Cacao in the Circular Economy: A Review on Innovations from Its By-Products

Abstract

1. Introduction

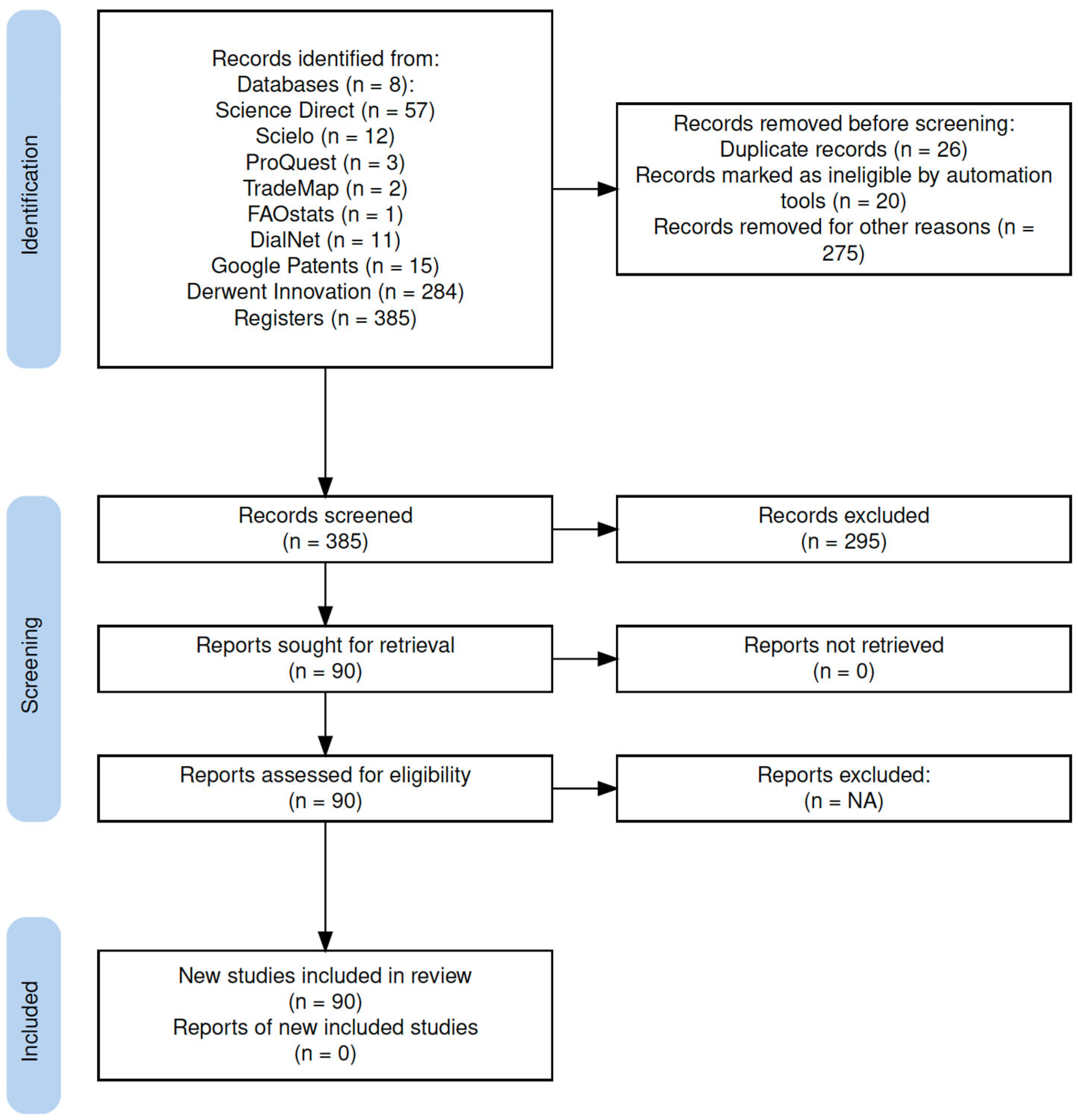

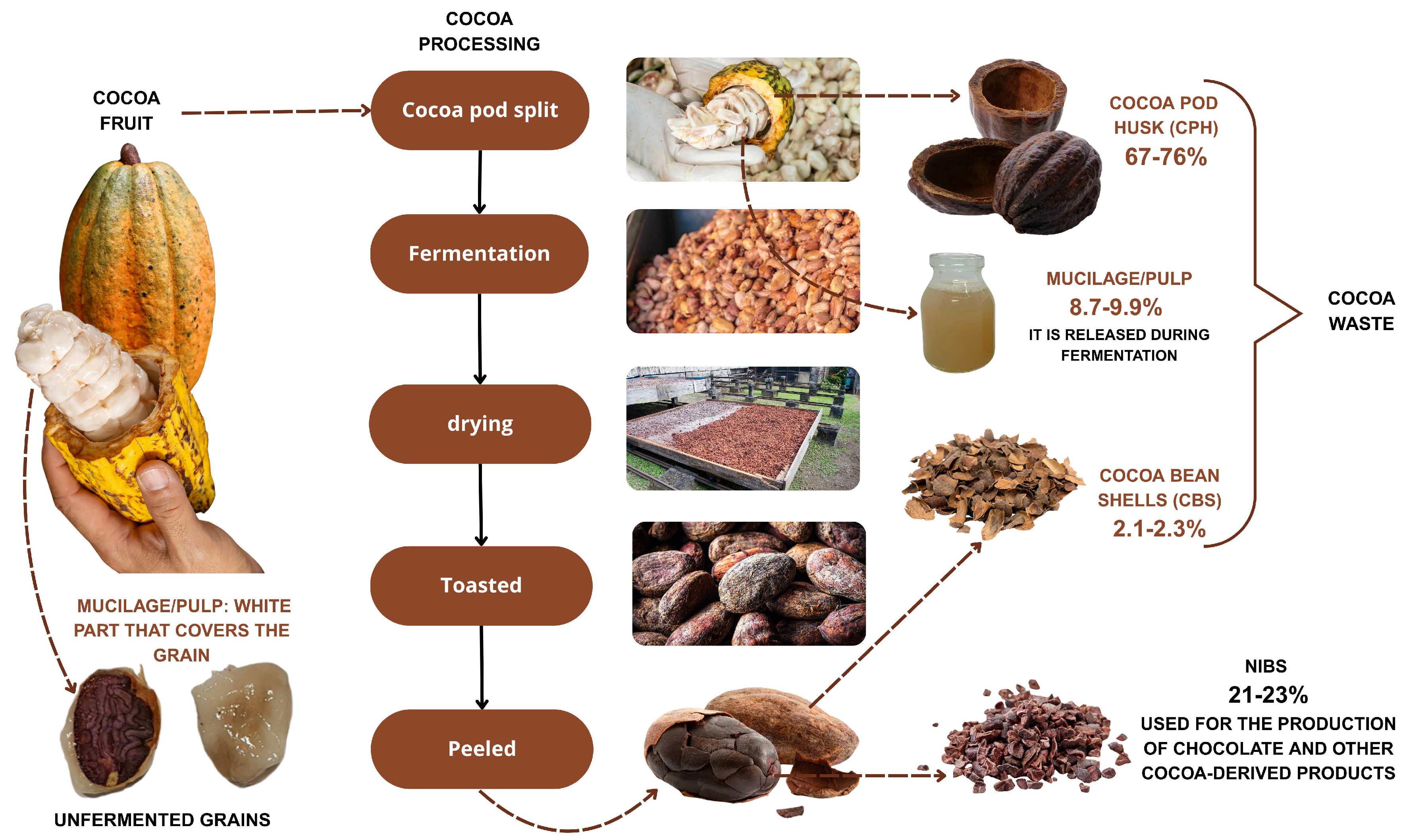

2. Methodology

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, R.; Das, R.; Sangwan, S.; Rohatgi, B.; Khanam, R.; Peera, S.K.P.G.; Das, S.; Lyngdoh, Y.A.; Langyan, S.; Shukla, A.; et al. Utilisation of Agro-Industrial Waste for Sustainable Green Production: A Review. Environ. Sustain. 2021, 4, 619–636. [Google Scholar] [CrossRef]

- François, M.; Pontes, M.C.G.; da Silva, A.L.; Mariano-Neto, E. Impacts of Cacao Agroforestry Systems on Climate Change, Soil Conservation, and Water Resources: A Review. Water Policy 2023, 25, 564–581. [Google Scholar] [CrossRef]

- Meza-Sepúlveda, D.C.; Castro, A.M.; Zamora, A.; Arboleda, J.W.; Gallego, A.M.; Camargo-Rodríguez, A.V. Bio-Based Value Chains Potential in the Management of Cacao Pod Waste in Colombia, a Case Study. Agronomy 2021, 11, 693. [Google Scholar] [CrossRef]

- Salazar-Camacho, N.A.; Delgadillo-Mirquez, L.; Sanchez-Echeverri, L.A.; Tovar-Perilla, N.J. Evaluating Sustainable Alternatives for Cacao Waste Utilization Using the Analytic Hierarchy Process. Sustainability 2024, 16, 7817. [Google Scholar] [CrossRef]

- Isabel, A.; Maldonado, L.; Bugarin, A.; Iquise, A.; Dolianitis, B.M.; Vinícius Tres, M.; Zabot, G.L.; Olivera-Montenegro, L. Integration of Emerging and Conventional Technologies for Obtaining By-Products from Cacao Pod Husk and Their Application. Processes 2025, 13, 1264. [Google Scholar] [CrossRef]

- Godoy Padilla, D.J.; Daza La Plata, R.; Fernández Curi, L.M.; Layza Mendiola, A.E.; Roque Alcarraz, R.E.; Hidalgo Lozano, V.; Gamarra Carrillo, S.G.; Gómez Bravo, C.A. Characterization of the Nutritional Value of Agroindustrial By-Products for Cattle Feeding in the San Martin Region, Peru. Cienc. Tecnol. Agropecu. 2020, 21, 1374. [Google Scholar] [CrossRef]

- Ordoñez, E.S.; Leon-Arevalo, A.; Rivera-Rojas, H.; Vargas, E. Quantification of Total Polyphenols and Antioxidant Capacity in Skins and Seeds from Cacao (Theobroma cacao L.), Tuna (Opuntia ficus indica Mill), Grape (Vitis vinífera) and Uvilla (Pourouma cecropiifolia). Sci. Agropecu. 2019, 10, 175–183. [Google Scholar] [CrossRef]

- FAOSTAT. Estadisticas de Producción de Alimentos. Available online: https://www.fao.org/faostat/es/#data/QCL (accessed on 4 May 2022).

- Campos-Vega, R.; Nieto-Figueroa, K.H.; Oomah, B.D. Cacao (Theobroma cacao L.) Pod Husk: Renewable Source of Bioactive Compounds. Trends Food Sci. Technol. 2018, 81, 172–184. [Google Scholar] [CrossRef]

- Vriesmann, L.C.; de Mello Castanho Amboni, R.D.; De Oliveira Petkowicz, C.L. Cacao Pod Husks (Theobroma cacao L.): Composition and Hot-Water-Soluble Pectins. Ind. Crops Prod. 2011, 34, 1173–1181. [Google Scholar] [CrossRef]

- Akinjokun, A.I.; Petrik, L.F.; Ogunfowokan, A.O.; Ajao, J.; Ojumu, T.V. Isolation and Characterization of Nanocrystalline Cellulose from Cacao Pod Husk (CPH) Biomass Wastes. Heliyon 2021, 7, e06680. [Google Scholar] [CrossRef]

- Dewan, A.; Malik, M.; Shobhit; Chaudhary, V.; Sharma, A. Packaging Applications of Cacao Pod Husk. In Agro-Wastes for Packaging Applications; CRC Press: Boca Raton, FL, USA, 2024; pp. 264–287. [Google Scholar] [CrossRef]

- Nešić, A.; Lučić, M.; Vesković, J.; Mandić, L.J.; Momčilović, M.; Miletić, A.; Onjia, A. Impact of Chocolate Cadmium on Vulnerable Populations in Serbia. Foods 2025, 14, 18. [Google Scholar] [CrossRef] [PubMed]

- Valadez-Carmona, L.; Plazola-Jacinto, C.P.; Hernández-Ortega, M.; Hernández-Navarro, M.D.; Villarreal, F.; Necoechea-Mondragón, H.; Ortiz-Moreno, A.; Ceballos-Reyes, G. Effects of Microwaves, Hot Air and Freeze-Drying on the Phenolic Compounds, Antioxidant Capacity, Enzyme Activity and Microstructure of Cacao Pod Husks (Theobroma cacao L.). Innov. Food Sci. Emerg. Technol. 2017, 41, 378–386. [Google Scholar] [CrossRef]

- Neto, B.A.d.M.; Carvalho, E.A.; Pontes, K.V.; Barretto, W.d.S.; do Sacramento, C.K. Chemical, Physico-Chemical and Sensory Characterization of Mixed Açai (Euterpe oleracea) and Cacao’s Honey (Theobroma cacao) Jellies. Rev. Bras. Frutic. 2013, 35, 587–593. [Google Scholar] [CrossRef]

- Ramos-Escudero, F.; Rojas-García, A.; Cádiz-Gurrea, M.d.l.L.; Segura-Carretero, A. High Potential Extracts from Cacao Byproducts through Sonotrode Optimal Extraction and a Comprehensive Characterization. Ultrason. Sonochem. 2024, 106, 106887. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Tran, A.X.; Le, V.A.T. Microencapsulation of Phenolic-Enriched Extract from Cacao Pod Husk (Theobroma cacao L.). Powder Technol. 2021, 386, 136–143. [Google Scholar] [CrossRef]

- de Oliveira, P.Z.; de Souza Vandenberghe, L.P.; Rodrigues, C.; de Melo Pereira, G.V.; Soccol, C.R. Exploring Cacao Pod Husks as a Potential Substrate for Citric Acid Production by Solid-State Fermentation Using Aspergillus niger Mutant Strain. Process Biochem. 2022, 113, 107–112. [Google Scholar] [CrossRef]

- Bickel Haase, T.; Klis, V.; Hammer, A.K.; Pinto Lopez, C.; Verheyen, C.; Naumann-Gola, S.; Zorn, H. Fermentation of Cacao Pod Husks with Pleurotus salmoneo-stramineus for Food Applications. Food Sci. Nutr. 2024, 12, 2551–2566. [Google Scholar] [CrossRef]

- Chochkov, R.; Denkova, R.; Denkova, Z.; Denev, P.; Vasileva, I.; Dessev, T.; Simitchiev, A.; Nenov, V.; Slavov, A. Utilization of Industrial Rosa damascena Mill. By-Products and Cacao Pod Husks as Natural Preservatives in Muffins. Period. Polytech. Chem. Eng. 2022, 66, 157–166. [Google Scholar] [CrossRef]

- Nguyen, V.L.; Tran, M.T.; Nguyen-Thi, T.D.; Nguyen, M.A.; Le, M.T.; Nguyen, T.M.; Nguyen, Q.D. Valorization of Cacao (Theobroma cacao L.) Pod Husks as a Fruit Pulp Substitute in Mango Jam Formulations: Effects on Jam Qualities during Storage and Sensory Discrimination. Sustain. Food Technol. 2025, 3, 333–342. [Google Scholar] [CrossRef]

- Yepes-Nuñez, J.J.; Urrútia, G.; Romero-García, M.; Alonso-Fernández, S. Declaración PRISMA 2020: Una Guía Actualizada Para La Publicación de Revisiones Sistemáticas. Rev. Esp. Cardiol. 2021, 74, 790–799. [Google Scholar] [CrossRef]

- Gavrilova, N.G. Contemporary Global Production and Consumption of Cacao: An Assessment. IOP Conf. Ser. Earth Environ. Sci. 2021, 839, 022095. [Google Scholar] [CrossRef]

- Vallejo, C.; Díaz, R.; Morales, W.; Soria, R.; Fabian, V.; Chang, J.; Baren, C. Utilización Del Mucílago de Cacao, Tipo Nacional y Trinitario, En La Obtención de Jalea. Rev. ESPAMCIENCIA 2016, 7, 51–58. [Google Scholar]

- Dewi, S.R.; Stevens, L.; Irvine, D.; Ferrari, R. Microwave-Assisted Extraction of Phenolic From Cacao Pod Husks—An Alternative for Valorisation. In Proceedings of the 18th International Conference on Microwave and High-Frequency Applications: AMPERE 2021, Gothenburg, Sweden, 13–16 September 2021; Volume 1. [Google Scholar]

- Guirlanda, C.P. Caracterização, Estudo do Processamento e Conservação do Mel de Cacau. Ph.D. Thesis, Universidade Federal de Minas Gerais, Belo Horizonte, Brazil, 2022. [Google Scholar]

- Trademap. Lista de Importadores Para el Producto Seleccionado en 2022 Producto: 18 Cacao y Preparados de Cacao. Available online: https://www.trademap.org/Country_SelProduct.aspx?nvpm=1%7C%7C%7C%7C%7C18%7C%7C%7C2%7C1%7C1%7C1%7C1%7C%7C2%7C1%7C%7C1 (accessed on 16 September 2022).

- Delgado-Ospina, J.; Lucas-González, R.; Viuda-Martos, M.; Fernández-López, J.; Pérez-Álvarez, J.Á.; Martuscelli, M.; Chaves-López, C. Bioactive Compounds and Techno-Functional Properties of High-Fiber Co-Products of the Cacao Agro-Industrial Chain. Heliyon 2021, 7, e06799. [Google Scholar] [CrossRef]

- Brunerová, A.; Roubík, H.; Brožek, M.; Herák, D.; Šleger, V.; Mazancová, J. Potential of Tropical Fruit Waste Biomass for Production of Bio-Briquette Fuel: Using Indonesia as an Example. Energies 2017, 10, 2119. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, M.; Chen, H.; Li, Y.; Chen, S. Globalization, Green Economy and Environmental Challenges: State of the Art Review for Practical Implications. Front. Environ. Sci. 2022, 10, 870271. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Pieroni, M.P.P.; Pigosso, D.C.A.; Soufani, K. Circular Business Models: A Review. J. Clean. Prod. 2020, 277, 123741. [Google Scholar] [CrossRef]

- Rivera-López, S.; Yasser Nuñez-Betacourt, E.; Revilla-Chaviano, A.; Ernesto Luquez-Gaitan, C. Análisis de La Competitividad Del Cacao (Theobroma cacao) Mexicano. Cienc. Tecnol. Agropecu. 2024, 25, e3427. [Google Scholar] [CrossRef]

- Anoraga, S.B.; Shamsudin, R.; Hamzah, M.H.; Sharif, S.; Saputro, A.D. Cacao By-Products: A Comprehensive Review on Potential Uses, Waste Management, and Emerging Green Technologies for Cacao Pod Husk Utilization. Heliyon 2024, 10, e35537. [Google Scholar] [CrossRef]

- Ganguly, P.; Sengupta, S.; Das, P.; Bhowal, A. Valorization of Food Waste: Extraction of Cellulose, Lignin and Their Application in Energy Use and Water Treatment. Fuel 2020, 280, 118581. [Google Scholar] [CrossRef]

- Molina Martínez, R.; Ramos Martínez, M.F. Variables Que Impiden Incrementar las Exportaciones de Cacao en Grano del Estado de Tabasco. Cimexus 2020, 15, 63–81. [Google Scholar] [CrossRef]

- Nogueira Soares Souza, F.; Rocha Vieira, S.; Leopoldina Lamounier Campidelli, M.; Abadia Reis Rocha, R.; Milani Avelar Rodrigues, L.; Henrique Santos, P.; de Deus Souza Carneiro, J.; Maria de Carvalho Tavares, I.; Patrícia de Oliveira, C. Impact of Using Cacao Bean Shell Powder as a Substitute for Wheat Flour on Some of Chocolate Cake Properties. Food Chem. 2022, 381, 132215. [Google Scholar] [CrossRef] [PubMed]

- Koul, B.; Yakoob, M.; Shah, M.P. Agricultural Waste Management Strategies for Environmental Sustainability. Environ. Res. 2022, 206, 112285. [Google Scholar] [CrossRef] [PubMed]

- Priyangini, F.; Walde, S.G.; Chidambaram, R. Extraction Optimization of Pectin from Cacao Pod Husks (Theobroma cacao L.) with Ascorbic Acid Using Response Surface Methodology. Carbohydr. Polym. 2018, 202, 497–503. [Google Scholar] [CrossRef]

- Santana, M.; Isabel, P.; Quijano, M.; Barragan, A.; Viteri, R.; Manzano, P.; Hernández, J.; Quijano-Avilés, M.; Barragán, A.; Chóez-Guaranda, I.; et al. Polyphenols Extracted from Theobroma cacao Waste and Its Utility as Antioxidant. Emir. J. Food Agric. 2017, 29, 45–50. [Google Scholar] [CrossRef]

- Tirado, C.B.; Montanez, M.Y.C.; Basto, L.A.B. NEXTCOA: “Desarrollo de Nuevos Procesos y Productos Para la Valorización de Mucílago y Granos de Cacao en el Departamento de Santander”. Mem. Inst. UIS 2019, 1. Available online: https://revistas.uis.edu.co/index.php/memoriasuis/article/view/10071 (accessed on 19 April 2025).

- Gour, A.; Kour, D.; Dogra, A.; Manhas, D.; Wazir, P.; Digra, S.K.; Kumar, A.; Nandi, U. Epicatechin Exerts Dual Action to Shield Sickling and Hydroxyurea-Induced Myelosuppression: Implication in Sickle Cell Anemia Management. Toxicol. Appl. Pharmacol. 2022, 449, 116113. [Google Scholar] [CrossRef]

- Campo-Vega, R.; Oomah, D.; Vergara-Castañeda, H.A. Food Wastes and By-Products, 1st ed.; Campo-Vega, R., Oomah, D., Vergara-Castañeda, H.A., Eds.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2020; ISBN 9781119534105. [Google Scholar]

- Lu, F.; Rodriguez-Garcia, J.; Van Damme, I.; Westwood, N.J.; Shaw, L.; Robinson, J.S.; Warren, G.; Chatzifragkou, A.; McQueen Mason, S.; Gomez, L.; et al. Valorisation Strategies for Cacao Pod Husk and Its Fractions. Curr. Opin. Green Sustain. Chem. 2018, 14, 80–88. [Google Scholar] [CrossRef]

- Quiroz-Eraso, S.; Rodríguez-Castaño, G.P.; Acosta-González, A. Interactions between Polyphenols from Theobroma cacao and Lactobacillales to Evaluate the Potential of a Combined Strategy for Intestinal Free-Fatty Acid Removal. Curr. Res. Food Sci. 2023, 7. [Google Scholar] [CrossRef]

- Benítez-Correa, E.; Bastías-Montes, J.M.; Acuña-Nelson, S.; Muñoz-Fariña, O. Effect of Choline Chloride-Based Deep Eutectic Solvents on Polyphenols Extraction from Cacao (Theobroma cacao L.) Bean Shells and Antioxidant Activity of Extracts. Curr. Res. Food Sci. 2023, 7, 100614. [Google Scholar] [CrossRef]

- Velásquez-Reyes, D.; Rodríguez-Campos, J.; Avendaño-Arrazate, C.; Gschaedler, A.; Alcázar-Valle, M.; Lugo-Cervantes, E. Forastero and Criollo Cacao Beans, Differences on the Profile of Volatile and Non-Volatile Compounds in the Process from Fermentation to Liquor. Heliyon 2023, 9, e15129. [Google Scholar] [CrossRef]

- Cortez, D.; Quispe-Sanchez, L.; Mestanza, M.; Oliva-Cruz, M.; Yoplac, I.; Torres, C.; Chavez, S.G. Changes in Bioactive Compounds during Fermentation of Cacao (Theobroma cacao) Harvested in Amazonas-Peru. Curr. Res. Food Sci. 2023, 6, 100494. [Google Scholar] [CrossRef] [PubMed]

- Azmin, S.N.H.M.; Hayat, N.A.B.M.; Nor, M.S.M. Development and Characterization of Food Packaging Bioplastic Film from Cacao Pod Husk Cellulose Incorporated with Sugarcane Bagasse Fibre. J. Bioresour. Bioprod. 2020, 5, 248–255. [Google Scholar] [CrossRef]

- Boegman, S.J.; Carodenuto, S.; Rebitt, S.; Grant, H.; Cisneros, B. Seeing through Transparency in the Craft Chocolate Industry: The What, How, and Why of Cacao Sourcing. J. Agric. Food Res. 2023, 14, 100739. [Google Scholar] [CrossRef]

- de Souza Correia Cozentino, I.; Veloso de Paula, A.; Augusto Ribeiro, C.; Duran Alonso, J.; Grimaldi, R.; Luccas, V.; Taranto, M.P.; Cardoso Umbelino Cavallini, D. Development of a Potentially Functional Chocolate Spread Containing Probiotics and Structured Triglycerides. LWT 2022, 154, 112746. [Google Scholar] [CrossRef]

- Hedayati, S.; Tarahi, M.; Ashrafi-Dehkordi, E. Dietary Fibers from Fruit Processing Waste. In Adding Value to Fruit Wastes: Extraction, Properties, and Industrial Applications; Academic Press: Cambridge, MA, USA, 2024; pp. 131–165. [Google Scholar] [CrossRef]

- Caballero-Tovar, A.F.; Sandoval-Aldana, A.P.; Fernández-Quintero, A. Effect of the Incorporation of Sugars and Citric Acid in Low Cacao Butter Emulsions. J. Food Eng. 2023, 360, 111722. [Google Scholar] [CrossRef]

- Guan, X.; Chan, K.C.; Lei, L.; Kinloch, I.A.; Bissett, M.A. Graphene Interleaved SiOx/C Spheres Via Molecular Polymerization as High-Stability Lithium-Ion Battery Anodes. Electrochim. Acta 2023, 469, 143247. [Google Scholar] [CrossRef]

- Plasencia-Verde, C.C.; Grabiel-Rios, K.S.; Luque, J.A.; Best, I.K. Evaluación del Potencial Energético de Residuos de Cacao (Theobroma cacao L.) por Medio de Celdas de Combustible Microbiano (CCM). Inf. Tecnológica 2021, 32, 89–98. [Google Scholar] [CrossRef]

- Luis, I.E.; Reinoso, C. Obtención de un Biocombustible Sólido por Torrefacción Húmeda a Partir de la Cáscara de la Mazorca de Cacao Para la Generación de Energía. Master’s Thesis, Escuela Politécnica Nacional, Quito, Equador, 2018. [Google Scholar]

- Dewi, S.R.; Stevens, L.A.; Pearson, A.E.; Ferrari, R.; Irvine, D.J.; Binner, E.R. Investigating the Role of Solvent Type and Microwave Selective Heating on the Extraction of Phenolic Compounds from Cacao (Theobroma cacao L.) Pod Husk. Food Bioprod. Process. 2022, 134, 210–222. [Google Scholar] [CrossRef]

- Mehta, N.; Kumar, P.; Verma, A.K.; Umaraw, P.; Kumar, Y.; Malav, O.P.; Sazili, A.Q.; Domínguez, R.; Lorenzo, J.M. Microencapsulation as a Noble Technique for the Application of Bioactive Compounds in the Food Industry: A Comprehensive Review. Appl. Sci. 2022, 12, 1424. [Google Scholar] [CrossRef]

- Monsalvo Carrillo, F. Plan de Mercadeo Chocolates de la Costa S.A.S. Master’s Thesis, Universidad EAFIT, Pereira, Colombia, 2021. [Google Scholar]

- Dimartino, G.; Mukherjee, I.; Precio, W. Edible Products. Patent BR112023001518A2, 14 February 2023. Available online: https://patents.google.com/patent/BR112023001518A2/en?oq=BR112023001518 (accessed on 18 February 2025).

- Romero Cortes, T.; Cuervo-Parra, J.A.; José Robles-Olvera, V.; Rangel Cortes, E.; López Pérez, P.A. Experimental and Kinetic Production of Ethanol Using Mucilage Juice Residues from Cacao Processing. Int. J. Chem. React. Eng. 2018, 16, 20170262. [Google Scholar] [CrossRef]

- Saavedra-Sanabria, O.L.; Durán, D.; Cabezas, J.; Hernández, I.; Blanco-Tirado, C.; Combariza, M.Y. Cellulose Biosynthesis Using Simple Sugars Available in Residual Cacao Mucilage Exudate. Carbohydr. Polym. 2021, 274, 118645. [Google Scholar] [CrossRef] [PubMed]

- Sakinah, A.; Fikri, I.D. Cacao Powder Antioxidant Activity Test Using Cyclic Voltammetry and Differential Pulse Voltammetry Methods. Chem. Mater. 2023, 2, 30–34. [Google Scholar] [CrossRef]

- Rodríguez-Castro, R.; Guerrero, R.; Valero, A.; Franco-Rodriguez, J.; Posada-Izquierdo, G. Cacao Mucilage as a Novel Ingredient in Innovative Kombucha Fermentation. Foods 2024, 13, 1636. [Google Scholar] [CrossRef] [PubMed]

- Herwig, B. Bomba Para Fruto de Cacao, Proceso Para su Producción y Uso en la Industria Alimentaria. Patent BE1027939B1, 3 August 2021. Available online: https://patents.google.com/patent/BE1027939B1/en?oq=BE1027939-B1 (accessed on 18 February 2025).

- Hoppe, T.; Bachmeir, J.; Aretz, J. Verfahren zur Gewinnung Einer Zuckerhaltigen Substanz aus Einer Kakaofrucht und Verwendung der Zuckerhaltigen Substanz bei der Herstellung von Schokolade. Patent EP3777550A1, 17 February 2021. Available online: https://patents.google.com/patent/EP3777550A1/de?oq=EP3777550-A1 (accessed on 17 February 2025).

- Batista Vieira, J.; Kuschel, B.; Festring, D. Lebensmittelprodukte, Zutaten, Verfahren und Verwendungen. Patent EP3824738A1, 26 May 2021. Available online: https://patents.google.com/patent/EP3824738A1/de?oq=EP3824738-A1 (accessed on 18 February 2025).

- Castro, A.J.; Glazier, B.D.; Ben-Yoseph, E.M.; Hsu, C.-H.; Kelley, S.; Unlu, E.; Willcocks, N.A.; Collins, T.M. Sprühgetrocknete Kakaomasse. Patent EP4007498A4, 13 September 2023. Available online: https://patents.google.com/patent/EP4007498A4/de?oq=++EP4007498-A4 (accessed on 18 February 2025).

- Da Silva Freitas, R.V.; De Assis Cavalcante, J.; Honorato Da Silva, F.L.; De Souza Costa, I.I.; Da Silva Negreiros, J.K.; Abrantes Sarmento, D.H. Process for Obtaining Cacao Pulp Powder. Patent BR102019025711A2, 15 June 2021. Available online: https://patents.google.com/patent/BR102019025711A2/en?oq=++BR102019025711-A2 (accessed on 18 February 2025).

- Vieira, J.B.; Kuschel, B.; Festring, D. Lebensmittelprodukte, Zutaten, Verfahren und Verwendungen. Patent EP3837989A1, 23 June 2021. Available online: https://patents.google.com/patent/EP3837989A1/de?oq=EP3837989-A1 (accessed on 18 February 2025).

- Cinar, Z.Ö.; Atanassova, M.; Tumer, T.B.; Caruso, G.; Antika, G.; Sharma, S.; Sharifi-Rad, J.; Pezzani, R. Cacao and Cacao Bean Shells Role in Human Health: An Updated Review. J. Food Compos. Anal. 2021, 103, 104115. [Google Scholar] [CrossRef]

- Garcia Gonzalez, E.; Serna Murillo, A.M.; Córdoba Pantoja, D.A.; Marín Aricapa, J.G.; Montalvo Rodríguez, C.; Ordoñez Narváez, G.A. Evaluación de Los Parametros Fisico-Químicos, Microbiologicos y de Calidad En La Fermentación Espontanea de Granos de Cacao En Una Unidad Productiva de La Unión, Florida (Valle Del Cauca). Rev. Colomb. Investig. Agroind. 2019, 6, 41. [Google Scholar] [CrossRef]

- Mikucka, W.; Zielińska, M.; Bułkowska, K.; Witońska, I. Valorization of Distillery Stillage by Polyphenol Recovery Using Microwave-Assisted, Ultrasound-Assisted and Conventional Extractions. J. Environ. Manag. 2022, 322, 116150. [Google Scholar] [CrossRef]

- Collazos, M.; Palacios, M. Aprovechamiento de la Miel de Cacao en la Elaboración de un Natural con Potencial Aplicación en la Chocolatera. Engineer’s Thesis, Universidad de los Andes, Bogota, Colombia, 2021. [Google Scholar]

- Disca, V.; Capuano, E.; Arlorio, M. Colonic Fermentation of Enzymatically Treated Cacao Bean Shells (CBSs) and Short Chain Fatty Acids (SCFAs) Production. LWT 2024, 202, 116311. [Google Scholar] [CrossRef]

- Santos, L.G.; Martins, V.G. Optimization of the Green Extraction of Polyphenols from the Edible Flower Clitoria ternatea by High-Power Ultrasound: A Comparative Study with Conventional Extraction Techniques. J. Appl. Res. Med. Aromat. Plants 2023, 34, 100458. [Google Scholar] [CrossRef]

- Moya-Guerra, M.; Suárez-Morales, J.; Hernández-Ramos, E. Utilización de la Cascarilla de Cacao Como Fuente de Fibra Dietética y Antioxidantes en la Elaboración de Galletas Dulces. Cienc. Tecnol. Aliment. 2015, 22, 39–44. [Google Scholar]

- Mellinas, A.C.; Jiménez, A.; Garrigós, M.C. Optimization of Microwave-Assisted Extraction of Cacao Bean Shell Waste and Evaluation of Its Antioxidant, Physicochemical and Functional Properties. LWT 2020, 127, 109361. [Google Scholar] [CrossRef]

- Grassia, M.; Messia, M.C.; Marconi, E.; Demirkol, Ş.; Erdoğdu, F.; Sarghini, F.; Cinquanta, L.; Corona, O.; Planeta, D. Microencapsulation of Phenolic Extracts from Cacao Shells to Enrich Chocolate Bars. Plant Foods Hum. Nutr. 2021, 76, 449–457. [Google Scholar] [CrossRef] [PubMed]

- Straka, D.; Ivanišová, E.; Gabríny, L.; Hleba, L. Technological, Physicochemical and Antioxidant Properties of Malt Wort Enriched with Cacao Shells. J. Microbiol. Biotechnol. Food Sci. 2025, 14, e10777. [Google Scholar] [CrossRef]

- Lessa, O.A.; Franco, M. Nanocellulose from Cacao Bean Shell Processes and Production. Patent BR102020003432A2, 31 August 2021. Available online: https://patents.google.com/patent/BR102020003432A2/en?oq=BR102020003432-A2 (accessed on 18 February 2025).

- Soyeur, J.-L.; Jamsazzadeh, K.Z. Nutritional Composition Containing Cacao Beans Shell. Patent BE1027918B1, 16 July 2021. Available online: https://patents.google.com/patent/BE1027918B1/en?oq=BE1027918-B1 (accessed on 18 February 2025).

- Kowalczyk, K.; Wilpiszewska, K.; Skowrońska, D.; Sęk, M. Product of Cacao Bean Husks Management and Method of Cacao Bean Husks Management. Patent PL441732A1, 15 January 2024. Available online: https://patents.google.com/patent/PL441732A1/en?oq=PL441732-A1 (accessed on 18 February 2025).

- Suarez-Otero, M.S.; Gestal, E.P.; Perez, A.L.; Perez, A.L.; Fernandez, J.M.D. Método de Obtención de Bebidas y Condimentos a Partir de Cascarilla de Cacao, una Bebida Funcional, una Bebida Funcional y Probiótica, y un Condimento. Patent ES2985020A1, 4 November 2024. Available online: https://patents.google.com/patent/ES2985020A1/es?oq=ES2985020-A1 (accessed on 18 February 2025).

- Packaging Strategies Papel de Cacao: Una Opción de Embalaje Ecológica y Segura Para los Alimentos | 27/05/2016 | Empaques de Marca | Estrategias de Empaquetado. Available online: https://www.packagingstrategies.com/articles/93693-cacao-paper-an-eco-friendly-food-safe-packaging-option (accessed on 19 April 2025).

- Kumasi Kumasi: Innovación En el Mundo del Cacao. Available online: https://cacaomotum.it/kumasi-produttore-di-bevande-di-polpa-di-cacao/ (accessed on 19 April 2025).

- Chocolate Lucacao. Té de Cáscara de Cacao—Chocolate Lucacao. Available online: https://www.lucocoachocolate.com/shop/cocoahusktea?srsltid=AfmBOor1GLv0ym0RYk5OeSQA4_qoCcXuypKeS7DMnomAzRgpWD-lFsTkcacaohusktea (accessed on 19 April 2025).

- Beskid Chocolate. Cacao Tea—Cacao Husk 100 g—Beskid Chocolate EU. Available online: https://beskidchocolate.eu/product/cacao-tea-cocoa-husk-100g/ (accessed on 19 April 2025).

- Toufood. Mücilage—Freeze-Dried Cacao Mucilage—Toufood.Com. Available online: https://www.toufood.com/product/mucilage-freeze-dried-cocoa-mucilage/?lang=en (accessed on 19 April 2025).

- KOA Productos—Jugo de Cacao, Concentrados y Pulpas Secas. Available online: https://koa-impact.com/products/ (accessed on 19 April 2025).

- Valrhona Oabika—El Oro Del Cacao | Chocolate Valrhona. Available online: https://www.valrhona.com/it/i-prodotti/per-i-professionisti/gamma-laboratorio/100-cacao/oabika/oabika-l-oro-del-cacao (accessed on 19 April 2025).

- EFSA Panel on Contaminants in the Food Chain. EUR-Lex Statement on Tolerable Weekly Intake for Cadmium. EFSA J. 2014, 9, 1975. [Google Scholar] [CrossRef]

| Compound | Study | Conclusion | Reference |

|---|---|---|---|

| Obtaining alcohol by Pichia kudriavzevii | Fermentation of sugars using Pichia kudriavzevii to obtain ethanol (13.8 g/L) | Cacao mucilage can be an economical and viable source for ethanol. | [60] |

| Obtaining cacao honey powder by spray drying for use as a sweetener | An exploratory study of spray-drying technology to obtain cacao honey powder. Drying conditions were evaluated using the same temperature and flow parameters, with variation in maltodextrin, methocel, and whey protein in the formulations with cacao mucilage. | Several formulations were made with maltodextrin plus whey protein isolate. The 29:1 formulation of maldodextrin and whey protein showed better retention of antioxidant compounds relative to the other formulations. The application of non-thermal technologies and the production of cacao honey powder with added protein are shown as potential innovations for cacao cultivation and the food industry. | [27] |

| Obtaining bacterial cellulose from cacao mucilage | An evaluation of the potential of cacao mucilage (CME) as a carbon source for the production of bacterial cellulose (BC) in a static fermentation process using the bacterial strain Gluconacetobacter xylinus (ATCC®23768™). | High sugar content, low pH of cacao mucilage, and limited sources of nitrogen affect BC yields by hindering the growth of G. xylinus. Even so, this process becomes an alternative to take advantage of the waste in the production of bacterial cellulose (BC), taking into account that this agro-industrial waste is rich in nutrients. | [61] |

| Extraction and characterization of cacao mucilage and application in the production of food and biopolymers | Methods of extracting cacao mucilage, along with physical and chemical properties, such as its sugar content and phenolic compounds, were investigated. Applications in the food industry, such as sweetener and biopolymer production, were evaluated. | Cacao mucilage has the potential to be used in food and biodegradable packaging, contributing to sustainability and waste reduction. | [62] |

| Patent Number | Country/Institution | Patent Information | Reference |

|---|---|---|---|

| BE1027939-B1 | Belgium | Production of cacao pulp used in confectionery products such as beverages, ice cream, jams, or chocolate products. | [64] |

| BE1027944-B1 | Belgium | Production of pasteurized cacao fruit-juice concentrate used in confectionery products such as beverages, ice cream, jams, or chocolate products. It involves the pre-processing of cacao material by selecting cacao pods. | [64] |

| EP3777550-A1 | European Patent Office | It describes an optimized method for obtaining a sugary substance from cacao mucilage and its application in the production of chocolate and confectionery products. | [65] |

| EP3824738-A1 | European Patent Office | It presents an innovative method for the production of confectionery products from a composition derived from cacao pulp, using an enzymatic treatment with pectinase. | [66] |

| WO2021026089-A2; WO2021026089-A3; AU2020324404-A1; CN114206122-A; EP4007498-A2; BR112022002010-A2; US2022279807-A1; EP4007498-A4 | European Patent Office; Austria; China; World Intellectual Property Organization (WIPO); Brazil; United States | The development of a new food ingredient based on dried cacao pulp, highlighting its application in products such as dark chocolate, chewing gum, fat-free candies, and ice cream. | [67] |

| BR102019025711-A2 | European Patent Office | It describes an innovative method for obtaining cacao pulp powder by means of a drying process, with application in the food, cosmetic, and pharmaceutical industries. | [68] |

| EP3837989-A1 | European Patent Office | It describes a method for the production of confectionery products, particularly chocolate, using cacao pulp with an enzymatic treatment, for the reduction of polysaccharide content. | [69] |

| Compound | Study | Conclusion | Reference |

|---|---|---|---|

| CBS flour as an input in the production of bakery products | An evaluation of the use of CBS flour in the production of biscuits as a source of dietary fiber and antioxidant phenolic compounds. | CBS is an alternative for the addition of antioxidant and fiber compounds. In addition, cacao bean husk flour represents a good source of protein and can be used in food-processing processes. | [76] |

| Phenolic compounds of an antioxidant nature | Microwave-assisted extraction and bromatological characterization of phenolic compounds of antioxidant character in the CBS. | CBS represents a good source of antioxidant compounds and alternates proteins. | [77] |

| Phenolic compounds of antioxidant character in and microencapsulation | The extraction of phenolic compounds and microencapsulation, using maltodextrin/dextrose. The final product was added in dark chocolate bars. | The microencapsulated product from CBS added to dark chocolate bars enhanced the functional value. | [78] |

| CBS flour as a substitute for conventional bakery flour | The use of CBS flour as a substitute for conventional baker’s flour. Positive results were obtained in terms of sensory acceptance in mixtures with up to 75% CBS in the total mixture for the production of chocolate cakes. | CBS flour as a component of replacement of common flour and use of nutritional intake. It also provides phenolic compounds of an antioxidant nature. | [36] |

| Patent Number | Countries | Patent Description | Reference |

|---|---|---|---|

| BR102020003432-A2 | Brazil | The development of a process for obtaining nanocellulose without chemical or enzymatic pretreatments, in which bioactive compounds are preserved. | [80] |

| BE1027918-B1 | Belgium | The development of a gelled pasta intended as a filling or topping in pastry products. | [81] |

| PL441732-A1 | Poland | It describes a product designed as a combustible material. | [82] |

| ES2985020-A1 | Spain | It describes a method for the production of functional beverages, probiotic beverages, and condiments from CBS. | [83] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sotelo-Coronado, L.E.; Oviedo-Argumedo, W.; Alvis-Bermúdez, A. Cacao in the Circular Economy: A Review on Innovations from Its By-Products. Processes 2025, 13, 2098. https://doi.org/10.3390/pr13072098

Sotelo-Coronado LE, Oviedo-Argumedo W, Alvis-Bermúdez A. Cacao in the Circular Economy: A Review on Innovations from Its By-Products. Processes. 2025; 13(7):2098. https://doi.org/10.3390/pr13072098

Chicago/Turabian StyleSotelo-Coronado, Liliana Esther, William Oviedo-Argumedo, and Armando Alvis-Bermúdez. 2025. "Cacao in the Circular Economy: A Review on Innovations from Its By-Products" Processes 13, no. 7: 2098. https://doi.org/10.3390/pr13072098

APA StyleSotelo-Coronado, L. E., Oviedo-Argumedo, W., & Alvis-Bermúdez, A. (2025). Cacao in the Circular Economy: A Review on Innovations from Its By-Products. Processes, 13(7), 2098. https://doi.org/10.3390/pr13072098