1.1. Background

As an essential component of clean energy, natural gas is increasingly prominent in the energy consumption structure, and it is mainly transported by pipeline. However, pipeline transport faces complex safety challenges, especially the potential threats to safe operation related to third-party construction activities. These threats include construction activities such as the use of excavators and ground engineering. If not properly managed, they could cause accidental damage to pipelines, leading to natural gas leaks and posing a risk to public safety. Therefore, developing efficient and accurate natural gas pipeline monitoring technologies is crucial for ensuring the reliability of national energy supply and the stability of economic development [

1].

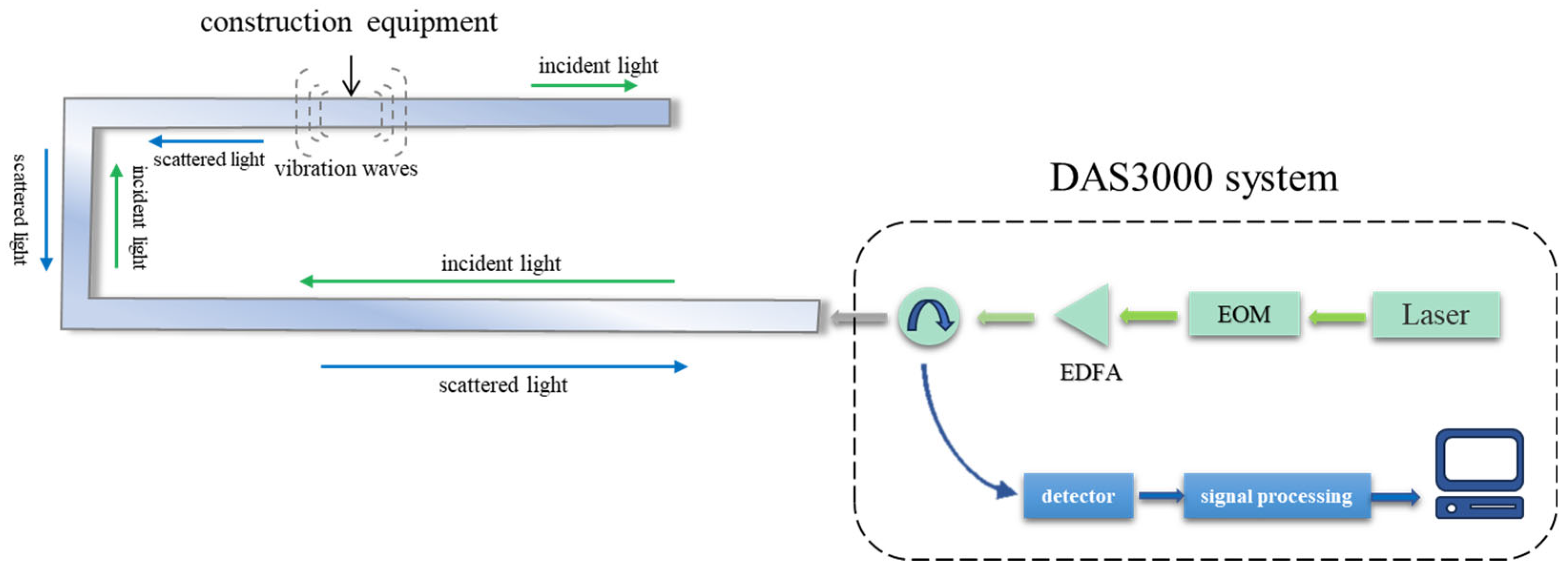

With the continuous advancement of sensing technology, distributed fiber optic monitoring technology has gradually become one of the important means of pipeline monitoring. This technology uses fiber optic sensors laid along the pipeline to leverage the high sensitivity of optical fibers to environmental changes, capturing physical phenomena such as vibrations and temperature changes around the pipeline in real-time, thereby identifying potential threats. However, despite the powerful detection capabilities of fiber optic monitoring systems, extracting useful information from large amounts of noisy raw signals remains a technical challenge that urgently needs to be addressed in practical applications [

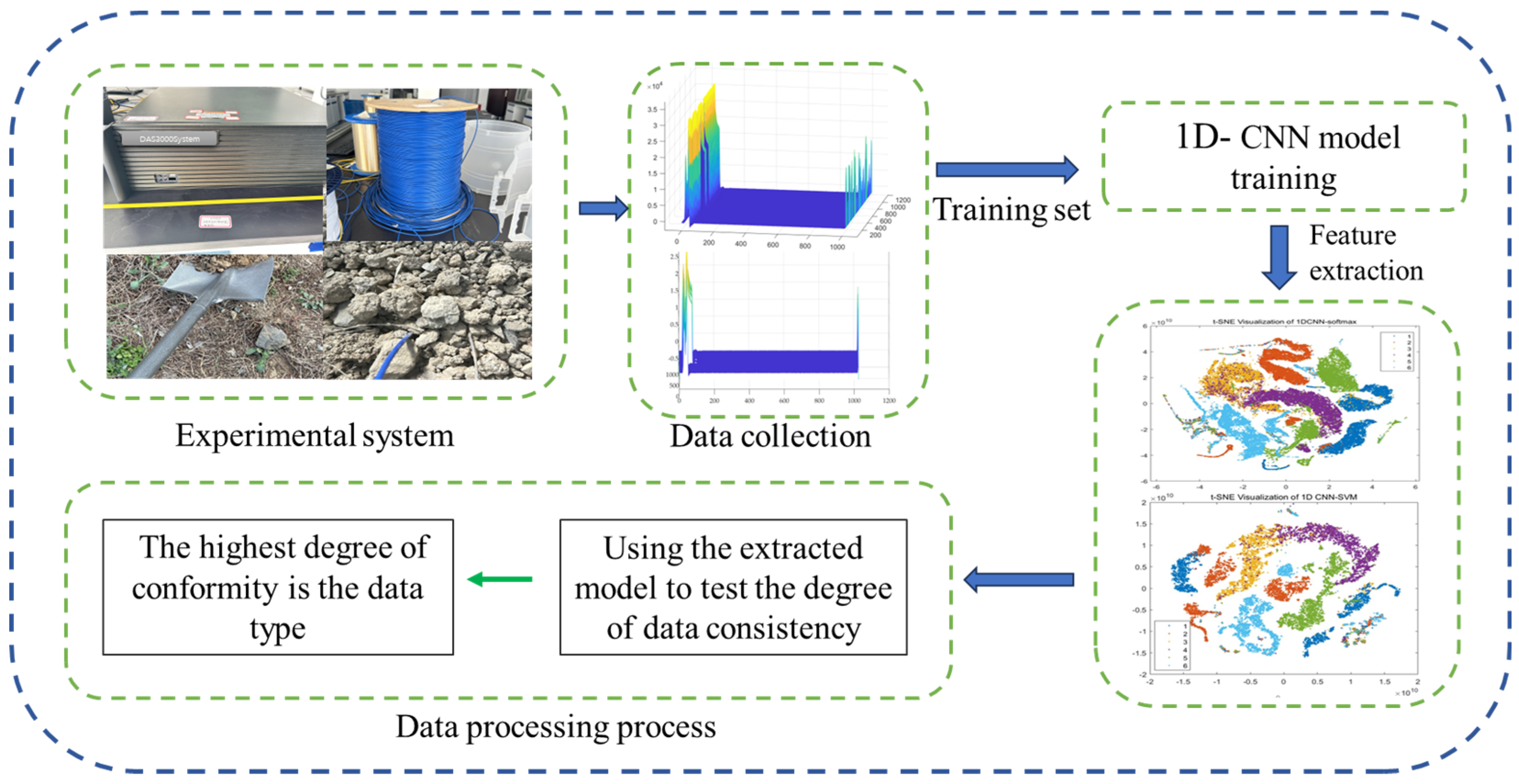

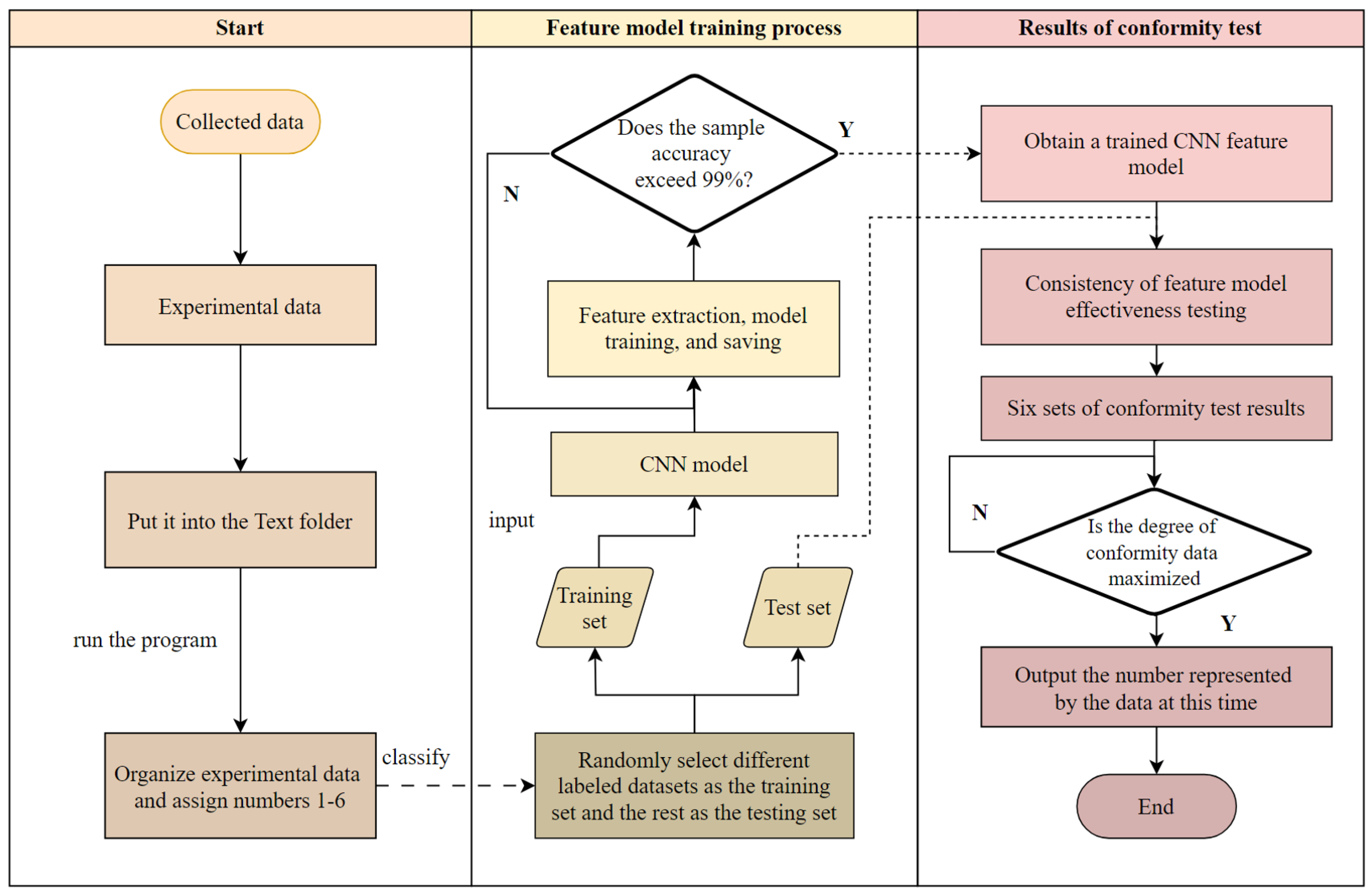

2]. This paper’s research centers on the safety monitoring of natural gas pipelines in densely populated regions under the impact of third-party construction. Based on the 1D-CNN-SVM algorithm, it extracts useful features from the redundant original signals and classifies the distributed optical fiber monitoring signals in accordance with the features to tackle the challenges in this context. In this context, the integration of advanced machine learning models such as 1D-CNN and SVM with distributed fiber optic sensing systems offers a promising solution. These algorithms enable efficient feature extraction and precise classification of vibration signals associated with different types of pipeline threats. By automating the recognition of abnormal patterns from complex sensor data, the system can provide early warnings for construction activities or accidental impacts, significantly improving the safety and operational management of natural gas pipelines in high-risk urban areas.

1.2. Related Works

Conventional monitoring signal recognition methods require preprocessing of raw signals to extract fault features, such as wavelet transform (WT), ensemble empirical mode decomposition (EEMD) [

3], and variational mode decomposition (VMD) [

4]. Subsequently, classification algorithms are used to detect fault types, with representative classifiers including back propagation neural networks (BPNN), convolutional neural networks (CNNs), and support vector machines (SVMs) [

5,

6].

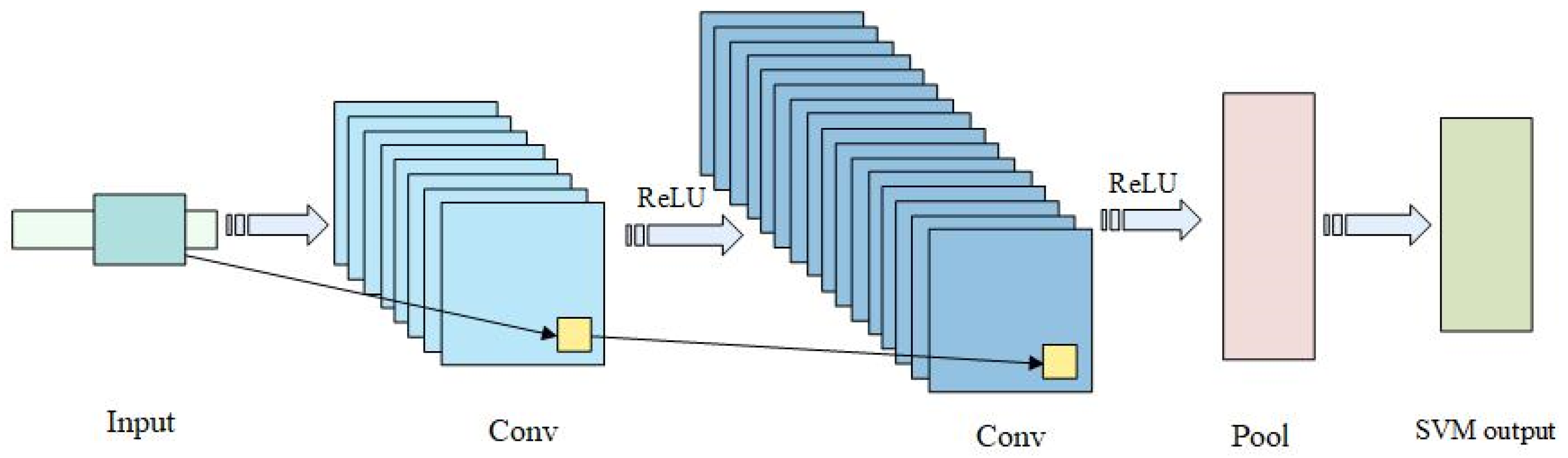

As a powerful deep learning model, the CNN integrates feature extraction and classification recognition, demonstrating significant advantages in signal processing and classification fields while saving time. In recent years, intelligent fault diagnosis algorithms based on CNNs have developed rapidly. Their outstanding advantage is their highly automated feature extraction capabilities, which can directly learn and extract important features from raw monitoring data, reducing the dependence on manual intervention and domain knowledge [

7,

8]. In low signal-to-noise ratio environments, CNNs can exhibit higher robustness, gradually replacing traditional signal processing methods in natural gas pipeline fiber optic monitoring applications. One-dimensional convolutional neural networks (1D-CNNs), in particular, can effectively balance recognition speed and effectiveness when processing one-dimensional signals. Huang et al. [

9] directly input various raw vibration signals into a one-dimensional convolutional neural network for recognition, achieving intelligent fault diagnosis and improving diagnostic accuracy and operational efficiency. Ma et al. [

10] used a CNN with multi-scale feature fusion to recognize four types of fiber optic vibration signals, achieving relatively good recognition results. Houdan et al. [

11] used a 1D-CNN to extract frequency domain features of fiber optic perimeter signals, showing significant recognition effects for signals with complex frequency components. Li et al. [

12] implemented electromechanical vibration signal fault diagnosis based on a 1-DCNN, demonstrating good recognition rates, robustness, generalization ability, and noise resistance performance. However, despite the many advantages of convolutional neural networks, they still face some challenges in practical applications. The original data are typically complex and redundant, with a large quantity of noise signals present. Moreover, the signal characteristics generated by different physical vibrations vary significantly, which gives rise to difficulties in classification and processing. This is especially true in complex environments where vibration signals are readily susceptible to interference from external factors. For instance, the vibration signals produced by events like excavator operation, walking, running, impact, theft, and natural gas leakage possess diverse frequencies, amplitudes, and durations. Consequently, traditional vibration signal analysis methods struggle to achieve high-precision classification. Therefore, it is necessary to combine advanced feature extraction algorithms and machine learning technologies to bolster the model’s capacity to discriminate complex vibration features and withstand noise. In 2019, Wu et al. compared classifiers such as softmax, SVM, RF, and XGB and found that the 1D-CNN-SVM combination had the best performance, with an average accuracy rate of over 98% in recognizing five typical DAS signals, significantly outperforming traditional machine learning and 2D-CNN-related deep learning methods [

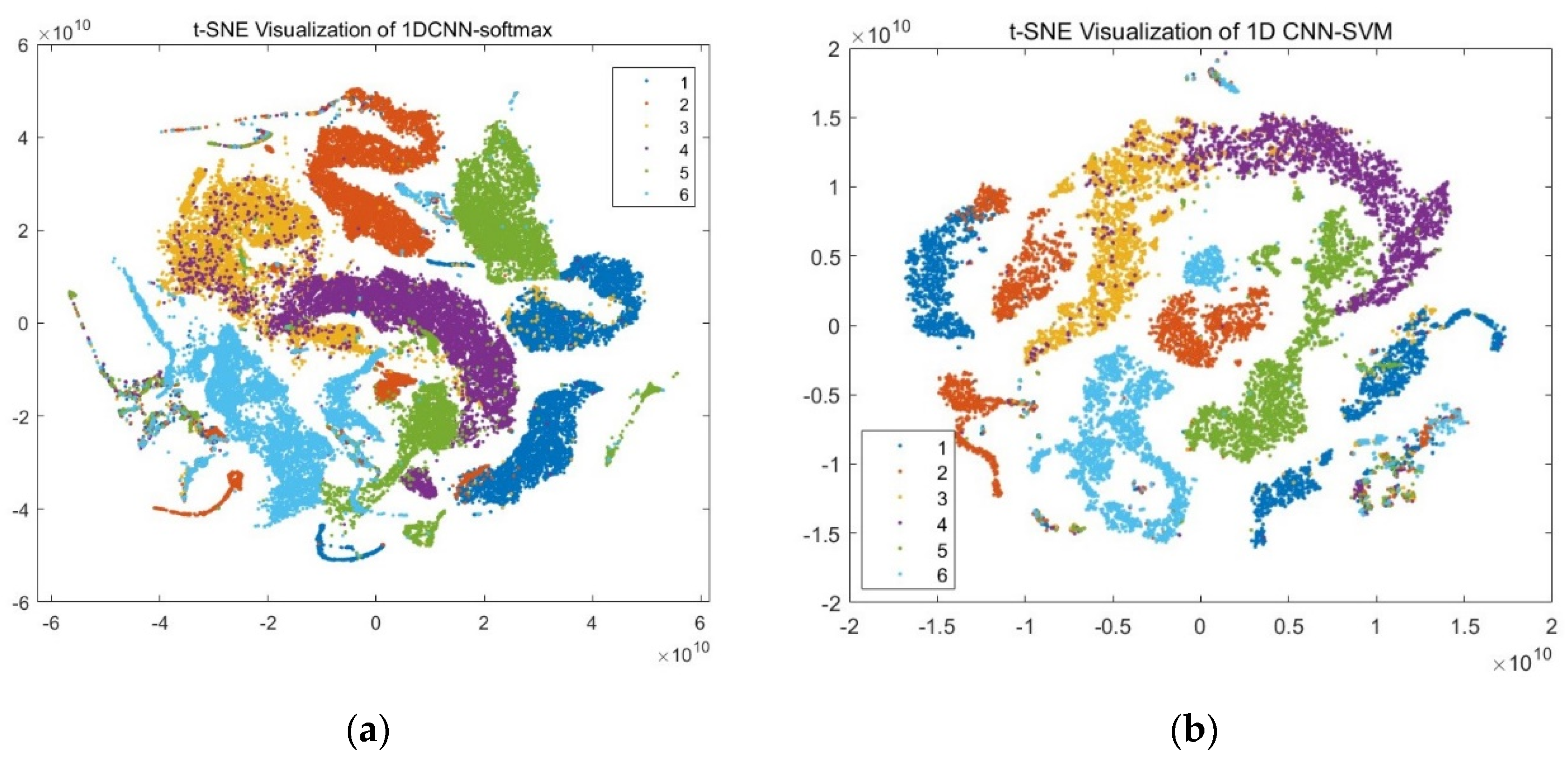

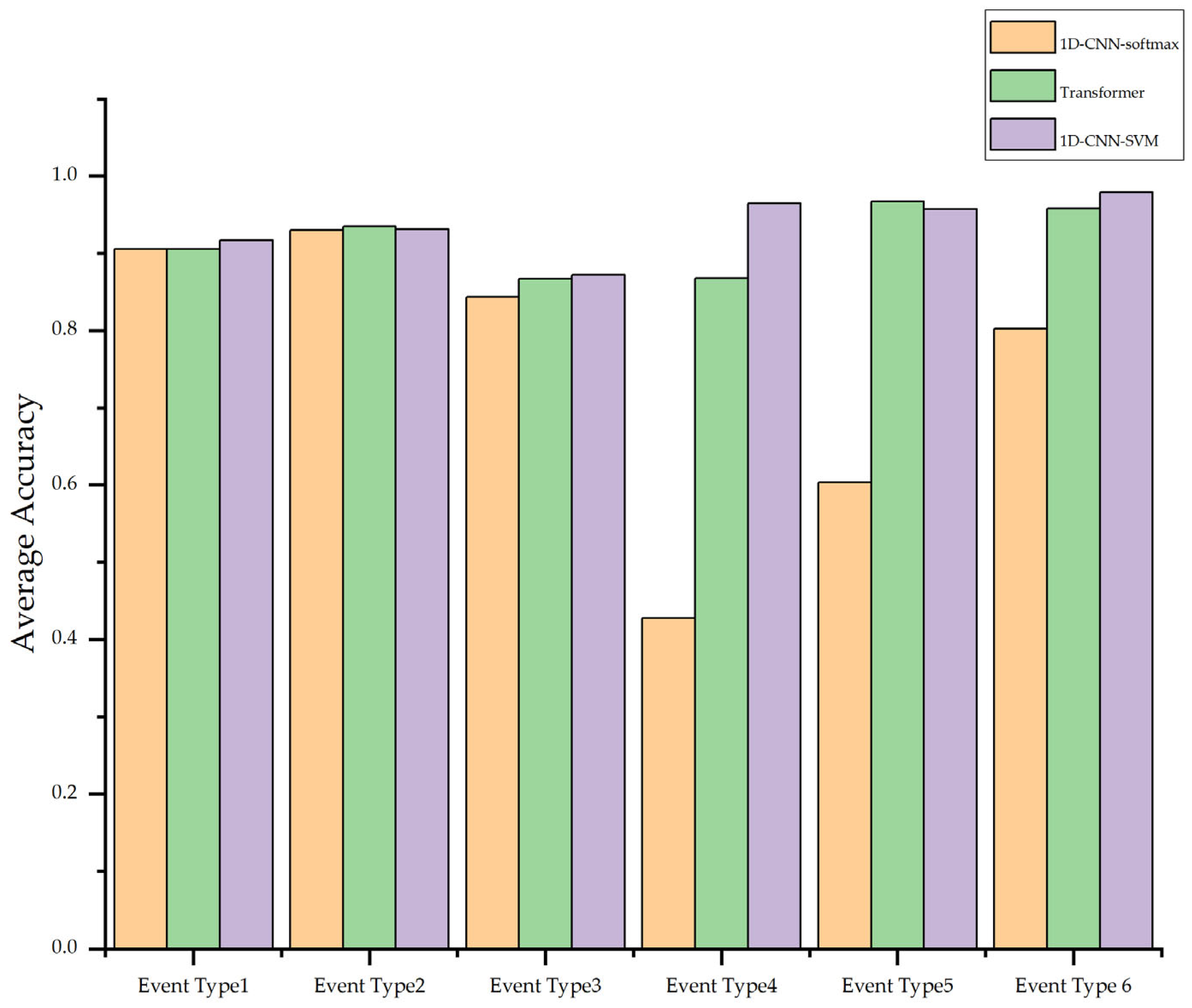

13].

Additionally, when using a 1D-CNN in combination with a Softmax classifier, classification bias may occur due to insufficient samples in certain categories or insufficiently labeled data. At the same time, the process of labeling unlabeled data is both time-consuming and labor-intensive, thereby diminishing the efficiency of data processing [

14]. In contrast, few-shot learning [

2,

3] can achieve rapid learning with a small number of samples when data are limited, greatly improving the learning efficiency and classification accuracy of the model. Existing methods have two main shortcomings:

- (1)

Although the 1D-CNN algorithm performs well on large sample datasets [

15], it exhibits instability in few-shot learning scenarios, potentially leading to reduced classification accuracy. Most studies mentioned in the literature focus on large-scale datasets, with relatively little research on adaptability and classification accuracy for small sample data.

- (2)

SVM demonstrates strong learning ability for small samples and good classification applications [

16], but for large-scale datasets, it has high computational complexity and low efficiency. This indicates that while SVM is suitable for small samples, it has high computational complexity for large-scale datasets.

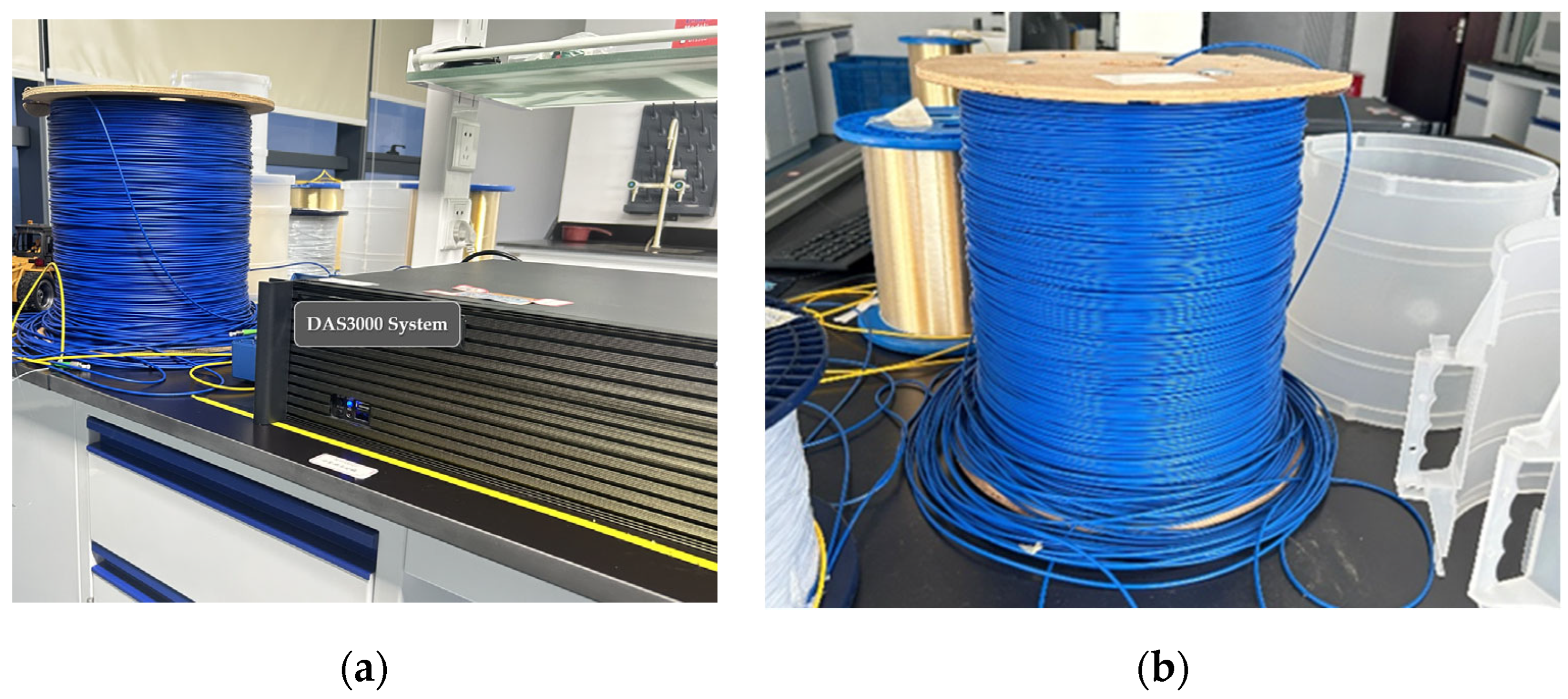

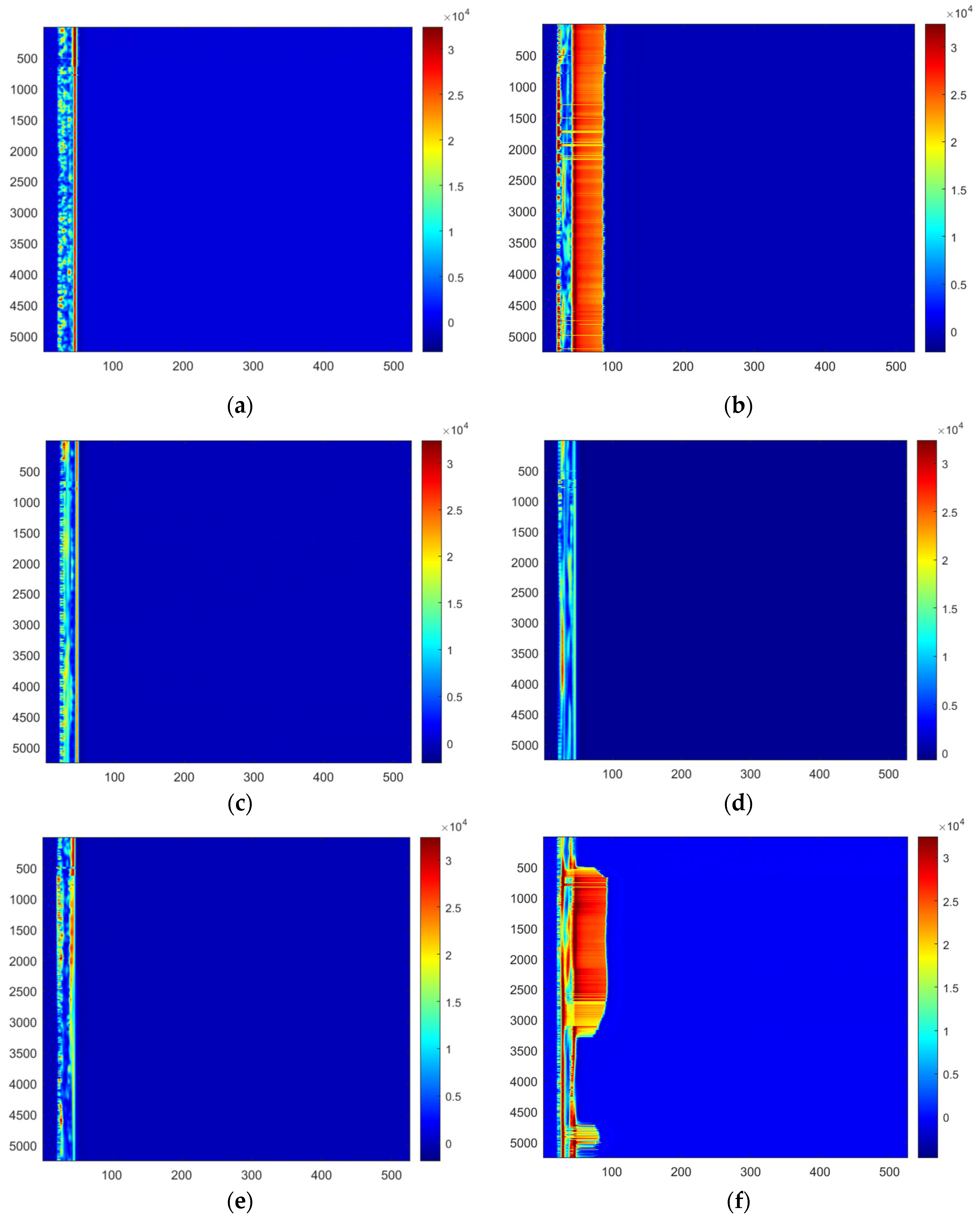

Fiber optic vibration signals are characterized by complexity and high dimensionality, making data preprocessing challenging. For example, one set of data in this study is 10,241 × 1025 in size, which is large, numerous, and extremely complex [

17]. The key challenge is how to effectively extract features and reduce data dimensionality while ensuring that classifiers like SVM can maintain high accuracy on small sample data. Therefore, in fiber optic data analysis, it is crucial to focus on optimizing algorithms and data processing techniques to improve the accuracy and efficiency of data analysis [

18,

19].

As mentioned above, to address these issues, this paper proposes an improved method combining the 1D-CNN and SVM, utilizing 1D-CNN’s feature extraction capabilities and SVM’s advantage in few-shot learning to achieve accurate analysis and recognition of distributed fiber optic monitoring signals [

20]. The proposed approach sustains a high level of classification accuracy even in small-sample scenarios while simultaneously enhancing computational efficiency and model robustness. Experimental evaluations further confirm its reliable performance across a variety of fiber optic vibration signal types, highlighting its strong applicability to natural gas pipeline safety monitoring. These findings offer meaningful insights that may inform the advancement of intelligent pipeline surveillance technologies [

21,

22]. Although DFOS technologies such as Φ-OTDR have shown great potential in pipeline monitoring due to their real-time and distributed sensing capabilities, most existing studies still rely on conventional feature engineering and classifiers, which limits adaptability under complex environments. Although deep learning techniques have gained traction in recent years, their performance tends to decline in small-sample contexts due to overfitting and limited generalization. To address this limitation, combining the automated feature extraction capability of a 1D-CNN with the strong classification efficacy of an SVM under sparse data conditions offers a promising pathway for improving the practical interpretation of distributed fiber optic sensing (DFOS) data in complex real-world environments.