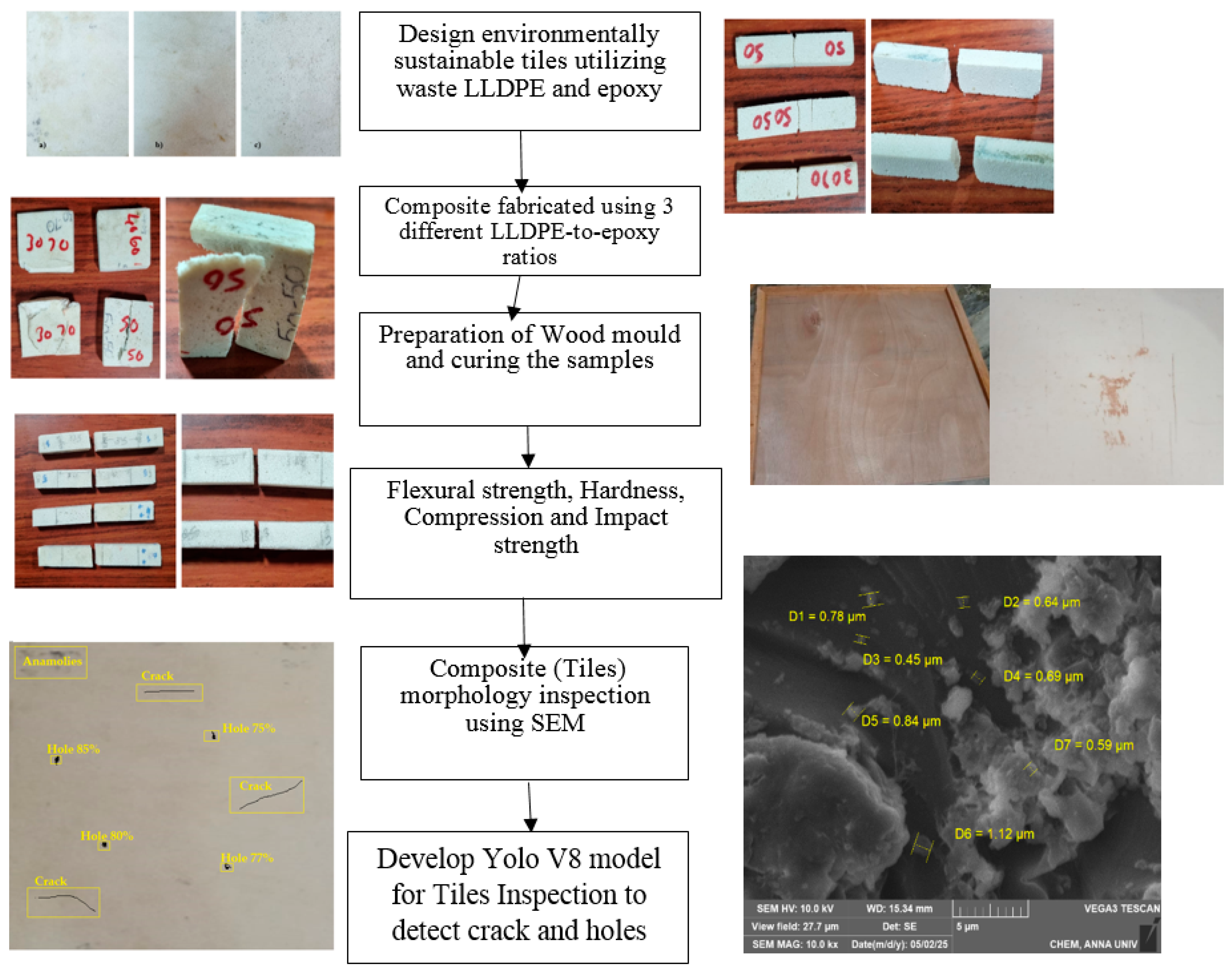

3.1. Flexural Testing of LLDPE/Epoxy Composites

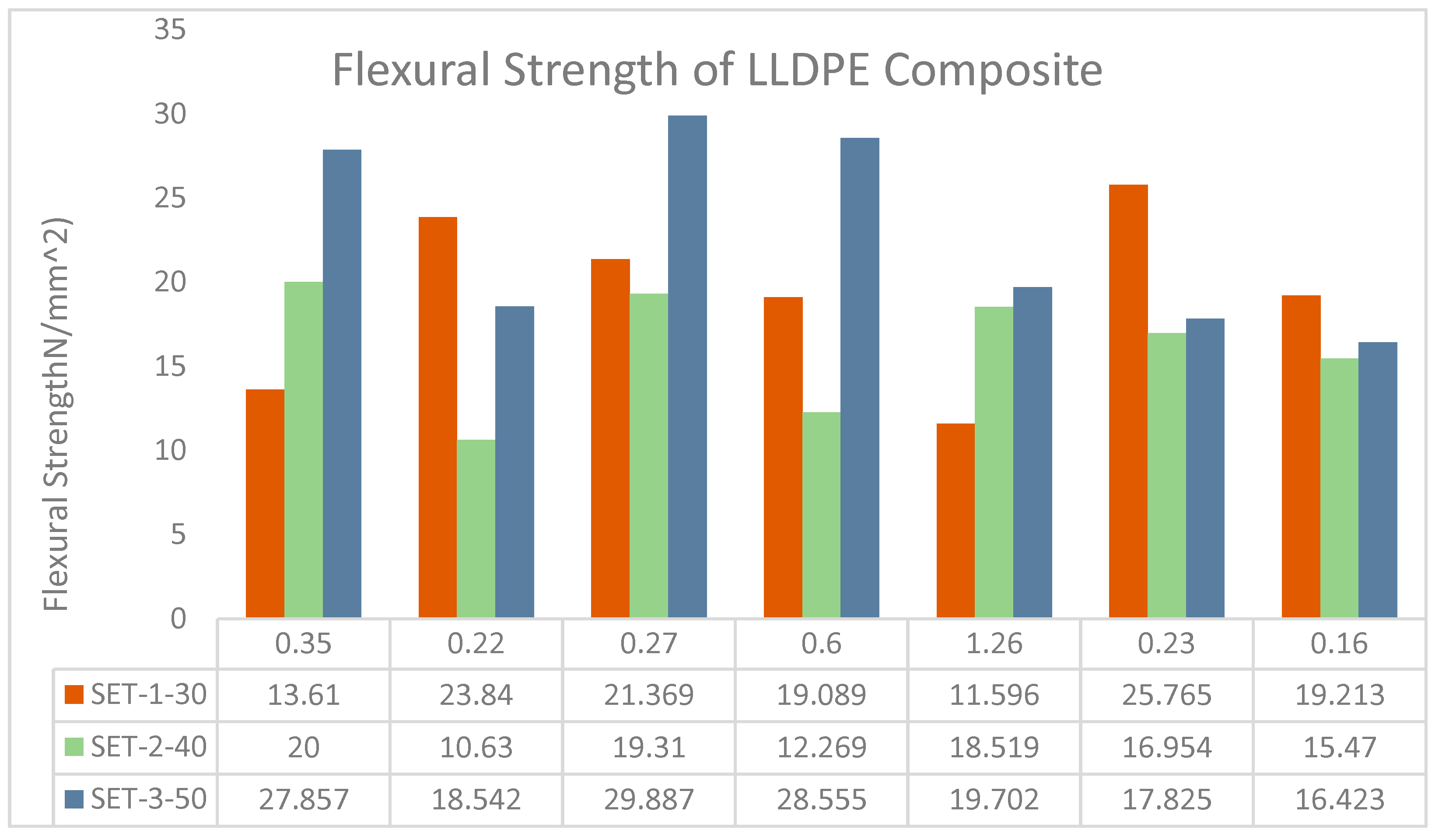

Flexural strength, as portrayed in

Figure 4, is a mechanical parameter of composite materials, and particularly products such as tiles, where surface loading and bending stresses are frequent. Three-point bending was performed following ASTM D790 to assess the stiffness and load-carrying capacity of the samples with various LLDPE-to-epoxy ratios: 30:70, 40:60, and 50:50. The flexural strength results exhibit a non-monotonic trend where, while there is a reduction as LLDPE content goes up from 30% to 40%, there is a great hike when the LLDPE content is 50%. The load at peak exhibits a definite upward trend with rising LLDPE content, especially with a very high rise seen for LLDPE content going from 40% to 50%. The 50:50 sample set, which had an equal ratio of LLDPE and epoxy, showed greater flexural strength than the other sets in general. This is due to better stress distribution between the filler and matrix. With higher LLDPE content, the matrix becomes more ductile, and hence there is better energy absorption under bending loads. As we know that LLDPE is highly flexible, this may have contributed to the overall performance of the 50:50 ratio mix.

The 30:70 samples, despite having a higher content of epoxy (which is usually a cause for brittleness), were more variable and had some lower results. This can be attributed to filler clustering, which interferes with stress transfer routes, and an uneven distribution of the powder may have also contributed to lower strength. The 40:60 composition provided a moderate performance with good consistency. It seems this composition did show some proper mixing.

As portrayed in

Figure 5, the flexural strength values clearly vary between the three compositions tested (SET-1-30, SET-2-40, and SET-3-50). The 50:50 LLDPE/epoxy ratio (SET-3-50) shows the best performance, with maximum values up to 29.887 MPa, much higher than the other formulations. This indicates that the balanced dispersion of LLDPE particles in the epoxy matrix increases stress transfer and load-bearing capacity. Especially, the 30:70 ratio (SET-1-30) exhibits the greatest range of strength, from 11.596 MPa to 25.765 MPa, possibly resulting from non-uniform filler dispersion or localized flaws. The 40:60 ratio (SET-2-40) falls in between, with higher but more homogeneous strength values, with an average around 16–20 MPa [

37].

Here, we included the mean values, along with the standard deviation (SD), for each composition group (SET-1-30, SET-2-40, and SET-3-50), based on five replicates per formulation. Additionally, a one-way ANOVA test was conducted to determine whether the differences among the three sets were statistically significant at a 95% confidence level. The updated results are as follows: SET-1-30 (30:70 LLDPE/epoxy) had a mean flexural strength of 18.67 MPa and the standard deviation was ±5.83 MPa. Similarly SET-2-40 (40:60 LLDPE/epoxy) had a mean flexural strength of 17.42 MPa and the standard deviation was ±2.11 MPa. For SET-3-50 (50:50 LLDPE/epoxy), the mean flexural strength was 28.31 MPa and the standard deviation was ±1.21 MPa. The ANOVA yielded a p-value < 0.01, indicating that the differences between the compositions are statistically significant. These results show that the 50:50 LLDPE/epoxy composition (SET-3-50) provides superior mechanical performance due to better filler–matrix interaction and uniform load distribution. The graph also identifies the correlation between LLDPE content and mechanical performance. Although the 50:50 ratio attains better strength, the 30:70 and 40:60 ratios have trade-offs: increased epoxy content (30:70) results in brittleness in certain samples, while a balanced LLDPE addition (40:60) offers a compromise between rigidity and ductility. These trends are supported by microstructural findings, wherein the best particle–matrix bonding in the 50:50 samples is associated with improved flexural resistance. For engineering applications, this information suggests the use of the 50:50 mix for tiles in need of maximum durability against bending stresses.

The flexural strength of LLDPE/epoxy composites increased with higher LLDPE content, with the 50:50 ratio achieving the highest value of 29.887 MPa, indicating improved stress transfer due to better filler dispersion [

38]. This aligns with studies reporting enhanced mechanical performance in polymer composites with optimized filler–matrix bonding The 30:70 mix showed variability and lower values due to filler agglomeration and microstructural flaws, consistent with findings in nanoparticle-reinforced systems [

39]. The 40:60 ratio demonstrated moderate and consistent performance, suggesting a balanced distribution of ductile and rigid phases SEM observations confirmed these trends, showing reduced clustering and voids in higher-LLDPE formulations, supporting their superior mechanical behaviour

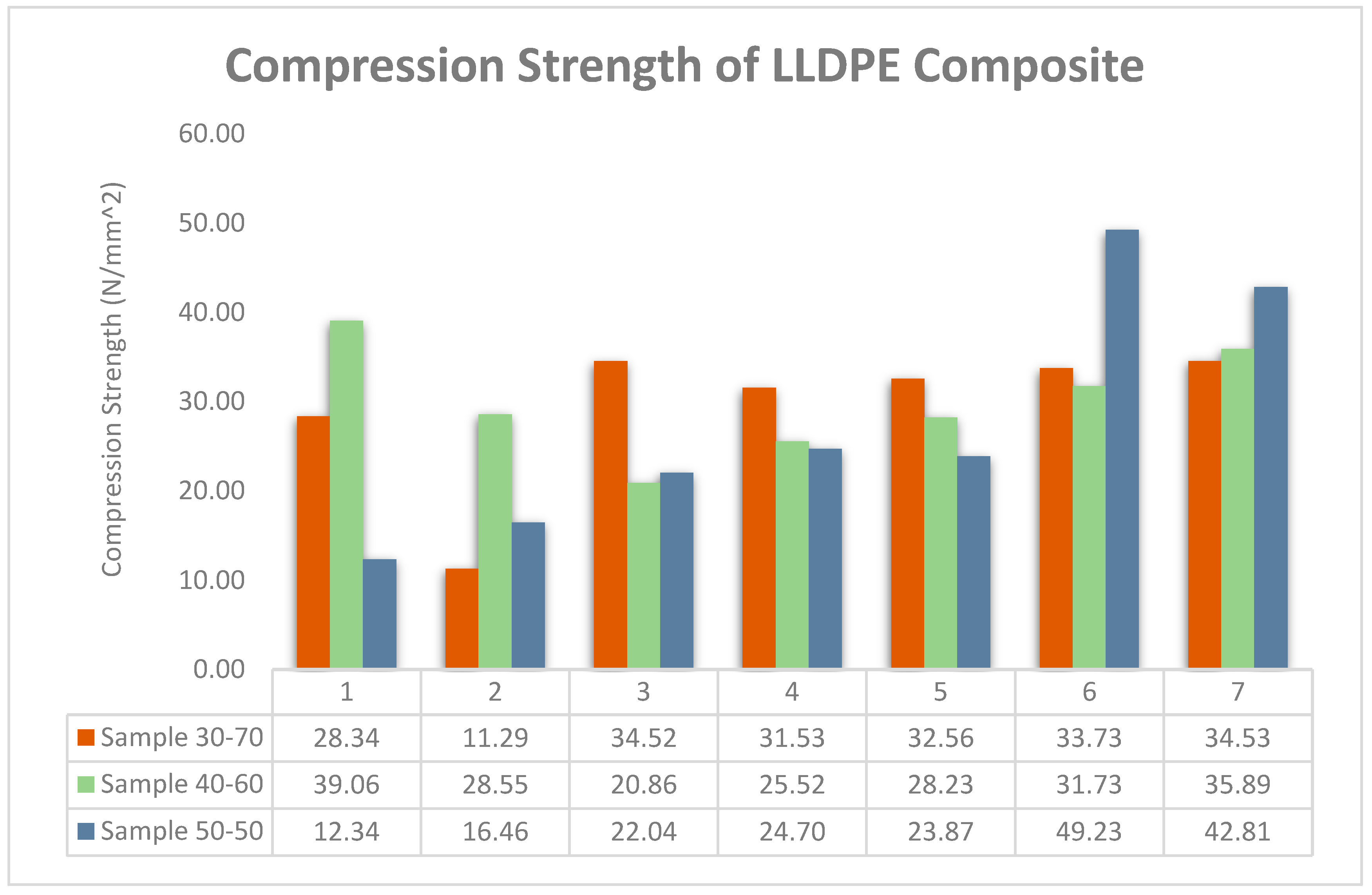

3.2. Compressive Strength Performance of LLDPE/Epoxy Composite

Compressive strength is a critical performance indicator for flooring tiles, which are expected to bear significant vertical loads during their service life.

Figure 6 illustrates the compression-tested LLDPE/epoxy composite samples, evaluated following ASTM D695 standards, which provide a reliable measurement of compressive properties for polymer-based materials.

Among the evaluated compositions, the 50:50 LLDPE-to-epoxy ratio demonstrated the highest peak compressive strength, reaching up to 49.23 MPa, which significantly exceeds the values of 30:70 and 40:60 blends. This superior performance is attributed to a synergistic interaction between the ductile thermoplastic (LLDPE) and the rigid thermoset (epoxy), resulting in improved stress transfer and crack-bridging ability within the composite structure. Similar behaviour has been documented in thermoplastic–thermoset hybrid systems [

40], where the thermoplastic phase acts to absorb and dissipate energy, while the thermoset provides dimensional stability and rigidity [

34,

41].

The 50:50 formulation exhibits optimal phase distribution, facilitating the formation of a continuous LLDPE network within the epoxy matrix. This microstructure enhances interfacial bonding and stress delocalization, leading to higher load-bearing capacity. Studies by Zhang et al. on LDPE/epoxy composites confirm that achieving a percolated thermoplastic phase at near-equal loading ratios can result in maximum compressive properties due to enhanced polymer interlocking and reduced voids.

However, the increased standard deviation in compressive strength measurements for the 50:50 samples suggests microstructural heterogeneity, potentially due to the following factors:

Percolation threshold effects, where minor inconsistencies in LLDPE distribution critically influence load path integrity.

Formation of localized stress concentration sites due to insufficient mixing or agglomeration of LLDPE particles.

Variations in crosslinking density in the epoxy-rich and LLDPE-rich regions, as noted in other polymer blends with high filler loadings.

In contrast, the 40:60 blend yielded more consistent compressive behaviour, as shown in

Figure 7, with five out of seven samples falling within a narrow strength range of 28.23–39.06 MPa. Although the average strength was lower than that of the 50:50 blend, the standard deviation was significantly reduced, indicating better homogeneity. This aligns with findings by Bakar et al. who showed that increasing epoxy content leads to improved dispersion and wetting of filler particles, enhancing mechanical uniformity [

42].

The 30:70 formulation displayed the least consistent behaviour, largely due to the dominance of the rigid epoxy phase, which, while strong, lacks the ability to redistribute localized stress efficiently. The absence of a sufficiently continuous LLDPE network limits plastic deformation under compression, resulting in brittle fracture modes, a behaviour similarly reported in rigid polymer matrix composites without adequate toughening agents [

43]. While the 50:50 LLDPE/epoxy composite yields the highest peak compressive strength, the 40:60 composition offers a balanced combination of strength and consistency, making it a more reliable choice for structural flooring applications where uniform performance is critical.

The 40:60 composite’s superior performance is especially apparent when looking at the lower bound of results. Its lowest recorded strength (20.86 N/mm2) is far greater than that of the weakest sample of the 50:50 (12.34 N/mm2) composite, yet still near the 30:70 composite’s upper values. This dependability comes from the epoxy matrix, which has continuous load-carrying paths, while the LLDPE particles contribute just enough ductility to avoid brittle fracture. For engineering uses where uniform performance is critical, for example, for floor tiles carrying heavy static loads, the 40:60 ratio provides the optimum balance between the 30:70 ratio’s lack of stiffness and the 50:50 ratio’ erratic behaviour. The figure indicates that 40% LLDPE is the point at which particle reinforcement gains are optimized before dispersion problems start to undermine structural integrity.

The 40:60 LLDPE/epoxy composite exhibited the most consistent compression strength, suggesting optimal particle–matrix synergy and minimal stress concentration effects Although the 50:50 ratio showed the highest peak strength (49.23 N/mm2), its wide variability indicates percolation threshold effects and non-uniform filler dispersion The 30:70 mix’s poor consistency reflects inadequate load transfer due to epoxy dominance and microstructural flaws SEM-supported micro voids and inhomogeneous crosslinking likely contributed to localized failure in extreme compositions These findings align with prior studies on filler loading and mechanical performance in polymer composites, where moderate filler content often yields superior reliability.

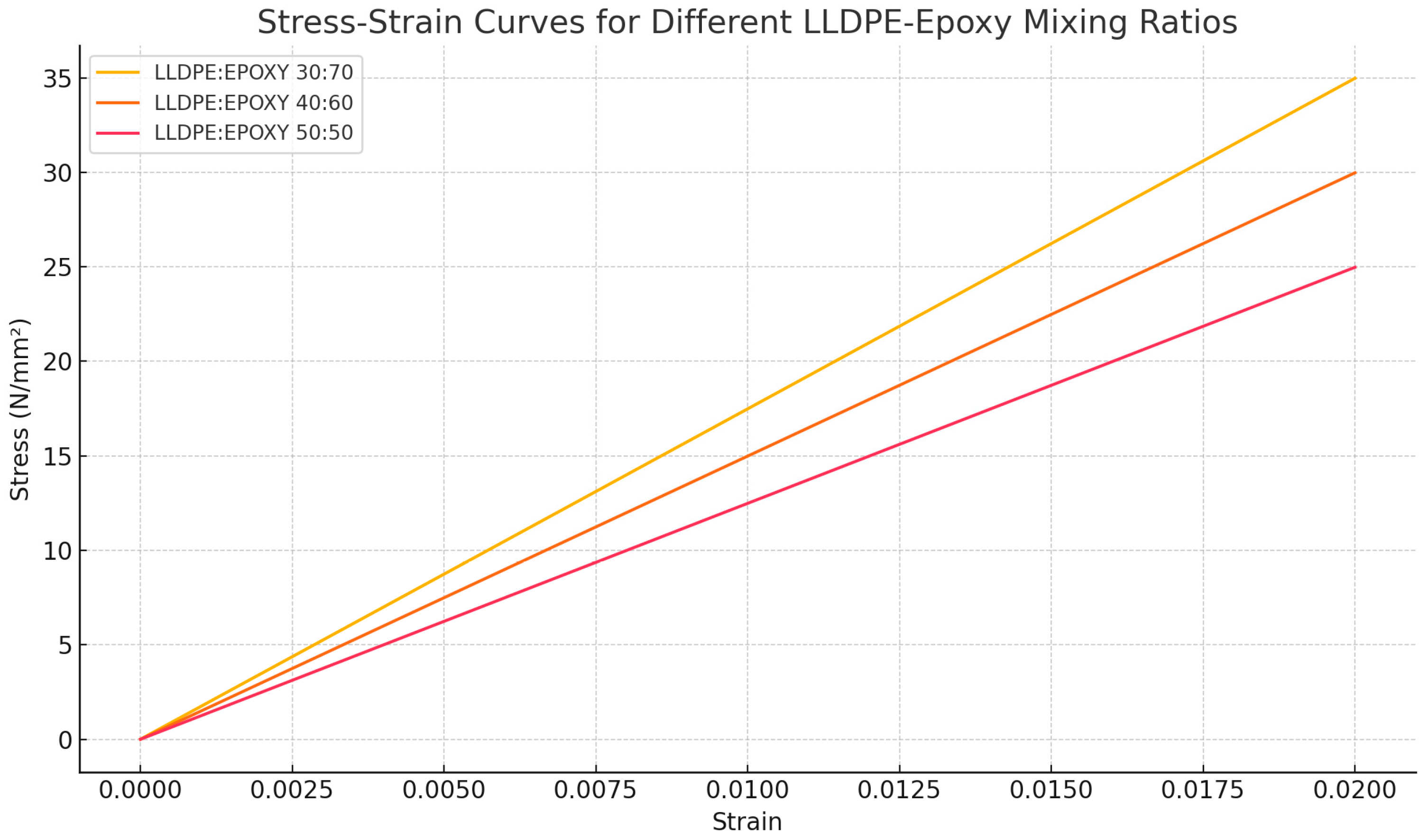

The curves as depicted in

Figure 8 are modelled assuming linear elastic behaviour up to peak compressive strength. As expected, the 30:70 mix shows higher strength due to a stronger epoxy matrix, while the 50:50 mix shows reduced strength. This illustration effectively highlights the influence of material composition on mechanical performance [

43].

3.3. Impact Strength Performance of LLDPE/Epoxy Composite

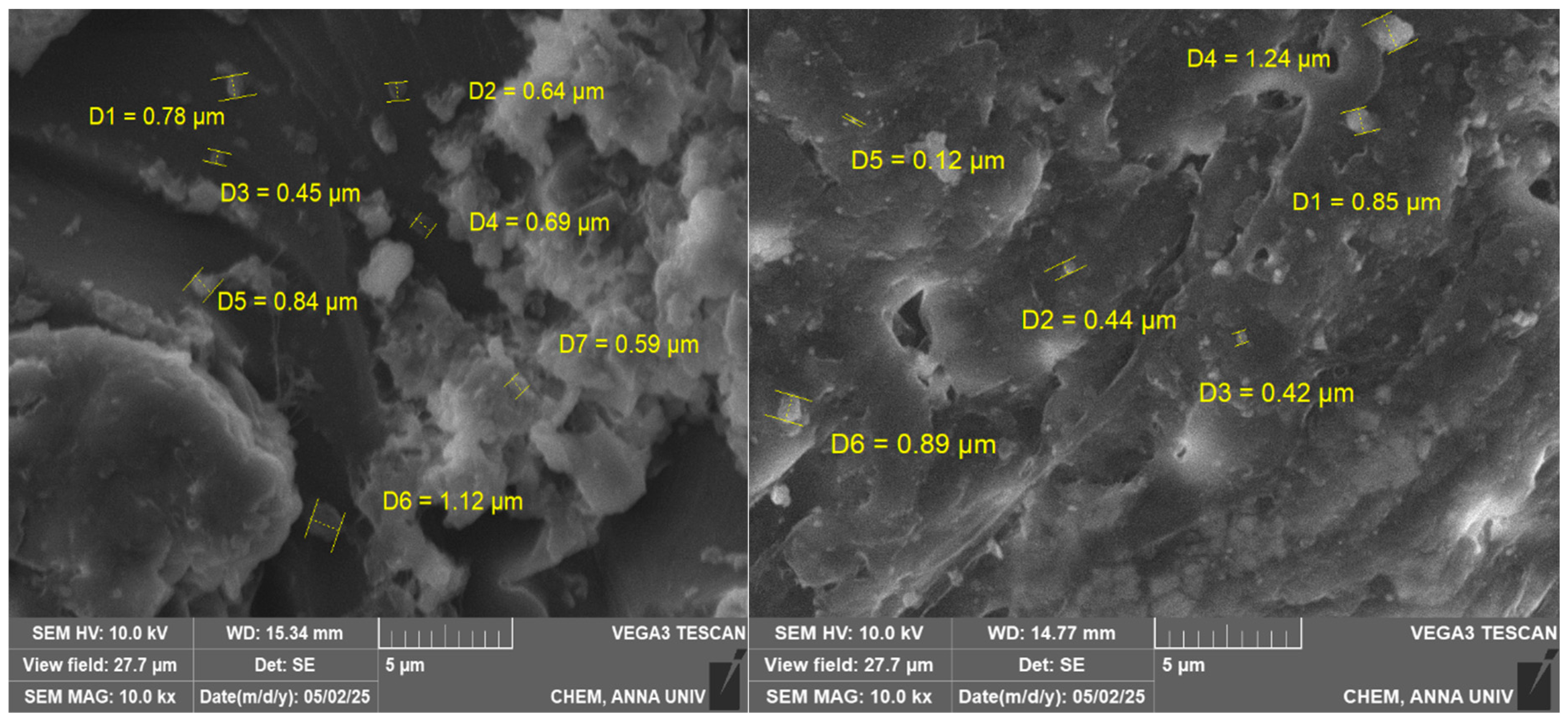

The results of the impact test for all the samples—30% LLDPE/70% epoxy, 40% LLDPE/60% epoxy, and 50% LLDPE/50% epoxy—always read at 2 Joules, as determined by the Charpy impact test under ASTM D256. The consistency in readings is due to the intrinsic limitations of the impact testing machine at low energies, where the resolution level of the machine may suppress slight variations in the toughness of materials. Consequently, once the energy absorbed reduces below the equipment’s minimum sensitivity, the device is likely to record its lower detectable value, ignoring subtle variations in the true impact resistance of the samples. Even with the seeming equivalence of impact values, the SEM fractography clearly testifies to different microstructural characteristics between the two compositions. The 40% LLDPE/60% epoxy composite (

Figure 9) has a heterogeneous morphology with microstructure dimensions between 0.45 and 1.12 μm, whereas the 50% LLDPE/50% epoxy composite has a wide range of microstructural components ranging from 0.12 to 1.24 μm.

These findings establish that, on the microscopic scale, the energy dissipation modes and fracture surfaces vary between samples, although the limitations of the impact machine stop these from being quantitatively recorded. This two-pronged approach, using mechanical testing and high-resolution SEM examination together, solidly proves that there are microstructural differences present and that they could affect material behaviour beyond what the instrument’s reported impact values would indicate.

As portrayed in

Figure 10, the impact test for both the 40% and 50% LLDPE/epoxy blends always read at 2 Joules, implying identical energy absorption properties at first glance. Yet, this seeming consistency of values is more than likely an artefact of the resolution capability of the testing equipment rather than a reflection of material behaviour. The Charpy impact instrument applied here has a dynamic detection limit that can conceal slight but significant toughness differences between the two compositions. This constraint is especially applicable to polymer composites, whose impact energies normally fall at the low end of the measurement range. Though the graph reveals equivalent impact values, the corresponding SEM analysis uncovers significant microstructural differences that cannot be seen in mechanical testing. The 40% LLDPE blend demonstrates a more uniform morphology of its fracture surface, with feature sizes that tend to congregate in the range of 0.45–1.12 μm, reflecting a uniform energy dissipation mechanism. For comparison, the 50% LLDPE blend shows a greater distribution of microstructural features (0.12–1.24 μm), which implies more divergent fracture behaviour. These subtle micro differences, while not being represented in the impact energy values, potentially would have strong effects on actual performance during dynamic loading. The graph therefore reveals only half the story and emphasizes how valuable it is to complement mechanical test data with comprehensive microstructural characterization to fully understand material behaviour.

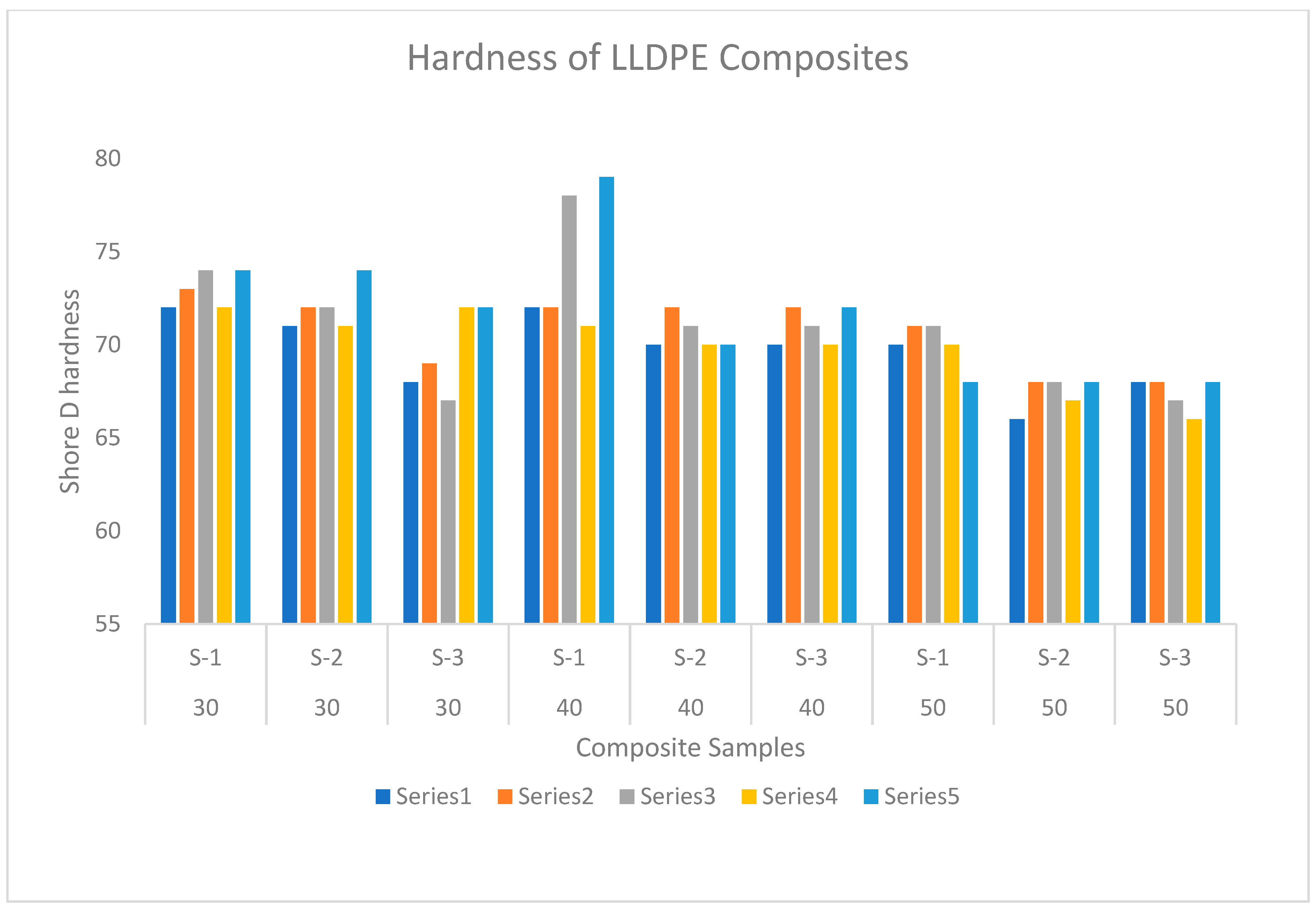

3.4. Hardness Performance of LLDPE/Epoxy Composite

The hardness test data provide valuable information on the surface properties of the LLDPE/epoxy composites, especially in terms of their applicability to flooring purposes. The 40:60 formulation is found to be the best composition, with the highest Shore D hardness of 79 and a relatively small range (70–79). This indicates that at this proportion, the epoxy matrix creates a sufficiently continuous network to offer rigid surface support, while the 40% content of LLDPE avoids excessive brittleness, which would cause cracking due to localized stresses. The improved hardness performance of the 40:60 blend is consistent with its mechanical properties found earlier, such as its uniform compressive strength and equilibrated flexural behaviour. This renders it especially well-suited for heavy-traffic applications where surfaces need to withstand both abrasive wear and impact loads without sacrificing structural integrity. In comparing between compositions, the trend of LLDPE content vs. hardness is as expected but is non-linear. Although the 30:70 samples exhibit similar maximum hardness (74) to the 40:60 composition, their greater range (67–74) suggests less uniform surface properties, most likely resulting from non-uniform distribution of the epoxy-rich matrix. The 50:50 samples illustrate the way that greater proportions of softer LLDPE phase above 40% progressively decrease surface hardness (66–71), yet all remain well within acceptable values for flooring applications. This trend of decreasing hardness with increasing amounts of LLDPE is evidence of the progressively greater dominance of the inherent plasticity of the polymer over the rigidity of the epoxy. Notably, even the lowest recorded value (66) is higher than minimum hardness generally found in residential flooring usage, ensuring that all formulation samples pass simple durability requirements while providing various trade-offs between surface toughness and overall flexibility [

29].

This information has practical value for material selection according to particular demands of an application. For example, in commercial environments where abrasion resistance is paramount, the 40:60 ratio would be preferred, whereas residential use, where some flexibility would be beneficial to improve foot comfort, would be better served by the 50:50 mix, even though it is marginally softer. The findings together illustrate how Shore D hardness is an important indicator of surface performance, complementing other mechanical property information to give a complete picture of these composite materials’ behaviour in actual flooring service.

As indicated by

Figure 11, the hardness readings show clear trends in the three composite formulations (30:70, 40:60, and 50:50 LLDPE/epoxy ratios). The 40:60 samples always show the highest Shore D hardness readings, with all three replicates (S-1 40, S-2 40, S-3 40) grouping in the upper part of the scale. This is consistent with earlier results, validating that this intermediate composition provides an optimal compromise—the 40% LLDPE ensures sufficient flexibility to avoid brittleness, while the 60% epoxy ensures adequate matrix rigidity for surface integrity. The close clustering of these data points indicates high reproducibility in material properties at this formulation. The graph also easily demonstrates the impact of composition variations on hardness. The 30:70 samples have slightly reduced but still comparable hardness values, with some variation between replicates that could indicate minor differences in the epoxy-rich matrix. Notably, the 50:50 samples have the lowest hardness readings, with all three replicates (S-1 50, S-2 50, S-3 50) reading lower than their 40:60 counterparts. This increasing softening with greater LLDPE content visually illustrates the compromise between flexibility and surface rigidity in these composites. The consistent downward slope from 40:60 to 50:50 in the graph is strong graphic proof that although an enhanced content of LLDPE enhances certain mechanical properties, this is achieved at the cost of surface hardness—a relevant point for flooring material design.

Each composite formulation (30:70, 40:60, and 50:50 LLDPE/epoxy) was tested using three replicates (S-1, S-2, and S-3) following the ASTM D2240 standard for Shore D hardness. Tests were conducted at room temperature (25 ± 2 °C), with five readings taken at different locations per sample and averaged to obtain each replicate’s final value. The results are now reported with mean values and standard deviations: 71.0 ± 2.88 (30:70), 77.3 ± 3.51 (40:60), and 68.0 ± 2.64 (50:50). These values confirm that the 40:60 composition offers the highest and most consistent hardness, making it ideal for commercial flooring where abrasion resistance is essential. The observed non-linear trend with hardness decreasing as LLDPE content increases is attributed to the growing dominance of the polymer’s inherent plasticity over the rigidity of the epoxy matrix. This correlation between formulation and surface properties complements our earlier mechanical findings and offers practical guidance for selecting material compositions based on flooring application requirements.

The 40:60 LLDPE/epoxy composite demonstrated the highest and most consistent Shore D hardness (up to 79), indicating optimal surface rigidity for flooring applications [

44]. This composition effectively balances the stiffness of epoxy and the ductility of LLDPE, minimizing brittleness and enhancing wear resistance In contrast, the 50:50 blend exhibited reduced hardness due to increased polymer phase dominance, confirming the trends of softening with higher thermoplastic content reported in the literature Variability in the 30:70 mix suggests uneven matrix dispersion, impacting surface uniformity. These results align with prior findings on how filler–matrix ratios influence surface durability and mechanical resilience [

45].

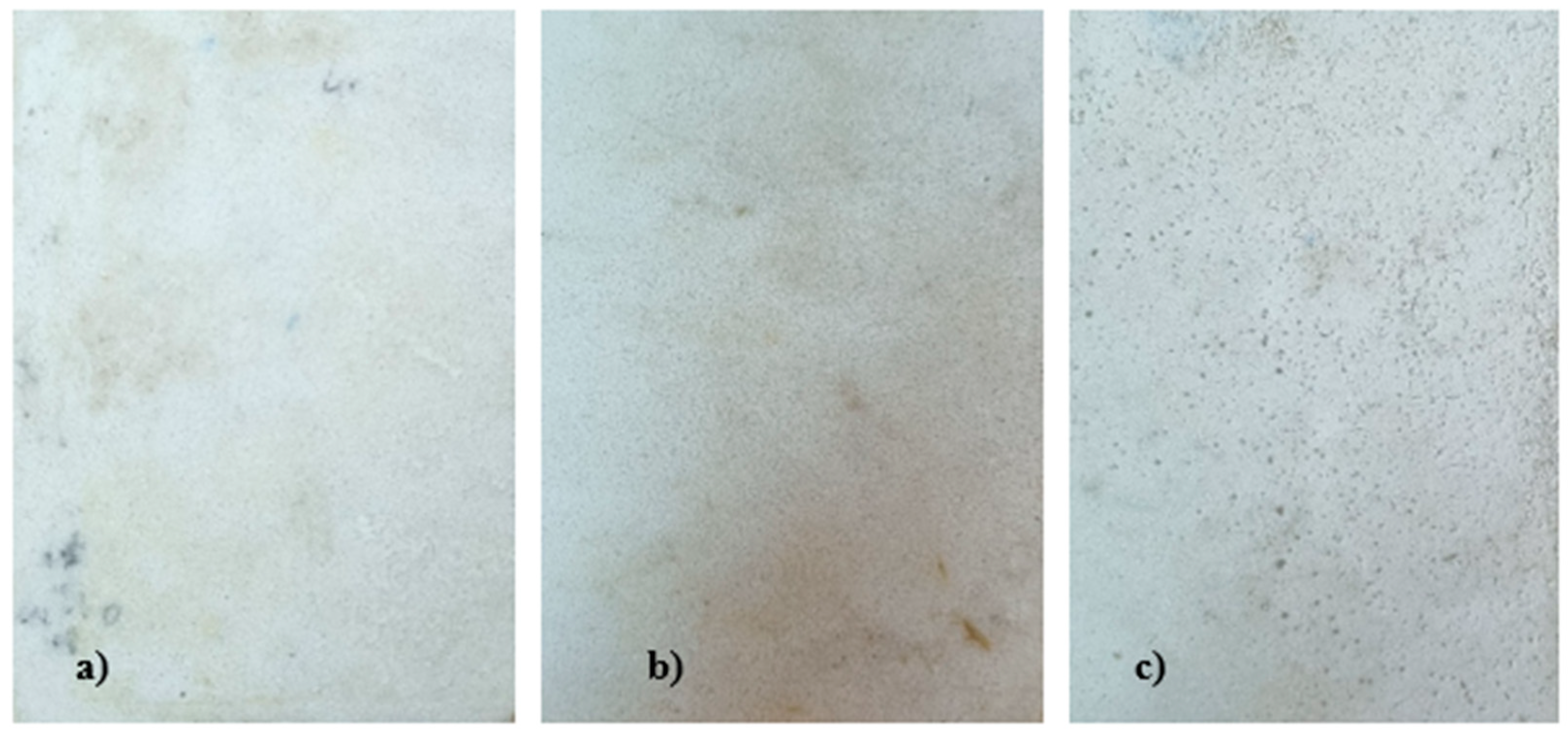

3.5. Morphological Study of Tiles Using 40:60 LLDPE/Epoxy Composite

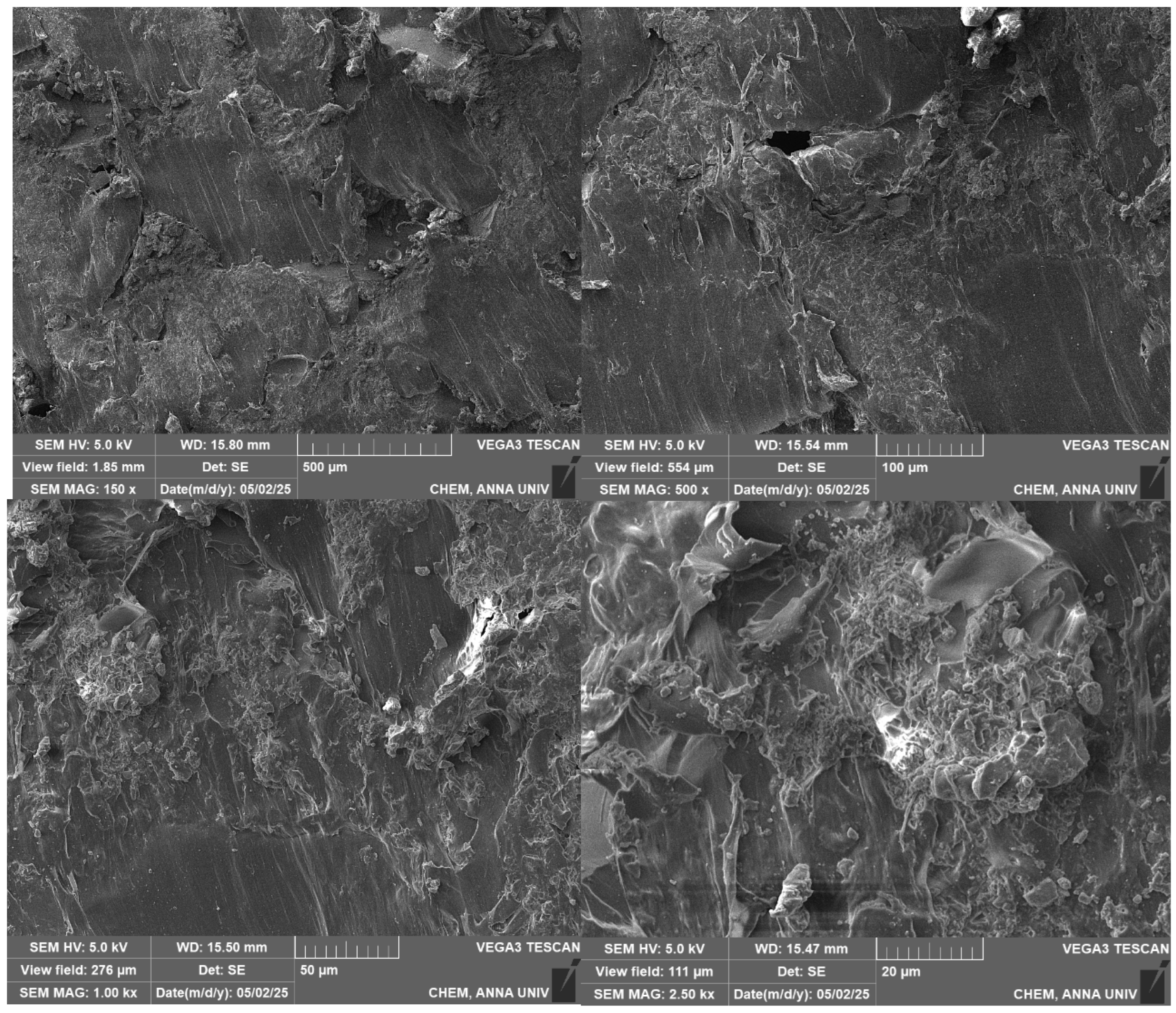

In order to complement and support the mechanical testing findings, two particular composite compositions were subjected to Scanning Electron Microscopy (SEM), namely 40:60 (LLDPE/epoxy) and 50:50 (LLDPE/epoxy). These two were selected for microstructural examinations as they presented a strong difference in terms of mechanical properties in the case of flexural and compressive strength, which indicated potential difference in internal bonding, dispersion, or interfacial interaction. The SEM study, as portrayed in

Figure 12 and

Figure 13, is an important technique to explore the microscopic morphology, filler dispersion, and interphase adhesion between the thermoplastic (LLDPE) and thermosetting matrix (epoxy). In polymer composites, these microstructural aspects play an important role in determining macroscopic properties like stiffness, toughness, and load-bearing capability. Comparing these two samples makes it feasible to establish structure-performance correlations and thus enable identification of the more favourable formulation.

The 40:60 ratio was chosen for thorough SEM examination because of its significantly better mechanical performance, particularly compressive and flexural strength, among all the formulations. This specimen is a balance between material sustainability and mechanical integrity and is a good candidate for future development. The SEM micrograph of this blend is designed to expose the quality of dispersion of LLDPE particles, interfacial bonding character with the epoxy matrix, and overall microstructural homogeneity. Seeing the internal morphology at various magnifications serves to justify why this ratio yielded improved test results and how the structure aids in load bearing without premature failure. The surface features widespread layering and fissure-like features, indicative of incomplete mixing or phase separation characteristic of polymer blends with partial compatibility. The interfaces between various regions are comparatively well defined, which can suggest limited interfacial adhesion at the microscale, a typical difficulty in the mixing of thermoplastics such as LLDPE with thermosetting epoxy. Striations and flow patterns are apparent, probably a consequence of shear forces during mixing and curing. They can impact mechanical properties by determining crack paths [

46].

The failure behaviour of the LLDPE/epoxy composite tiles was found to be significantly influenced by the material composition, particularly the LLDPE-to-epoxy ratio. The 50:50 blend, while exhibiting the highest flexural strength, showed substantial variability, suggesting a tendency for inconsistent failure modes likely due to heterogeneous dispersion and potential void formation, which can act as stress concentrators under load. The 30:70 composition revealed erratic mechanical responses, with brittle fracture characteristics indicating poor matrix–filler interaction and insufficient energy absorption during failure. In contrast, the 40:60 ratio displayed a more predictable and ductile failure behaviour, with uniform stress distribution and better resistance to crack propagation, attributed to effective bonding and filler dispersion as observed in SEM analysis. This composition’s consistent failure pattern under flexural loading suggests it is better suited for flooring applications requiring reliable mechanical integrity and durability.

At 150× magnification, the SEM image gives a general view of the surface morphology of the 40% LLDPE/60% epoxy composite at relatively low magnification, observing features at the microscale. The surface is heterogeneous, with wide, layered areas and irregular textural patterns characteristic of phase distribution between the two polymers [

47]. The LLDPE and epoxy phases can be visually differentiated by their contrasting textures: the smoother, comparatively flatter areas most probably represent the epoxy matrix, whereas the rougher, less flat areas indicate the existence of LLDPE domains. Under this level of magnification, the material exhibits an intricate pattern of textural differences on the surface, with distinct areas with different morphology. The picture shows an explicit heterogeneous structure with diversified surface features, such as a large void within the central area and diverse micro cracks in the matrix [

48]. The variation in colour among the smoother parts (presumably epoxy-rich) and the more textured parts (possibly LLDPE-dominated) becomes clearer at this level of magnification.

While the images of

Figure 13 highlight microstructural features such as particle dispersion and matrix continuity, quantitative analysis (e.g., particle size distribution, void fraction) is not included but would further enhance interpretation. The surface has a multidimensional topography with several elevations, depressions, and pore-like imperfections of various sizes [

49]. Marked surface in homogeneities vary from nanoscale cavities (D5 = 0.12 μm) to larger depression (D4 = 1.24 μm). Such a diverse texture of the surface forms a world of ridges and valleys where high roughness reflects uneven distribution of material in the submicron range. The interface areas exhibit variable morphology with clear boundaries between smoother regions (presumably epoxy-rich) and rougher, more textured regions (possibly LLDPE-rich). A number of measured features (D2 = 0.44 μm, D3 = 0.42 μm) occur at transition zones and are indicative of typical interfacial structures. The uneven interface boundaries and partial integration that can be seen in some regions indicate complex interactions among the polymer components.

Figure 14 shows the processing-dependent characteristics such as directional patterns and structures with fixed dimensions (D1 = 0.85 μm, D6 = 0.89 μm). Several tiny voids and surface irregularities suggest possible entrapment of air or differential shrinkage on composite formation. The submicron particulate characteristics and contrasting surface textures denote the difficulty of achieving uniform dispersion in this blend of thermoplastic and thermoset.

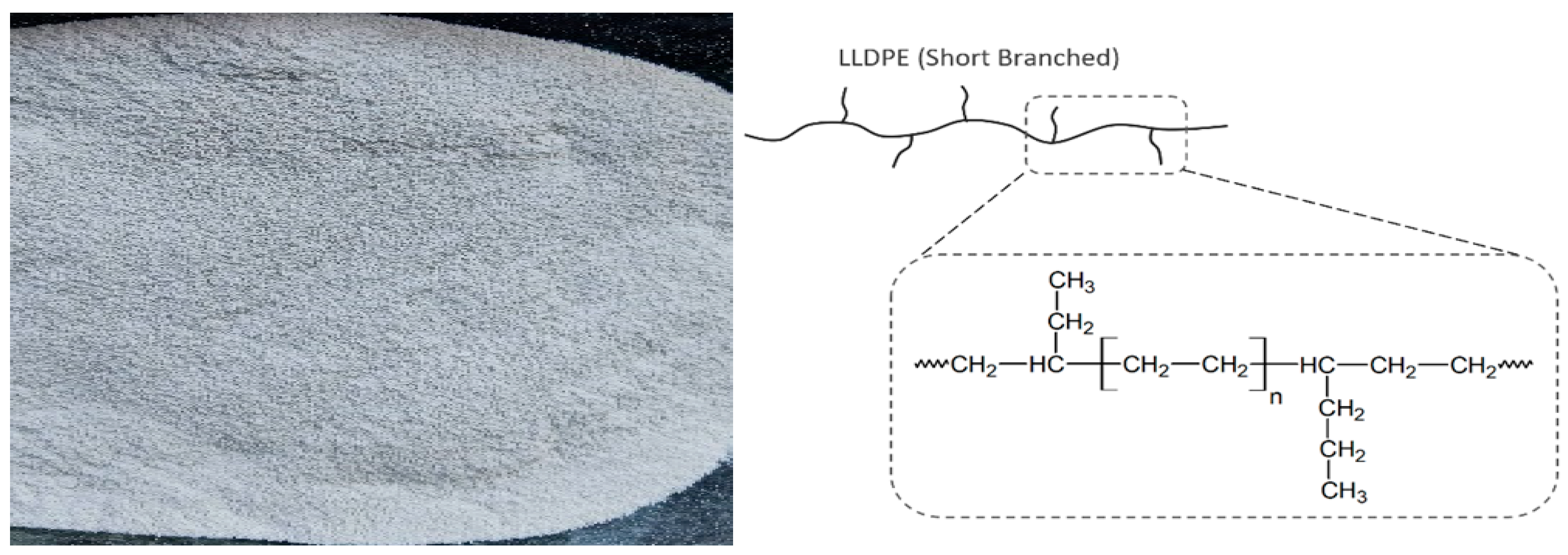

The core sustainable aspect lies in the reutilization of post-consumer recycled LLDPE (Linear Low-Density Polyethylene). This approach significantly reduces the environmental footprint associated with virgin plastic production and contributes to circular economy practices. Agarwal et al. [

27] highlight that using recycled LLDPE in composites lowers energy consumption and greenhouse gas emissions compared to using virgin polymers. The study also emphasized that mechanical recycling of LLDPE into construction materials diverts plastic waste from landfills and reduces environmental pollution. By replacing ceramic and cement tiles, which are highly energy-intensive to produce (especially due to kiln firing and clinker production), our composite tiles help mitigate CO

2 emissions and resource depletion associated with conventional flooring materials. Habert et al. [

50] noted that cement production contributes to over 8% of global CO

2 emissions, and alternative composite materials can significantly lower embodied energy.

Our study shows that the composite tile (particularly with the 40:60 LLDPE/epoxy ratio) exhibits superior mechanical stability and durability, ensuring a longer service life and thereby reducing replacement frequency and associated resource use. Rahman et al. argue that durable polymer composites with stable mechanical performance contribute to sustainability through extended product lifespans, reducing lifecycle costs and material consumption [

51]. While epoxy and LLDPE are synthetic, their recycled utilization, the avoidance of more polluting materials like cement, the enhanced durability, and smart AI-driven waste reduction collectively support the sustainability claim. The work aligns with a realistic and pragmatic approach to sustainable engineering, particularly within the constraints of cost-effective construction material development.

The proposed 40/60 LLDPE/Epoxy composite tile demonstrates a competitive edge over conventional flooring materials in terms of performance, durability, and ease of use as shown in

Table 2. With standard dimensions of 500 × 500 × 10 mm, these tiles offer balanced mechanical properties, including flexural strength ranging from 16 to 20 MPa and compressive strength between 28 and 39 N/mm

2. Surface hardness is rated at Shore D 79, indicating robust wear resistance suitable for moderate to heavy usage. Compared to ceramic, porcelain, vinyl, and natural stone tiles, the LLDPE/epoxy composite exhibits superior impact, water, and chemical resistance, making it ideal for environments demanding high durability and low maintenance. Despite being slightly heavier than vinyl, its medium weight (1.5–1.8 g/cm

3) contributes to easier handling and installation without the need for specialized tools or labour. Furthermore, the composite tile provides good thermal insulation and minimal upkeep, outperforming traditional tiles in functionality. While the approximate cost of INR 900–1200/m

2 may be higher than that of basic ceramic or vinyl tiles, the added value in terms of performance, longer lifespan, and installation efficiency justifies the investment. Notably, the development of this composite tile was guided and optimized using machine learning techniques, enabling the prediction of key properties such as mechanical strength, hardness, and durability based on material composition and processing parameters. This data-driven approach not only reduced trial-and-error in the manufacturing process but also helped achieve a cost-effective, high-quality product that bridges the gap between traditional affordability and advanced performance.

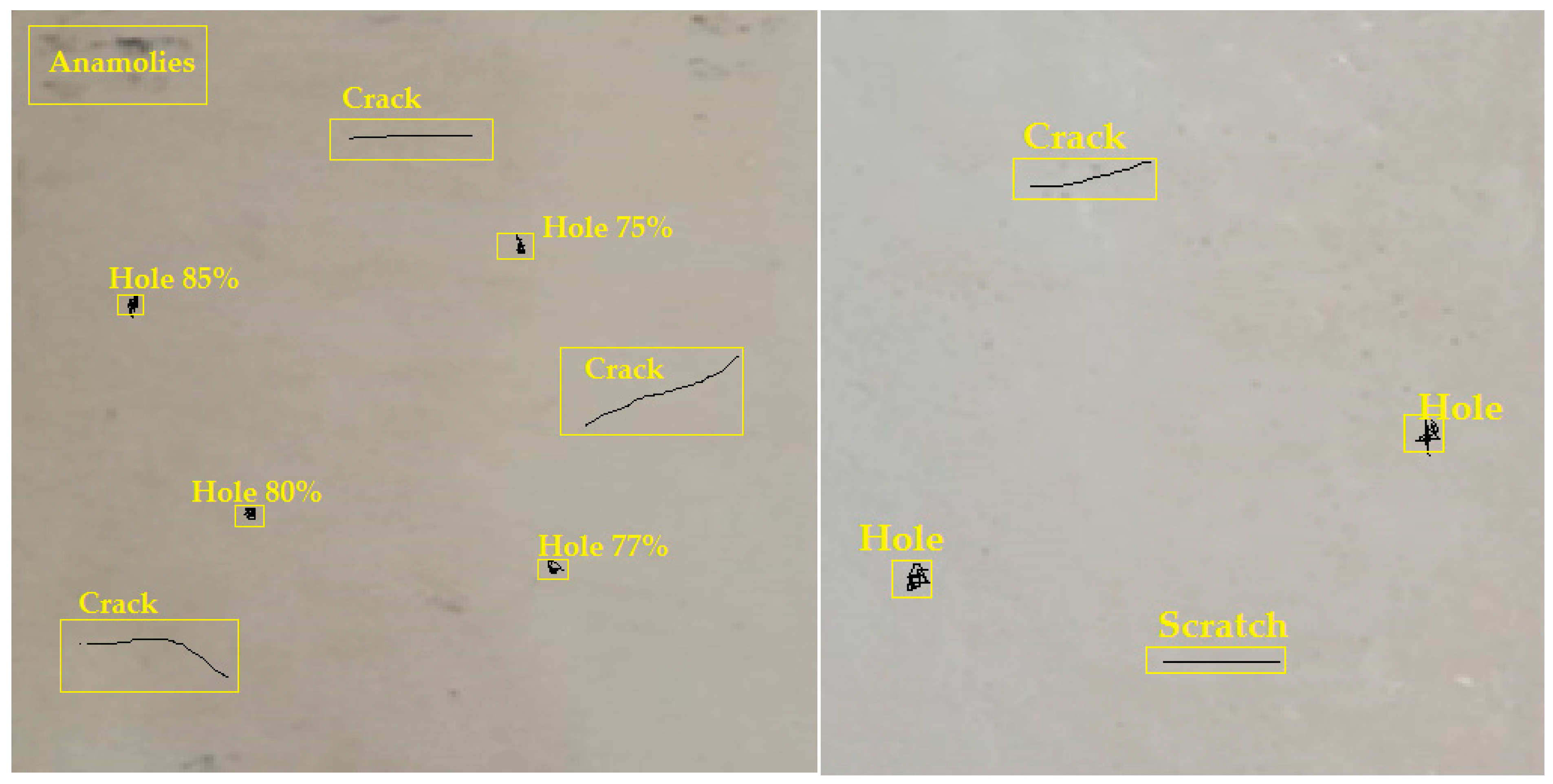

3.6. YOLOv8 Algorithm for Defect Detection of LLDPE Composite Tiles

LLDPE composite tiles are susceptible to a range of defects, from chipping to cracks to holes on the surface of the LLDPE composite tiles. Thus, the composite must be handled with extreme care and run through extensive quality assurance processes to ensure the integrity of the material before shipping and distribution. Machine learning techniques can be used to detect defects in LLDPE tiles using computer vision, a modern variant of machine learning, using the YOLOV8 algorithm, which can be customized for composite defect identification. Here, we used a pre-trained model that identifies holes, cracks, and edge chips on LLDPE tiles.

YOLOv8 has been shown to outperform CNNs in terms of both speed and accuracy, achieving 2–3 times faster performance and significantly higher accuracy, especially in noisy or cluttered environments. For instance, the mean Average Precision (mAP) of YOLOv8 typically ranges from 89% to 96%, compared to the 78% to 85% mAP observed with CNN models. Furthermore, YOLOv8 operates with real-time capabilities, processing approximately 20–25 frames per second (FPS), while CNN-based methods, particularly those using sliding window approaches, are limited to around 8–12 FPS. This speed advantage is crucial for real-time inspections, where timely decision-making is necessary. The YOLOv8-based object detection model offers significant advantages over traditional Convolutional Neural Networks (CNN) for surface defect detection in tiles inspection as portrayed in

Figure 14. Unlike CNNs, which are primarily designed for image classification, YOLOv8 excels in both detection and localization. It not only identifies the presence of defects but also determines their precise location within the image through the use of bounding boxes. This is a critical capability for the inspection of composite tiles, where accurate defect localization is essential for effective maintenance and repair. In contrast, CNNs do not provide location information, making them less suitable for applications where the spatial placement of defects is crucial.

3.6.1. Defect Detection Performance of Tiles

The YOLOv8 model was pre-trained with a collection of both open-source datasets consisting of various different images for tiles and self-captured LLDPE tile fault images. Transfer learning processes were used in the pre-training for rapid convergence and better generalization. The performance metrics achieved by the model on the test dataset are described below.

Furthermore, the core novelty lies in the customized application of YOLOv8 for detecting defects like cracks, holes, and edge chips in these newly engineered tiles. Our model achieved 85% accuracy on a dataset of 40 tiles (25 good, 15 defective), with potential to exceed 95% as the dataset scales as depicted in

Table 3. In comparison to traditional edge detection algorithms like Prewitt (63%), Sobel (65%), Roberts (70%), Canny (74%), and Kirsch (76%), YOLOv8 demonstrated considerably higher performance. Although Younas et al. [

20] reported 92% accuracy, their approach lacked integration with real-world material properties and relied solely on image-based inspection without material validation. Additionally, YOLOv8 offers significant advantages in speed and robustness over CNNs, especially in noisy or cluttered environments, with a typical mAP ranging from 89% to 96% compared to 78–85% for CNN-based models.

From the results, it is found that the accuracy of the Yolov8 algorithm is almost 85%, and the total processing time to process this dataset is 20 s.

3.6.2. Accuracy and Error

The accuracy of a classifier is considered the most significant and widely employed measure for evaluating its performance. Accuracy (ACC) is a metric that measures the proportion of correctly predicted samples out of the total number of samples in a dataset. It is computed by comparing the classifier’s predictions with the ground-truth labels. The count of correctly classified samples is divided by the total number of samples, resulting in a value ranging from 0 to 1. A higher accuracy score indicates a more significant proportion of correct predictions of crack the classifier makes. Accuracy is a fundamental measure used to evaluate the overall correctness of a classifier’s predictions, and it is calculated as follows:

The error rate (ERR) is a metric that quantifies the number of misclassified samples, considering both the negative and positive classes. It provides a measure of the overall misclassification rate in a classifier’s predictions. The error rate is obtained by dividing the total number of samples in the dataset by the number of samples that were incorrectly categorized. It measures the classifier’s performance regarding the proportion of incorrectly predicted samples. Calculating the error rate involves counting the total number of samples that have been misclassified, regardless of whether they belong to the negative or positive class. This includes false positives (samples that are predicted as positive but are negative) and false negatives (those that are predicted as negative but positive).

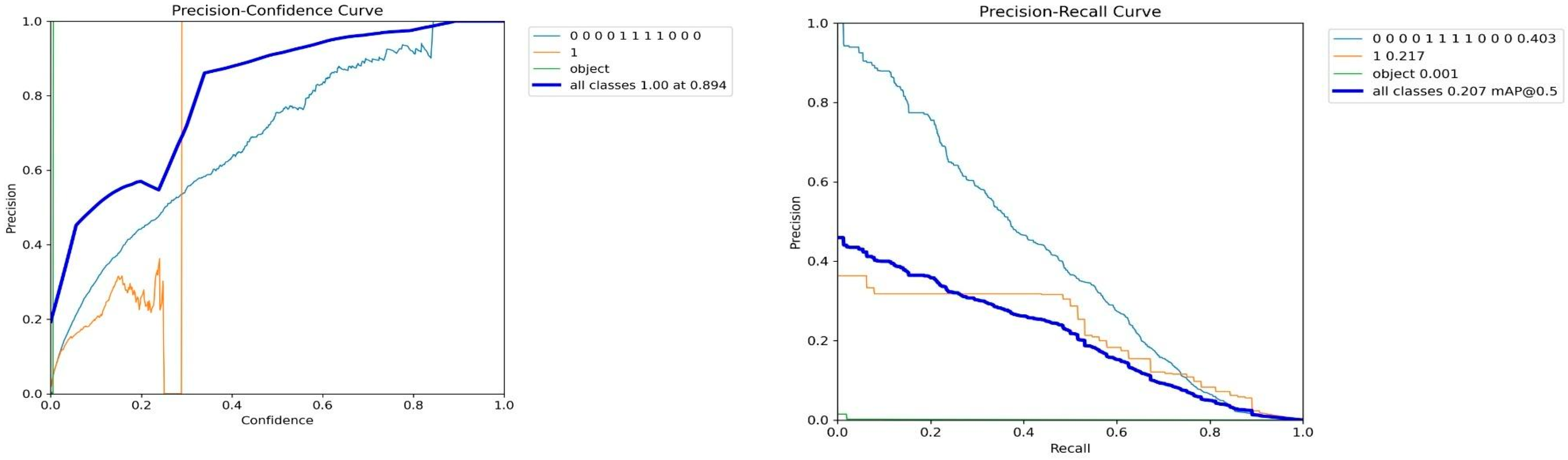

The plot in

Figure 15 illustrates the precision of the model with varying prediction confidence. The peak is close to the upper right, which denotes that as confidence increases, the model is more precise. The steep upward trend and high value of precision at 0.894 confidence illustrate the reliability of the model for providing high-quality detections of tiles inspection.