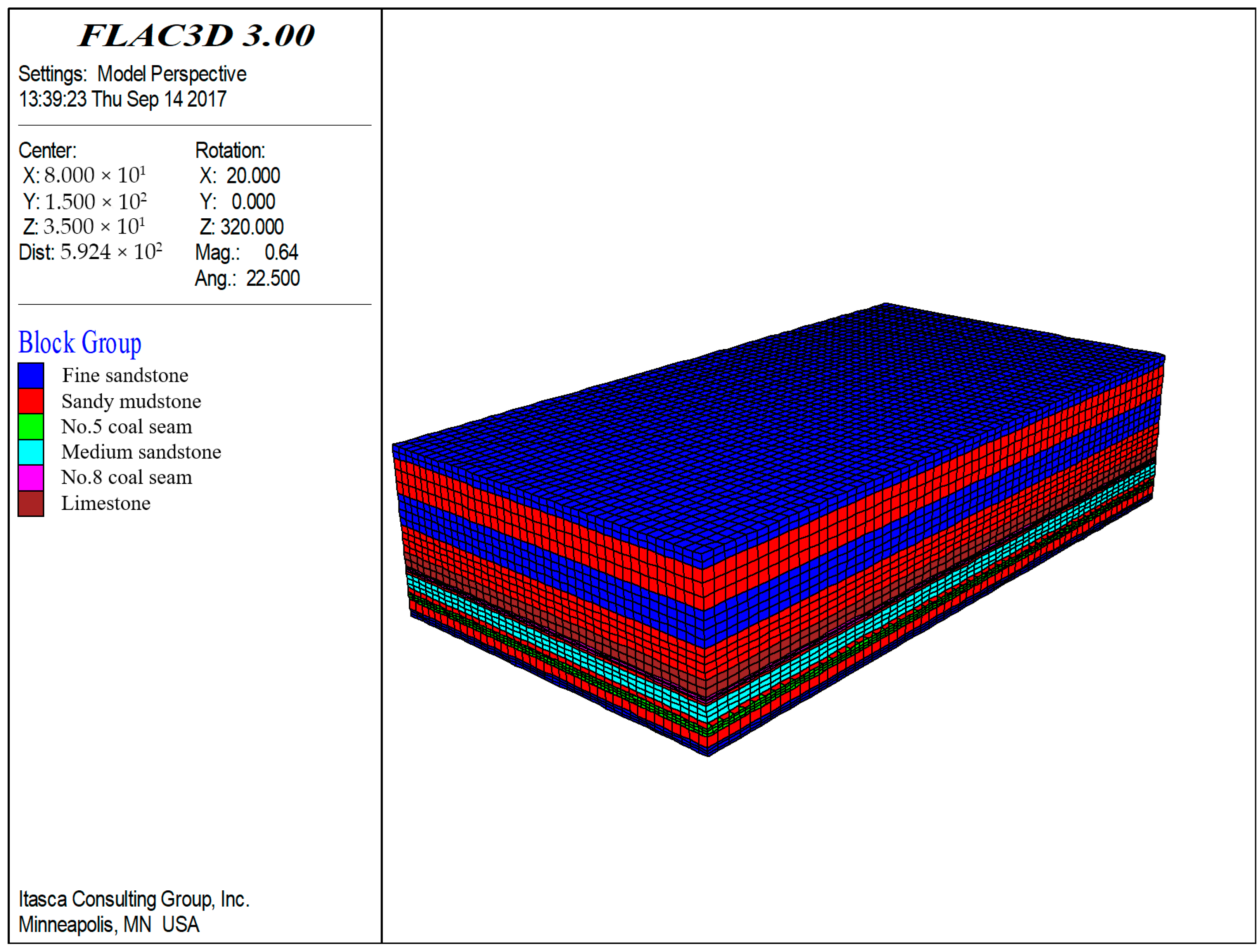

2.3. Numerical Modeling Framework

3. Results and Discussion

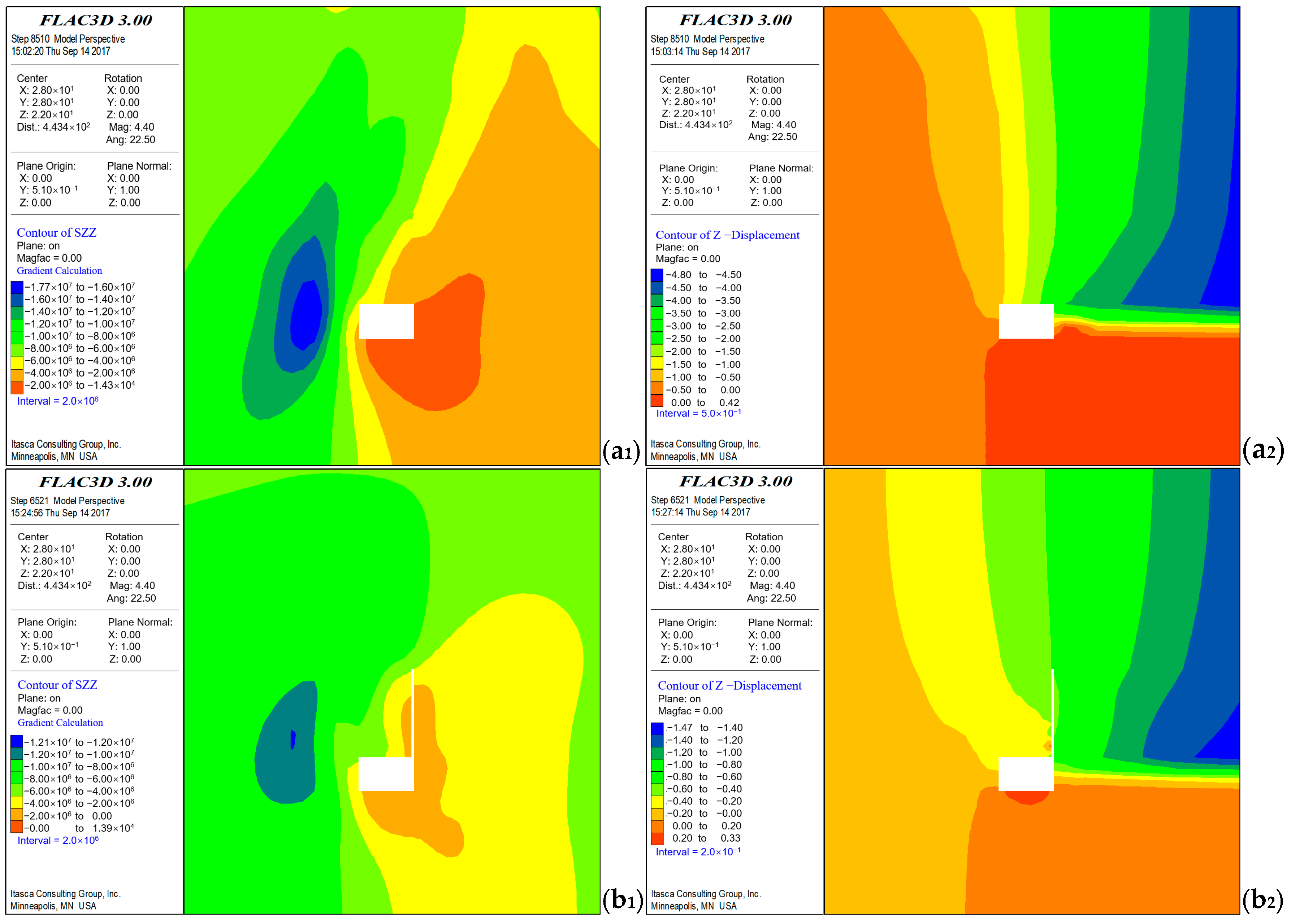

3.1. Evolution of Mine Pressure During Roof Cutting and Pressure Relief Entry Retaining Subsection

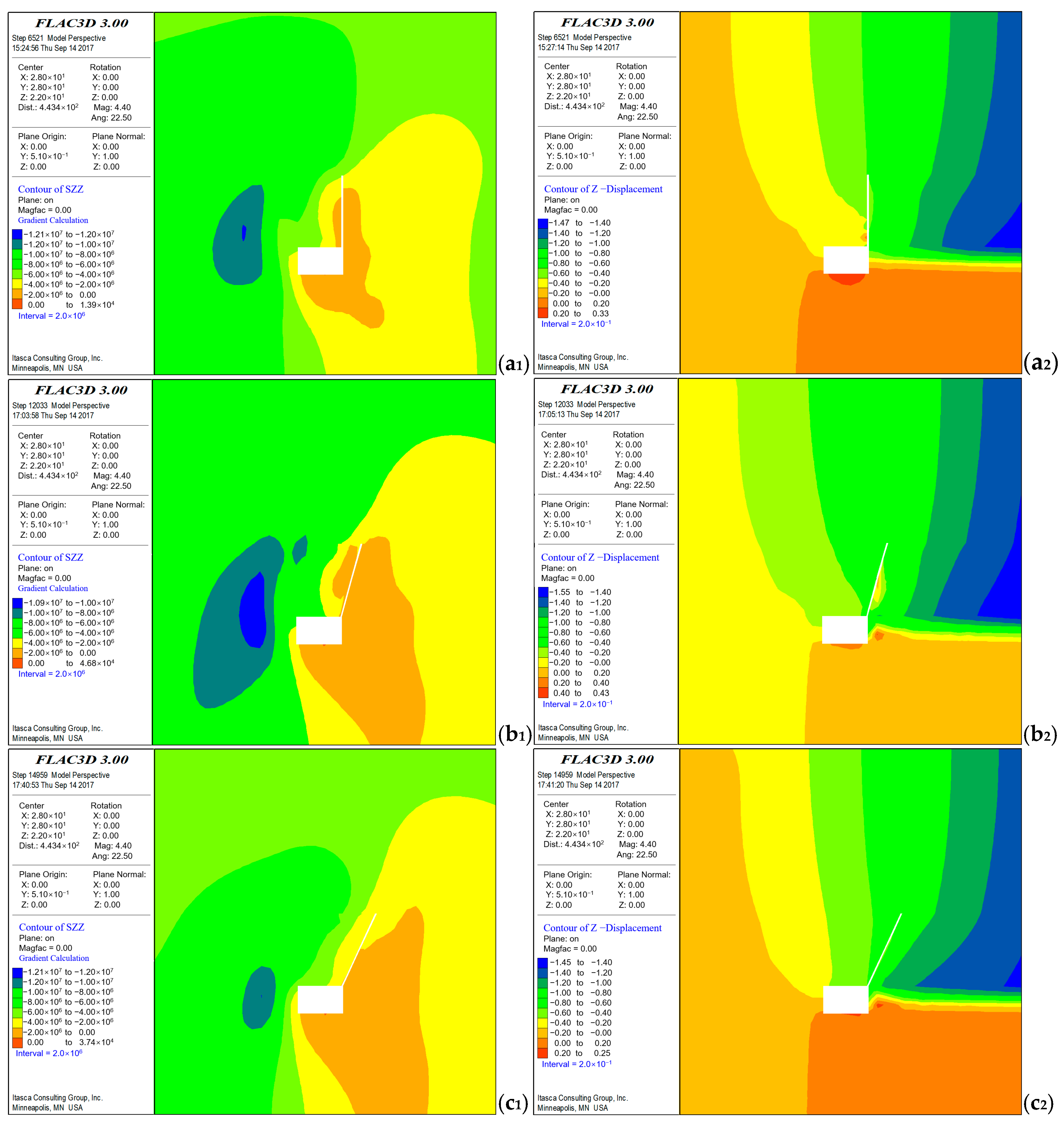

3.2. Impact of Roof Cutting Height on Stress Redistribution and Deformation Behavior

3.3. Effect of Roof Cutting Angle on Mechanical Response of Roadway

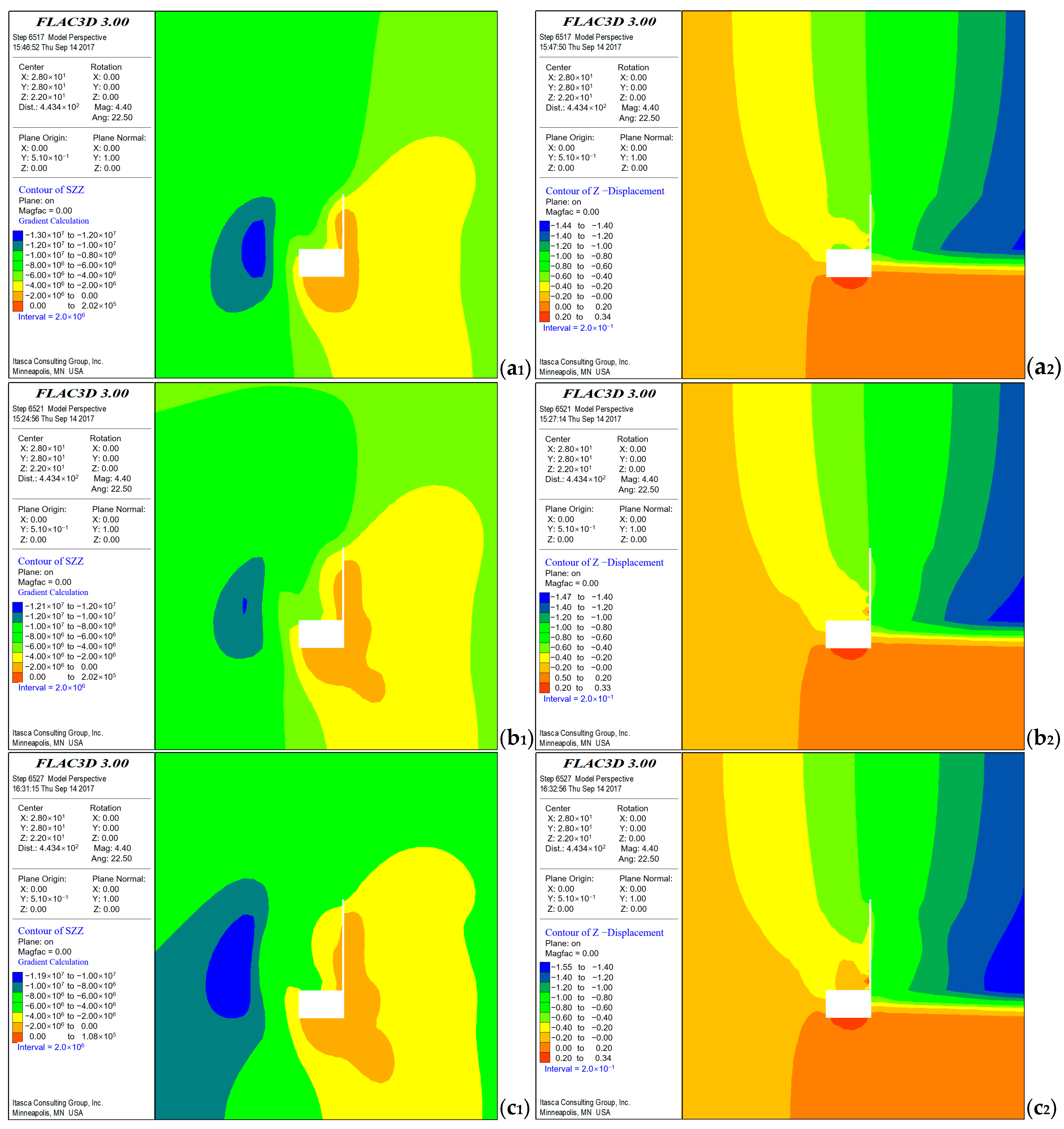

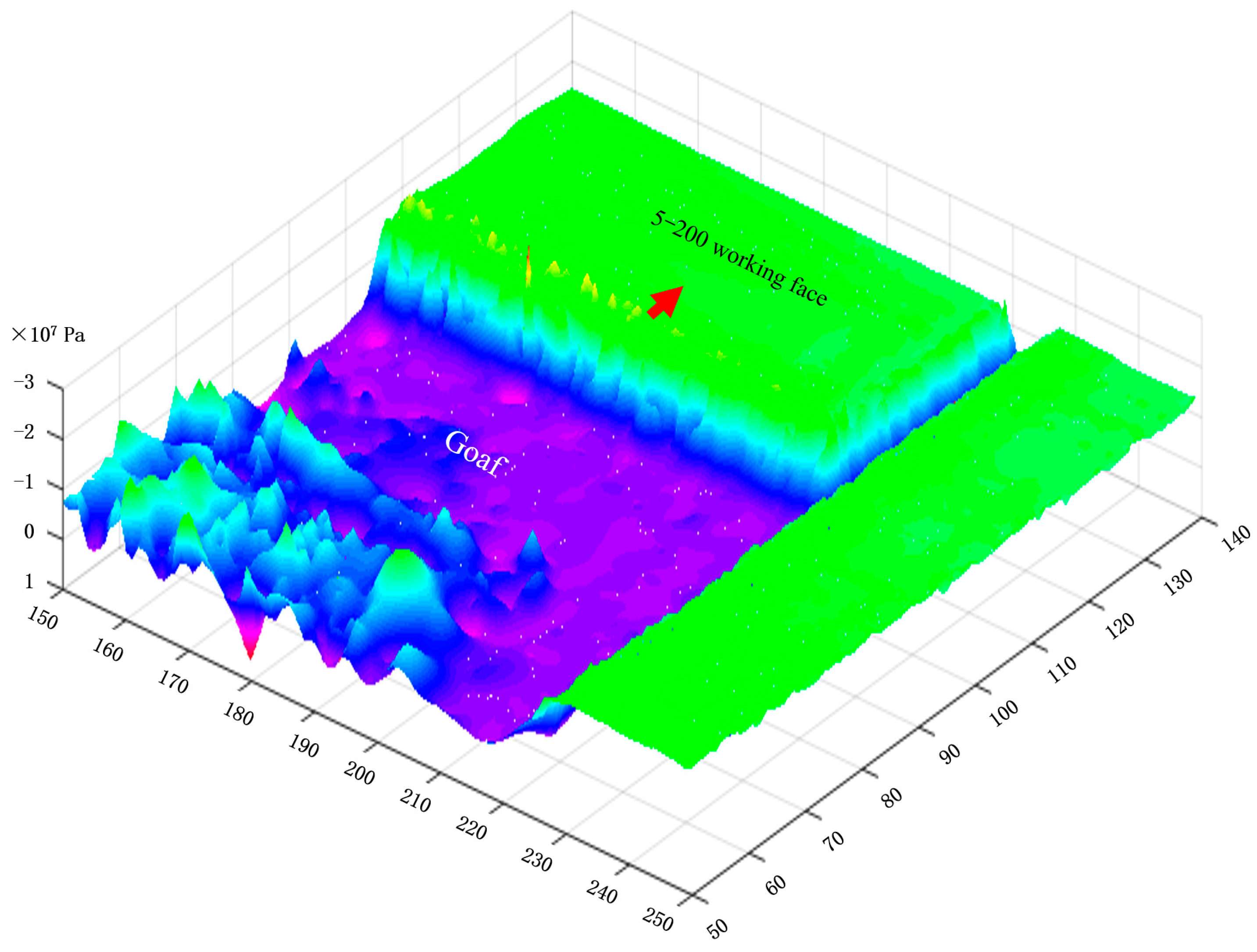

3.4. Spatial Stress Distribution During Actual Roof Cutting Mining Progression

- (1)

- The stress field exhibits a distinct gradient. While the roadway lies in a low-stress zone, significant stress recovery occurs in the goaf, especially near the coal mass. Stress concentrations persist near the face, reflecting strong spatial heterogeneity in stress redistribution.

- (2)

- A pronounced stress resurgence initiates 15 m behind the face, intensifying at 25 m, particularly in central regions. Stress magnitude attenuates toward the roadway, confirming that mining-induced disturbance weakens spatially with distance.

- (3)

- The roadway constructed via roof cutting remains in a stable, low-stress environment. Minimal deflection of the gangue wall and weak stress recovery ensure favorable long-term stability of the entry.

- (4)

- Peak vertical stress ahead of the face gradually reduces from the center outward and diminishes further with increased distance. On the roadway side, a similar trend is observed, confirming stress attenuation patterns.

4. Engineering Applications and Effectiveness

4.1. Stress Response and Pressure Evolution Under RCGSER

4.2. Engineering Application and Effect Analysis

5. Conclusions

- (1)

- Numerical simulations indicate that properly selected roof cutting parameters significantly enhance surrounding rock stability. With a cutting height of 8 m and an inclination angle of 15°, the redistribution of stress achieves an optimal unloading effect. The peak stress zone along the coal rib shifts from 4 m to approximately 6–7 m from the roadway, the vertical stress peak is reduced from 13.0 MPa to 11.9 MPa, and the maximum roof settlement drops from 2500 mm (without cutting) to 200–300 mm. Simultaneously, the extent of the plastic zone is notably reduced, indicating that this parameter configuration effectively mitigates stress concentration and deformation.

- (2)

- Field measurements validate that roof cutting substantially alleviates dynamic pressure behavior. Monitoring data from the return-air roadway show that the initial weighting interval increases from 16.5 m to 20.5 m, while the periodic weighting interval extends from 27.5 m to 33.0 m—an increase of 4.0 m and 5.5 m, respectively. Additionally, the average working resistance of hydraulic supports drops by approximately 12%, reflecting a delayed roof breakage pattern, a reduction in stress fluctuation frequency, and a more stable mining stress environment. These results demonstrate that roof cutting plays a key role in regulating the main roof’s activity and reducing dynamic load intensity.

- (3)

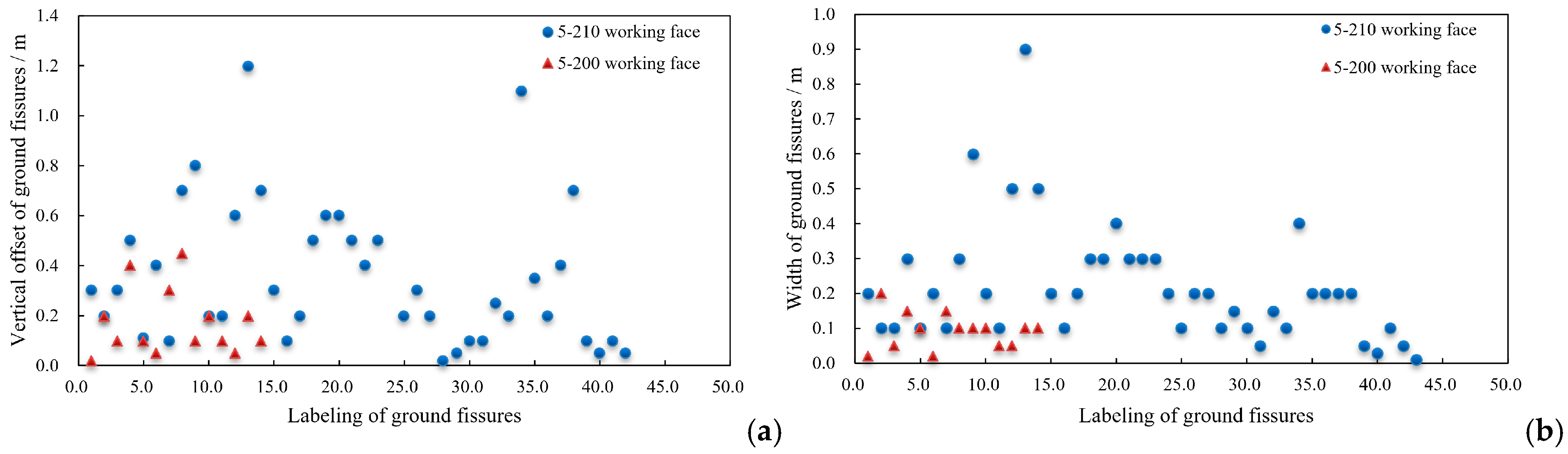

- Roof cutting significantly mitigates surface disturbance. Compared to the adjacent 5-210 panel, which followed conventional mining without roof cutting, the 5-200 panel exhibited much narrower surface cracks—mostly within the range of 0.05–0.2 m in width and 0.1–0.4 m in vertical offset. In contrast, the 5-210 panel presented wider and deeper fractures, with most cracks exceeding 0.1 m in width and 0.2 m in vertical separation. This indicates that the implementation of roof cutting creates a buffer zone that disrupts the upward propagation of mining-induced stress, thereby improving surface subsidence control.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, J.; Tian, Y.; Yan, X.; Yang, J.; Wang, Y.; Xu, W.; Xie, K. Approach and potential of replacing oil and natural gas with coal in China. Front. Energy 2020, 14, 419–431. [Google Scholar] [CrossRef]

- Dai, H.; Su, Y.; Kuang, L.; Liu, J.; Gu, D.; Zou, C. Contemplation on China’s energy-development strategies and initiatives in the context of its carbon neutrality goal. Engineering 2021, 7, 1684–1687. [Google Scholar] [CrossRef]

- Li, Y.; Pan, S.; Ning, S.; Shao, L.; Jing, Z.; Wang, Z. Coal measure metallogeny: Metallogenic system and implication for resource and environment. Sci. China Earth Sci. 2022, 65, 1211–1228. [Google Scholar] [CrossRef]

- Xu, B.; Lin, B. Investigating drivers of CO2 emission in China’s heavy industry: A quantile regression analysis. Energy 2020, 206, 118159. [Google Scholar] [CrossRef]

- Huang, X.; Chen, W.; Wang, Y.; Wang, W.; Liu, Z. Annual Development Report on World Energy; Social Sciences Academic Press: Beijing, China, 2024. [Google Scholar]

- Qiao, Y.; Wang, G. Recent Status of Production, Administration Policies, and Low-Carbon Technology Development of China’s Steel Industry. Metals 2024, 14, 480. [Google Scholar] [CrossRef]

- Liao, Z.; Yao, Q. Flexibility is needed in China’s national carbon market. Nat. Clim. Change 2022, 12, 106–107. [Google Scholar] [CrossRef]

- National Bureau of Statistics of China. China Energy Statistical Yearbook 2023; China Statistics Press: Beijing, China, 2024. [Google Scholar]

- Tan, W.; Xi, B. Toward carbon emission reduction in steel production by substituting pulverized coal and coke with biochar. ACS EST Eng. 2024, 4, 1253–1255. [Google Scholar] [CrossRef]

- Lin, B.; Raza, M.Y. Coal and economic development in Pakistan: A necessity of energy source. Energy 2020, 207, 118244. [Google Scholar] [CrossRef]

- Ge, S.; Fan, J.; Liu, S.; Song, M.; Xian, Y.; Wang, B.; Teng, T. Low carbon modern coal-based energy technology system and development strategy. J. China Coal Soc. 2024, 49, 203–223. [Google Scholar]

- National Bureau of Statistics of China. Available online: http://www.ce.cn/xwzx/gnsz/gdxw/202301/18/t20230118_38353362.shtml (accessed on 20 February 2025).

- EI. Statistical Review of World Energy; Energy Institute: London, UK, 2023. [Google Scholar]

- Xie, H.; Wu, L.; Zheng, D. Prediction on the energy consumption and coal demand of China in 2025. J. China Coal Soc. 2019, 44, 1949–1960. [Google Scholar]

- Yang, Z.; Li, W.; Pei, Y.; Qiao, W.; Wu, Y. Classification of the type of eco-geological environment of a coal mine district a case study of an ecologically fragile region in Western China. J. Clean. Prod. 2018, 174, 1513–1526. [Google Scholar] [CrossRef]

- Gu, D.; Zhang, Y.; Cao, Z. Technical progress of water resource protection and utilization by coal mining in China Coal. Sci. Technol. 2016, 44, 1–7. [Google Scholar]

- Hu, X.; Zhang, Q. Mine Water Treatment, Resource Utilization and Prospects in Coal Mining Areas of Western China. Mine Water Environ. 2024, 43, 210–230. [Google Scholar] [CrossRef]

- Fan, L.; Ma, X. A review on investigation of water-preserved coal mining in western China. Int. J. Coal Sci. Technol. 2018, 5, 411–416. [Google Scholar] [CrossRef]

- Wang, G.; Pang, Y. Full-mechanized coal mining and caving mining method evaluation and key technology for thick coal seam. J. China Coal Soc. 2018, 43, 33–42. [Google Scholar]

- Zhang, S.; Wang, H.; He, X.; Guo, S.; Xia, Y.; Zhou, Y.; Liu, K.; Yang, S. Research progress, problems and prospects of mine water treatment technology and resource utilization in China. Crit. Rev. Environ. Sci. Technol. 2020, 50, 31–383. [Google Scholar] [CrossRef]

- Liu, B.; Wang, Y.; Zhang, J.; Hou, S.; He, M.; Wu, X.; Li, H. Comparative Analysis on the Safety Characteristics of N00 Mining Method with Conventional 121 Mining Method. Geotech. Geol. Eng. 2024, 42, 321–338. [Google Scholar] [CrossRef]

- Tao, Z.G.; Song, Z.G.; He, M.C.; Meng, Z.G.; Pang, S.H. Principles of the roof cut short-arm beam mining method (110 method) and its mining-induced stress distribution. Int. J. Min. Sci. Tech. 2018, 28, 391–396. [Google Scholar] [CrossRef]

- Liu, J.; He, M.; Wang, J.; Dono, A.R.; Ming, C.; Guo, S.; Liu, P. Effect of the roof cutting technique on the overlying geotechnical structure in coal mining. Bull. Eng. Geol. Environ. 2023, 82, 289. [Google Scholar] [CrossRef]

- Guo, P. Study and Application on Gob-side Entry Retaining by Roof Cut and Pressure Relief in Hecaogou Coal Mine in Yanan. Ph.D. Thesis, China University of Mining & Technology, Beijing, China, 2018. [Google Scholar]

- Jin, Z. Study on Overburden Strata Movement Law and Deformation Mechanism of Surrounding Rock in Short Distance Coal seam Mining in Shaping Coal Mine. Ph.D. Thesis, China University of Mining & Technology, Beijing, China, 2018. [Google Scholar]

- He, M.C.; Song, Z.Q.; Wang, A.; Yang, H.H.; Qi, H.G.; Guo, Z.G. Theory of longwall mining by using roof cuting short wall team and 110 method—The third mining science and technology reform. Coal Sci. Technol. Mag. 2017, 1, 1–9+13. [Google Scholar]

- He, M.C. Theory and engineering practice for non-pillars mining with automagical entry formation and 110 mining method. J. Min. Saf. Eng. 2023, 40, 869–881. [Google Scholar]

- Wang, Q.; He, M.C.; Wang, Y.C.; Liu, J.T.; Xue, H.J. Research progress and prospect of automatically formed roadway by roof cutting and pressure relief without pillars. J. Min. Saf. Eng. 2023, 40, 429–447. [Google Scholar]

- He, M.C. Technological progress promotes scientific coal production capacity to a higher level. Sci. News 2017, 10, 90. [Google Scholar]

- He, M.C.; Wang, Y.J.; Yang, J.; Gao, Y.B.; Gao, Q.; Wang, S.B. Zonal characteristics and its influence factors of working face pressure using roof cutting and pressure-relief mining method with no pillar and roadway formed automatically. J. China Univ. Min. Technol. 2018, 47, 4–12. [Google Scholar]

- Wang, Q.; Gao, H.K.; Yu, H.C.; Jiang, B.; Liu, B.H. Method for measuring rock mass characteristics and evaluating the grouting-reinforced effect based on digital drilling. Rock Mech. Rock Eng. 2019, 52, 841–851. [Google Scholar] [CrossRef]

- He, M.C. Latest progress of soft rock mechanics and engineering in China. J. Rock Mech. Geotech. Eng. 2014, 6, 165–179. [Google Scholar] [CrossRef]

- Zhang, G.; He, M.; Yu, X.; Huang, Z. Research on the Technique of No-Pillar Mining with Gob-Side Entry Formed by Advanced Roof Caving in the Protective Seam in Baijiao Coal Mine. J. Min. Saf. Eng. 2011, 28, 511–516. [Google Scholar]

- Nagtegaal, J.C.; Parks, D.M.; Rice, J.R. On Numerically Accurate Finite Element Solutions in the Fully Plastic Range. Comp. Meth. Appl. Mech. Eng. 1974, 4, 153–177. [Google Scholar] [CrossRef]

- Bathe, K.J.; Wilson, E.L. Numerical Methods in Finite Element Analysis; Prentice-Hall Inc.: Englewood Cliffs, NJ, USA, 1976. [Google Scholar]

| Layer Number | Thickness/m | Bulk /109 Pa | Shear /109 Pa | Friction/° | Tension /106 Pa | Density /103 kg/m3 | Cohesion /106 Pa |

|---|---|---|---|---|---|---|---|

| Limestone | 6 | 16 | 17 | 36 | 5.9 | 2.5 | 5.6 |

| No. 8 coal seam | 2.4 | 1 | 2 | 31 | 0.7 | 1.4 | 1.1 |

| Sandy mudstone | 0.7 | 9 | 9 | 30 | 3.7 | 2.1 | 1.5 |

| Medium sandstone | 6.1 | 11 | 12 | 33 | 4.9 | 2.4 | 3.5 |

| Sandy mudstone | 2.1 | 9 | 9 | 30 | 3.7 | 2.0 | 1.7 |

| No. 5 coal seam | 3 | 1 | 2 | 30 | 0.6 | 1.4 | 1.1 |

| Sandy mudstone | 3.3 | 10 | 9 | 31 | 3.3 | 2.1 | 1.6 |

| Fine sandstone | 2.8 | 13 | 15 | 38 | 4.9 | 2.4 | 5.4 |

| Area | Monitoring Points | Maximum Pressure /MPa | Average Pressure /MPa |

|---|---|---|---|

| Pressure in the gob-side entry retaining side | 149# | 32.7 | 19.5 |

| 141# | 33.0 | 21.2 | |

| Mean | 32.8 | 20.3 | |

| Pressure in the middle of the working face | 85# | 41.8 | 33.0 |

| 37# | 35.0 | 33.0 | |

| Mean | 38.4 | 33.0 | |

| Periodic weighting interval in the side unaffected by roof cutting | 9# | 35.0 | 27.6 |

| 2# | 32.4 | 21.3 | |

| Mean | 33.7 | 24.5 |

| Area | Monitoring Points | First Weighting/m | Periodic Weighting Interval/m |

|---|---|---|---|

| Periodic weighting interval in the gob-side entry retaining side | 149# | 49 | 33 |

| 141# | 43 | 29 | |

| Mean | 46 | 31 | |

| Periodic weighting interval in the middle of the working face | 85# | 38 | 18 |

| 37# | 38 | 18 | |

| Mean | 38 | 18 | |

| Periodic weighting interval in the side unaffected by roof cutting | 9# | 43 | 21 |

| 2# | 41 | 30 | |

| Mean | 42 | 25.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Song, D.; Zhang, L.; Luo, B. Mechanical Behavior and Stress Mechanism of Roof Cutting Gob-Side Entry Retaining in Medium-Thick Coal Seams. Processes 2025, 13, 2649. https://doi.org/10.3390/pr13082649

Zhang D, Song D, Zhang L, Luo B. Mechanical Behavior and Stress Mechanism of Roof Cutting Gob-Side Entry Retaining in Medium-Thick Coal Seams. Processes. 2025; 13(8):2649. https://doi.org/10.3390/pr13082649

Chicago/Turabian StyleZhang, Dongping, Dongming Song, Longping Zhang, and Bin Luo. 2025. "Mechanical Behavior and Stress Mechanism of Roof Cutting Gob-Side Entry Retaining in Medium-Thick Coal Seams" Processes 13, no. 8: 2649. https://doi.org/10.3390/pr13082649

APA StyleZhang, D., Song, D., Zhang, L., & Luo, B. (2025). Mechanical Behavior and Stress Mechanism of Roof Cutting Gob-Side Entry Retaining in Medium-Thick Coal Seams. Processes, 13(8), 2649. https://doi.org/10.3390/pr13082649