Optimizing Texture and Drying Behavior of Squid (Todarodes pacificus) for Elder-Friendly Applications Using Alkaline Pretreatment and Intermittent Drying: An Experimental and Numerical Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

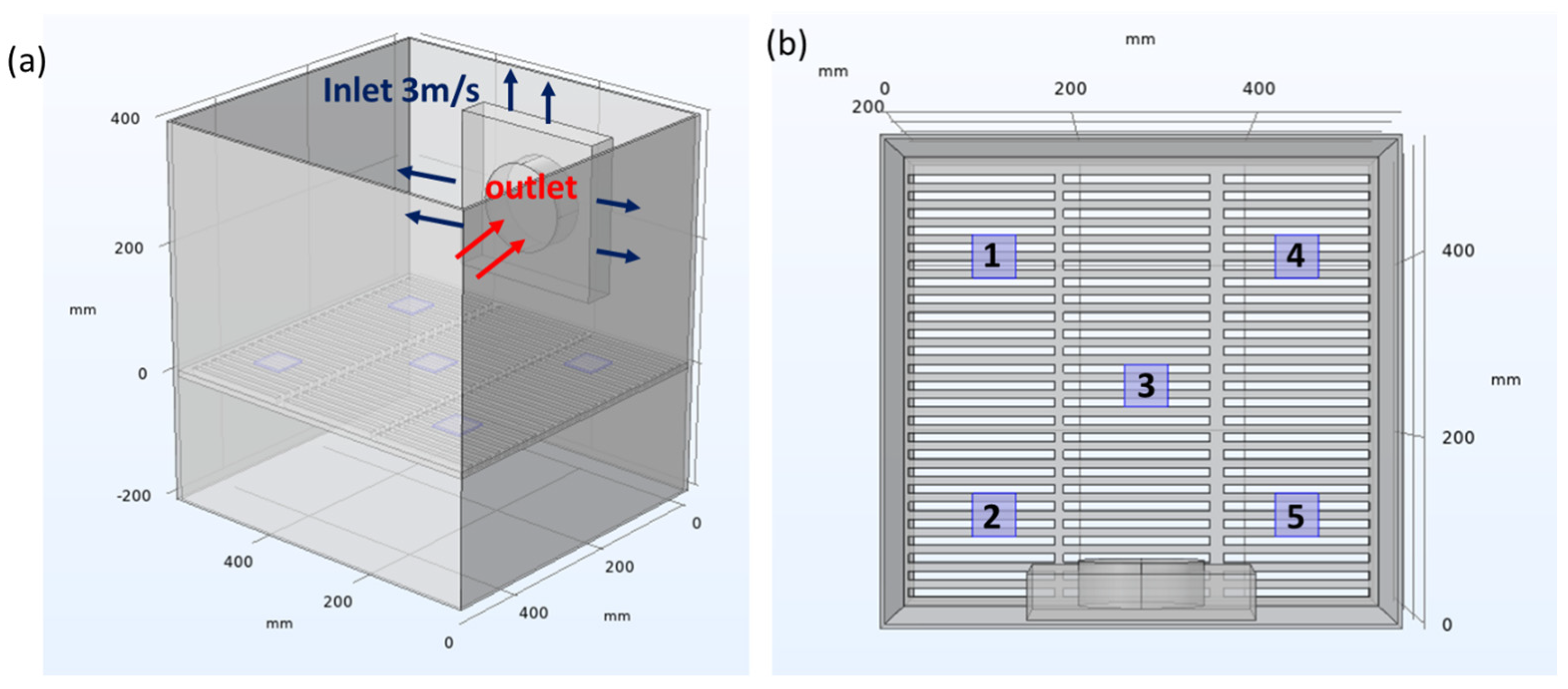

2.2. Drying Procedure

2.3. Moisture Content Determination and Drying Kinetic of Squid

2.4. Texture Analysis

2.5. Scanning Electron Microscopy (SEM)

2.6. Color Measurement

2.7. Microbial Analysis of Dried Squid

2.8. Water Activitiy Analysis of Dried Squid

2.9. Numerical Simulation

2.9.1. Modeling of Heat and Moisture Transport in Squid Sample

2.9.2. Modeling of the Internal Temperature and Moisture Fields of the Sample

2.10. Statistical Analysis

3. Results

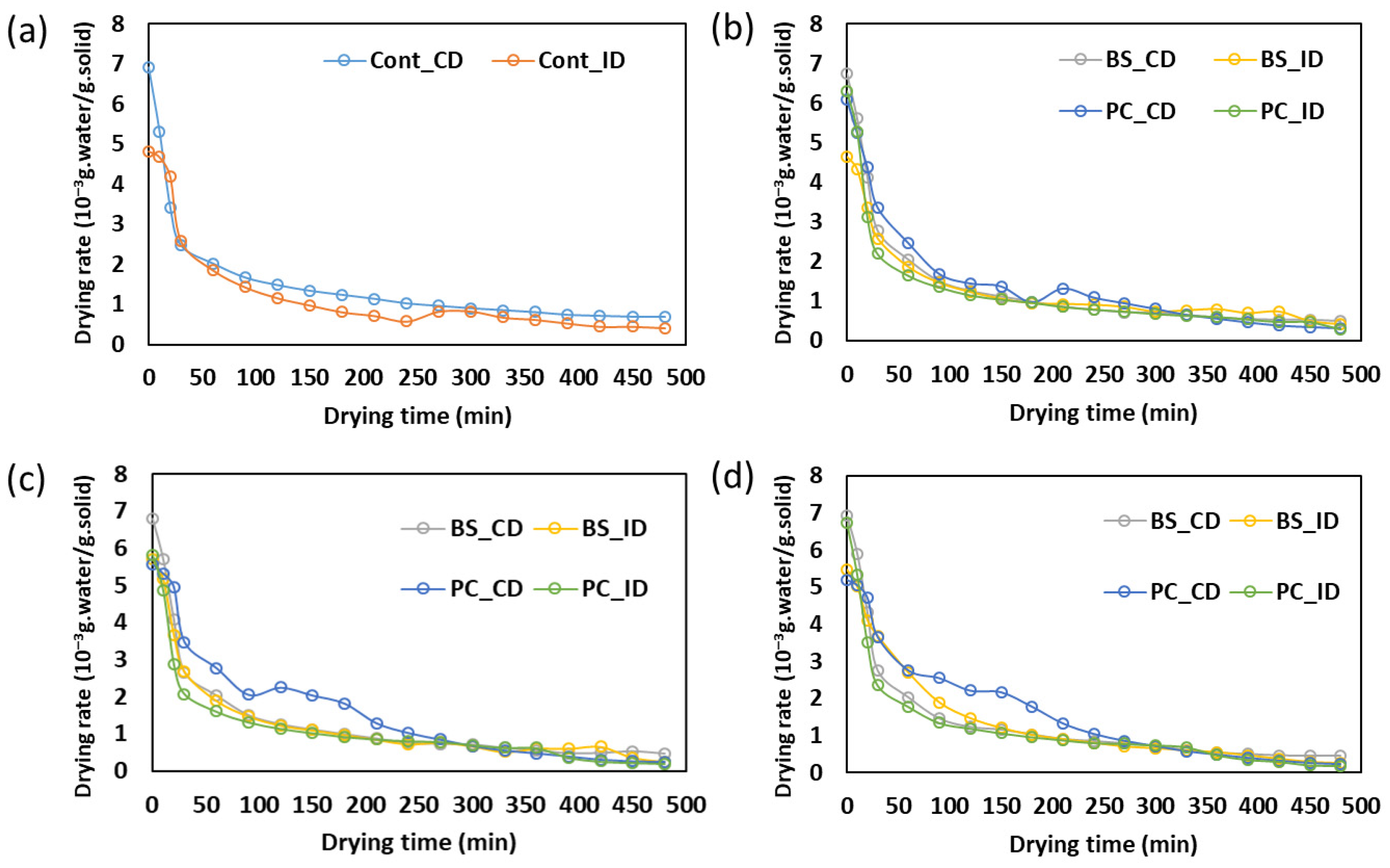

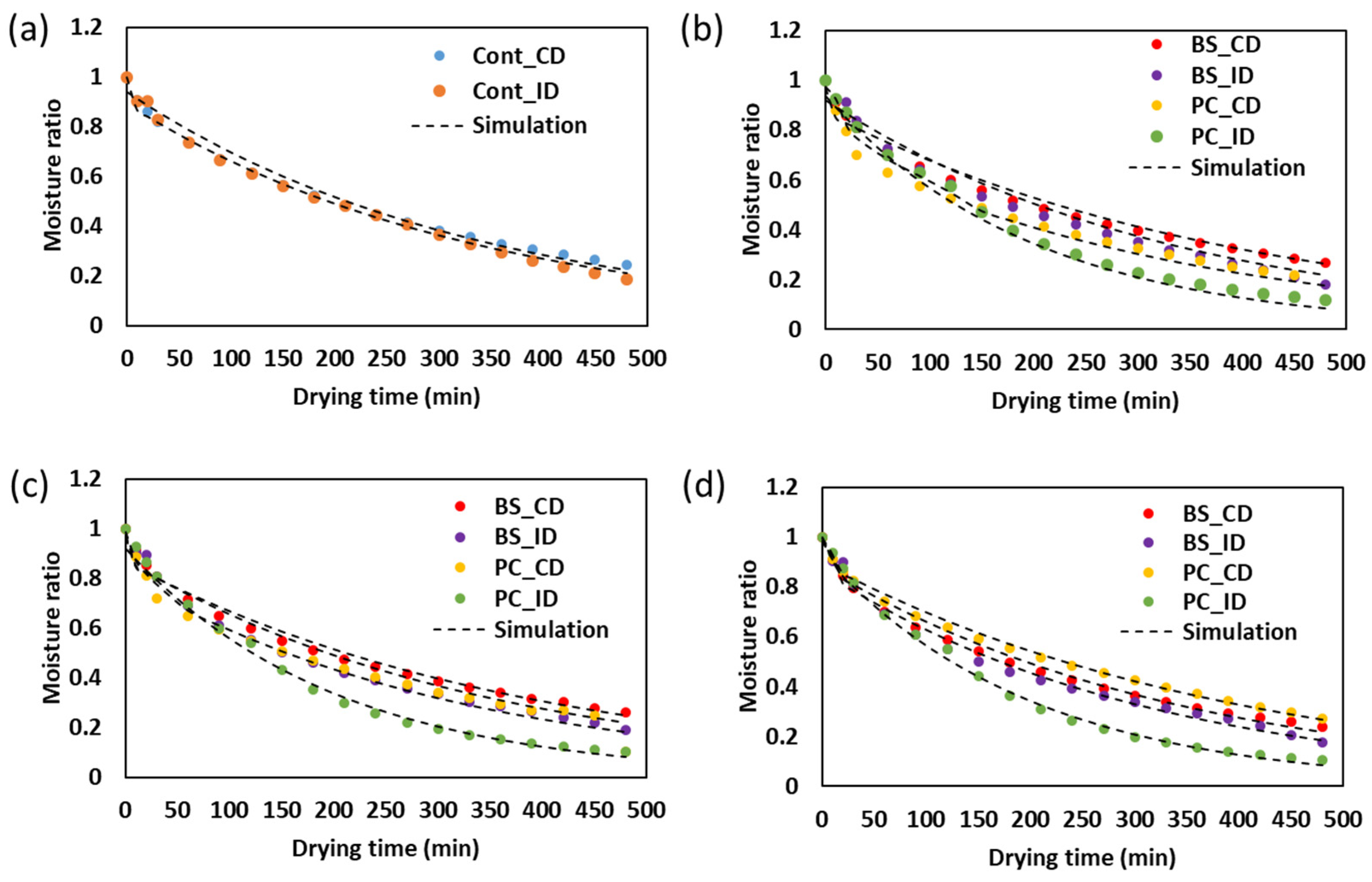

3.1. Drying Characteristics of Squid

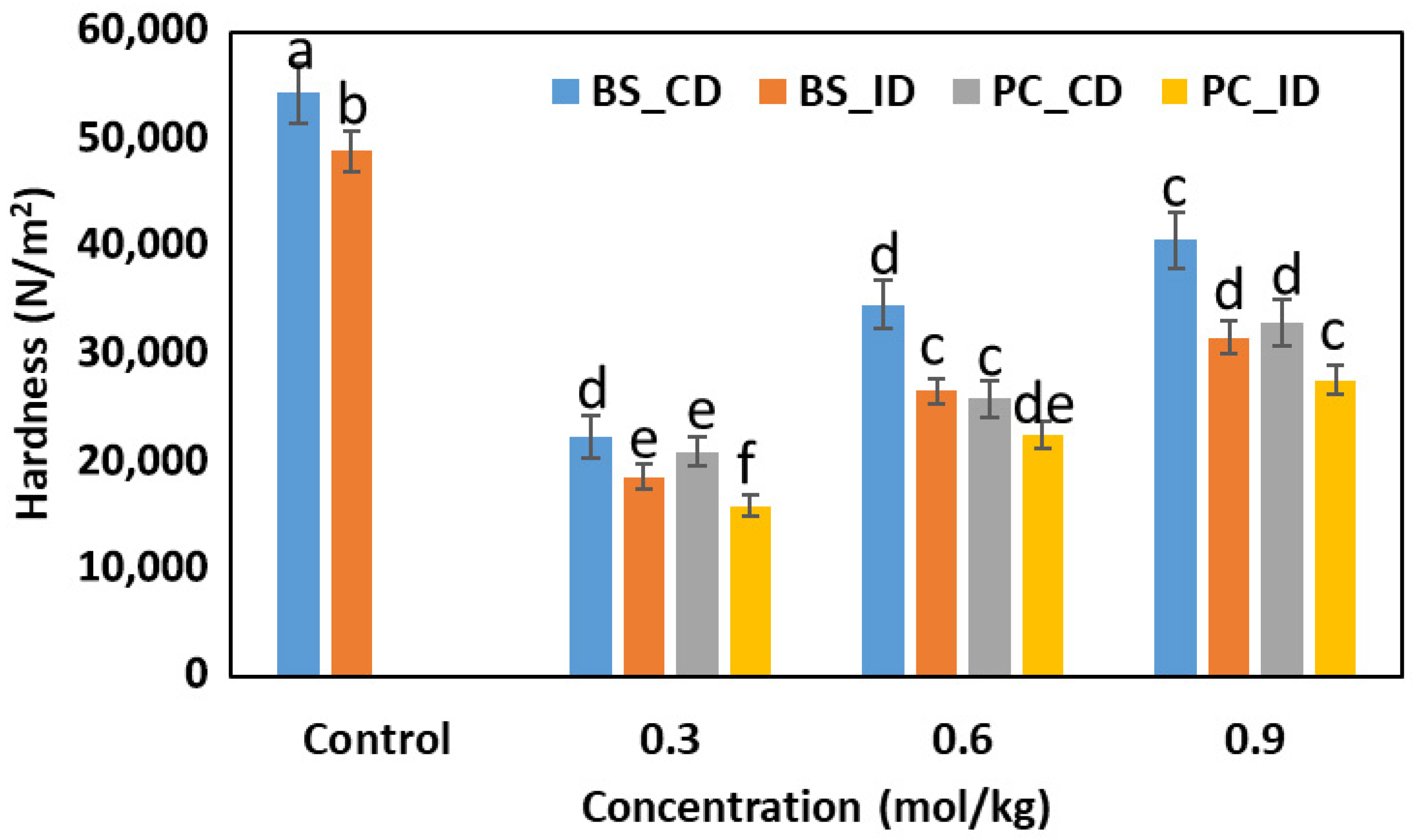

3.2. Texture Characteristics of Dried Squid

3.3. Color Changes in Dried Squid

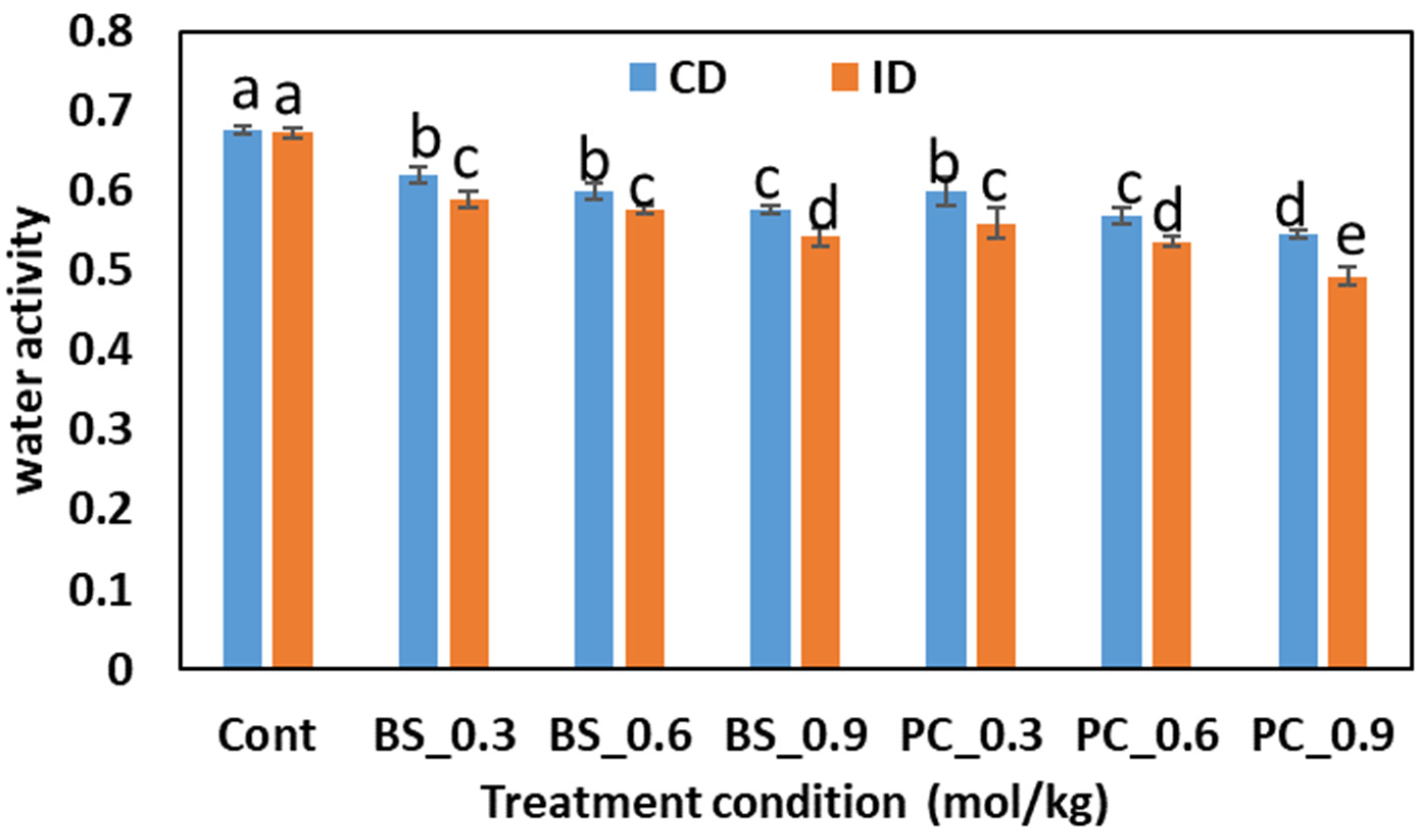

3.4. Water Activity of Dried Squid

3.5. Scanning Electron Microscopy of Dried Squid

3.6. Storability Analysis

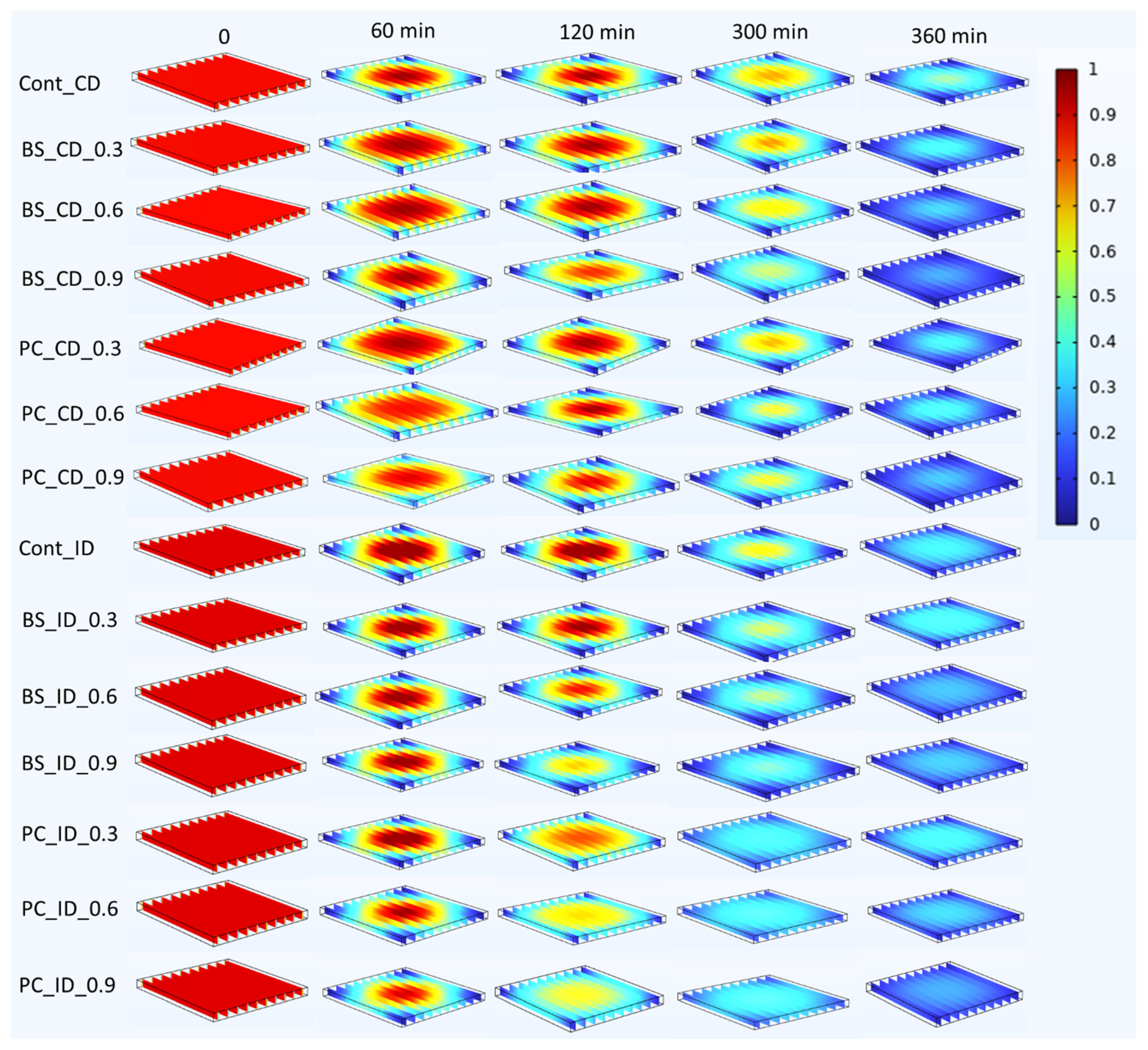

3.7. Numerical Simulation of Heat and Mass Transfer in Squid During Drying Proccess

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pearce, R.; Conlon, C.; Beck, K.; Mumme, K.; Mazahery, H.; Batty, R.; von Hurst, P. The effect of motivation type on intake and nutritional status of vitamin B12, omega-3 fatty acids, iron and nutrition knowledge in individuals following a vegan diet. Proc. Nutr. Soc. 2024, 83, E136. [Google Scholar] [CrossRef]

- Viji, P.; Debbarma, J.; Rao, B.Á. Nutritional significance of seafood. In Training Manual on Value Addition of Seafood; ICAR-Central Institute of Fisheries Technology: Cochin, India, 2018. [Google Scholar]

- Cui, Z.; Manoli, T.; Nikitchina, T.; Mo, H. Trends of Processed Products of Squid 2020. Available online: https://card-file.ontu.edu.ua/handle/123456789/16728 (accessed on 25 April 2025).

- Chen, J.M.; Li, F.; Zheng, Y.Q.; Shi, X.; Guo, Y. The review of comprehensive utilization with high value of squid processing by-products. Fish. Mod. 2015, 42, 44–47. [Google Scholar]

- Cheng, S.; Su, W.; Yuan, L.; Tan, M. Recent developments of drying techniques for aquatic products: With emphasis on drying process monitoring with innovative methods. Dry. Technol. 2021, 39, 1577–1594. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, X.; Qiao, K.; Chen, B.; Xu, M.; Cai, S.; Liu, Z. Combined effects of cold and hot air drying on physicochemical properties of semi-dried Takifugu obscurus fillets. Foods 2023, 12, 1649. [Google Scholar] [CrossRef]

- Khan, M.A.; Moradipour, M.; Obeidullah, M.; Quader, A.A. Heat and mass transport analysis of the drying of freshwater fishes by a forced convective air-dryer. J. Food Process Eng. 2021, 44, e13574. [Google Scholar] [CrossRef]

- Tan, C.H.; Hii, C.L.; Borompichaichartkul, C.; Phumsombat, P.; Kong, I.; Pui, L.P. Valorization of fruits, vegetables, and their by-products: Drying and bio-drying. Dry. Technol. 2022, 40, 1514–1538. [Google Scholar] [CrossRef]

- Thiyagalingam, S.; Kulinski, A.E.; Thorsteinsdottir, B.; Shindelar, K.L.; Takahashi, P.Y. Dysphagia in older adults. Mayo Clin. Proc. 2021, 96, 488–497. [Google Scholar] [CrossRef]

- De Sire, A.; Ferrillo, M.; Lippi, L.; Agostini, F.; de Sire, R.; Ferrara, P.E.; Migliario, M. Sarcopenic dysphagia, malnutrition, and oral frailty in elderly: A comprehensive review. Nutrients 2022, 14, 982. [Google Scholar] [CrossRef]

- IDDSI. Testing Methods. Available online: https://iddsi.org/Testing-Methods (accessed on 25 April 2025).

- Xiong, G.; Fu, X.; Pan, D.; Qi, J.; Xu, X.; Jiang, X. Influence of ultrasound-assisted sodium bicarbonate marination on the curing efficiency of chicken breast meat. Ultrason. Sonochem. 2020, 60, 104808. [Google Scholar] [CrossRef]

- Zhao, D.; Wei, J.; Hao, J.; Han, X.; Ding, S.; Yang, L.; Zhang, Z. Effect of sodium carbonate solution pretreatment on drying kinetics, antioxidant capacity changes, and final quality of wolfberry (Lycium barbarum) during drying. LWT 2019, 99, 254–261. [Google Scholar] [CrossRef]

- Lin, H.T.V.; Wu, H.X.; Sung, W.C. Hardness and quality of abalone (Haliotis discus hannai diversicolor diversicolor) muscle as suitably softened for seniors. Int. J. Food Prop. 2021, 24, 579–591. [Google Scholar] [CrossRef]

- Liu, Y.; Kang, Z.L.; Ge, Q.; Hou, Q.; Liu, R.; Meng, X. Effect of water and sodium carbonate swelling on the texture properties and water distribution of dried Abalone rugosa muscle. Food Mater. Res. 2023, 4, E004. [Google Scholar] [CrossRef]

- Nam, S.H.; Ha, Y.S.; Kim, T.W. Effects of drying methods based on exhaust cycle and time on the quality and drying of red peppers. J. Biosyst. Eng. 2014, 39, 101–110. [Google Scholar] [CrossRef]

- Park, H.W.; Yoon, W.B. Effects of air movement in a hot air dryer on the drying characteristics of colored potato (Solanum tuberosum L.) using computational fluid dynamics. Int. J. Agric. Biol. Eng. 2018, 11, 232–240. [Google Scholar] [CrossRef]

- Soydan Karabacak, M. Finite Element Modelling and Simulation of Drying Isotropic and Anisotropic Food Samples. Ph.D. Thesis, Middle East Technical University, Ankara, Türkiye, 2013. Available online: https://open.metu.edu.tr/handle/11511/22289 (accessed on 25 April 2025).

- Sun, D.W.; Hu, Z. CFD simulation of coupled heat and mass transfer through porous foods during vacuum cooling process. Int. J. Refrig. 2003, 26, 19–27. [Google Scholar] [CrossRef]

- Oyinloye, T.M.; Yoon, W.B. Characterization of the powder flow behavior of cooked Adzuki bean using image analysis and grinding models. J. Food Eng. 2024, 381, 112159. [Google Scholar] [CrossRef]

- Ghanem, T.H.M.; Nsasrat, L.S.; Younis, O.S.; Metwally, K.A.; Salem, A.; Orban, Z.; Elwakeel, A.E. Thin-layer modeling, drying parameters, and techno-enviro-economic analysis of a solar dried salted tilapia fish fillets. Sci. Rep. 2025, 15, 5073. [Google Scholar] [CrossRef]

- Page, G.E. Factors Influencing the Maximum Rates of Air Drying Shelled Corn in Thin layers. Master’s Thesis, Purdue University, West Lafayette, IN, USA, 1949. [Google Scholar]

- Erbay, Z.; Icier, F. A review of thin layer drying of foods: Theory, modeling, and experimental results. Crit. Rev. Food Sci. Nutr. 2010, 50, 441–464. [Google Scholar] [CrossRef]

- Midilli, A.; Kucuk, H.; Yapar, Z. A new model for single-layer drying. Dry. Technol. 2002, 20, 1503–1513. [Google Scholar] [CrossRef]

- Henderson, S.M.; Pabis, S. Grain drying theory. II. Temperature effects on drying coefficients. J. Agric. Eng. Res. 1961, 6, 169–174. [Google Scholar]

- Deng, Y.; Luo, Y.; Wang, Y.; Yue, J.; Liu, Z.; Zhong, Y.; Yang, H. Drying-induced protein and microstructure damages of squid fillets affected moisture distribution and rehydration ability during rehydration. J. Food Eng. 2014, 123, 23–31. [Google Scholar] [CrossRef]

- Park, H.W.; Han, W.Y.; Yoon, W.B. Drying characteristics of soybean (Glycine max) using continuous drying and intermittent drying. Int. J. Food Eng. 2018, 14, 20180057. [Google Scholar] [CrossRef]

- Komolafe, C.A. Numerical Simulation of the 3D simultaneous heat and mass transfer in a forced convection solar drying system integrated with thermal storage material. J. Sol. Energy Eng. 2023, 145, 051012. [Google Scholar] [CrossRef]

- Tu, Q.; Ma, Z.; Wang, H. Investigation of wet particle drying process in a fluidized bed dryer by CFD simulation and experimental measurement. Chem. Eng. J. 2023, 452, 139200. [Google Scholar] [CrossRef]

- Singh, S.; Kumar, S. Development of convective heat transfer correlations for common designs of solar dryer. Energy Convers. Manag. 2012, 64, 403–414. [Google Scholar] [CrossRef]

- Chen, C.; Pan, Z. An overview of progress, challenges, needs and trends in mathematical modeling approaches in food drying. Dry. Technol. 2023, 41, 2586–2605. [Google Scholar] [CrossRef]

- Delfiya, D.A.; Prashob, K.; Murali, S.; Alfiya, P.V.; Samuel, M.P.; Pandiselvam, R. Drying kinetics of food materials in infrared radiation drying: A review. J. Food Process Eng. 2022, 45, e13810. [Google Scholar] [CrossRef]

- da Silva, W.P.; Rodrigues, A.F.; Silva, C.M.D.E.; Gomes, J.P. Numerical approach to describe continuous and intermittent drying including the tempering period: Kinetics and spatial distribution of moisture. Dry. Technol. 2017, 35, 272–280. [Google Scholar] [CrossRef]

- Jung, J.; Zhao, Y. Alkali- or acid-induced changes in structure, moisture absorption ability and deacetylating reaction of β-chitin extracted from jumbo squid (Dosidicus gigas) pens. Food Chem. 2014, 152, 355–362. [Google Scholar] [CrossRef]

- Vidotto, D.C.; Tavares, G.M. Impact of dry heating in an alkaline environment on the structure and foaming properties of whey proteins. Food Bioprocess Technol. 2020, 13, 1755–1764. [Google Scholar] [CrossRef]

- Inyang, U.E.; Oboh, I.O.; Etuk, B.R. Kinetic models for drying techniques—Food materials. Adv. Chem. Eng. Sci. 2018, 8, 27–48. [Google Scholar] [CrossRef]

- Wang, J.; Xu, Z.; Lu, W.; Zhou, X.; Liu, S.; Zhu, S.; Ding, Y. Improving the texture attributes of squid meat (Sthenoteuthis oualaniensis) with slight oxidative and phosphate curing treatments. Food Res. Int. 2024, 176, 113829. [Google Scholar] [CrossRef]

- Konishi, F.; Fukunaga, Y.; Yoneda, C.; Shimomura, M.; Kasai, M.; Hatae, K. Changes in physicochemical properties and microstructure of dried squid during softening treatment. J. Sci. Food Agric. 2003, 83, 1565–1570. [Google Scholar] [CrossRef]

- Harikedua, S.D.; Mireles DeWitt, C.A. Preventing soft texture fish fillets through brine injection technology. J. Food Qual. 2017, 2017, 1875872. [Google Scholar] [CrossRef]

- Pacheco-Aguilar, R.; Mazorra-Manzano, M.A.; Ramírez-Suárez, J.C. Functional properties of fish protein hydrolysates from Pacific whiting (Merluccius productus) muscle produced by a commercial protease. Food Chem. 2008, 109, 782–789. [Google Scholar] [CrossRef] [PubMed]

- Chiou, T.K.; Chang, H.K.; Lo, L.; Lan, H.L.; Shiau, C.Y. Changes in chemical constituents and physical indices during processing of dried-seasoned squid. Fish. Sci. 2000, 66, 708–715. [Google Scholar] [CrossRef]

- Fathi, F.; Ebrahimi, S.N.; Matos, L.C.; Oliveira, M.B.P.P.; Alves, R.C. Emerging drying techniques for food safety and quality: A review. Compr. Rev. Food Sci. Food Saf. 2022, 21, 1125–1160. [Google Scholar] [CrossRef]

- Butkhot, N.; Soodsawaeng, P.; Samutsan, S.; Chotmongcol, K.; Vuthiphandchai, V.; Nimrat, S. New perspectives for surveying and improving Thai dried seafood qualities using antimicrobials produced by Bacillus velezensis BUU004 against foodborne pathogens. ScienceAsia 2019, 45, 116–126. [Google Scholar] [CrossRef]

- Fu, N.; Chen, X.D. Towards a maximal cell survival in convective thermal drying processes. Food Res. Int. 2011, 44, 1127–1149. [Google Scholar] [CrossRef]

- Tan, H.; Yu, Y.; Zhu, Y.; Liu, T.; Miao, R.; Hu, R.; Chen, J. Impacts of size reduction and alkaline-soaking pretreatments on microbial community and organic matter decomposition during wheat straw composting. Bioresour. Technol. 2022, 360, 127549. [Google Scholar] [CrossRef]

- Gram, L. Microbiological spoilage of fish and seafood products. In Compendium of the Microbiological Spoilage of Foods and Beverages; Springer: New York, NY, USA, 2009; pp. 87–119. [Google Scholar]

- Arvanitoyannis, I.S.; Veikou, A.; Panagiotaki, P. Osmotic dehydration: Theory, methodologies, and applications in fish, seafood, and meat products. In Progress in Food Preservation; Rahman, M.S., Ed.; Wiley: Hoboken, NJ, USA, 2012; pp. 161–189. [Google Scholar]

| Model Name | Model Name | References |

|---|---|---|

| Page | [22] | |

| Newton | MR = e−kt | [23] |

| Midilli–Kucuk equation | [24] | |

| Henderson and Pabis | [25] |

| Property | Density (ρ) (kg/m3) | Specific Heat (cp) (kJ/kg·K) | Thermal Conductivity (k) (W/m·K) | Reference |

|---|---|---|---|---|

| Control | 1065 ± 5 cd | 3.25 ± 0.03 d | 0.48 ± 0.02 b | |

| BS_ 0.3 | 1070 ± 4 cd | 3.31 ± 0.04 c | 0.49 ± 0.01 b | |

| BS_ 0.6 | 1082 ± 5 b | 3.38 ± 0.04 ab | 0.52 ± 0.02 a | |

| BS_ 0.9 | 1095 ± 6 a | 3.42 ± 0.05 a | 0.54 ± 0.02 a | |

| PC_ 0.3 | 1073 ± 5 c | 3.29 ± 0.03 cd | 0.50 ± 0.02 ab | |

| PC_ 0.6 | 1088 ± 6 b | 3.35 ± 0.03 b | 0.53 ± 0.02 a | |

| PC_ 0.9 | 1100 ± 6 a | 3.40 ± 0.04 a | 0.55 ± 0.03 a | |

| Aluminum | 2700 | 0.9 | 232.4 | COMSOL multiphysics (Version 5.1) |

| Air (at 40 °C) | Ideal gas model | 6.10−7T2 − 4.10−5T + 1 | 7.10−5T + 0.0238 | [17] |

| Concentration | a | b | k | n | R-Square | SSE | RMSE | Required Drying Time (min) | |

|---|---|---|---|---|---|---|---|---|---|

| Cont_CD | 0.9984 | −0.0002 | 0.0207 | 0.6447 | 0.9999 | 8.3 × 10−5 | 0.0024 | 495 | |

| Cont_ID | 1.0020 | −0.0004 | 0.0197 | 0.6364 | 0.9986 | 1.7 × 10−3 | 0.0105 | 461 | |

| BS_CD_0.3 | 1.0040 | −0.0001 | 0.0251 | 0.6213 | 0.9997 | 2.9 × 10−4 | 0.0044 | 478 | |

| BS_CD_0.6 | 1.0030 | −0.0001 | 0.0246 | 0.6296 | 0.9998 | 2.0 × 10−4 | 0.0037 | 482 | |

| BS_CD_0.9 | 1.0030 | −0.0001 | 0.0257 | 0.6278 | 0.9996 | 3.6 × 10−4 | 0.0049 | 491 | |

| PC_CD_0.3 | 1.0080 | −0.0004 | 0.0609 | 0.4651 | 0.9925 | 7.9 × 10−3 | 0.0229 | 477 | |

| Midilli–Kucuk equ | PC_CD_0.6 | 1.0080 | −0.0004 | 0.0580 | 0.4557 | 0.9869 | 1.4 × 10−2 | 0.0301 | 483 |

| PC_CD_0.9 | 1.0020 | −0.0003 | 0.0270 | 0.5627 | 0.9998 | 1.4 × 10−4 | 0.0030 | 489 | |

| BS_ID_0.3 | 1.0100 | −0.0002 | 0.0167 | 0.7089 | 0.9978 | 2.7 × 10−3 | 0.0134 | 431 | |

| BS_ID_0.6 | 1.0070 | 0.0000 | 0.0193 | 0.7124 | 0.9978 | 2.6 × 10−3 | 0.0131 | 439 | |

| BS_ID_0.9 | 1.0100 | −0.0001 | 0.0214 | 0.6872 | 0.9961 | 4.6 × 10−3 | 0.0174 | 455 | |

| PC_ID_0.3 | 0.9844 | 0.0000 | 0.0069 | 0.9385 | 0.9980 | 3.2 × 10−3 | 0.0146 | 421 | |

| PC_ID_0.6 | 0.9856 | −0.0001 | 0.0060 | 0.9936 | 0.9982 | 3.0 × 10−3 | 0.0142 | 428 | |

| PC_ID_0.9 | 0.9883 | −0.0001 | 0.0061 | 0.9883 | 0.9983 | 3.0 × 10−3 | 0.0141 | 435 | |

| Cont_CD | 0.9185 | 0.0030 | 0.9870 | 1.3 × 10−2 | 0.0277 | ||||

| Cont_ID | 0.9411 | 0.0033 | 0.9925 | 8.9 × 10−3 | 0.0229 | ||||

| BS_CD_0.3 | 0.9035 | 0.0028 | 0.9745 | 2.4 × 10−2 | 0.0372 | ||||

| BS_CD_0.6 | 0.9029 | 0.0029 | 0.9751 | 2.3 × 10−2 | 0.0372 | ||||

| BS_CD_0.9 | 0.9025 | 0.0031 | 0.9774 | 2.3 × 10−2 | 0.0365 | ||||

| PC_CD_0.3 | 0.8642 | 0.0035 | 0.9574 | 4.5 × 10−2 | 0.0514 | ||||

| Henderson and Pabis | PC_CD_0.6 | 0.8733 | 0.0033 | 0.9554 | 4.6 × 10−2 | 0.0521 | |||

| PC_CD_0.9 | 0.9135 | 0.0026 | 0.9834 | 1.5 × 10−2 | 0.0295 | ||||

| BS_ID_0.3 | 0.9428 | 0.0034 | 0.9890 | 1.3 × 10−2 | 0.0280 | ||||

| BS_ID_0.6 | 0.9190 | 0.0035 | 0.9792 | 2.4 × 10−2 | 0.0378 | ||||

| BS_ID_0.9 | 0.9193 | 0.0035 | 0.9777 | 2.6 × 10−2 | 0.0391 | ||||

| PC_ID_0.3 | 0.9659 | 0.0048 | 0.9971 | 4.6 × 10−3 | 0.0164 | ||||

| PC_ID_0.6 | 0.9740 | 0.0053 | 0.9969 | 5.3 × 10−3 | 0.0176 | ||||

| PC_ID_0.9 | 0.9757 | 0.0052 | 0.9971 | 4.9 × 10−3 | 0.0170 | ||||

| Cont_CD | 0.0154 | 0.7260 | 0.9988 | 1.2 × 10−3 | 0.0085 | ||||

| Cont_ID | 0.0100 | 0.8160 | 0.9948 | 6.2 × 10−3 | 0.0190 | ||||

| BS_CD_0.3 | 0.0207 | 0.6683 | 0.9994 | 5.7 × 10−4 | 0.0058 | ||||

| BS_CD_0.6 | 0.0210 | 0.6702 | 0.9996 | 4.2 × 10−4 | 0.0050 | ||||

| BS_CD_0.9 | 0.0210 | 0.6794 | 0.9992 | 7.9 × 10−4 | 0.0068 | ||||

| PC_CD_0.3 | 0.0344 | 0.6183 | 0.9864 | 1.4 × 10−2 | 0.0290 | ||||

| Page model | PC_CD_0.6 | 0.0301 | 0.6320 | 0.9797 | 2.1 × 10−2 | 0.0352 | |||

| PC_CD_0.9 | 0.0163 | 0.6986 | 0.9973 | 2.4 × 10−3 | 0.0119 | ||||

| BS_ID_0.3 | 0.0115 | 0.7970 | 0.9970 | 3.6 × 10−3 | 0.0146 | ||||

| BS_ID_0.6 | 0.0179 | 0.7255 | 0.9977 | 2.6 × 10−3 | 0.0125 | ||||

| BS_ID_0.9 | 0.0177 | 0.7270 | 0.9959 | 4.8 × 10−3 | 0.0168 | ||||

| PC_ID_0.3 | 0.0084 | 0.9022 | 0.9978 | 3.5 × 10−3 | 0.0144 | ||||

| PC_ID_0.6 | 0.0086 | 0.9166 | 0.9978 | 3.7 × 10−3 | 0.0148 | ||||

| PC_ID_0.9 | 0.0082 | 0.9203 | 0.9980 | 3.5 × 10−3 | 0.0143 | ||||

| Cont_CD | 0.0034 | 0.9595 | 4.1 × 10−2 | 0.0476 | |||||

| Cont_ID | 0.0036 | 0.9505 | 2.3 × 10−2 | 0.0358 | |||||

| BS_CD_0.3 | 0.0033 | 0.9322 | 6.3 × 10−2 | 0.0590 | |||||

| BS_CD_0.6 | 0.0033 | 0.9336 | 6.3 × 10−2 | 0.0591 | |||||

| BS_CD_0.9 | 0.0036 | 0.9388 | 6.1 × 10−2 | 0.0584 | |||||

| PC_CD_0.3 | 0.0043 | 0.8901 | 1.2 × 10−1 | 0.0803 | |||||

| Newton | PC_CD_0.6 | 0.0040 | 0.8939 | 1.1 × 10−1 | 0.0781 | ||||

| PC_CD_0.9 | 0.0030 | 0.9469 | 4.7 × 10−2 | 0.0512 | |||||

| BS_ID_0.3 | 0.0037 | 0.9783 | 2.6 × 10−2 | 0.0383 | |||||

| BS_ID_0.6 | 0.0040 | 0.9573 | 5.0 × 10−2 | 0.0526 | |||||

| BS_ID_0.9 | 0.0040 | 0.9560 | 5.1 × 10−2 | 0.0535 | |||||

| PC_ID_0.3 | 0.0050 | 0.9945 | 8.7 × 10−3 | 0.0220 | |||||

| PC_ID_0.6 | 0.0055 | 0.9956 | 7.6 × 10−3 | 0.0205 | |||||

| PC_ID_0.9 | 0.0054 | 0.9959 | 6.9 × 10−3 | 0.0196 |

| Sample | L* | a* | b* | ΔE |

|---|---|---|---|---|

| Fresh | 58.21 ± 0.09 a | 1.91 ± 0.07 m | 4.32 ± 0.05 o | — |

| Control_CD | 30.99 ± 0.01 m | 7.27 ± 0.02 e | 6.23 ± 0.01 n | 27.80 |

| Control_ID | 37.62 ± 0.02 h | 7.38 ± 0.06 c | 10.08 ± 0.04 a | 22.07 |

| BS_CD_0.3 | 34.17 ± 0.01 k | 7.91 ± 0.01 b | 7.88 ± 0.02 j | 25.03 |

| BS_CD_0.6 | 36.82 ± 0.01 j | 7.12 ± 0.02 f | 8.12 ± 0.01 h | 22.34 |

| BS_CD_0.9 | 40.83 ± 0.03 e | 5.45 ± 0.02 k | 8.84 ± 0.02 e | 18.30 |

| PC_CD_0.3 | 40.49 ± 0.01 f | 7.34 ± 0.01 d | 6.91 ± 0.01 m | 18.71 |

| PC_CD_0.6 | 37.35 ± 0.03 i | 7.01 ± 0.02 g | 8.54 ± 0.02 f | 21.88 |

| PC_CD_0.9 | 33.41 ± 0.03 l | 7.02 ± 0.02 g | 7.45 ± 0.01 l | 25.51 |

| BS_ID_0.3 | 40.79 ± 0.03 e | 7.12 ± 0.02 f | 9.11 ± 0.02 c | 18.81 |

| BS_ID_0.6 | 41.95 ± 0.03 c | 4.68 ± 0.02 l | 8.08 ± 0.01 i | 16.92 |

| BS_ID_0.9 | 41.43 ± 0.02 d | 5.93 ± 0.02 j | 8.99 ± 0.01 d | 17.87 |

| PC_ID_0.3 | 45.18 ± 0.10 b | 6.71 ± 0.01 i | 7.81 ± 0.01 k | 14.32 |

| PC_ID_0.6 | 39.68 ± 0.01 g | 8.04 ± 0.02 a | 9.16 ± 0.01 b | 20.11 |

| PC_ID_0.9 | 36.82 ± 0.01 j | 6.94 ± 0.03 h | 8.43 ± 0.01 g | 22.35 |

| Storage Condition (°C) | |||||

|---|---|---|---|---|---|

| 25 °C | 40 °C | ||||

| Sample | Initial (0 Day) | 7 Days | 14 Days | 7 Days | 14 Days |

| Control_CD | 2.70 ± 0.11 a | 2.72 ± 0.08 a | 2.88 ± 0.05 ab | 2.90 ± 0.13 a | 2.92 ± 0.03 a |

| Control_ID | 2.58 ± 0.03 ab | 2.61 ± 0.01 a | 2.87 ± 0.04 a | 2.79 ± 0.15 ab | 2.90 ± 0.05 a |

| BS_CD_0.3 | 2.59 ± 0.01 ab | 2.60 ± 0.01 a | 2.74 ± 0.05 abc | 2.72 ± 0.08 ab | 2.83 ± 0.09 a |

| BS_CD_0.6 | 2.58 ± 0.03 ab | 2.59 ± 0.01 a | 2.73 ± 0.09 abc | 2.70 ± 0.11 ab | 2.76 ± 0.02 a |

| BS_CD_0.9 | 2.60 ± 0.01 ab | 2.61 ± 0.01 a | 2.65 ± 0.06 c | 2.72 ± 0.08 ab | 2.86 ± 0.06 a |

| PC_CD_0.3 | 2.67 ± 0.15 a | 2.70 ± 0.11 a | 2.73 ± 0.06 c | 2.71 ± 0.09 ab | 2.81 ± 0.06 a |

| PC_CD_0.6 | 2.57 ± 0.04 ab | 2.58 ± 0.03 a | 2.61 ± 0.07 c | 2.72 ± 0.08 ab | 2.89 ± 0.07 a |

| PC_CD_0.9 | 2.68 ± 0.14 a | 2.72 ± 0.08 a | 2.74 ± 0.04 abc | 2.71 ± 0.09 ab | 2.81 ± 0.08 a |

| BS_ID_0.3 | 2.42 ± 0.16 b | 2.58 ± 0.03 a | 2.71 ± 0.03 c | 2.62 ± 0.02 b | 2.77 ± 0.01 a |

| BS_ID_0.6 | 2.71 ± 0.09 a | 2.71 ± 0.09 a | 2.72 ± 0.08 bc | 2.80 ± 0.14 ab | 2.85 ± 0.07 a |

| BS_ID_0.9 | 2.61 ± 0.01 ab | 2.63 ± 0.04 a | 2.65 ± 0.08 c | 2.73 ± 0.06 ab | 2.85 ± 0.07 a |

| PC_ID_0.3 | 2.59 ± 0.01 ab | 2.61 ± 0.01 a | 2.63 ± 0.06 c | 2.71 ± 0.04 ab | 2.89 ± 0.02 a |

| PC_ID_0.6 | 2.58 ± 0.03 ab | 2.59 ± 0.01 a | 2.62 ± 0.07 c | 2.74 ± 0.05 ab | 2.83 ± 0.07 a |

| PC_ID_0.9 | 2.61 ± 0.01 ab | 2.71 ± 0.09 a | 2.73 ± 0.05 abc | 2.73 ± 0.07 ab | 2.83 ± 0.05 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oyinloye, T.M.; Yoon, W.B. Optimizing Texture and Drying Behavior of Squid (Todarodes pacificus) for Elder-Friendly Applications Using Alkaline Pretreatment and Intermittent Drying: An Experimental and Numerical Study. Processes 2025, 13, 2592. https://doi.org/10.3390/pr13082592

Oyinloye TM, Yoon WB. Optimizing Texture and Drying Behavior of Squid (Todarodes pacificus) for Elder-Friendly Applications Using Alkaline Pretreatment and Intermittent Drying: An Experimental and Numerical Study. Processes. 2025; 13(8):2592. https://doi.org/10.3390/pr13082592

Chicago/Turabian StyleOyinloye, Timilehin Martins, and Won Byong Yoon. 2025. "Optimizing Texture and Drying Behavior of Squid (Todarodes pacificus) for Elder-Friendly Applications Using Alkaline Pretreatment and Intermittent Drying: An Experimental and Numerical Study" Processes 13, no. 8: 2592. https://doi.org/10.3390/pr13082592

APA StyleOyinloye, T. M., & Yoon, W. B. (2025). Optimizing Texture and Drying Behavior of Squid (Todarodes pacificus) for Elder-Friendly Applications Using Alkaline Pretreatment and Intermittent Drying: An Experimental and Numerical Study. Processes, 13(8), 2592. https://doi.org/10.3390/pr13082592