Simulation and Optimization of a Novel FLNG Liquefaction Process Based on Supersonic Swirling Separation and Nitrogen Expansion Refrigeration

Abstract

1. Introduction

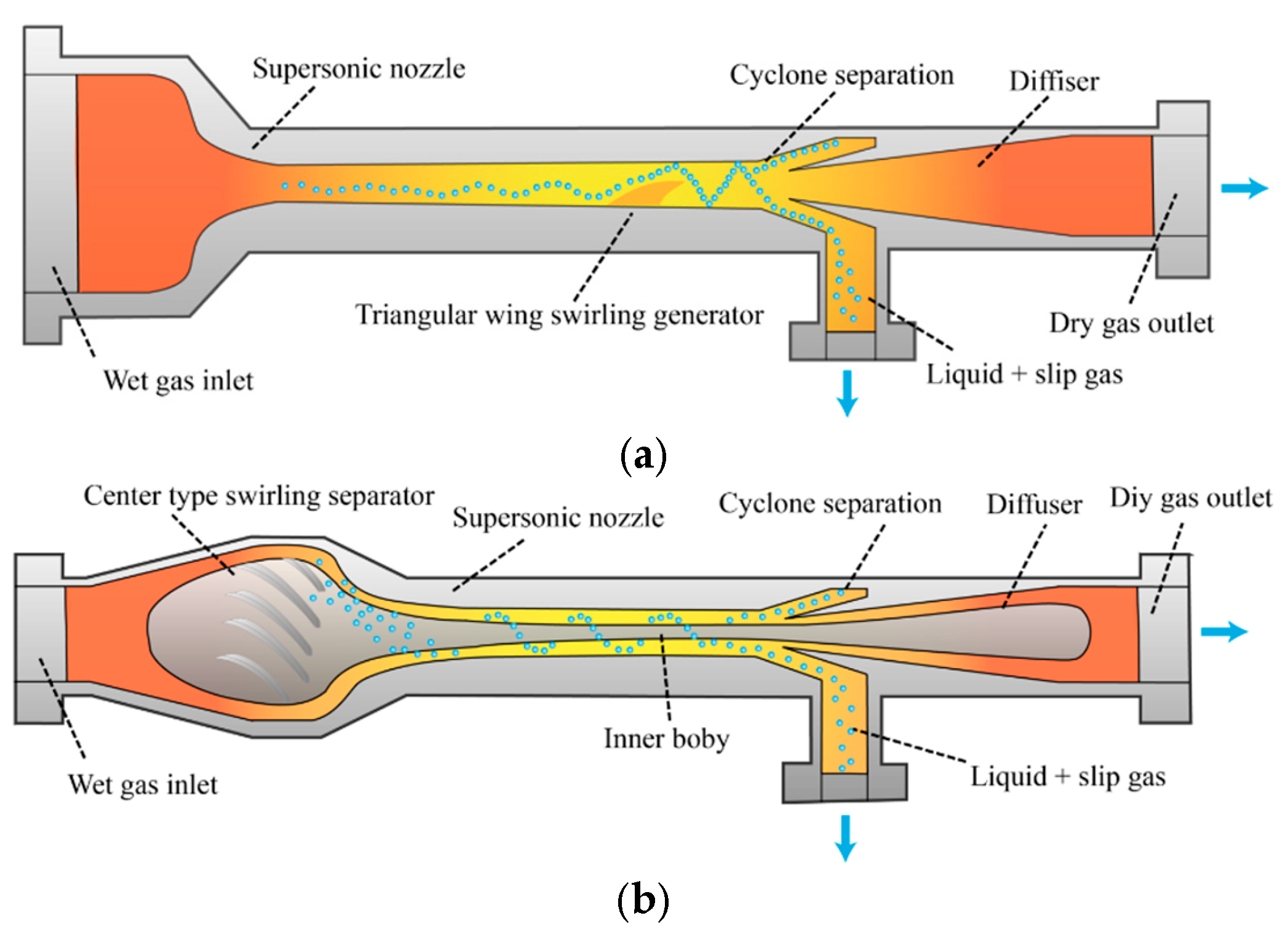

2. Supersonic Swirling Separation Technology

2.1. Principle of Supersonic Swirling Separation

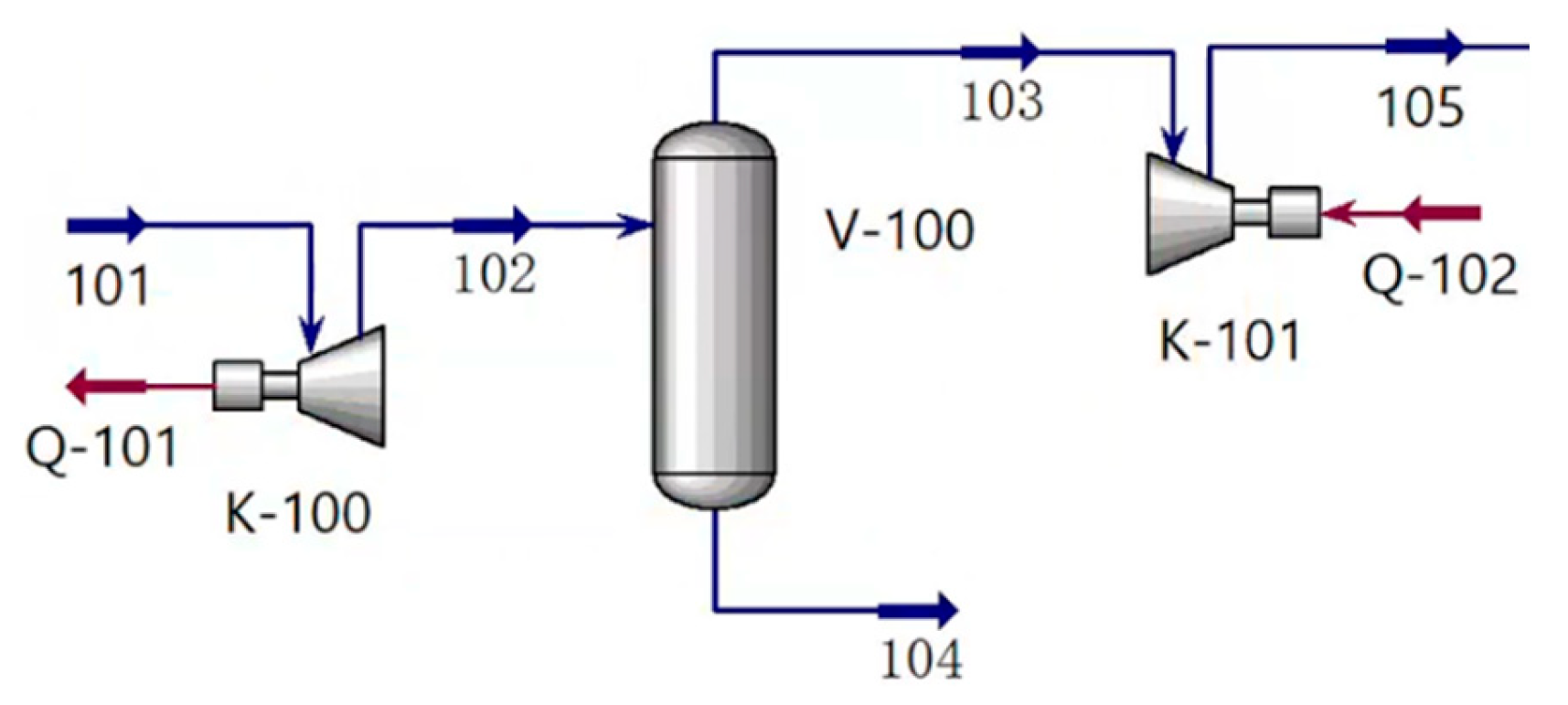

2.2. Equivalent Simulation of Supersonic Swirling Separator

3. Simulation and Optimization of Novel FLNG Liquefaction Process

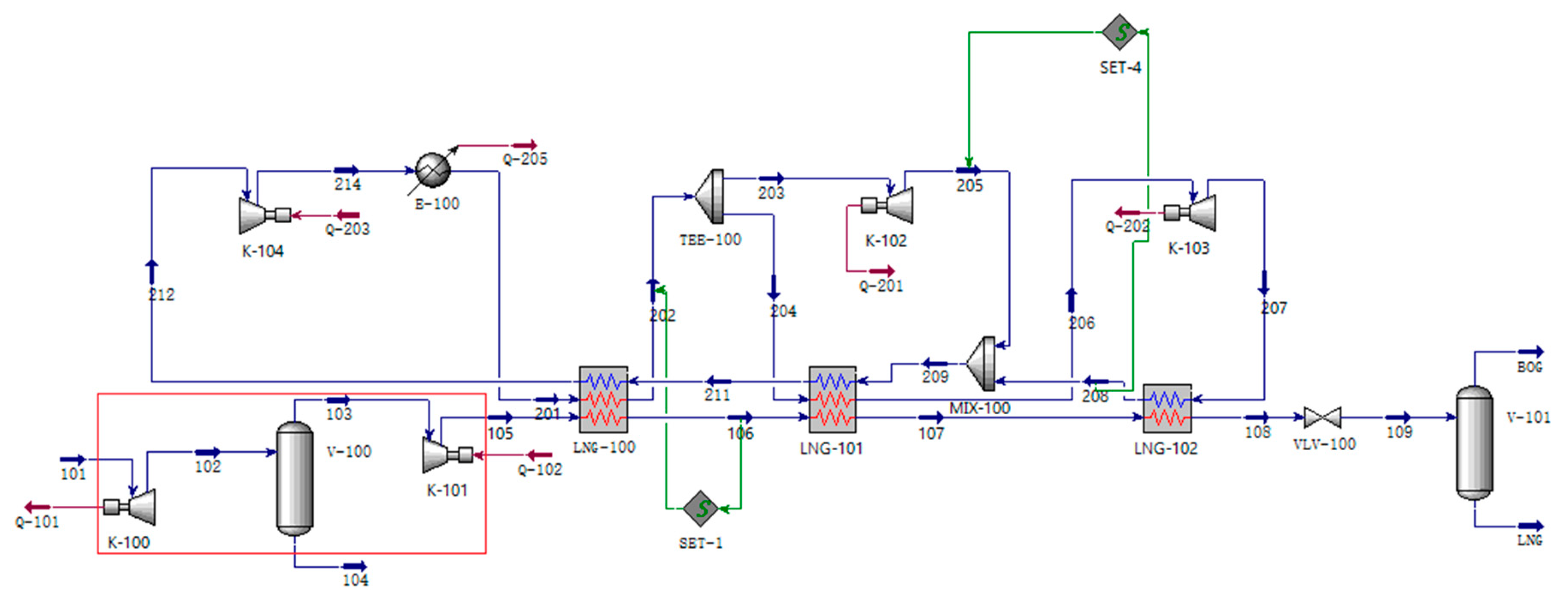

3.1. Process Introduction

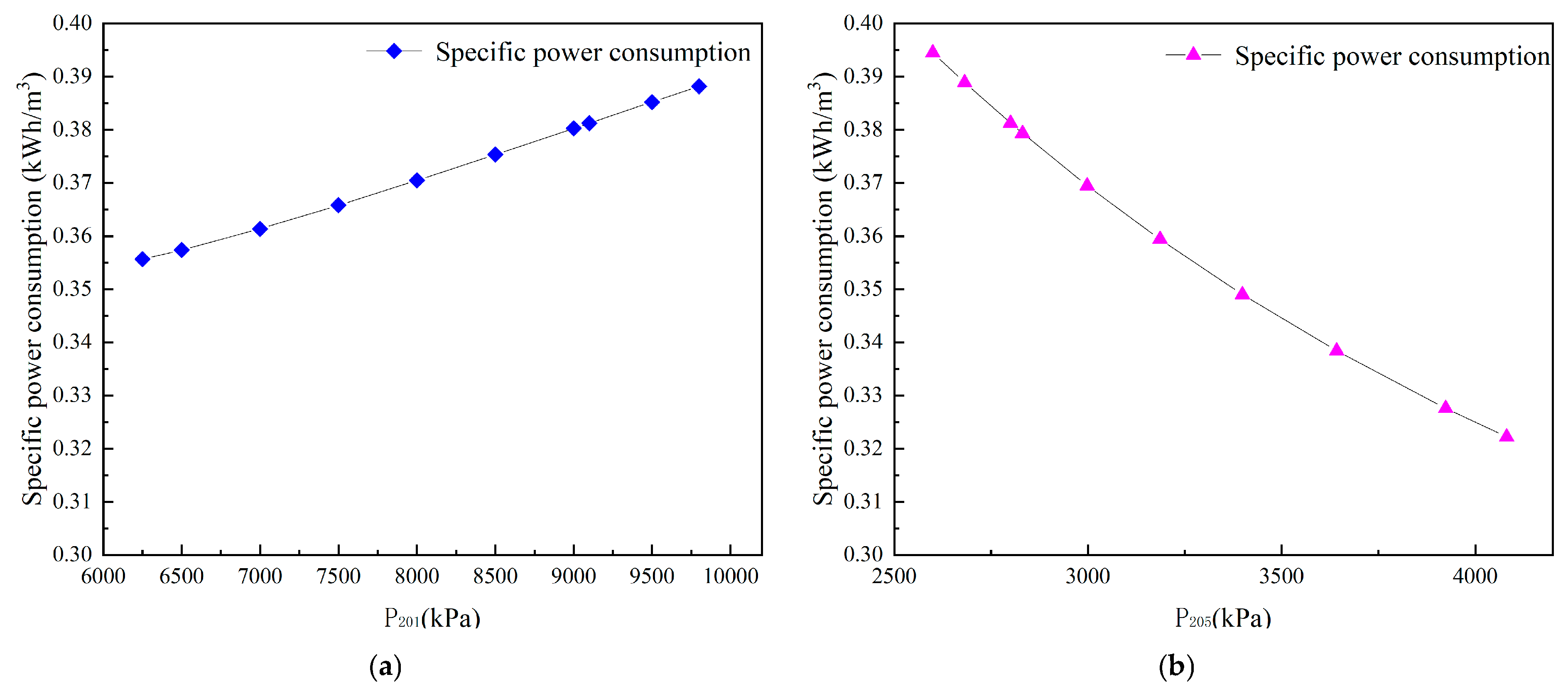

3.2. Process Optimization

3.3. Basic Data and Simulation Settings

4. Results and Discussion

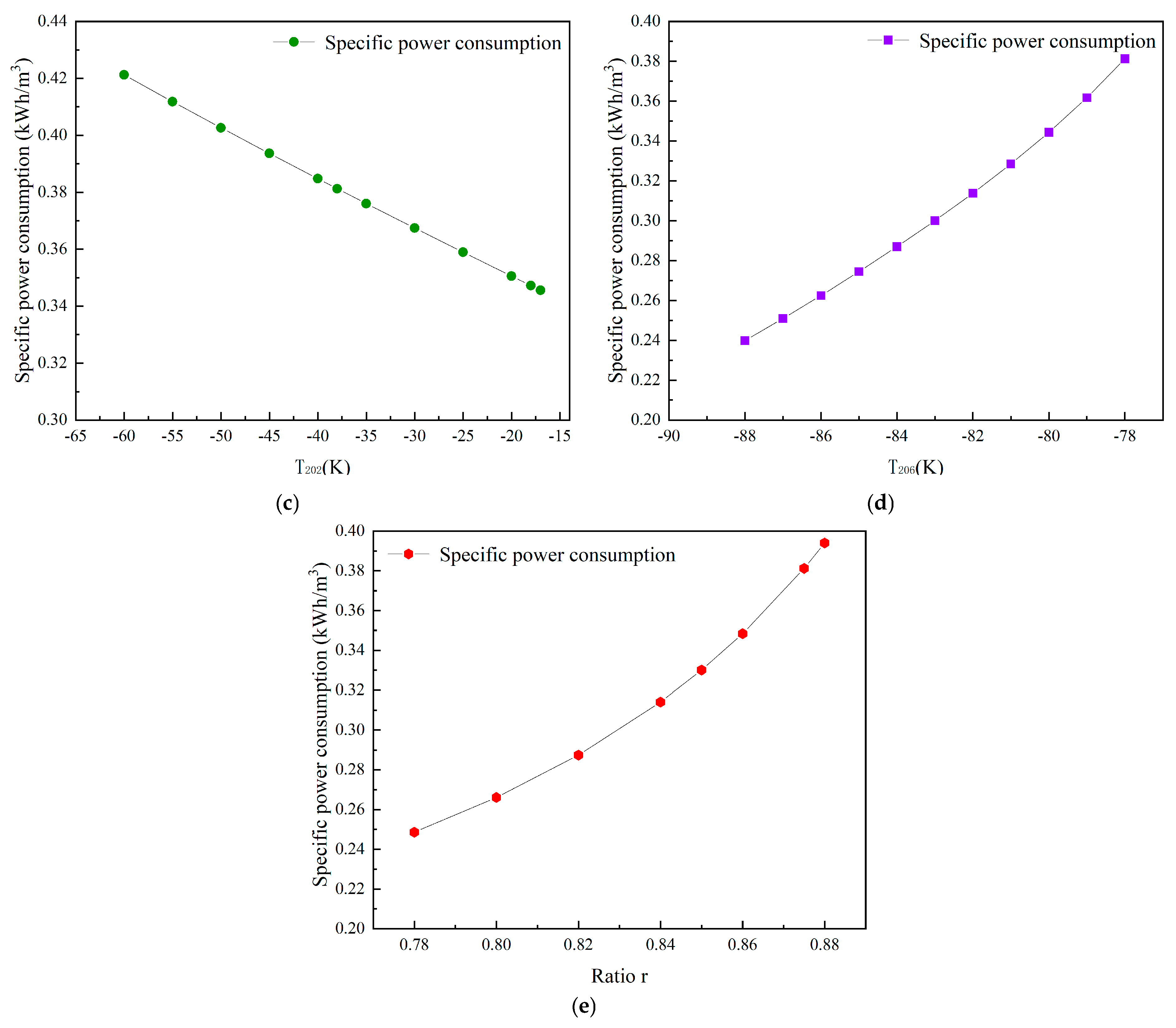

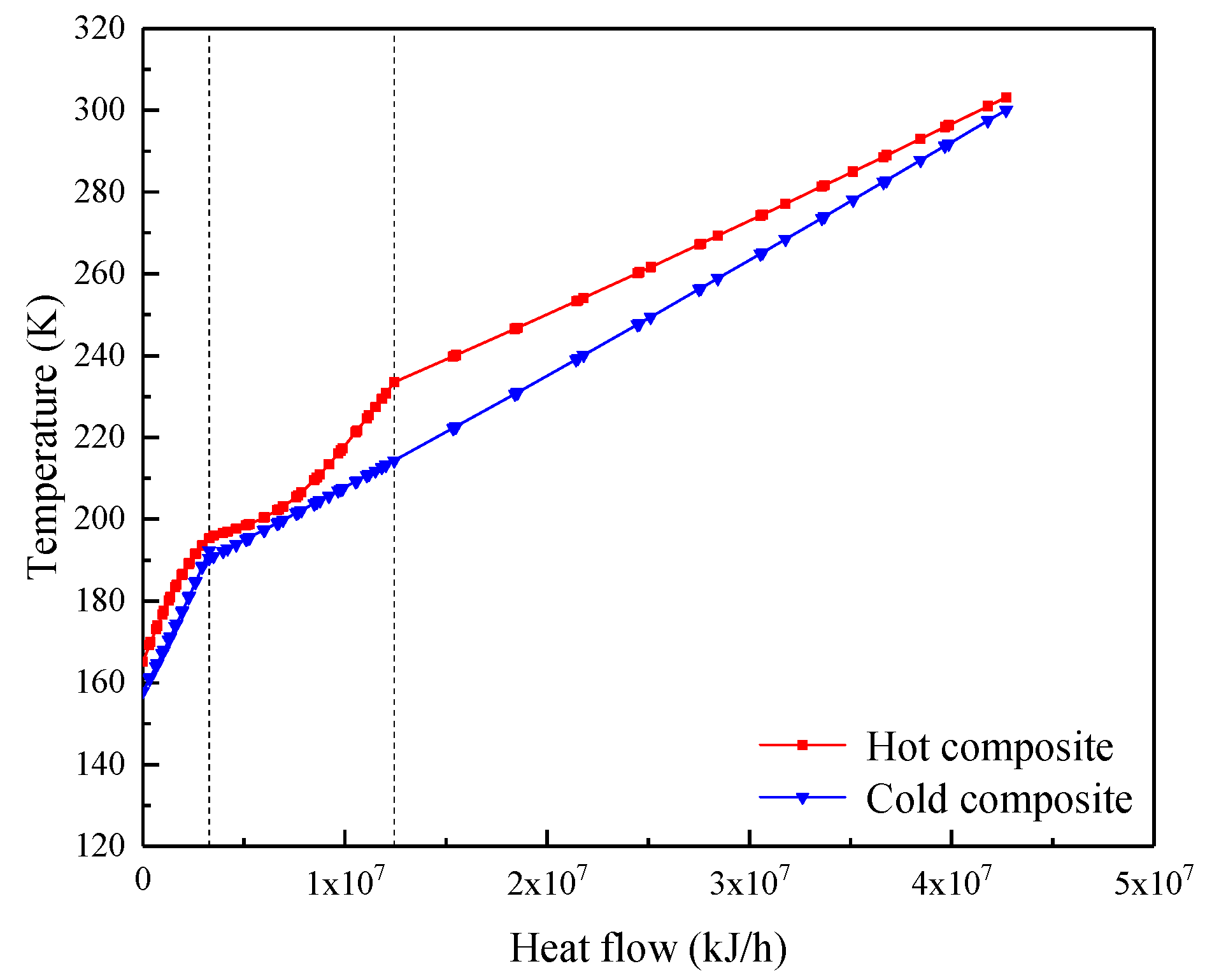

4.1. Optimization Results for Key Parameters

4.2. Exergy Analysis

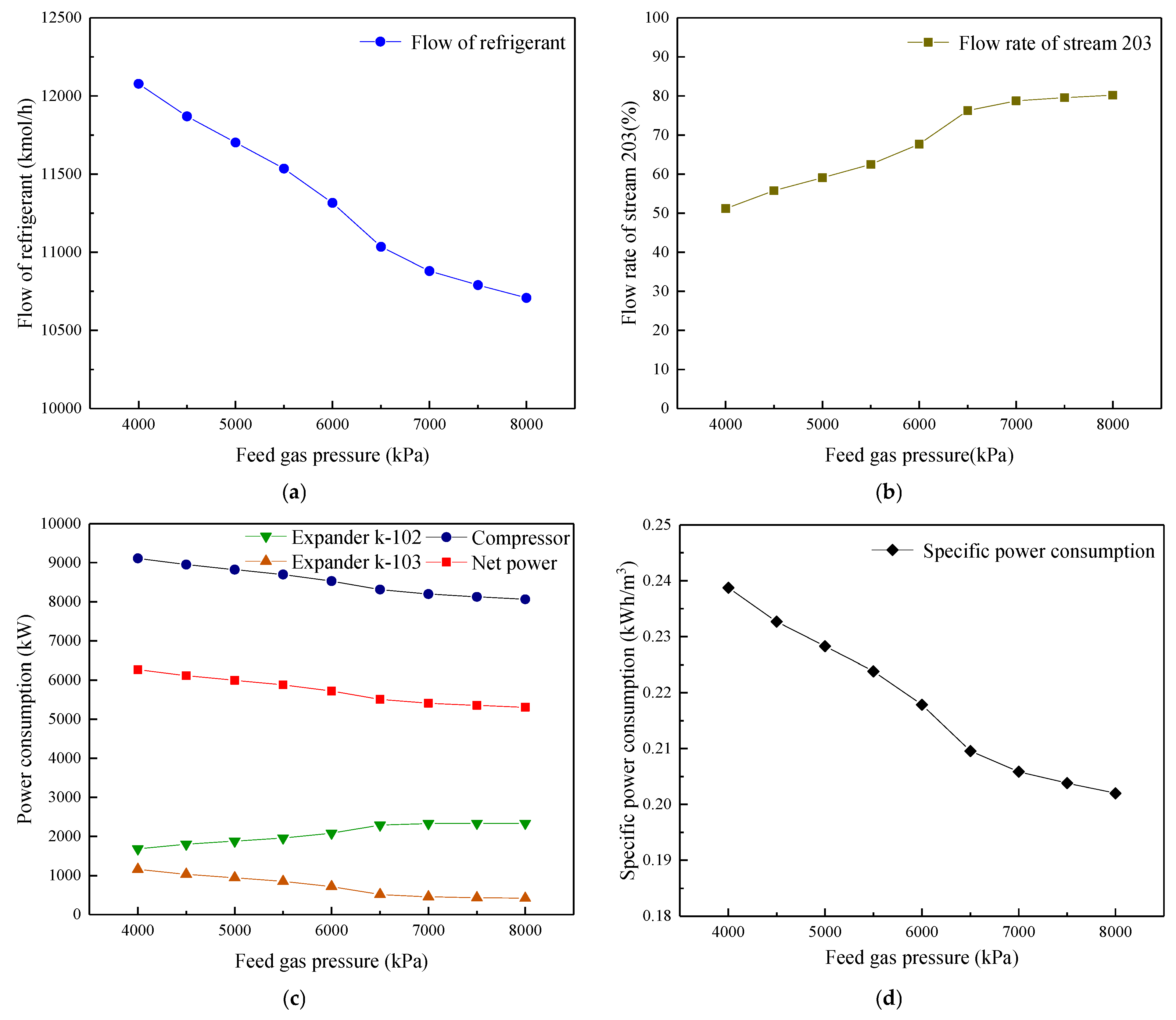

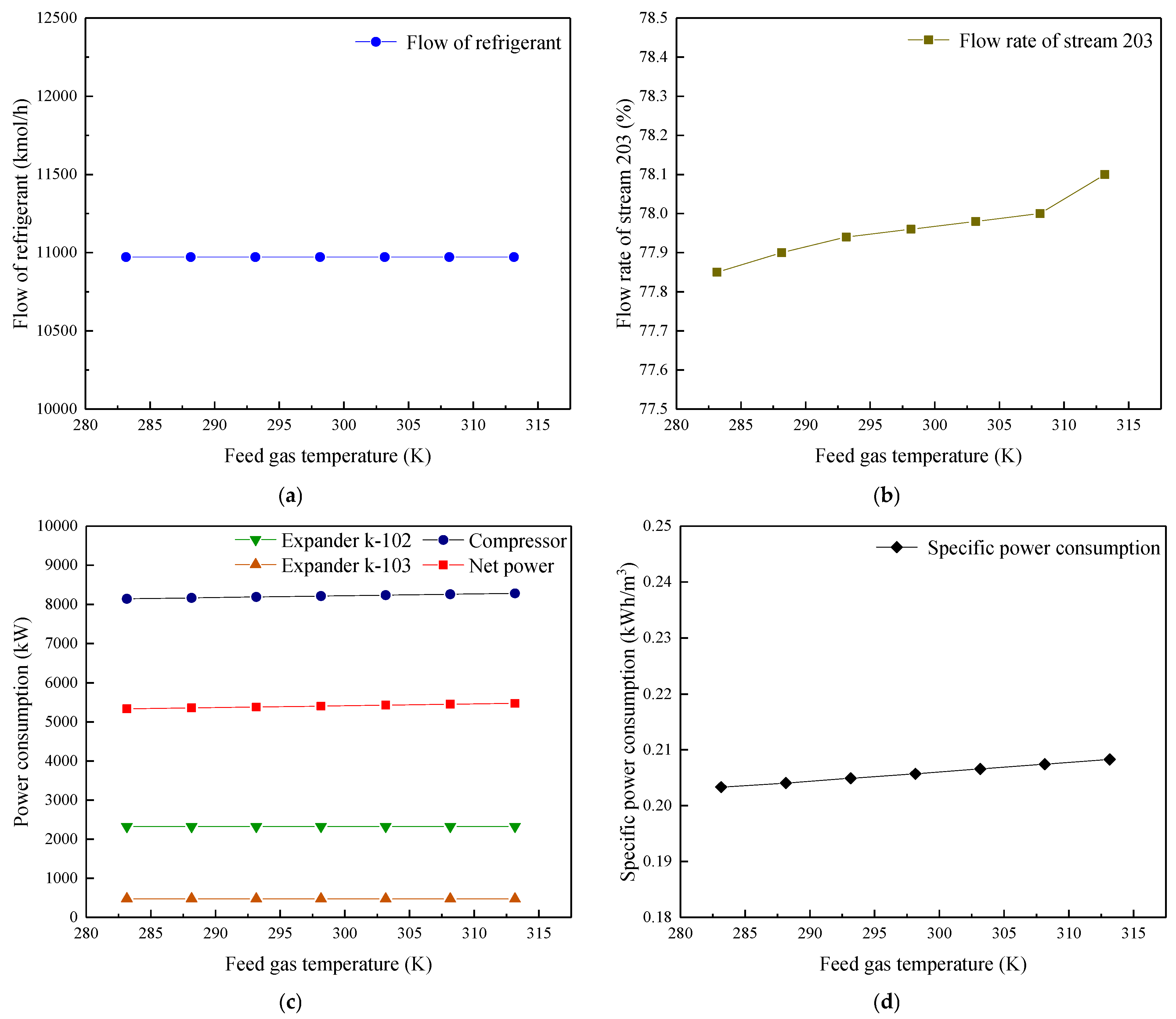

4.3. Sensitivity Analysis of Parameters

4.4. Performance Analysis

5. Conclusions

- Under the same inlet conditions for feed gas, an equivalent calculation model is used to simulate the supersonic swirling separator, finding that the average relative error of the expander module simulation is only 3.764%. Within the pressure range of 5000 kPa to 30,000 kPa and temperature range of 283 K to 343 K, the average relative error of the simulated temperature after expansion is only 0.175% and 0.804%, while the average relative error of outlet temperature is 0.156% and 0.309%, respectively. When the appropriate key parameters are set, the equivalent calculation model for the supersonic swirling separator can be effectively used in liquefaction process research.

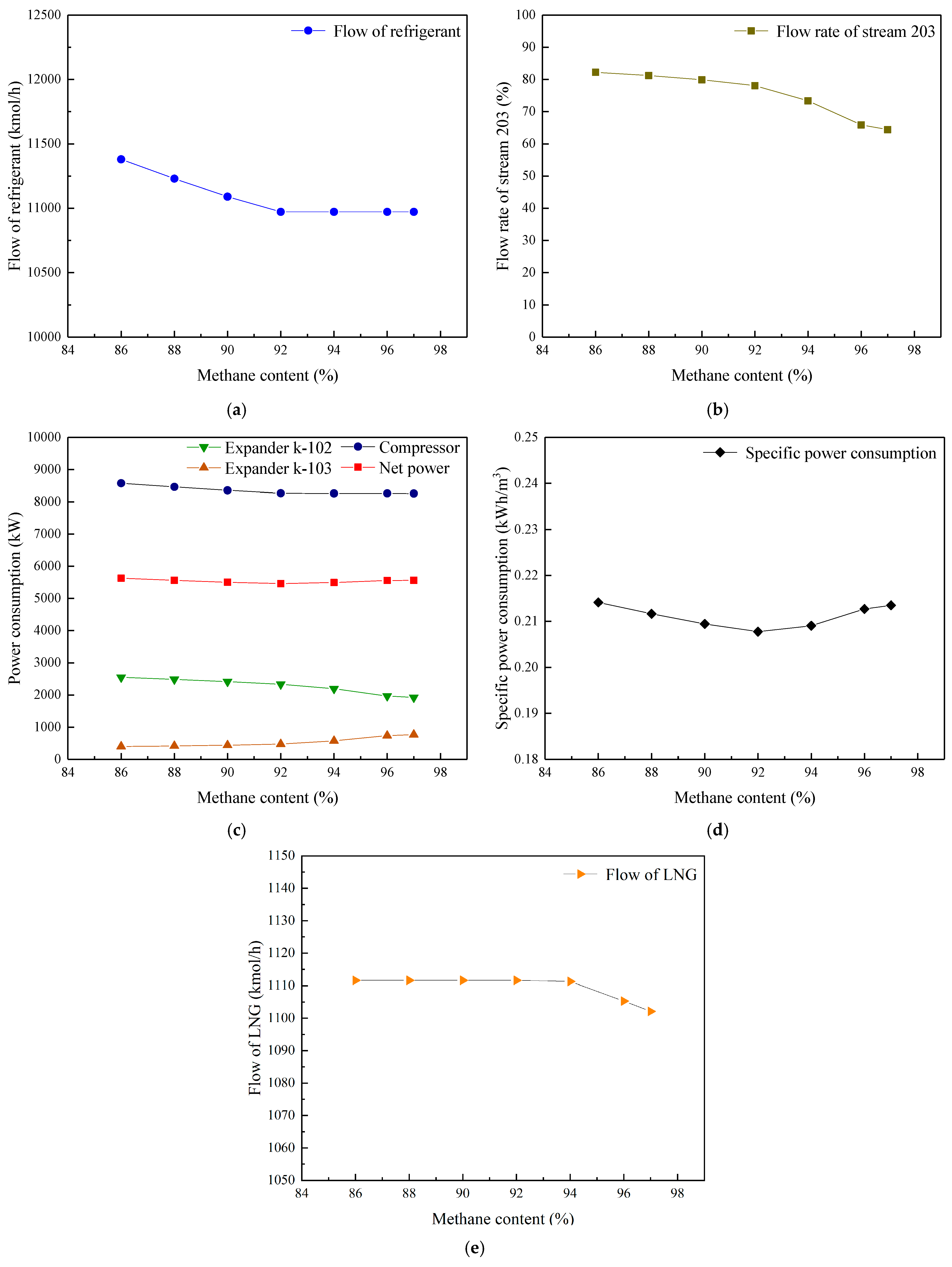

- The LNG storage pressure and temperature of the novel FLNG liquefaction process are improved to 2000 kPa and 164.35 K, respectively, with a specific power consumption of only 0.208 kWh/m3, fully reducing the production energy consumption per unit of LNG product. The main equipment contributing to exergy loss includes the cooler, expander, and compressor, with exergy losses accounting for 28.85%, 26.48%, and 21.70%, respectively. This liquefaction process is relatively adaptable to changes in feed gas pressure, temperature, and methane content. Specific power consumption slightly increases with feed gas temperature and pressure, while it first decreases and then increases with changes in methane content, showing slight fluctuations.

- This liquefaction process is relatively adaptable to changes in feed gas pressure, temperature, and methane content. The trend of key parameter changes is as follows: specific power consumption decreases with the increasing feed gas pressure, slightly increases with the increasing feed gas temperature, and first decreases and then increases with the increasing methane content, with slight fluctuations. The refrigerant flow rate decreases with the increase of feed gas pressure, is insensitive to changes in feed gas temperature, and decreases with the increase of methane content. When the methane content exceeds 92%, the refrigerant flow rate tends to stabilize. The flow rate of the main expander increases with the increasing feed gas pressure and temperature and decreases with the increasing methane content.

- The novel FLNG liquefaction process integrates supersonic swirling separation technology and pressurized liquefaction technology, requiring a low CO2 removal rate, possessing moisture pretreatment capability, having less equipment, and saving a significant amount of valuable deck space. It also features low specific power consumption, minimal impact from swaying, and high safety, providing significant advantages for future offshore natural gas development.

- Although the new FLNG liquefaction process proposed in this article is aimed at solving the problem of offshore natural gas extraction, its idea of eliminating CO2 pretreatment equipment and adopting a supersonic cyclone separator for dehydration, which significantly reduces the footprint, coincides with the requirements of small-scale onshore liquefaction units. It can be further studied as a solution for intensive onshore liquefaction units. At the same time, this article focuses on the various technical performance, equipment quantity, etc., of the liquefaction process, and has not conducted in-depth research on economic indicators such as investment cost and operating cost. Economic research is essential for implementation in the real world and should be a direction for further research in the future.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dou, L.R.; Wen, Z.X.; Wang, J.J.; Wang, Z.M.; He, Z.J.; Liu, X.B.; Zhang, N.N. Analysis of the world oil and gas exploration situation in 2021. Pet. Explor. Dev. 2022, 49, 1033–1044. [Google Scholar] [CrossRef]

- Zhang, N.N.; Wang, Q.; Wang, J.J.; Hou, L.H.; Li, H.W.; Li, Q. Characteristics of oil and gas discoveries in recent 20 years and future exploration in the world. China Pet. Explor. 2018, 23, 44–53. [Google Scholar]

- Wang, C.J.; Wei, L.R.; Zhang, L. Process Technology of Floating LNG. Chem. Ind. 2018, 28, 27–29. [Google Scholar]

- Kerbers, I.; Hartnell, G. A breakthrough for Floating LNG? In Proceedings of the 24th World Gas Conference, Buenos Aires, Argentina, 5–9 October 2009; IGU: Vevey, Switzerland, 2009; pp. 5–9. [Google Scholar]

- Azhar, F.B.; Narayanan, M.; Dominichini, S. Petronas FLNG satu—The advantages of a mid scale facility. In Proceedings of the 18th International Conference & Exhibition on Liquefied Natural Gas, Perth, Australia, 11–15 April 2016; Gas Technology Institute: Des Plaines, IL, USA, 2016; pp. 798–812. [Google Scholar]

- Zhao, Y.X.; Yao, Z.; Wang, X.F.; Chen, Y.C.; Li, X. Global FLNG project development status and prospects. Int. Pet. Econ. 2023, 31, 55–71, 105. [Google Scholar]

- Xiong, X.J.; Lin, W.S.; Gu, A.Z. Integration of CO2 cryogenic removal with a natural gas pressurized liquefaction process using gas expansion refrigeration. Energy 2015, 93, 1–9. [Google Scholar] [CrossRef]

- Chen, Z.; Ju, Y.L. Design and analysis of FLNG liquefaction and NGL recovery process adopting nitrogen expansion cycle with CO2 trans-critical pre-cooling. J. Chem. Eng. Jpn. 2016, 44, 5–11. [Google Scholar]

- Chang, X.Y.; Zhang, Y.Y.; Zhu, J.L.; Li, Y.X.; Zhang, M.X.; Yang, X.Y. Optimization of the process of nitrogen expansion refrigeration of BOG and the analysis of the adaptability of the sea. Chem. Ind. Eng. Prog. 2017, 36, 1619–1627. [Google Scholar]

- He, T.; Lin, W.S. Nitrogen expansion liquefaction and separation process for natural gas with high ethane content. CIESC J. 2018, 69, 226–231. [Google Scholar]

- Yu, X.C.; Xie, B.; Li, Y.X.; Li, Y.; Wang, Q.; Cheng, B.; Wang, C.S. Experimental verification analysis of propane pre-cooling and dual nitrogen expansion liquefaction process adaptable for floating liquid natural gas (FLNG) in south China sea deep water gas field. In Proceedings of the 35th International Conference on Ocean, Offshore and Arctic Engineering, Busan, Republic of Korea, 19–25 June 2016; ASME: New York, NY, USA, 2016. [Google Scholar]

- Yu, X.C.; Xie, B.; Li, Y.X.; Liu, M.E.; Li, Y.; Wang, Q.; Zhu, X.S.; Zhu, J.L. Optimization of FLNG liquefaction process used for the development of deepwater gas field in the South China Sea. Oil Gas Stor. Transp. 2018, 37, 228–235. [Google Scholar]

- Son, H.; Kim, J.K. Energy-efficient process design and optimization of dual-expansion systems for BOG (Boil-off gas) Re-liquefaction process in LNG-fueled ship. Energy 2020, 203, 117823. [Google Scholar] [CrossRef]

- Lee, S.H.; Seo, Y.; Chang, D. Techno-economic Analysis of Acid Gas Removal and Liquefaction for Pressurized LNG. IOP Conf. Ser. Mater. Sci. Eng. 2018, 358, 012066. [Google Scholar] [CrossRef]

- Gao, L.; Wang, J.X.; Binama, M.; Li, Q.; Cai, W.H. The design and optimization of natural gas liquefaction processes: A review. Energies 2022, 15, 7895. [Google Scholar] [CrossRef]

- Lin, W.S.; Xiong, X.J.; Gu, A.Z. Optimization and thermodynamic analysis of a cascade PLNG (pressurized liquefied natural gas) process with CO2 cryogenic removal. Energy 2018, 161, 870–877. [Google Scholar] [CrossRef]

- Xiong, X.J.; Lin, W.S.; Gu, A.Z. Design and optimization of offshore natural gas liquefaction processes adopting PLNG (pressurized liquefied natural gas) technology. J. Nat. Gas Sci. Eng. 2016, 30, 379–387. [Google Scholar] [CrossRef]

- Zhu, J.L.; Liu, J.H.; Li, Z.H.; Li, Y.X.; Wang, W.C.; Liu, M.E.; Li, E.D.; Li, Y.; Wang, Y.F. Research status and development trends of FPLNG pretreatment and liquefaction integrated process. Low-Carbon Chem. Chem. Eng. 2024, 49, 112–122. [Google Scholar]

- Cai, W.H.; Gao, L.; Wang, Z.X.; Duan, X.Y.; Bian, J.; Hua, Y.H.; Che, X.J. A new method for calculating the solubility of carbon dioxide in liquefied natural gas. Nat. Gas Ind. 2023, 43, 108–116. [Google Scholar]

- Cai, W.H.; Gao, L.; Wang, J.X.; Bian, J.; Wang, B.B.; Li, Q.Y.; Wang, Y. Molecular dynamics investigation of dissolution of carbon dioxide in methane. J. China Univ. Pet. (Nat. Sci. Ed.) 2023, 47, 158–167. [Google Scholar]

- Yang, Y.; Wen, C. CFD modeling of particle behavior in supersonic flows with strong swirls for gas separation. Sep. Purif. Technol. 2017, 174, 22–28. [Google Scholar] [CrossRef]

- Wen, C.; Ding, H.; Yang, Y. Optimisation study of a supersonic separator considering nonequilibrium condensation behaviour. Energy Convers. Manag. 2020, 222, 113210. [Google Scholar] [CrossRef]

- Yang, Y.; Wen, C.; Wang, S.L.; Feng, Y.Q. Numerical simulation of real gas flows in natural gas supersonic separation processing. J. Nat. Gas Sci. Eng. 2014, 21, 829–836. [Google Scholar] [CrossRef]

- Machado, P.B.; Monteiro, J.G.M.; Medeiros, J.L.; Epsom, H.D.; Araujo, O.Q.F. Supersonic separation in onshore natural gas dew point plant. J. Nat. Gas Sci. Eng. 2012, 6, 43–49. [Google Scholar] [CrossRef]

- Niknam, P.H.; Mortaheb, H.R.; Mokhtarani, B. Dehydration of low-pressure gas using supersonic separation: Experimental investigation and CFD analysis. J. Nat. Gas Sci. Eng. 2018, 52, 202–214. [Google Scholar] [CrossRef]

- Cao, X.W.; Bian, J. Supersonic separation technology for natural gas processing: A review. Chem. Eng. Process. 2019, 136, 138–151. [Google Scholar] [CrossRef]

- Deng, Q.H.; Jiang, Y.; Hu, Z.F.; Li, J.; Feng, Z.P. Condensation and expansion characteristics of water steam and carbon dioxide in a Laval nozzle. Energy 2019, 175, 694–703. [Google Scholar] [CrossRef]

- Li, K.Y. Study on Supersonic Expansion Liquefaction Technology of Natural Gas. Master’s Thesis, China University of Petroleum, Qingdao, China, 2015. [Google Scholar]

- Zhu, C. Research on Natural Gas Condensation Characteristics in Supersonic separators. Master’s Thesis, Southwest Petroleum University, Chengdu, China, 2015. [Google Scholar]

- Bian, J.; Cao, X.W.; Yang, W.; Yu, H.X.; Yin, P.B. Influence of inlet pressure on supersonic liquefaction of natural gas mixtures. Chin. J. High Press. Phys. 2018, 32, 3–9. [Google Scholar]

- Bian, J.; Cao, X.W.; Yang, W.; Yin, P.B.; Liu, Y. Effect of inlet temperature on supersonic liquefaction characteristics of natural gas. J. Refrig. 2019, 40, 107–113. [Google Scholar]

- Zhao, X.K. Study on mechanism of CO2 Removal from Natural Gas with Supersonic Swirling Separation Technology. Master’s Thesis, China University of Petroleum, Qingdao, China, 2018. [Google Scholar]

- Yang, Y.; Wen, C.; Wang, S.L.; Feng, Y.Q. Effect of inlet and outlet flow conditions on natural gas parameters in supersonic separation Process. PLoS ONE 2014, 9, 110313. [Google Scholar] [CrossRef] [PubMed]

- Xiong, X.J. Research on Frost Point and Pressurized Liquefaction Process of CO2-Contained Natural Gas. Ph.D. Thesis, Shanghai Jiao Tong University, Shanghai, China, 2016. [Google Scholar]

- Wu, J.X. Research on FLNG Expansion Refrigeration Natural Gas Liquefaction Process. Master’s Thesis, Southwest Petroleum University, Chengdu, China, 2018. [Google Scholar]

| Reference | Components of Feed Gas |

|---|---|

| Reference [28] | CH4: 98%; C2H6: 1%; C3H8: 1%; |

| Reference [29] | CH4: 87.06%; C2H6: 8.19%; C3H8: 3.15%; n-C4H10:0.56%; i-C4H10: 0.34%; H2O: 0.21%; N2: 0.32%; CO2: 0.12%; H2: 0.05%; |

| Reference [30] | CH4: 90%; C2H6: 10%; |

| Reference [31] | CH4: 90%; C2H6: 10%; |

| Reference [32] | CH4: 90%; CO2: 10%; |

| Reference [33] | CH4: 91.36%; C2H6: 3.63%; C3H8: 1.44%; i-C4H10: 0.26%; n-C4H10: 0.46%; i-C5H12: 0.17%; n-C5H12: 0.16%; H2O: 0.03%; N2: 2.04%; CO2: 0.45%; |

| Reference | Inlet Pressure (kPa) | Inlet Temperature (K) | Pressure After Expansion (kPa) | Temperature After Expansion (K) | ||

|---|---|---|---|---|---|---|

| Literature Data | Simulation Data | Relative Error | ||||

| Reference [28] | 4000 | 240 | 100 | 110 | 113.25 | 2.95% |

| Reference [29] | 840 | 288.15 | 200 | 210 | 204.33 | 2.70% |

| Reference [30] | 5500 | 270 | 427.2 | 162.31 | 159.95 | 1.45% |

| 6000 | 270 | 502.45 | 170.02 | 162.05 | 4.69% | |

| 6500 | 270 | 614.39 | 173.01 | 165.25 | 4.49% | |

| Reference [31] | 6000 | 265 | 564.64 | 171.57 | 163.35 | 4.79% |

| 6000 | 270 | 549.88 | 168.87 | 164.15 | 2.80% | |

| 6000 | 275 | 524.3 | 161.77 | 164.35 | 1.59% | |

| 6000 | 280 | 489.98 | 151.39 | 164.05 | 8.36% | |

| Reference [32] | 7500 | 273.15 | 1136.77 | 179.50 | 177.50 | 1.11% |

| 8000 | 273.15 | 1272.34 | 184.81 | 178.84 | 3.23% | |

| 8500 | 273.15 | 1367.47 | 186.93 | 179.25 | 4.11% | |

| 8000 | 270 | 1099.34 | 185.51 | 174.18 | 6.11% | |

| 8000 | 275 | 1251.58 | 183.07 | 179.01 | 2.22% | |

| 8000 | 280 | 1328.8 | 171.88 | 181.96 | 5.86% | |

| Average relative error | 3.764% | |||||

| Inlet Temperature (K) | Inlet Pressure (kPa) | Pressure After Expansion (kPa) | Temperature After Expansion (K) | Outlet Back Pressure (kPa) | Outlet Temperature (K) | ||

|---|---|---|---|---|---|---|---|

| Literature Data [33] | Simulation Data | Literature Data [33] | Simulation Data | ||||

| 300 | 5000 | 2957.19 | 264.98 | 263.615 | 4250 | 294.14 | 294.48 |

| 10,000 | 6064.89 | 264.83 | 264.462 | 8500 | 293.13 | 293.61 | |

| 20,000 | 11,017.30 | 260.23 | 263.183 | 17,000 | 295.33 | 294.56 | |

| 30,000 | 14,224.51 | 256.51 | 260.17 | 25,500 | 299.41 | 297.33 | |

| Average relative error | 0.175% | 0.156% | |||||

| Inlet Temperature (K) | Inlet Pressure (kPa) | Pressure After Expansion (kPa) | Temperature After Expansion (K) | Outlet Back Pressure (kPa) | Outlet Temperature (K) | ||

|---|---|---|---|---|---|---|---|

| Literature Data [33] | Simulation Data | Literature Data [33] | Simulation Data | ||||

| 283 | 10,000 | 6068.18 | 249.52 | 248.99 | 8500 | 276.23 | 275.93 |

| 303 | 6068.18 | 267.71 | 267.25 | 8500 | 296.75 | 296.26 | |

| 323 | 6051.04 | 286.16 | 285.49 | 8500 | 317.24 | 316.42 | |

| 343 | 6036.75 | 304.56 | 304.31 | 8500 | 337.03 | 336.72 | |

| Average relative error | 0.804% | 0.309% | |||||

| Components | Mole Fraction (%) |

|---|---|

| Methane | 92.0818 |

| Ethane | 4.9856 |

| Propane | 0.1995 |

| Isobutane | 0.0336 |

| n-Butane | 0.0324 |

| Neopentane | 0.0025 |

| Isopentane | 0.0147 |

| Pentane | 0.0064 |

| n-Hexane | 0.0086 |

| Heptane | 0.0032 |

| Nitrogen | 2.0128 |

| Carbon dioxide | 0.5 |

| Water | 0.1189 |

| Parameters | Value |

|---|---|

| Storage pressure of LNG | 2000 kPa |

| Heat exchanger pressure drop | 20 kPa |

| Cooler pressure drop | 20 kPa |

| Cooler outlet temperature | 303.15 K |

| Compressor isentropic efficiency | 85% |

| Expander isentropic efficiency | 80% |

| Parameter | Population Size | Maximum Iteration Number | Crossover Rate | Mutation Rate |

|---|---|---|---|---|

| Numerical value | 50 | 300 | 0.8 | 0.2 |

| Decision Variables | Lower Limit | Upper Limit |

|---|---|---|

| P201/kPa | 2000 | 10,000 |

| P205/kPa | 1000 | 5000 |

| T202/K | 303.15 | 195.95 |

| T206/K | 195.95 | 165.15 |

| r | 0.5 | 0.9 |

| P201/kPa | P205/kPa | T202/K | T206/K | r |

|---|---|---|---|---|

| 9128.50 | 4083.50 | 233.55 | 195.35 | 0.78 |

| Refrigerant Flow | LNG Product Flow | Compressor Power | Expander k-102 Power | Expander k-103 Power | Specific Power Consumption |

|---|---|---|---|---|---|

| 10,964 kmol/h | 1112 kmol/h | 8265.90 kW | 2330.0 kW | 475.1 kW | 0.208 kWh/m3 |

| Equipment | Exergy Equation | Distribution of Exergy Loss |

|---|---|---|

| Cooler | 28.85% | |

| Expander | 26.48% | |

| Compressor | 21.70% | |

| Heat exchanger | 16.78% | |

| Supersonic separator | 4.52% | |

| Throttle valve | 1.67% |

| Equipment Type | Double Nitrogen Expansion Liquefaction [35] | CO2 Precooling N2-CH4 Expansion Liquefaction Process [35] | Conventional Nitrogen Expansion Liquefaction Process [34] | Single Nitrogen Expansion with Pressurized Liquefaction Process [34] | Novel FLNG Liquefaction Process |

|---|---|---|---|---|---|

| Gas pressure | 5000 kPa | 5000 kPa | 5000 kPa | 5000 kPa | 6660 kPa |

| Gas temperature | 307.65 K | 307.65 K | 308.15 K | 308.15 K | 310.15 K |

| Storage pressure | 120 kPa | 120 kPa | 110 kPa | 2000 kPa | 2000 kPa |

| Storage temperature | 113.85 K | 113.85 K | 111.00 K | 165.00 K | 164.35 K |

| Specific power consumption | 0.504 kWh/m3 | 0.394 kWh/m3 | 0.338 kWh/m3 | 0.225 kWh/m3 | 0.208 kWh/m3 |

| Number of key pieces of equipment | 13 | 16 | 19 | 8 | 9 |

| Footprint | Medium | Large | Larger | Larger | Larger |

| CO2 removal rate requirement | High | High | High | Low | Low |

| Moisture pretreatment capacity | No | No | No | No | Yes |

| Swaying effect | Small | Small | Small | Small | Small |

| Flammable refrigerants | No | Yes | No | No | No |

| Security | Higher | High | Higher | Higher | Higher |

| Offshore adaptability | Good | Good | Good | Excellent | Excellent |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, L.; Wang, Z.; Qiu, G.; Hua, Y.; Bian, J.; Cai, W. Simulation and Optimization of a Novel FLNG Liquefaction Process Based on Supersonic Swirling Separation and Nitrogen Expansion Refrigeration. Processes 2025, 13, 2530. https://doi.org/10.3390/pr13082530

Gao L, Wang Z, Qiu G, Hua Y, Bian J, Cai W. Simulation and Optimization of a Novel FLNG Liquefaction Process Based on Supersonic Swirling Separation and Nitrogen Expansion Refrigeration. Processes. 2025; 13(8):2530. https://doi.org/10.3390/pr13082530

Chicago/Turabian StyleGao, Lei, Zhaoxi Wang, Guodong Qiu, Yihuai Hua, Jiang Bian, and Weihua Cai. 2025. "Simulation and Optimization of a Novel FLNG Liquefaction Process Based on Supersonic Swirling Separation and Nitrogen Expansion Refrigeration" Processes 13, no. 8: 2530. https://doi.org/10.3390/pr13082530

APA StyleGao, L., Wang, Z., Qiu, G., Hua, Y., Bian, J., & Cai, W. (2025). Simulation and Optimization of a Novel FLNG Liquefaction Process Based on Supersonic Swirling Separation and Nitrogen Expansion Refrigeration. Processes, 13(8), 2530. https://doi.org/10.3390/pr13082530