Multi-Physical Field Intensification Process for Shale Oil Emulsion Dehydration: Parameter Optimization and Mechanisms Exploration

Abstract

1. Introduction

2. Methodology

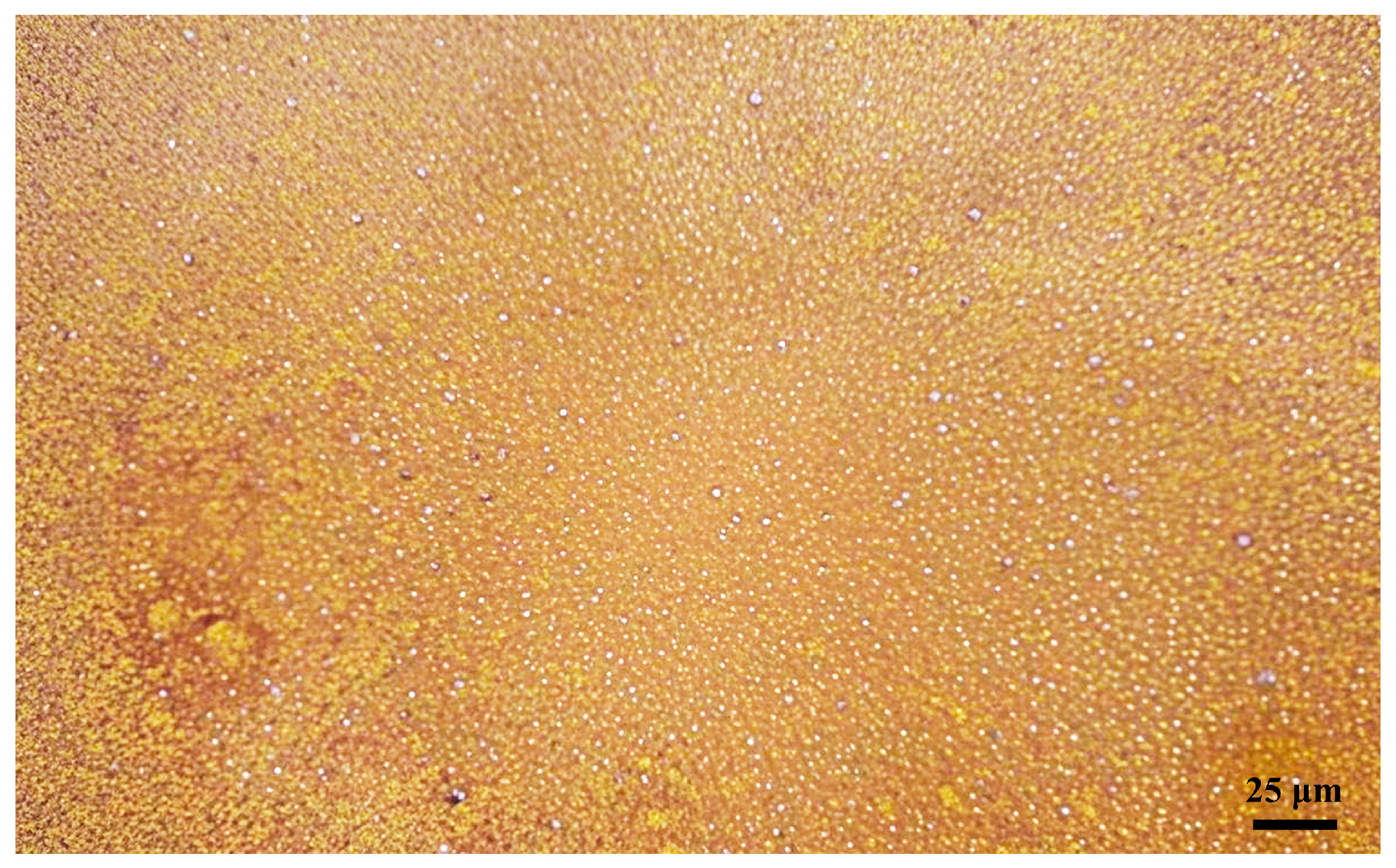

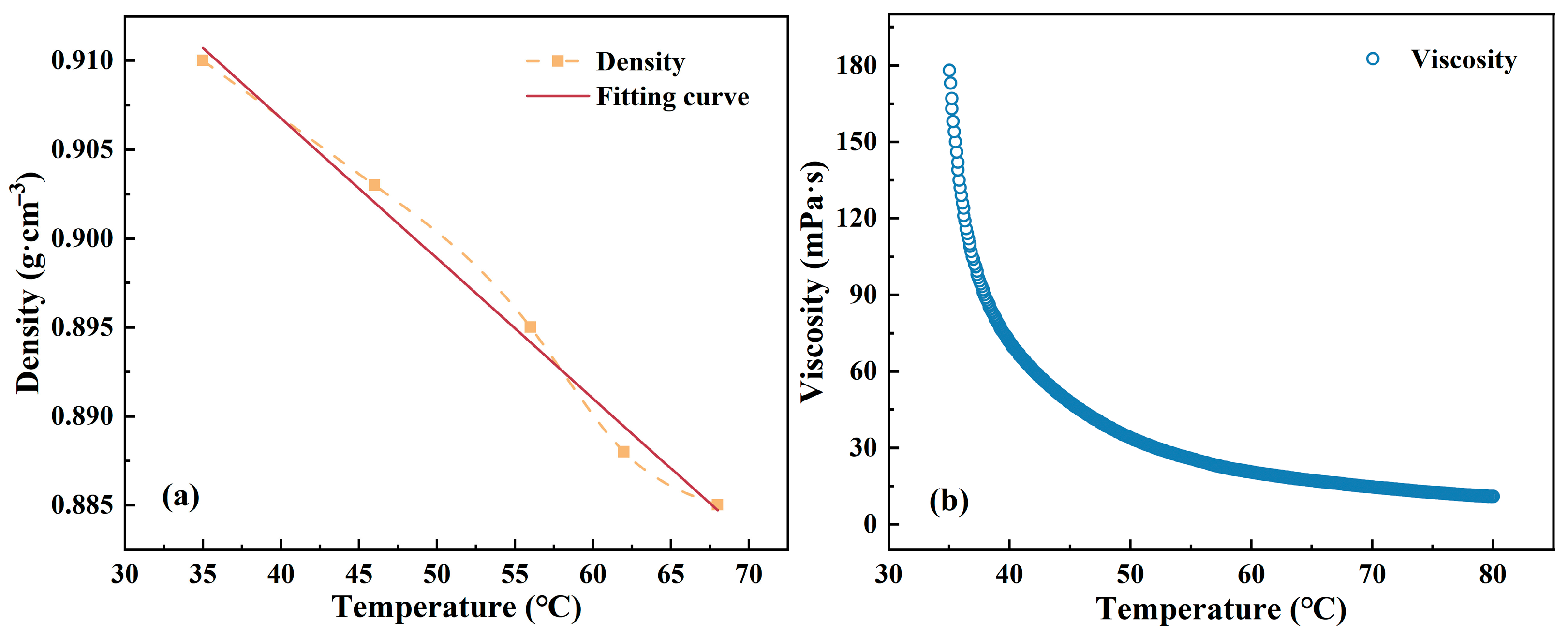

2.1. Materials

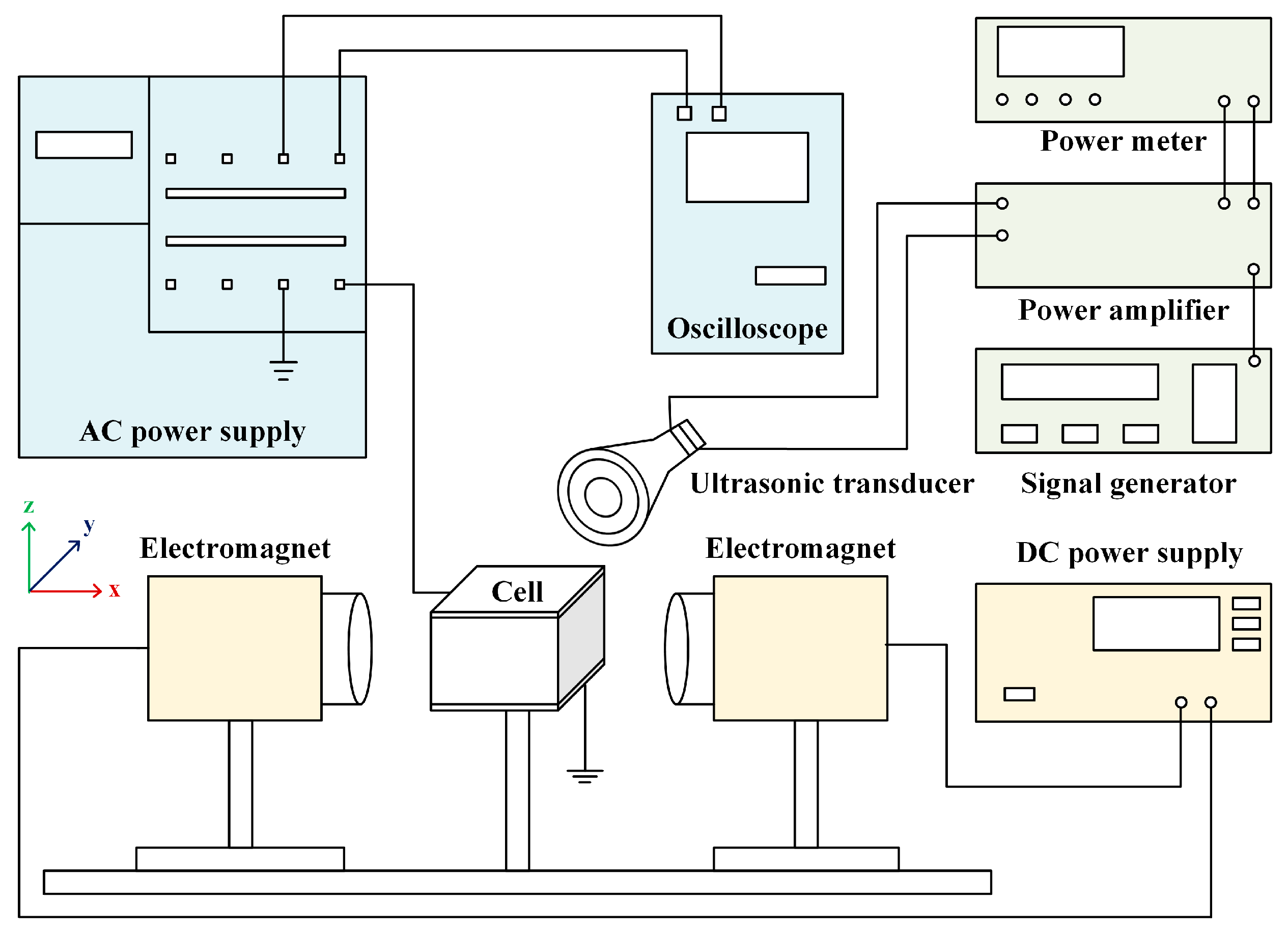

2.2. Experimental Setup

2.3. Performance Evaluation Indicators

3. Results

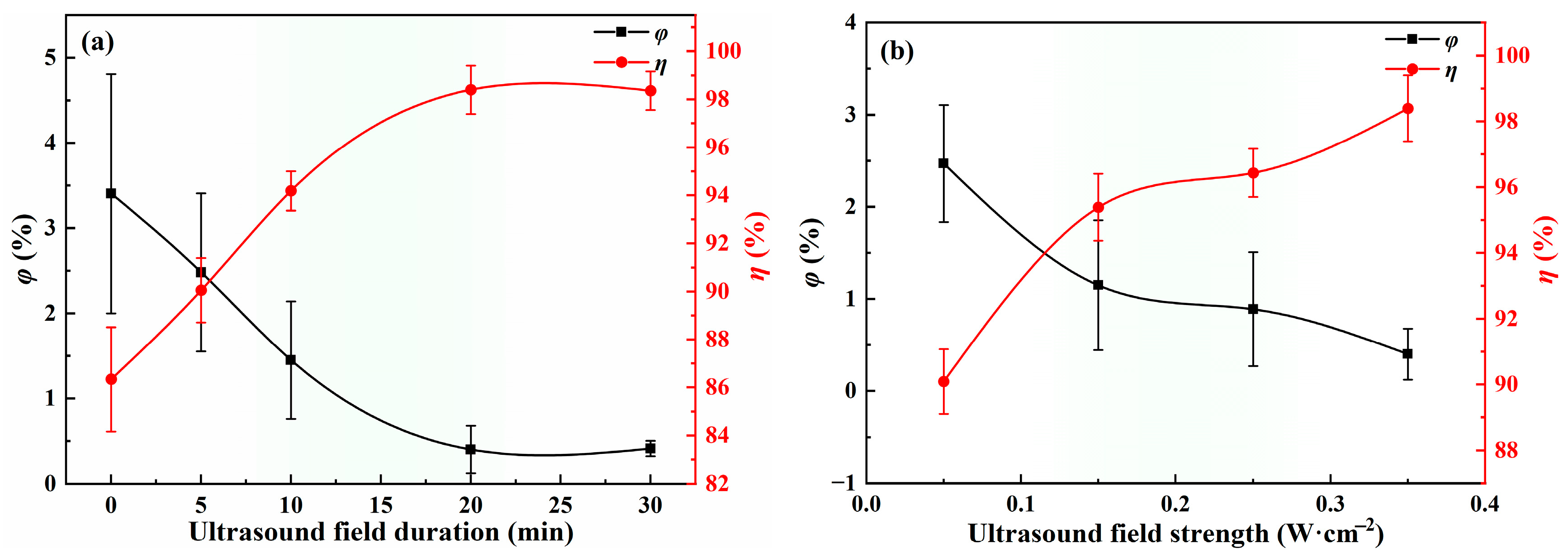

3.1. Dehydration Characteristics of Shale Oil Emulsion Under a Single Physical Field

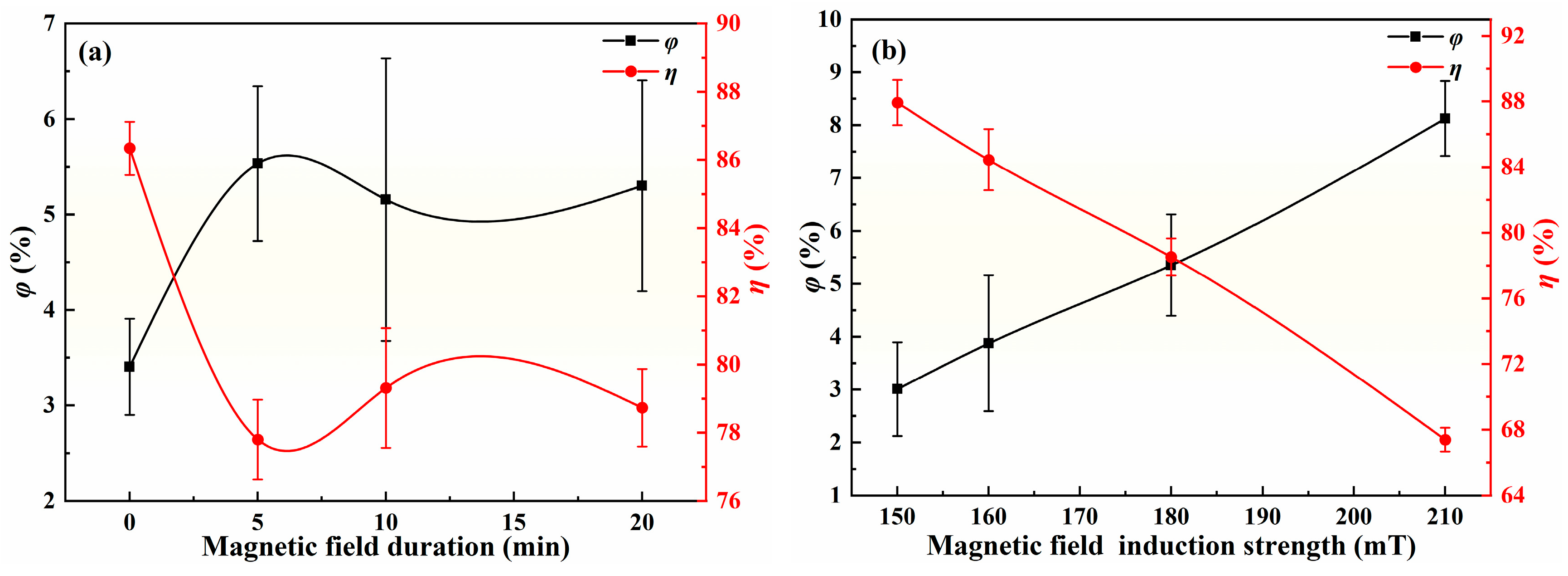

3.2. Dehydration Characteristics of Shale Oil Emulsion Under Dual Physical Fields

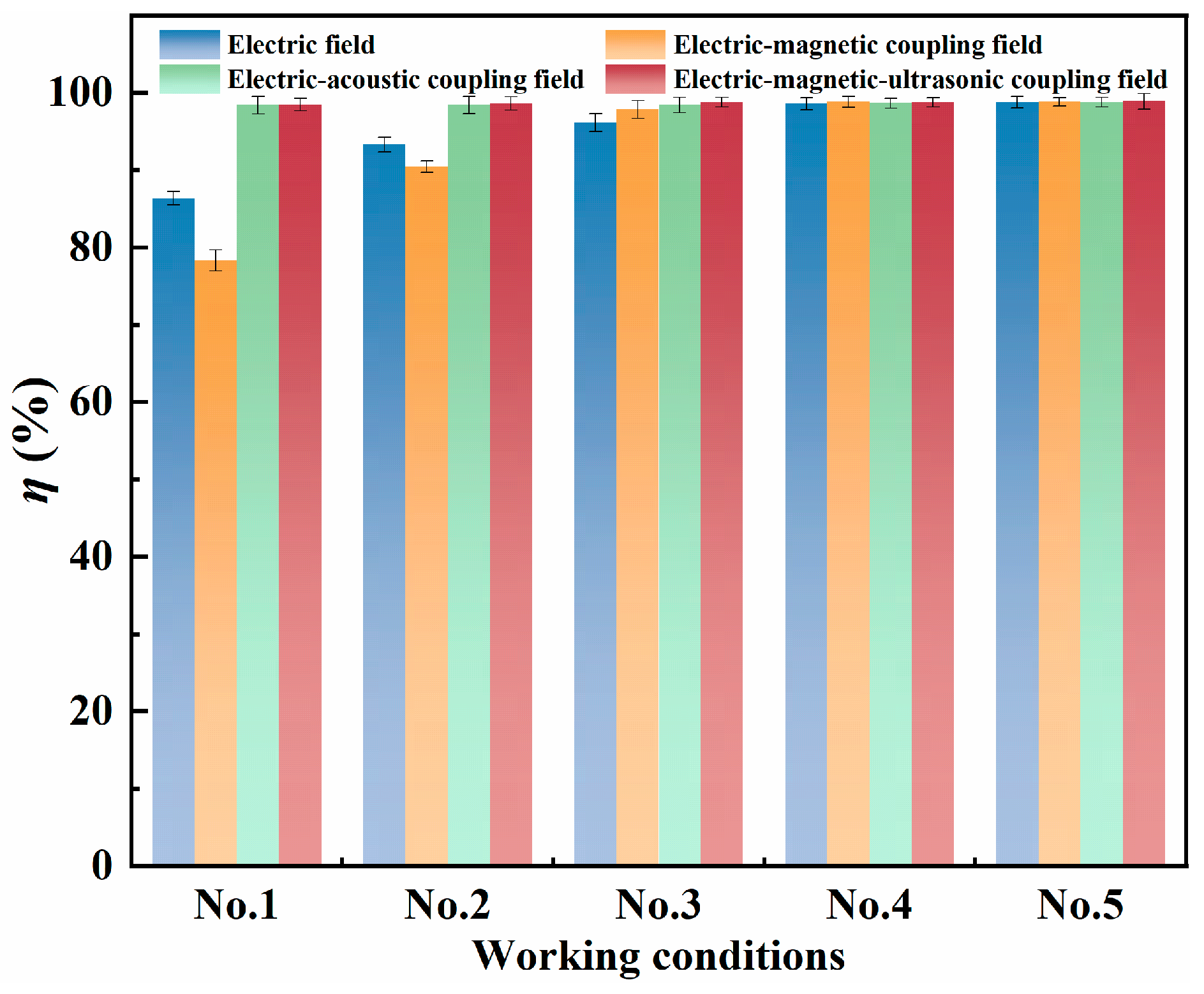

3.3. Dehydration Characteristics of Shale Oil Emulsion Under Multiple Coupled Fields

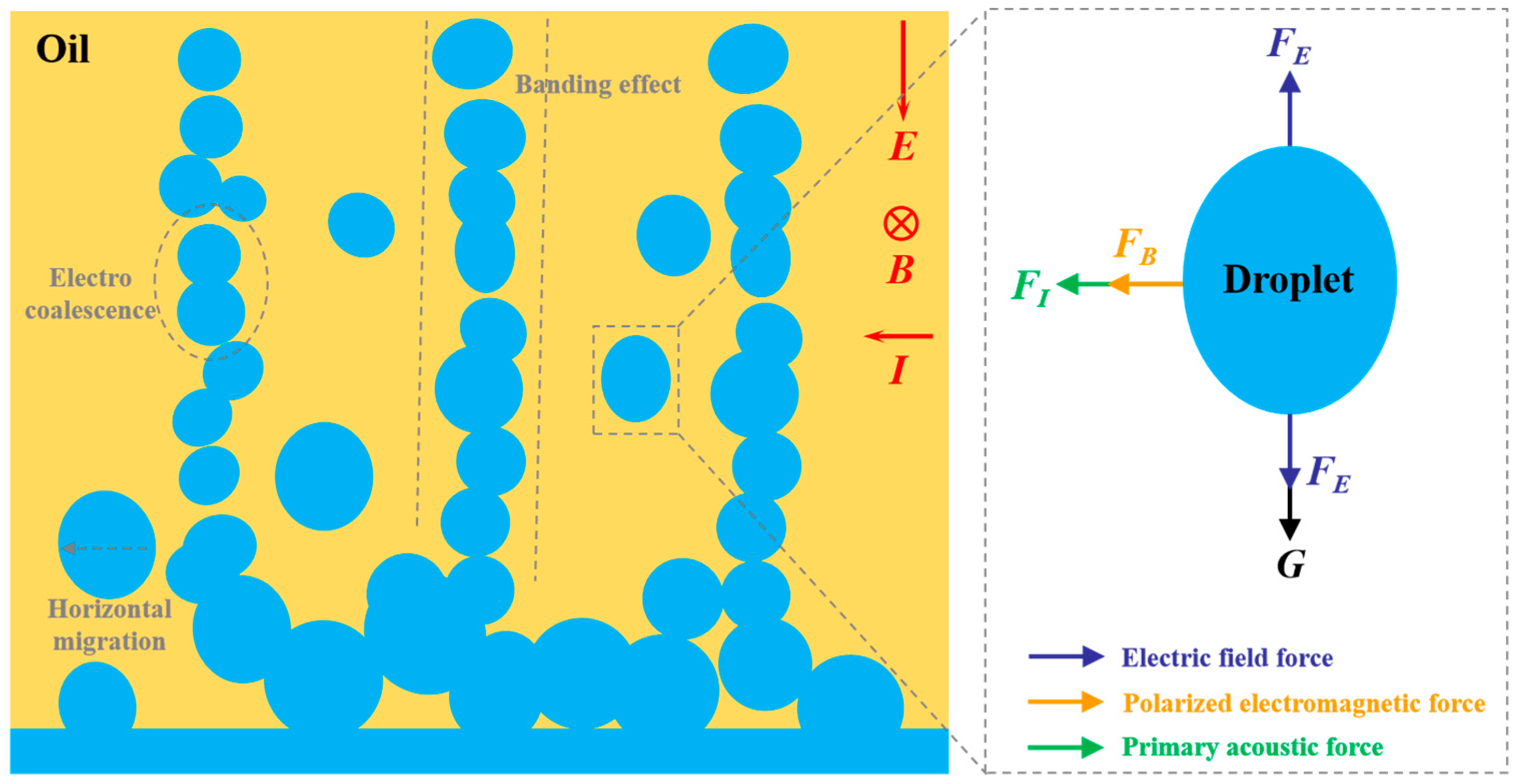

3.4. Dehydration Mechanisms Based on the Droplet Force Model Under Multiple Coupled Fields

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, H.; Li, T.; Li, Z.; Fan, D.; Zhang, L.; Yang, Y.; Zhang, K.; Zhong, J.; Yao, J. Shale oil redistribution-induced flow regime transition in nanopores. Energy 2023, 282, 128553. [Google Scholar] [CrossRef]

- He, L.; Lin, F.; Li, X.; Sui, H.; Xu, Z. Interfacial sciences in unconventional petroleum production: From fundamentals to applications. Chem. Soc. Rev. 2015, 44, 5446–5494. [Google Scholar] [CrossRef] [PubMed]

- Cai, J.; Jiao, X.; Wang, H.; He, W.; Xia, Y. Multiphase fluid-rock interactions and flow behaviors in shale nanopores: A comprehensive review. Earth-Sci. Rev. 2024, 257, 104884. [Google Scholar] [CrossRef]

- Yang, D.; Li, M.; Cheng, X.; Feng, Q.; Yang, F.; He, L. Electrical dehydration performance of shale oil: From emulsification characteristics to dehydration mechanisms. Colloids Surf. A Physicochem. Eng. Asp. 2023, 676, 132205. [Google Scholar] [CrossRef]

- Guo, K.; Du, L.; Lü, Y.; He, L.; Luo, X.; Bai, Y. Double layer characteristics of droplets dispersed with Na2CO3 in EMSF that is applied to dehydration of Shale oil. Chem. Eng. Process. 2023, 194, 109587. [Google Scholar] [CrossRef]

- Tian, Y.; Qi, Y.; Chen, S.; Han, H.; Wang, H.; Gong, X.; Zhang, M.; Jiang, X.; Chen, Y. Recombination of hydrogen bonds clipping interfacial film effectively for dehydrated tight oil. Sep. Purif. Technol. 2023, 319, 124093. [Google Scholar] [CrossRef]

- McCoy, T.M.; Pottage, M.J.; Tabor, R.F. Graphene Oxide-Stabilized Oil-in-Water Emulsions: pH-Controlled Dispersion and Flocculation. J. Phys. Chem. C 2014, 118, 4529–4535. [Google Scholar] [CrossRef]

- Yang, D.; Feng, Y.; Wang, B.; Liu, Y.; Zheng, Y.; Sun, X.; Peng, J.; Feng, M.; Wang, D. An asymmetric AC electric field of triboelectric nanogenerator for efficient water/oil emulsion separation. Nano Energy 2021, 90, 106641. [Google Scholar] [CrossRef]

- Gu, Y.; Xia, Q.; Liu, B.; Zhao, Y.; Pu, L.; Ding, J.; Liu, Y.; Li, E.; Vecitis, D.C.; Gao, G. Electric Demulsification Membrane Technology for Confined Separation of Oil–Water Emulsions. Environ. Sci. Technol. 2024, 58, 20277–20288. [Google Scholar] [CrossRef]

- Chen, J.; Weng, S.; Tao, W.; Song, M.; Zhang, L. Measuring carbon neutrality and exploring the threshold effects of its driving factors: Evidence from China. Appl. Energy 2024, 373, 123824. [Google Scholar] [CrossRef]

- Zhang, J.; Meng, H.; Chen, L.; Zhang, Y.; Fu, Z.; Xie, Y.; Guo, H. Reversing climate policy stereotypes: Evidence from an energy-dependent region and China’s major economic circles. Appl. Energy 2025, 380, 125026. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, W.; Wang, Z.; Hu, L.; Hou, J.; An, T. Green Electricity and Green Hydrogen Demonstration Construction of Yumen Oilfield. China Oil Gas 2024, 31, 23–28. [Google Scholar]

- Eow, J.S.; Ghadiri, M. Electrostatic enhancement of coalescence of water droplets in oil: A review of the technology. Chem. Eng. J. 2002, 85, 357–368. [Google Scholar] [CrossRef]

- Tian, Y.; Qi, Y.; Chen, S.; Qiao, Z.; Han, H.; Chen, Z.; Wang, H.; Zhang, Y.; Chen, H.; Wang, L.; et al. Hydrogen bond recombination regulated by strongly electronegative functional groups in demulsifiers for efficient separation of oil–water emulsions. J. Hazard. Mater. 2024, 461, 132525. [Google Scholar] [CrossRef]

- Huang, X.; He, L.; Luo, X.; Xu, K.; Lü, Y.; Yang, D. Charge-Transfer-Induced Noncoalescence and Chain Formation of Free Droplets under a Pulsed DC Electric Field. Langmuir 2020, 36, 14255–14267. [Google Scholar] [CrossRef]

- Li, B.; Ju, M.; Dou, X.; Li, N.; Zhang, W.; Sun, Z.; Yu, K.; Wang, J.; Wang, Z. Assessing nanoparticle-surfactant-salt synergistic effects on droplet–droplet electrocoalescence by molecular dynamics simulations. J. Mol. Liq. 2022, 367, 120570. [Google Scholar] [CrossRef]

- Niu, J.; Wang, J.; Zeng, X.F. A New Type Apparatus Used in Laboratory Aging Oil Electric Dehydration. Dev. Innov. Mach. Electr. Prod. 2013, 26, 55–57. [Google Scholar] [CrossRef]

- Jin, Y.; Hu, J.; Sun, Z.; Wang, Z. Experimental Study of Factors Acting on the Performance of High-Voltage and High-Frequency Pulse Electrostatic Dewatering Process. J. Chem. Eng. Chin. Univ. 2010, 24, 917–922. [Google Scholar] [CrossRef]

- Chen, Q.; Wei, X.; Wang, Y.; Zhu, B. Composite Crude Oil Electric Dewatering High-Voltage Power Supply and Its Control Device. CN101550353B, 5 October 2023. [Google Scholar]

- Hamidi, H.; Haddad, A.S.; Otumudia, E.W.; Rafati, R.; Mohammadian, E.; Azdarpour, A.; Pilcher, W.G.; Fuehrmann, P.W.; Sosa, L.R.; Cota, N.; et al. Recent applications of ultrasonic waves in improved oil recovery: A review of techniques and results. Ultrasonics 2021, 110, 106288. [Google Scholar] [CrossRef]

- Heydari, M.; Amirjani, A.; Bagheri, M.; Sharifian, I.; Sabahi, Q. Eco-friendly pesticide based on peppermint oil nanoemulsion: Preparation, physicochemical properties, and its aphicidal activity against cotton aphid. Environ. Sci. Pollut. Res. 2020, 27, 6667–6679. [Google Scholar] [CrossRef]

- Bo, J.X. Study on Dehydration Characteristics and Mechanism of Crude Oil Emulsion Under the Combination of Ultrasonic and Electric Field. Master’s Thesis, Harbin University of Science and Technology, Harbin, China, 2020. [Google Scholar]

- Zhu, Z.; Hou, L.; Zhang, X.; Liu, J.; Sun, X.; Xiong, Y. Research on Apparent Viscosity Variation of Water-in-Oil Waxy Crude Oil Emulsions Induced by a Magnetic Field. Ind. Eng. Chem. Res. 2024, 63, 17901–17916. [Google Scholar] [CrossRef]

- Tao, R.; Xu, X. Reducing the Viscosity of Crude Oil by Pulsed Electric or Magnetic Field. Energy Fuels 2006, 20, 2046–2051. [Google Scholar] [CrossRef]

- Homayuni, F.; Hamidi, A.A.; Vatani, A.; Shaygani, A.A.; Dana, R.F. The Viscosity Reduction of Heavy and Extra Heavy Crude Oils by a Pulsed Magnetic Field. Pet. Sci. Technol. 2011, 29, 2407–2415. [Google Scholar] [CrossRef]

- Guo, K.; Lv, Y.; He, L.; Luo, X.; Yang, D. Experimental study on the dehydration performance of synergistic effect of electric field and magnetic field. Chem. Eng. Process. 2019, 142, 107555. [Google Scholar] [CrossRef]

- Guo, K.; Lv, Y.; He, L.; Luo, X.; Yang, D. Separation characteristics of water-in-oil emulsion under the coupling of electric field and magnetic field. Energy Fuels 2019, 33, 2565–2574. [Google Scholar] [CrossRef]

- Guo, K.; Lv, Y.; He, L.; Luo, X.; Zhao, J. Experimental study on the effect of spatial distribution and action order of electric field and magnetic field on oil-water separation. Chem. Eng. Process. 2019, 145, 107658. [Google Scholar] [CrossRef]

- Eow, J.S.; Ghadiri, M.; Sharif, A.O.; Williams, T.J. Electrostatic enhancement of coalescence of water droplets in oil: A review of the current understanding. Chem. Eng. J. 2001, 84, 173–192. [Google Scholar] [CrossRef]

- Huang, X.; He, L.; Luo, X.; Yin, H. Droplet dynamic response in low-viscosity fluid subjected to a pulsed electric field and an alternating electric field. AIChE J. 2020, 66, e16869. [Google Scholar] [CrossRef]

- Yang, D.; Wu, H.; Sun, H.; He, L.; Guo, Y. Ultra-high frequency and Self-adaptive voltage technology for water separation from oil emulsion. Sep. Purif. Technol. 2021, 279, 119732. [Google Scholar] [CrossRef]

- Li, B.; Dou, X.; Yu, K.; Li, N.; Zhang, W.; Xu, H.; Sun, Z.; Wang, Z.; Wang, J. Molecular dynamics simulations of nanoparticle-laden drop–interface electrocoalescence behaviors under direct and alternating current electric fields. J. Mol. Liq. 2021, 344, 117875. [Google Scholar] [CrossRef]

- Aryafard, E.; Farsi, M.; Rahimpour, M.R.; Raeissi, S. Modeling electrostatic separation for dehydration and desalination of crude oil in an industrial two-stage desalting plant. J. Taiwan Inst. Chem. Eng. 2016, 58, 141–147. [Google Scholar] [CrossRef]

- Luo, X.; Yan, H.; Huang, X.; Yang, D.; Wang, J.; He, L. Breakup characteristics of aqueous droplet with surfactant in oil under direct current electric field. J. Colloid Interface Sci. 2017, 505, 460–466. [Google Scholar] [CrossRef] [PubMed]

- Campos-Sofia, M.; Silveira-Font, Y.; Moro-Martínez, A.; Mulet-González, D.; Falcón-Hernández, J. Caracterización microscópica de mezclas de petróleo y agua con tratamiento eléctrico y magnético. Tecnol. Quim. 2016, 36, 210–224. [Google Scholar]

- Guo, K.; Bai, Y.; Yuan, F.; Liu, X.; Ling, X.; Wang, L.; Du, L. Critical coalescence electric intensity of water droplets adsorbing surfactant molecules under electromagnetic synergy field. Chem. Eng. Process. 2023, 191, 109481. [Google Scholar] [CrossRef]

- Guo, K.; Du, L.; Ling, X.; Lü, Y.; He, L.; Luo, X. Microscopic Mechanism for Gradient Diffusion of Salt-Containing Droplets Induced by Electromagnetic Synergy: A Molecular Dynamics Study. Langmuir 2024, 40, 15926–15932. [Google Scholar] [CrossRef]

- Li, M.; Yang, D.; Lv, S.; Zhao, X.; Wang, J.; Xia, M.; He, L. Understanding the enhancement mechanism of critical electric field strength for salt-laden droplets electric coalescence through synchronous coupled magnetic field. Colloids Surf. A Physicochem. Eng. Asp. 2024, 703, 135254. [Google Scholar] [CrossRef]

- Guo, K.; Liu, X.; Du, L.; Lü, Y.; Luo, X.; Ling, X. Electrocoalescence Behavior of Droplets Dispersed with Na2CO3 in Oil under the Electromagnetic Synergy Field. J. Phys. Chem. B 2023, 127, 5668–5675. [Google Scholar] [CrossRef]

- Li, M.; Yang, D.; Chen, C.; Lv, S.; Miao, J.; He, L. Expansion and growth of liquid bridge in saline water-in-oil emulsion under synchronized magnetic field coupled low-intensity electric field. Phys. Fluids 2024, 36, 072013. [Google Scholar] [CrossRef]

- Guo, K.; Du, L.; Lü, Y.; Bai, Y.; He, L.; Luo, X. Synchronous magnetization to weaken the hindrance of surfactants to droplet coalescence during electric dehydration. Phys. Fluids 2024, 36, 012104. [Google Scholar] [CrossRef]

- Luo, X.; Cao, J.; Yan, H.; Gong, H.; Yin, H.; He, L. Study on separation characteristics of water in oil (W/O) emulsion under ultrasonic standing wave field. Chem. Eng. Process. 2018, 123, 214–220. [Google Scholar] [CrossRef]

- Luo, X.; Cao, J.; Yin, H.; Yan, H.; He, L. Droplets banding characteristics of water-in-oil emulsion under ultrasonic standing waves. Ultrason. Sonochem. 2018, 41, 319–326. [Google Scholar] [CrossRef] [PubMed]

- Cheng, P.Y.; Schachman, H.K. Studies on the validity of the Einstein viscosity law and Stokes’ law of sedimentation. J. Polym. Sci. 1955, 16, 19–30. [Google Scholar] [CrossRef]

- Ha, J.-W.; Yang, S. Deformation and breakup of Newtonian and non-Newtonian conducting drops in an electric field. J. Fluid Mech. 2000, 405, 131–156. [Google Scholar] [CrossRef]

- Klingenberg, D.J.; van Swol, F.; Zukoski, C.F. The small shear rate response of electrorheological suspensions. II. Extension beyond the point–dipole limit. J. Chem. Phys. 1991, 94, 6170–6178. [Google Scholar] [CrossRef]

- Pangu, G.D.; Feke, D.L. Droplet transport and coalescence kinetics in emulsions subjected to acoustic fields. Ultrasonics 2007, 46, 289–302. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Oil–water interfacial tension (mN·m−1) | 25.41 |

| Zeta potential (mV) | −5.06 |

| Relative dielectric constant | 1.94 |

| Wax content (w.%) | 16.47 |

| Saturates (w.%) | 50.86 |

| Aromatics (w.%) | 16.07 |

| Resins (w.%) | 17.47 |

| Asphaltenes (w.%) | 0.50 |

| External Field Strength | Duration | Operating Temperature | Pre-Treatment Water Content | Post-Treatment Water Content | Relative Dewatering Rate |

|---|---|---|---|---|---|

| Single magnetic field | |||||

| 210 mT | 10 min | 70 °C | 24.92% | 22.42% | 10.00% |

| 210 mT | 30 min | 70 °C | 24.92% | 23.21% | 6.86% |

| Single ultrasonic field | |||||

| 0.35 W·cm−2 | 10 min | 70 °C | 24.92% | 24.45% | 1.89% |

| 0.35 W·cm−2 | 30 min | 70 °C | 24.92% | 23.55% | 5.50% |

| No. | Electric Field | Magnetic Field | Ultrasonic Field | T (℃) | φ (%) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Strength (kV·m−1) | Frequency (kHz) | Duration (min) | Strength (mT) | Duration (min) | Strength (W·cm−2) | Duration (min) | |||

| 1 | 150 | 5 | 60 | 210 | 10 | 0.35 | 20 | 70 | 0.38 |

| 2 | 200 | 5 | 60 | 210 | 10 | 0.35 | 20 | 70 | 0.35 |

| 3 | 250 | 5 | 60 | 210 | 10 | 0.35 | 20 | 70 | 0.30 |

| 4 | 250 | 5 | 60 | 210 | 10 | 0.35 | 20 | 75 | 0.31 |

| 5 | 250 | 5 | 60 | 210 | 10 | 0.35 | 20 | 80 | 0.28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, Y.; Huang, Q.; Li, Q.; Li, Z.; Yang, D.; Li, M.; Liang, B. Multi-Physical Field Intensification Process for Shale Oil Emulsion Dehydration: Parameter Optimization and Mechanisms Exploration. Processes 2025, 13, 2167. https://doi.org/10.3390/pr13072167

Liang Y, Huang Q, Li Q, Li Z, Yang D, Li M, Liang B. Multi-Physical Field Intensification Process for Shale Oil Emulsion Dehydration: Parameter Optimization and Mechanisms Exploration. Processes. 2025; 13(7):2167. https://doi.org/10.3390/pr13072167

Chicago/Turabian StyleLiang, Yuejiu, Qian Huang, Qing Li, Zhibiao Li, Donghai Yang, Mofan Li, and Bing Liang. 2025. "Multi-Physical Field Intensification Process for Shale Oil Emulsion Dehydration: Parameter Optimization and Mechanisms Exploration" Processes 13, no. 7: 2167. https://doi.org/10.3390/pr13072167

APA StyleLiang, Y., Huang, Q., Li, Q., Li, Z., Yang, D., Li, M., & Liang, B. (2025). Multi-Physical Field Intensification Process for Shale Oil Emulsion Dehydration: Parameter Optimization and Mechanisms Exploration. Processes, 13(7), 2167. https://doi.org/10.3390/pr13072167