Assessment of Carbon Footprint for Organization in Frozen Processed Seafood Factory and Strategies for Greenhouse Gas Emission Reduction

Abstract

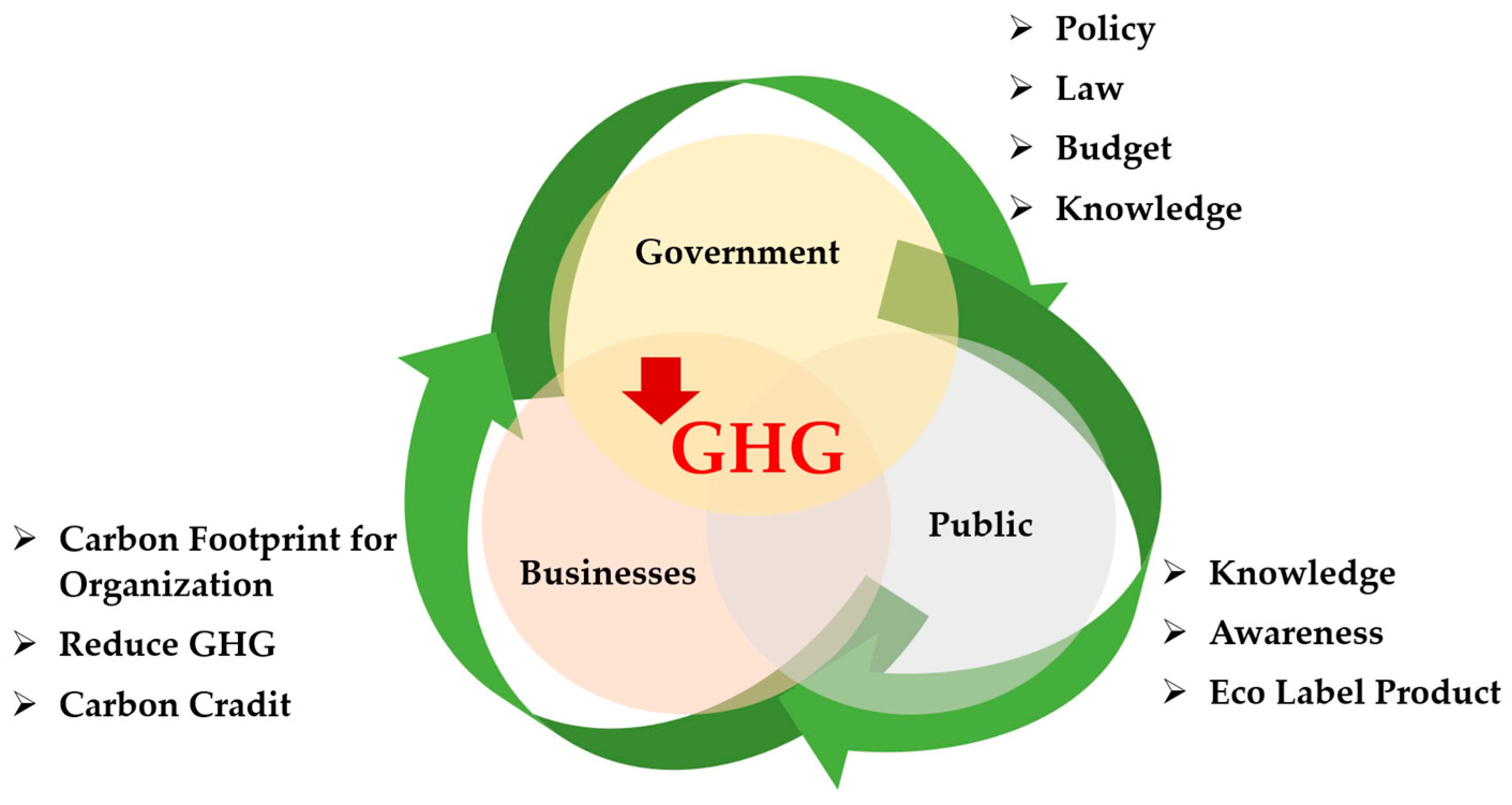

1. Introduction

- Scope 1: Direct Emissions: GHG emissions from sources directly owned or controlled by the organization, including stationary and mobile fuel combustion, industrial processes, chemical use in wastewater treatment, and refrigerant leaks.

- Scope 2: Indirect Energy-Related Emissions: GHG emissions from purchased electricity, steam, heating, cooling, and compressed air used within the organization.

- Scope 3: Other Indirect Emissions: GHG emissions from activities outside the organization’s direct control, including upstream and downstream activities such as raw material procurement, supply chain transportation, employee commuting, business travel, and waste disposal. Scope 3 emissions are further divided into 15 subcategories according to ISO 14064-1:2018: (2018) [6]. The organization can determine the method for assessing Scope 3 greenhouse gas emissions, as some categories of data may be difficult to collect or cannot be collected. However, the organization must specify the method for selecting Scope 3.

1.1. Literature Review

1.2. Research Objective

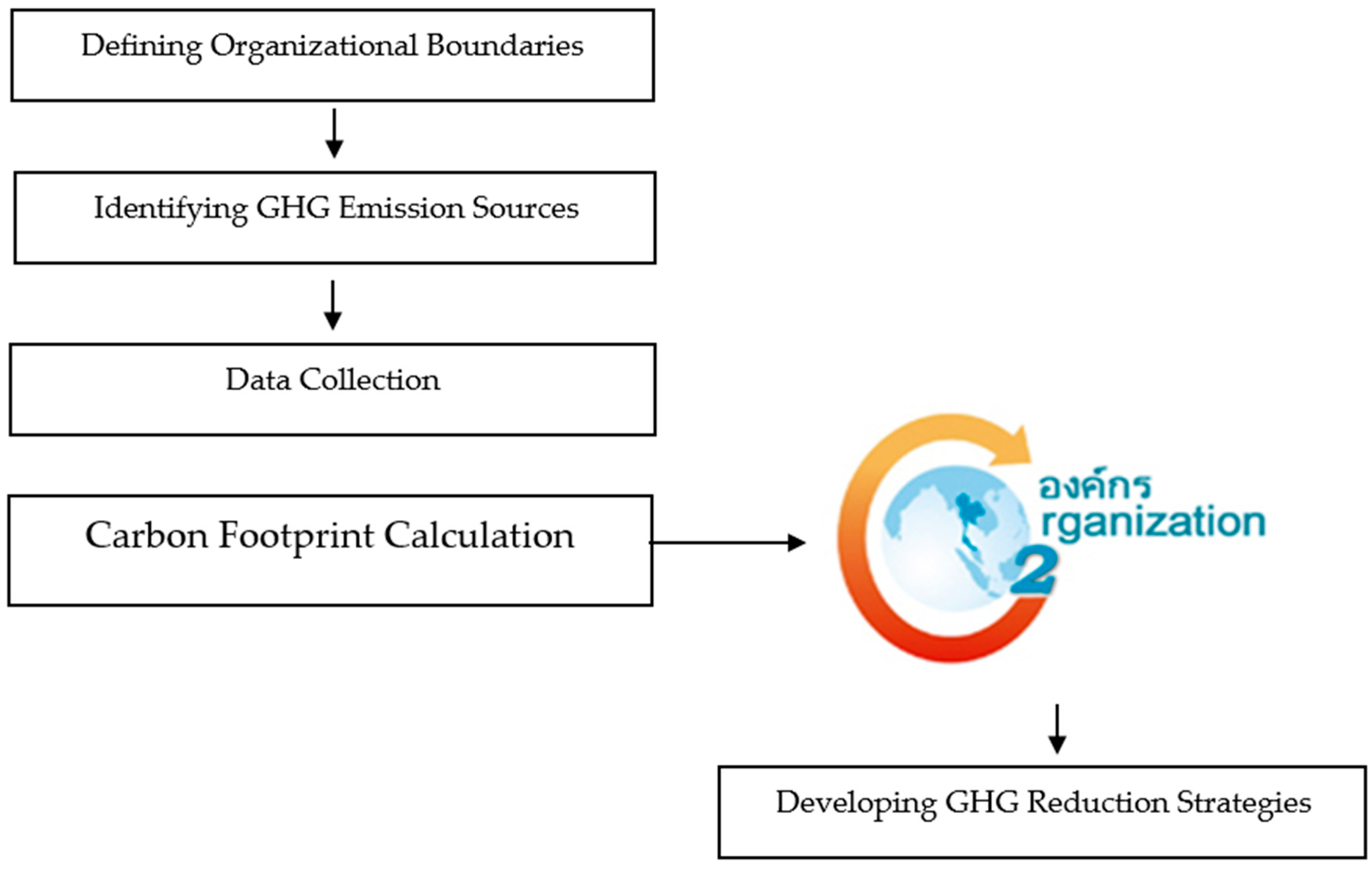

1.3. Research Methodology

- Defining Organizational Boundaries. This study adopts a control approach, focusing on operational control, as outlined in the factory operation license No.009000000125295. This includes subsidiaries and nearby facilities that fall under the organization’s operational control.

- Identifying GHG Emission Sources. A site survey was conducted to analyze all organizational activities and categorize emissions into three scopes. Scope 1 (Direct Emissions): Emissions directly generated by the organization, including fuel combustion, industrial processes, and refrigerant leaks. Scope 2 (Indirect Emissions from Energy Use): Emissions from purchased electricity, steam, heating, cooling, and compressed air. Scope 3 (Other Indirect Emissions): Emissions from upstream and downstream activities, including supply chain operations, transportation, and employee commuting.

- Data Collection. Resource usage data was collected from 1 January to 31 December 2024, with primary data recorded monthly. Supporting documents, such as inventory requests, receipts, and fuel consumption reports, were used for verification.

- Carbon Footprint Calculation. The Carbon Footprint for Organization was calculated using activity data (AD) and the emission factor (EF), based on the formula from the Thailand Greenhouse Gas Management Organization (Public Organization), 2022) [11]where:GHGi = ADi × EFiGHGi = Greenhouse gas emissions from activity i, measured in tons of CO2eq.ADi = Activity data related to GHG emissions, measured in appropriate units.EFi = Emission factor for activity i, aligned with the corresponding activity data.

- Developing GHG Reduction Strategies. The carbon footprint data was analyzed to identify significant emission sources, focusing on activities contributing at least 10% of total emissions. The percentage of emissions for each activity was calculated using the equation:where:Percent = Percentage of total GHG emissions from a specific activity.GHG_adi = GHG emissions from the activity of interest (tons of CO2eq).GHG_adt = Total GHG emissions from all activities (tons of CO2eq).

1.4. Research Findings

2. Conclusions and Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Climate Change Institute; The Federation of Thai Industries. Basic Knowledge of Evaluating an Organization’s Carbon Footprint; Climate Change Institute: Bangkok, Thailand; The Federation of Thai Industries: Bangkok, Thailand, 2023. [Google Scholar]

- Thailand Greenhouse Gas Management Organization (Public Organization). Measures to Reduce Greenhouse Gas Emissions in the Industrial Sector; Thailand Greenhouse Gas Management Organization: Bangkok, Thailand, 2019.

- Office of Natural Resource and Environment Policy and Planning. Thailand’s Fourth Biennial Update Report; Office of Natural Resource and Environment Policy and Planning: Bangkok, Thailand, 2022. [Google Scholar]

- Pisit Wongsahasri. Freezing Technology; Fisheries Industrial Technology Research and Development Division, Department of Fisheries: Bangkok, Thailand, 2020. [Google Scholar]

- Management System Certification Institute (Thailand). Carbon Footprint for Organization–TGO (CFO). 2024. Available online: https://www.masci.or.th/service/carbon-footprint-for-organization-cfo/ (accessed on 22 June 2024).

- ISO 14064-1:2018; Greenhouse Gases-Part1: Specification with Guidance at the Organization Level for Quantification and Reporting of Greenhouse Gas Emissions and Removals. CH-1223 Vernier: Geneva, Switzerland, 2018.

- Patcharee Srirod. Carbon Footprint for Organization and Sustainability Reduction of Greenhouse Gas Emissions for Regional Environment Office. Master’s Thesis, National Institute of Development Administration, Bangkok, Thailand, 2019. Available online: https://repository.nida.ac.th/handle/662723737/5000 (accessed on 22 June 2024).

- Sommana, C.; Sampattagul, S. Assessing and Managing Greenhouse Gases using Carbon Footprint for Organization of Electronic Manufacturing Company. 2021; pp. 1–9.

- Tian, G.; Yang, Y.; Xu, X.; Chen, Y.; Yang, B.; Wu, X.; Wang, X. The Net Zero Emissions Decision Model of the Sustainable Path of Chinese Business Parks. Buildings 2023, 13, 2638. [Google Scholar] [CrossRef]

- Safaa, L.; Atalay, A.; Makutėnienė, D.; Perkumienė, D.; Bouazzaoui, I.E. Assessment of Carbon Footprint Negative Effects for Nature in International Traveling. Sustainability 2023, 15, 12510. [Google Scholar] [CrossRef]

- Thailand Greenhouse Gas Management Organization (Public Organization). Requirements for Calculating and Reporting an Organization’s Carbon Footprint; Thailand Greenhouse Gas Management Organization: Bangkok, Thailand, 2022.

| Item | Greenhouse Gas Emissions (Tons of CO2eq) | Proportion (%) | Proportion (%) 1 + 2 | Proportion (%) 1 + 2 + 3 |

|---|---|---|---|---|

| Scope 1: Stationary combustion | ||||

| Wood chips/firewood/biomass (boiler) | 569.52 | 4.49 | 2.03 | 0.95 |

| LPG (production process, R&D, bioreactor, and cooking boiler) | 931.11 | 7.34 | 3.32 | 1.56 |

| Diesel (generator) | 12.42 | 0.10 | 0.04 | 0.02 |

| Gasoline (lawnmower, chainsaw) | 2.07 | 0.02 | 0.01 | 0.00 |

| Biogas (generator) | 0.19 | 0.00 | 0.00 | 0.00 |

| Scope 1: Mobile combustion | ||||

| Diesel (truck) | 840.72 | 6.63 | 2.99 | 1.41 |

| Diesel (backhoe loader) | 3.58 | 0.03 | 0.01 | 0.01 |

| Diesel (electric forklift) | 44.93 | 0.35 | 0.16 | 0.08 |

| Gasoline (car) | 21.21 | 0.17 | 0.08 | 0.04 |

| Gasoline (motorcycle) | 0.86 | 0.1 | 0.00 | 0.00 |

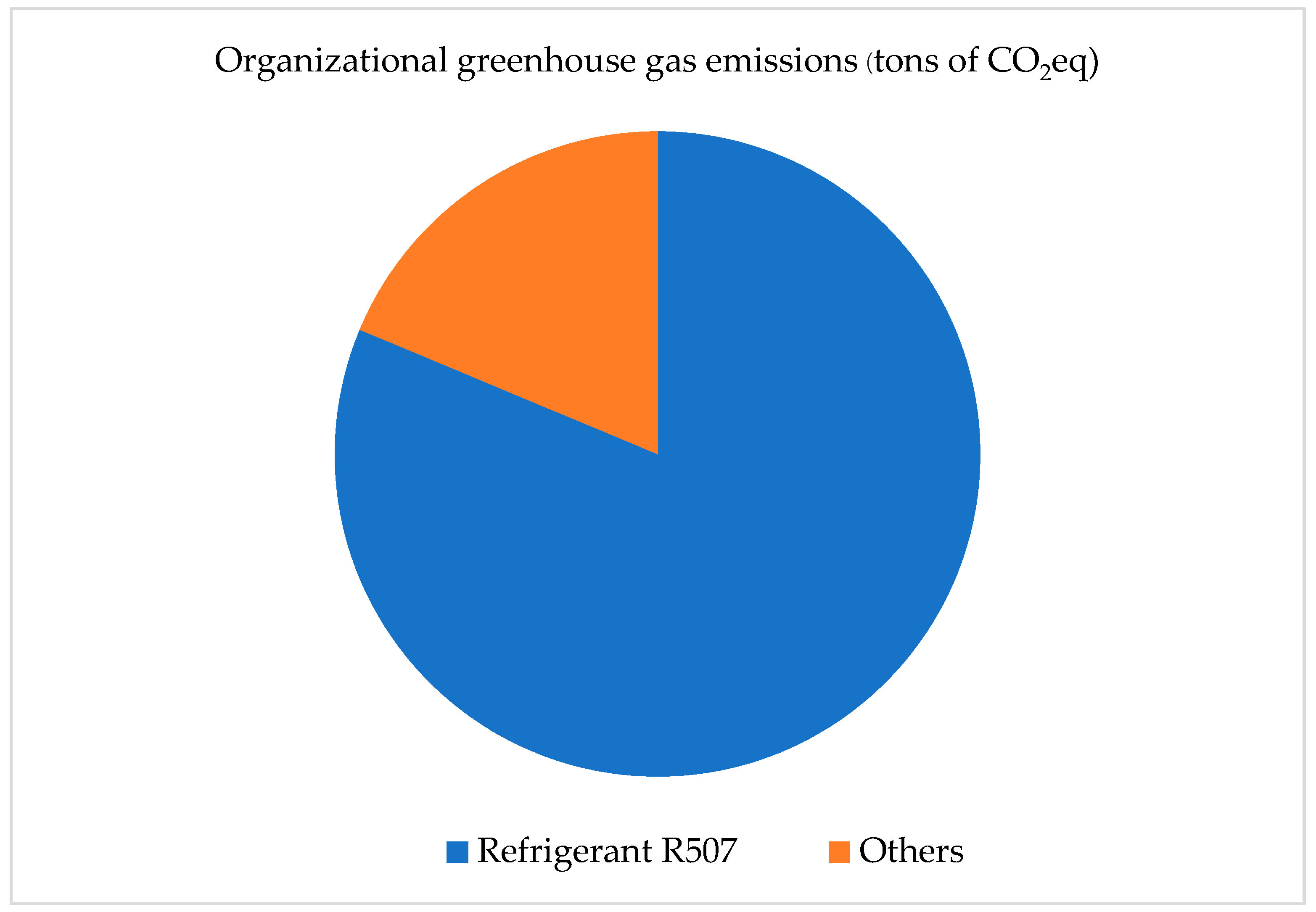

| Scope 1: Fugitive emissions | ||||

| R410a (large and small air conditioning units) | 130.41 | 1.03 | 0.46 | 0.22 |

| R134a (large air conditioning units) | 11.05 | 0.09 | 0.04 | 0.02 |

| R134a (large air conditioning units—container) | 35.10 | 0.28 | 0.12 | 0.06 |

| R507 (refrigeration system for production process) | 9906.71 | 78.10 | 35.27 | 16.61 |

| CH4 (methane leakage from biogas system) | 0.29 | 0.00 | 0.00 | 0.00 |

| CH4 (methane leakage from digesters) | 174.28 | 1.37 | 0.62 | 0.29 |

| Total Scope 1 | 12,684.43 | 100.00 | 45.16 | 21.26 |

| Direct GHG emissions (separate reporting) | ||||

| Wood chips/firewood/biomass (boiler) | 33,571.46 | 98.66 | ||

| Biogas (generator) | 191.04 | 0.56 | ||

| R22 (refrigeration system for production process) | 264.00 | 0.78 | ||

| Total separate reports | 34,026.50 | 100.00 | ||

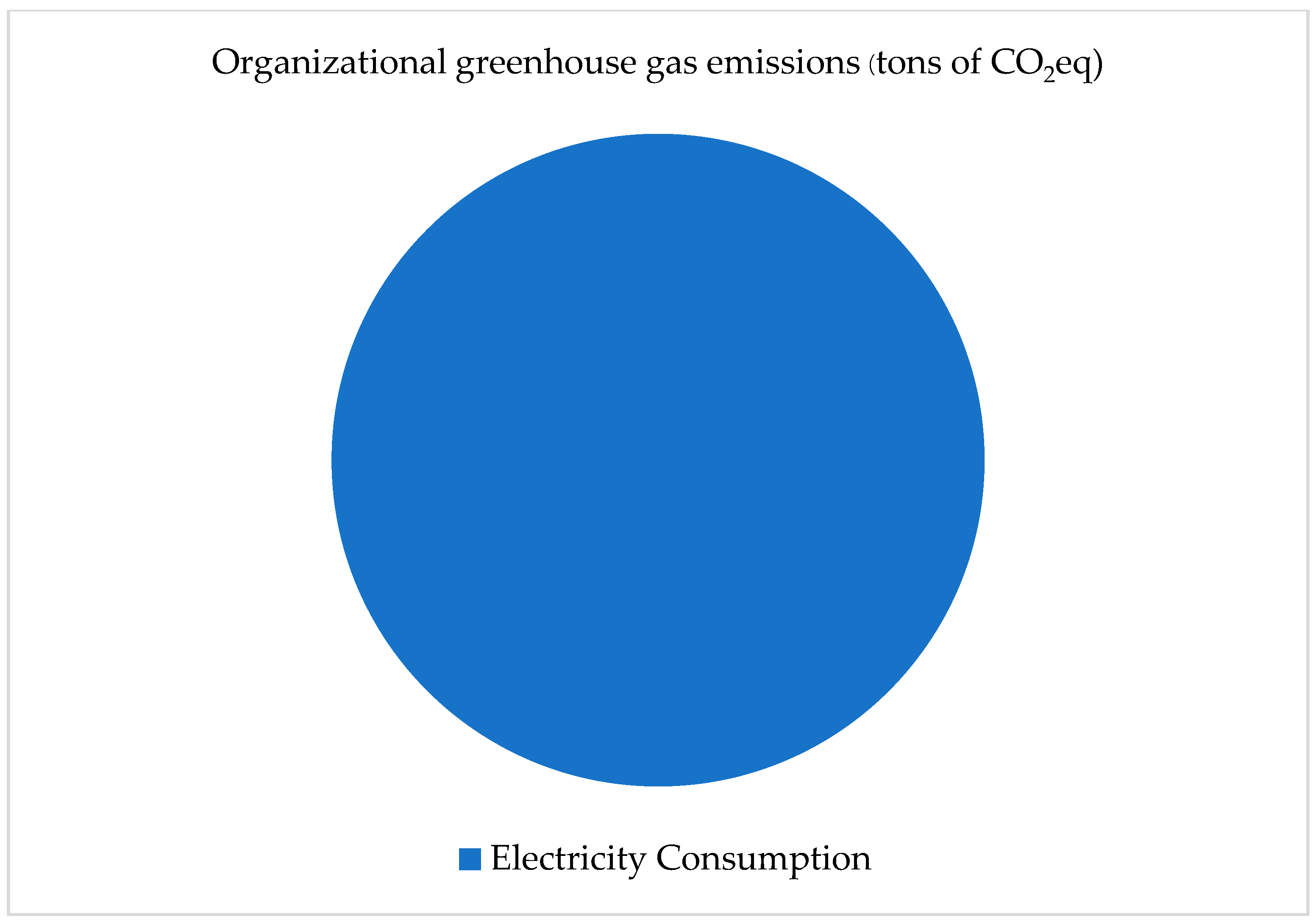

| Scope 2: Energy consumption | ||||

| Energy consumption | 15,402.46 | 100.00 | 54.84 | 25.82 |

| Total Scope 2 | 15,402.46 | 100.00 | 54.84 | 25.82 |

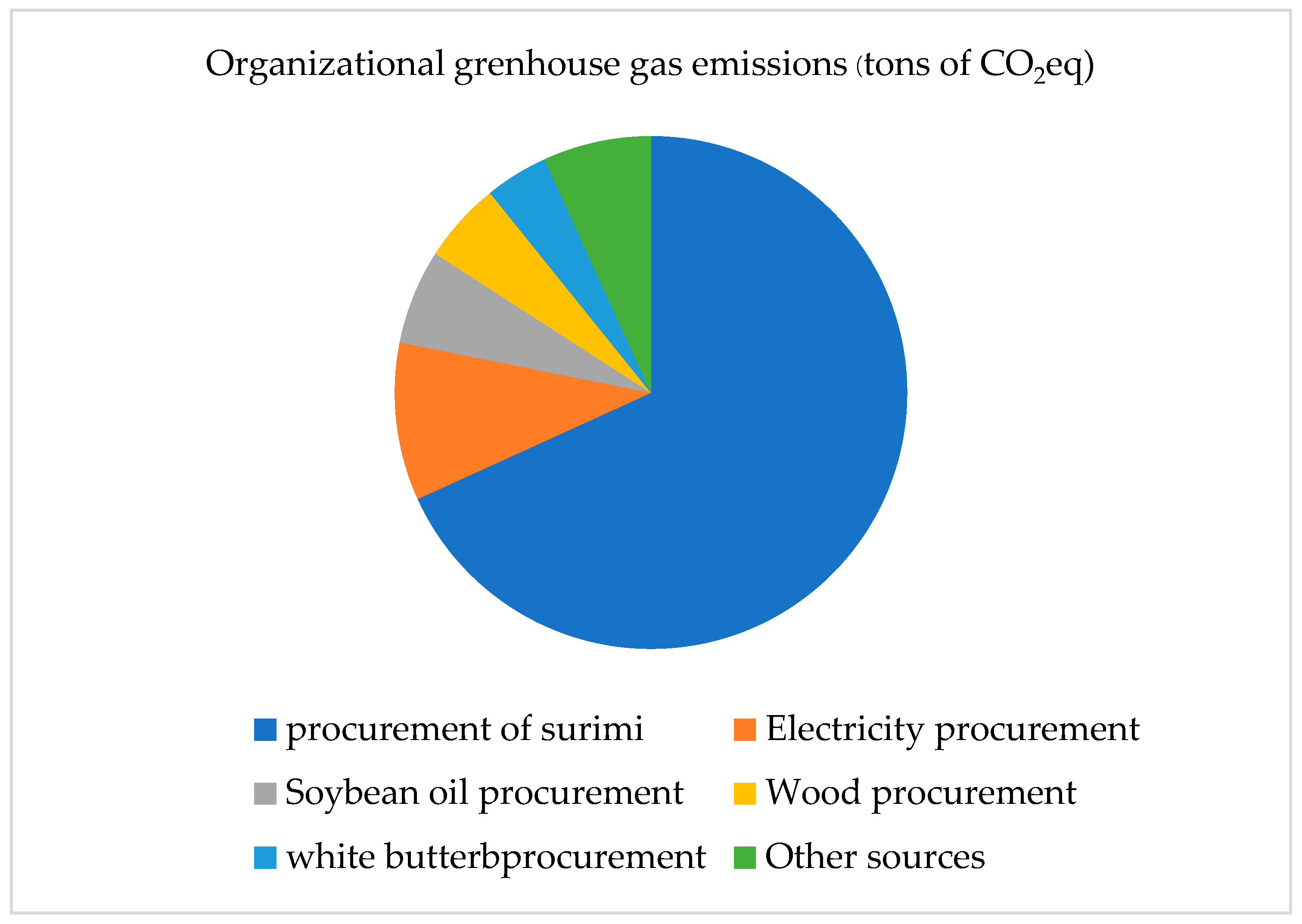

| Scope 3: The procurement of raw materials and services | ||||

| Surimi (processed fish meat) | 20,843.96 | 66.04 | 34.94 | |

| Soybean oil | 1823.95 | 5.78 | 3.06 | |

| Modified starch | 967.92 | 3.07 | 1.62 | |

| Shortening | 1216.10 | 3.85 | 2.04 | |

| Salt | 2.35 | 0.01 | 0.00 | |

| Modified starch K1 | 762.23 | 2.41 | 1.28 | |

| Frozen white egg | 375.56 | 1.19 | 0.63 | |

| Sugar | 116.82 | 0.37 | 0.20 | |

| Corn starch | 139.32 | 0.44 | 0.23 | |

| Wheat starch (new) | 90.28 | 0.29 | 0.15 | |

| Scope 3: The procurement of fuel and energy | ||||

| The procurement of wood | 1554.03 | 4.92 | 2.61 | |

| The procurement of LPG | 256.66 | 0.81 | 0.43 | |

| The procurement of diesel | 115.39 | 0.37 | 0.19 | |

| The procurement of electricity and electricity consumption | 4.36 | 0.01 | 0.01 | |

| Scope 3: Waste generated from production process | ||||

| Waste (landfilling and incineration) | 252.58 | 0.80 | 0.42 | |

| Total Scope 3 | 31,563.55 | 100.00 | 52.91 | |

| Scope | Activity | GHG Reduction Strategies |

|---|---|---|

| 1 | Use of E507 in the refrigeration system of the production process |

|

| 2 | Electricity consumption |

|

| 3 | Procurement of raw materials |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iamchamnan, P.; Saithanoo, S.; Putsukee, T.; Intasuwan, S. Assessment of Carbon Footprint for Organization in Frozen Processed Seafood Factory and Strategies for Greenhouse Gas Emission Reduction. Processes 2025, 13, 1990. https://doi.org/10.3390/pr13071990

Iamchamnan P, Saithanoo S, Putsukee T, Intasuwan S. Assessment of Carbon Footprint for Organization in Frozen Processed Seafood Factory and Strategies for Greenhouse Gas Emission Reduction. Processes. 2025; 13(7):1990. https://doi.org/10.3390/pr13071990

Chicago/Turabian StyleIamchamnan, Phuanglek, Somkiat Saithanoo, Thaweesak Putsukee, and Sompop Intasuwan. 2025. "Assessment of Carbon Footprint for Organization in Frozen Processed Seafood Factory and Strategies for Greenhouse Gas Emission Reduction" Processes 13, no. 7: 1990. https://doi.org/10.3390/pr13071990

APA StyleIamchamnan, P., Saithanoo, S., Putsukee, T., & Intasuwan, S. (2025). Assessment of Carbon Footprint for Organization in Frozen Processed Seafood Factory and Strategies for Greenhouse Gas Emission Reduction. Processes, 13(7), 1990. https://doi.org/10.3390/pr13071990