Optimization of Machining Efficiency of Aluminum Honeycomb Structures by Hybrid Milling Assisted by Longitudinal Ultrasonic Vibrations

Abstract

1. Introduction

2. Materials and Methods

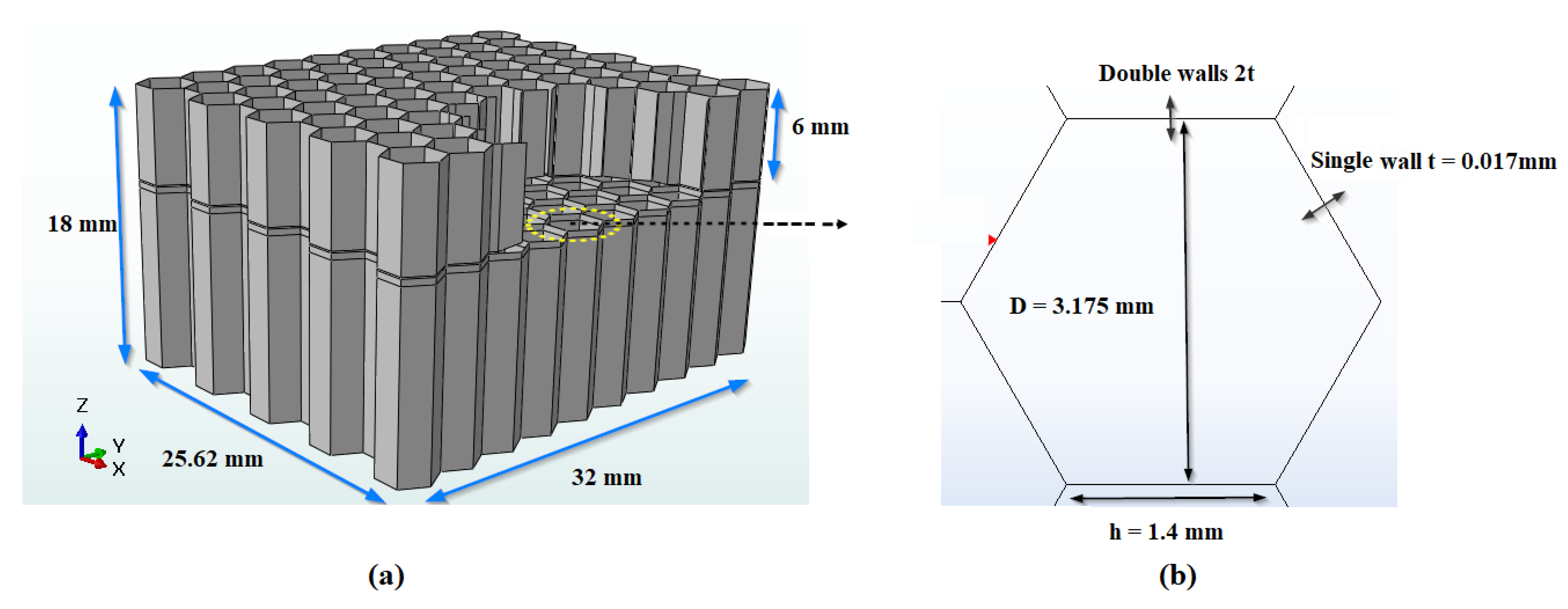

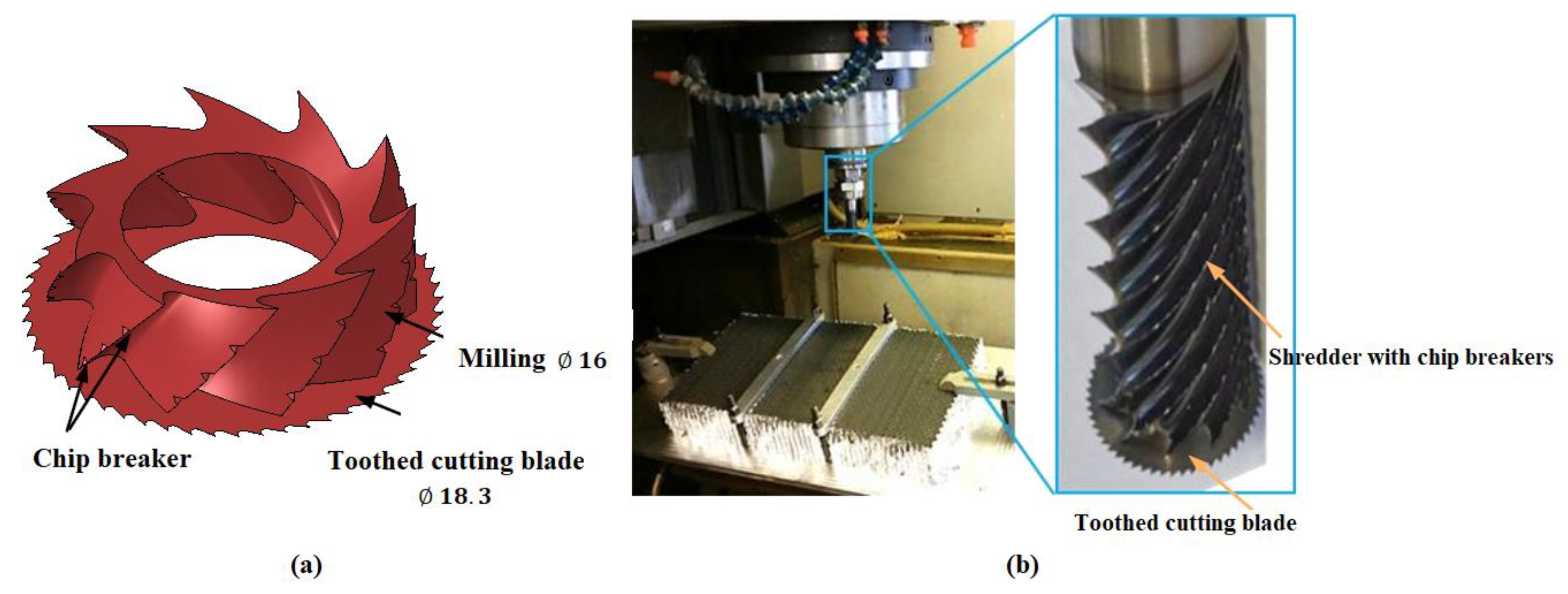

2.1. The Cutting Tool and the Structure Studied

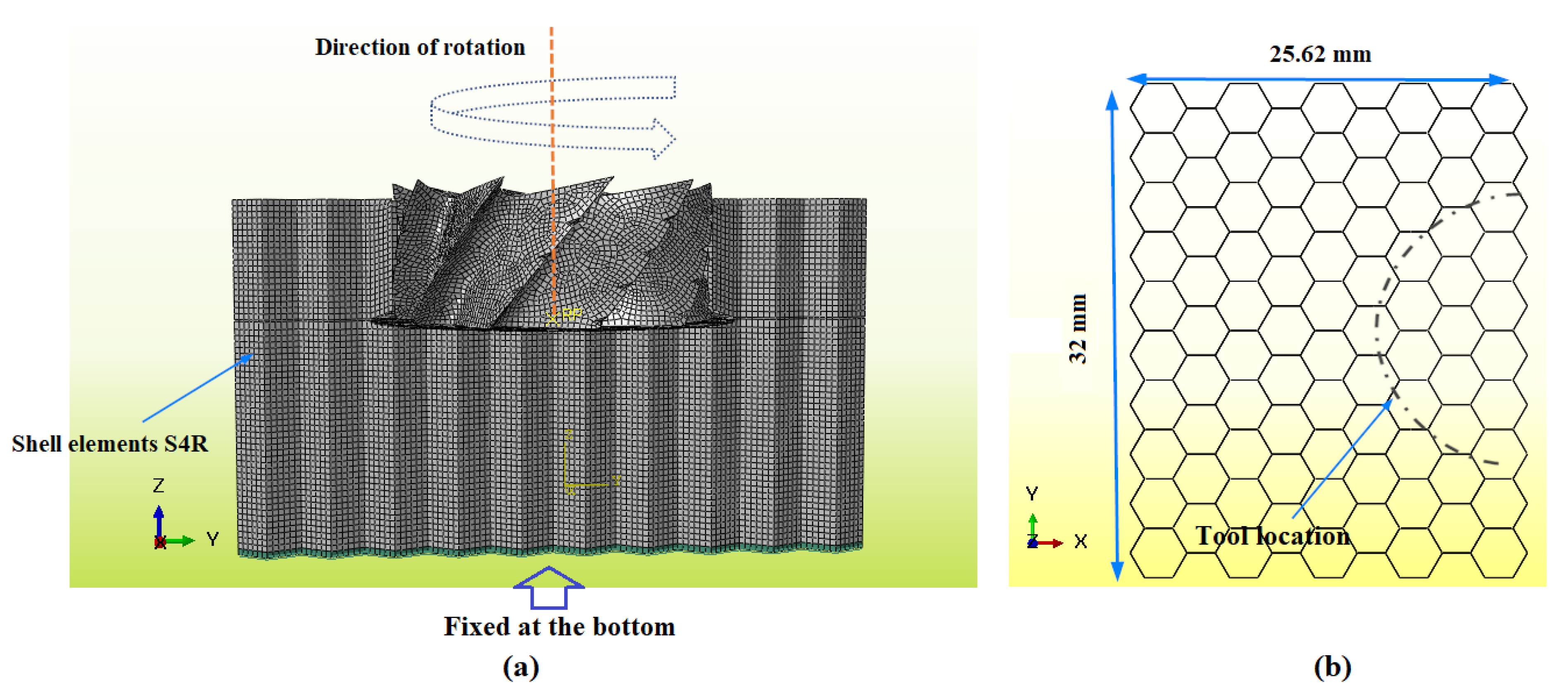

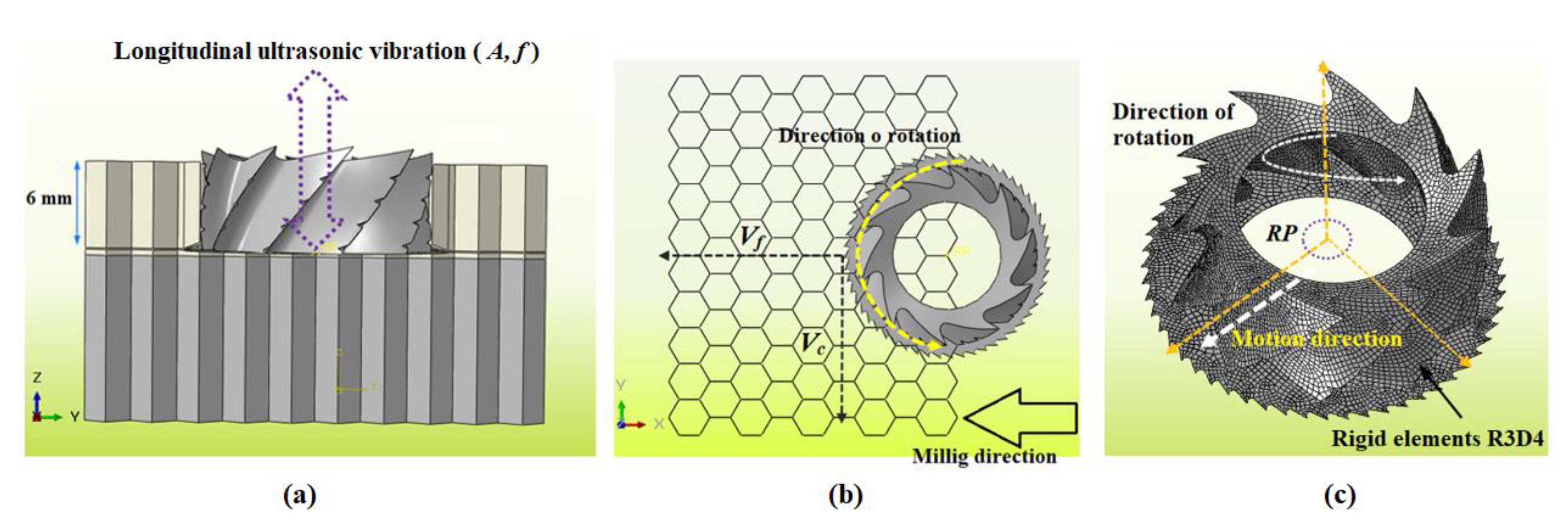

2.2. Presentation of Experimental and Numerical Methodologies

3. Fundamental Material Properties, Degradation Processes, and Failure Criteria

4. Cutting Force and Its Components

5. Results and Discussion

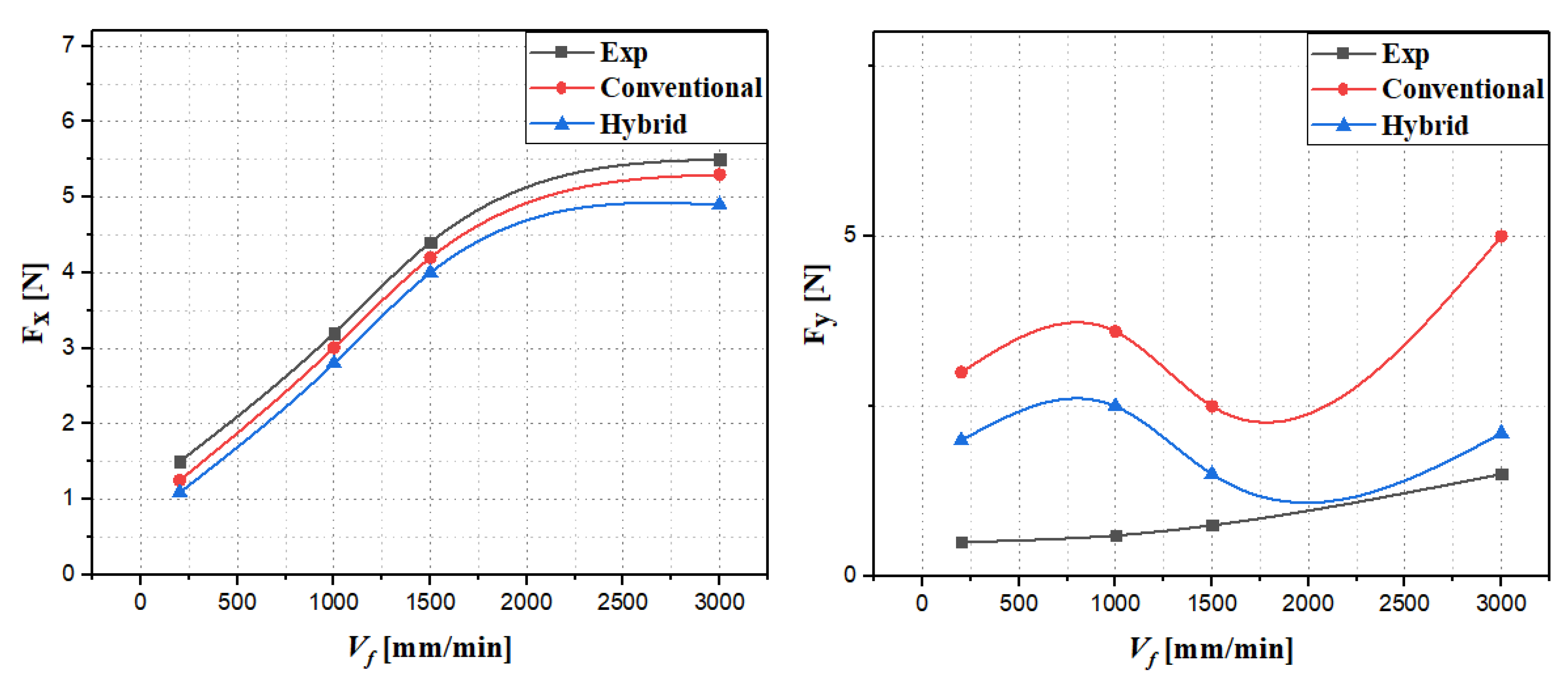

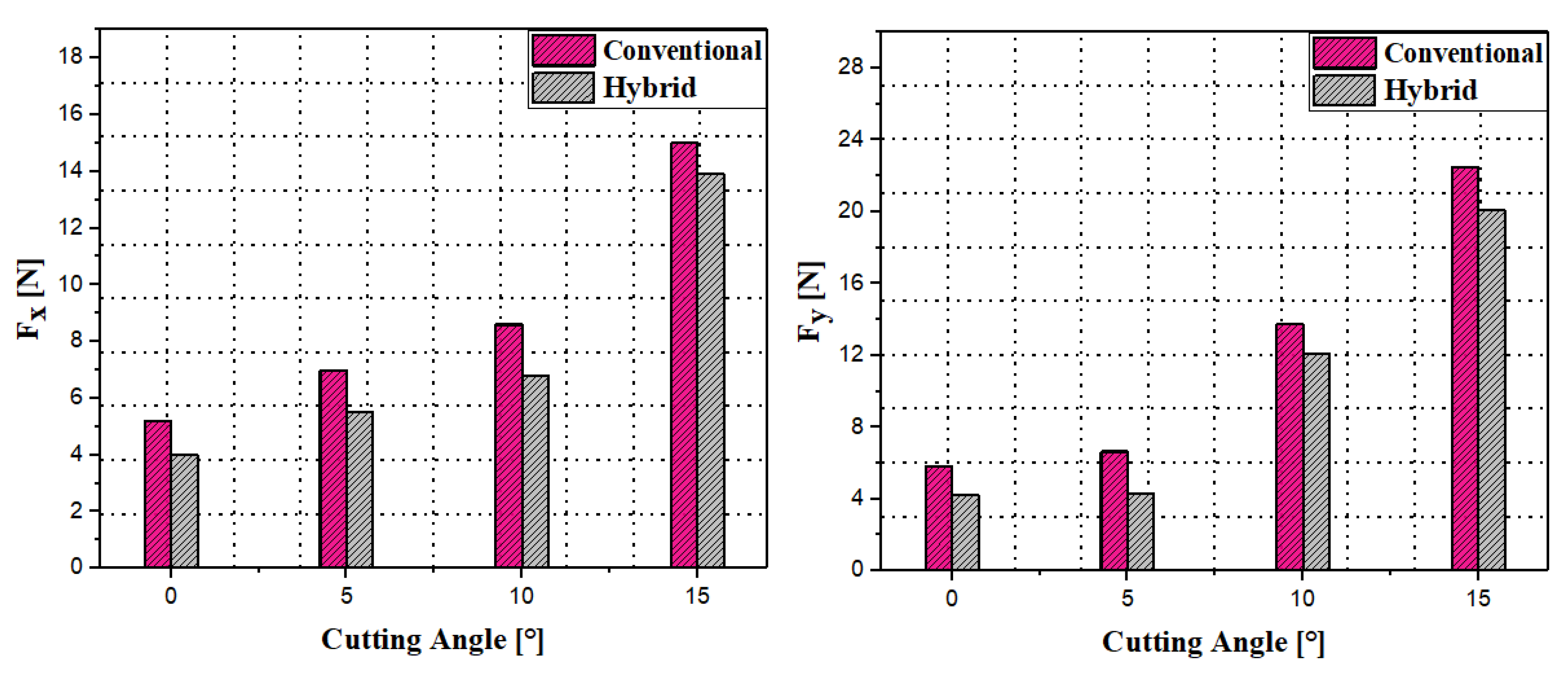

5.1. Comparative Study of the Influence of Feed Rate on Cutting Forces in Hybrid and Conventional Cutting

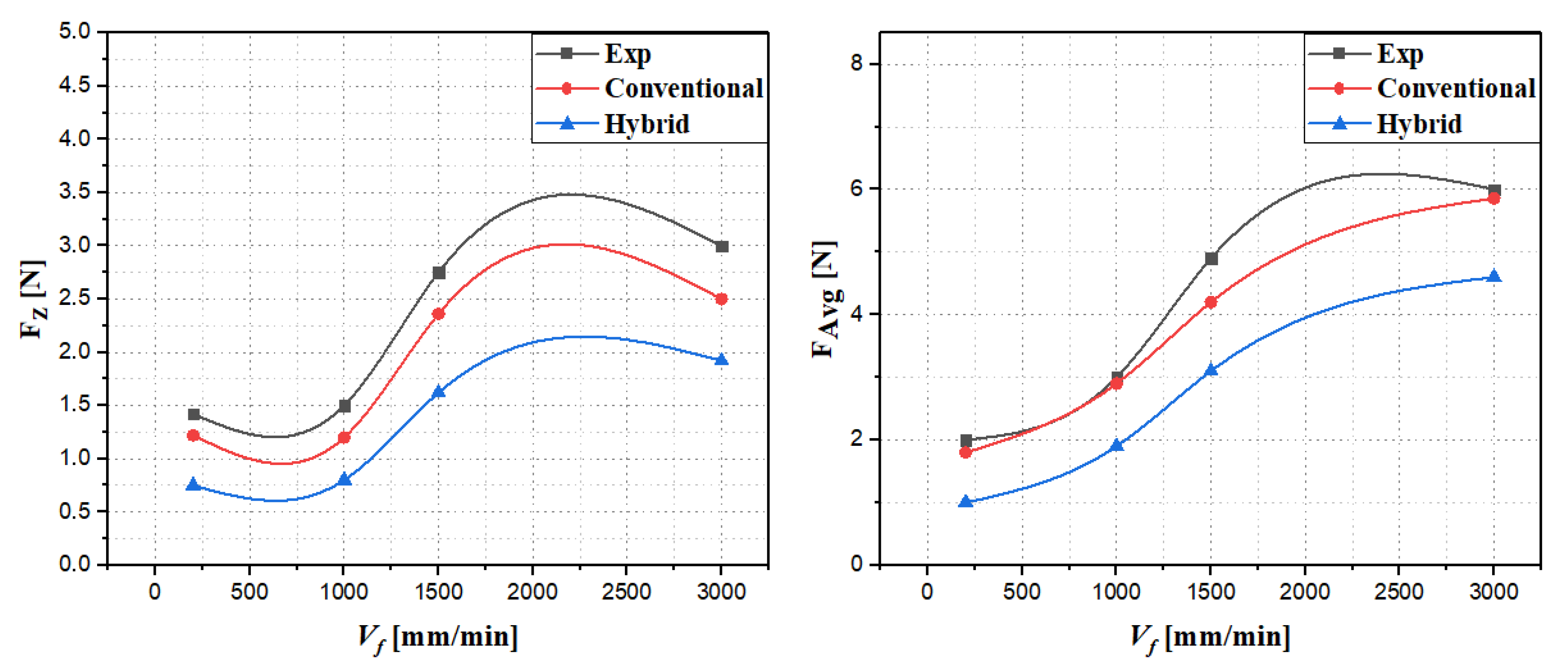

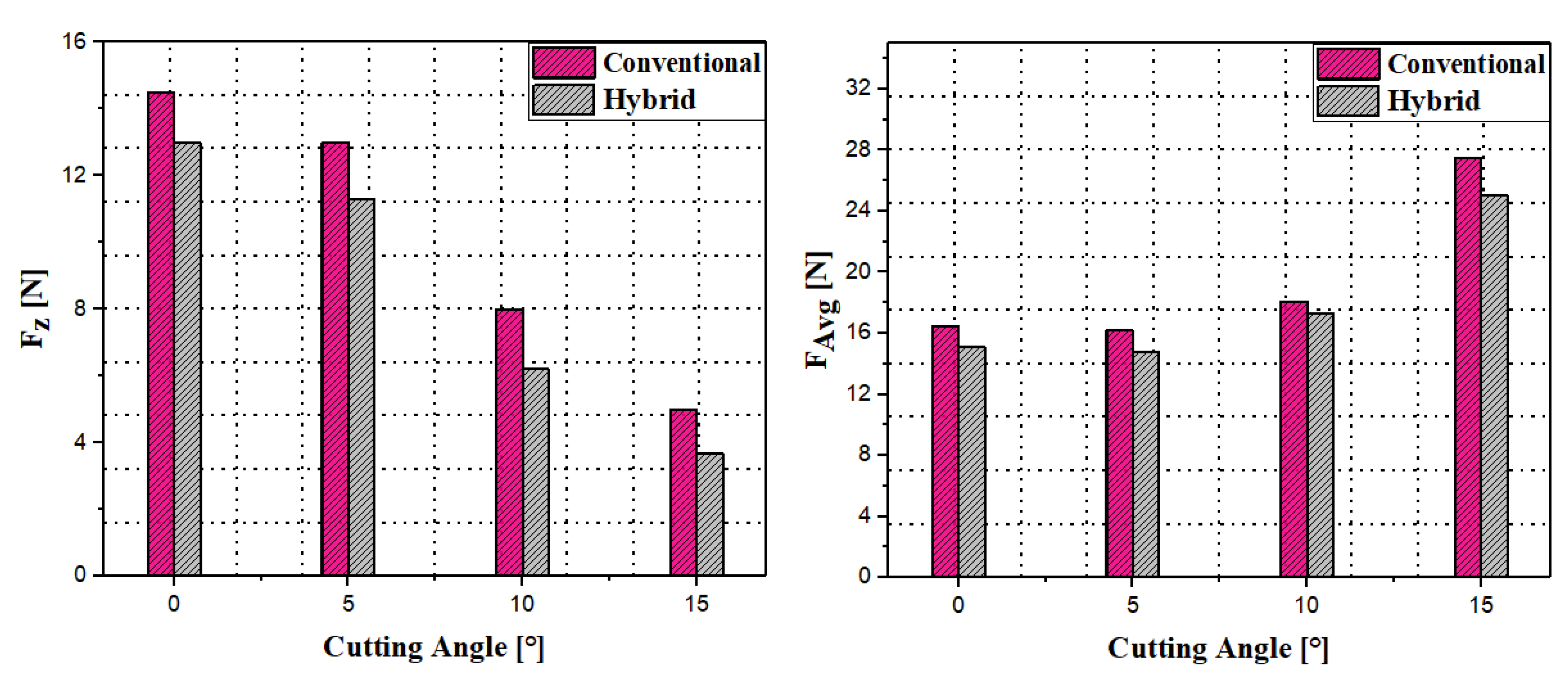

5.2. Impact of Cutting Angle on Cutting Force and Their Components in Hybrid and Conventional Machining

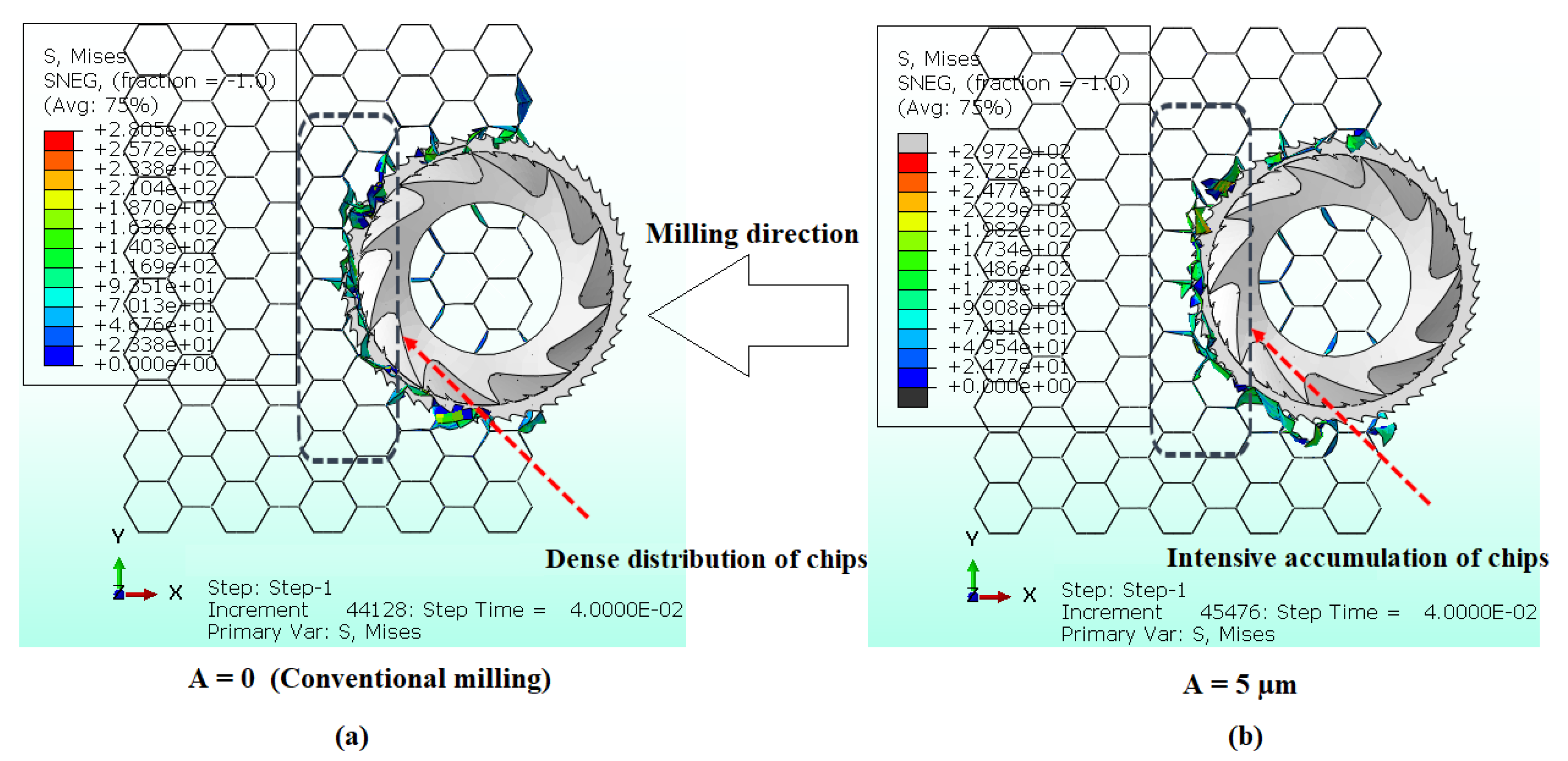

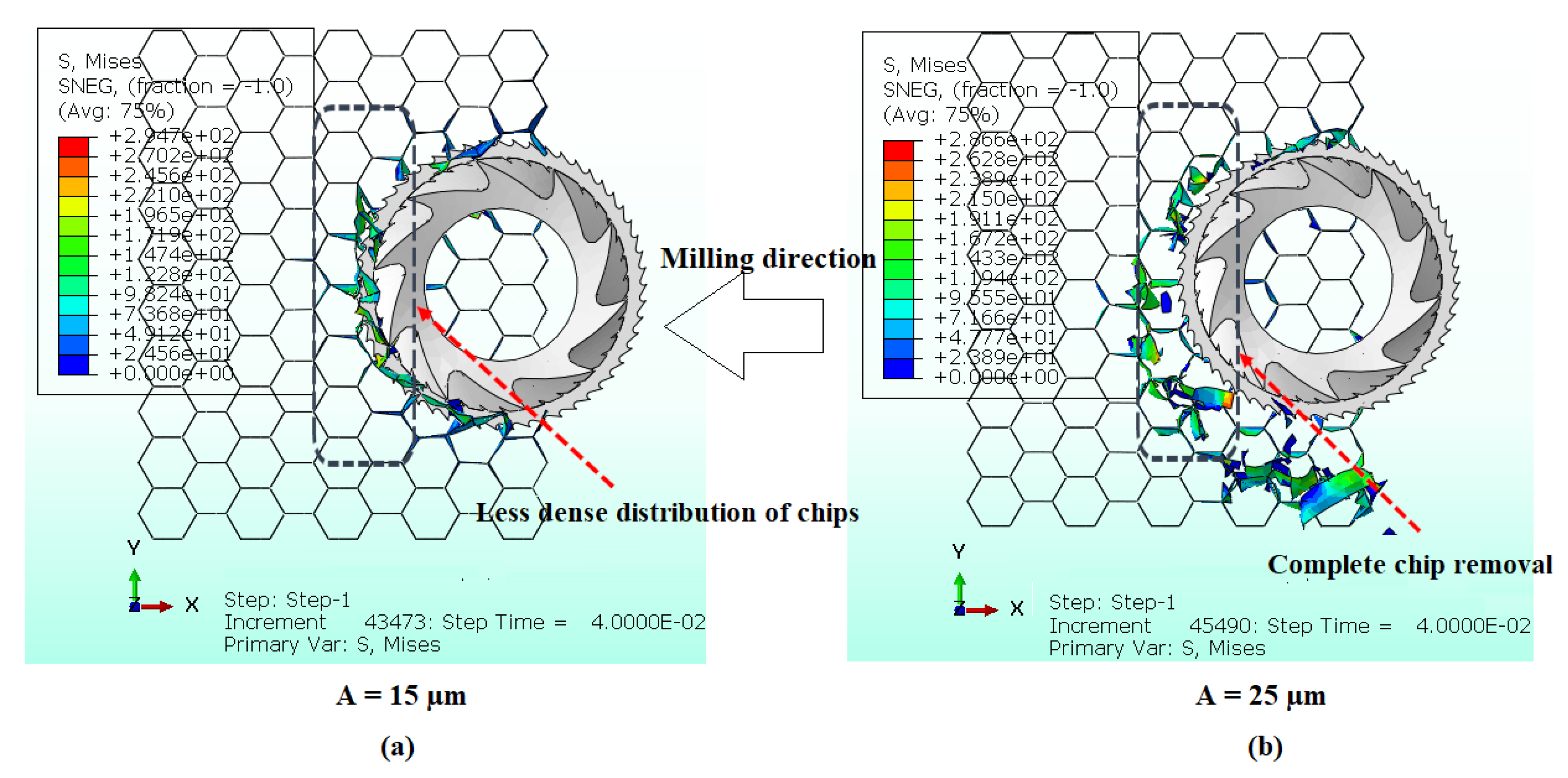

5.3. Analysis of Chip Distribution in Front of the Cutting Tool as a Function of the Amplitude of Ultrasonic Vibrations

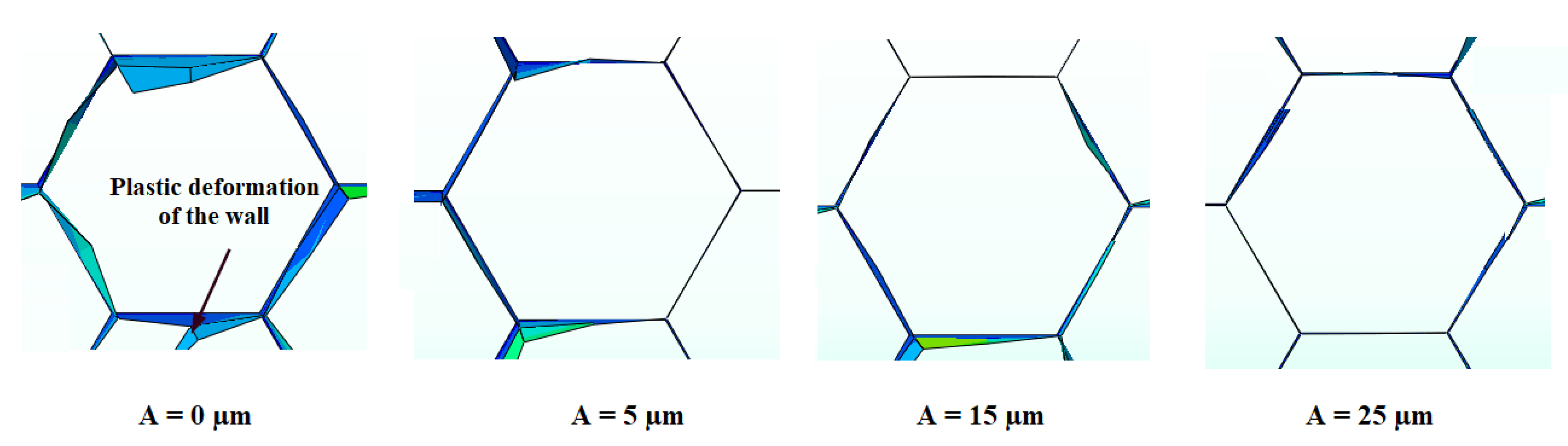

5.4. Analysis of Machined Surface Quality as a Function of Ultrasonic Vibration Amplitude

6. Conclusions

- The ultrasonic vibration-assisted hybrid approach enables reduction the components of the cutting force of up to 42% compared to conventional milling, improving process efficiency and cutting tool durability.

- Ultrasonic vibrations at an amplitude of 15 µm promote chip breakage when milling honeycomb structures, optimizing evacuation, reducing build-up, and thus improving cutting efficiency and extending tool life.

- The present study shows that the integration of ultrasonic vibrations improves surface quality, reduces plastic deformation, increases cutting accuracy, and decreases mechanical defects.

- Hybrid cutting optimizes process efficiency by reducing tool forces by 10 to 30%, through more efficient friction management and improved chip evacuation, with ideal rake angles between 10° and 15° to improve stability and cut quality.

- Hybrid ultrasonic machining, an efficient and flexible solution for milling complex metal structures, improves productivity and quality and is particularly advantageous for the aerospace sector, where component precision and durability are crucial.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ahmad, S.; Zhang, J.; Feng, P.; Yu, D.; Wu, Z.; Ke, M. Processing technologies for Nomex honeycomb composites (NHCs): A critical review. Compos. Struct. 2020, 250, 112545. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, W.; Gao, W. Out-of-plane shear property analysis of Nomex honeycomb sandwich structure. J. Reinf. Plast. Compos. 2021, 40, 165–175. [Google Scholar] [CrossRef]

- Ndiaye, E.B.; Maréchal, P.; Duflo, H. Adhesion characterization and defect sizing of sandwich honeycomb composites. Ultrasonics 2015, 62, 103–111. [Google Scholar] [CrossRef] [PubMed]

- Min, D.; Pei-lei, Z.; Zhen-Yu, Z.; Shun, Y. A novel assembly technology of aluminum alloy honeycomb structure. Int. J. Adv. Manuf. Technol. 2010, 46, 1253–1258. [Google Scholar] [CrossRef]

- Qiu, K.; Ming, W.; Shen, L.; An, Q.; Chen, M. Study on the cutting force in machining of aluminum honeycomb core material. Compos. Struct. 2017, 164, 58–67. [Google Scholar] [CrossRef]

- Wang, Z.; Tian, H.; Lu, Z.; Zhou, W. High-speed axial impact of aluminum honeycomb–Experiments and simulations. Compos. Part B Eng. 2014, 56, 1–8. [Google Scholar] [CrossRef]

- Ashab, A.S.M.; Ruan, D.; Lu, G.; Xu, S.; Wen, C. Experimental investigation of the mechanical behavior of aluminum honeycombs under quasi-static and dynamic indentation. Mater. Des. 2015, 74, 138–149. [Google Scholar] [CrossRef]

- An, Q.; Dang, J.; Ming, W.; Qiu, K.; Chen, M. Experimental and numerical studies on defect characteristics during milling of aluminum honeycomb core. J. Manuf. Sci. Eng. 2019, 141, 031006. [Google Scholar] [CrossRef]

- Yip-Hoi, D.; Gill, D.; Gahan, J.; Travis, G.; Mackaay, L. Material stiffness and cutting parameters for honeycomb aluminum sandwich panel: A comparison with bulk material. Procedia Manuf. 2019, 34, 385–392. [Google Scholar] [CrossRef]

- Wang, Y.; Gan, Y.; Liu, H.; Han, L.; Wang, J.; Liu, K. Surface quality improvement in machining an aluminum honeycomb by ice fixation. Chin. J. Mech. Eng. 2020, 33, 20. [Google Scholar] [CrossRef]

- Zarrouk, T.; Nouari, M.; Salhi, J.E.; Makich, H.; Salhi, M.; Atlati, S.; Salhi, N. Optimization of the milling process for aluminum honeycomb structures. Int. J. Adv. Manuf. Technol. 2022, 119, 4733–4744. [Google Scholar] [CrossRef]

- Hirayama, A. Method for Cutting Honeycomb Core. U.S. Patent No. 6,740,268, 25 May 2004. [Google Scholar]

- Wang, F.; Liu, J.; Li, L.; Shu, Q. Green machining of aluminum honeycomb treated using ice fixation in cryogenic. Int. J. Adv. Manuf. Technol. 2017, 92, 943–952. [Google Scholar] [CrossRef]

- Wang, F.; Wang, Y. Investigate on milling force of cryogenic cooling processing aluminum honeycomb treated by ice fixation. Int. J. Adv. Manuf. Technol. 2018, 98, 1253–1265. [Google Scholar] [CrossRef]

- Wang, F.; Wang, Y. Optimization of cryogenic milling parameters for aluminum honeycomb treated by ice fixation method. Int. J. Adv. Manuf. Technol. 2018, 99, 2271–2281. [Google Scholar] [CrossRef]

- Zarrouk, T.; Salhi, J.E.; Nouari, M.; Salhi, M.; Kodad, J. Influence of the cutting tool geometry on milling aluminum honeycomb structures. Int. J. Adv. Manuf. Technol. 2023, 126, 313–324. [Google Scholar] [CrossRef]

- Sun, J.; Qin, Y.; Xing, W.; Kang, R.; Dong, Z.; Wang, Y. Study on cell wall deformation in ultrasonic cutting aluminum honeycomb by straight-blade knife. Ultrasonics 2024, 144, 107444. [Google Scholar] [CrossRef] [PubMed]

- Kuo, C.; Chen, C.; Jiang, S.; Chen, Y. Effects of the tool geometry, cutting and ultrasonic vibration parameters on the cutting forces, tool wear, machined surface integrity and subsurface damages in routing of glass fiber-reinforced honeycomb cores. J. Manuf. Process. 2023, 104, 59–75. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Kang, R.; Sun, J.; Jia, Z.; Dong, Z. Analysis of influence on ultrasonic-assisted cutting force of Nomex honeycomb core material with straight knife. J. Mech. Eng. 2017, 53, 73–82. [Google Scholar] [CrossRef]

- Zhang, X.; Dong, Z.; Wang, Y.; Xu, Z.; Song, H.; Kang, R. Charization of surface microscopic of Nomex honeycomb after ultrasonic assisted cutting. J. Mech. Eng. 2017, 53, 90–99. [Google Scholar] [CrossRef]

- Sun, J.; Dong, Z.; Wang, X.; Wang, Y.; Qin, Y.; Kang, R. Experimental study on ultrasonic cutting of aluminum honeycombs. J. Mech. Eng. 2017, 53, 128–135. [Google Scholar] [CrossRef]

- Sun, J.; Dong, Z.; Wang, X.; Wang, Y.; Qin, Y.; Kang, R. Simulation and experimental study of ultrasonic cutting for aluminum honeycomb by disc cutter. Ultrasonics 2020, 103, 106102. [Google Scholar] [CrossRef] [PubMed]

- Zarrouk, T.; Nouari, M.; Salhi, J.E.; Benbouaza, A. Numerical simulation of rotary ultrasonic machining of the Nomex honeycomb composite structure. Machines 2024, 12, 137. [Google Scholar] [CrossRef]

- Jaafar, M. Étude Expérimentale et Simulation Numérique de L’usinage des Matériaux en Nids D’abeilles: Application au Fraisage des Structures Nomex® et Aluminium. Ph.D. Thesis, Université de Lorraine, Nancy, France, 2018. [Google Scholar]

- Heimbs, S. Virtual testing of sandwich core structures using dynamic finite element simulations. Comput. Mater. Sci. 2009, 45, 205–216. [Google Scholar] [CrossRef]

- Foo, C.C.; Chai, G.B.; Seah, L.K. Mechanical properties of Nomex material and Nomex honeycomb structure. Compos. Struct. 2007, 80, 588–594. [Google Scholar] [CrossRef]

- Tie, B.; Tian, B.Y.; Aubry, D. Theoretical and numerical modeling of membrane and bending elastic wave propagation in honeycomb thin layers and sandwiches. J. Sound Vib. 2016, 382, 100–121. [Google Scholar] [CrossRef]

- Sahare, S.B.; Untawale, S.P.; Chaudhari, S.S.; Shrivastav, R.L.; Kamble, P.D. Experimental investigation of end milling operation on Al2024. Mater. Today: Proc. 2017, 4, 1357–1365. [Google Scholar] [CrossRef]

- Moshat, S.; Datta, S.; Bandyopadhyay, A.; Pal, P. Optimization of CNC end milling process parameters using PCA-based Taguchi method. Int. J. Eng. Sci. Technol. 2010, 2, 95–102. [Google Scholar] [CrossRef]

- Akbar, F.; Mativenga, P.T.; Sheikh, M.A. An experimental and coupled thermo-mechanical finite element study of heat partition effects in machining. Int. J. Adv. Manuf. Technol. 2010, 46, 491–507. [Google Scholar] [CrossRef]

- Wang, X.; Shi, J. Validation of Johnson-Cook plasticity and damage model using impact experiment. Int. J. Impact Eng. 2013, 60, 67–75. [Google Scholar] [CrossRef]

- Yameogo, D.; Haddag, B.; Makich, H.; Nouari, M. A physical behavior model including dynamic recrystallization and damage mechanisms for cutting process simulation of the titanium alloy Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2019, 100, 333–347. [Google Scholar] [CrossRef]

- Akbari, M.; Buhl, S.; Leinenbach, C.; Wegener, K. A new value for Johnson Cook damage limit criterion in machining with large negative rake angle as basis for understanding of grinding. J. Mater. Process. Technol. 2016, 234, 58–71. [Google Scholar] [CrossRef]

- Alberdi, A.; Artaza, T.; Suárez, A.; Rivero, A.; Girot, F. An experimental study on abrasive waterjet cutting of CFRP/Ti6Al4V stacks for drilling operations. Int. J. Adv. Manuf. Technol. 2016, 86, 691–704. [Google Scholar] [CrossRef]

- Dolatabadi, F. Étude de L’influence du Mode de Lubrification sur les Performances D’usinage du Composite à Matrices D’aluminium. Ph.D. Thesis, École Polytechnique de Montréal, Montreal, QC, Canada, 2010. [Google Scholar]

- Zarrouk, T.; Nouari, M.; Salhi, J.E. Numerical study on rotary ultrasonic machining (RUM) characteristics of Nomex honeycomb composites (NHCs) by UCSB cutting tool. Int. J. Adv. Manuf. Technol. 2024, 132, 5351–5366. [Google Scholar] [CrossRef]

- Keshavanarayana, S.; Thotakuri, M.V. Off-axis compression behaviour of honeycomb core in WT-plane. Int. J. Crashworthiness 2009, 14, 173–181. [Google Scholar] [CrossRef]

| Property | Unit | Value |

|---|---|---|

| Density | Kg/m3 | 2700 |

| Elastic modulus | GPa | 73 |

| Poisson’s ratio | - | 0.33 |

| Thermal conductivity | W/m °C | 117 |

| Specific heat | J/kg °C | 875 |

| A (MPa) | B (MPa) | C | n | m | Tf (°K) | T0 (°K) |

|---|---|---|---|---|---|---|

| 265 | 426 | 0.015 | 0.15 | 0.34 | 683 | 300 |

| Parameters Properties | Value |

|---|---|

| d1 | 0.306 |

| d2 | 0.0446 |

| d3 | –1.72 |

| d4 | 0.0056 |

| d5 | 0.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beldi, O.; Zarrouk, T.; Abbadi, A.; Nouari, M.; Abbadi, M.; Salhi, J.-E.; Barboucha, M. Optimization of Machining Efficiency of Aluminum Honeycomb Structures by Hybrid Milling Assisted by Longitudinal Ultrasonic Vibrations. Processes 2025, 13, 2348. https://doi.org/10.3390/pr13082348

Beldi O, Zarrouk T, Abbadi A, Nouari M, Abbadi M, Salhi J-E, Barboucha M. Optimization of Machining Efficiency of Aluminum Honeycomb Structures by Hybrid Milling Assisted by Longitudinal Ultrasonic Vibrations. Processes. 2025; 13(8):2348. https://doi.org/10.3390/pr13082348

Chicago/Turabian StyleBeldi, Oussama, Tarik Zarrouk, Ahmed Abbadi, Mohammed Nouari, Mohammed Abbadi, Jamal-Eddine Salhi, and Mohammed Barboucha. 2025. "Optimization of Machining Efficiency of Aluminum Honeycomb Structures by Hybrid Milling Assisted by Longitudinal Ultrasonic Vibrations" Processes 13, no. 8: 2348. https://doi.org/10.3390/pr13082348

APA StyleBeldi, O., Zarrouk, T., Abbadi, A., Nouari, M., Abbadi, M., Salhi, J.-E., & Barboucha, M. (2025). Optimization of Machining Efficiency of Aluminum Honeycomb Structures by Hybrid Milling Assisted by Longitudinal Ultrasonic Vibrations. Processes, 13(8), 2348. https://doi.org/10.3390/pr13082348