Geological Conditions and Reservoir Formation Models of Low- to Middle-Rank Coalbed Methane in the Northern Part of the Ningxia Autonomous Region

Abstract

1. Introduction

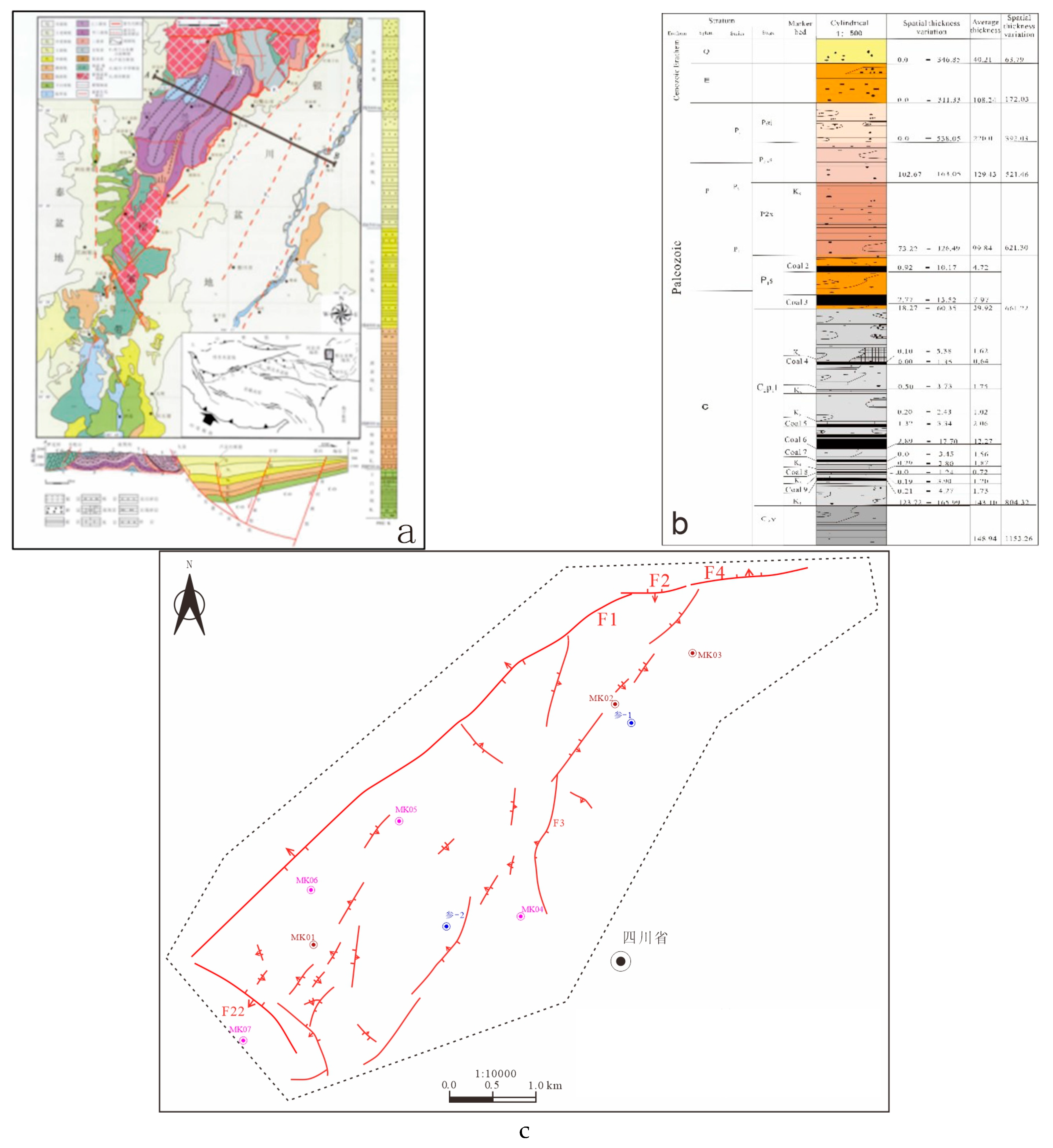

2. Geological Setting and Experimental Principle

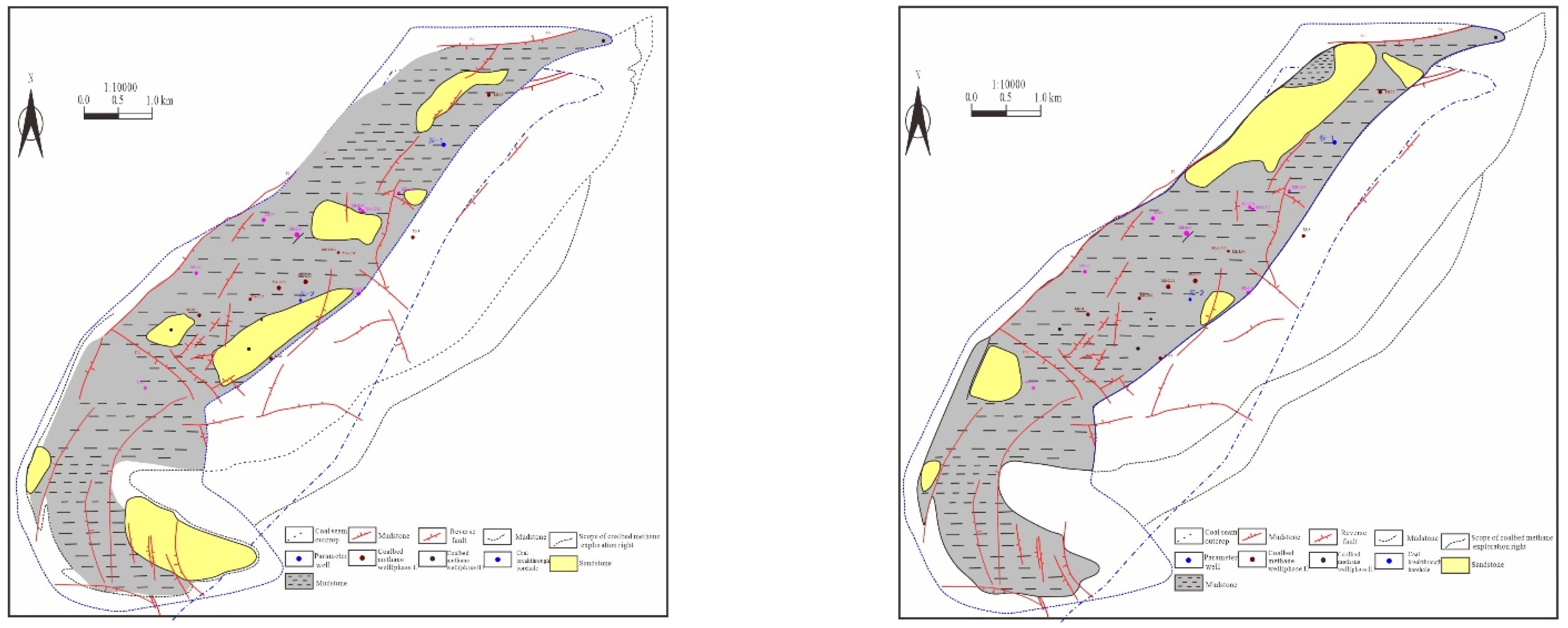

2.1. Geological Setting

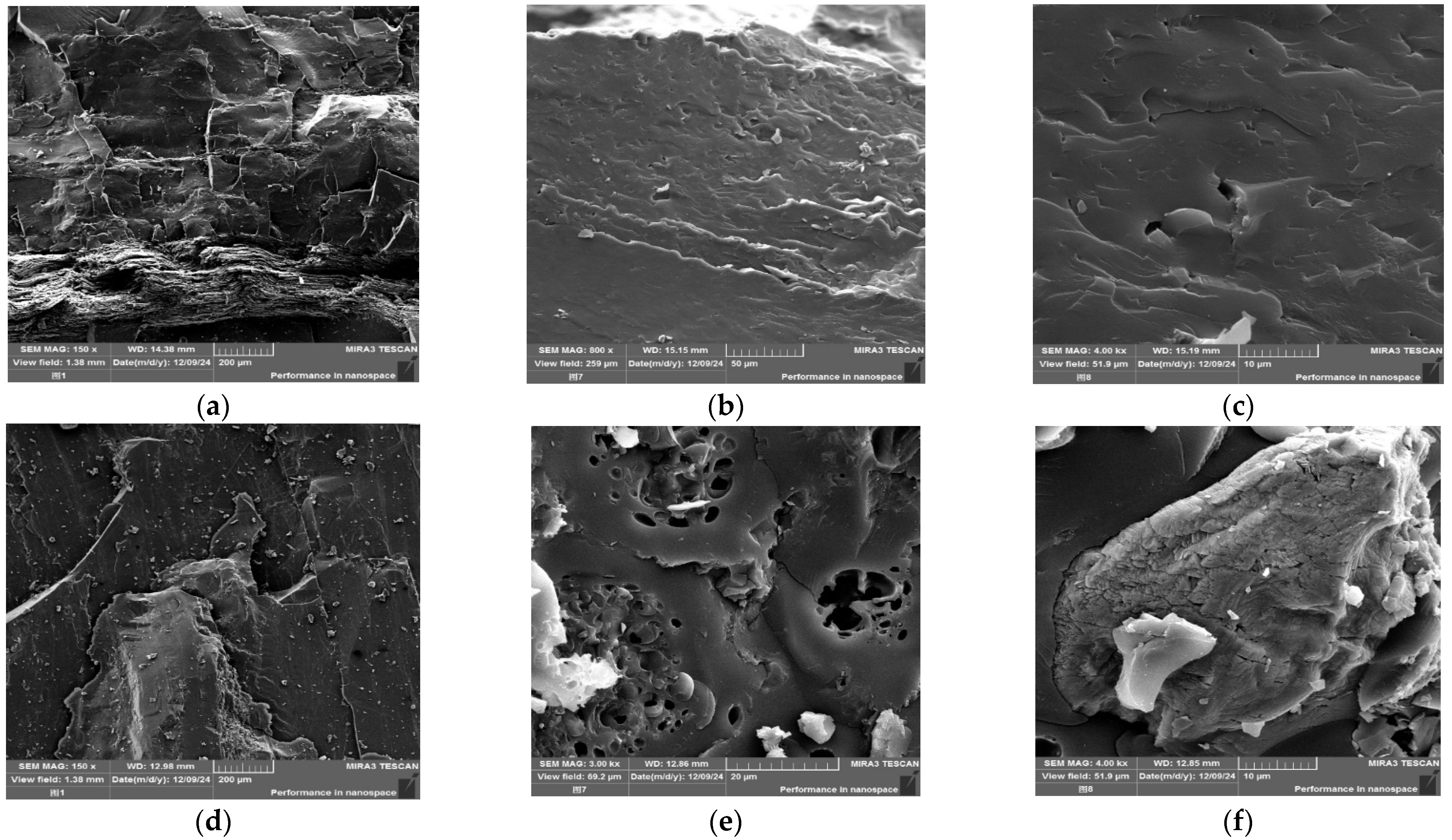

2.2. SEM Experimental Method

2.3. Low-Temperature Liquid Nitrogen Adsorption Experimental Method

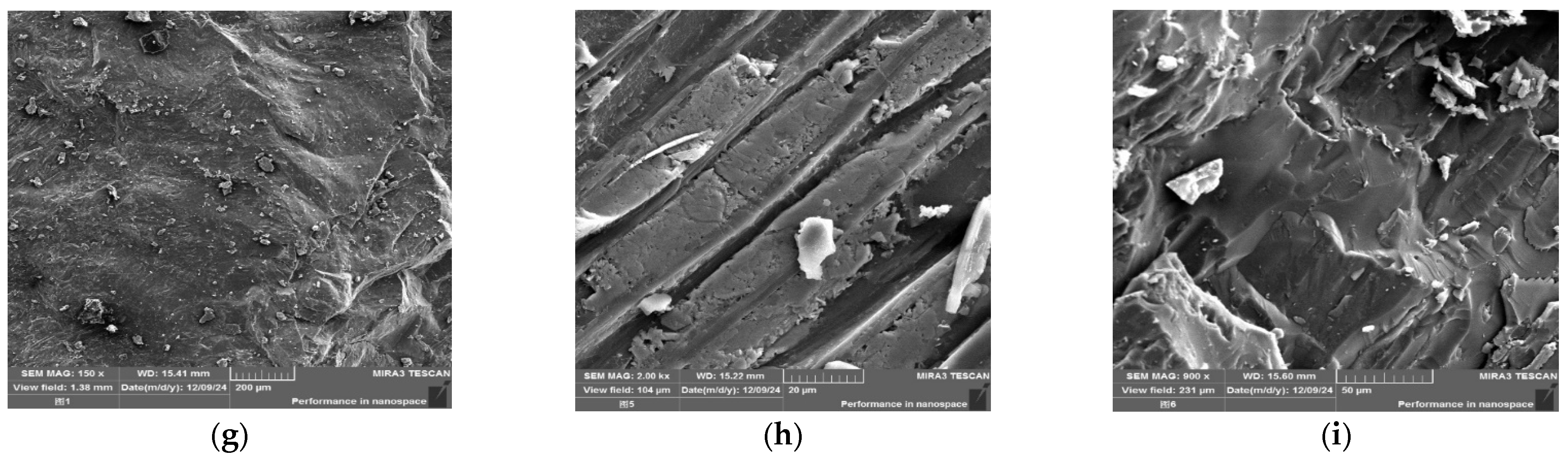

2.4. High-Pressure Mercury Intrusion Porosimetry Method

3. Results and Discussion

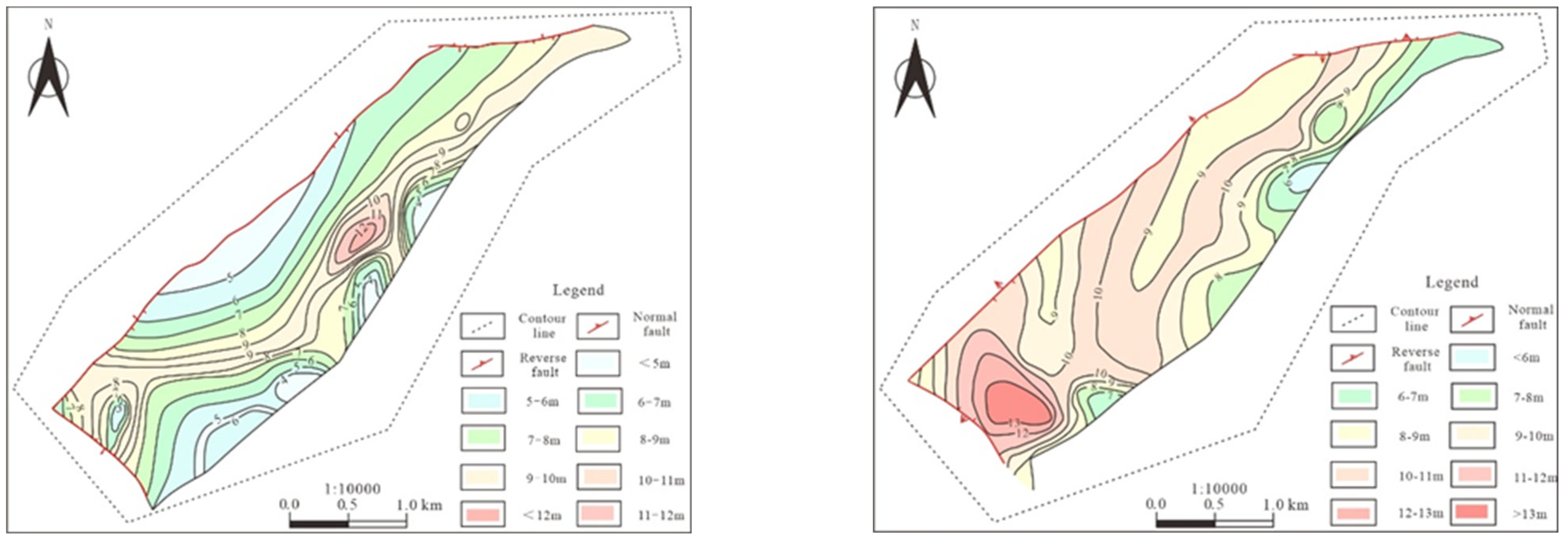

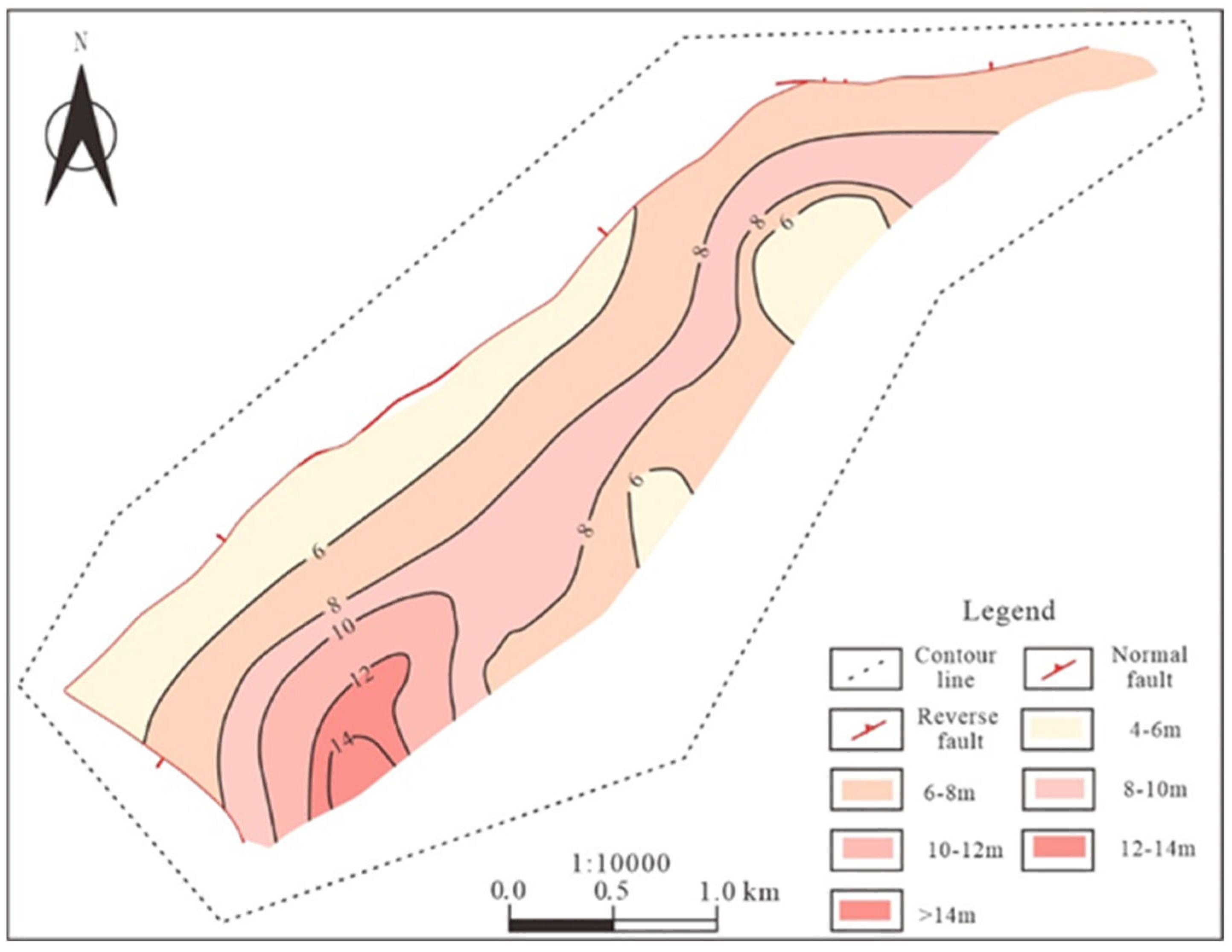

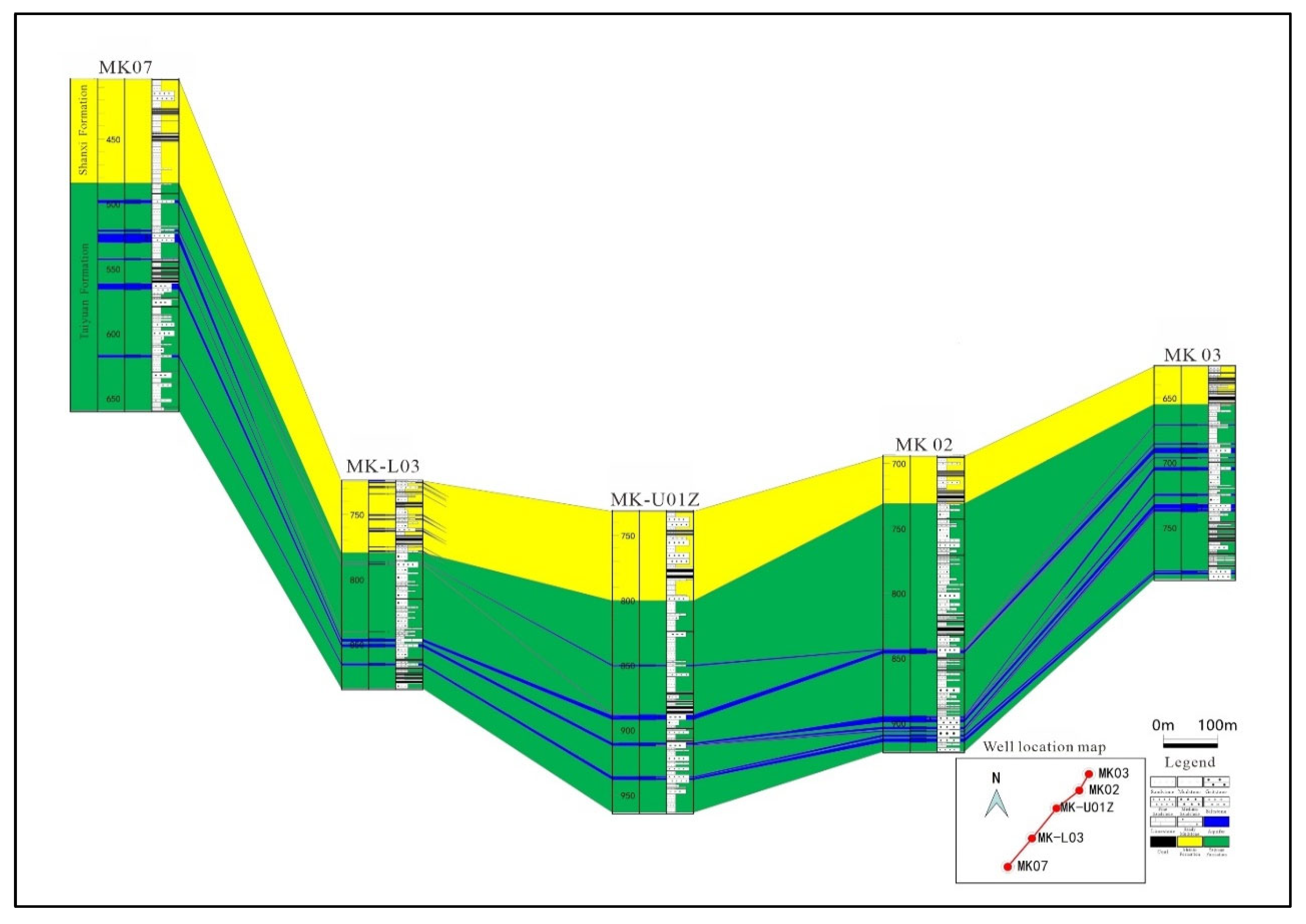

3.1. Thickness and Buried Depth

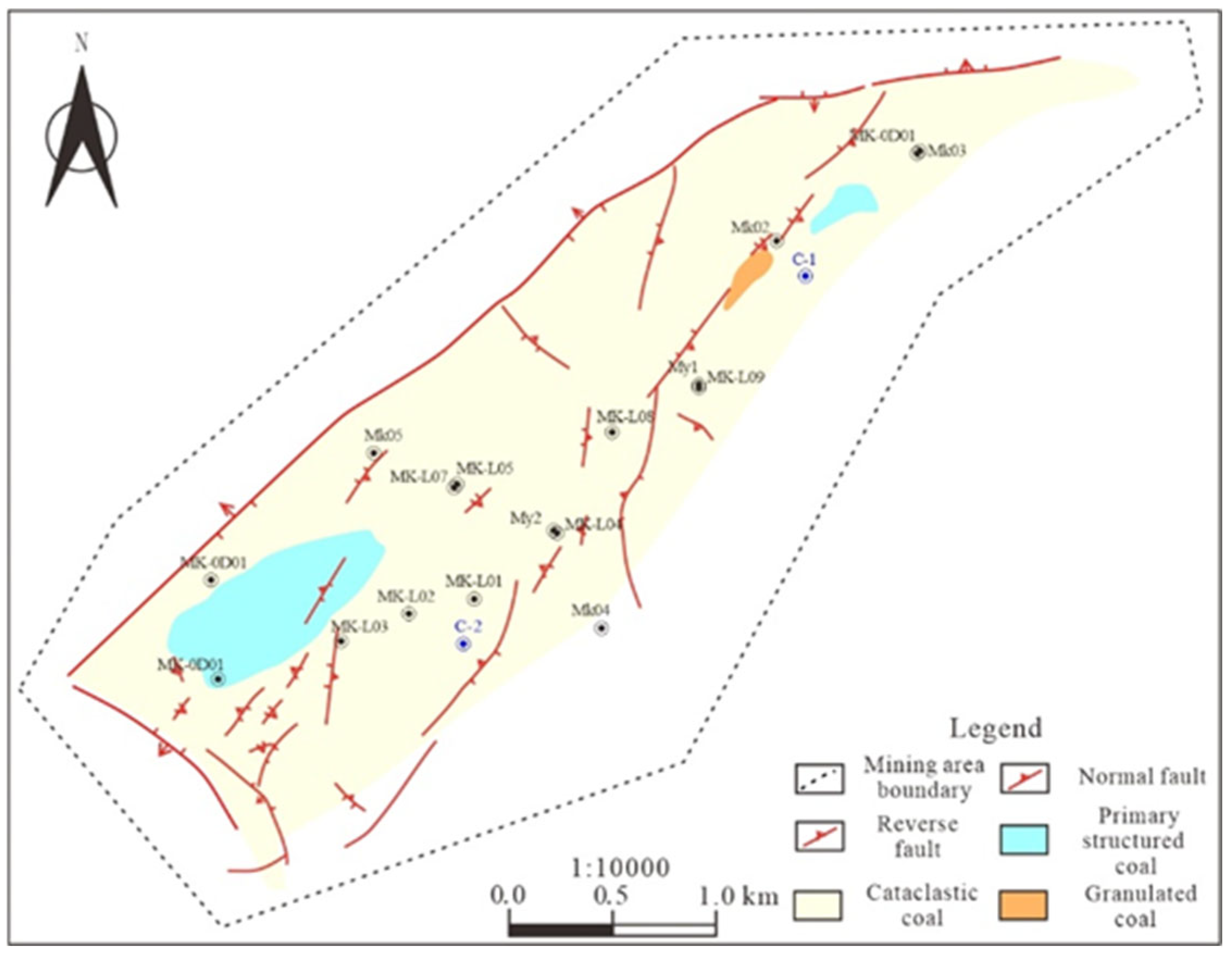

3.2. Coal Petrographic Characteristics and Gas-Bearing Properties

3.2.1. Coal Quality

3.2.2. Coal Seam Gas-Bearing

3.2.3. Characteristics of Coal Seam Roof and Floor

3.2.4. Physical Characteristics of Coal Reservoirs

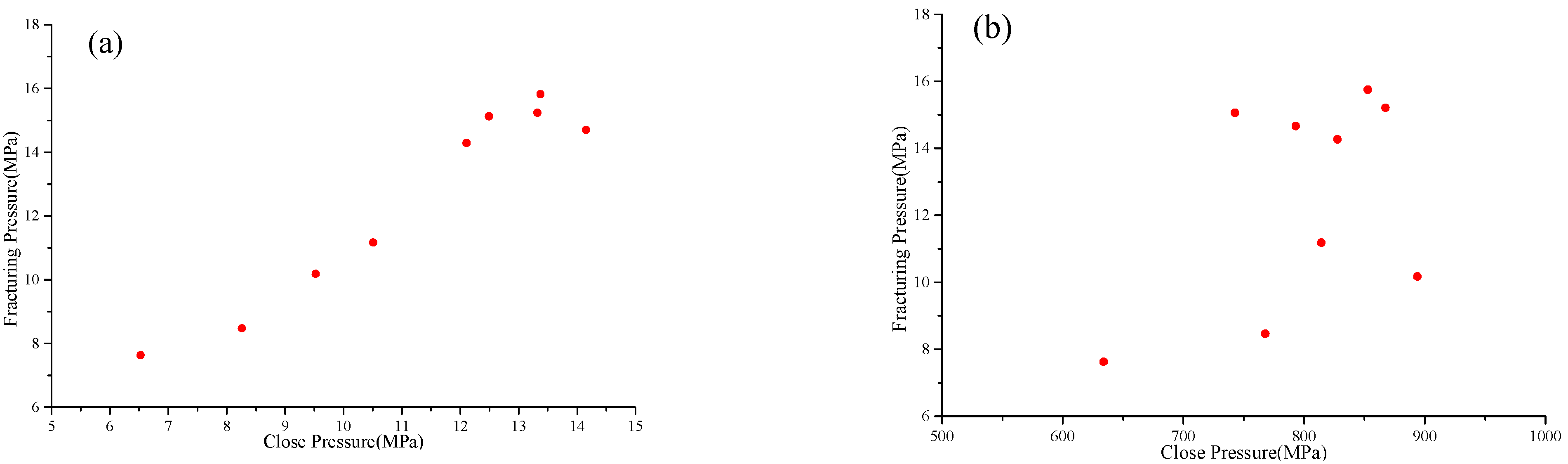

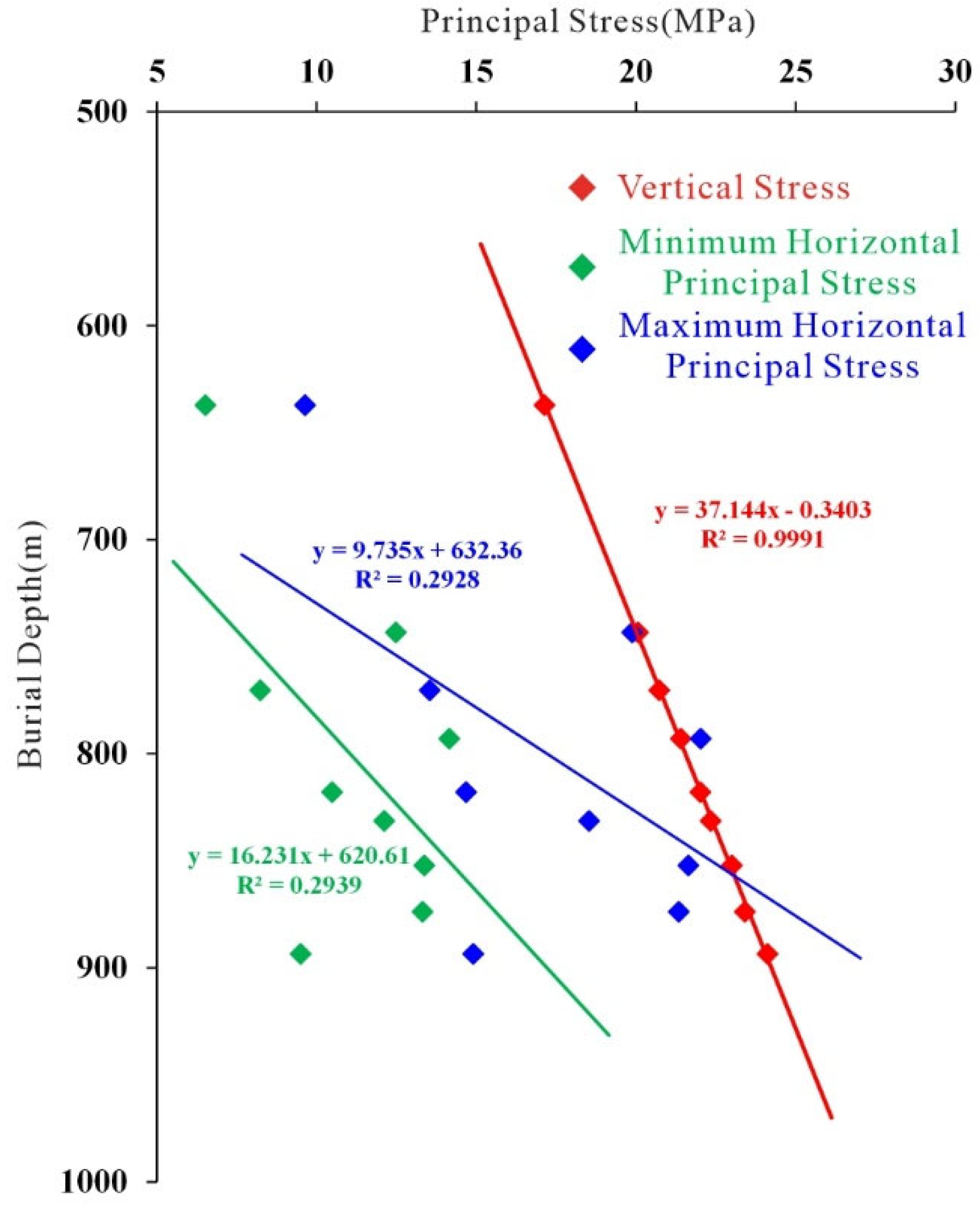

3.2.5. In-Situ Stress Conditions

3.3. Geological Conditions for CBM Enrichment

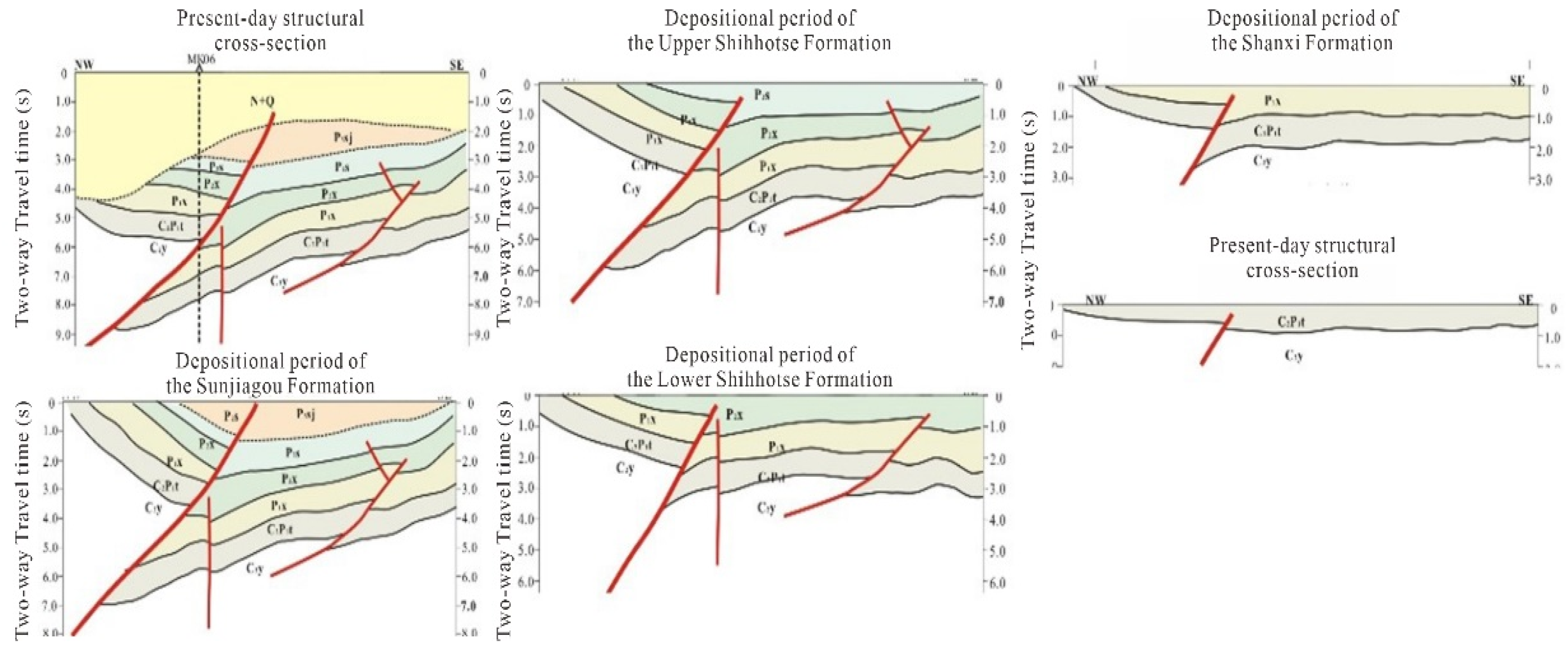

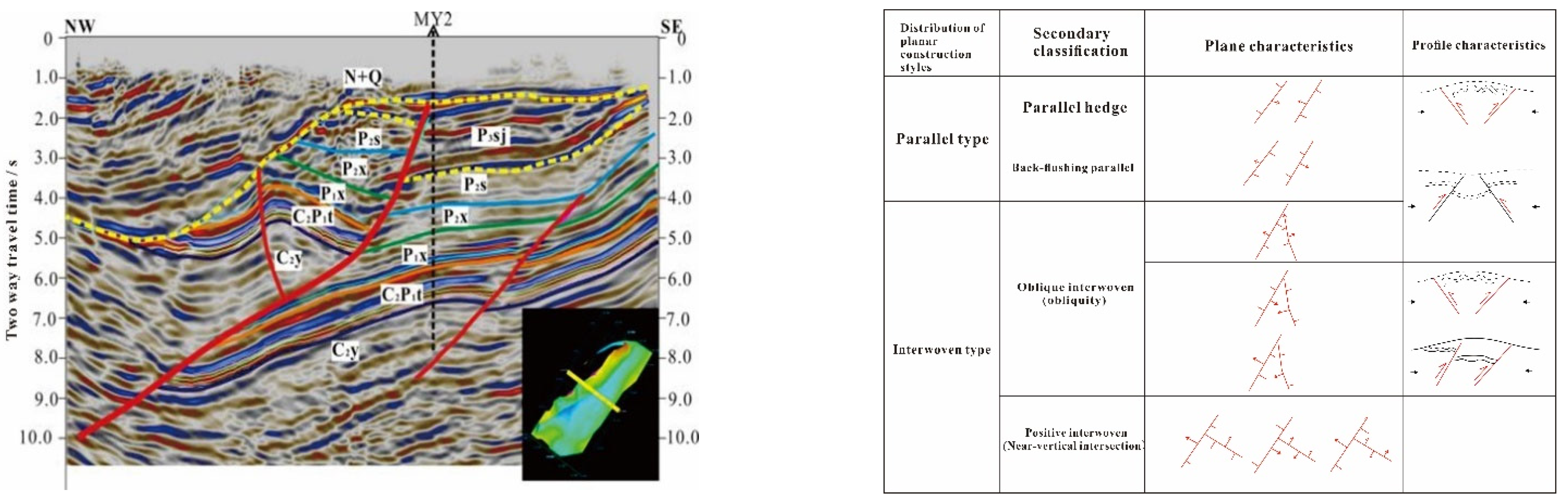

3.3.1. Construction Conditions

3.3.2. Sedimentary Environment

3.3.3. Hydrodynamic Effects

3.4. CBM Accumulation Patterns

3.4.1. Steep Limb of Syncline-Structural-Fault Escape Type

3.4.2. Syncline Axial Zone-Structural-Hydrodynamic Sealing Type

3.4.3. Gentle Limb of Syncline-Lithology-Hydraulic Sealing Type

4. Conclusions

- (1)

- The Permian–Triassic coal-bearing strata, including coal seam 6 of the Taiyuan Formation and coal seam 3 of the Shanxi Formation, exhibit significant thickness and are dominated by thermogenic coalbed methane (CBM) (the thickness of coal seams 2 and 3 in the footwall of the fault F1 is 4.7–11.7 m, with an average of 5.8 m. The thickness of coal seams 5 and 6 is 5.9–13.3 m, with an average of 6.5 m). These strata are buried at suitable depths with mudstone as the primary roof rock, providing favorable gas-bearing properties and good reservoir conditions.

- (2)

- The primary factors influencing CBM enrichment include structural conditions, depositional environments, and hydrodynamic regimes. The broad, gentle syncline and a series of reverse faults formed by compressional forces provide effective sealing for CBM accumulation. The barrier island–shoreface–lagoon depositional environment of the Taiyuan Formation and the fluvial–delta–lacustrine environment of the Shanxi Formation created favorable conditions for the formation of thick coal seams in seams 6 and 3, while also affecting the distribution of roof lithology. The groundwater within the coal-bearing strata shows a high degree of mineralization and a relatively connate water environment, which is conducive to CBM preservation and enrichment.

- (3)

- Based on the analysis of CBM enrichment conditions, three typical CBM accumulation models are identified: the syncline steep limb–structural–fault escape type, the syncline axis–structural–hydrodynamic sealing type, and the syncline gentle limb–lithologic–hydrodynamic sealing type.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, F.Y.; Zhen, H.B.; Li, S.G.; Wang, B.; Zhang, L.; Wang, Y.B.; Yu, W.C.; Zhu, W.P.; Xu, B.R.; Yang, Y.; et al. History and development direction of iterative upgrading of deep coalbed methane reservoir reconstruction technology—Taking Daji Block in the eastern margin of Ordos Basin as an example. Coal Sci. Technol. 2025, 53, 1–18. [Google Scholar]

- Guo, G.S.; Xu, F.Y.; Liu, L.F.; Cai, Y.D.; Qiu, W.; Chen, Z.H.; Deng, J.; Li, Z.L. Enrichment and accumulation law and favorable area evaluation of deep coalbed methane in Fugu area of Ordos Basin. Coalf. Geol. Explor. 2024, 52, 81–91. [Google Scholar]

- Xu, F.Y.; Nie, Z.H.; Sun, W.; Xiong, X.Y.; Xu, B.R.; Zhang, L.; Shi, X.S.; Liu, Y.; Liu, S.R.; Zhao, Z.P.; et al. Theoretical and technical system for efficient development of deep coalbed methane in the eastern margin of Ordos Basin. Coal J. 2024, 49, 528–544. [Google Scholar]

- Qin, Y. Research progress of deep coalbed methane geology in China. Pet. J. 2023, 44, 1791–1811. [Google Scholar]

- Song, Y.; Zhao, M.J.; Hong, F.; Liu, S.B.; Qin, S.F.; Wang, H.Y. Pool-Forming Stages and Enrichment Models of Medium—To High-Rank Coalbed Methane. Acta Geol. Sin.-Engl. Ed. 2010, 84, 1539–1546. [Google Scholar]

- Tao, S.; Chen, S.D.; Pan, Z.J. Current status, challenges, and policy suggestions for coalbed methane industry development in China: A review. Energy Sci. Eng. 2019, 7, 1059–1074. [Google Scholar] [CrossRef]

- Xu, F.Y.; Hou, W.; Xiong, X.Y.; Xu, B.R.; Wu, P.; Wang, H.Y.; Feng, K.; Yun, J.; Li, S.G.; Zhang, L.; et al. The status and development strategy of coalbed methane industry in China. Pet. Explor. Dev. 2023, 50, 765–783. [Google Scholar] [CrossRef]

- Li, S.; Qin, Y.; Tang, D.Z.; Shen, J.; Wang, J.J.; Chen, S.D. Comprehensive review of deep coalbed methane and recent developments in China. Int. J. Coal Geol. 2023, 279, 104369. [Google Scholar] [CrossRef]

- Qin, Y.; Moore, T.A.; Shen, J. Resources and geology of coalbed methane in China: A review. Int. Geol. Rev. 2018, 60, 777–812. [Google Scholar] [CrossRef]

- Zhang, J.J.; Chang, X.C.; Lv, D.W.; Wang, D.D.; Dai, X.G.; Zhang, X.Y.; Ji, Y.K.; Li, M.H.; Liu, H.Y.; Zheng, X.; et al. Research and evaluation of CO2 geological storage in coal seam development area under double carbon target. Coal Sci. Technol. 2023, 51, 206–214. [Google Scholar]

- Li, Y.; Guo, T.; Liu, X.; Peng, S.P. Resource potential and development direction of low rank coalbed methane resources in China. Pet. Nat. Gas Geol. 2024, 45, 1537–1554. [Google Scholar]

- Zhang, Q.; Jiang, W.P. Study on the gas production potential of surface development of low rank coalbed methane in China. Coal Sci. Technol. 2016, 44, 211–215. [Google Scholar]

- Liu, D.M.; Wang, Y.J.; Cai, Y.D. Analysis of main controlling geological factors and accumulation mode of low-rank coalbed methane enrichment. Coal Sci. Technol. 2018, 46, 1–8. [Google Scholar]

- Wang, S.; Shao, L.Y.; Sun, Q.P.; Hou, H.H.; Gao, S.; Lu, J.; Sun, B. Characteristics and exploration potential of coalbed methane reservoirs in Jiergalangtu Sag, Erlian Basin. Coalf. Geol. Explor. 2017, 45, 63–69. [Google Scholar]

- Fan, C.J.; Yang, L.; Sun, H.; Luo, M.K.; Zhou, L.J.; Yang, Z.H.; Li, S. Recent Advances and Perspectives of CO2-Enhanced Coalbed Methane: Experimental, Modeling, and Technological Development. Energy Fuels 2023, 37, 3371–3412. [Google Scholar] [CrossRef]

- Tang, S.; Xi, Z.; Zhang, S.; Zhang, F.; Duan, L.J.; Tian, W.G.; Wang, M.Z. The occurrence phase and gas bearing evolution of deep coalbed methane. Coal Sci. Technol. 2025, 53, 91–100. [Google Scholar]

- Leng, K.Q.; Guan, B.; Liu, W.; Jiang, C.; Cong, S.N.; Xin, Y.L. Research progress of coalbed methane extraction. Energy Rep. 2024, 12, 5728–5746. [Google Scholar] [CrossRef]

- Sun, P.; Wang, B.; Sun, F.J. Study on accumulation model of low rank coalbed methane in China. Pet. J. 2009, 30, 648–653. [Google Scholar]

- Sun, F.J.; Li, W.Z.; Sun, Q.P.; Sun, P.; Tian, G.W.; Chen, Y.J.; Chen, Z.H. Exploration of low-rank coal gas in Jiergalangtu Sag, Erlian Basin. Pet. J. 2017, 38, 485–492. [Google Scholar]

- Huang Fu, Y.H.; Kang, Y.S.; Deng, Z. Accumulation model and exploration direction of low rank coalbed methane. Pet. J. 2019, 40, 786–797. [Google Scholar]

- Yang, X.; Tang, S.; Xi, Z.; Zhang, S.H.; Zhang, Q.; Zhang, K.; Lin, D.; Wang, J. Dynamic evolution and differential enrichment of deep coalbed methane: A case study in Qinshui Basin. Int. J. Coal Geol. 2025, 299, 104696. [Google Scholar] [CrossRef]

- Moore, T.A. Coalbed methane: A review. Int. J. Coal Geol. 2012, 101, 36–81. [Google Scholar] [CrossRef]

- Ramos, A.C.B. Three-Dimensional AVO Analysis and Anisotropic Modeling Applied to Fracture Characterization in Coalbed Methane Reservoirs, Cedar Hill Field, San Juan Basin, New Mexico; ProQuest LLC: Ann Arbor, MI, USA, 1993. [Google Scholar]

- Zhang, J.; Wei, C.; Zhao, C.; Zhang, T.; Lu, G.W.; Zou, M.J. Effects of nano-pore and macromolecule structure of coal samples on energy parameters variation during methane adsorption under different temperature and pressure. Fuel 2021, 289, 119804. [Google Scholar] [CrossRef]

- Yao, P.; Zhang, J.; Lv, D.; Vandeginste, V.; Chang, X.C.; Zhang, X.Y.; Wang, D.D.; Han, S.B.; Liu, Y. Effect of water occurrence in coal reservoirs on the production capacity of coalbed methane by using NMR simulation technology and production capacity simulation. Geoenergy Sci. Eng. 2024, 243, 213353. [Google Scholar] [CrossRef]

- Yang, R.C.; Zhang, H.; Zhang, J.; Wang, F.J.; Li, M.H.; Yin, T.T.; Wen, S.P.; Han, Y.N. Effects of Nanopore Structure Heterogeneity of Coal Samples on Adsorption Ability and Porosity-Permeability Variation. Energy Fuels 2023, 37, 2721–2734. [Google Scholar] [CrossRef]

- Chang, X.; Han, R.; Zhang, J.; Vandeginste, V.; Zhang, X.Y.; Liu, Y.; Han, S.B. Prediction of Coal Body Structure of Deep Coal Reservoirs Using Logging Curves: Principal Component Analysis and Evaluation of Factors Influencing Coal Body Structure Distribution. Nat. Resour. Res. 2025, 34, 1023–1044. [Google Scholar] [CrossRef]

- Shi, R.; Bian, L.H.; Zhang, W.; Ma, Z.; Jiao, J.H.; Shen, J. Prediction model for free gas content in deep coal seams based on effective porosity. J. China Univ. Min. Technol. 2025, 54, 161–171. [Google Scholar]

- Yang, Z.B.; Li, C.L.; Guo, Q.Z.; Wang, B.; Liu, C.Q.; Qun, H.L.; Liang, Y.H.; Wang, Y.Q. Distribution law of different occurrence states of deep coalbed methane in Baijiahai uplift, Junggar Basin, Xinjiang. J. China Univ. Min. Technol. 2025, 54, 127–137. [Google Scholar]

- Zhang, D.F.; Meng, K.; Huang, Y.G.; Wang, H.; Zheng, X.P.; Hu, W.W.; Liu, Y.; Liu, B.X.; He, M.Q.; Wang, B.; et al. Characteristics and geological significance of carbon isotope of methane in analytical gas of Carboniferous Benxi Formation coal and rock in Ordos Basin. Geosci. Nat. Gas 2025, 1672–1926. [Google Scholar]

- Fang, S.M.; Zhao, C.B.; Chai, C.Z.; Liu, B.J.; Feng, S.Y.; Liu, M.J.; Lei, Q.Y.; Liu, H. Seismological evidence of crustal structure and tectonics in Yinchuan fault basin. Accord. Geophys. J. 2009, 52, 1768–1775. [Google Scholar]

- Hou, X.B.; Cui, H.Z.; Huan, Y.L. Structural styles and evolution of different structural layers in Yinchuan Basin. J. Northeast Pet. Univ. 2012, 36, 28–33. [Google Scholar]

- Huang, X.F.; Shi, W.; Li, H.Q.; Chen, L.; Cen, M. Cenozoic tectonic evolution of the Yinchuan Basin: Constraints from the kinematics of the main boundary faults of the Yinchuan Basin. Geol. Front. 2013, 20, 199–210. [Google Scholar]

- Deng, Q.D.; Cheng, S.P.; Min, W.; Yang, G.Z.; Ren, D.W. Discussion on Cenozoic tectonic activity and dynamics of Ordos block. J. Geomech. 1999, 5, 13–22. [Google Scholar]

- Liu, J.H. Helan Mountain. Analysis of Cenozoic extensional uplift and fault friction-induced thermal apatite fission track in Qinling Mountains. Int. Earthq. Dyn. 2010, 3, 31–33. [Google Scholar]

- Zhang, X.D.; Li, P.P.; Heng, S.; Sun, Q.Y.; Hu, X.F. Effect of coal structure on adsorption-desorption and production characteristics of coalbed methane. Coalf. Geol. Explor. 2016, 44, 40–45. [Google Scholar]

- Zhao, J.P.; Zhang, Y.Q.; Zhang, S.; Wang, H.L.; Pi, H.B.; Xiong, J.P. The influence of coal structure on the productivity of coalbed methane wells and its countermeasures. China Coalbed Methane 2017, 14, 9–12. [Google Scholar]

- Kang, Y.S.; Deng, Z.; Huang Fu, Y.H.; Mao, D.L. Accumulation model and exploration direction of high saturation-ultrasaturation zone of medium rank coalbed methane. Pet. J. 2020, 41, 1555–1566. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Xu, Q.; Wang, S.; Miao, Q.; Zhang, Z.; Xu, X.; Guo, H. Geological Conditions and Reservoir Formation Models of Low- to Middle-Rank Coalbed Methane in the Northern Part of the Ningxia Autonomous Region. Processes 2025, 13, 2079. https://doi.org/10.3390/pr13072079

Wang D, Xu Q, Wang S, Miao Q, Zhang Z, Xu X, Guo H. Geological Conditions and Reservoir Formation Models of Low- to Middle-Rank Coalbed Methane in the Northern Part of the Ningxia Autonomous Region. Processes. 2025; 13(7):2079. https://doi.org/10.3390/pr13072079

Chicago/Turabian StyleWang, Dongsheng, Qiang Xu, Shuai Wang, Quanyun Miao, Zhengguang Zhang, Xiaotao Xu, and Hongyu Guo. 2025. "Geological Conditions and Reservoir Formation Models of Low- to Middle-Rank Coalbed Methane in the Northern Part of the Ningxia Autonomous Region" Processes 13, no. 7: 2079. https://doi.org/10.3390/pr13072079

APA StyleWang, D., Xu, Q., Wang, S., Miao, Q., Zhang, Z., Xu, X., & Guo, H. (2025). Geological Conditions and Reservoir Formation Models of Low- to Middle-Rank Coalbed Methane in the Northern Part of the Ningxia Autonomous Region. Processes, 13(7), 2079. https://doi.org/10.3390/pr13072079