Optimization of Chip Morphology in Deep Hole Trepanning of Titanium Alloy

Abstract

1. Introduction

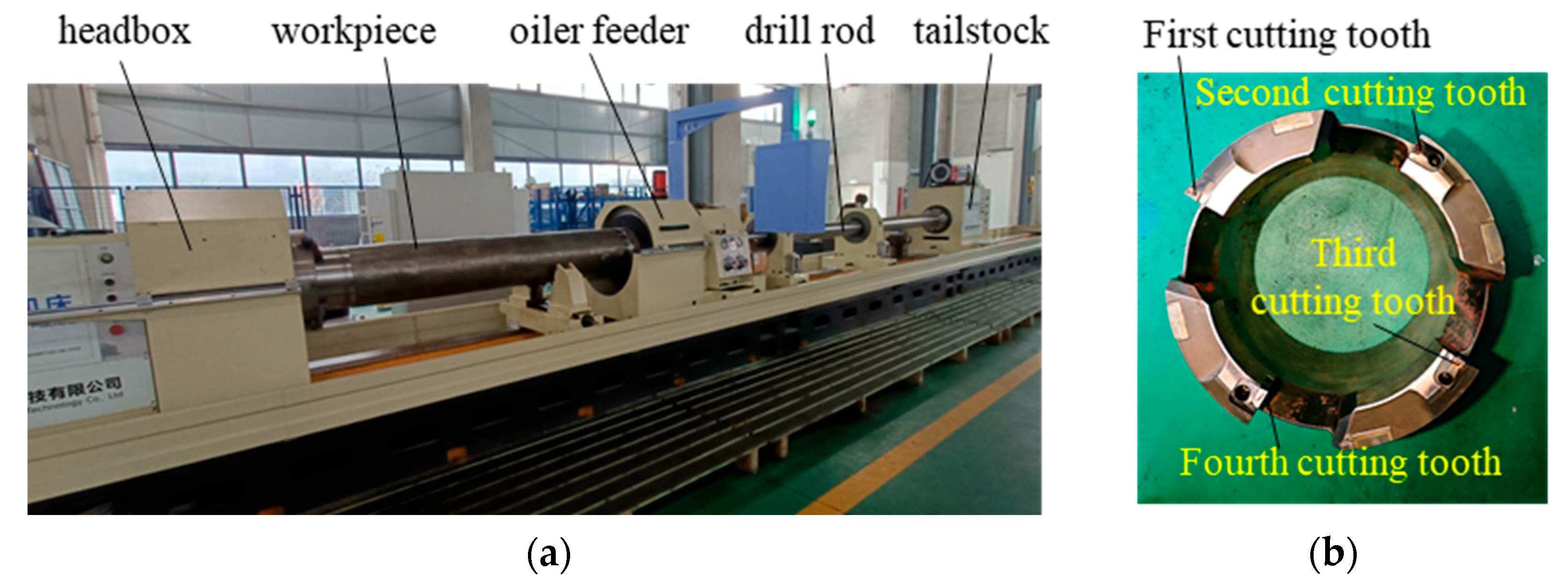

2. Experimental Methods

3. Results and Analysis

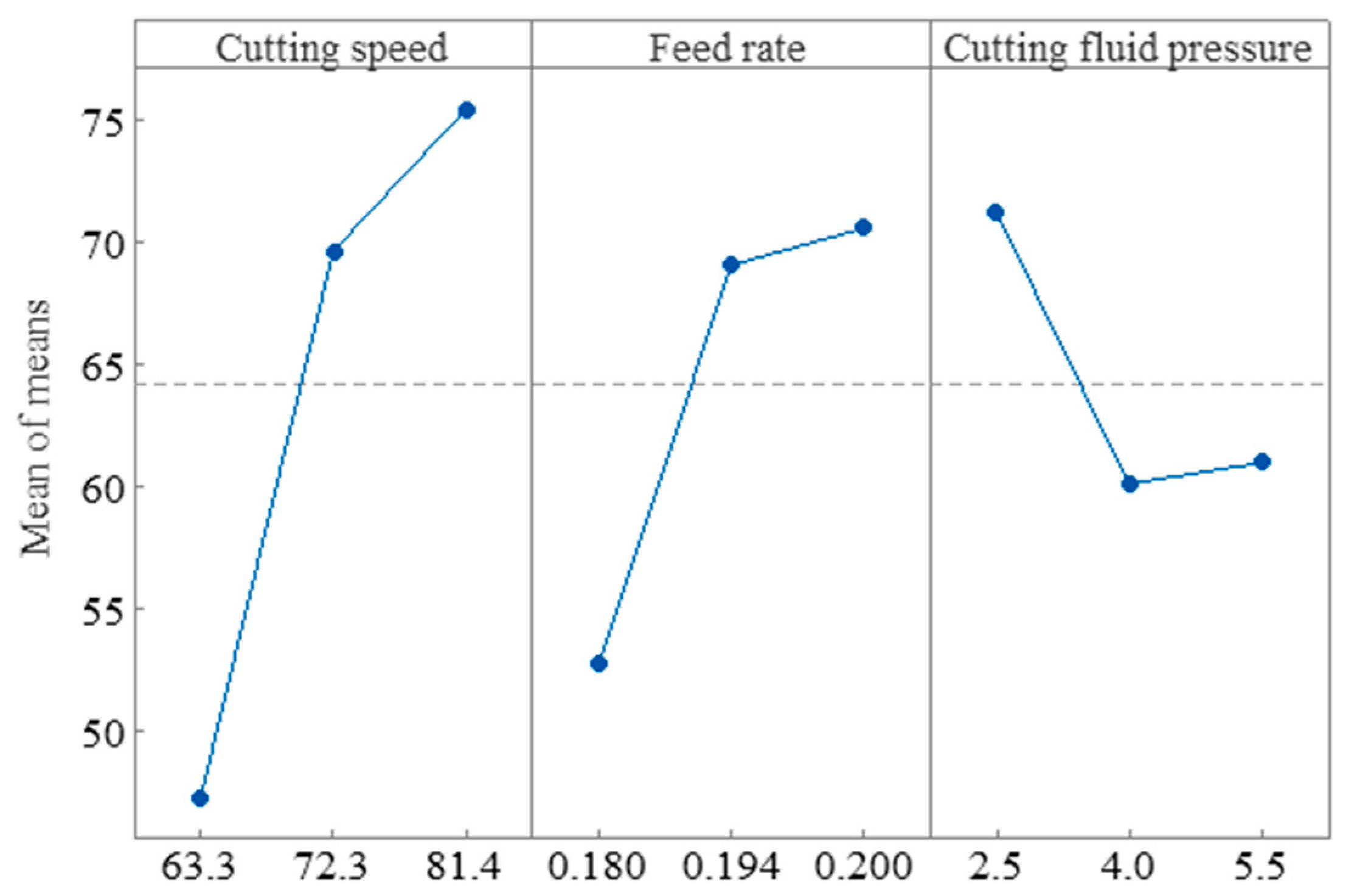

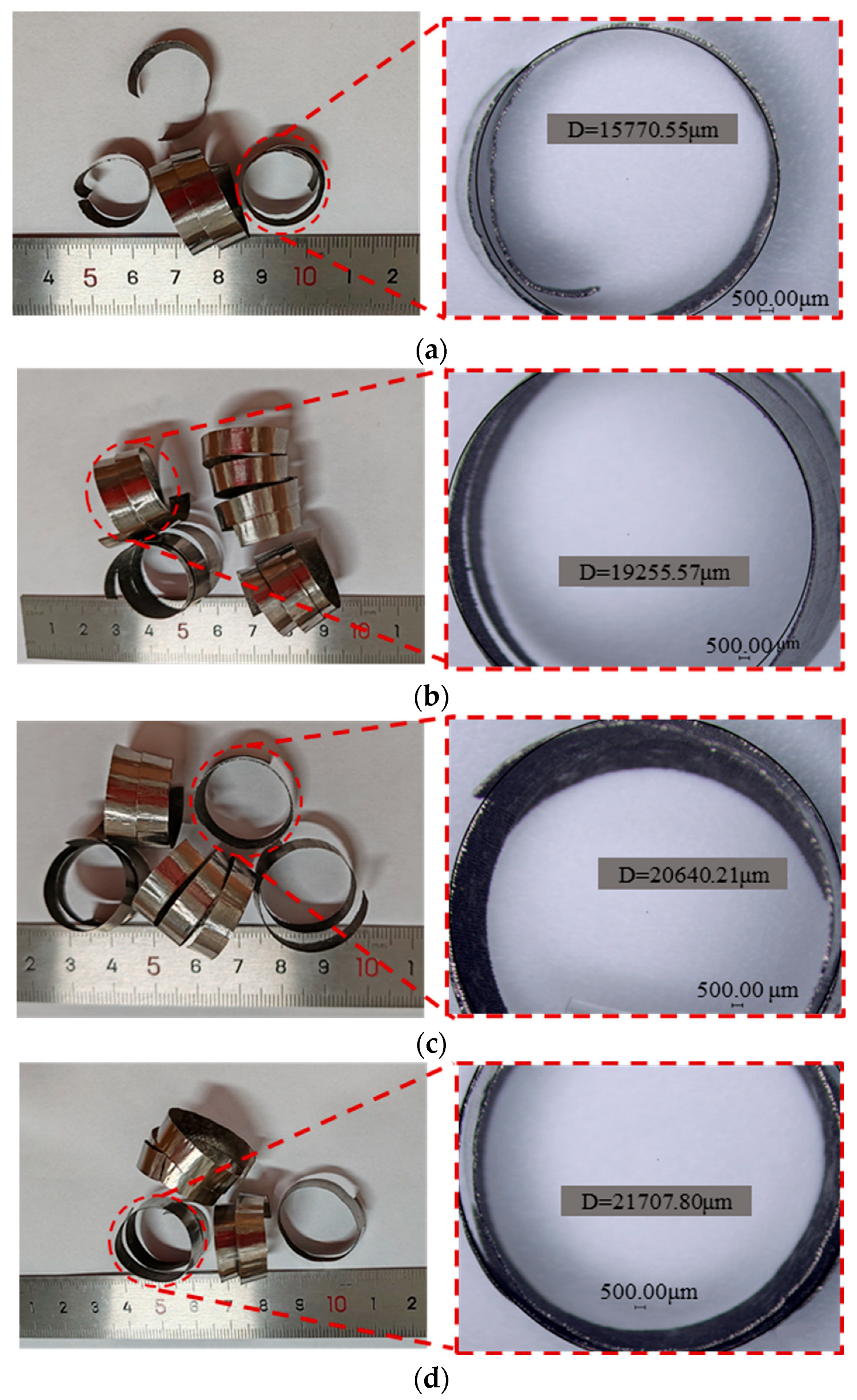

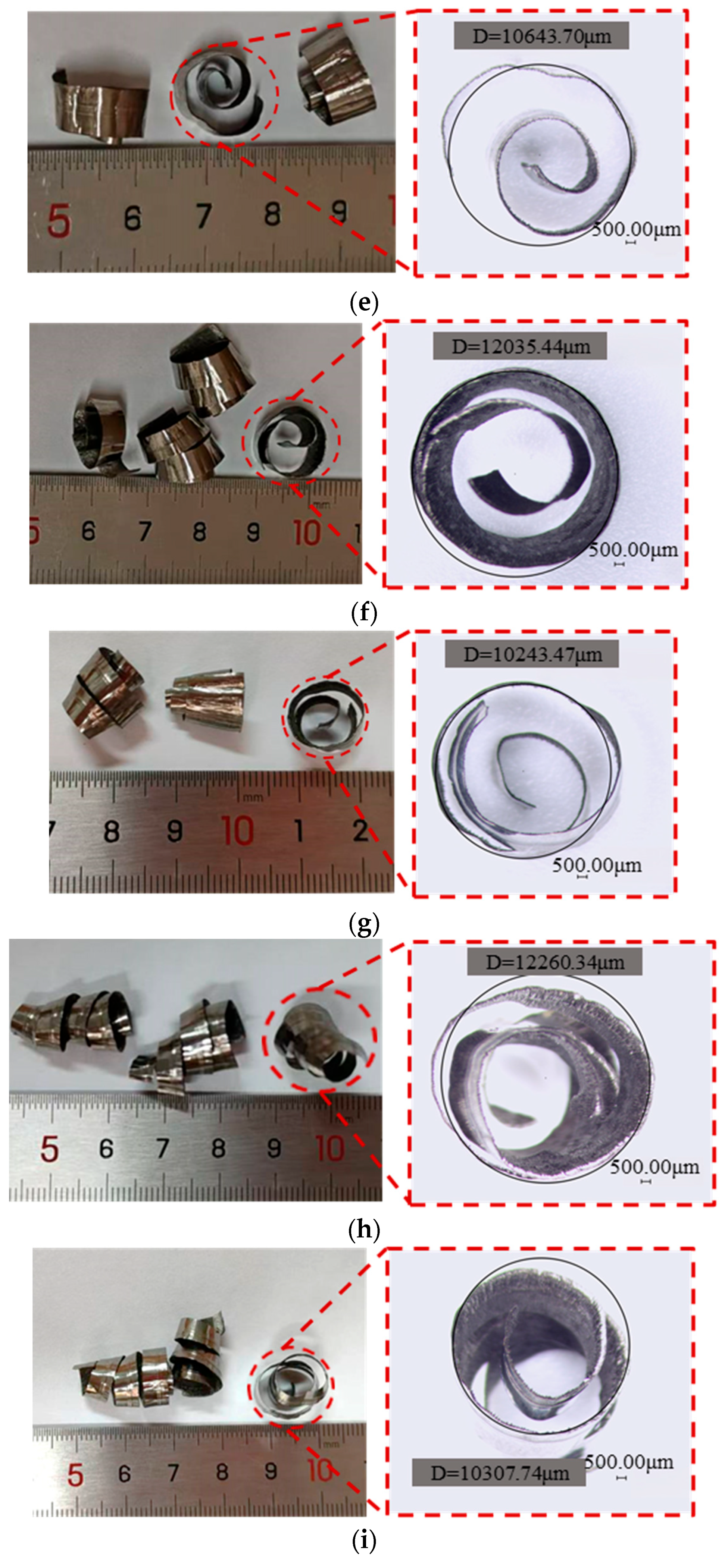

3.1. Analysis of the Orthogonal Experiment

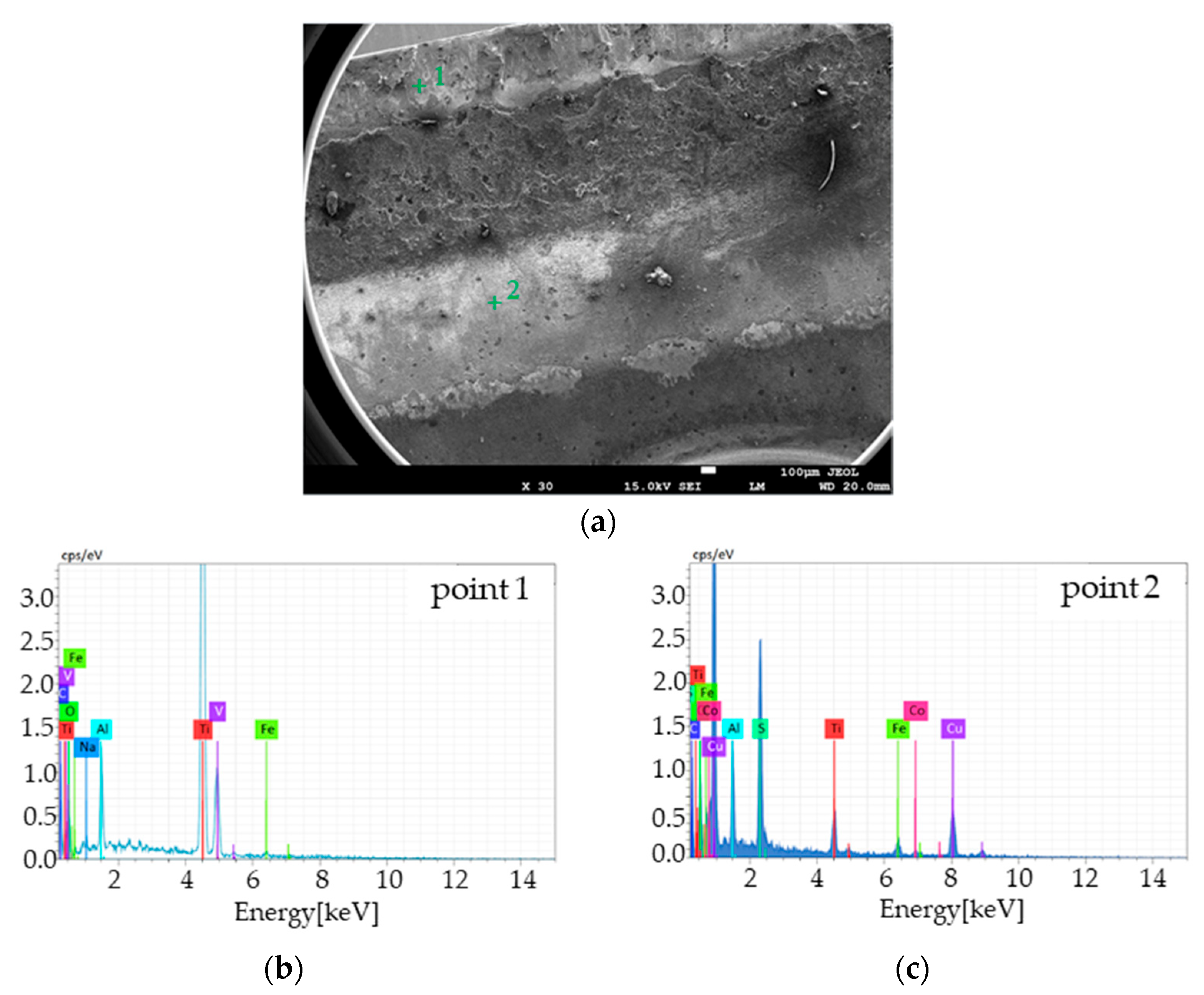

3.2. Tool Wear

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, Q.; Sun, Q.; Xin, S.; Chen, Y.; Wu, C.; Wang, H.; Xu, J.; Wan, M.; Zeng, W.; Zhao, Y. High-Strength Titanium Alloys for Aerospace Engineering Applications: A Review on Melting-Forging Process. Mater. Sci. Eng. A 2022, 845, 143260. [Google Scholar] [CrossRef]

- Topa, A.; Cerik, B.C.; Kim, D.K. A Useful Manufacturing Guide for Rotary Piercing Seamless Pipe by ALE Method. J. Mar. Sci. Eng. 2020, 8, 756. [Google Scholar] [CrossRef]

- Yuan, C.G.; Pramanik, A.; Basak, A.K.; Prakash, C.; Shankar, S. Drilling of Titanium Alloy (Ti6Al4V)–A Review. Mach. Sci. Technol. 2021, 25, 637–702. [Google Scholar] [CrossRef]

- Feng, Y.; Zheng, H.; Han, X.; Liu, Z. The Effect of Trepanning Parameters on Wear of Tool and Surface Quality of Titanium Alloy. Adv. Mech. Eng. 2022, 14, 16878132221114719. [Google Scholar] [CrossRef]

- Yang, H.; Chen, Y.; Xu, J.; Ladonne, M.; Lonfier, J.; Ding, W. Chip Control Analysis in Low-Frequency Vibration-Assisted Drilling of Ti–6Al–4V Titanium Alloys. Int. J. Precis. Eng. Manuf. 2020, 21, 565–584. [Google Scholar] [CrossRef]

- Binali, R.; Kuntoğlu, M.; Pimenov, D.; Usca, Ü.; Gupta, M.; Korkmaz, M. Advance monitoring of hole machining operations via intelligent measurement systems: A critical review and future trends. Measurement 2022, 201, 111757. [Google Scholar] [CrossRef]

- Oezkaya, E.; Michel, S.; Biermann, D. Chip formation simulation and analysis of the mechanical loads during micro single-lip deep hole drilling of Inconel 718 with varying cooling lubricant pressure. Prod. Eng. Res. Devel. 2021, 15, 299–309. [Google Scholar] [CrossRef]

- Han, X.; Liu, Z.; Feng, Y. Experimental Research on the Deep-Hole Boring of Pure Niobium Tube. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020, 234, 1124–1132. [Google Scholar] [CrossRef]

- Sharif, A.; Hussain, A.; Habib, N.; Alam, W.; Hanif, M.I.; Noon, A.A.; Khan, M.I. Experimental Investigation of Hole Quality and Chip Analysis during the Dry Drilling Process of Al6061-T6. J. Mater. Manuf. 2023, 2, 21–30. [Google Scholar] [CrossRef]

- Sun, J.; Guo, Y.B. A New Multi-View Approach to Characterize 3D Chip Morphology and Properties in End Milling Titanium Ti–6Al–4V. Int. J. Mach. Tools Manuf. 2008, 48, 1486–1494. [Google Scholar] [CrossRef]

- Polli, M.L.; Cardoso, M.J. Effects of Process Parameters and Drill Point Geometry in Deep Drilling of SAE 4144M under MQL. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 137. [Google Scholar] [CrossRef]

- Słodki, B.; Zębala, W.; Struzikiewicz, G. Correlation Between Cutting Data Selection and Chip Form in Stainless Steel Turning. Mach. Sci. Technol. 2015, 19, 217–235. [Google Scholar] [CrossRef]

- Feng, Y.; Zheng, H.; Han, X.; Liu, Z. Multiobjective Optimization of Cutting Parameters for TA10 Alloy Deep-Hole Drilling. Materials 2022, 15, 4366. [Google Scholar] [CrossRef] [PubMed]

- Moghaddas, A. Characterization of Thrust Force, Temperature, Chip Morphology and Power in Ultrasonic-Assisted Drilling of Aluminium 6061. Int. J. Adv. Manuf. Technol. 2022, 118, 979–994. [Google Scholar] [CrossRef]

- Tian, Y.; Zou, P.; Yang, X.; Kang, D. Study on Chip Morphology and Surface Roughness in Ultrasonically Assisted Drilling of 304 Stainless Steel. Int. J. Adv. Manuf. Technol. 2020, 108, 2079–2090. [Google Scholar] [CrossRef]

- Zębala, W.; Struzikiewicz, G.; Słodki, B. Reduction of Power Consumption by Chip Breakability Control in Ti6Al4V Titanium Alloy Turning. Materials 2020, 13, 2642. [Google Scholar] [CrossRef]

- Singh, J.; Gill, S.S.; Dogra, M.; Singh, R. A Review on Cutting Fluids Used in Machining Processes. Eng. Res. Express 2021, 3, 012002. [Google Scholar] [CrossRef]

- Wang, P.; Gao, R.; Yan, R. A deep learning-based approach to material removal rate prediction in polishing. CIRP Ann. 2017, 66, 429–432. [Google Scholar] [CrossRef]

- Somayaji, B.; Bhat, R.; Naik, N.; Rajendra, B. Optimization of Turning Parameters and Cooling Techniques for Enhanced Machining Performance of EN8 Steel Using L9 Orthogonal Array. Eng. Proc. 2023, 59, 243. [Google Scholar] [CrossRef]

- Tschätsch, H. Applied Machining Technology; Springer: Berlin/Heidelberg, Germany, 2010; pp. 39–41. [Google Scholar]

- Rahim, E.; Kamdani, K.; Sharif, S. Performance evaluation of uncoated carbide tool in high speed drilling of Ti6Al4V. J. Adv. Mech. Des. Syst. Manuf. 2008, 2, 522–531. [Google Scholar] [CrossRef][Green Version]

- Li, X.; Zhai, C.; He, W.; Lu, Y.; Zhang, B. Experimental investigation of tool wear and machining quality of BTA deep-hole drilling in low-carbon alloy steel SA-5083. Materials 2023, 16, 6686. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Huang, C.; Tang, Z.; Chen, Z.; Liu, H.; Chen, Z.; Niu, J.; Wang, Z. Effect of drilling parameters on the hole surface integrity of low alloy steel for nuclear power during BTA deep hole drilling. Int. J. Adv. Manuf. Technol. 2023, 127, 565–577. [Google Scholar] [CrossRef]

- Liu, Z.; Xu, J.; Han, S.; Chen, M. A Coupling Method of Response Surfaces (CRSM) for Cutting Parameters Optimization in Machining Titanium Alloy under Minimum Quantity Lubrication (MQL) Condition. Int. J. Precis. Eng. Manuf. 2013, 14, 693–702. [Google Scholar] [CrossRef]

- Abdelnasser, E.; El-Sanabary, S.; Nassef, A.; Barakat, A.; Elkaseer, A. Influence of Technological Parameters on Chip Formation and Chip Control in Precision Hard Turning of Ti-6Al-4V. Micromachines 2023, 14, 1973. [Google Scholar] [CrossRef] [PubMed]

- Usca, Ü.; Uzun, M.; Şap, S.; Kuntoğlu, M.; Giasin, K.; Pimenov, D.; Wojciechowski, S. Tool wear, surface roughness, cutting temperature and chips morphology evaluation of Al/TiN coated carbide cutting tools in milling of Cu–B–CrC based ceramic matrix composites. J. Mater. Res. Technol. 2022, 16, 1243–1259. [Google Scholar] [CrossRef]

- Zhao, S.; Meng, F.; Fan, B.; Dong, Y.; Wang, J.; Qi, X. Evaluation of wear mechanism between TC4 titanium alloys and self-lubricating fabrics. Wear 2023, 512, 204532. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, H.; Wang, B.; Huang, J.; Zhou, M.; Wang, L.; Xi, Y.; Jia, H.; Xu, S.; Liu, H.; et al. A Review of Research on Improving Wear Resistance of Titanium Alloys. Coatings 2024, 14, 786. [Google Scholar] [CrossRef]

| Tooth | First Cutting Tooth | Second Cutting Tooth | Third Cutting Tooth | Fourth Cutting Tooth |

|---|---|---|---|---|

| Tooth Width (mm) | 9.5 | 6.3 | 6.5 | 9.2 |

| Rake Angle (°) | 5 | 5 | 7 | 7 |

| Relief Angle (°) | 10 | 11 | 10 | 11 |

| Level | Factor | ||

|---|---|---|---|

| Cutting Speed (m·min−1) | Feed Rate (mm·rev−1) | Cutting Fluid Pressure (MPa) | |

| 1 | 63.3 | 0.18 | 2.5 |

| 2 | 72.3 | 0.194 | 4 |

| 3 | 81.4 | 0.2 | 5.5 |

| NO | Cutting Speed (m·min−1) | Feed Rate (mm·rev−1) | Cutting Fluid Pressure (MPa) | Chip Volume Ratio of First Cutting Tooth (R1) | Chip Volume Ratio of Third Cutting Tooth (R2) |

|---|---|---|---|---|---|

| 1 | 63.3 | 0.18 | 2.5 | 41.53 | 14.51 |

| 2 | 63.3 | 0.194 | 4 | 52.66 | 13.64 |

| 3 | 63.3 | 0.2 | 5.5 | 47.75 | 39.82 |

| 4 | 72.3 | 0.18 | 4 | 51.44 | 15.36 |

| 5 | 72.3 | 0.194 | 5.5 | 69.92 | 34.43 |

| 6 | 72.3 | 0.2 | 2.5 | 87.68 | 57.56 |

| 7 | 81.4 | 0.18 | 5.5 | 65.39 | 61.45 |

| 8 | 81.4 | 0.194 | 2.5 | 84.71 | 79.58 |

| 9 | 81.4 | 0.2 | 4 | 76.37 | 71.37 |

| Chip volume ratio of first cutting tooth (R1) | Factors | Cutting Speed (A) | Feed Rate (B) | Cutting Fluid Pressure (C) |

| k1 | 47.313 | 52.787 | 71.307 | |

| k2 | 69.680 | 69.097 | 60.157 | |

| k3 | 75.490 | 70.600 | 61.020 | |

| Range /R | 28.177 | 17.813 | 11.150 | |

| Order of Importance: A > B > C | ||||

| Optimal Level: A1B1C2 | ||||

| Chip volume ratio of third cutting tooth (R2) | Factors | Cutting Speed (A) | Feed Rate (B) | Cutting Fluid Pressure (C) |

| k1 | 22.657 | 30.440 | 50.550 | |

| k2 | 35.783 | 42.550 | 33.457 | |

| k3 | 70.800 | 56.250 | 44.233 | |

| Range /R | 48.143 | 25.810 | 17.093 | |

| Order of Importance: A > B > C | ||||

| Optimal Level: A1B1C2 | ||||

| Source | DF | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|

| Cutting Speed | 2 | 59.42% | 1327.95 | 663.97 | 14.71 | 0.064 |

| Feed rate | 2 | 26.20% | 585.59 | 292.80 | 6.49 | 0.134 |

| Cutting fluid pressure | 2 | 10.33% | 230.88 | 115.44 | 2.56 | 0.281 |

| Error | 2 | 4.04% | 90.30 | 45.15 | ||

| Total | 8 | 100% | 2234.72 |

| Source | DF | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|

| Cutting Speed | 2 | 71.24% | 3716.26 | 1858.13 | 91.50 | 0.011 |

| Feed rate | 2 | 19.18% | 1000.50 | 500.25 | 24.63 | 0.039 |

| Cutting fluid pressure | 2 | 8.80% | 459.14 | 229.57 | 11.30 | 0.081 |

| Error | 2 | 0.78% | 40.61 | 20.31 | ||

| Total | 8 | 100% | 5216.51 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, F.; Han, X.; Qiu, L.; Ma, H. Optimization of Chip Morphology in Deep Hole Trepanning of Titanium Alloy. Processes 2025, 13, 2082. https://doi.org/10.3390/pr13072082

Xie F, Han X, Qiu L, Ma H. Optimization of Chip Morphology in Deep Hole Trepanning of Titanium Alloy. Processes. 2025; 13(7):2082. https://doi.org/10.3390/pr13072082

Chicago/Turabian StyleXie, Fan, Xiaolan Han, Lipeng Qiu, and Haikuan Ma. 2025. "Optimization of Chip Morphology in Deep Hole Trepanning of Titanium Alloy" Processes 13, no. 7: 2082. https://doi.org/10.3390/pr13072082

APA StyleXie, F., Han, X., Qiu, L., & Ma, H. (2025). Optimization of Chip Morphology in Deep Hole Trepanning of Titanium Alloy. Processes, 13(7), 2082. https://doi.org/10.3390/pr13072082