Abstract

Agri-food waste management poses a growing challenge in the pursuit of sustainable development. This bibliographic review analyses the scientific literature from 2014 to 2025 to examine current methods of agro-waste valorisation and the application of circular-economy principles in the transformation of biological waste into valuable resources. Special attention is given to nanofibers—particularly nanocellulose—and other high-value biocomponents. The review assesses these recovery practices’ economic, ecological, and health-related impacts and the relevant barriers to implementation. Potential application domains are discussed, and estimations of waste quantities and future trends are provided. The findings highlight the importance of investment in sustainable technologies and increased stakeholder awareness in efforts to optimize agri-food waste valorisation and support the transition to a more sustainable agricultural sector.

1. Introduction

A sustainable food chain is essential for global food security, environmental protection, and efficient resource use. Integrating biomass plays a key role in optimizing resource flows, reducing waste, and promoting greener agricultural practices.

The farming sector significantly contributes to economic growth and food production. As the global population increases, food production and distribution have expanded to meet demand. However, this sector also generates substantial waste, which impacts the environment year-round, depending on the agricultural activities [1,2]. Livestock operations and processing generate leftovers and byproducts across the agricultural value chain [3]. This type of waste poses a high risk to human and animal health and harms the environment. It can be successfully integrated into new production processes for advanced valorisation, obtaining value-added merchandise in different industrial areas such as bioenergy, biocomposites, absorbents, or fertilizers [4,5,6].

Biological waste recovery is essential for reducing environmental impacts and increasing economic efficiency. The valorisation techniques reduce agricultural production costs, decrease soil and water pollution, lower greenhouse gas emissions, and create new jobs in bioeconomy-related industries [7].

This study reviews the literature on biowaste reuse methods, their benefits, and associated challenges. This paper’s originality lies in the estimation of biowaste trends based on statistical data. Future directions for economic development are suggested, with an emphasis on using nanofibers in food preservation to reduce food waste and promote sustainability. Three conceptual maps are introduced to visualize biowaste valorisation’s economic, environmental, and health benefits.

Integrating biomass into the food chain reduces waste, improves soil fertility, and produces renewable energy [8]. Widespread adoption of these practices can protect the environment and ensure a balanced, responsible food system.

1.1. Background Premises

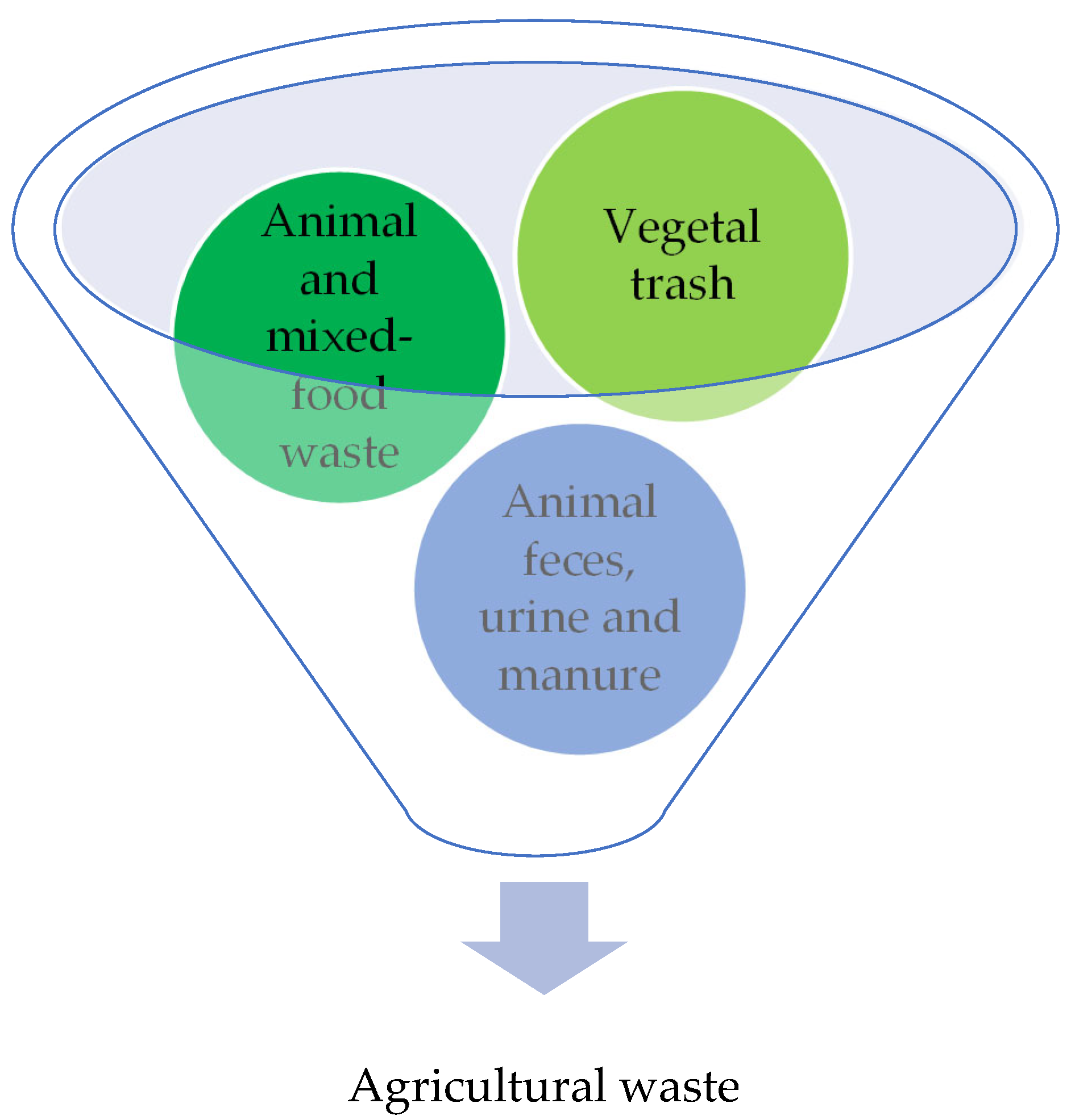

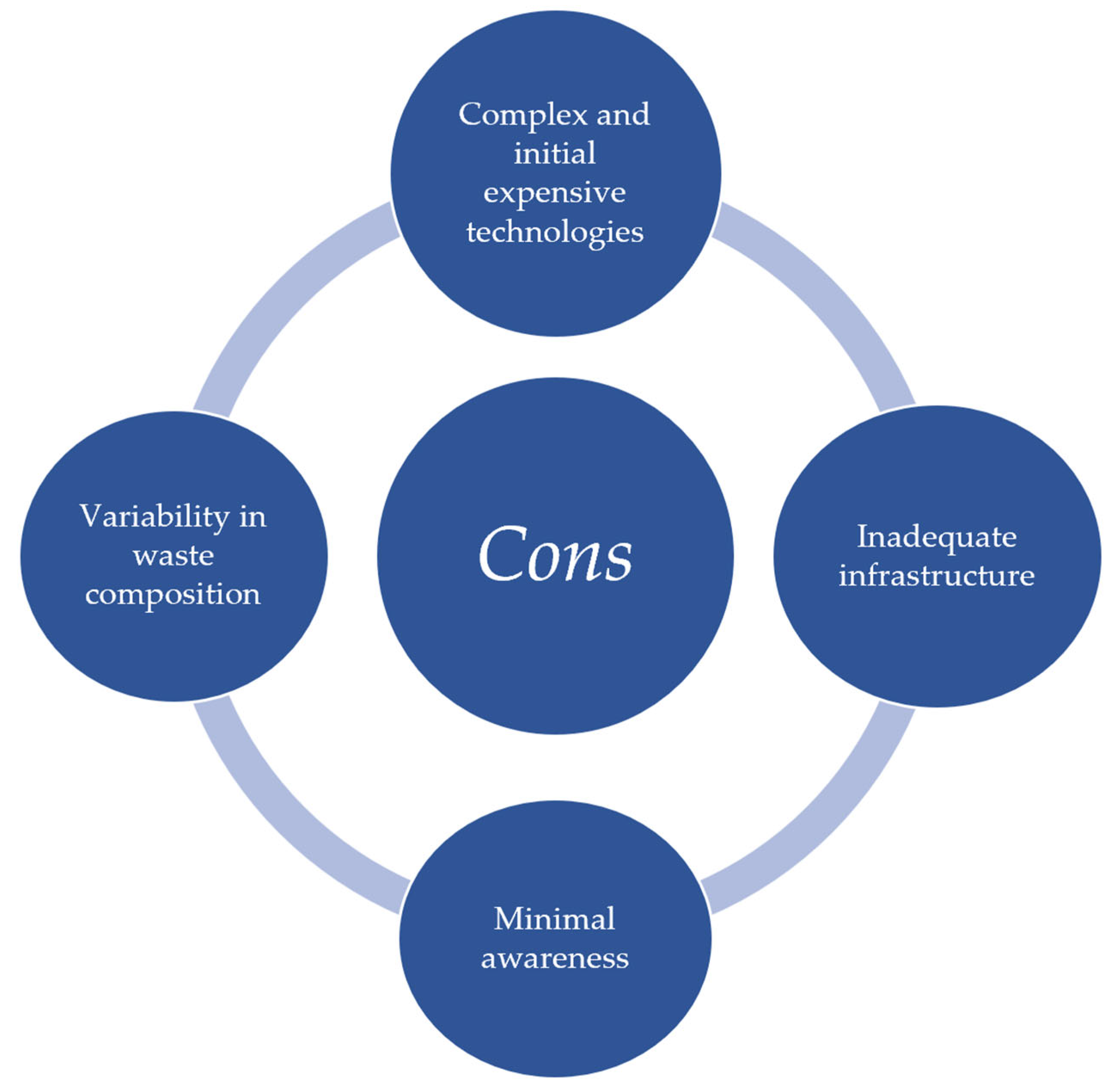

According to the data in the EUROSTAT database [9], agricultural waste includes multiple subcategories (Figure 1). These range from sludges, plant and animal tissues, and manure to effluents treated off-site. This classification, based on the 2008/98/EC Directive [10], includes waste from agriculture, aquaculture, forestry, and food processing (Appendix).

Figure 1.

Main categories of agricultural waste streams relevant to biowaste valorisation.

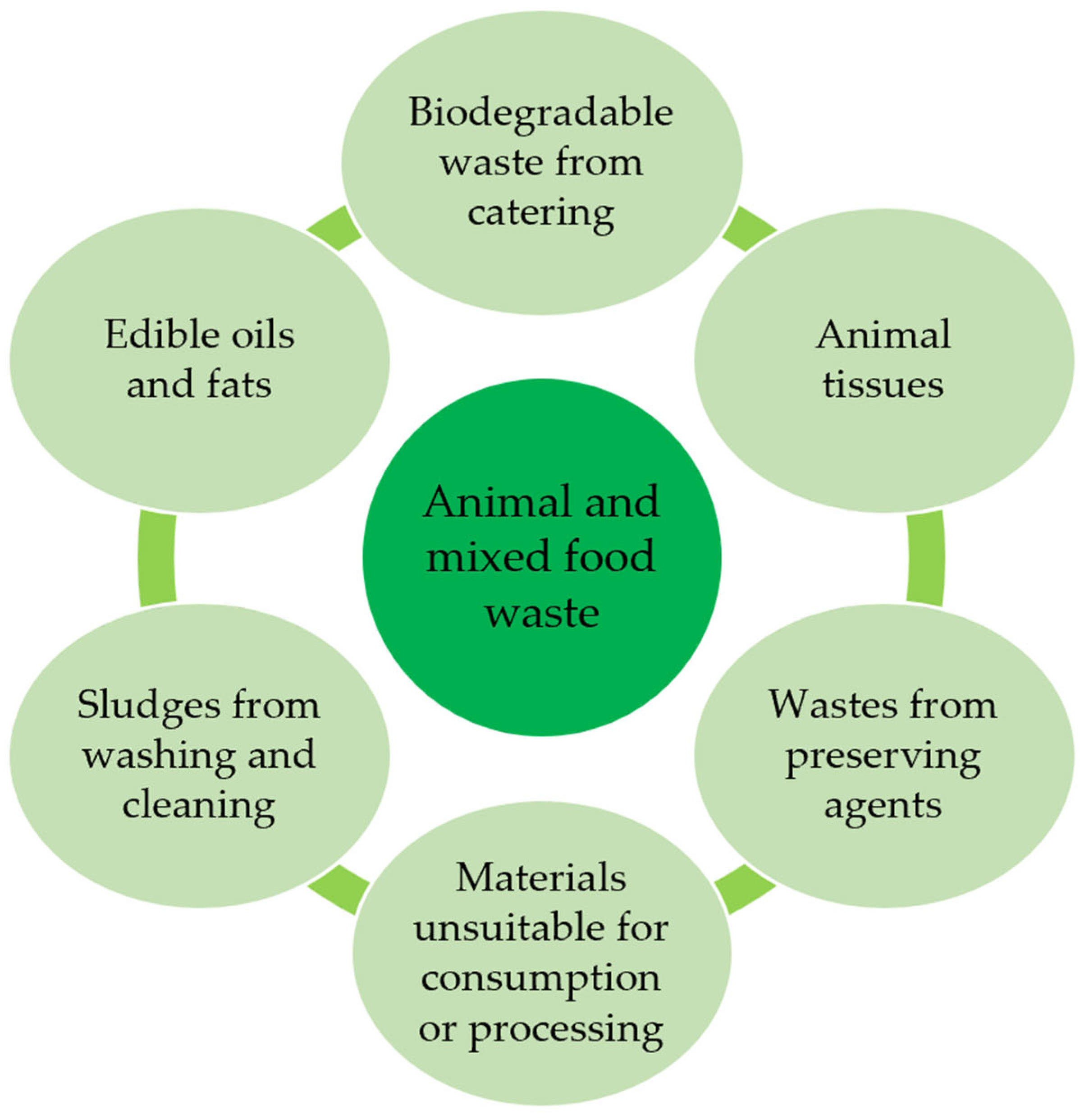

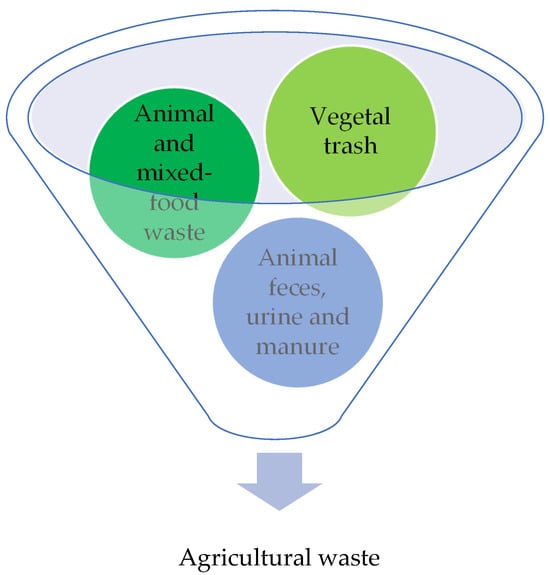

Figure 2 details the possible components of the animal and mixed-food waste. Its overview shows several subcomponents and elements considered raw materials in other processes. In present efforts, two current tendencies are implemented. One of them is part of the circular-economy concept and targets the reuse of waste. The second supposes the implementation of new technologies with low environmental impact. Independent of type, whether agro-waste, fast-food waste, or wastewater, all of the waste considered here could pass through a digestion process. The resulting two main products of this would be the digestate and the biogas. The digested material has increased mineral bioavailability and is suitable for use as a fertilizer in agriculture and horticulture. The utilization methods are various, and range from soil incorporation to foliar application. The main uses of biogas are in energy and bioplastic production. All mechanisms described are based on research and development actions and significantly contribute to implementing circular-economy principles [11].

Figure 2.

Sources and components of animal and mixed-food waste relevant to agro-industrial valorisation.

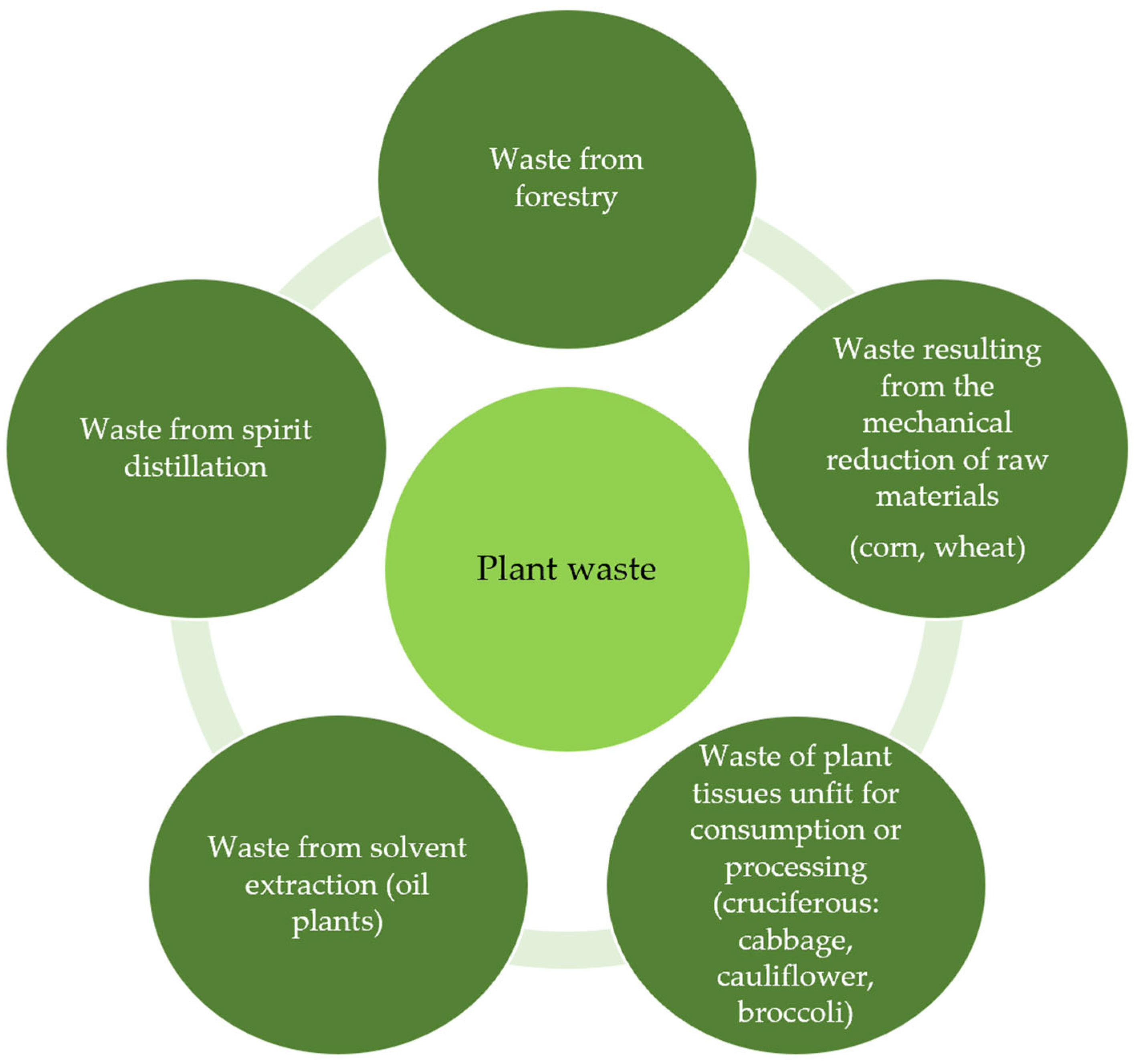

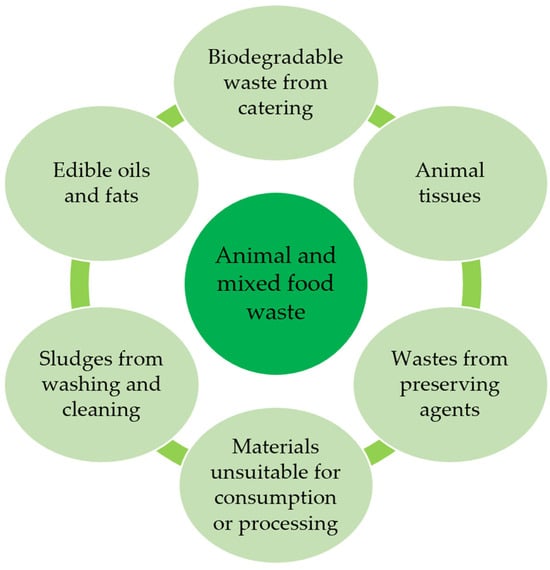

Vegetal waste, also known as plant trash, is the organic material from botanical species and greenery-based products that are discarded or no longer needed. This waste category includes various parts, such as stems, leaves, roots, fruits, and other residual components. It can be generated from multiple sources, including agricultural activities, food processing industries, landscaping, and households (Figure 3).

Figure 3.

Main sources and categories of plant-based agricultural waste.

Despite its potential, only a small portion of agricultural waste is valorised. The rest is typically burned or landfilled [2]. As the amount of such garbage in rural waste is about five times higher than levels in municipal solid waste, rural waste has a high content of materials that can be valorised for use in other activity sectors, contributing to resource conservation, economic growth, and the circular economy [3,12,13].

As mentioned above, food and vegetable refuse represents, overall, a significant part of the trash generated in the world. Different procedures are being used to estimate the quantity of this waste, since such details could give an overview of the general attributes of food waste. Caldeira et al. proposed two techniques to approximate the amount. One uses as its inputs the quantities of raw materials, as well as subsequent materials that are imported into the distribution chain before the product reaches the final consumer. The other technique is based on the amounts of biodegradable loss reported by the economic entities that carry out activities in the field. The results presented were similar [14]. In many countries [15], including EU Member States, these types of waste are managed through various methods such as composting, recycling, and biogas production [16].

Reducing food and vegetable waste is an important objective for initiatives aiming to decrease environmental impact and promote sustainability. Efforts are being made globally to improve waste management, increase recycling, and promote sustainable production and consumption practices.

To better interpret and understand the evolution of waste generation in the EU, it is necessary to analyse and compare specific data by waste category, management methods, and environmental policies implemented during recent years. Based on this premise, this paper will highlight the evolution of two waste categories based on the total amounts of animal and vegetal waste.

The present paper compares different ways of valorising agricultural waste, such as the production of bioethanol [13,17], biochar [3,17], heat energizer [18], ultra-high-performance concrete [19], and asphalt [20] pigments [21] or phytosanitary [22] binder, or fibre extraction. Such perspectives highlight the wide spectrum of ways in which vegetable wastes can be seen as raw resources.

1.2. Waste Amount Prediction Calculation

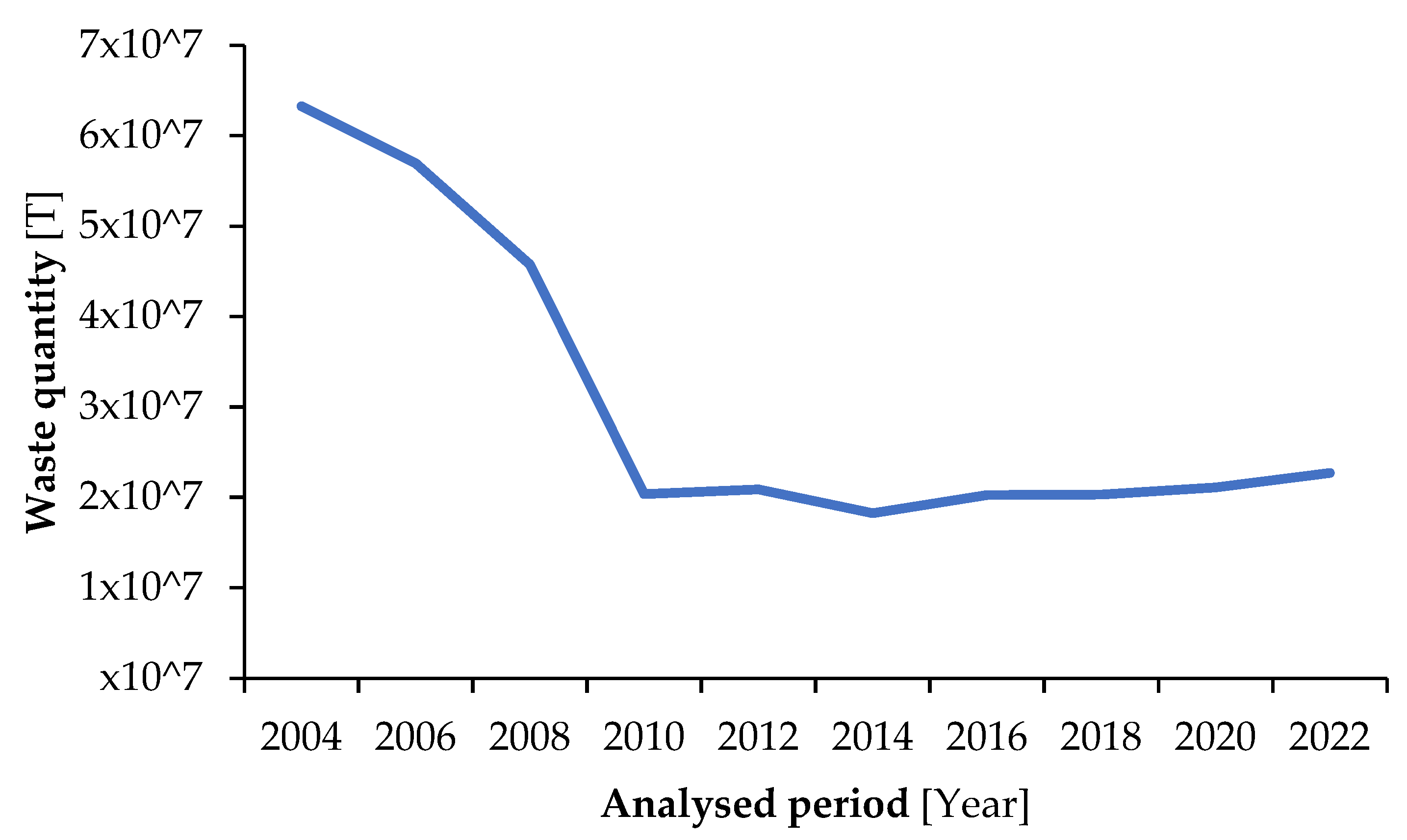

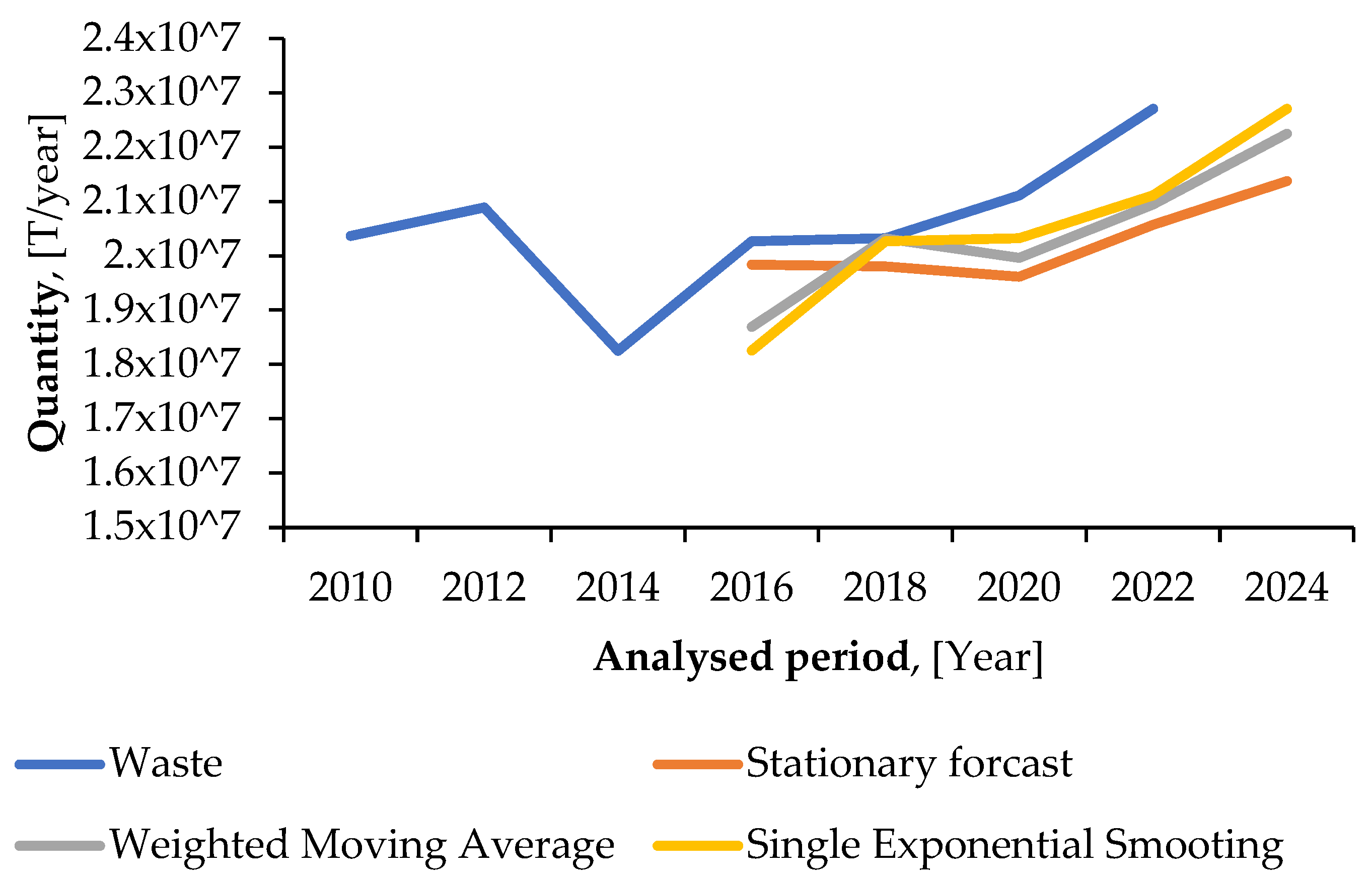

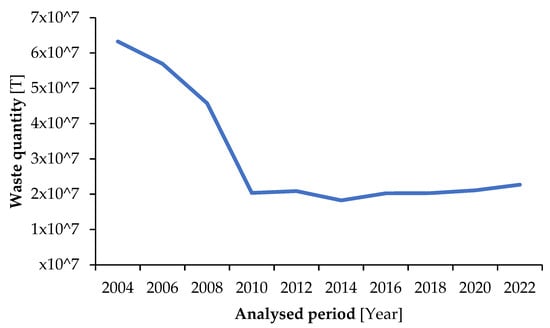

This study also introduces an estimate of agro-waste quantities based on Eurostat data, using resources relevant to agriculture, forestry, and fishing, for the period between 2004 and 2022. Figure 4 shows this trend.

Figure 4.

The evolution of waste generated in the agriculture, forestry, and fishing areas. Source: Eurostat.

Since the inputs used are not characterized by seasonality or a well-defined trend, we based our calculations on the determination of the MAD (mean absolute deviation), MSE (mean square error), and MAPE (mean absolute percent error) as parts of SF (stationary forecasting). This selection was grounded in the relevant background knowledge. The values considered are the total amounts reported at the European level. The data reported in 2010 reported levels approximately one-third of those in 2004. In the following analysed period, some limited fluctuation of the recorded values was observed. The WMA (weighted moving average) and the SES (single exponential smoothing) complemented this method. In both cases, the resolver facility from MS Excel was used to improve the prediction error. The percentual deviation calculated was 5.24 with SES and 5.25 with WMA, compared to the SF, the estimated value of which was 5.7. The main contribution was assigned to the third value of the average group, with a considered contribution of 80, and to the first one, with 17%, to optimize the prediction error, in the case of the WMA method.

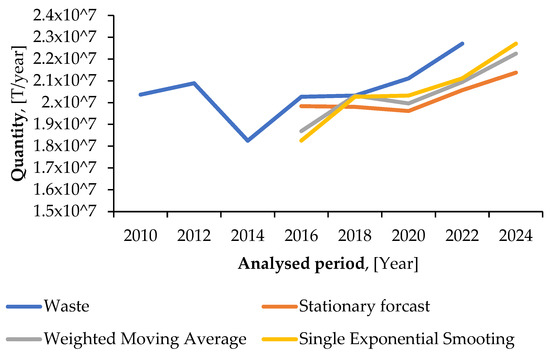

For this reason, data from the period 2010–2022 were used to forecast the next evolution. The moving averages considered were for three years. The forecast was calculated for the next consecutive year, 2024 (Figure 5).

Figure 5.

The evolution of the waste generated in the agriculture, forestry, and fishing areas. Source: Eurostat.

The predictive evaluation shows an increasing trend of agro-waste being produced at the European level. A median assessment of the provisional quantity and the potential deviation calculated is around 22,250,000.00 T ± 5.24% for 2024, with an ascending trend, compared to 2014, when it registered the minimum value for the period evaluated. One possible factor for such a situation could be tested by increasing the size of cultivated agricultural areas. One positive secondary result would be an increase in raw materials from reuse and a lower need for novel inputs from direct production, implicitly reducing stress on natural resources.

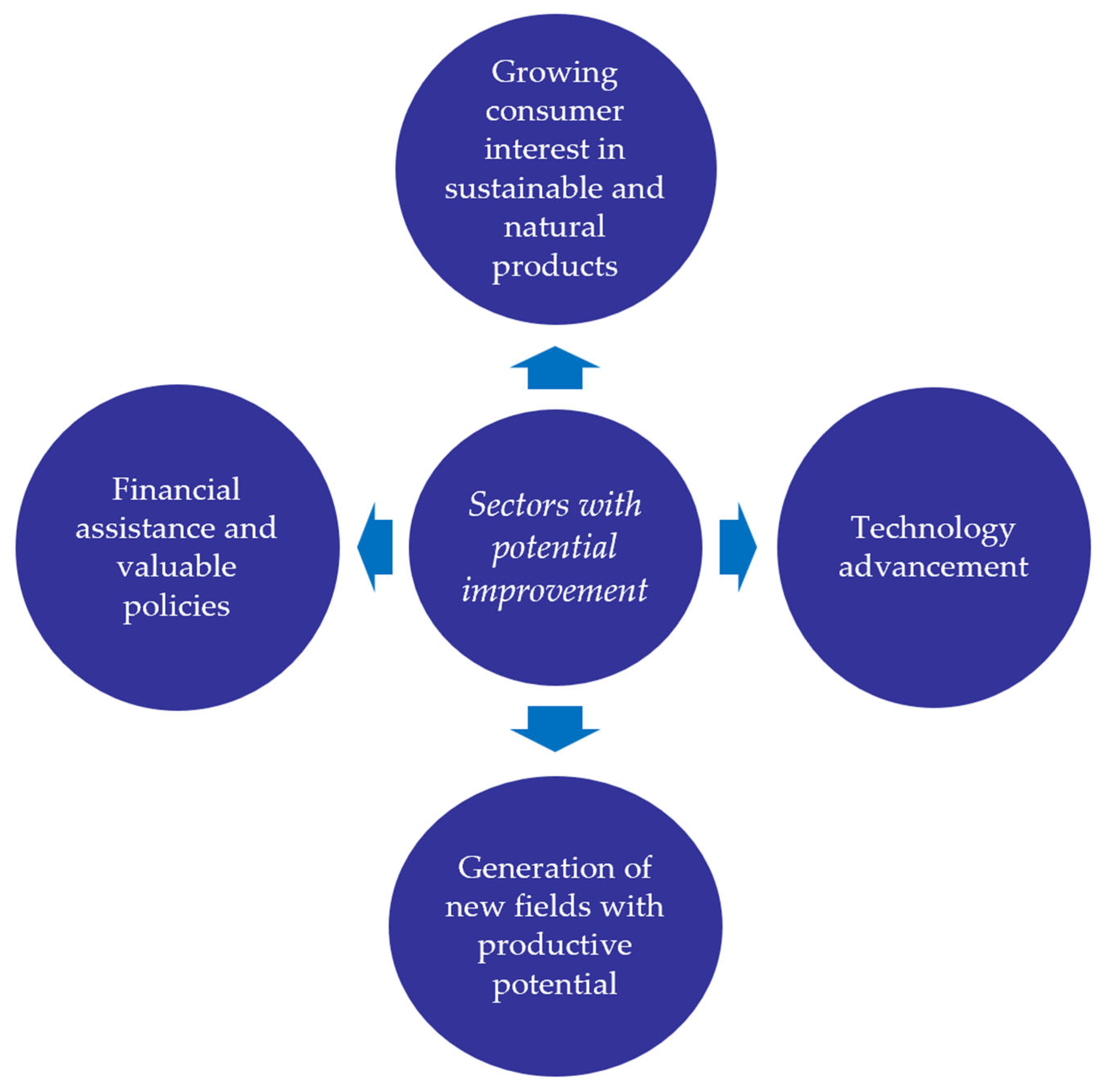

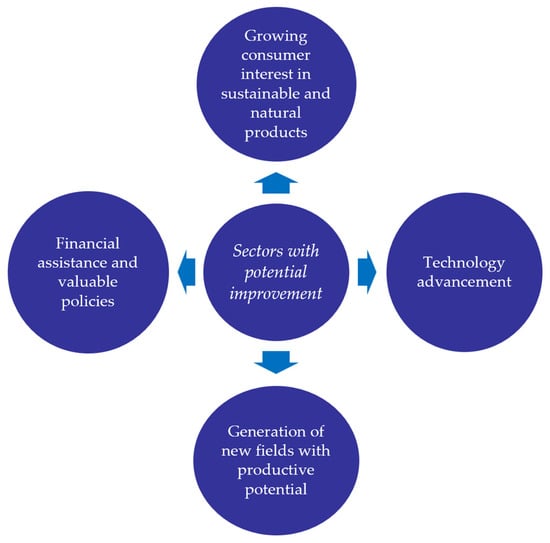

An increased amount of waste from agricultural activities can also be seen as an opportunity for their advanced recovery [23,24,25,26]; see Figure 6.

Figure 6.

Key sectors and drivers with the potential to enhance agro-waste valorisation.

An increased demand for practical and organic merchandise has been observed. New technologies with low levels of ecosystem impact must be developed to accomplish such a requirement properly. Agro-wastes represent valuable sources of macro components that could accomplish such aspirations. A noteworthy percentage of such wastes is composed of cellulosic, hemicellulosic, or lignin biocomponents [27]. Wheat straw may be a valuable raw material for improved lignocellulose fibres [28]. Besides reducing the quantity of trash to be disposed of in the environment, the designed composite may have additional properties. Lounis et al. observed a biopolymer film’s antibacterial characteristics, waterproof nature and oxygen impermeability, studying a substance that was composed of corn starch and olive pomace meal [29]. Using the same macromolecule as its main constituent, Abe et al. suggested the potential for food packaging of the product obtained. Cellulose and xylan function as the main excipients. These products have exhibited photoprotective features [30], an important aspect of food production. Waste fibres represent potential fillers for starch-based composites. Significant potential was observed in banana inflorescence waste for applications providing water impermeability, mechanical strength, and thermal properties to the composite in which they were incorporated [31]. Green chemistry must be promoted throughout all areas of biotechnology, in order to reach eco-friendliness targets in as many fields as possible. One general characteristic of natural polymers is seen in their deficiencies concerning mechanical properties and impermeability. One viable solution is represented by their integration into composites that could limit or eliminate these deficiencies [32,33]. Efforts to ensure the sustainability of such products generally consider their design as a whole, from the raw materials used, to all of the technological steps and auxiliary techniques involved [34]. The review compiled by Li et al. mentioned different possibilities for efforts aiming to increase the competitiveness of polyhydroxyalkanoates, with respect to some of their properties, through block and graft crosslinking [35]. Improving the mechanical characteristics of such biocomposites could increase their applicability in food packaging. The results obtained by Oyewole et al. were cited in their proposal that carbon sources and agro-waters such as maize cob, plantain stem, and sugarcane bagasse should be utilized, underlining the “eco-neutrality” of these materials. Knowing that the PHA are natural polyesters, the esterification reaction was made in the presence of Pseudomonas aeruginosa [36].

Another consequence of this approach is reflected in the evolution of emerging directions of industrial growth, such as the movement to bioplastics and biofertilizers [37], two product classes with a high contamination degree. Table 1 summarizes some of the recent concepts in product design based on agro-waste valorisation. The use of biomass-derivative polymers such as starch, cellulose, poly(lactic acid), polyhydroxyalkanoates, chitosan, gelatine, or zein could contribute to the development of sustainable packaging alternatives [38].

Table 1.

New value-added products based on biowaste waste recovery.

The use of biofertilizers implies compliance with the necessities determined for each plant variety. Lim et al. underlined in their research that the product characteristics in substances obtained from different agro-wastes exhibit specific particularities [47].

Productive performance will not be possible without preparing an economic and legislative framework. Prioritizing necessary research and development in these fields will increase the potential to find entrepreneurs interested in investing in these domains.

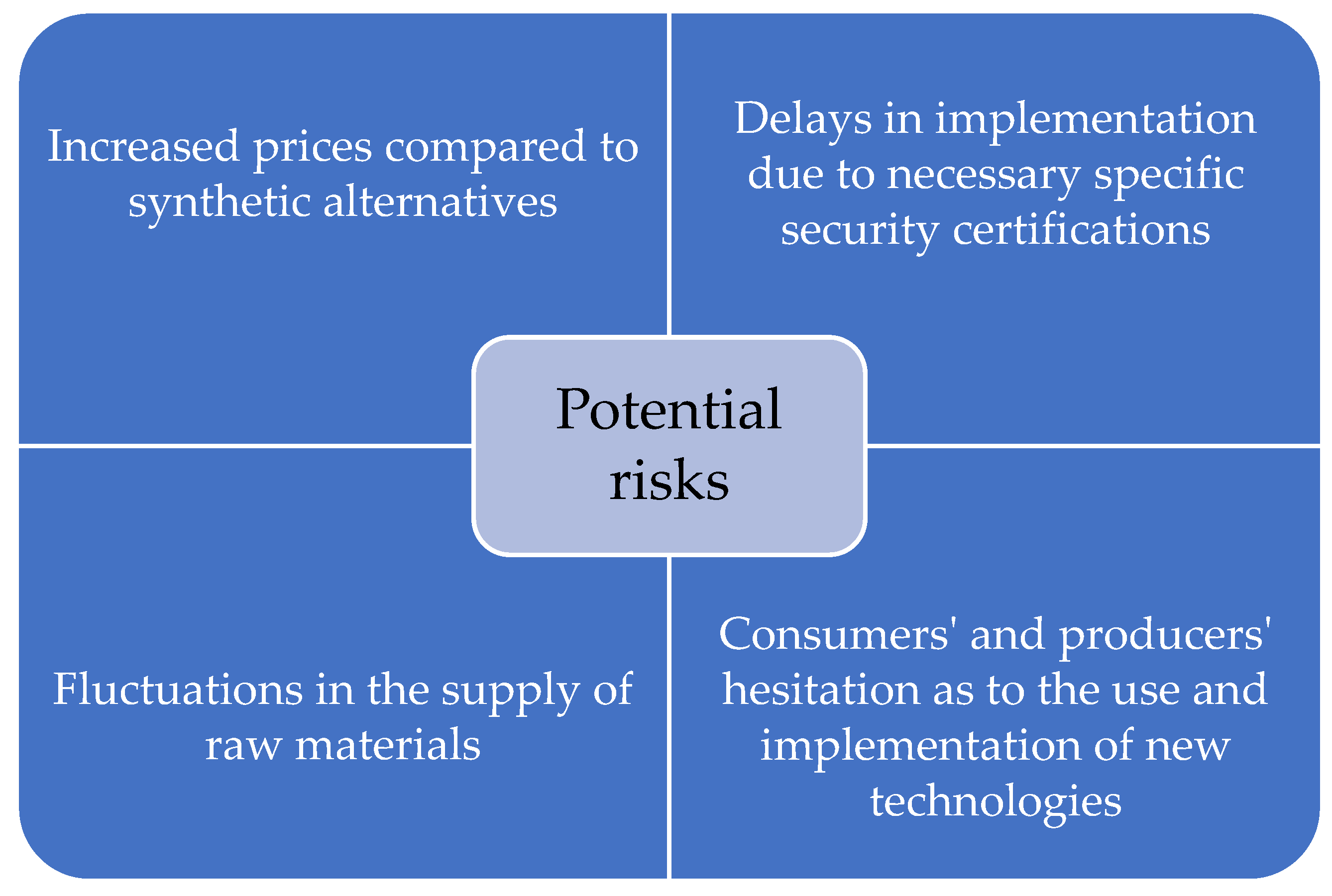

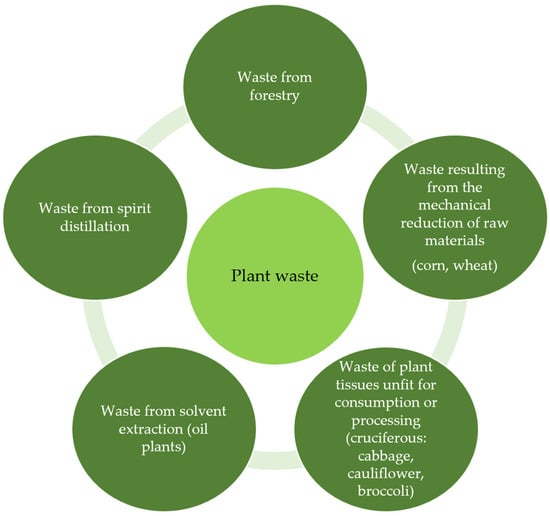

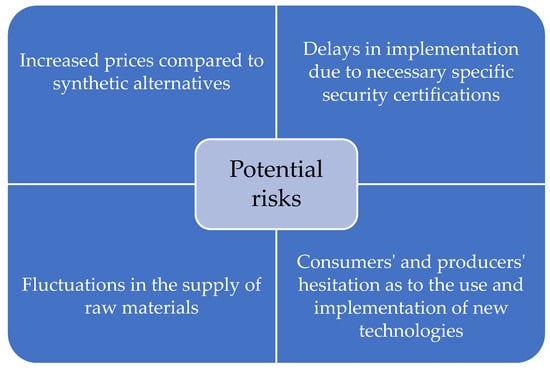

In addition to the opportunities that come with implementing agro-waste valorisation, we have to mention some of the threats that could be encountered during the process. Figure 7 summarizes a few of the potential situations that currently should be considered before starting an activity in the field.

Figure 7.

Potential risks and limitations associated with agro-waste valorisation initiatives.

It is well known that scientific and research progress involves the allocation of funds, and this is reflected in the prices of the new technologies designed. Such a situation initially causes novel techniques to be less competitive than classical ones, but could be reversed, for example, in the context of producing synthetic packaging materials or fertilizers. Another aspect that targets the financial element is related to the mechanisms involved in certifying new products. The process itself could create a series of steps to guarantee the accomplishment of safety standards. The situation could be time consuming and economically costly.

Also related to the economic dimension, one specific element of this field comes from its seasonality. There is a considerable fluctuation in agro-waste availability. Wastes from corn, wheat, sunflower, or cruciferous harvest could be mentioned here. The amount annually produced could fluctuate due to the influence of climate change or economic instability. Attempts to limit the effects of such hazards may result in the design of versatile valorisation processes. These could be adapted to the transformation of wastes or byproducts with similar chemical compositions. For example, trash produced in wood manufacturing, such as sawdust, branches, and tree barks, may be less affected by weather variability.

In addition to the consumer’s possible resistance to new raw materials used in food production, the same attitude could be encountered with respect to producers. Novel technological processes presuppose investments that are not ensured a quick reimbursement.

2. Economic, Health-Related, and Ecological Benefits

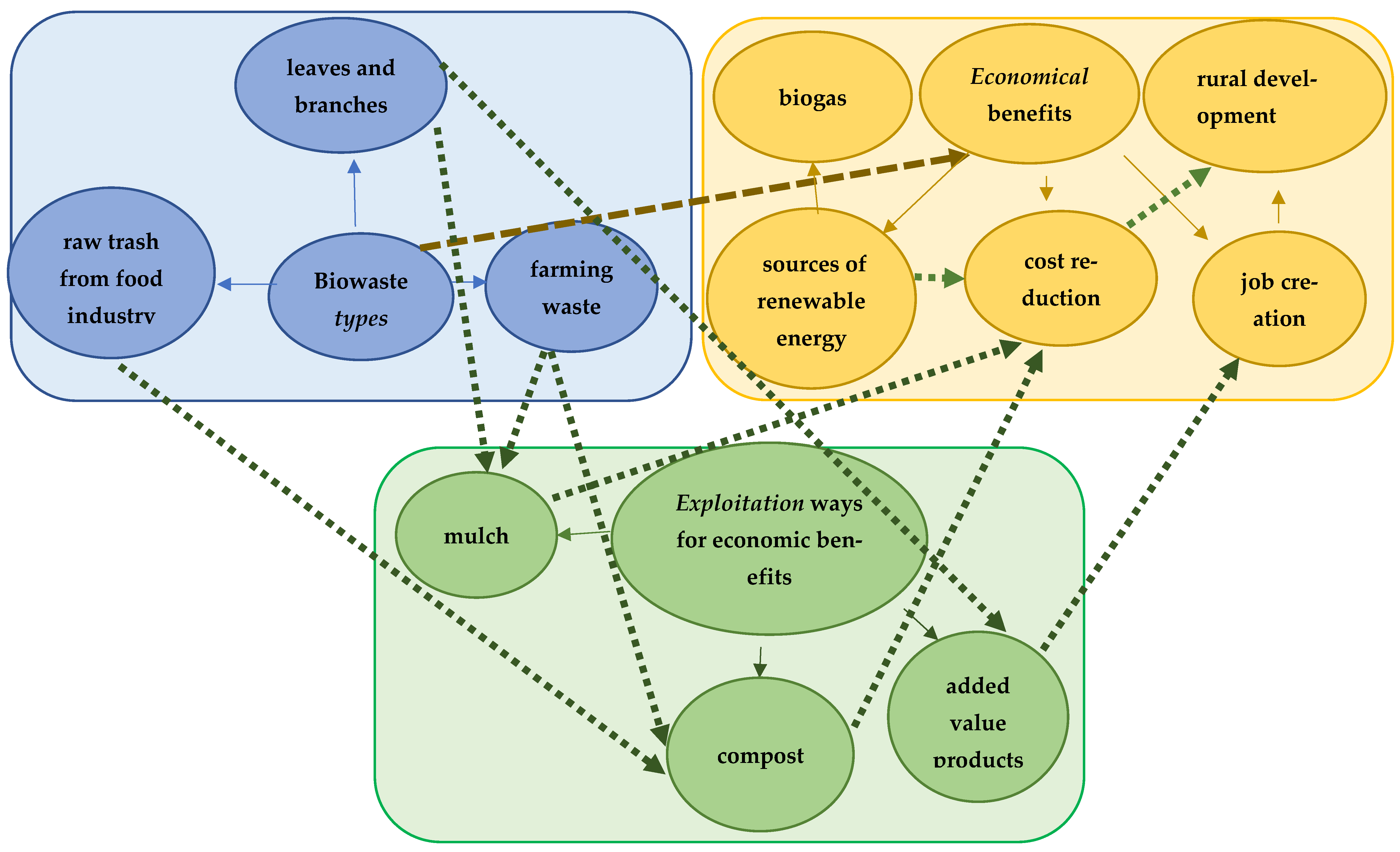

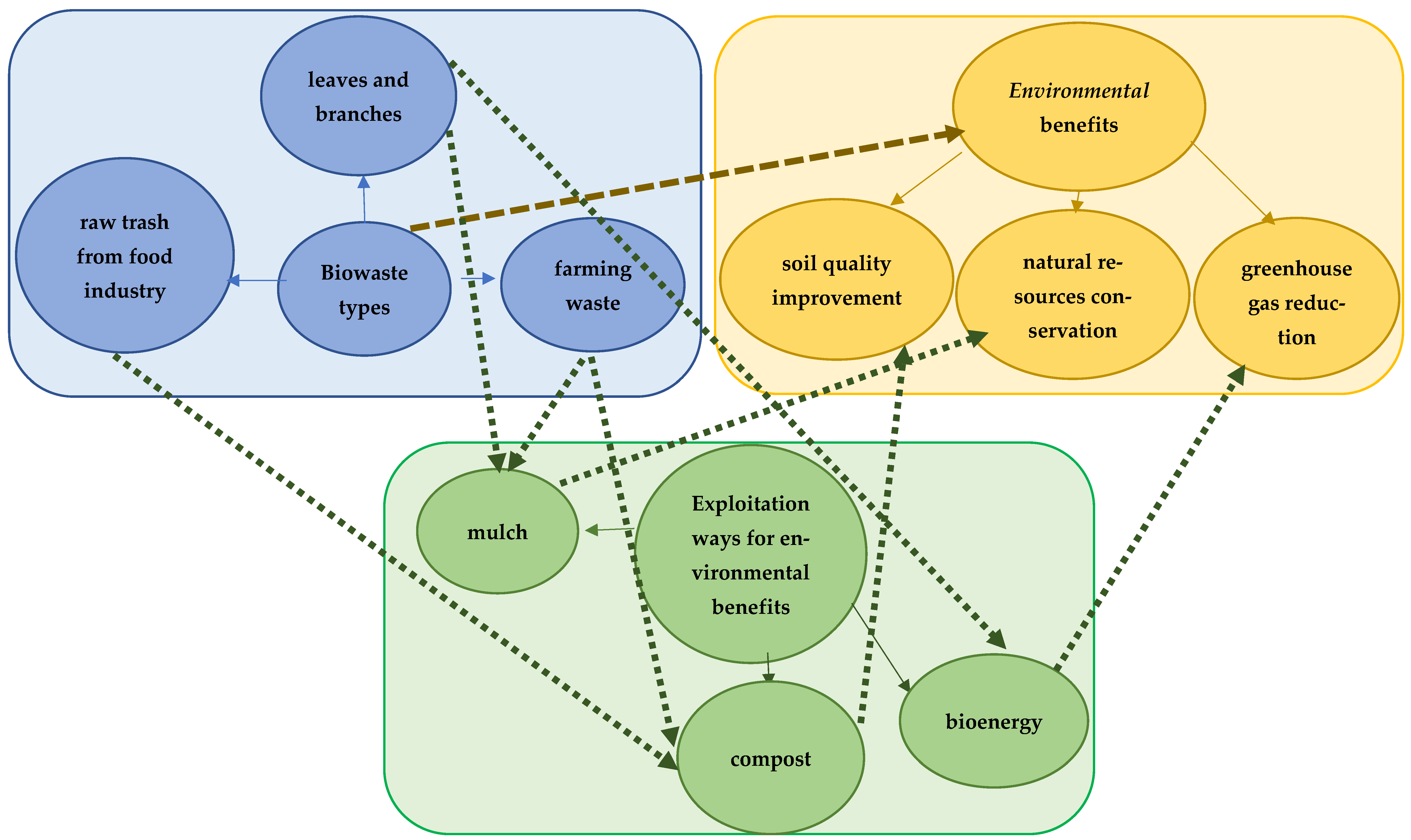

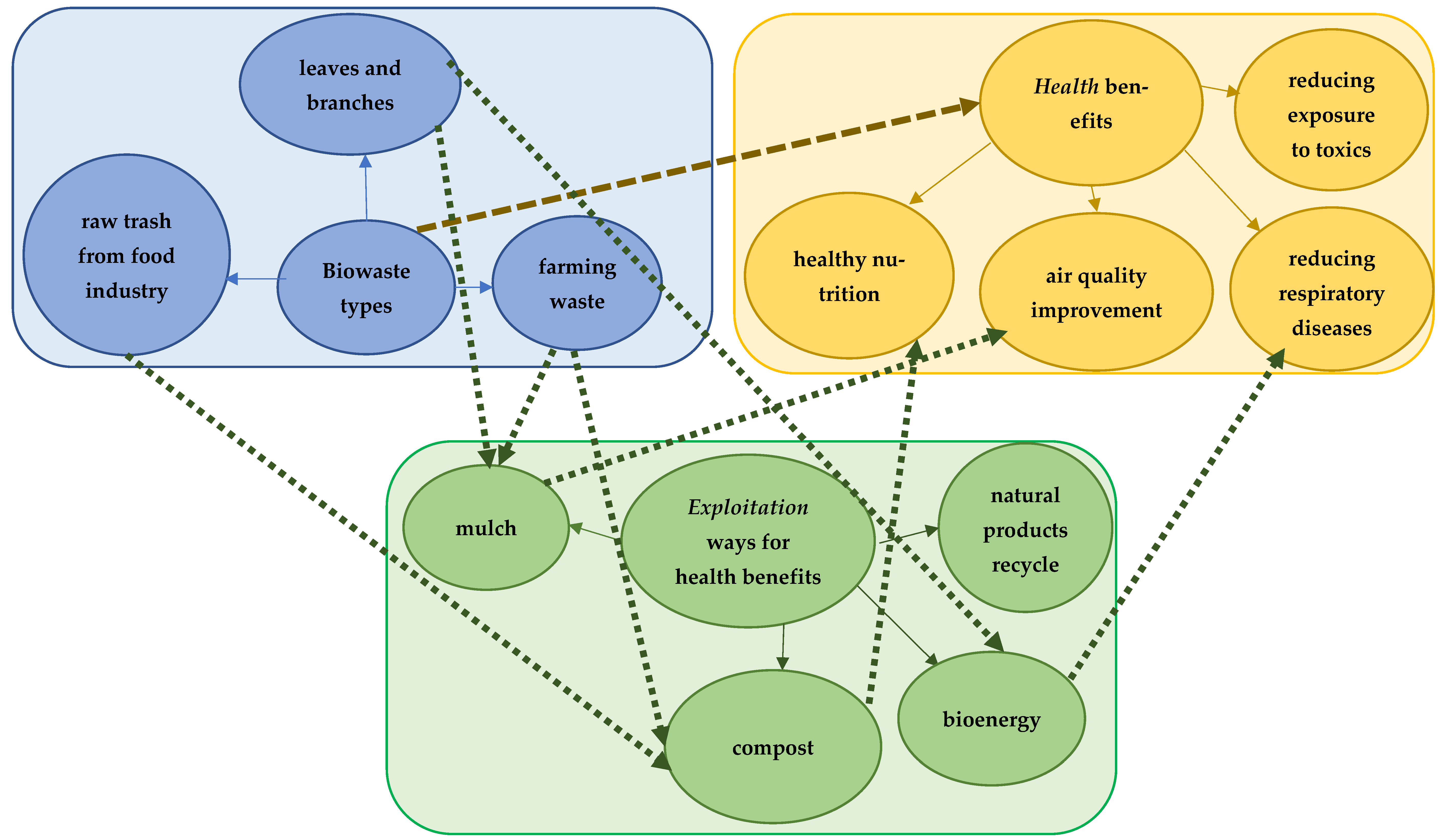

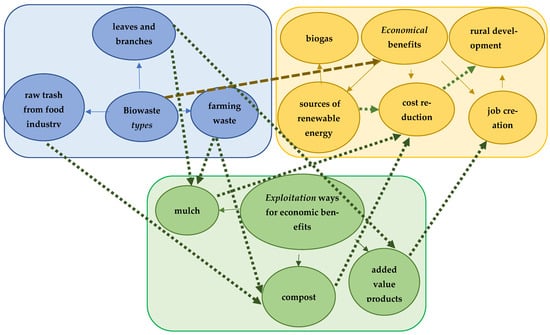

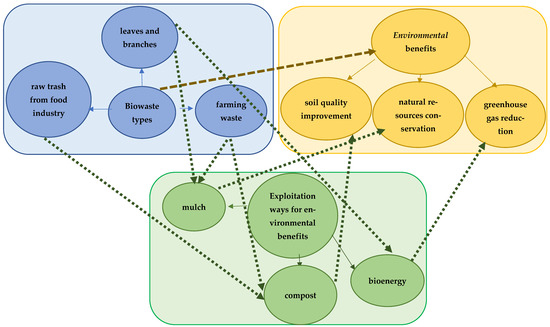

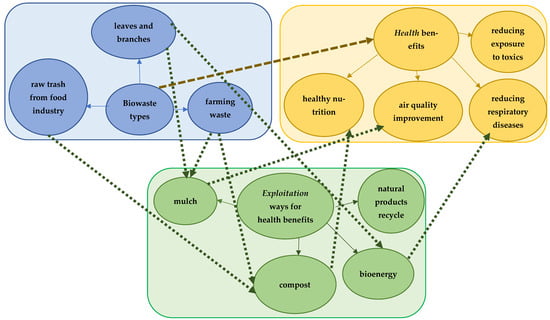

Traditionally, industrial processes have relied heavily on non-renewable natural resources. However, growing awareness of climate change and environmental degradation has prompted a shift toward more sustainable practices. The circular economy, which emphasizes resource efficiency and waste minimization, positions agro-waste valorisation as a crucial strategy due to the versatility and abundance of biomass [48]. Figure 8, Figure 9 and Figure 10 present an integrative vision of the advantages and mechanisms implied by vegetable waste valorisation.

Figure 8.

A conceptual chart highlighting the economic advantages of agro-waste valorisation.

Figure 9.

A conceptual chart highlighting the environmental advantages of biowaste valorisation.

Figure 10.

A conceptual chart highlighting the health advantages of biowaste valorisation.

Analysing the information graphically illustrated above, common points can be observed. Green trash recoverability has multiple implications, such as economic consequences through cost reductions and decreased environmental impact. Reducing waste and the development of possible green methods for conversion could prompt a re-evaluation of the impact on the ecosystem. Such a vision contributes to a sustainable agricultural mechanism [49].

2.1. Cost-Effectiveness-Based Advantages of Agro-Waste Valorisation

Figure 8 graphically suggests the possible advantages of agro-waste valorisation from a financial point of view. Three main areas are identified: the classes of waste, the economic implications of such an approach, and the mechanisms implied. The economic benefits manifest in four key areas: job creation, reduced production costs, bioenergy generation, and enhanced farmer income. From a labour market perspective, agro-waste valorisation initiatives are associated with notable employment opportunities. For example, collecting and recovering 1000 tons of food and organic waste can generate an approximately 60% higher increase in the gross domestic product (GDP) and create 40% more employment opportunities than conventional disposal methods [50]. Hiranobe et al. [51] and Munagala et al. [52] highlight a key economic benefit of using lignocellulosic biomass—like sugarcane bagasse—as feedstock for biofuel production: the creation of rural employment through new market opportunities.

In addition to employment benefits, agro-waste valorisation can spur innovation in product development and increase the general agro-economic significance of the waste resulting after harvest [53,54]. Although most of the studies are preliminary and developed under in vitro conditions, they suggest the potential in considering materials in this class of wastes to be potential raw materials [55]. Most research indicates the likelihood of good antimicrobial, antioxidant [56], and anti-inflammatory [57] properties. Integrating biowaste into advanced applications, such as nanotechnology, contributes to economic efficiency. Proper ethical and legislative frameworks must be developed [58], ones independent of the ultimate aims of these repurposing techniques, especially in the farm, medical, and food fields.

The financial aspect could be better served through the possibility of energy generation. Products such as biogas or biodiesel could be used in farming-specific activities or be sold [59]. Research indicates that 1 ton of dry agro-waste—such as rice husks, corn cobs, or food and garden residues—can produce approximately 300–400 m3 of biogas, equating to 600–800 kWh of electricity. Likewise, fruit peel biomass yields 346 to 389 L of bioethanol per tonne, with sweet sorghum bagasse providing around 157 L/t [60,61].

Regardless of the way chosen, a positive economic outcome will increase income. Beyond energy production, agro-waste also shows promise in industrial applications. Therefore, establishing industries that use agro-waste as a raw material is essential for local circular-economy development. These initiatives have been shown to promote job creation, thereby contributing to local income growth and regional development [62]. One aspect that cannot be neglected is the need to inform local entrepreneurs about the initial investments required when supporting new technology [63]. The total cost refers both to equipment cost and employment training. After studying several business models in agro-waste valorisation, Donner et al. underlined the importance of the supplier’s implied warranty in ensuring the quality of products [64]. Since there is a cycling path, the wastes and the byproducts usually intended for discard represent the starting point for another process in this concept.

Innovative business models can significantly enhance agro-waste valorisation technologies’ economic viability and local acceptance, especially in rural and resource-constrained settings. These models should be inclusive, scalable, and adapted to local ecosystems. Figure 11 shows several effective and emerging business model types that can improve agro-waste valorisation technologies’ economic viability and local acceptance.

Figure 11.

Emerging innovative business models supporting agro-waste valorisation and circular bioeconomy development.

Considering the inherent variation in the chemical composition of the vegetables and the other biowastes, ensuring a minimal guiding specification for the product is advisable. The quality and quantity, along with the wide range of variation, will also determine the different fabrication yields, which are finally reflected in production costs.

Agro-waste valorisation stimulates investment and innovation. Baseri underlined a possible green approach involving waste valorisation in the fabric dyeing process. Such a process would sustain the future use of natural colour pigments and mordants obtained from vegetable waste such as C. oblonga leaf, banana peel, or gallnut [65]. Jalil et al. highlighted the environmental, economic, and technological performance involved in possibly incorporating pineapple foliage into recovered cotton, resulting in innovative textile materials obtained from the processing of natural fibres [66]. The development and implementation of such solutions are a sustainable response to the increasing demand for organic and sustainable products, adding value to the local and international agro-economy. Such initiatives contribute to developing a more resilient economy and less dependence on non-renewable resources. In this context, the current trend to the development of fuels besides classical biofuels could be underlined by the trend to biohydrogens. This application is sustainable, considering the chemical composition of vegetable wastes and their potential uses [67]. The financial viability of agro-waste valorisation can be better understood by comparing it to conventional waste management costs [68].

Each year, approximately 1.3 billion tonnes of edible food are lost or wasted globally, an amount associated with the emission of about 3.3 billion tonnes of greenhouse gases. The environmental impacts of food waste range from −347 to 2969 kg CO2 equivalent per tonne, while the economic costs vary between −$100 and $138 per tonne, depending on various factors across the food supply chain and waste management systems. Despite ongoing efforts to reduce food waste and valorise its unavoidable existence, achieving meaningful environmental and economic benefits likely requires a transdisciplinary approach [69]. In financial terms, alternative waste treatments such as anaerobic digestion (AD) and composting vary in their cost structures and benefits, compared to traditional landfilling. Converting agro-waste via anaerobic digestion typically involves dedicated costs between €80 and €109 per tonne, depending on the country and technology level. Composting, by comparison, ranges from €45 per tonne for basic on-farm setups to €128 per tonne for high-tech facilities. Shifting from landfill to AD adds €2–5 per tonne to the cost (versus landfill), whereas transitioning to composting adds €13–29 per tonne. While composting is less capital-intensive and operationally cheaper, AD’s ability to produce energy generates additional income, which can compensate for its higher upfront costs [70,71].

These figures illustrate the financial trade-offs and highlight how AD and composting can treat agro-waste sustainably and provide cost-effective alternatives to landfills, especially when energy recovery or byproduct utilization is factored in.

Moreover, practices such as mulching reduce chemical input costs and serve as eco-friendly alternatives that enhance rural ecosystem sustainability. In this context, the strategic use of biowaste and organic fertilizers supports the agricultural transition toward a bioeconomy model, reducing the environmental impact of waste disposal while enhancing soil fertility and sustainability [72].

2.2. Ecosystems-Based Benefits of Agro-Waste Valorisation

There are two main mechanisms through which the ecosystem could benefit from biowaste valorisation. These are pollution reduction and biodiversity protection. The actions that can ensure the desired outcomes discussed above include decreases in greenhouse gas emissions and the minimisation of the use of synthetic fertilizers. The use of compost and manure also contributes to soil and biodiversity conservation. Their integration into the valorisation system may serve as a path to reaching carbon neutrality in the livestock sector and simultaneously offer a green route for phosphorus biocompound recovery [73]

Composting and anaerobic digestion are key techniques in transforming biowaste into valuable products. These processes reduce landfill dependence, prevent the release of toxic substances involved in burning organic matter, and limit soil and groundwater contamination [74]. Composting avoids the burning of organic waste and prevents the release of toxic substances into the atmosphere, protecting air quality. At the same time, soil and groundwater contamination is reduced through the uncontrolled disposal of organic waste.

An important direction in which biowaste, especially those materials characterized by a high ratio of polysaccharides [75], could be orientated is the obtaining of bioplastics. The current trend is to limit the production of synthetic plastics that negatively impact several ecosystems. A direction that is gaining increased attention from researchers is the development of biocomposites that incorporate biowaste components. As to strengthening [76], a substance’s attributes are usually tested based on the performance exhibited by the specific biopolymers of the agro trash, such as cellulose, hemicellulose, lignin, or starch. Pattnaik et al. obtained good results for a biocomposite developed using limited chemical modification of the main structural polymer. The matrix was obtained using a Fabaceae family representative, Vigna unguiculata, and reinforcement from jute fibre and vetiver root [77]. Ashraf et al. developed an application based on watermelon seeds that could be successfully applied in different engineering fields [78]. Such efforts can be included among the efforts to reduce the anthropic-activity footprint.

In highlighting the environmental benefits of incorporating agro-waste into secondary industrial cycles, their potential uses are worth mentioning, in addition to their uses as biofuels [79], for remediation efforts [80] or as biocatalyst sources [81]. The decontaminative attributes depend on the main biopolymer within the waste. Differences have been evidenced by Steiger et al., who tested the efficiency of composites containing wheat hay or oat husk for methylene blue chelation [82]. El-Qelish et al. highlighted the good prospects for including dual valve shells and macroalgae waste in the context of two development directions. The research team proved the applicability of these two materials as components of a composite with absorbent capacities and as raw materials for green methane production. The chelating capacities were tested for tetracycline [83], a compound from the antibiotic group. The feasibility of possibly being implicated in remedial processes, the durable sanitation procedures associated with aquatic areas, and depuration sustain the interest in valorising biowaste. Not only could the natural shell secondary use process avert a biohazard, but it could also increase the demand for seafood dishes. Among these applications are also different products that have a calcareous coat. The hydroxyapatite contained in shells has significant potential for linking mercury ions [84]. Pine bark may be considered a biosorbent for pesticide and pharma product recovery. Lago et al. also underlined the efficiency of a sorbent composite for at least two treatment cycles [85].

The catalytic properties are relevant in green application development because they decrease the energy requirements and harmful chemical levels. Another important aspect when discussing the integration of biowaste and the associated eco-friendly generated benefits is the possibility of applying green methods to obtain them. Such purposes could be considered the expectation of ecological farming [86]. The green agriculture concept could be implemented precisely through vegetable waste valorisation. Natural stimulants in biotrash [87] could represent a link in the circular economy.

2.3. Health Benefits of Biowaste Valorisation

Biowaste valorisation also contributes significantly to public health by reducing environmental pollutants. For instance, curbing open-air agro-waste burning improves air quality and reduces respiratory risks linked to airborne particulate matter. Reducing agro-waste burning in open areas could ensure an improvement in air quality. A significant impact of such action could be represented by pollution reduction with respect to different particles. Improved atmospheric parameters may be obtained by using biofuels resulting from the implementation of biotechnologies in biomass processing.

Besides direct combustion, another source of suspended particles could be the dried leaves that may be blown from open land by the wind and translocated into inhabited areas. The fine dust inhaled may cause respiratory diseases, since different pathogens or toxins could function as vectors [88]. All actions in the circular-economy concept, particularly recycling and the reduction of uncontrolled waste disposal, contribute to reducing exposure to toxic substances.

Another significant consideration that can be observed in Figure 10 is the opportunity to ensure quality nourishment by biowaste valorisation. Composting vegetable waste could ensure natural fertilizers and help to grow healthier food. The organic farming concept is an increasing trend relative to farmers and consumers.

The market for functional foods is continuously expanding. Incorporating bio-synthesized anthocyanins, oils, acids, or flavonoids obtained from marcs (seeds [89], roots, or leaves) to colour, flavour, or increase a food’s nutritional value [25] builds up confidence in organic products. It opens the possibility of developing added-value products [90] that may have bioactive molecules incorporated [91]. El-Shamy et al. underlined the wide range of possible applications of pomegranate peels and seeds [92]. Among them, pectines and polyphenols are interesting macromolecules that may be used for their gelling properties for increased nutritional yield. New applications could be developed considering the large diversity of molecules with dietary values. Cynara cardunculus var. scolymus has the potential for application in milk fermentative products containing proteolytic catalysts. It also has insoluble fibres such as inulin, cellulose, and hemicellulose [93], which could be valorised in products ensuring the digestive tract’s proper functioning. This could gain attention, since over half of the plant is considered trash, and can be of assistance with environmental issues.

Depending on the processing conditions, other valuable compounds could be considered for extraction, such as the hydrosoluble vitamins, in the context of most vegetables, or the liposoluble ones in the cases of avocado, or the pulp wastes of different nuts. The waste treatment parameters influence the extraction-component yields. The temperature and grounding ratio are important in handling [94].

Aside from green manure, biological agriculture also implies reduced pesticide use. This technique benefits the production of salubrious foods, reduces synthetic pest control, and improves soil quality.

A new research direction could target seafood waste to obtain valuable components that may also be considered for food, agriculture, health, or pharmaceutical applications [95]. Uranga et al. underlined the good results for a potential carrier that had as components chitin from squid pen and fish gelatine [96].

Biowaste recovery offers major opportunities for environmental protection, reducing pollution, supporting soil sustainability, and reducing greenhouse gas emissions [97]. Widespread adoption of these practices can accelerate the transition to a circular economy, promoting resource efficiency and protecting biodiversity.

3. Nanofiber Applications in the Food Industry

Edible nanofibers are ultrafine structures—typically with diameters below 100 nm—derived from natural polymers such as proteins, polysaccharides, and lipids [98]. These materials have garnered considerable attention in the food industry due to their multifunctional properties, including improved texture, controlled nutrient release, emulsion stabilization, and enhanced preservation [99]. Functionalization of natural nanofibers such as cellulose, chitosan, and collagen can significantly enhance their applicability in food systems. This often involves the incorporation of nanoparticles or the use of advanced processing technologies [100].

Food Preservation and Shelf Life Extension

Edible nanofibers with antioxidant and antimicrobial properties can prevent oxidation and microbiological contamination. Materials incorporating natural fibres have proved to have low permeability to water and oxygen [101]. A key challenge in developing such packaging is improving its hydrophobicity, as excessive moisture transfer can degrade food quality. Electrospinning, vapor deposition, plasma treatment, and polymer blending have enhanced water resistance [102].

Vegetable proteins incorporated into coating mixtures have exhibited promising functionalities regarding their mechanical, permeability-related, and bactericide attributes [103]. Packaging materials containing nutritional fibres/nanofibers and oxidoreductase enzymes such as superoxide dismutase or catalase can help prevent fat degradation.

The attributes of packaging have to be correlated to the product’s specific requirments. One of the most critical elements is the degree of food perishability. Fresh fruits or vegetables, raw dairy, meat, and fish have to be ensured, first of all, antimicrobial protection. The mechanical components of possible coating materials must be considered in the case of berries. A chitosan base structured [104] and functionalized with different natural bioactive molecules could be considered in such cases. The polysaccharide derivative of chitin can maintain the composite firmness.

Other natural additives, like the essential oils obtained from thyme, oregano, or cinnamon, could provide protective effects for meat and dairy products. Throughout nanoencapsulation, the antimicrobial properties of natural essential oils could be enhanced [105]. In such cases, targeted pathogenic or non-pathogenic bacteria can affect the innocuity of goods. In the case of refrigerated foods, the synergetic effects of soy protein nanofibers with zinc ions may result in a bacteriostatic effect. Table 2 summarizes some recent research in composites developed to prolong the shelf life of food.

Table 2.

New nanofiber-based edible packaging products that exhibit preservation properties.

Generally, the polymers and additives used to test the improvement of the food quality were first-cycle raw materials. These data could be corroborated against the data regarding waste that can serve as raw materials for bioactive components. Such information could provide a basis for designing sustainable processes with a low environmental impact that implies efficient biowaste management. Mathura et al. underlined the possibilities of incorporating hemicellulose from green waste in a sustainable perspective [118]. Palanisamy et al. comprehensively described the specific attributes of nanocellulose that accomplish these targets [119]. The biopolymers resulting from the biotrash have an important attribute: their biodegradability. Zhang et al. tested the possibility of incorporating apple pomace into packaging materials. The macromolecules of interest were pectin and lignocellulose [120]. Their characteristics recommended them as durable alternatives to classical wrapping products [121]. Depending on the aim, additional benefits could be represented by the polymers’ feature of being hydrolysable or indigestible. Microstructures such as cellulose or hemicellulose could be recommended to improve foods’ digestibility. In turn, starch base structures may be considered for gradual unit release.

Edible nanofibers are revolutionizing the food industry, with extensive applications in food texture, nutrient delivery, biodegradable packaging, emulsion stabilization, preservation, and functional product development. These technologies contribute to food products’ safety, quality, and sustainability, opening new perspectives for healthy and innovative nutrition; one significant domain for obtaining them is agro-waste [122]. Their processing contributes to ecosystem protection through the creation of sustainable mechanisms.

4. Discussion

This review addresses a timely issue at the intersection of biotechnology, the circular economy, and food sustainability. It explores biowaste valorisation on a global scale, framed by pressing challenges such as resource scarcity, climate change, and the urgent need to reduce the ecological footprint of agri-food systems.

Biowaste refers to organic materials derived from agricultural, agro-industrial, or domestic sources. The review highlights key distinctions among biodegradable household waste (food waste), agrarian residues (e.g., straw, leaves, stalks), food industry byproducts (e.g., bran, whey, and slaughterhouse waste), and waste from fishing and aquaculture. This classification is critical when selecting suitable recovery technologies and evaluating the potential for reintegration into food or bio-based economic cycles.

One significant contribution of this work is the integration of biowaste recovery within the circular food chain paradigm, within which resources are recycled internally or reintroduced as inputs. Benefits include reducing food waste and landfill volumes, improving resource efficiency through nutrient and energy recovery, enhancing agricultural resilience by reducing reliance on synthetic fertilizers and imported feed, and creating new income opportunities for farmers and bioeconomy entrepreneurs.

From an ecological perspective, biowaste valorisation aligns with industrial ecology and agroecology principles, facilitating the transition from a linear consumption model to a circular system where “waste becomes a resource.” Understanding the food chain ecology and biogeochemical cycles is essential for the reintegration of organic residues into agricultural ecosystems without disrupting the natural balance. This review emphasizes the reduction of pressure on natural resources by reusing waste as organic fertilizers and soil amendments, preserving soil microbial biodiversity by replacing synthetic inputs with biologically composted products, preventing water pollution and greenhouse gas emissions through controlled anaerobic biodegradation, and restoring carbon and nitrogen cycles sustainably.

The review further highlights the importance of integrated ecological resource management, viewing waste streams as environmental challenges and opportunities for ecological restoration and natural capital recovery. It underscores the need for systemic thinking to understand better the complex interrelationships between the environment and food production.

Within the circular-economy framework, the valorisation of biowaste is advocated as a means to transform waste into renewable economic resources aligned with material efficiency, reuse, and sustainable innovation principles. This approach “closes the loop” in the agri-food chain, reducing economic losses related to food waste and disposal while generating added value through marketable products such as biofertilizers, animal feed, bioplastics, and additives. It also fosters new circular business models, encourages innovation in bioeconomy and agrotechnology, and promotes industrial partnerships and local supply chains based on industrial symbiosis.

Finally, this review emphasizes the critical role of regulatory frameworks and fiscal incentives in promoting circular technologies and investments in infrastructure and smart logistics for efficient waste collection and processing. From an economic standpoint, it calls for comprehensive cost–benefit analyses that account for positive externalities, including pollution reduction, job creation in the bioeconomy, and enhanced food security.

5. Limitations, Challenges, and Future Perspectives

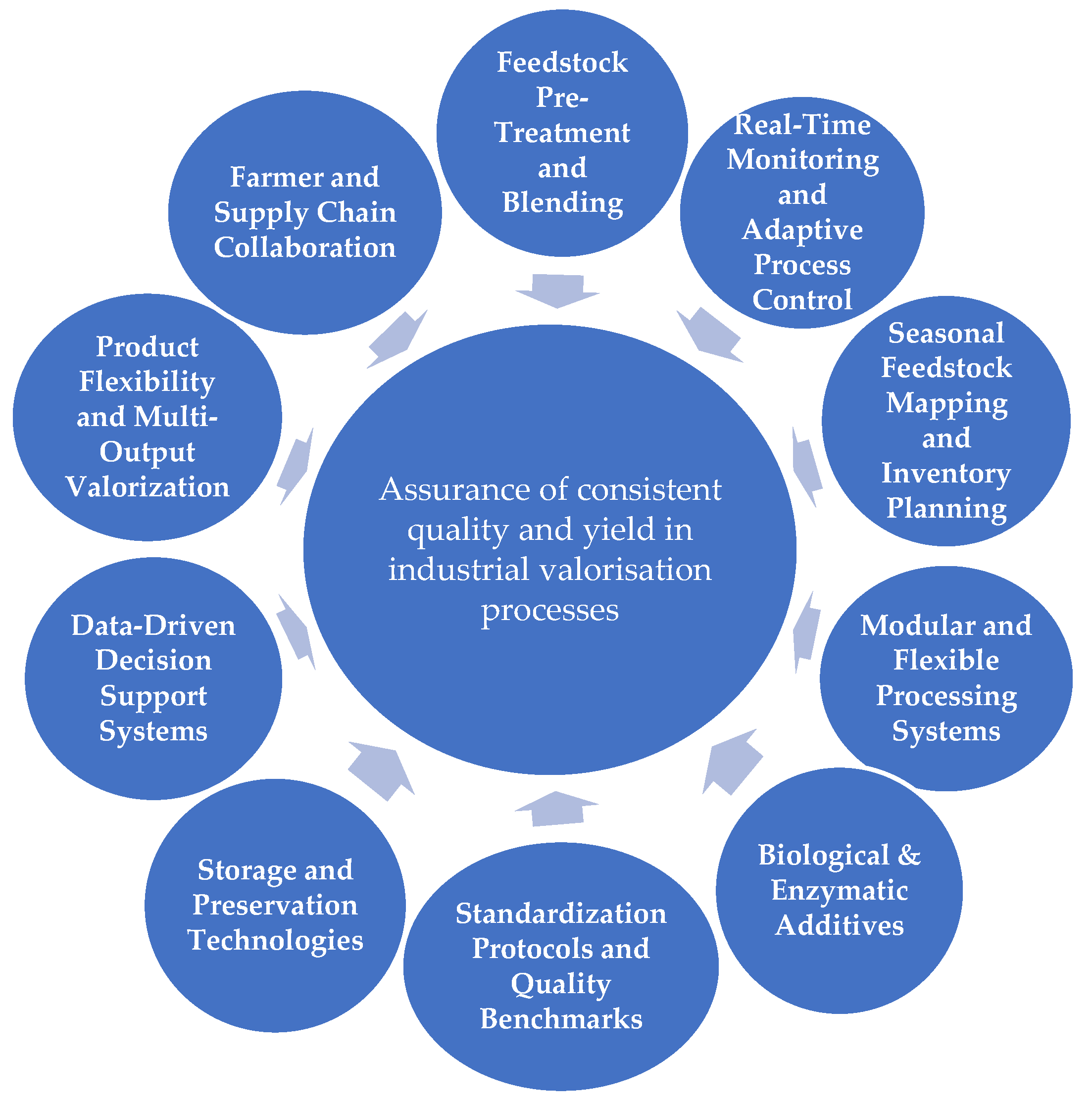

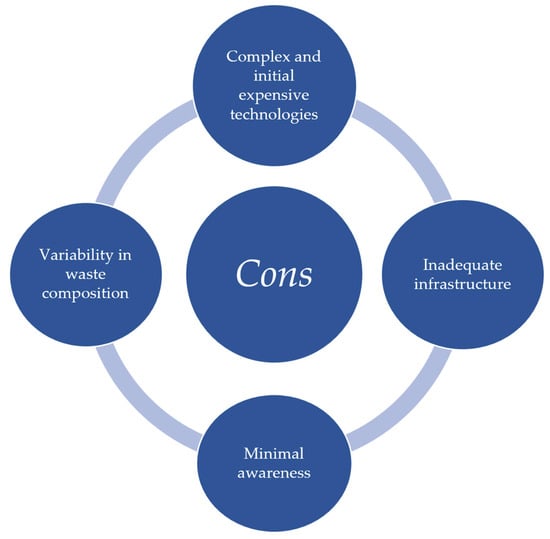

The valorisation of agricultural biowaste offers substantial economic, environmental, and health-related benefits. However, several limitations continue to hinder its widespread adoption, particularly on a commercial or industrial scale. These challenges can be broadly categorized as technological, economic, logistical, legislative, and socio-educational.

Biowaste valorisation is often constrained by limited infrastructure, especially in rural regions, where effective collection, processing, and specialized treatments are lacking. Seasonal variations in waste composition further impact conversion yields.

Seasonal variability in agro-waste composition presents a significant challenge to maintaining consistent quality and yield in industrial valorisation processes such as composting, anaerobic digestion, biochar production, or bio-refining. A combination of technological, logistical, and process-control strategies, as shown in Figure 12, can be employed to manage this variability effectively.

Figure 12.

Key strategies to ensure consistent quality and yield in industrial agro-waste valorisation processes.

The high cost of transportation to centralized facilities reduces competitiveness, especially in the absence of consistent policy supports such as subsidies, tax breaks, or carbon credits. Additionally, a lack of trained personnel and public awareness hinders widespread adoption.

Public awareness and education campaigns are crucial for overcoming socio-educational barriers to biowaste valorisation, especially in rural and underdeveloped regions. To be effective, such campaigns must go beyond simple information dissemination and foster behavioural change, community ownership, and knowledge transfer (Figure 13).

Figure 13.

Key approaches to the improved acceptance of biowaste valorisation.

High transportation and handling costs may render waste-derived products less competitive than conventional alternatives. Government incentives or subsidies could play a vital role in offsetting these expenses and encouraging the development of decentralized waste valorisation hubs.

A well-optimized policy framework must combine financial incentives, decentralized infrastructure, regulatory clarity, and community engagement to unlock the socio-economic potential of agro-waste valorisation in rural and underdeveloped regions. When embedded in broader sustainability and climate strategies, such policies can drive both rural development and circular-economy goals.

There is a pressing need for improved awareness and technical training among farmers, agribusinesses, and local authorities. Many stakeholders remain unaware of biowaste recovery’s environmental and economic advantages or are hesitant to adopt unfamiliar technologies.

Despite these challenges, biowaste valorisation is expected to grow significantly, driven by advancements in smart farming, renewable energy, and sustainability-driven policies. Investments in integrated systems—such as solar-powered biorefineries or farms using anaerobic digesters—will enhance energy efficiency and reduce reliance on fossil fuels. These innovations will likely provide a competitive edge to producers who adopt sustainable technologies over those relying on conventional methods.

Emerging technologies that reduce initial investment and operational costs in agro-waste valorisation prioritize scalability, energy efficiency, and decentralized processing (Table 3). Integrating low-tech methods like solar drying with innovative tools like AI and sensors can significantly cut capital and operational expenses. Success in rural or underdeveloped regions depends on flexible, low-maintenance systems that align with the local supply chain.

Table 3.

Emerging cost-efficient technologies for agro-waste valorisation and their suitability for rural deployment.

Furthermore, developing green fertilizers derived from agricultural waste could expand the market for organic and eco-labelled food products. With consumer interest increasingly favouring environmentally conscious brands, integrating waste-to-value strategies into the supply chain may strengthen brand reputation and foster resilient economic ecosystems.

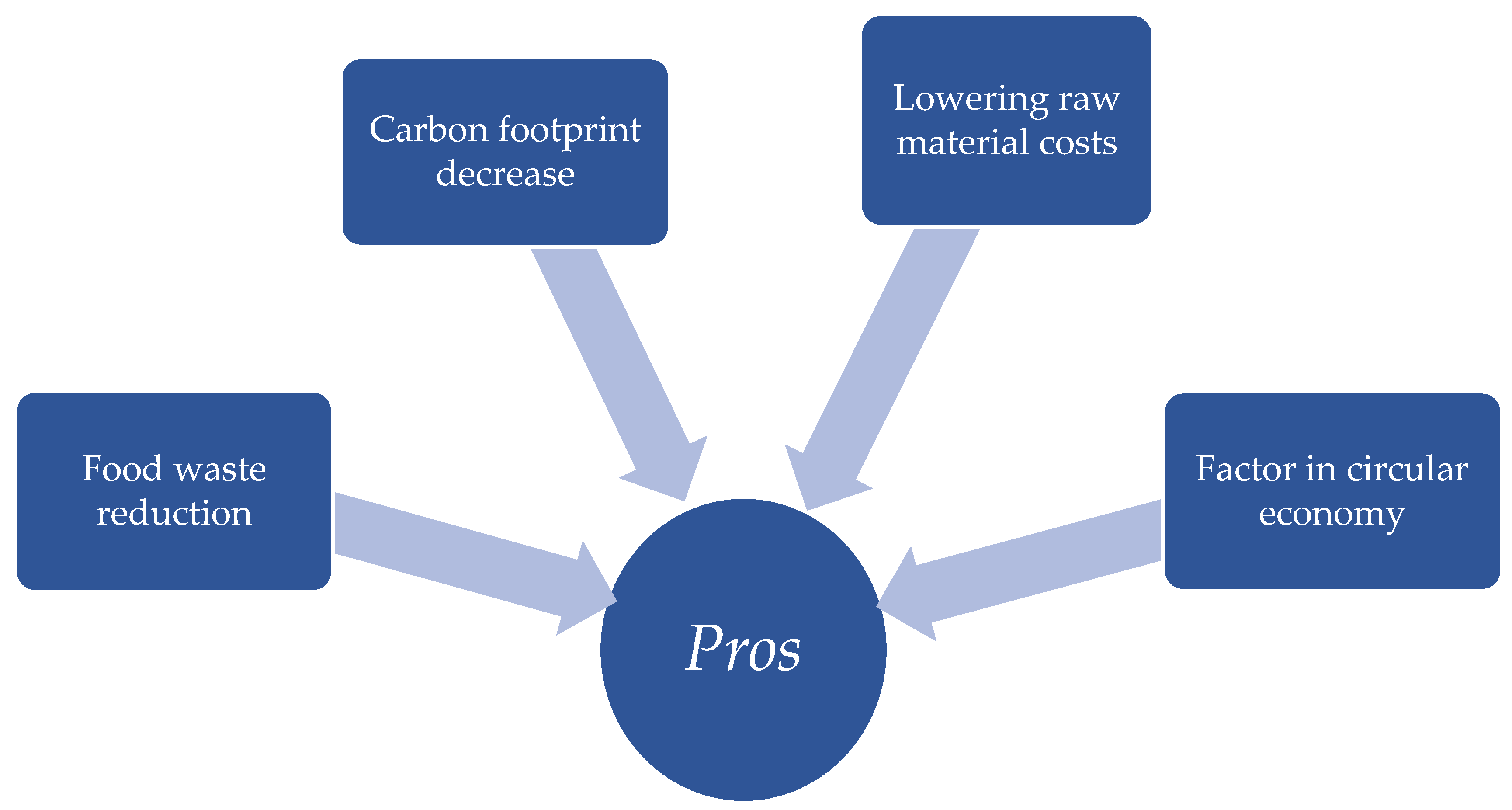

Biowaste valorisation has strengths and weaknesses. These aspects are synthesized in Figure 14 and Figure 15, analysing the literature in the field.

Figure 14.

Benefits of agro-waste valorisation.

Figure 15.

Limitations on agro-waste valorisation.

Economic variables such as market demand for bioproducts (e.g., biofertilizers, biogas, and biofuels) and policy frameworks also influence the feasibility of biowaste conversion.

Although agricultural waste recovery has excellent potential, these limitations make implementing solutions difficult. However, investments in technology, infrastructure, education, and government policies can help overcome these obstacles, making waste recovery a viable and effective practice in the long term [131].

6. Conclusions

The effective valorisation of agri-food waste represents a strategic opportunity to enhance resource efficiency, reduce the environmental burden, and support the development of sustainable, circular production systems. By integrating recycling, composting, and bioenergy technologies, organic waste streams can be converted into high-value products such as biofertilizers, biogas, and biopolymers.

This study highlights the importance of combining technical innovation with supportive policy frameworks and stakeholder engagement. To minimize waste generation and maximize recovery efficiency, it is essential to underline the importance of public education, food labelling that is more transparent, and incentives for decentralized processing facilities. Additionally, investments in waste valorisation infrastructure—particularly in rural and agricultural regions—can overcome current logistical and economic barriers.

Due to advances in processing technologies, innovative farming systems, and life-cycle-based product design, adopting circular-economy principles within the agri-food sector is increasingly feasible. These approaches align with global sustainability goals and open new pathways for economic diversification and industrial competitiveness.

With the decline of technological costs and increased regulatory pressures, agricultural waste recovery is expected to become a core component of sustainable food and energy systems. Future efforts should prioritize scalable, cost-effective solutions and promote interdisciplinary collaboration across agriculture, engineering, and the environmental sciences. The valorising of agro-waste can contribute significantly to climate-neutral, resilient, and resource-efficient processes [132].

Author Contributions

Funding

This research received no external funding.

Data Availability Statement

No new data were created or analysed in this study. Data sharing does not apply to this article.

Acknowledgments

Project financed by the “Aurel Vlaicu” University of Arad through the research grant UAV-IRG-1-2025-3.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Singh, R.B.; Srinagesh, B.; Anand, S. Urban Health Risk and Resilience in Asian Cities; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar] [CrossRef]

- Phiri, R.; Mavinkere Rangappa, S.; Siengchin, S.; Oladijo, O.P.; Dhakal, H.N. Development of sustainable biopolymer-based composites for lightweight applications from agricultural waste biomass: A review. Adv. Ind. Eng. Polym. Res. 2023, 6, 436–450. [Google Scholar] [CrossRef]

- Lou, J.; Rezaee Babadi, M.; Otadi, M.; Tarahomi, M.; Van Le, Q.; Ali Khonakdar, H.; Li, C. Agricultural waste valorization towards (nano)catalysts for the production of chemicals and materials. Fuel 2023, 351, 128935. [Google Scholar] [CrossRef]

- El-Ramady, H.; Brevik, E.C.; Bayoumi, Y.; Shalaby, T.A.; El-Mahrouk, M.E.; Taha, N.; Elbasiouny, H.; Elbehiry, F.; Amer, M.; Abdalla, N.; et al. An Overview of Agro-Waste Management in Light of the Water-Energy-Waste Nexus. Sustainability 2022, 14, 15717. [Google Scholar] [CrossRef]

- Bonciu, E.; Păunescu, R.A.; Roșculete, E.; Păunescu, G. Waste management in agriculture. Sci. Pap. Ser. Manag. Econ. Eng. Agric. Rural Dev. 2021, 21, 219–228. [Google Scholar]

- Zhao, J.; Yu, L.; Ma, H.; Zhou, F.; Yang, K.; Wu, G. Corn stalk-based activated carbon synthesized by a novel activation method for high-performance adsorption of hexavalent chromium in aqueous solutions. J. Colloid Interface Sci. 2020, 578, 650–659. [Google Scholar] [CrossRef]

- Mishra, B.; Mohanta, Y.K.; Reddy, C.N.; Reddy, S.D.M.; Mandal, S.K.; Yadavalli, R.; Sarma, H. Valorization of agro-industrial biowaste to biomaterials: An innovative circular bioeconomy approach. Circ. Econ. 2023, 2, 100050. [Google Scholar] [CrossRef]

- Islam, N.F.; Gogoi, B.; Saikia, R.; Yousaf, B.; Narayan, M.; Sarma, H. Encouraging circular economy and sustainable environmental practices by addressing waste management and biomass energy production. Reg. Sustain. 2024, 5, 100174. [Google Scholar] [CrossRef]

- Eurostat-European Commission. Available online: https://ec.europa.eu/eurostat/databrowser/view/env_wasgen/default/table?lang=en (accessed on 11 July 2023).

- Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:02000D0532-20150601 (accessed on 14 May 2025).

- Sharma, P.; Bano, A.; Verma, K.; Yadav, M.; Varjani, S.; Singh, S.P.; Tong, Y.W. Food waste digestate as biofertilizer and their direct applications in agriculture. Bioresour. Technol. Rep. 2023, 23, 101515. [Google Scholar] [CrossRef]

- Awogbemi, O.; Von Kallon, D.V. Pretreatment techniques for agricultural waste. Case Stud. Chem. Environ. Eng. 2022, 6, 100229. [Google Scholar] [CrossRef]

- Awogbemi, O.; Von Kallon, D.V. Valorization of agricultural wastes for biofuel applications. Heliyon 2022, 8, e11117. [Google Scholar] [CrossRef]

- Caldeira, C.; De Laurentiis, V.; Ghose, A.; Corrado, S.; Sala, S. Grown and thrown: Exploring approaches to estimate food waste in EU countries. Resour. Conserv. Recycl. 2021, 168, 105426. [Google Scholar] [CrossRef]

- Phonthanukitithaworn, C.; Maitree, N.; Naruetharadhol, P. Eco-innovation policies for food waste management: A European Union-ASEAN comparison. J. Open Innov. Technol. Mark. Complex. 2024, 10, 100295. [Google Scholar] [CrossRef]

- Scherhaufer, S.; Moates, G.; Hartikainen, H.; Waldron, K.; Obersteiner, G. Environmental impacts of food waste in Europe. Waste Manag. 2018, 77, 98–113. [Google Scholar] [CrossRef] [PubMed]

- Okolie, J.A.; Jimoh, T.; Akande, O.; Okoye, P.U.; Ogbaga, C.C.; Adeleke, A.A.; Ikubanni, P.P.; Güleç, F.; Amenaghawon, A.N. Pathways for the valorization of animal and human waste to biofuels, sustainable materials, and value-added chemicals. Environments 2023, 10, 46. [Google Scholar] [CrossRef]

- Shukla, I. Potential of renewable agricultural wastes in the smart and sustainable steelmaking process. J. Clean. Prod. 2022, 370, 133422. [Google Scholar] [CrossRef]

- Alyami, M.; Hakeem, I.Y.; Amin, M.; Zeyad, A.M.; Tayeh, B.A.; Agwa, I.S. Effect of agricultural olive, rice husk and sugarcane leaf waste ashes on sustainable ultra-high-performance concrete. J. Build. Eng. 2023, 72, 106689. [Google Scholar] [CrossRef]

- Fareed, A.; Zaidi, S.B.A.; Ahmad, N.; Hafeez, I.; Ali, A.; Ahmad, M.F. Use of agricultural waste ashes in asphalt binder and mixture: A sustainable solution to waste management. Constr. Build. Mater. 2020, 259, 120575. [Google Scholar] [CrossRef]

- Amalina, F.; Abd Razak, A.S.; Krishnan, S.; Zularisam, A.; Nasrullah, M. Dyes removal from textile wastewater by agricultural waste as an absorbent—A review. Clean. Waste Syst. 2022, 3, 100051. [Google Scholar] [CrossRef]

- Hussain, O.A.; Hathout, A.S.; Abdel-Mobdy, Y.E.; Rashed, M.; Rahim, E.A.; Fouzy, A. Preparation and characterization of activated carbon from agricultural wastes and their ability to remove chlorpyrifos from water. Toxicol. Rep. 2023, 10, 146–154. [Google Scholar] [CrossRef]

- Dey, T.; Bhattacharjee, T.; Nag, P.; Ritika; Ghati, A.; Kuila, A. Valorization of agro-waste into value added products for sustainable development. Bioresour. Technol. Rep. 2021, 16, 100834. [Google Scholar] [CrossRef]

- Ufitikirezi, J.d.D.M.; Filip, M.; Ghorbani, M.; Zoubek, T.; Olšan, P.; Bumbálek, R.; Strob, M.; Bartoš, P.; Umurungi, S.N.; Murindangabo, Y.T.; et al. Agricultural Waste Valorization: Exploring Environmentally Friendly Approaches to Bioenergy Conversion. Sustainability 2024, 16, 3617. [Google Scholar] [CrossRef]

- Bala, S.; Garg, D.; Sridhar, K.; Inbaraj, B.S.; Singh, R.; Kamma, S.; Tripathi, M.; Sharma, M. Transformation of agro-waste into value-added bioproducts and bioactive compounds: Micro/nano formulations and application in the agri-food-pharma sector. Bioengineering 2023, 10, 152. [Google Scholar] [CrossRef] [PubMed]

- Capanoglu, E.; Nemli, E.; Tomas-Barberan, F. Novel approaches in the valorization of agricultural wastes and their applications. J. Agric. Food Chem. 2022, 70, 6787–6804. [Google Scholar] [CrossRef]

- Ferreira, D.C.M.; dos Santos, P.N.; Santos, F.H.; Molina, G.; Pelissari, F.M. Sustainability approaches for agrowaste solution: Biodegradable packaging and microbial polysaccharides bio-production. Sci. Total Environ. 2023, 886, 163922. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Zhang, X.; Lin, K.; Chen, Y.; Cheng, B.; Pan, P.; Niu, S.; Huang, L.; Li, J.; Chen, L. High-strength lignocellulosic material from agro-waste. Ind. Crops Prod. 2024, 220, 119204. [Google Scholar] [CrossRef]

- Lounis, F.M.; Benhacine, F.; Hadj-Hamou, A.S. Improving water barrier properties of starch based bioplastics by lignocellulosic biomass addition: Synthesis, characterization and antibacterial properties. Int. J. Biol. Macromol. 2024, 283, 137823. [Google Scholar] [CrossRef]

- Abe, M.M.; Portinho, J.L.; Gonçalves, M.d.M.C.; Sanvezzo, P.B.; Freitas, C.d.; de Souza, J.F.; Carneiro, R.; Ferragut, C.; Costa, M.L.; Aouada, M.R.d.M.; et al. Development of polysaccharide bioplastic: Analysis of thermo-mechanical properties and different environmental implications. J. Clean. Prod. 2024, 469, 143163. [Google Scholar] [CrossRef]

- Pongsuwan, C.; Boonsuk, P.; Sermwittayawong, D.; Aiemcharoen, P.; Mayakun, J.; Kaewtatip, K. Banana inflorescence waste fiber: An effective filler for starch-based bioplastics. Ind. Crops Prod. 2022, 180, 114731. [Google Scholar] [CrossRef]

- Xu, J.; Sagnelli, D.; Faisal, M.; Perzon, A.; Taresco, V.; Mais, M.; Giosafatto, C.V.L.; Hebelstrup, K.H.; Ulvskov, P.; Jørgensen, B.; et al. Amylose/cellulose nanofiber composites for all-natural, fully biodegradable and flexible bioplastics. Carbohydr. Polym. 2021, 253, 117277. [Google Scholar] [CrossRef]

- Rahman, M.M.; Hossain, M.I.; Hassan, M.M.; Ghos, B.C.; Rahman, M.S.; Gafur, M.A.; Alam, M.A.; Zuhanee, M.K.A. Cellulose nanocrystal (CNC) from okra plant (Abelmoschus esculentus L.) stalks as a reinforcement in bionanocomposite fabrication: Extraction, processing, and characterization study. Carbohydr. Polym. Technol. Appl. 2024, 8, 100581. [Google Scholar] [CrossRef]

- Reshmy, R.; Madhavan, A.; Philip, E.; Paul, S.A.; Sindhu, R.; Binod, P.; Pugazhendhi, A.; Sirohi, R.; Pandey, A. Sugarcane bagasse derived nanocellulose reinforced with frankincense (Boswellia serrata): Physicochemical properties, biodegradability and antimicrobial effect for controlling microbial growth for food packaging application. Environ. Technol. Innov. 2021, 21, 101335. [Google Scholar] [CrossRef]

- Li, Z.; Yang, J.; Loh, X.J. Polyhydroxyalkanoates: Opening doors for a sustainable future. NPG Asia Mater. 2016, 8, e265. [Google Scholar] [CrossRef]

- Adebayo Oyewole, O.; Usman Abdulmalik, S.; Onozasi Abubakar, A.; Ishaku Chimbekujwo, K.; Dorcas Obafemi, Y.; Oyegbile, B.; Peter Abioye, O.; David Adeniyi, O.; Chidi Egwim, E. Production of polyhydroxyalkanoate (pha) by pseudomonas aeruginosa (ol405443) using agrowastes as carbon source. Clean. Mater. 2024, 11, 100217. [Google Scholar] [CrossRef]

- Elegbede, J.A.; Ajayi, V.A.; Lateef, A. Microbial valorization of corncob: Novel route for biotechnological products for sustainable bioeconomy. Environ. Technol. Innov. 2021, 24, 102073. [Google Scholar] [CrossRef]

- Topuz, F.; Uyar, T. Electrospinning of sustainable polymers from biomass for active food packaging. Sustain. Food Technol. 2024, 2, 1266–1296. [Google Scholar] [CrossRef]

- Amir, M.; Rizvi, S.F.; Asif, M.; Ahmad, A.; Alshammari, M.B.; Gupta, A.; Zaheer, M.R.; Roohi, R. Polyhydroxybutyrate (PHB) bioplastic characterization from the isolate Pseudomonas stutzeri PSB1 synthesized using potato peel feedstock to combat solid waste management. Biocatal. Agric. Biotechnol. 2024, 57, 103097. [Google Scholar] [CrossRef]

- Babu, A.; Kumar, A.R.; Amrutha, N.R.; Madhurya, S.; Punil Kumar, H.N.; Reddy, J.P.; Murthy, P.S.K.; Varaprasad, K. Utilizing foxtail millet husk waste for sustainable new bioplastic composites with enhanced thermal stability and biodegradability. Int. J. Biol. Macromol. 2024, 282, 137283. [Google Scholar] [CrossRef]

- Kee, S.H.; Ganeson, K.; Rashid, N.F.M.; Yatim, A.F.M.; Vigneswari, S.; Amirul, A.-A.A.; Ramakrishna, S.; Bhubalan, K. A review on biorefining of palm oil and sugar cane agro-industrial residues by bacteria into commercially viable bioplastics and biosurfactants. Fuel 2022, 321, 124039. [Google Scholar] [CrossRef]

- Famiglietti, M.; Mirpoor, S.F.; Caporale, A.G.; Cappelli, C.; Tarallo, O.; Mariniello, L. Hydrocolloid-based bioplastics: Degradation in characterized soils. Int. J. Biol. Macromol. 2025, 284, 137988. [Google Scholar] [CrossRef]

- Alonso-González, M.; Felix, M.; Romero, A.; Sergi, C.; Bavasso, I.; Sarasini, F. Lab-scale biocomposite manufacturing: Exploring rice bran-based bioplastics reinforced with natural fillers through extrusion and injection molding. Resour. Conserv. Recycl. 2025, 212, 107990. [Google Scholar] [CrossRef]

- Abdullah, J.A.A.; Perdomo, C.A.A.; Núñez, L.A.H.; Rivera-Flores, O.; Sánchez-Barahona, M.; Guerrero, A.; Romero, A. Lychee peel extract-based magnetic iron oxide nanoparticles: Sustainable synthesis, multifaceted antioxidant system, and prowess in eco-friendly food preservation. Food Bioprod. Process. 2024, 145, 148–157. [Google Scholar] [CrossRef]

- Moure Abelenda, A.; Semple, K.T.; Herbert, B.M.J.; Aggidis, G.; Aiouache, F. Valorization of agrowaste digestate via addition of wood ash, acidification, and nitrification. Environ. Technol. Innov. 2022, 28, 102632. [Google Scholar] [CrossRef]

- Kannan, M.B.; Ronan, K. Conversion of biowastes to biomaterial: An innovative waste management approach. Waste Manag. 2017, 67, 67–72. [Google Scholar] [CrossRef]

- Lim, S.-F.; Matu, S.U. Utilization of agro-wastes to produce biofertilizer. Int. J. Energy Environ. Eng. 2015, 6, 31–35. [Google Scholar] [CrossRef]

- Aguilar-Rivera, N. Economic Viability and Policy Implications of Agriculture Waste Valorization: Social and Economic Impacts, Policy Frameworks, and Regulations. In Transforming Agriculture Residues for Sustainable Development: From Waste to Wealth; Arora, J., Joshi, A., Ray, R.C., Eds.; Springer Nature: Cham, The Switzerland, 2024; pp. 393–419. [Google Scholar] [CrossRef]

- Prado-Acebo, I.; Cubero-Cardoso, J.; Lu-Chau, T.A.; Eibes, G. Integral multi-valorization of agro-industrial wastes: A review. Waste Manag. 2024, 183, 42–52. [Google Scholar] [CrossRef]

- Karić, N.; Maia, A.S.; Teodorović, A.; Atanasova, N.; Langergraber, G.; Crini, G.; Ribeiro, A.R.L.; Đolić, M. Bio-waste valorisation: Agricultural wastes as biosorbents for removal of (in)organic pollutants in wastewater treatment. Chem. Eng. J. Adv. 2022, 9, 100239. [Google Scholar] [CrossRef]

- Hiranobe, C.T.; Gomes, A.S.; Paiva, F.F.G.; Tolosa, G.R.; Paim, L.L.; Dognani, G.; Cardim, G.P.; Cardim, H.P.; dos Santos, R.J.; Cabrera, F.C. Sugarcane Bagasse: Challenges and Opportunities for Waste Recycling. Clean Technol. 2024, 6, 662–699. [Google Scholar] [CrossRef]

- Munagala, M.; Shastri, Y.; Nagarajan, S.; Ranade, V. Production of Bio-CNG from sugarcane bagasse: Commercialization potential assessment in Indian context. Ind. Crops Prod. 2022, 188, 115590. [Google Scholar] [CrossRef]

- Mahale, M.R.; Kodam, K.M. Chapter 7—The emergence of agrowaste valorization: A revolutionizing sustainability. In Sustainable Management of Agro-Food Waste; Rai, S., Bhardwaj, A.K., Colla, L.M., Eds.; Academic Press: Cambridge, MA, USA, 2025; pp. 87–104. [Google Scholar] [CrossRef]

- Popa, I.; Vasile, V.; Lambrache, S. Superior capitalization of vegetable waste and natural agro-industrial by-products by creating innovative products for construction. Socio-economic predictive analyses. Sci. Papers. Ser. E Land Reclam. Earth Obs. Surv. Environ. Eng. 2024, 13, 340–347. [Google Scholar]

- Schiebel, C.S.; Bueno, L.R.; Pargas, R.B.; de Mello Braga, L.L.V.; da Silva, K.S.; Fernandes, A.C.V.U.; dos Santos Maia, M.H.; de Oliveira, N.M.T.; Bach, C.; Maria-Ferreira, D. Exploring the biological activities and potential therapeutic applications of agro-industrial waste products through non-clinical studies: A systematic review. Sci. Total Environ. 2024, 950, 175317. [Google Scholar] [CrossRef]

- Lee, J.; Kim, M.; Jung, J.; Heo, J.W.; Lee, K.H.; Kim, S.; Son, H.; Chun, Y.; Yoo, H.Y. Valorization of persimmon calyx, an industrial biowaste, as a potential resource for antioxidant production. Environ. Technol. Innov. 2023, 30, 103038. [Google Scholar] [CrossRef]

- Bains, A.; Sridhar, K.; Singh, B.N.; Kuhad, R.C.; Chawla, P.; Sharma, M. Valorization of onion peel waste: From trash to treasure. Chemosphere 2023, 343, 140178. [Google Scholar] [CrossRef] [PubMed]

- Baiano, A. Recovery of Biomolecules from Food Wastes—A Review. Molecules 2014, 19, 14821–14842. [Google Scholar] [CrossRef]

- Arpit Singh, T.; Sharma, M.; Sharma, M.; Dutt Sharma, G.; Kumar Passari, A.; Bhasin, S. Valorization of agro-industrial residues for production of commercial biorefinery products. Fuel 2022, 322, 124284. [Google Scholar] [CrossRef]

- IEA. Average Biogas Production Yield by Tonne of Feedstock Type; IEA: Paris, France; Available online: https://www.iea.org/data-and-statistics/charts/average-biogas-production-yield-by-tonne-of-feedstock-type (accessed on 8 June 2025).

- Nazia Hossain, J.H.Z.T.M.I.M. A Review of Bioethanol Production from Plant-based Waste Biomass by Yeast Fermentation. Int. J. Technol. 2017, 8, 291–319. [Google Scholar] [CrossRef]

- Yaashikaa, P.R.; Kumar, P.S.; Varjani, S. Valorization of agro-industrial wastes for biorefinery process and circular bioeconomy: A critical review. Bioresour. Technol. Rep. 2022, 343, 126126. [Google Scholar] [CrossRef]

- Bentivoglio, D.; Chiaraluce, G.; Finco, A. Economic assessment for vegetable waste valorization through the biogas-biomethane chain in Italy with a circular economy approach. Front. Sustain. Food Syst. 2022, 6, 1035357. [Google Scholar] [CrossRef]

- Donner, M.; Gohier, R.; de Vries, H. A new circular business model typology for creating value from agro-waste. Sci. Total Environ. 2020, 716, 137065. [Google Scholar] [CrossRef]

- Baseri, S. Environmentally sound recycling of agricultural waste: A sustainable approach to develop bio-functional art textile. J. Environ. Manag. 2024, 366, 121758. [Google Scholar] [CrossRef]

- Jalil, M.A.; Repon, M.R.; Jurkonienė, S.; Haji, A.; Hussain, S.Z.; Shukhratov, S. Valorization of pineapple leaves: Effective conversion of agro waste to textile materials. Energy Sci. Eng. 2024, 12, 2426–2434. [Google Scholar] [CrossRef]

- Ragini, Y.P.; Karishma, S.; Kamalesh, R.; Saravanan, A.; TajSabreen, B.; Eswaar, D.K. Sustainable biorefinery approaches in the valorization of agro-food industrial residues for biofuel production: Economic and future perspectives. Sustain. Energy Technol. Assess. 2025, 75, 104239. [Google Scholar] [CrossRef]

- Hogg, D. Costs for Municipal Waste Management in the EU, Final Report to Directorate General Environment; Eunomia Research & Consulting Ltd.: Brussels, Belgium, 2001; Available online: https://ec.europa.eu/environment/pdf/waste/studies/euwastemanagement_annexes.pdf (accessed on 9 June 2025).

- Roy, P.; Mohanty, A.K.; Dick, P.; Misra, M. A Review on the Challenges and Choices for Food Waste Valorization: Environmental and Economic Impacts. ACS Environ. Au 2023, 3, 58–75. [Google Scholar] [CrossRef]

- Ashraf, A.I.; Mohareb, E.; Vahdati, M. Evaluation of life cycle cost for the comparison of decentralized waste to composting and landfilling of municipal solid waste. Discov. Sustain. 2024, 5, 202. [Google Scholar] [CrossRef]

- Hogg, D.; Favoino, E.; Nielsen, N.; Thompson, J.; Wood, K.; Penschke, A.; Economides, D.; Papageorgiou, S. Economic Analysis of Options for Managing Biodegradable Municipal Waste; Final report to the European Commission; European Commission: Bristol, UK, 2002. [Google Scholar]

- Badagliacca, G.; Testa, G.; La Malfa, S.G.; Cafaro, V.; Lo Presti, E.; Monti, M. Organic Fertilizers and Bio-Waste for Sustainable Soil Management to Support Crops and Control Greenhouse Gas Emissions in Mediterranean Agroecosystems: A Review. Horticulturae 2024, 10, 427. [Google Scholar] [CrossRef]

- He, X.; Wang, Y.; Zhang, Y.; Wang, C.; Yu, J.; Ohtake, H.; Zhang, T. The potential for livestock manure valorization and phosphorus recovery by hydrothermal technology—A critical review. Mater. Sci. Energy Technol. 2023, 6, 94–104. [Google Scholar] [CrossRef]

- Koul, B.; Yakoob, M.; Shah, M.P. Agricultural waste management strategies for environmental sustainability. Environ. Res. 2022, 206, 112285. [Google Scholar] [CrossRef] [PubMed]

- Mutmainna, I.; Gareso, P.L.; Suryani, S.; Tahir, D. Can agriculture and food waste be a solution to reduce environmental impact of plastic pollution? zero-waste approach for sustainable clean environment. Bioresour. Technol. 2025, 420, 132130. [Google Scholar] [CrossRef]

- Sholokhova, A.; Varžinskas, V.; Rutkaitė, R. Valorization of Agro-waste in Bio-based and Biodegradable Polymer Composites: A Comprehensive Review with Emphasis on Europe Perspective. Waste Biomass Valori. 2024, 16, 1537–1571. [Google Scholar] [CrossRef]

- Pattnaik, S.S.; Behera, D.; Das, N.; Dash, A.K.; Behera, A.K. Fabrication and characterization of natural fiber reinforced cowpea resin-based green composites: An approach towards agro-waste valorization. RSC Adv. 2024, 14, 25728–25739. [Google Scholar] [CrossRef]

- Ashraf, H.; Karahan, B.D. Biowaste valorization into valuable nanomaterials: Synthesis of green carbon nanodots and anode material for lithium-ion batteries from watermelon seeds. Mater. Res. Bull. 2024, 169, 112492. [Google Scholar] [CrossRef]

- Afolalu, S.; Salawu, E.; Ogedengbe, T.; Joseph, O.; Okwilagwe, O.; Emetere, M.; Yusuf, O.; Noiki, A.; Akinlabi, S. Bio-agro waste valorization and its sustainability in the industry: A review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1107, 012140. [Google Scholar] [CrossRef]

- Rao, P.; Rathod, V. Valorization of food and agricultural waste: A step towards greener future. Chem. Rec. 2019, 19, 1858–1871. [Google Scholar] [CrossRef] [PubMed]

- Falade, A.O. Valorization of agricultural wastes for production of biocatalysts of environmental significance: Towards a sustainable environment. Environ. Sustain. 2021, 4, 317–328. [Google Scholar] [CrossRef]

- Steiger, B.G.K.; Zhou, Z.; Anisimov, Y.A.; Evitts, R.W.; Wilson, L.D. Valorization of agro-waste biomass as composite adsorbents for sustainable wastewater treatment. Ind. Crops Prod. 2023, 191, 115913. [Google Scholar] [CrossRef]

- El-Qelish, M.; Maged, A.; Elwakeel, K.Z.; Bhatnagar, A.; Elgarahy, A.M. Dual valorization of coastal biowastes for tetracycline remediation and biomethane production: A composite assisted anaerobic digestion. J. Hazard. Mater. 2024, 465, 133143. [Google Scholar] [CrossRef]

- Mignardi, S.; Tocci, E.; Medeghini, L. Clam shell waste recycling and valorization for sustainable Hg remediation. Heliyon 2024, 10, e35375. [Google Scholar] [CrossRef]

- Lago, A.; Silva, B.; Tavares, T. Biowaste valorization on pharmaceuticals and pesticides abatement in aqueous environments. Sustain. Mater. Technol. 2024, 39, e00792. [Google Scholar] [CrossRef]

- Nichita, A.; Popa, M.E. The valorization of plant and animal by-products for food sustainability. Sci. Papers. Ser. D Anim. Sci. 2024, 67, 524. [Google Scholar]

- Puglia, D.; Pezzolla, D.; Gigliotti, G.; Torre, L.; Bartucca, M.L.; Del Buono, D. The Opportunity of Valorizing Agricultural Waste, Through Its Conversion into Biostimulants, Biofertilizers, and Biopolymers. Sustainability 2021, 13, 2710. [Google Scholar] [CrossRef]

- Srivastava, R.K.; Shetti, N.P.; Reddy, K.R.; Nadagouda, M.N.; Badawi, M.; Bonilla-Petriciolet, A.; Aminabhavi, T.M. Valorization of biowastes for clean energy production, environmental depollution and soil fertility. J. Environ. Manag. 2023, 332, 117410. [Google Scholar] [CrossRef]

- Zayed, A.; Badawy, M.T.; Farag, M.A. Valorization and extraction optimization of Citrus seeds for food and functional food applications. Food Chem. 2021, 355, 129609. [Google Scholar] [CrossRef] [PubMed]

- Bisht, B.; Gururani, P.; Aman, J.; Vlaskin, M.S.; Anna, I.K.; Irina, A.A.; Joshi, S.; Kumar, S.; Kumar, V. A review on holistic approaches for fruits and vegetables biowastes valorization. Mater. Today Proc. 2023, 73, 54–63. [Google Scholar] [CrossRef]

- Lamine, M.; Hamdi, Z.; Zemni, H.; Rahali, F.Z.; Melki, I.; Mliki, A.; Gargouri, M. From residue to resource: The recovery of high-added values compounds through an integral green valorization of citrus residual biomass. Sustain. Chem. Pharm. 2024, 37, 101379. [Google Scholar] [CrossRef]

- El-Shamy, S.; Farag, M.A. Novel trends in extraction and optimization methods of bioactives recovery from pomegranate fruit biowastes: Valorization purposes for industrial applications. Food Chem. 2021, 365, 130465. [Google Scholar] [CrossRef]

- Zayed, A.; Farag, M.A. Valorization, extraction optimization and technology advancements of artichoke biowastes: Food and non-food applications. LWT 2020, 132, 109883. [Google Scholar] [CrossRef]

- Fraguela-Meissimilly, H.; Bastías-Montes, J.M.; Ortiz-Viedma, J.A.; Tamarit-Pino, Y.; Claret-Merino, M.; Araneda-Flores, J. Valorization of extracts from maqui (Aristotelia chilensis) and calafate (Berberis microphylla) biowaste blends by supercritical fluid and pressurized liquid extraction. J. Agric. Food Res. 2024, 15, 100950. [Google Scholar] [CrossRef]

- Azelee, N.I.W.; Dahiya, D.; Ayothiraman, S.; Noor, N.M.; Rasid, Z.I.A.; Ramli, A.N.M.; Ravindran, B.; Iwuchukwu, F.U.; Selvasembian, R. Sustainable valorization approaches on crustacean wastes for the extraction of chitin, bioactive compounds and their applications—A review. Int. J. Biol. Macromol. 2023, 253, 126492. [Google Scholar] [CrossRef]

- Uranga, J.; Etxabide, A.; Cabezudo, S.; de la Caba, K.; Guerrero, P. Valorization of marine-derived biowaste to develop chitin/fish gelatin products as bioactive carriers and moisture scavengers. Sci. Total Environ. 2020, 706, 135747. [Google Scholar] [CrossRef]

- Blasi, A.; Verardi, A.; Lopresto, C.G.; Siciliano, S.; Sangiorgio, P. Lignocellulosic Agricultural Waste Valorization to Obtain Valuable Products: An Overview. Recycling 2023, 8, 61. [Google Scholar] [CrossRef]

- Karnwal, A.; Kumar, G.; Singh, R.; Selvaraj, M.; Malik, T.; Al Tawaha, A.R.M. Natural biopolymers in edible coatings: Applications in food preservation. Food Chem. X 2025, 25, 102171. [Google Scholar] [CrossRef]

- Jafarzadeh, S.; Salehabadi, A.; Mohammadi Nafchi, A.; Oladzadabbasabadi, N.; Jafari, S.M. Cheese packaging by edible coatings and biodegradable nanocomposites; improvement in shelf life, physicochemical and sensory properties. Trends Food Sci. Technol. 2021, 116, 218–231. [Google Scholar] [CrossRef]

- Ojo, A.M.; Omotunde, O.I.; Otugboyega, J. Perspective Chapter: Functionalization of Nanofibers—Applications in Food Technology. In Advances in Nanofiber Research—Properties and Uses; Ameen, S., Akhtar, M.S., Kong, I., Eds.; IntechOpen: Rijeka, Croatia, 2024. [Google Scholar] [CrossRef]

- Joshi, M.; Aayush, K.; Sharma, K.; Bose, I.; Khan, A.A.; Atanassova, M.; Yang, T.; Murariu, O.C.; Sharma, S.; Caruso, G. Fiber and nanofiber based edible packaging for enhancing the shelf life of food: A review. Food Biosci. 2024, 59, 103970. [Google Scholar] [CrossRef]

- Kalita, P.; Bora, N.S.; Gogoi, B.; Goswami, A.; Pachuau, L.; Das, P.J.; Baishya, D.; Roy, S. Improving the hydrophobic nature of biopolymer based edible packaging film: A review. Food Chem. 2025, 479, 143793. [Google Scholar] [CrossRef]

- Payal, A.; Sandeep, G.D.S.; Bammidi, M.; Narayandas, A.; Syed, I.; Rao, M.V. Recent advances in plant protein-based edible coatings for shelf-life enhancement of perishable and high nutritive value foods—A Review. Food Packag. Shelf Life 2025, 48, 101465. [Google Scholar] [CrossRef]

- César de Albuquerque Sousa, T.; de Lima Costa, I.H.; Gandra, E.A.; Meinhart, A.D. Use of edible coatings as a new sustainable alternative to extend the shelf life of strawberries (Fragaria ananassa): A review. J. Stored Prod. Res. 2024, 108, 102375. [Google Scholar] [CrossRef]

- Souza, E.J.D.d.; Pacheco, C.d.O.; Costa, I.H.d.L.; Dias, A.R.G.; Zavareze, E.d.R. Applications of nanotechnology in essential oil protection to extend the shelf life of fruits and vegetables: A review. Food Control 2025, 170, 111044. [Google Scholar] [CrossRef]

- Mokhtaran, L.; Sabahi, S.; Noshad, M.; Noori, S.M.A. Investigating the effects of basil (Ocimum basilicum L.)c mucilage and cellulose nanofiber-based edible films with post-probiotics on fish fillet shelf life. Appl. Food Res. 2025, 5, 100704. [Google Scholar] [CrossRef]

- Wu, X.; Liu, Z.; He, S.; Liu, J.; Shao, W. Development of an edible food packaging gelatin/zein based nanofiber film for the shelf-life extension of strawberries. Food Chem. 2023, 426, 136652. [Google Scholar] [CrossRef]

- Wang, J.; Qin, M.; Wang, W.; Xia, Y.; Wu, G.; Deng, H.; Lin, Q. Konjac glucomannan/carboxylated cellulose nanofiber-based edible coating with tannic acid maintains quality and prolongs shelf-life of mango fruit. Food Chem. 2025, 478, 143750. [Google Scholar] [CrossRef]

- Sethunga, M.; Gunathilake, K.D.P.P.; Ranaweera, K.K.D.S.; Munaweera, I. Antimicrobial and antioxidative electrospun cellulose acetate-essential oils nanofibrous membranes for active food packaging to extend the shelf life of perishable fruits. Innov. Food Sci. Emerg. Technol. 2024, 97, 103802. [Google Scholar] [CrossRef]

- Wu, X.; Liu, Z.; Liu, J.; He, S.; Shao, W. Development of novel intelligent and edible dual-functional electrospun nanofiber films for shrimp preservation and freshness monitoring in real-time. Food Biosci. 2024, 61, 104828. [Google Scholar] [CrossRef]

- Gao, S.; Zhang, Y.; Wang, R.; Li, F.; Zhang, Y.; Zhu, S.; Wei, H.; Zhao, L.; Fu, Y.; Ye, F. Fabrication and characterization of betulin/hydroxypropyl-beta-cyclodextrin inclusion complex nanofibers: A potential edible antibacterial and antioxidant packaging material. Food Chem. 2025, 481, 144059. [Google Scholar] [CrossRef]

- Dayisoylu, K.S.; Akboğa, Z.; Doğan, C.; Kaya, E.; Akgul, Y.; Doğan, N.; Eticha, A.K. Rapid fabrication of micro-nanofibers from grapevine leaf extract and gelatine via electroblowing: A novel approach for edible active food packaging. Int. J. Biol. Macromol. 2023, 253, 127309. [Google Scholar] [CrossRef]

- Afsar, L.; Hassanzadazar, H.; Shojaee-Aliabadi, S.; Aminzare, M. Galbanum nanocomposite coating containing Satureja khuzestanica essential oil for prolonging shrimp (Metapenaeus affinis) shelf life at various temperatures. LWT 2025, 215, 117169. [Google Scholar] [CrossRef]

- Doğan, N.; Doğan, C.; Eticha, A.K.; Gungor, M.; Akgul, Y. Centrifugally spun micro-nanofibers based on lemon peel oil/gelatin as novel edible active food packaging: Fabrication, characterization, and application to prevent foodborne pathogens E. coli and S. aureus in cheese. Food Control 2022, 139, 109081. [Google Scholar] [CrossRef]

- Kaniyamparambil, S.H.; Salim, M.H.; Al Marzooqi, F.; Mettu, S.; Otoni, C.G.; Banat, F.; Tardy, B.L. A comprehensive study on the potential of edible coatings with polysaccharides, polyphenol, and lipids for mushroom preservation. Int. J. Biol. Macromol. 2025, 306, 141494. [Google Scholar] [CrossRef] [PubMed]

- Al-Moghazy, M.; El-sayed, H.S.; Salama, H.H.; Nada, A.A. Edible packaging coating of encapsulated thyme essential oil in liposomal chitosan emulsions to improve the shelf life of Karish cheese. Food Biosci. 2021, 43, 101230. [Google Scholar] [CrossRef]