The Homology of Atmospheric Pollutants and Carbon Emissions in Industrial Parks: A Case Study in North China

Abstract

1. Introduction

2. Methodology

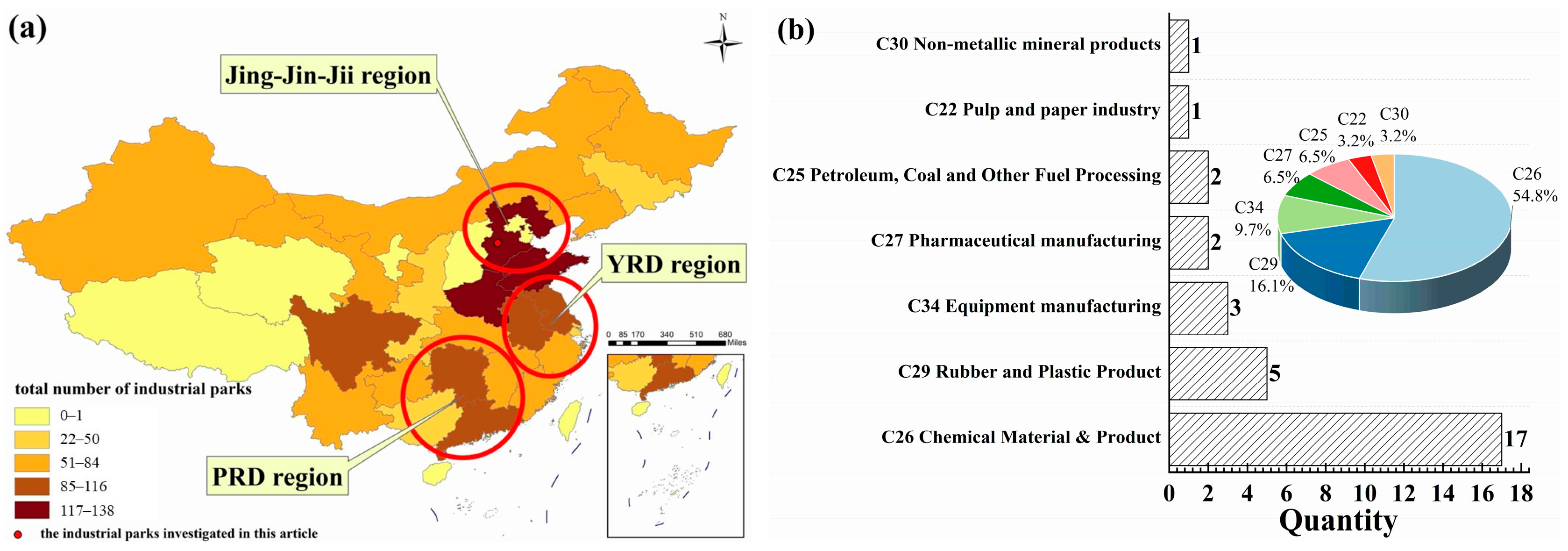

2.1. An Overview of the Study Area

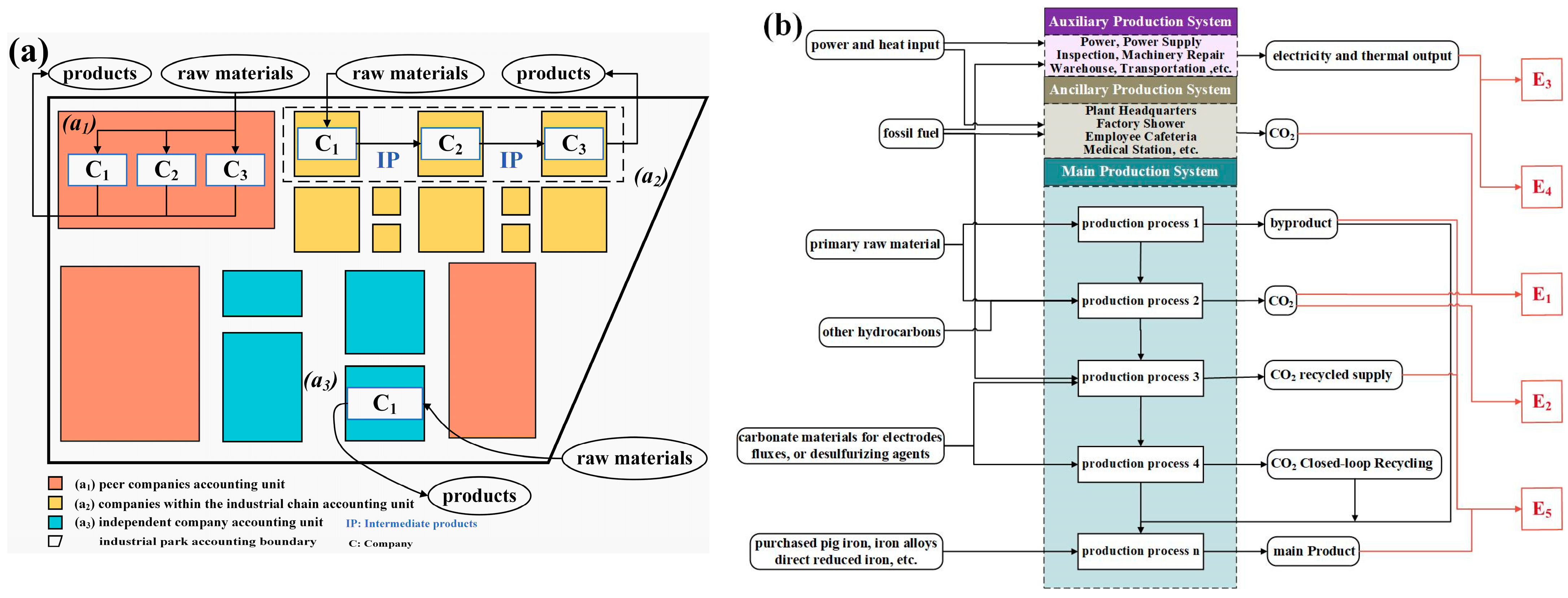

2.2. The Determination of the Accounting Boundaries and Scope

2.3. Methods for Carbon Emission Calculation

2.4. Calculation of Carbon Emission Intensity

2.5. Air Pollutant Equivalent Accounting and Data Sources

3. Results and Discussion

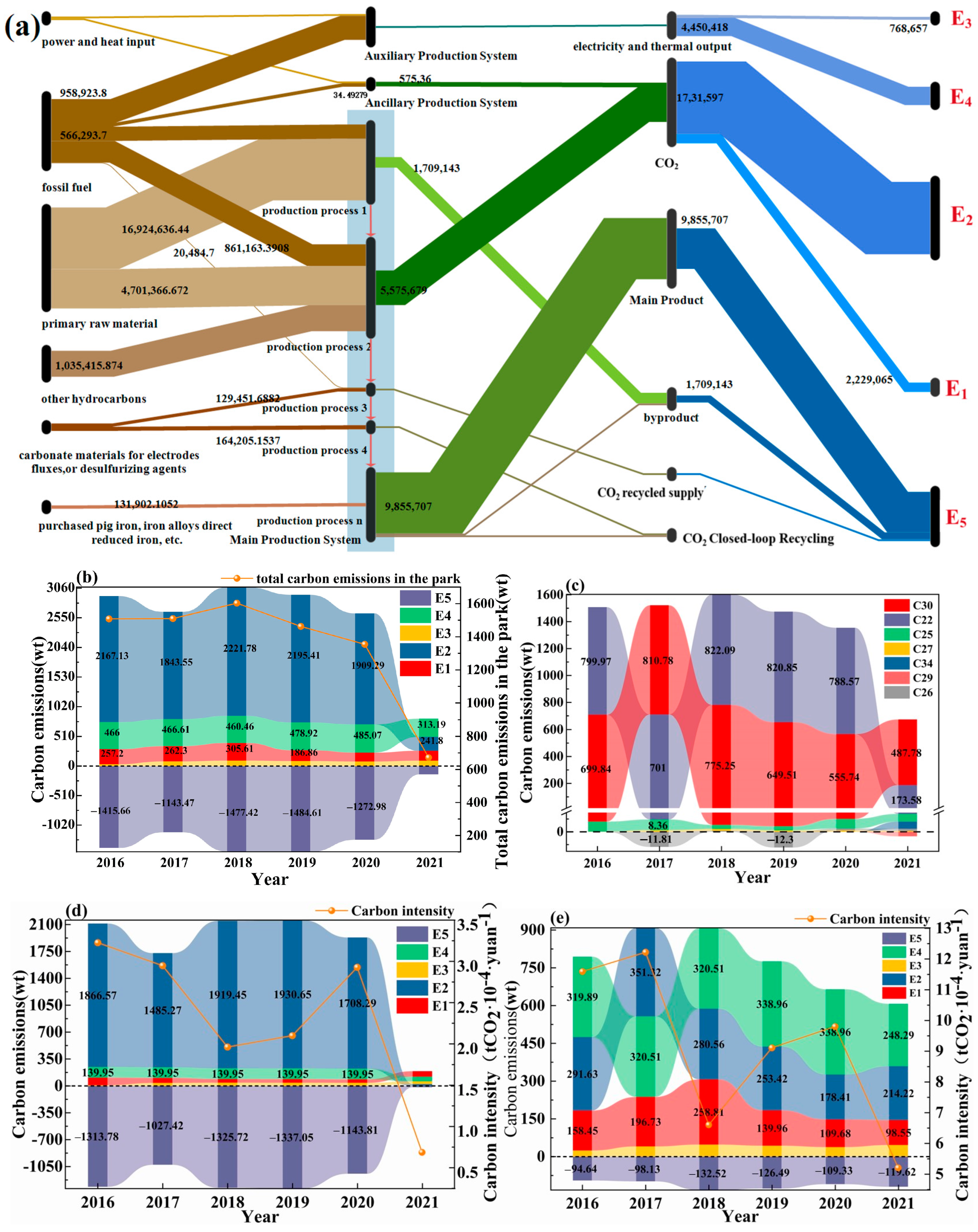

3.1. Characteristics of Carbon Emission Variations in Industrial Parks

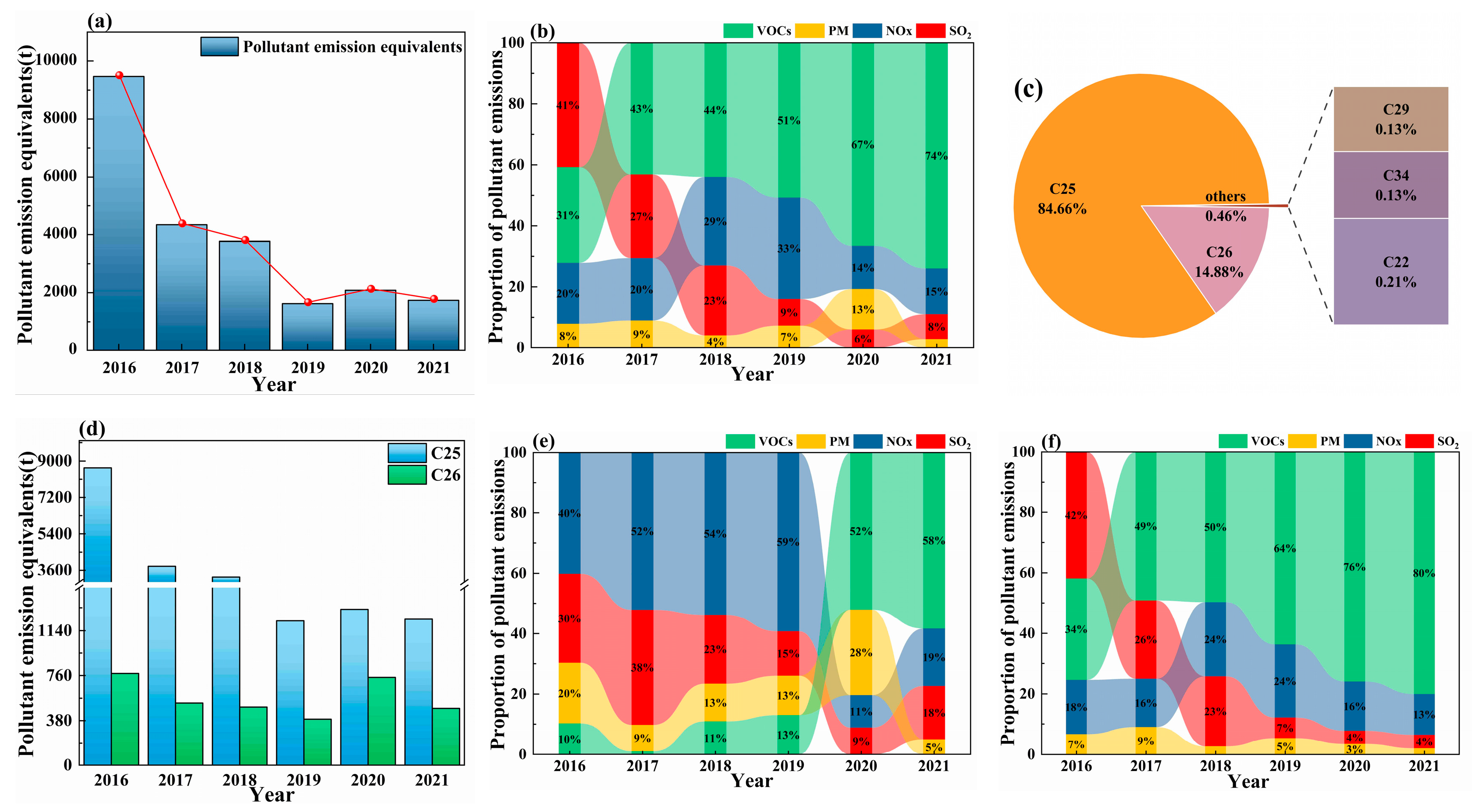

3.2. Characteristics of Pollutant Emission Distribution in Industrial Parks

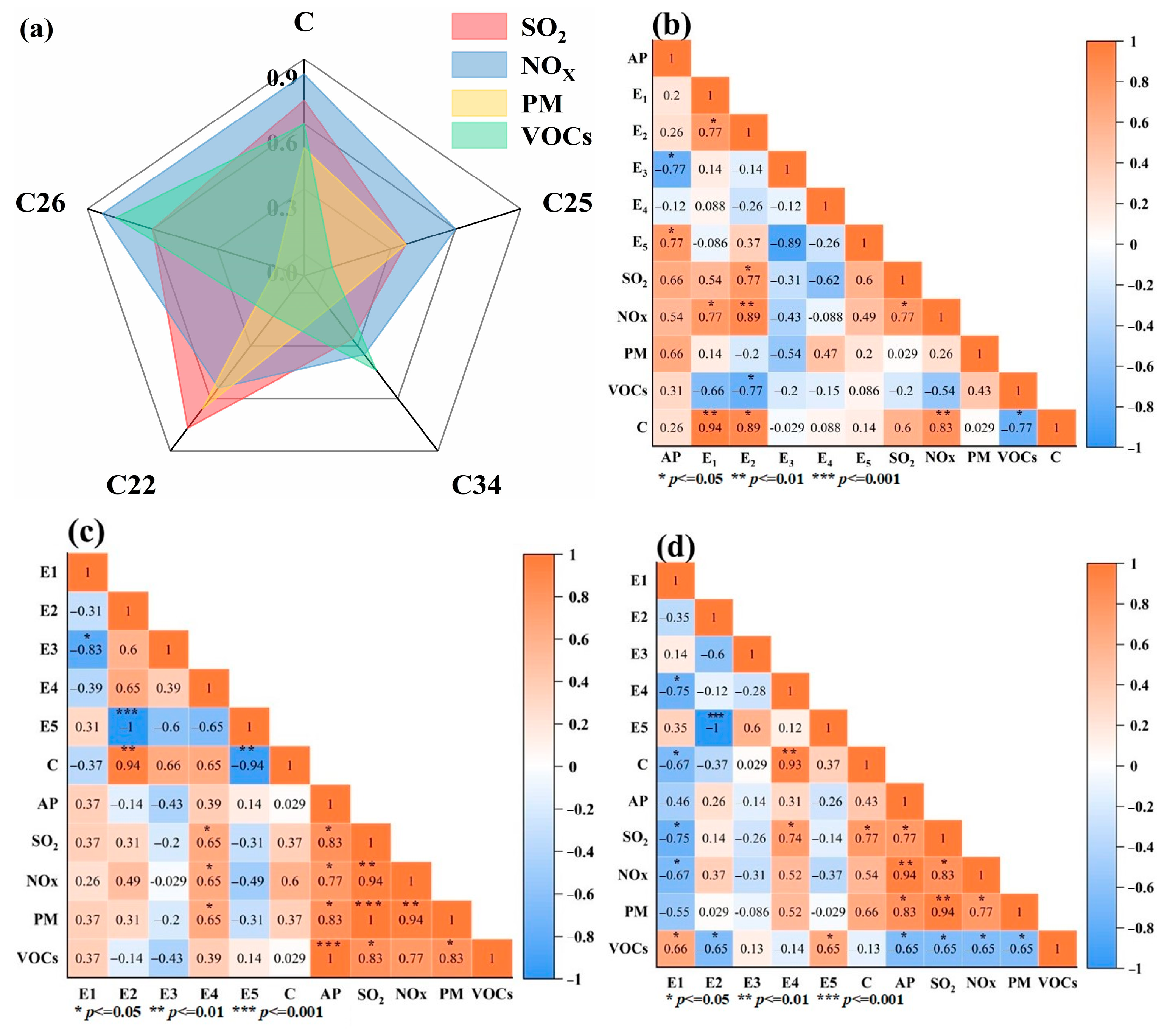

3.3. Influence of Law on Different Pollutants on Carbon Emissions

3.3.1. Processes of Carbon Emissions for Pollutant Types in Different Industries

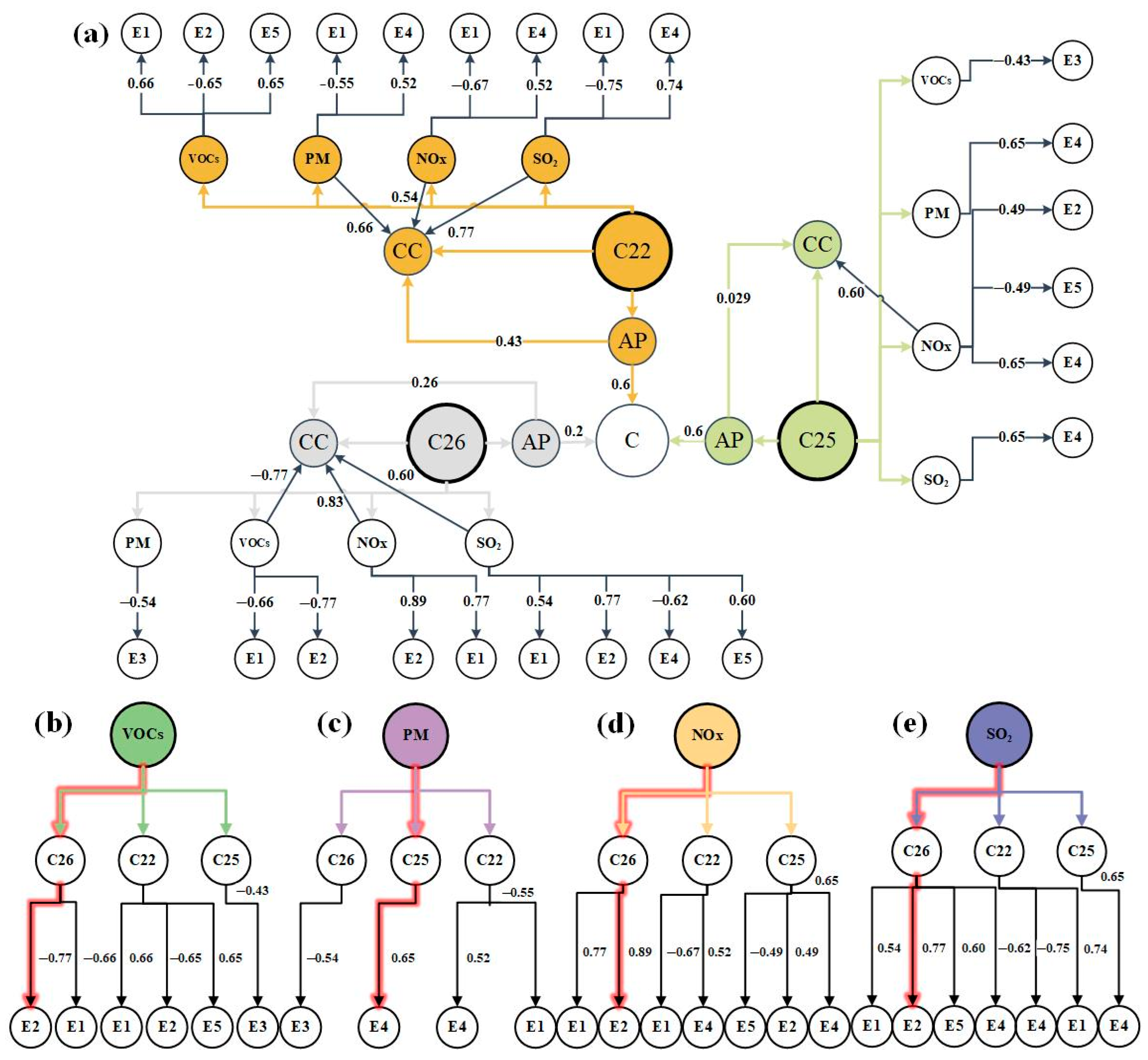

3.3.2. The Pathway Analysis Between Different Pollutants and the Distribution of Carbon Emissions

4. Conclusions

- From 2016 to 2021, the industrial park’s carbon emissions were reduced from 15.078 million tons to 6.715 million tons, with an average annual reduction rate of 15%, while the intensity annually decreased from 4.86 tons to 1.91 tons of CO2/CNY 10,000. These observations indicated that the park progressively achieved the dual control targets of total carbon emissions and intensity. Among these, the E2 emissions registered 70% of the total carbon emissions; hence, the park’s carbon emissions significantly decreased (from 21.9541 million tons to 2.418 million tons of CO2) after reducing the E2 impact. The reduction rate reached by C25 (26%) and C26 (7%) showed a significant diminution after applying the process upgrades and carbon control measures.

- This study selected SO2, NOx, PM, and VOCs as representative air pollutants, with emission volumes ranked from highest to lowest (i.e., VOCs, SO2, NOx, and PM). From 2016 to 2021, the total emissions of air pollutants decreased from 9466.19 tons to 1736.70 tons, with an average annual reduction rate of 40%. Thus, the C25 and C26 industries were the two largest polluting industries, registering 14.88% and 84.66% of the total pollutant emissions, respectively. Thus, focusing on the C26 industry, the significant diminution in the emissions of NOx (66%) and SO2 (73%) was the primary reason for the overall reduction in the pollutant emissions of the park.

- Furthermore, a strong positive correlation was found between the pollutants and the total carbon emissions, sharing a common source. For instance, in industry C26, we found higher correlations between carbon emissions with SO2 (0.77) and NOx (0.89). Based on that, NOx emissions are more suitable for being used as an indicator for carbon emissions during the production process of the raw chemical materials and chemical products manufacturing industry.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Olhoff, A.; Christensen, J.M. Emissions Gap Report 2020; UNEP DTU Partnership 2020; ISBN 978-92-807-3812-4. Available online: https://www.unep.org/emissions-gap-report-2020 (accessed on 12 January 2025).

- Trenberth, K.E.; Fasullo, J.T. An apparent hiatus in global warming? Earth’s Future 2013, 1, 19–32. [Google Scholar] [CrossRef]

- Agreement, P. Paris agreement. In Proceedings of the Report of the Conference of the Parties to the United Nations Framework Convention on Climate Change (21st Session, 2015: Paris), Paris, France, 30 November–13 December 2015; p. 2. [Google Scholar]

- NDRC. The 14th Five-Year Plan for National Economic and Social Development of the People’s Republic of China and the Long-Range Objectives Through the Year 2035. Available online: https://www.gov.cn/xinwen/2021-03/13/content_5592681.htm (accessed on 12 January 2025).

- Woerdman, E.; Roggenkamp, M.; Holwerda, M. Essential EU Climate Law; Edward Elgar Publishing: Cheltenham, UK, 2021. [Google Scholar]

- Biden, J. The Biden Plan for a Clean Energy Revolution and Environmental Justice. Available online: https://www.presidency.ucsb.edu/documents/biden-campaign-press-release-joe-biden-releases-his-plan-for-clean-energy-revolution (accessed on 12 January 2025).

- Liu, Z.; Ciais, P.; Deng, Z.; Lei, R.; Davis, S.J.; Feng, S.; Zheng, B.; Cui, D.; Dou, X.; Zhu, B. Near-real-time monitoring of global CO2 emissions reveals the effects of the COVID-19 pandemic. Nat. Commun. 2020, 11, 5172. [Google Scholar] [CrossRef] [PubMed]

- Yan, K.; Lv, Y.; Guo, Y.; Tian, J.; Chen, L. Review on Greenhouse Gas Accounting Methods on China’s Industrial Parks. Chin. J. Environ. Manag. 2021, 13, 13–23. [Google Scholar] [CrossRef]

- Ali, Y.; Pretaroli, R.; Socci, C.; Severini, F. Carbon and water footprint accounts of Italy: A Multi-Region Input-Output approach. Renew. Sustain. Energ. Rev. 2018, 81, 1813–1824. [Google Scholar] [CrossRef]

- Andrew, R.; Peters, G.P.; Lennox, J. Approximation and Regional Aggregation in Multi-Regional Input-Output Analysis for National Carbon Footprint Accounting. Econ. Syst. Res. 2009, 21, 311–335. [Google Scholar] [CrossRef]

- Chen, G.; Shan, Y.; Hu, Y.; Tong, K.; Wiedmann, T.; Ramaswami, A.; Guan, D.; Shi, L.; Wang, Y. Review on City-Level Carbon Accounting. Environ. Sci. Technol. 2019, 53, 5545–5558. [Google Scholar] [CrossRef]

- Kokoni, S.; Skea, J. Input-output and life-cycle emissions accounting: Applications in the real world. Clim. Policy 2014, 14, 372–396. [Google Scholar] [CrossRef]

- Andrade, J.C.S.; Dameno, A.; Pérez, J.; Almeida, J.M.D.; Lumbreras, J. Implementing city-level carbon accounting: A comparison between Madrid and London. J. Clean. Prod. 2018, 172, 795–804. [Google Scholar] [CrossRef]

- Lee, K.; Ko, J.; Jung, S. Quantifying uncertainty in carbon emission estimation: Metrics and methodologies. J. Clean. Prod. 2024, 452, 142141. [Google Scholar] [CrossRef]

- Li, Y.W.; Yang, X.X.; Du, E.S.; Liu, Y.L.; Zhang, S.X.; Yang, C.; Zhang, N.; Liu, C. A review on carbon emission accounting approaches for the electricity power industry. Appl. Energy 2024, 359, 122681. [Google Scholar] [CrossRef]

- Meng, Z.; Wang, H.; Wang, B. Empirical Analysis of Carbon Emission Accounting and Influencing Factors of Energy Consumption in China. Int. J. Environ. Res. Public Health 2018, 15, 2467. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.X.; Sun, W.Q.; Li, W.D.; Ma, G.Y. A carbon flow tracing and carbon accounting method for exploring CO emissions of the iron and steel industry: An integrated material-energy-carbon hub. Appl. Energy 2022, 309, 118485. [Google Scholar] [CrossRef]

- NDRC. Compilation of Greenhouse Gas Emission Accounting Guidelines for 24 Industries. Available online: https://www.cmenhu.cn/3425.html (accessed on 12 January 2025).

- Guo, Y.; Lv, Y.; Yan, K.; Tian, J.; Chen, L. Low-carbon development pathways of industrial parks in China. Chin. J. Environ. Manag. 2021, 13, 49–58. [Google Scholar]

- Zhang, M.; Wang, C.; Wang, S.S.; Wang, K.; Zhang, R.Q. Assessment of greenhouse gas emissions reduction potential in an industrial park in China. Clean Technol. Environ. Policy 2020, 22, 1435–1448. [Google Scholar] [CrossRef]

- Liu, L.X.; Zhang, B.; Bi, J.; Wei, Q.; Pan, H. The greenhouse gas mitigation of industrial parks in China: A case study of Suzhou Industrial Park. Energy Policy 2012, 46, 301–307. [Google Scholar] [CrossRef]

- Wang, H.S.; Lei, Y.; Wang, H.K.; Liu, M.M.; Yang, J.; Bi, J. Carbon reduction potentials of China’s industrial parks: A case study of Suzhou Industry Park. Energy 2013, 55, 668–675. [Google Scholar] [CrossRef]

- Tan, X.; Zeng, Y.; Gu, B.; Tan, X.; Xu, B. The accounting for greenhouse gas emissions of a low-carbon industrial park in China: A case study in Chongqing. Energy Procedia 2017, 142, 3176–3181. [Google Scholar] [CrossRef]

- Qi, J.; Chen, B. Greenhouse Gas Emission Inventory of Industrial Parks. Acta Ecol. Sin. 2015, 35, 2750–2760. [Google Scholar] [CrossRef]

- Hu, W.Q.; Tian, J.P.; Chen, L.J. Greenhouse gas emission by centralized wastewater treatment plants in Chinese industrial parks: Inventory and mitigation measures. J. Clean. Prod. 2019, 225, 883–897. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, S.; Gao, G.; Xue, X.; Song, H.; Zhang, R. Exploring the green and low-carbon development pathway for an energy-intensive industrial park in China. J. Clean. Prod. 2024, 459, 142384. [Google Scholar] [CrossRef]

- Li, Z.; Ding, J.; Tao, T.; Wang, S.; Pi, K.; Xiong, W. Novel Evaluation Method for Cleaner Production Audit in Industrial Parks: Case of a Park in Central China. Sustainability 2024, 16, 2330. [Google Scholar] [CrossRef]

- Lu, X.; Yao, T.; Fung, J.C.H.; Lin, C. Estimation of health and economic costs of air pollution over the Pearl River Delta region in China. Sci. Total Environ. 2016, 566–567, 134–143. [Google Scholar] [CrossRef] [PubMed]

- Gao, G.; Wang, S.; Xue, R.; Liu, D.; Ren, H.; Zhang, R. Uncovering the characteristics of air pollutants emission in industrial parks and analyzing emission reduction potential: Case studies in Henan, China. Sci. Rep. 2021, 11, 23709. [Google Scholar] [CrossRef] [PubMed]

- Hua, S.B.; Tian, H.Z.; Wang, K.; Zhu, C.Y.; Gao, J.J.; Ma, Y.L.; Xue, Y.F.; Wang, Y.; Duan, S.H.; Zhou, J.R. Atmospheric emission inventory of hazardous air pollutants from China’s cement plants: Temporal trends, spatial variation characteristics and scenario projections. Atmos. Environ. 2016, 128, 1–9. [Google Scholar] [CrossRef]

- Wang, H.; Gu, K.; Sun, H.; Xiao, H. Reconfirmation of the symbiosis on carbon emissions and air pollution: A spatial spillover perspective. Sci. Total Environ. 2023, 858, 159906. [Google Scholar] [CrossRef]

- Yi, H.; Zhao, L.; Qian, Y.; Zhou, L.; Yang, P. How to achieve synergy between carbon dioxide mitigation and air pollution control? Evidence from China. Sustain. Cities Soc. 2022, 78, 103609. [Google Scholar] [CrossRef]

- Jiang, P.; Khishgee, S.; Alimujiang, A.; Dong, H. Cost-effective approaches for reducing carbon and air pollution emissions in the power industry in China. J. Environ. Manag. 2020, 264, 110452. [Google Scholar] [CrossRef]

- Eggleston, H.; Buendia, L.; Miwa, K.; Ngara, T.; Tanabe, K. 2006 IPCC Guidelines for National Greenhouse Gas Inventories. 2006. Available online: https://www.osti.gov/etdeweb/biblio/20880391 (accessed on 12 January 2025).

- National Development and Reform Commission (NDRC). Guidelines for Greenhouse Gas Emissions Accounting and Reporting in Other Industrial Enterprises (Trial)—Compilation Notes. November 2015. Available online: https://www.ndrc.gov.cn/xxgk/zcfb/tz/201511/W020190905506438889540.pdf (accessed on 10 June 2025).

- Dixit, M.K.; Culp, C.H.; Fernandez-Solis, J.L. Calculating primary energy and carbon emission factors for the United States’ energy sectors. RSC Adv. 2014, 4, 54200–54216. [Google Scholar] [CrossRef]

- NDRC. China’s Greenhouse Gas Emission Accounting and Reporting Guidelines for the Iron and Steel Industry (Trial). Available online: https://www.gov.cn/gzdt/att/att/site1/20131104/001e3741a2cc13e13f1803.pdf (accessed on 12 January 2025).

- MEE; Ministry of Ecology and Environment of the People’s Republic of China G.O. Notice on the Management of Greenhouse Gas Emission Reporting for the Power Generation Industry for the Years 2023–2025. Available online: https://www.mee.gov.cn/xxgk2018/xxgk/xxgk06/202302/t20230207_1015569.html (accessed on 12 January 2025).

- GB/T 32150-2015; Standardization Administration of China (SAC). Guidelines for Greenhouse Gas Emissions Accounting and Reporting in Other Industrial Enterprises. Standards Press of China: Beijing, China, 2015; AQSRQ.

- Dong, F.; Yu, B.; Hadachin, T.; Dai, Y.; Wang, Y.; Zhang, S.; Long, R. Drivers of carbon emission intensity change in China. Resour. Conserv. Recycl. 2018, 129, 187–201. [Google Scholar] [CrossRef]

- Babcock, L.R., Jr. A combined pollution index for measurement of total air pollution. J. Air Pollut. Control Assoc. 1970, 20, 653–659. [Google Scholar] [CrossRef]

- Hassani, H.; Silva, E.S.; Al Kaabi, A.M. The role of innovation and technology in sustaining the petroleum and petrochemical industry. Technol. Forecast. Soc. Chang. 2017, 119, 1–17. [Google Scholar] [CrossRef]

- NDRC. Development Plan for the Petrochemical and Chemical Industry (2016–2020). Available online: https://www.ndrc.gov.cn/fggz/fzzlgh/gjjzxgh/201706/t20170622_1196825.html (accessed on 12 January 2025).

- SCNC. Air Pollution Prevention and Control Law of the People’s Republic of China. Available online: https://www.mee.gov.cn/ywgz/fgbz/fl/201811/t20181113_673567.shtml (accessed on 12 June 2025).

- Zhang, L.; Wang, Y.; Feng, C.; Liang, S.; Liu, Y.; Du, H.; Jia, N. Understanding the industrial NOx and SO2 pollutant emissions in China from sector linkage perspective. Sci. Total Environ. 2021, 770, 145242. [Google Scholar] [CrossRef] [PubMed]

- Zheng, C.H.; Shen, J.L.; Zhang, Y.X.; Huang, W.W.; Zhu, X.B.; Wu, X.C.; Chen, L.H.; Gao, X.; Cen, K.F. Quantitative assessment of industrial VOC emissions in China: Historical trend, spatial distribution, uncertainties, and projection. Atmos. Environ. 2017, 150, 116–125. [Google Scholar] [CrossRef]

- Zhang, Y.; Song, Y.; Zou, H. Transformation of pollution control and green development: Evidence from China’s chemical industry. J. Envron. Manag. 2020, 275, 111246. [Google Scholar] [CrossRef] [PubMed]

- MEE; Ministry of Ecology and Environment of the People’s Republic of China, G.O. Emission Standard of Pollutants for the Petroleum Chemical Industry. Available online: https://www.mee.gov.cn/ywgz/fgbz/bz/bzwb/dqhjbh/dqgdwrywrwpfbz/201505/W020150506394632230539.pdf (accessed on 14 June 2025).

- Simayi, M.; Shi, Y.Q.; Xi, Z.Y.; Ren, J.; Hini, G.; Xie, S.D. Emission trends of industrial VOCs in China since the clean air action and future reduction perspectives. Sci. Total Environ. 2022, 826, 153994. [Google Scholar] [CrossRef]

- Li, X.; Qiao, Y.B.; Shi, L. The aggregate effect of air pollution regulation on CO mitigation in China’s manufacturing industry: An econometric analysis. J. Clean. Prod. 2017, 142, 976–984. [Google Scholar] [CrossRef]

- Chae, Y. Co-benefit analysis of an air quality management plan and greenhouse gas reduction strategies in the Seoul metropolitan area. Environ. Sci. Policy 2010, 13, 205–216. [Google Scholar] [CrossRef]

- Shi, Q.W.; Liang, Q.Q.; Huo, T.F.; You, K.R.; Cai, W.G. Evaluation of CO2 and SO2 synergistic emission reduction: The case of China. J. Clean. Prod. 2023, 433, 139784. [Google Scholar] [CrossRef]

- Xie, X.; Weng, Y.W.; Cai, W.J. Co-Benefits of CO Mitigation for NO Emission Reduction: A Research Based on the DICE Model. Sustainability 2018, 10, 1109. [Google Scholar] [CrossRef]

- Del Rio, D.D.F.; Sovacool, B.K.; Griffiths, S.; Bazilian, M.; Kim, J.; Foley, A.M.; Rooney, D. Decarbonizing the pulp and paper industry: A critical and systematic review of sociotechnical developments and policy options. Renew. Sustain. Energy Rev. 2022, 167, 112706. [Google Scholar] [CrossRef]

- Fetisov, V.; Gonopolsky, A.M.; Davardoost, H.; Ghanbari, A.R.; Mohammadi, A.H. Regulation and impact of VOC and CO emissions on low-carbon energy systems resilient to climate change: A case study on an environmental issue in the oil and gas industry. Energy Sci. Eng. 2023, 11, 1516–1535. [Google Scholar] [CrossRef]

- Huang, C.; Chen, C.H.; Li, L.; Cheng, Z.; Wang, H.L.; Huang, H.Y.; Streets, D.G.; Wang, Y.J.; Zhang, G.F.; Chen, Y.R. Emission inventory of anthropogenic air pollutants and VOC species in the Yangtze River Delta region, China. Atmos. Chem. Phys. 2011, 11, 4105–4120. [Google Scholar] [CrossRef]

- Lin, B.Q.; Long, H.Y. Emissions reduction in China’s chemical industry—Based on LMDI. Renew. Sustain. Energ. Rev. 2016, 53, 1348–1355. [Google Scholar] [CrossRef]

- Lyu, Y.; Chen, L.J.; Tian, J.P.; Liu, R.; Zhou, Q. Realizing synergy between pollution reduction and carbon mitigation in industrial parks: From model development to tool application. J. Clean. Prod. 2024, 446, 141197. [Google Scholar] [CrossRef]

- Islam, A.; Teo, S.H.; Ng, C.H.; Taufiq-Yap, Y.H.; Choong, S.Y.T.; Awual, M.R. Progress in recent sustainable materials for greenhouse gas (NOx and SOx) emission mitigation. Prog. Mater. Sci. 2023, 132, 101033. [Google Scholar] [CrossRef]

- Liu, J.-Y.; Woodward, R.T.; Zhang, Y.-J. Has carbon emissions trading reduced PM2. 5 in China? Environ. Sci. Technol. 2021, 55, 6631–6643. [Google Scholar] [CrossRef]

| Types of Emissions | Carbon Emission Accounting Formulas | Reference |

|---|---|---|

| E1 | [35] | |

| E2 | [36] | |

| E3 | [18] | |

| E4 | [18] | |

| E5 | [36] |

| Air Pollutants | Equivalent Coefficient | Coefficient Values |

|---|---|---|

| SO2 | 1/0.95 | |

| NOx | 1/0.95 | |

| VOCS | 1/0.95 | |

| PM | 1/2.18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Chen, T.; Fang, F.; Wang, T.; Zhang, M.; Manuel, F. The Homology of Atmospheric Pollutants and Carbon Emissions in Industrial Parks: A Case Study in North China. Processes 2025, 13, 2070. https://doi.org/10.3390/pr13072070

Li Z, Chen T, Fang F, Wang T, Zhang M, Manuel F. The Homology of Atmospheric Pollutants and Carbon Emissions in Industrial Parks: A Case Study in North China. Processes. 2025; 13(7):2070. https://doi.org/10.3390/pr13072070

Chicago/Turabian StyleLi, Zhitao, Tianxiang Chen, Fei Fang, Tianzhi Wang, Mingzhe Zhang, and Fiallos Manuel. 2025. "The Homology of Atmospheric Pollutants and Carbon Emissions in Industrial Parks: A Case Study in North China" Processes 13, no. 7: 2070. https://doi.org/10.3390/pr13072070

APA StyleLi, Z., Chen, T., Fang, F., Wang, T., Zhang, M., & Manuel, F. (2025). The Homology of Atmospheric Pollutants and Carbon Emissions in Industrial Parks: A Case Study in North China. Processes, 13(7), 2070. https://doi.org/10.3390/pr13072070