Characteristics of Deep Coal Reservoirs Based on Logging Parameter Responses and Laboratory Data: A Case Study of the Logging Response Analysis of Reservoir Parameters Is Carried Out in Ordos Basin, China

Abstract

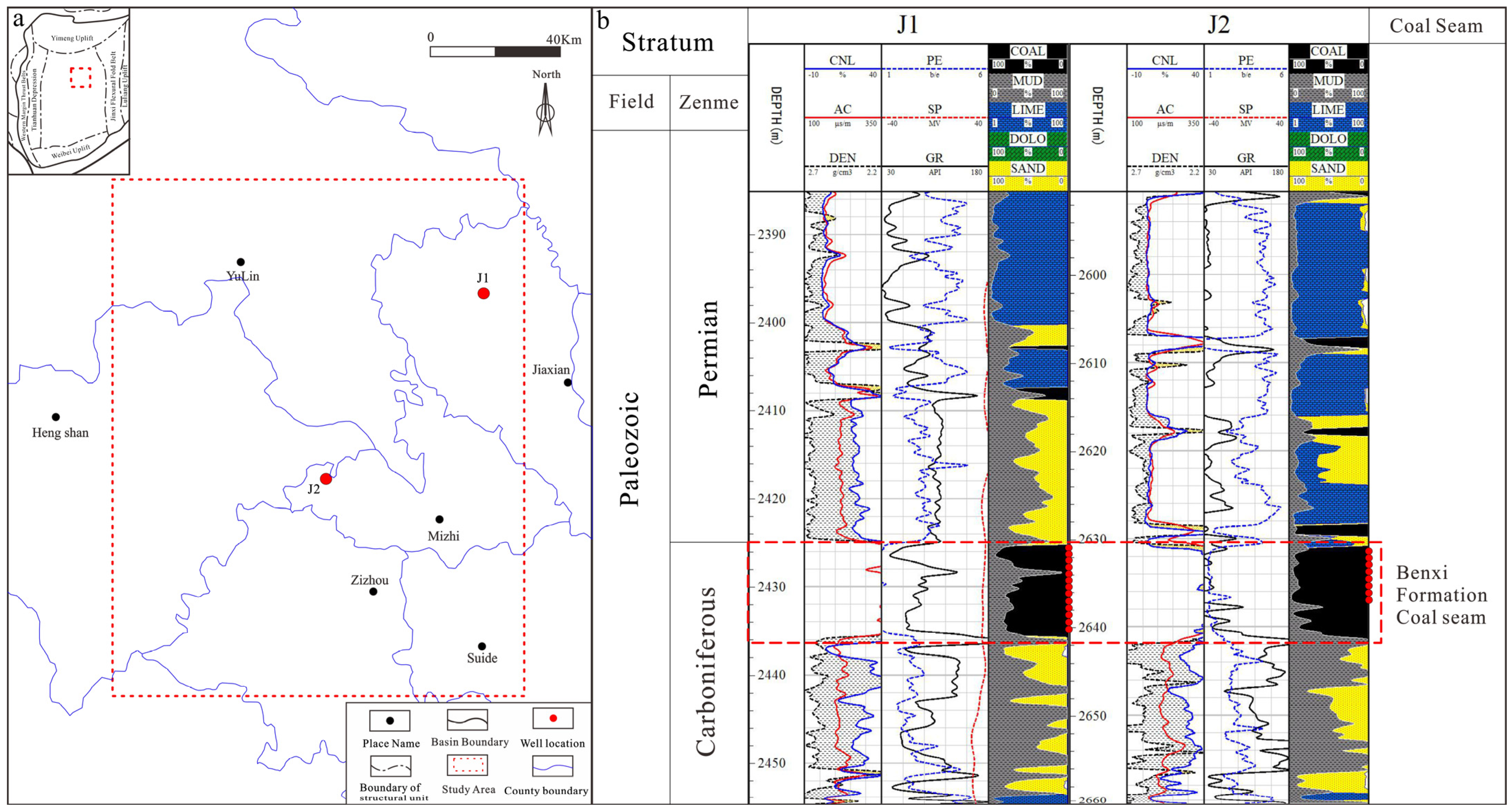

1. Geological Background

2. Experimental Samples and Model Establishment Methods

3. Results and Discussion

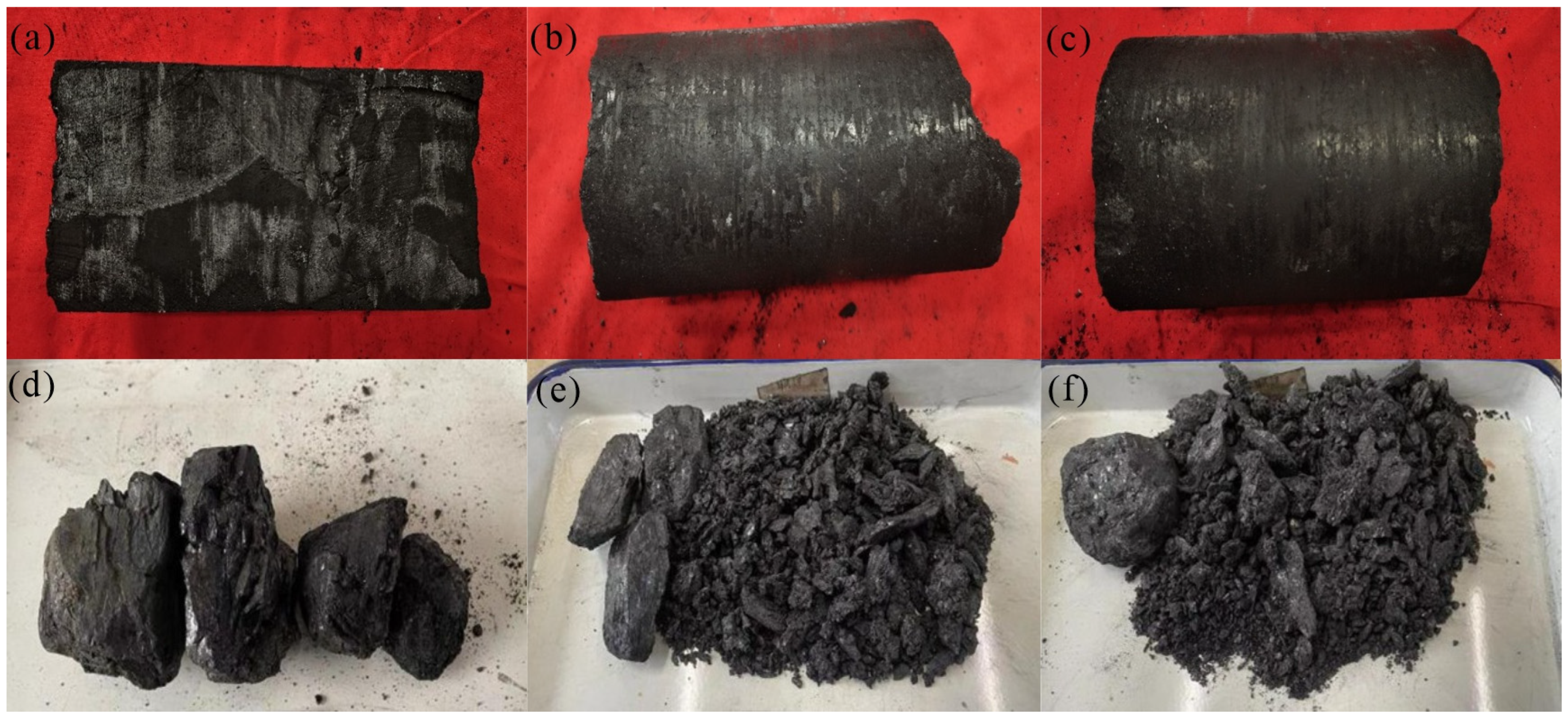

3.1. Coal Characteristics

3.2. Coal Reservoir Parameters and Logging Responses

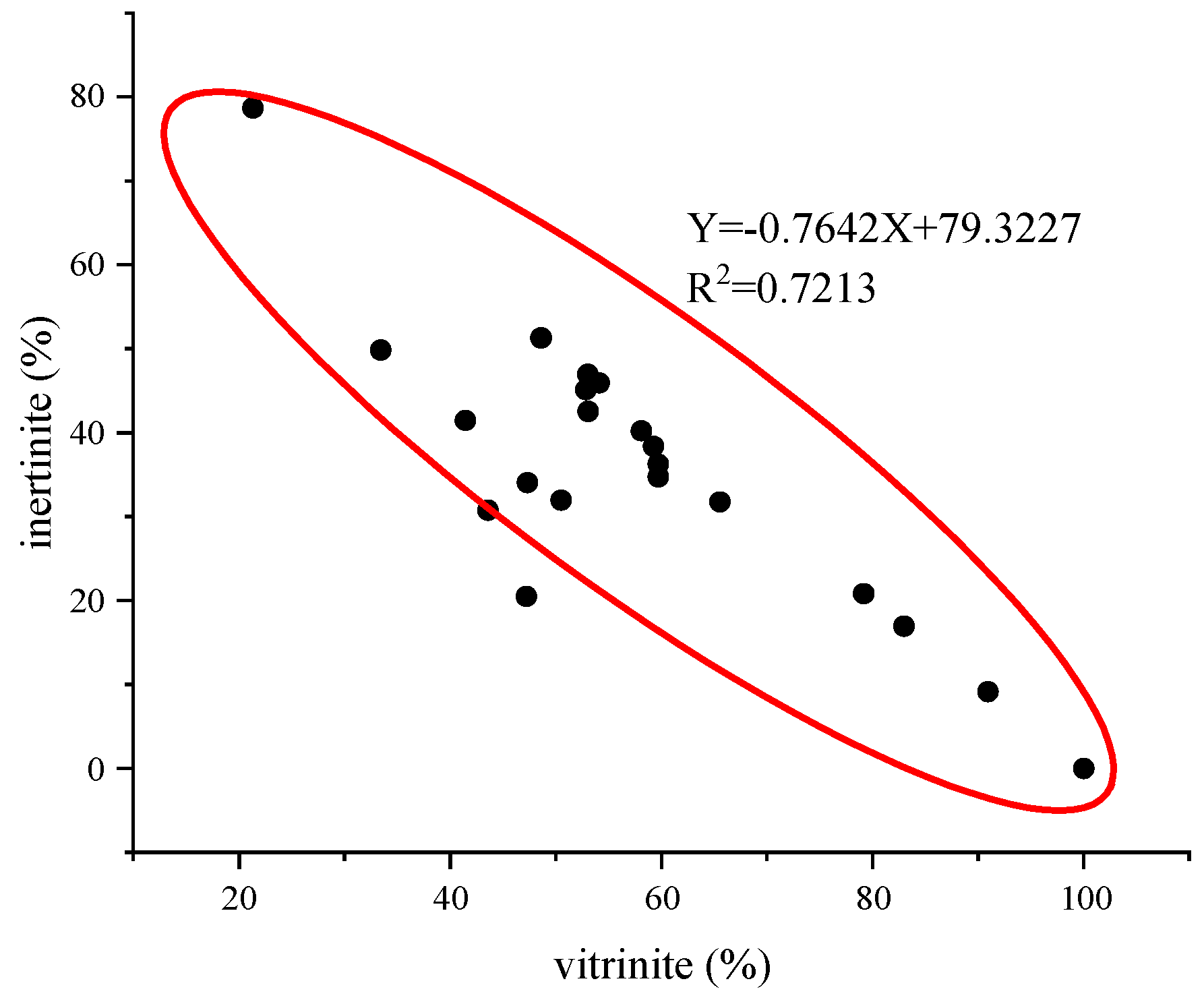

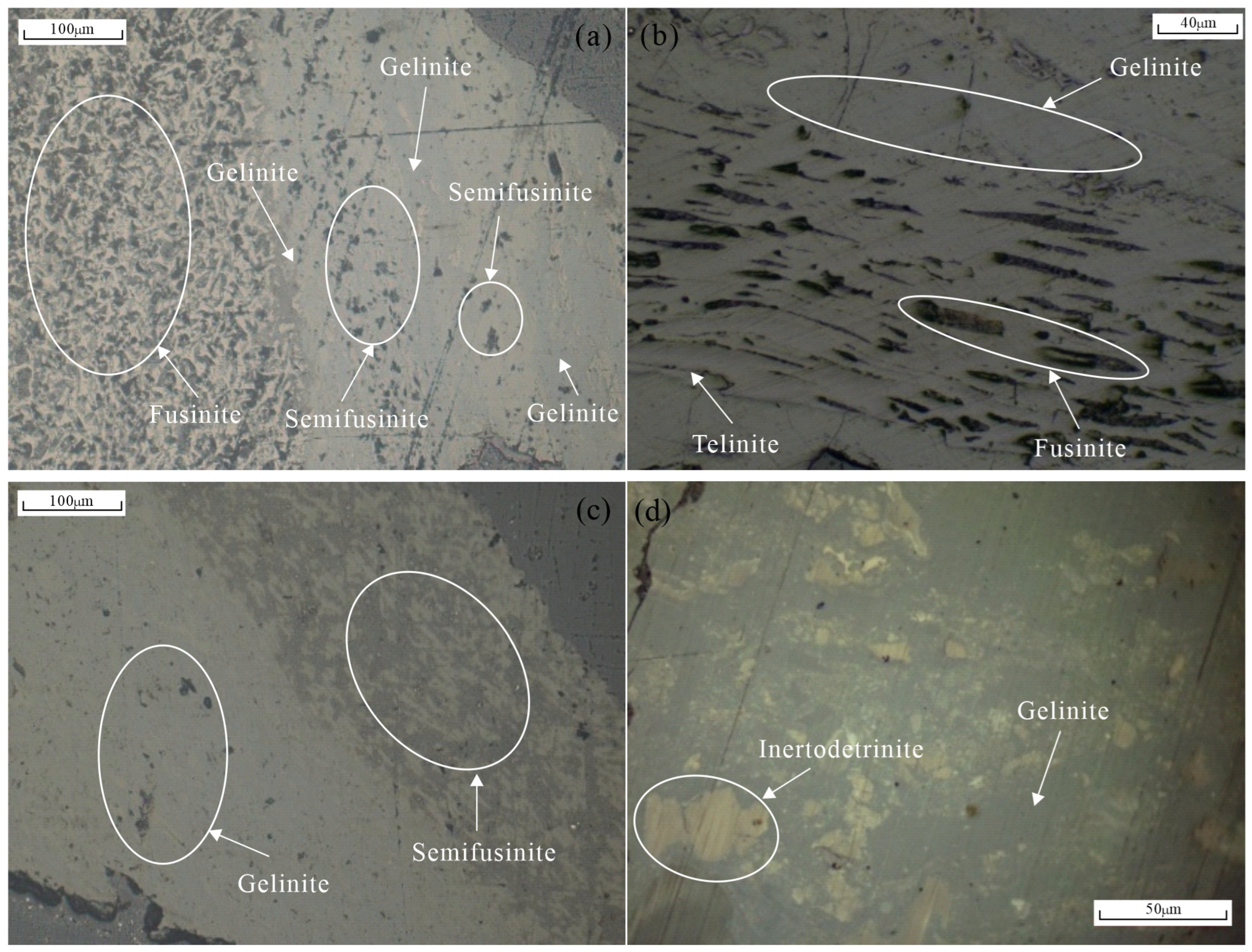

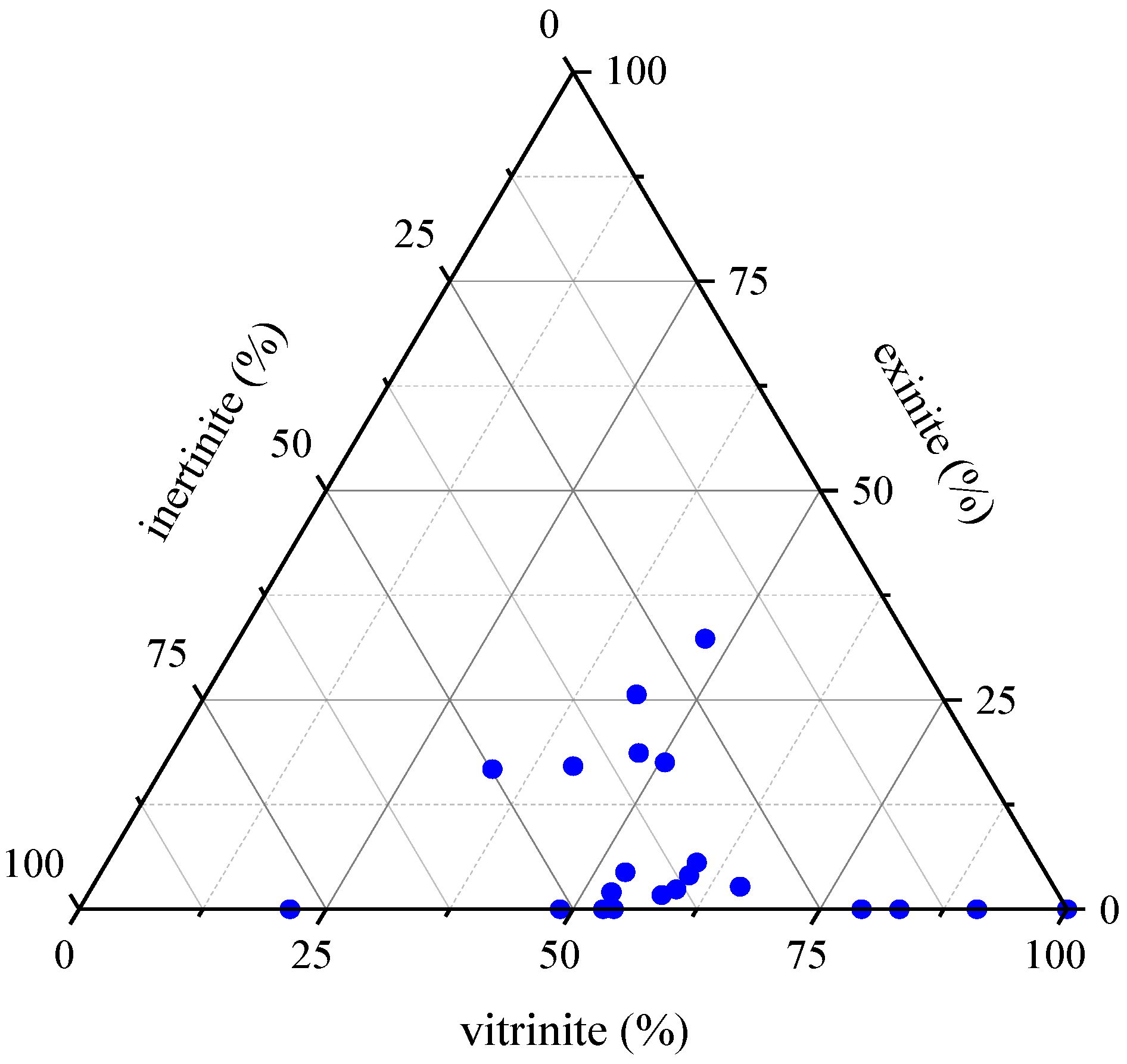

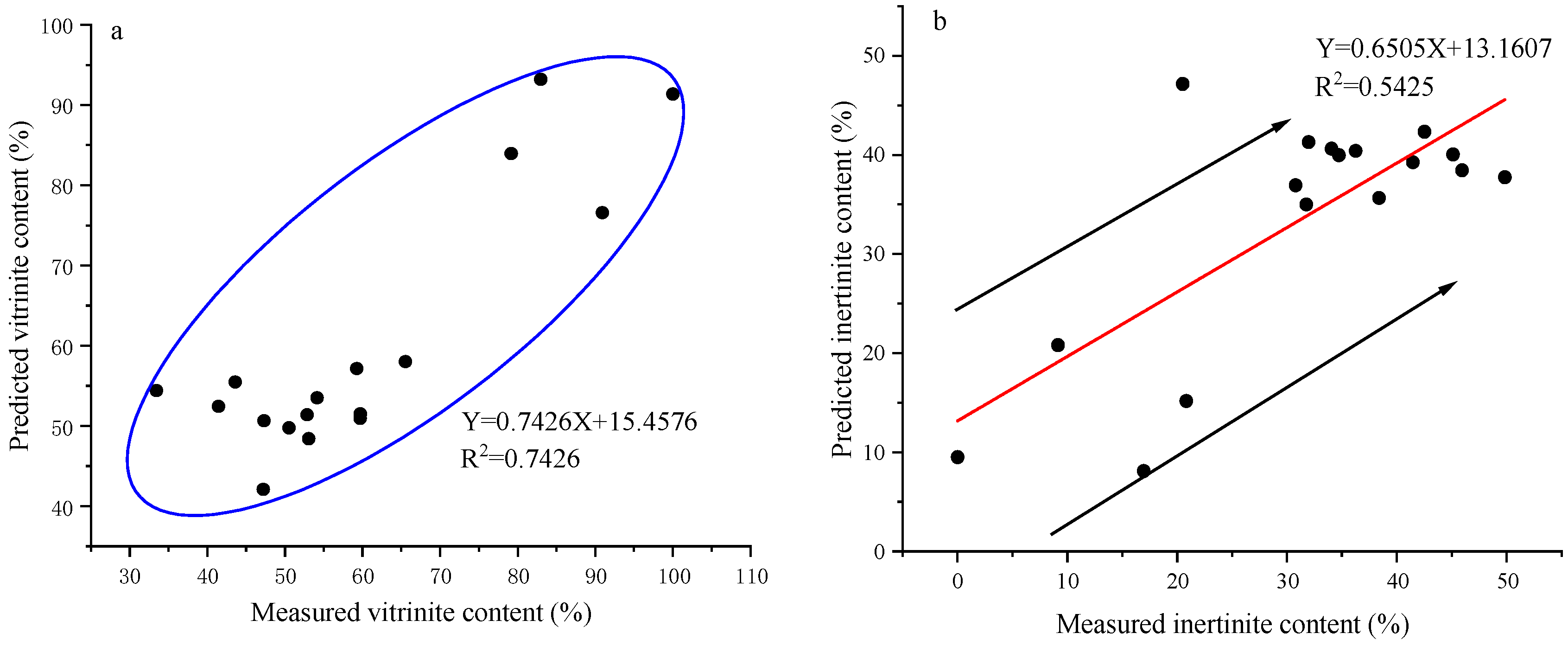

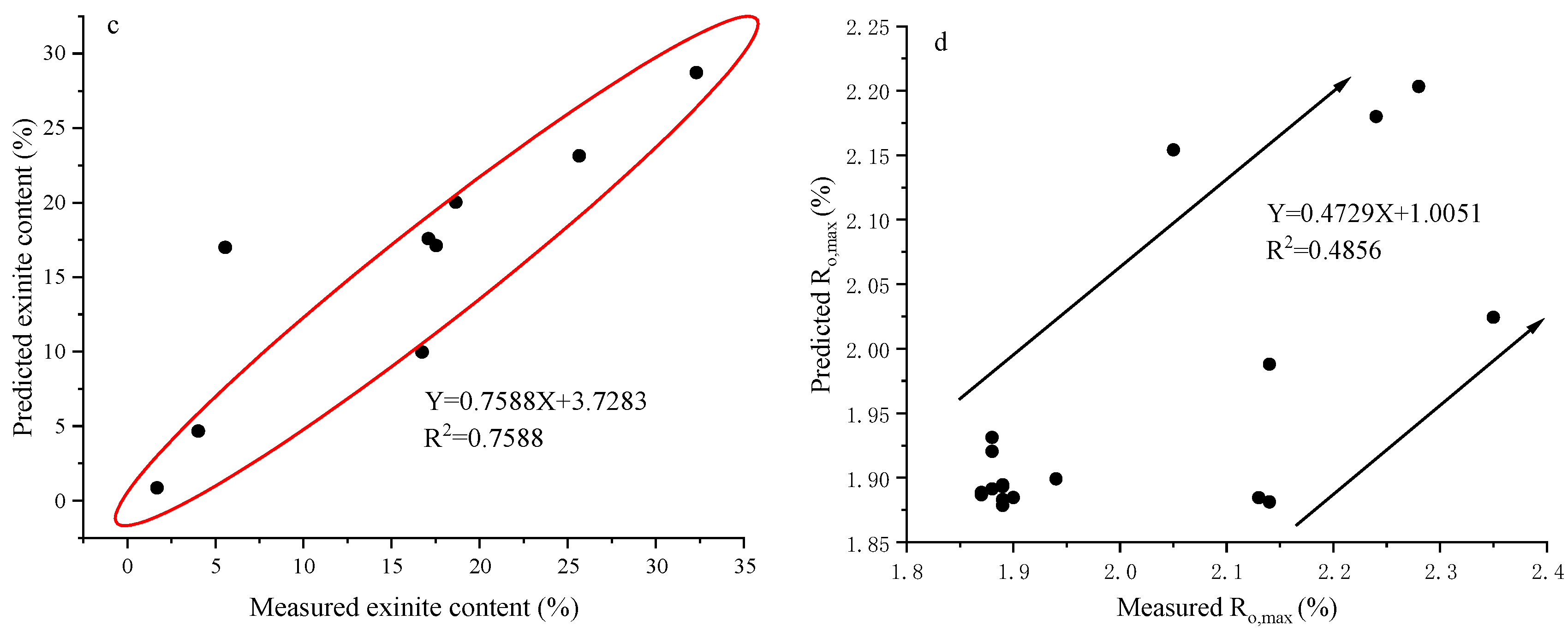

3.2.1. Coal Maceral

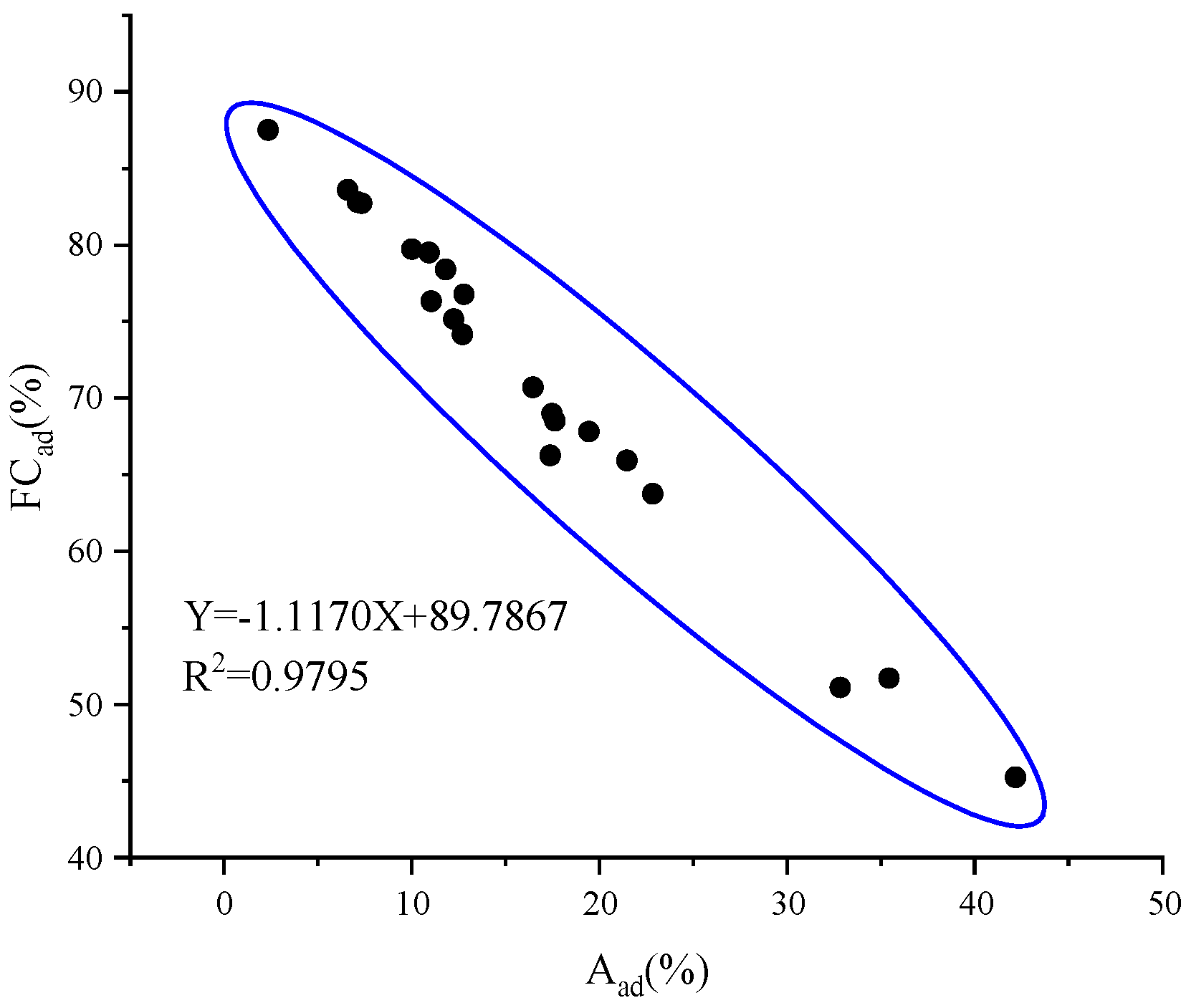

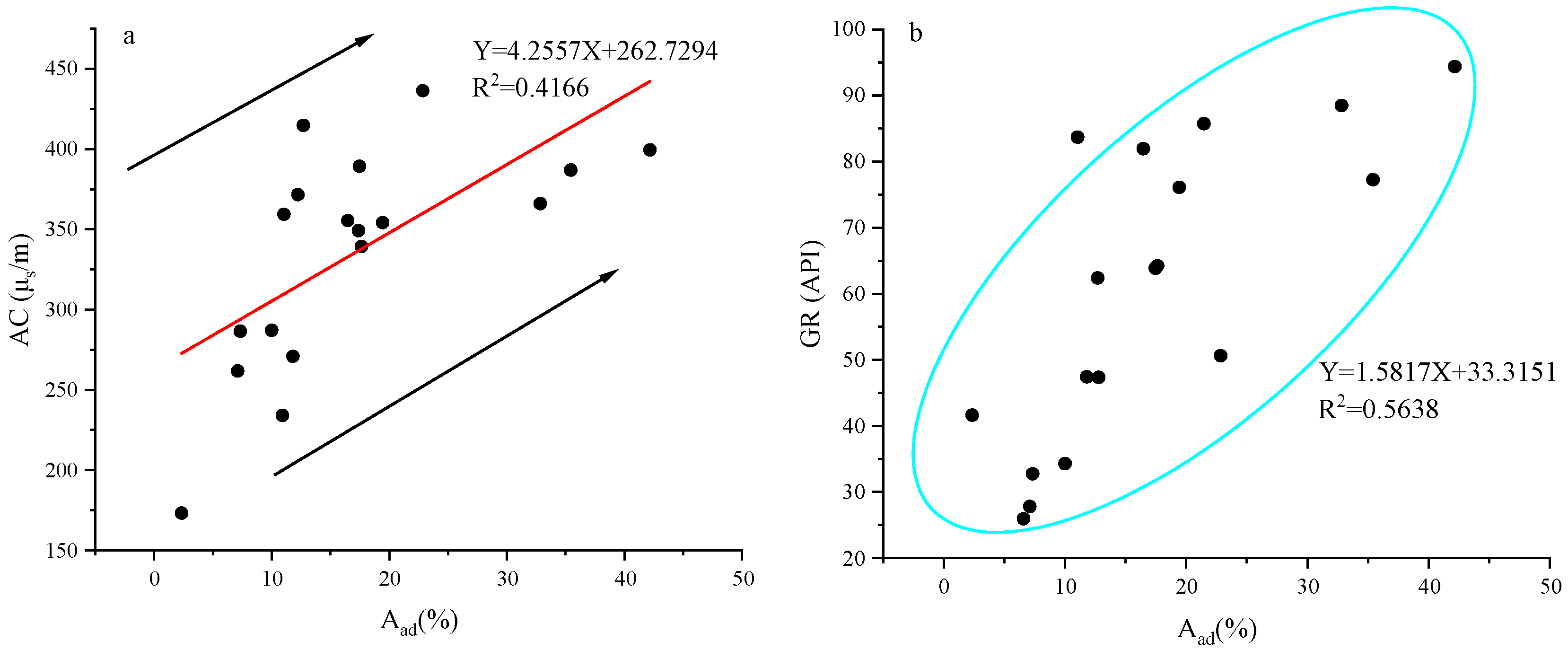

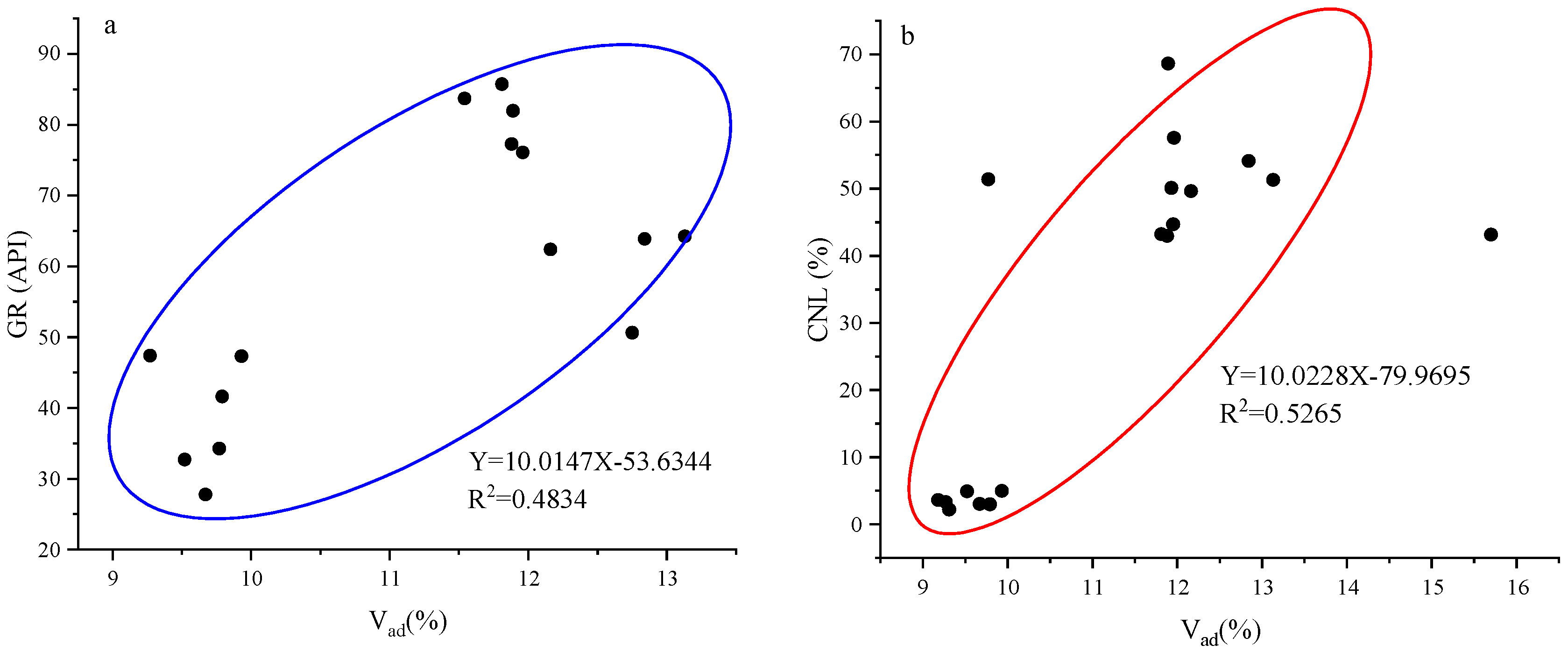

3.2.2. Industrial Components

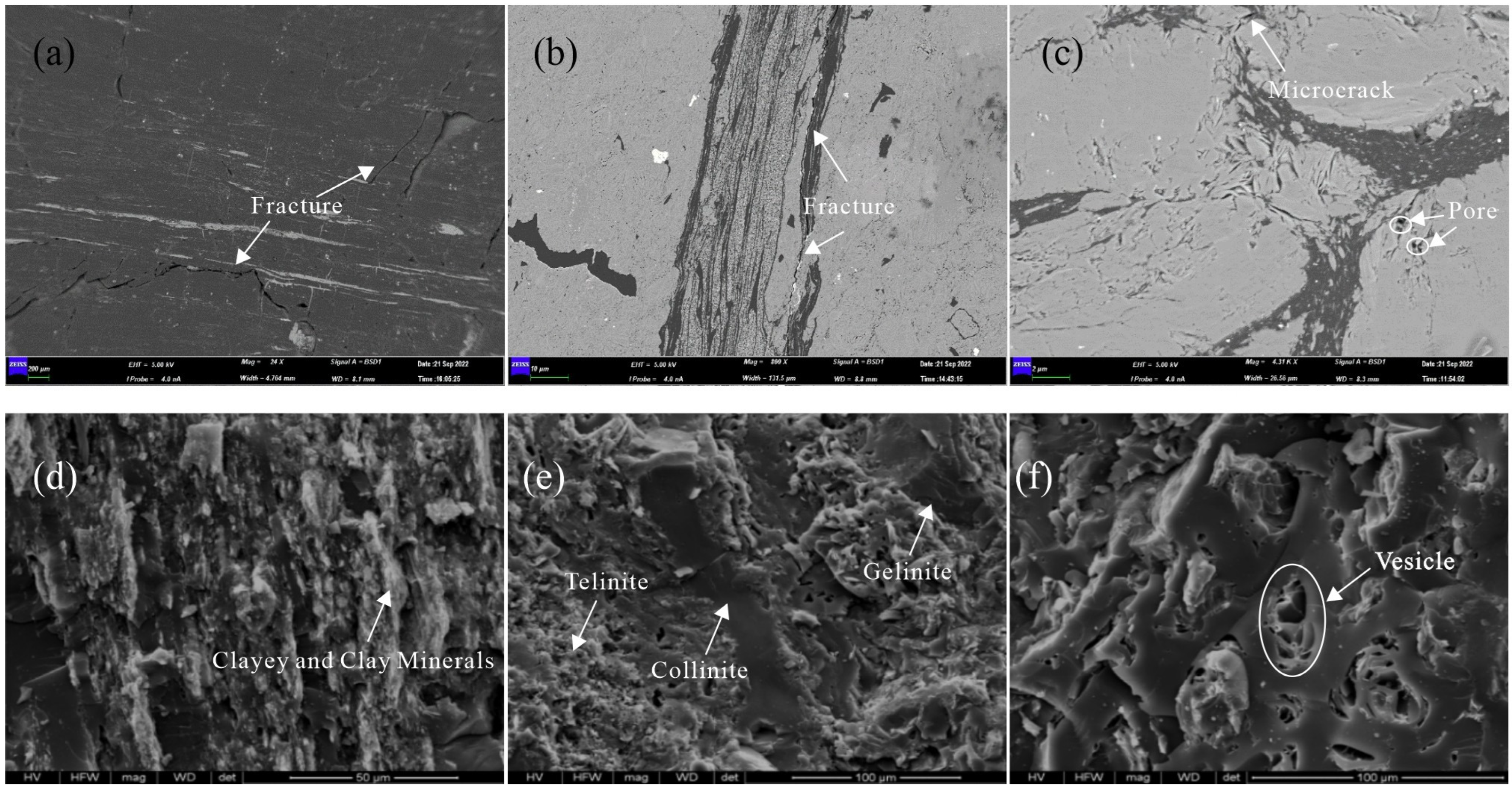

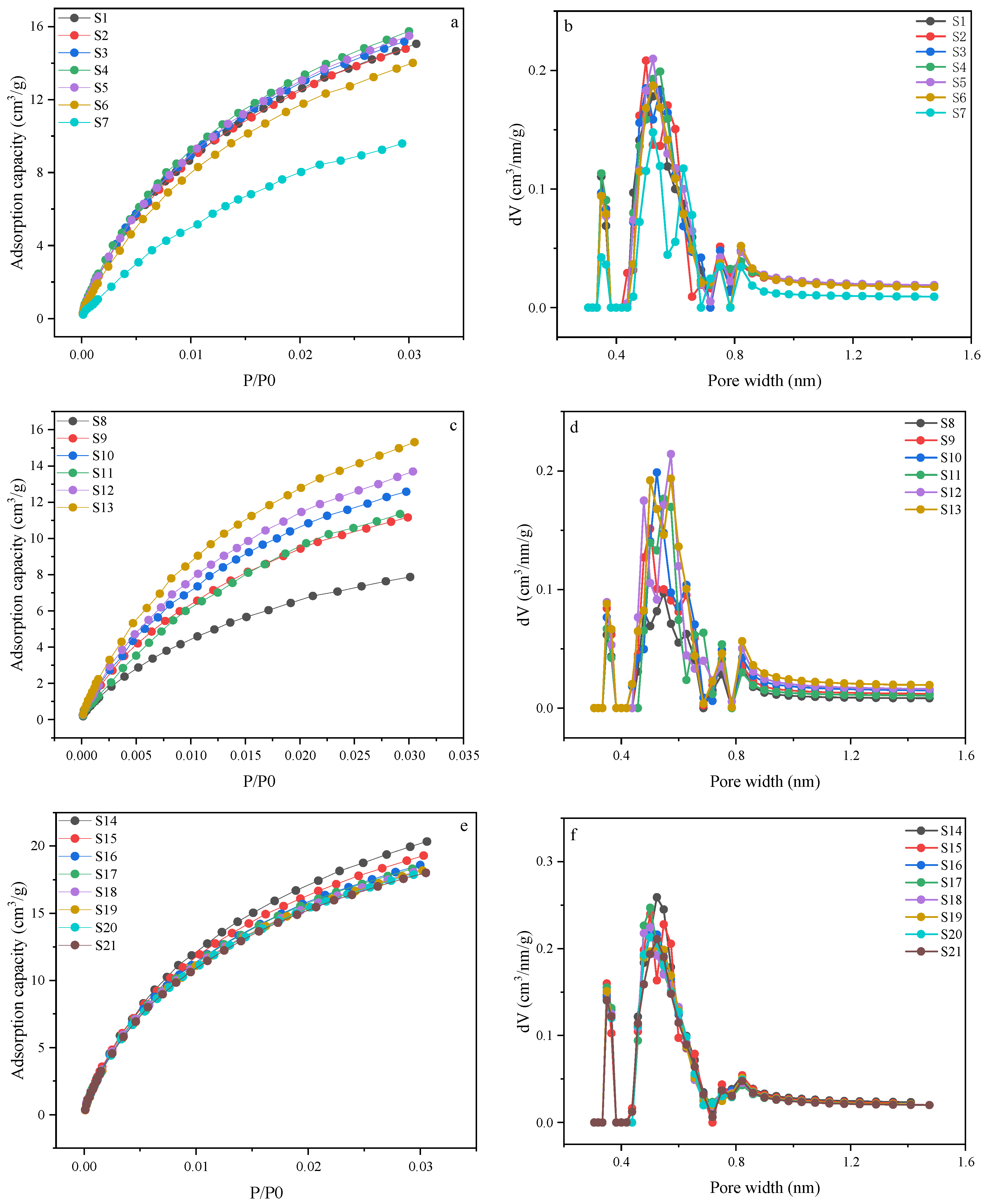

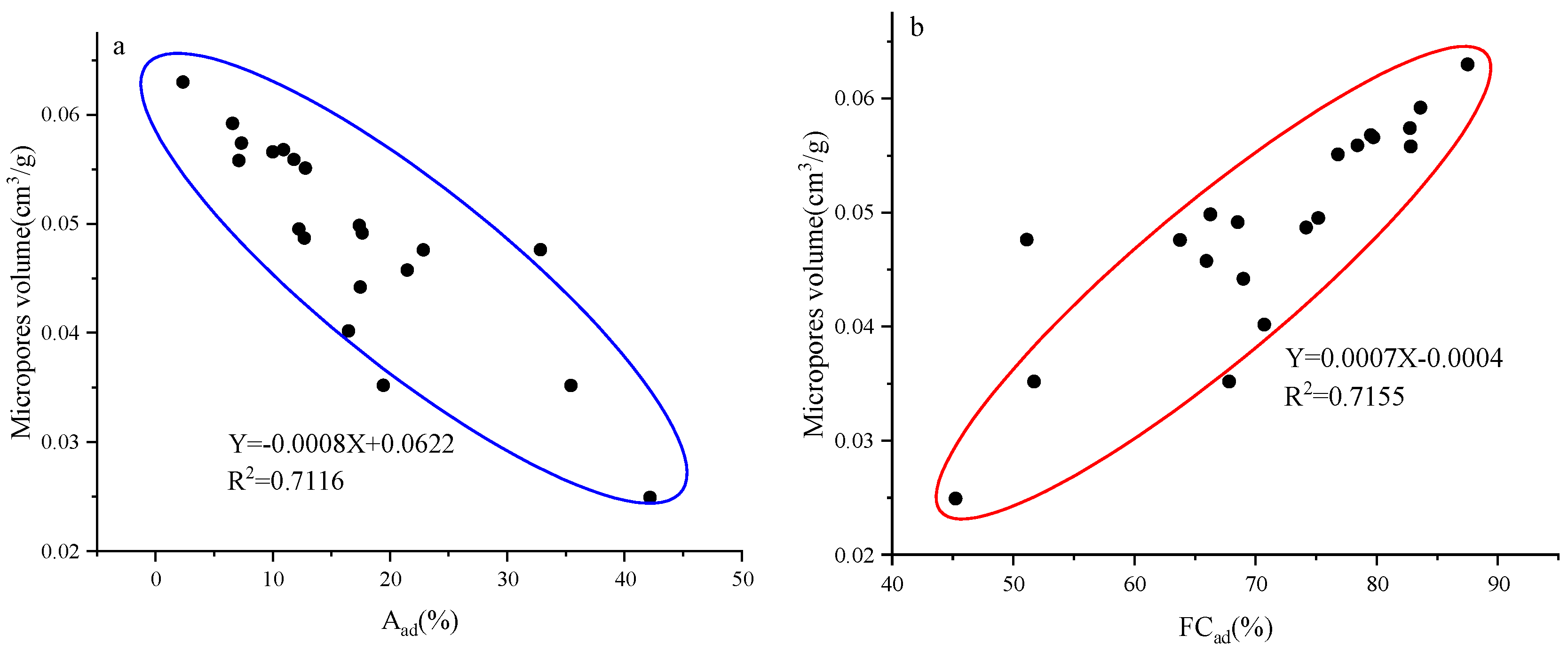

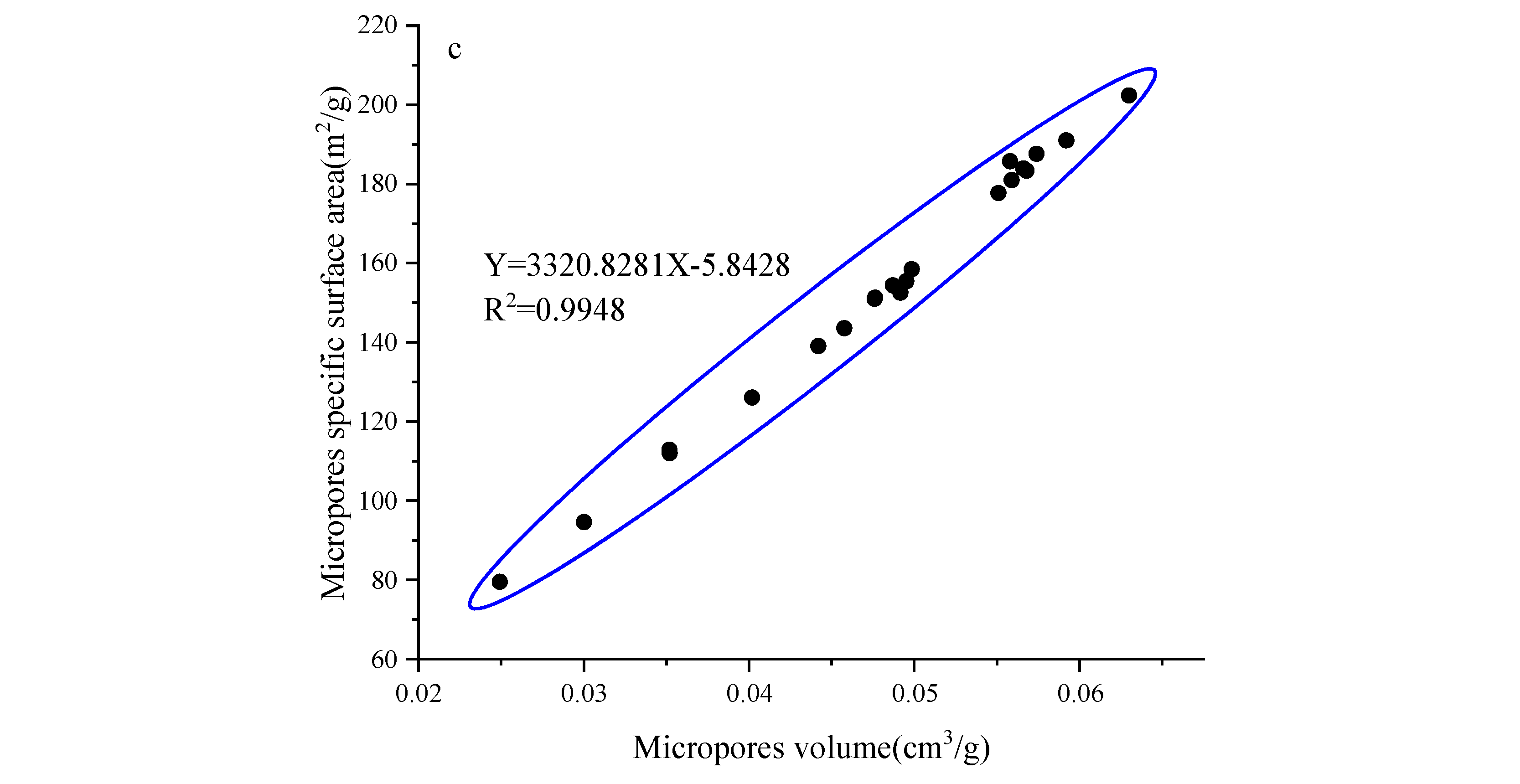

3.2.3. Development Characteristics of Pores and Fracture

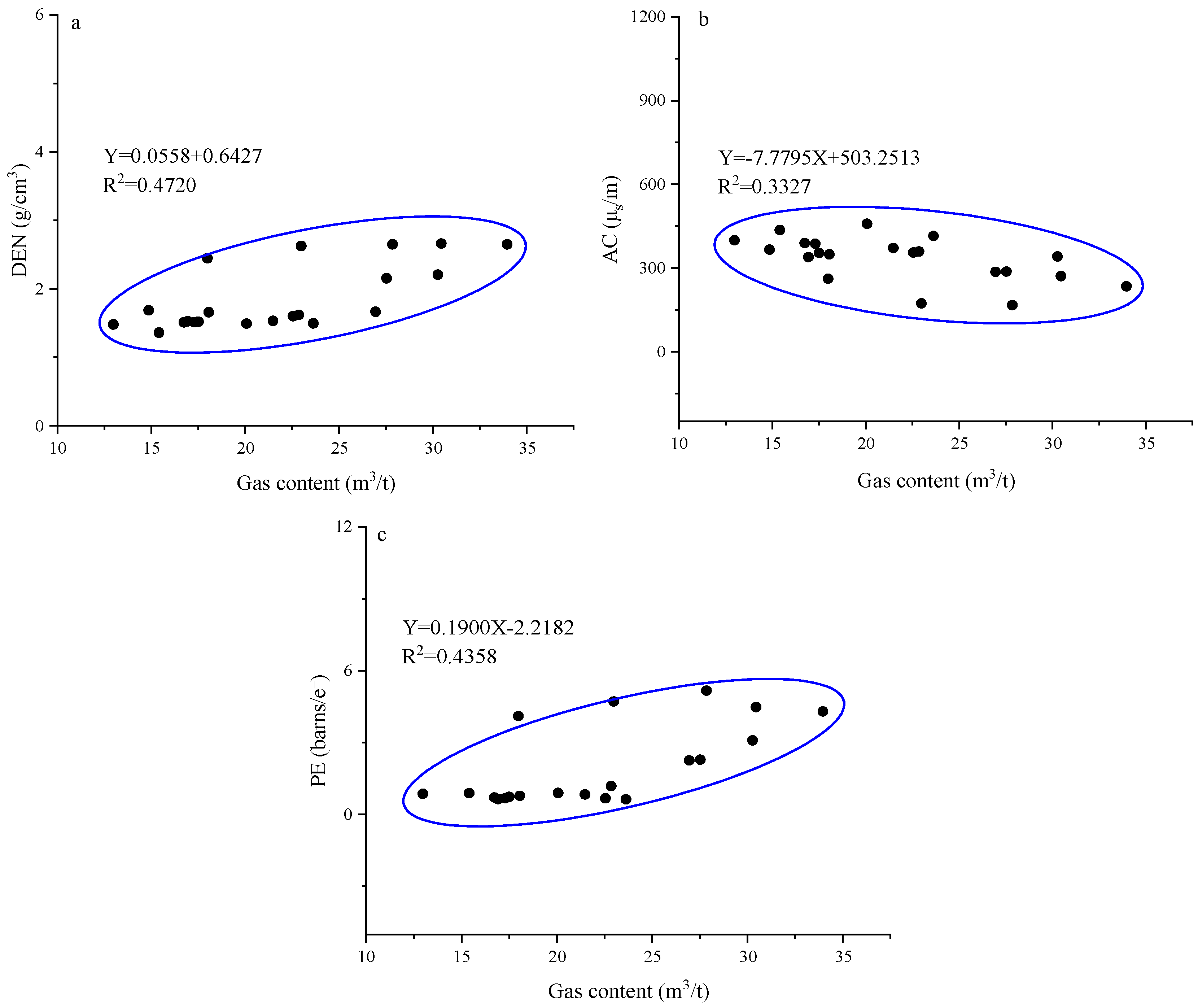

3.2.4. Gas-Bearing Logging Characteristics

3.3. Logging Interpretation Model and Verification of Coal Reservoir Parameters

3.3.1. Microscopic Component Logging Interpretation Model

3.3.2. Industrial Component Logging Interpretation Model

3.3.3. Micropore Pore Parameter Logging Interpretation Model

3.3.4. Gas Content Logging Interpretation Model

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, G.X.; Zhang, S.C.; He, H.Q.; He, X.X.; Zhao, Z.; Niu, X.B.; Xiong, X.Y.; Zhao, Q.; Guo, X.J.; Hou, Y.T.; et al. Coal-rock gas: Concept, connotation and classification criteria. Pet. Explor. Dev. 2024, 51, 897–911. [Google Scholar] [CrossRef]

- Li, G.X.; Jia, G.Z.; Zhao, Q.; Zhou, T.Q.; Gao, J.L. Coal-rock gas accumulation mechanism and the whole petroleum system of coal measures. Pet. Explor. Dev. 2025, 52, 33–49. [Google Scholar] [CrossRef]

- Li, G.; Wang, G.T.; Feng, N.C.; Chen, F.X.; Feng, Y.; Lu, C.G.; Tan, Y.N. Deep Coal-rock Gas in China: A Review of Distribution, Geological Characteristics, and Its Enrichment Conditions. ACS Omega 2025, 22, 23472–23491. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.Y.; Liu, W.H.; Qin, S.F.; Wang, W.C.; Gao, B. Gas-generating characteristics of coal rock and its marceral in thermal simulation. Pet. Geol. Explor. 2002, 24, 147–151. [Google Scholar]

- Ma, L. Unconventional Energy Moving Towards the “New”. China Petrochemical News, 9 December 2024. [Google Scholar]

- Zhao, Z.; Xu, W.L.; Zhao, Z.Y.; Yi, S.W.; Yang, W.; Zhang, Y.Q.; Sun, Y.S.; Zhao, W.B.; Shi, Y.H.; Zhang, C.L.; et al. Geological characteristics and exploration breakthroughs of coal rock gas in Carboniferous Benxi Formation, Ordos Basin, NW China. Pet. Explor. Dev. 2024, 51, 234–247+259. [Google Scholar] [CrossRef]

- Li, Y.; Xu, F.Y.; Tang, S.H.; Wang, Y.B.; Meng, S.Z.; Xu, Q. Progress and development direction of coalbed methane (coal-rock gas) exploration and development in the Ordos Basin. Nat. Gas. Ind. 2024, 44, 63–79. [Google Scholar]

- Li, M.R.; Shi, Y.H.; Fan, L.Y.; Dai, X.D.; Jing, X.Y.; Zhang, Y. Comparison of main reservoir characteristics between deep coal-rock gas of the No.8 coal seam of the Upper Paleozoic Benxi Formation and tight sand gas reservoirs, Ordos Basin. Pet. Nat. Gas. Geol. 2024, 45, 1590–1604. [Google Scholar]

- Huang, D.J.; Zhou, G.X.; Yang, Z.B.; Gu, J.Y.; Jing, X.Y.; Wang, J.A. Geochemical characterization of gas-water output from deep coalrock methane wells in the Ordos Basin and its geological responses. Pet. Nat. Gas. Geol. 2024, 45, 1617–1627. [Google Scholar]

- Al-Yaari, A.; Ching, D.L.C.; Sakidin, H.; Muthuvalu, M.S.; Zafar, M.; Alyousifi, Y.; Saeed, A.A.H.; Haruna, A. Optimum Volume Fraction and Inlet Temperature of an Ideal Nanoparticle for Enhanced Oil Recovery by Nanofluid Flooding in a Porous Medium. Processes 2023, 11, 401. [Google Scholar] [CrossRef]

- Al-Yaari, A.; Ching, D.L.C.; Sakidin, H.; Muthuvalu, M.S.; Zafar, M.; Haruna, A.; Merican, Z.M.A.; Yunus, R.B.; Al-dhawi, B.N.S.; Jagaba, A.H. The effects of nanofluid thermophysical properties on enhanced oil recovery in a heterogenous porous media. Case Stud. Chem. Environ. Eng. 2024, 9, 100556. [Google Scholar] [CrossRef]

- Yao, P.; Zhang, J.J.; Lv, D.W.; Vandeginste, V.; Chang, X.C.; Zhang, X.Y.; Wang, D.D.; Han, S.B.; Liu, Y. Effect of water occurrence in coal reservoirs on the production capacity of coalbed methane by using NMR simulation technology and production capacity simulation. Geoenergy Sci. Eng. 2024, 243, 213353. [Google Scholar] [CrossRef]

- Bondarenko, A.V.; Islamov, S.R.; Ignatyev, K.V.; Mardashov, D.V. Laboratory studies of polymer compositions for well-kill under increased fracturing. Perm J. Pet. Min. Eng. 2020, 20, 37–48. [Google Scholar] [CrossRef] [PubMed]

- Belousov, A.; Lushpeev, V.; Sokolov, A.; Sultanbekov, R.; Tyan, Y.; Ovchinnikov, E.; Shvets, A.; Bushuev, V.; Islamov, S. Experimental Research of the Possibility of Applying the Hartmann–Sprenger Effect to Regulate the Pressure of Natural Gas in Non-Stationary Conditions. Processes 2025, 13, 1189. [Google Scholar] [CrossRef]

- Han, S.B.; Bai, S.T.; Tang, Z.Y.; Rui, Y.R.; Gong, D.J.; Zhang, J.C. Nitrogen-rich gas shale logging evaluation and differential gas-bearing characterization of lower Cambrian formation in northern Guizhou, south China. Mar. Pet. Geol. 2020, 115, 104270. [Google Scholar] [CrossRef]

- Han, S.B.; Xiang, C.H.; Du, X.; Xie, L.F.; Bai, S.T.; Wang, C.S. Logging evaluation of deep multi-type unconventional gas reservoirs in the Songliao basin, northeast China: Implications from continental scientific drilling. Int. J. Coal Geol. 2023, 265, 104153. [Google Scholar] [CrossRef]

- Liu, C.Y.; Zhao, H.G.; Gui, X.J.; Yue, L.P.; Zhao, J.F.; Wang, J.Q. Space-Time Coordinate of the Evolution and Reformation and Mineralization Response in Ordos Basin. Acta Geol. Sin. 2006, 80, 617–638. [Google Scholar]

- Yu, X.H.; Wang, X.Z.; Wang, N.X.; Shan, X.; Zhou, J.S.; Han, X.Q.; Li, Y.L.; Du, Y.H.; Zhao, C.F. Sequence stratigraphic framework and sedimentary evolution characteristics of gas-bearing sandbody in the Upper Paleozoic in southeastern Ordos Basin. J. Palaeogeogr. 2017, 19, 935–954. [Google Scholar]

- Li, Q.M. Analysis on the Correlation of Different Types of oil and Gas Reservoirs in Mesozoic and Paleozoic in Ordos Basin. Master’s Thesis, Northwest University, Xi’an, China, 2021. [Google Scholar]

- Zhang, K. Tectonics and Resources of the Ordos Block; Shaanxi Science and Technology Press: Xi’an, China, 1989. [Google Scholar]

- Fu, J.H.; Luo, S.S.; Niu, X.B.; Lü, Q.Q.; Xu, L.M.; Feng, S.B.; Li, S.X. Sedimentary Characteristics of Channel Type Gravity Flow of the Member 7 of Yanchang Formation in the Longdong Area, Ordos Basin. Bull. Mineral. Petrol. Geochem. 2015, 34, 29–37. [Google Scholar]

- Li, D.S. Re—Understanding of Ordos Basin petroleum geology. Pet. Explor. Dev. 2004, 31, 1–7. [Google Scholar]

- Wang, R. Causes of Low Coalbed Methane Production Wells and Optimization of Reservoir Improvement Technology in A Block in the Eastern Ordos Basin. Master’s Thesis, Henan Polytechnic University, Jiaozuo, China, 2023. [Google Scholar]

- Chen, Q.H. Research on Sedimentary Systems and Hydrocarbons Enrichment of the Upper Palaeozoicof the Ordos Basin. Ph.D. Thesis, Northwest University, Xi’an, China, 2007. [Google Scholar]

- Tian, Y.; Zhong, J.H.; Wang, S.B.; Tao, H.S.; Liu, S.G.; Li, Y.; Sun, N.L.; Shao, Z.F.; Ni, L.T.; Mao, C.; et al. Seismites and their geological significances of the Triassic Yanchang Formation in Fuxian exploration area, Ordos Basin. J. Palaeogeogr. 2015, 17, 541–552. [Google Scholar]

- Li, Q.; Lu, H.; Wu, S.H.; Xia, D.L.; Li, J.S.; Qi, F.Q.; Fu, Y.P.; Wu, Y. Sedimentary origins and reservoir characteristics of the Triassic Chang 73 tuffs in the southern Ordos Basin. Pet. Nat. Gas. Geol. 2022, 43, 1141–1154. [Google Scholar]

- Li, J.; Luo, X.; Shan, X.Q.; Ma, C.H.; Hu, G.Y.; Yan, Q.T.; Liu, R.E.; Chen, H.H. Natural gas accumulation in the Upper Paleozoic of Ordos Basin, China. Pet. Explor. Dev. 2005, 32, 54–59. [Google Scholar]

- Yang, J.J. Tectonic Evolution and Oil-Gas Distribution Regularities in the Ordos Basin; Petroleum Industry Press: Beijing, China, 2002. [Google Scholar]

- Guo, S.L.; Meng, P.L.; Song, L.J.; Wang, S.C.; Shi, L.; Yang, G.P.; Fu, X.Y. Control effect of Taiyuan-based paleogeomorphology on the sand body in Mizhi Gasfield. Complex. Hydrocarb. Reserv. 2024, 17, 78–85. [Google Scholar]

- Wan, Y.P.; Wang, Z.C.; Han, S.B.; Qiao, Y.; Gao, H.T. Geological characteristics and resource potential of deep coalbed methane accumulation in Yan’an Gas Field, southeastern margin of Ordos Basin. Nat. Gas. Geosci. 2024, 35, 1724–1739. [Google Scholar]

- GB/T 18023-2000; Classification of Macrolithotype for Bituminous Coal. National Standard: Beijing, China, 2000.

- GB/T 6948-2008; Method of Determining Microscopically the Reflectance of Vitrinite in Coal. National Standard: Beijing, China, 2009.

- SY/T 5162-2021; Scanning Electron Microscope Analysis Method of Rock Samples. Petroleum Industry Standard: Beijing, China, 2021.

- GB/T 212-2008; Proximate Analysis of Coal. National Standard: Beijing, China, 2008.

- GB/T 21650.3-2011; Pore Size Distribution and Porosity of Solid Materials by Mercury Porosimetry and Gas Adsorption—Part 3: Analysis of Micropores by Gas Adsorption. National Standard: Beijing, China, 2011.

- GB/T 19559-2021; Method of Determining Coalbed Methane Content. National Standard: Beijing, China, 2021.

- Shi, Y.J.; He, Y.F.; Wan, J.B.; Guo, X.K.; Yu, H.G.; Yang, R.J. Research on logging evaluation methods for geological quality and gas content of deep coal measure gas. China Pet. Explor. 2024, 29, 126–141. [Google Scholar]

- Han, S.B.; Tang, Z.Y.; Bai, S.T.; Wan, L.; Rui, Y.R.; Gao, Y.; Huang, Y.J.; Wang, C.S. Application of elemental capture spectroscopy in deep tight reservoir evaluation: A case study of well SK-2. Earth Sci. Front. 2022, 29, 449–458. [Google Scholar]

- Han, S.B.; Du, X.; Bai, S.T.; Wang, C.S. Logging evaluation of deep lacustrine shale reservoir in Songliao Basin: A case study of international continental scientific drilling. J. Cent. South Univ. (Sci. Technol.) 2022, 53, 3271–3286. [Google Scholar]

- Wang, L.H.; Xiang, M. Study on Log Prediction Model of Coalbed Methane Content. Technol. Wind. 2018, 26, 144–145. [Google Scholar]

- Zhang, P.; Wang, K.; Yu, T.; Zhao, M.Z. Prediction of Coalbed Methane Content Based on Multiple Linear Regression Analysis. Coal Technol. 2016, 35, 112–115. [Google Scholar]

- Hu, Y.F.; Zhang, S.A.; Wu, Z.Y. Modeling Method of Coalbed Methane Content Based on Geological Multivariate Statistical Analysis: A Case Study of No. 3 Coal Seam in a Block in the Southern Qinshui Basin. Coal Geol. Explor. 2013, 41, 33–36. [Google Scholar]

- Han, S.B.; Xie, L.F.; Du, X.; Xiang, C.H.; Huang, J.; Tang, Z.Y.; Wang, C.S.; Brain, H.; Mahlstedt, N. Insights into organic metagenesis using Raman spectroscopy and high resolution mass spectrometry: A case study of the Shahezi formation, deep Songliao basin, China. Int. J. Coal Geol. 2023, 265, 104153. [Google Scholar] [CrossRef]

- Deng, Z.; Wang, H.Y.; Jiang, Z.X.; Ding, R.; Li, Y.Z.; Wang, T. Influence of deep coal pore and fracture structure on occurrence of coalbed methane: A case study of Daning-Jixian Block in eastern margin of Ordos Basin. Coal Sci. Technol. 2024, 52, 106–123. [Google Scholar]

| Samples | Depth (m) | Ro,max (%) | Coal Maceral Components | Proximate Components | Gas Content (m3/t) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Vitrinite (%) | Exinite (%) | Inertinite (%) | Mad (%) | Aad (%) | Vad (%) | FCad (%) | ||||

| S1 | 2425.45 | 1.96 | 59.26 | 2.36 | 38.38 | 0.48 | 32.83 | 15.57 | 51.12 | 14.85 |

| S2 | 2426.22 | 1.9 | 47.22 | 32.29 | 20.49 | 0.65 | 22.84 | 12.75 | 63.76 | 15.4 |

| S3 | 2427.27 | 1.88 | 50.52 | 17.53 | 31.96 | 0.98 | 12.69 | 12.16 | 74.17 | 23.63 |

| S4 | 2427.89 | 1.9 | 65.54 | 2.7 | 31.76 | 0.65 | 17.38 | 15.7 | 66.27 | 18.05 |

| S5 | 2428.65 | 1.89 | 52.86 | 2.02 | 45.12 | 0.65 | 12.23 | 11.95 | 75.17 | 21.48 |

| S6 | 2429.29 | 1.94 | 58.11 | 1.69 | 40.2 | 0.79 | 21.46 | 11.81 | 65.94 | 20.07 |

| S7 | 2429.9 | 1.89 | 33.45 | 16.72 | 49.83 | 1.09 | 11.04 | 11.54 | 76.33 | 22.85 |

| S8 | 2430.55 | 1.89 | 53.06 | 4.42 | 42.52 | 0.66 | 42.17 | 11.93 | 45.24 | 12.97 |

| S9 | 2431.01 | 1.88 | 59.71 | 4.03 | 36.26 | 0.98 | 35.42 | 11.88 | 51.72 | 17.3 |

| S10 | 2431.69 | 1.88 | 43.59 | 25.64 | 30.77 | 0.93 | 16.46 | 11.89 | 70.72 | 22.55 |

| S11 | 2432.6 | 1.89 | 59.72 | 5.56 | 34.72 | 0.79 | 19.43 | 11.96 | 67.82 | 17.5 |

| S12 | 2433.25 | 1.87 | 47.31 | 18.64 | 34.05 | 0.7 | 17.47 | 12.84 | 68.99 | 16.73 |

| S13 | 2434.08 | 1.87 | 41.45 | 17.09 | 41.45 | 0.72 | 17.63 | 13.13 | 68.52 | 16.93 |

| S14 | 2625.15 | 2.13 | 100 | 0 | 0 | 0.36 | 2.34 | 9.79 | 87.51 | 22.98 |

| S15 | 2627.31 | 2.14 | 53.05 | 0 | 46.94 | 0.5 | 6.58 | 9.31 | 83.61 | 27.85 |

| S16 | 2628.53 | 2.28 | 79.17 | 0 | 20.82 | 0.41 | 7.11 | 9.67 | 82.81 | 17.98 |

| S17 | 2628.8 | 1.97 | 54.14 | 0 | 45.93 | 0.41 | 7.33 | 9.52 | 82.74 | 26.95 |

| S18 | 2629.64 | 2.05 | 90.93 | 0 | 9.13 | 0.5 | 10 | 9.77 | 79.73 | 27.53 |

| S19 | 2630.35 | 2.14 | 82.98 | 0 | 16.95 | 0.39 | 10.92 | 9.18 | 79.51 | 33.96 |

| S20 | 2630.61 | 2.35 | 48.62 | 0 | 51.28 | 0.51 | 11.81 | 9.27 | 78.41 | 30.45 |

| S21 | 2630.94 | 2.24 | 21.35 | 0 | 78.67 | 0.5 | 12.78 | 9.93 | 76.79 | 30.27 |

| Sample | Micropore | |

|---|---|---|

| Pore Volume (cm3/g) | Specific Surface Area (m2/g) | |

| S1 | 0.047626 | 151.2911 |

| S2 | 0.047607 | 151.0338 |

| S3 | 0.048696 | 154.4125 |

| S4 | 0.049852 | 158.5131 |

| S5 | 0.049521 | 155.4454 |

| S6 | 0.045764 | 143.59 |

| S7 | 0.030009 | 94.586 |

| S8 | 0.024915 | 79.514 |

| S9 | 0.035183 | 112.8362 |

| S10 | 0.04018 | 126.0523 |

| S11 | 0.035195 | 112.02 |

| S12 | 0.044203 | 139.08 |

| S13 | 0.049163 | 152.5472 |

| S14 | 0.063 | 202.3744 |

| S15 | 0.0592 | 191.0065 |

| S16 | 0.0558 | 185.7854 |

| S17 | 0.0574 | 187.6201 |

| S18 | 0.0566 | 183.9549 |

| S19 | 0.0568 | 183.3466 |

| S20 | 0.0559 | 180.9863 |

| S21 | 0.0551 | 177.7513 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Zeng, J.; Liu, D.; Shi, Y.; Gao, H.; Tian, L.; He, Y.; Zhang, F.; Su, J. Characteristics of Deep Coal Reservoirs Based on Logging Parameter Responses and Laboratory Data: A Case Study of the Logging Response Analysis of Reservoir Parameters Is Carried Out in Ordos Basin, China. Processes 2025, 13, 2062. https://doi.org/10.3390/pr13072062

Yang X, Zeng J, Liu D, Shi Y, Gao H, Tian L, He Y, Zhang F, Su J. Characteristics of Deep Coal Reservoirs Based on Logging Parameter Responses and Laboratory Data: A Case Study of the Logging Response Analysis of Reservoir Parameters Is Carried Out in Ordos Basin, China. Processes. 2025; 13(7):2062. https://doi.org/10.3390/pr13072062

Chicago/Turabian StyleYang, Xiaoming, Jingbo Zeng, Die Liu, Yunhe Shi, Hongtao Gao, Lili Tian, Yufei He, Fengsheng Zhang, and Jitong Su. 2025. "Characteristics of Deep Coal Reservoirs Based on Logging Parameter Responses and Laboratory Data: A Case Study of the Logging Response Analysis of Reservoir Parameters Is Carried Out in Ordos Basin, China" Processes 13, no. 7: 2062. https://doi.org/10.3390/pr13072062

APA StyleYang, X., Zeng, J., Liu, D., Shi, Y., Gao, H., Tian, L., He, Y., Zhang, F., & Su, J. (2025). Characteristics of Deep Coal Reservoirs Based on Logging Parameter Responses and Laboratory Data: A Case Study of the Logging Response Analysis of Reservoir Parameters Is Carried Out in Ordos Basin, China. Processes, 13(7), 2062. https://doi.org/10.3390/pr13072062