Experimental Study on Plugging of Micro-Leakage Interlayer (MLI) in Underground Salt Cavern Gas Storage (Jintan, China)

Abstract

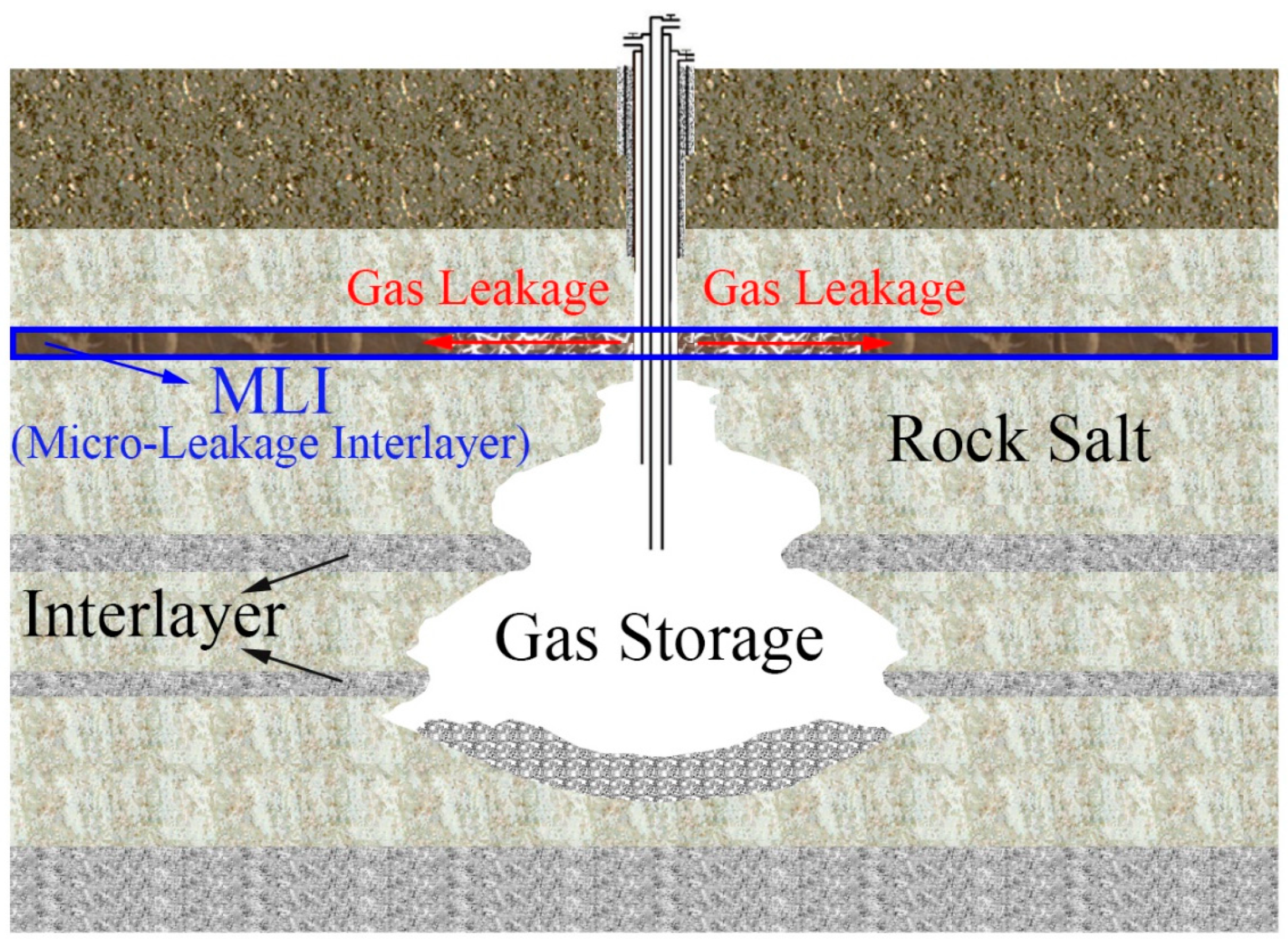

1. Introduction

2. The First Solution

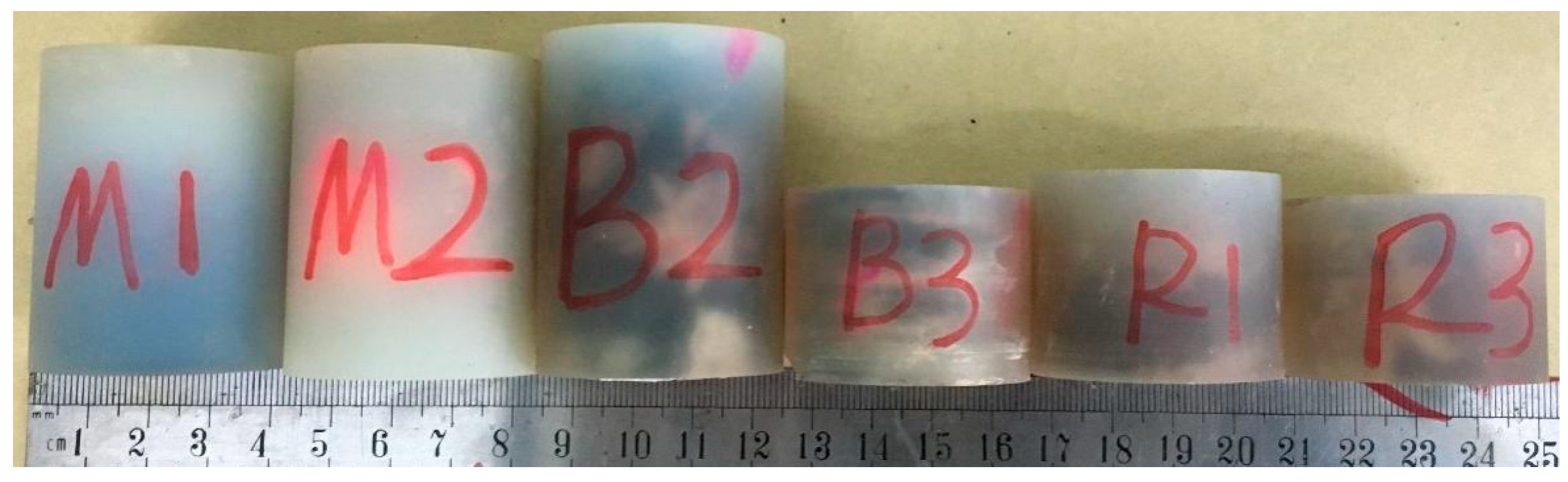

2.1. Specimen Preparation

2.2. Test Results and Analysis

2.2.1. SEM Tests

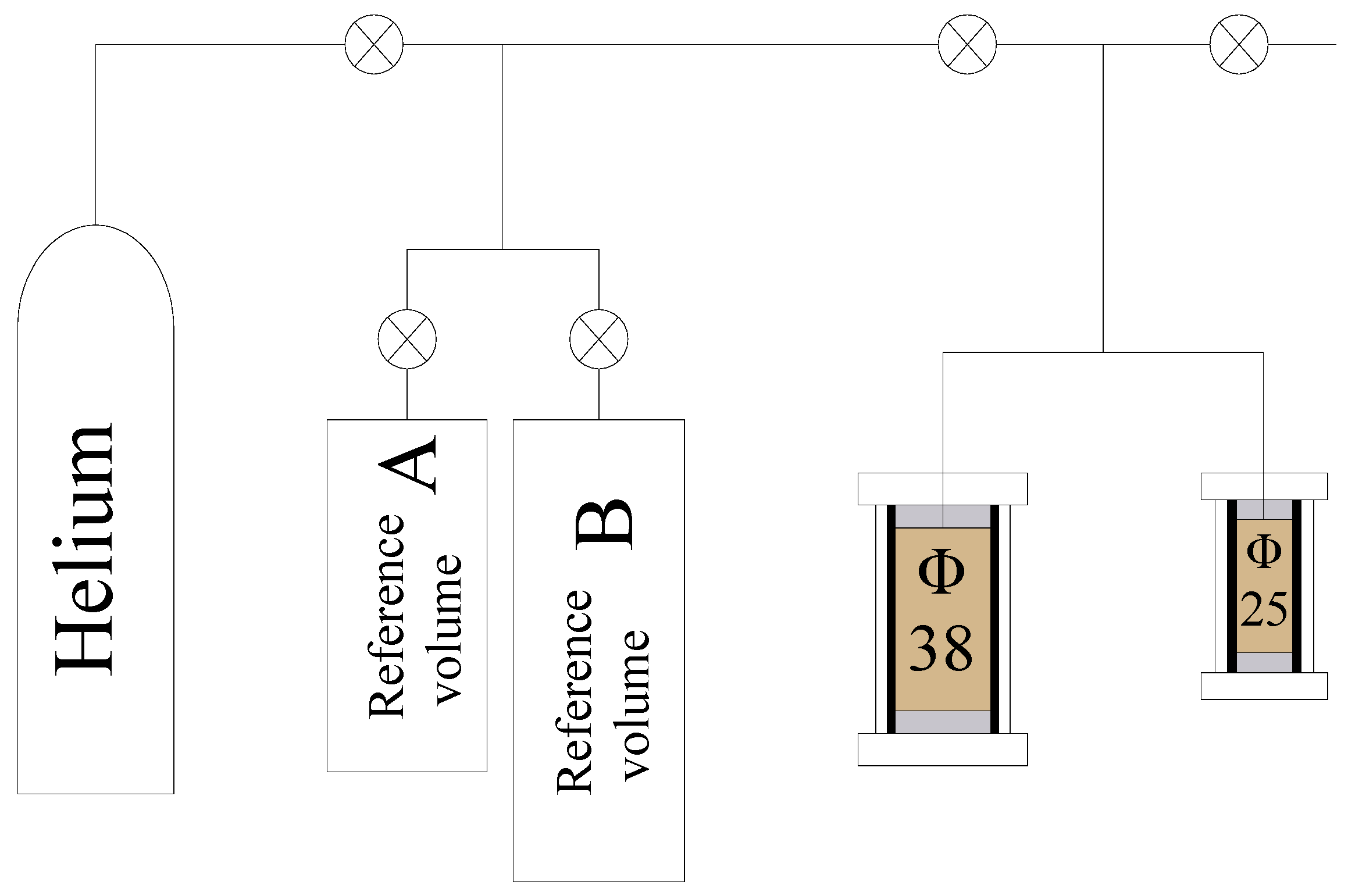

2.2.2. Porosity Tests

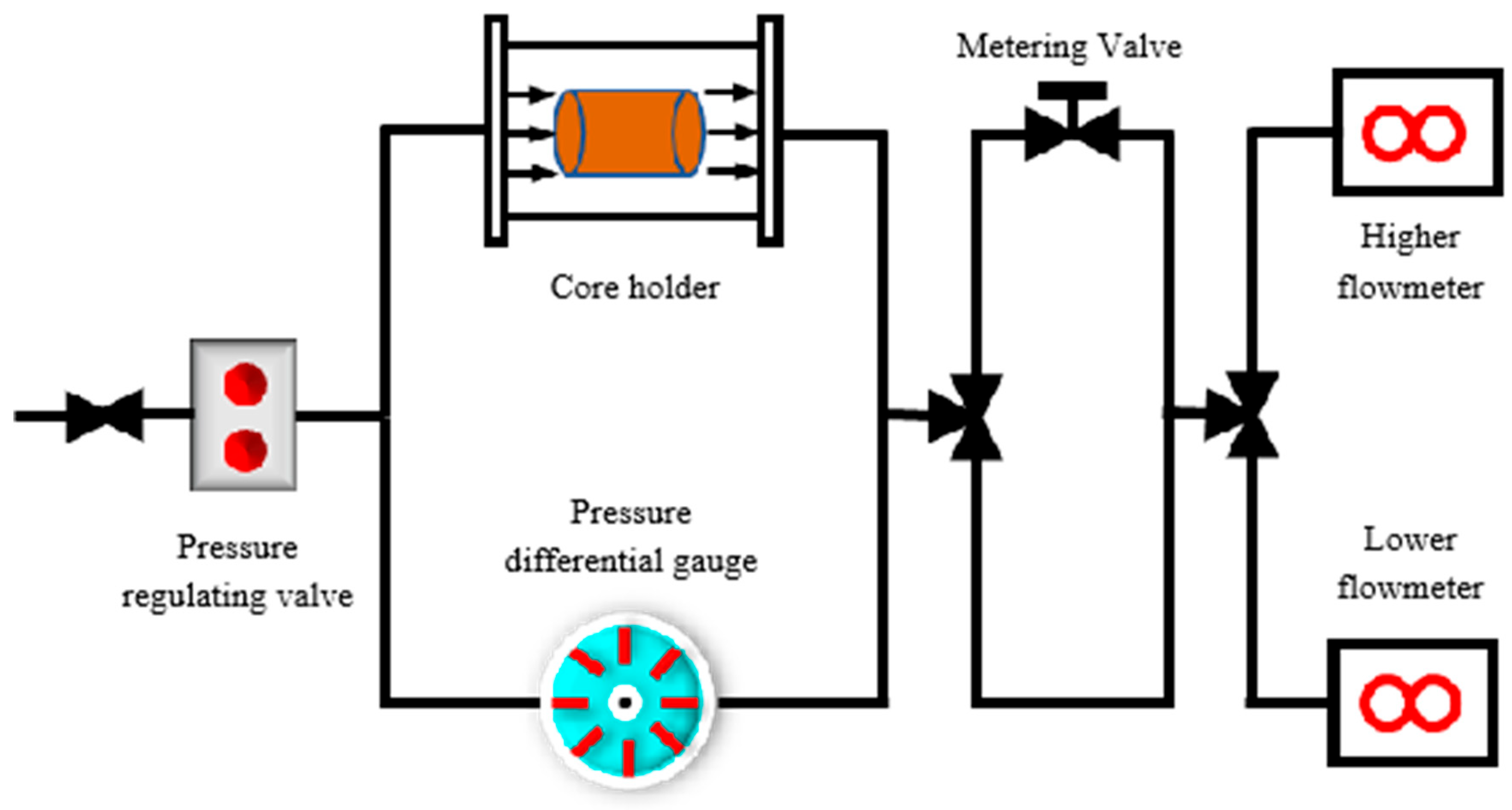

2.2.3. Permeability Tests

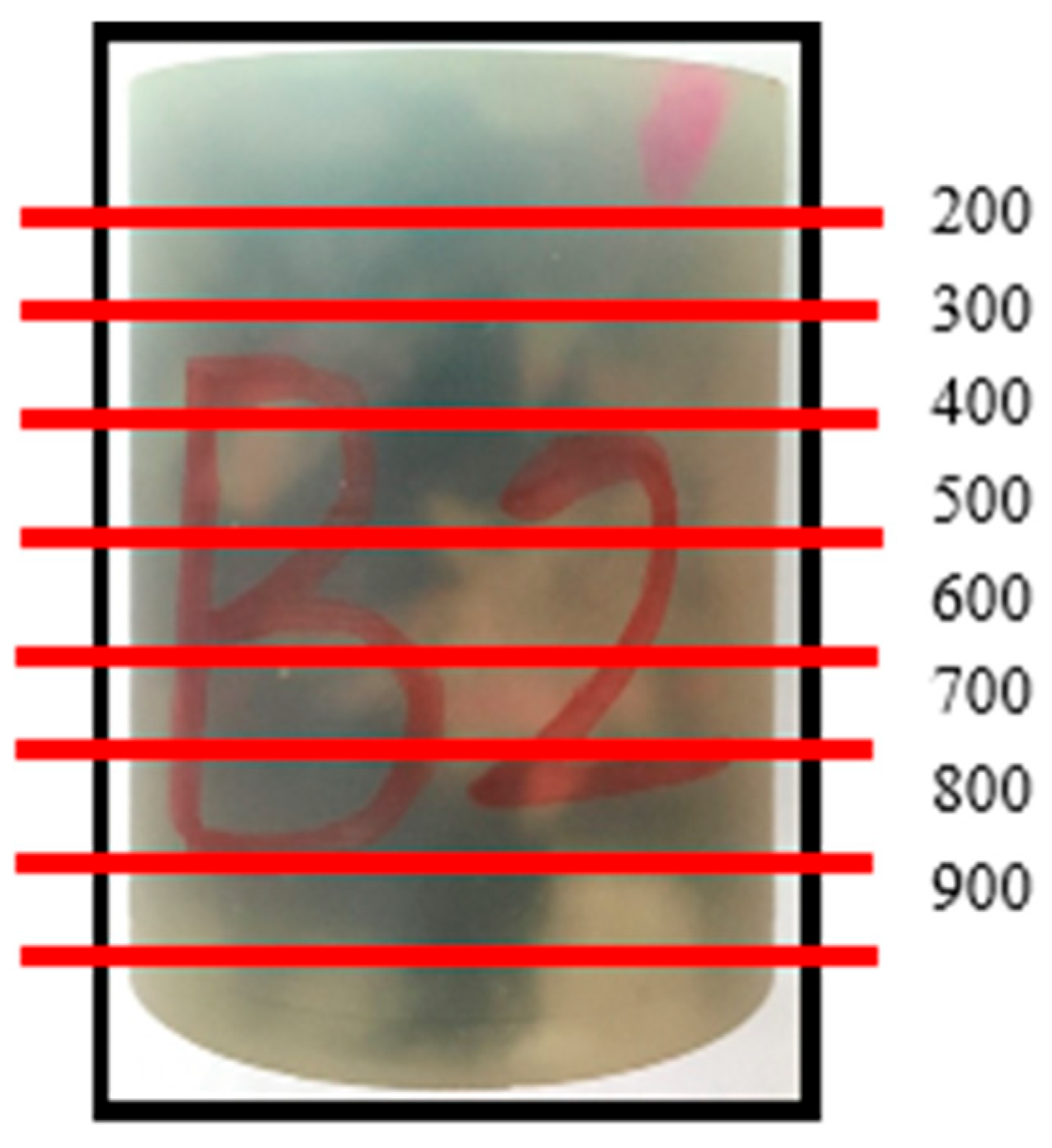

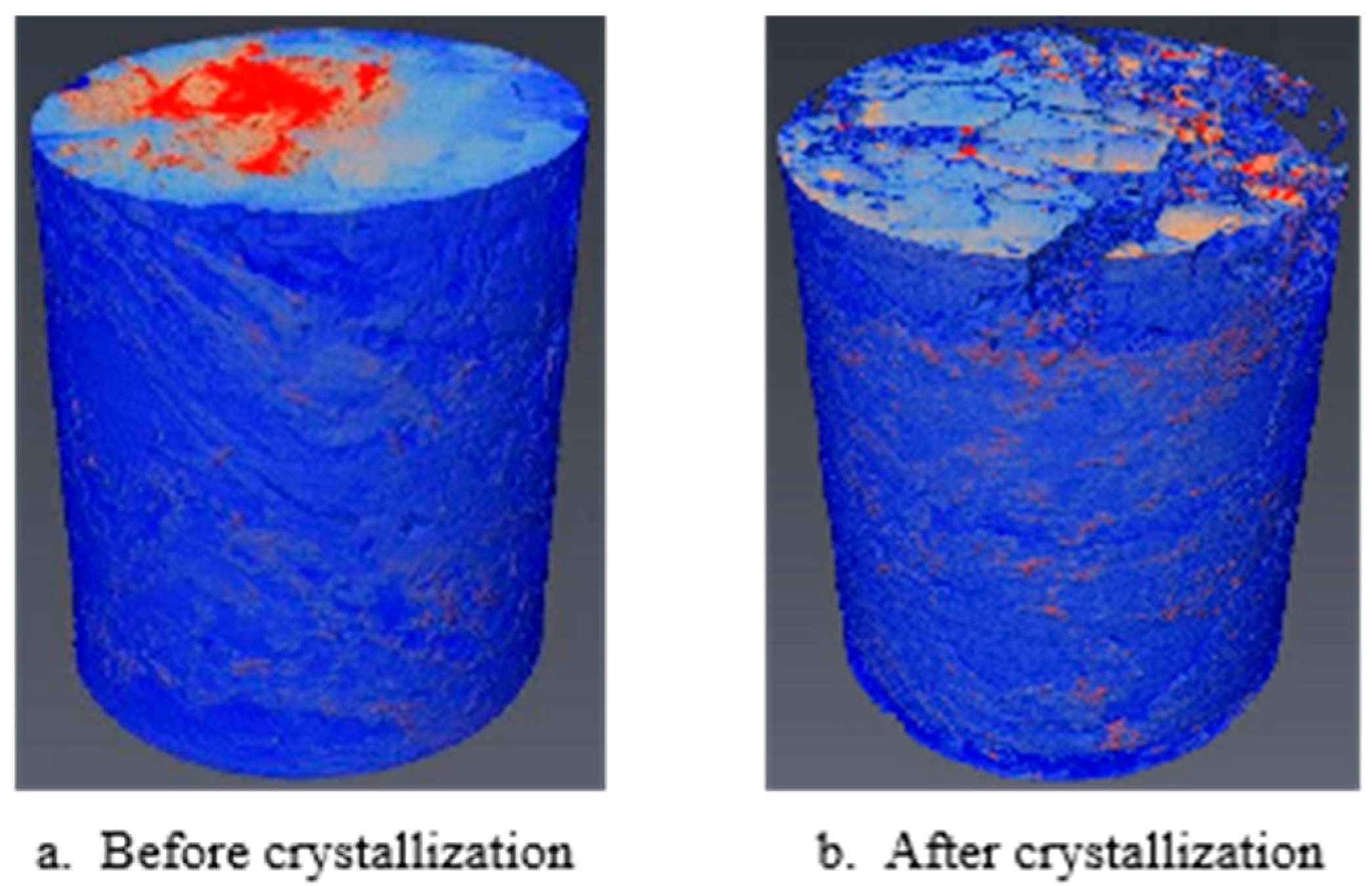

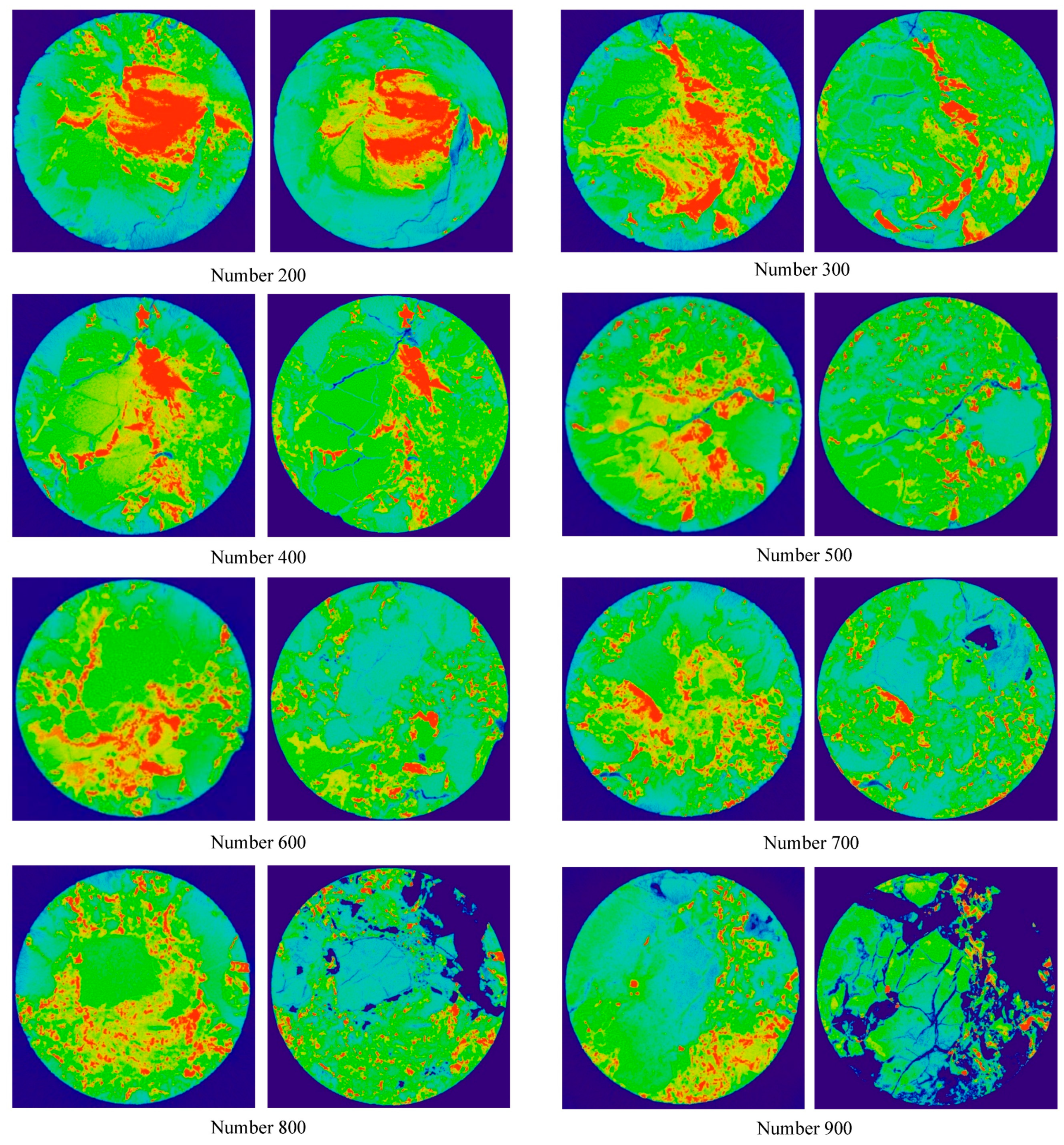

2.2.4. CT Tests

2.3. Result Analysis

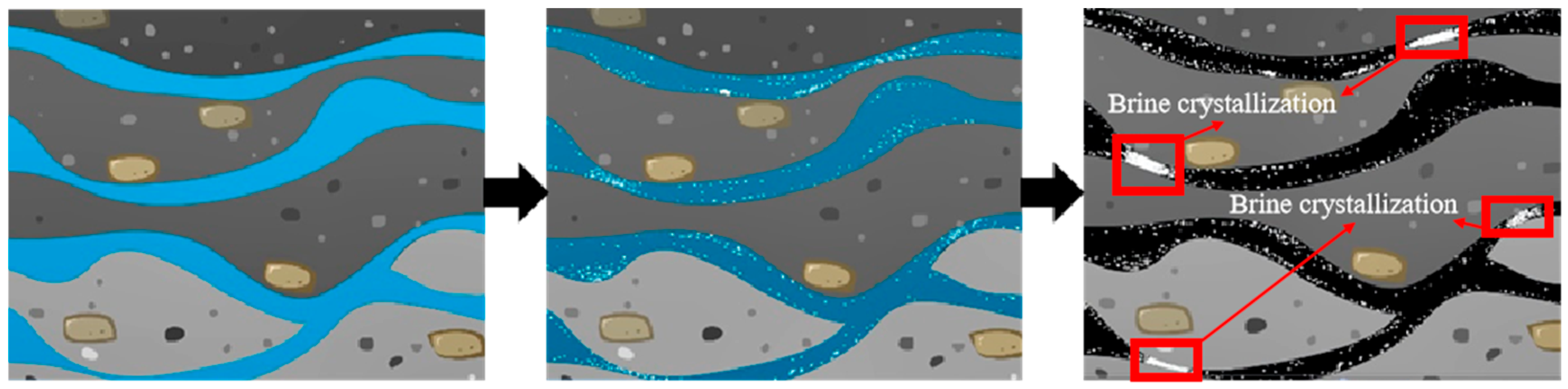

3. The Second Solution

- (1)

- Exhibit fine particle size for microcrack penetration: The cement particles must be ultrafine to ensure that the slurry can effectively penetrate the MLI.

- (2)

- Exhibit excellent filling performance. The slurry should exhibit low porosity and low permeability after hardening, ensuring that it can completely fill the voids and create a dense, impermeable barrier.

- (3)

- Exhibit high-pressure resistance and strength. The hardened slurry must possess sufficient strength to withstand high pressures to ensure long-term stability and effectiveness.

3.1. Specimen Preparation

3.2. Test Results and Analysis

3.2.1. Porosity and Permeability Tests

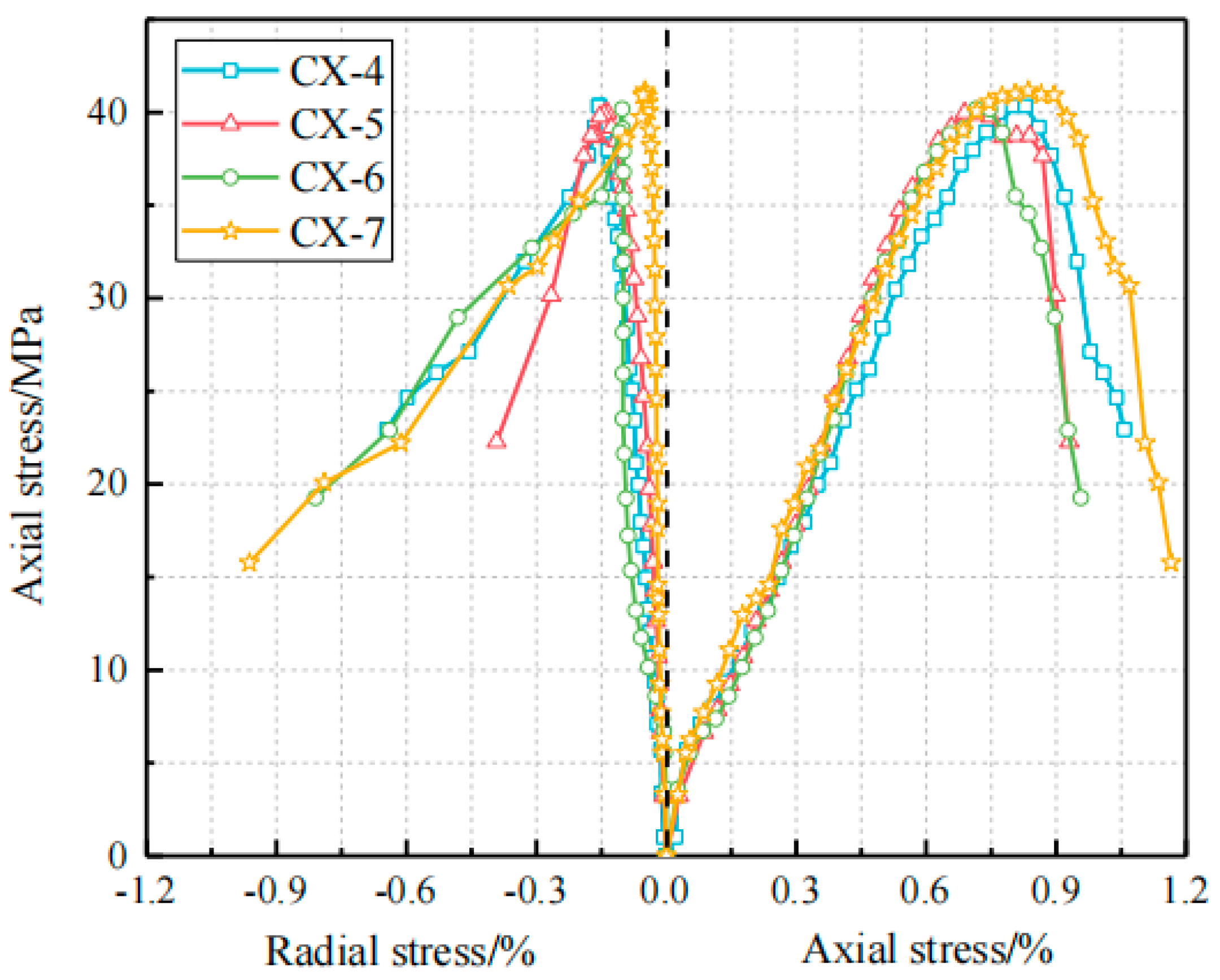

3.2.2. Strength Tests

3.3. Result Analysis

4. Summary and Conclusions

- (1)

- The permeability of the MLI cores is on the order of 10−16 m2, which is significantly higher than that of rock salt (less than 10−20 m2). This elevated permeability is the primary factor contributing to gas leakage through the MLI.

- (2)

- For the solution of brine crystallization. After crystallization, the porosity of the MLI cores exhibits a notable increase, indicating structural changes within the material. Similarly, the permeability of the MLI cores increases significantly post-crystallization, further exacerbating the risk of gas leakage. These results indicate that the plugging solution requires further exploration.

- (3)

- For the Brine Crystallization Combined with Ultrafine Cement Grouting Solution. The ultrafine cement particles have an average particle size of 3 µm, and the ultrafine cement slurry exhibits extremely low porosity and permeability, along with high strength. The salt crystals formed by brine can further enhance the plugging effectiveness of the slurry. The results indicate that this solution is highly feasible.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Peach, C.J. Influence of Deformation on the Fluid Transport Properties of Salt Rocks. Fac. Aardwetenschappen Rijksuniv. Utrecht 1991, 77, 238. [Google Scholar]

- Schulze, O.; Popp, T.; Kern, H. Development of damage and permeability in deforming rock salt. Eng. Geol. 2001, 61, 163–180. [Google Scholar] [CrossRef]

- Stormont, J.C.; Daemen, J.J.K. Laboratory study of gas permeability changes in rock salt during deformation. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1992, 29, 325–342. [Google Scholar] [CrossRef]

- Hunsche, U.; Hampel, A. Rock salt—The mechanical properties of the host rock material for a radioactive waste repository. Eng. Geol. 1999, 52, 271–291. [Google Scholar] [CrossRef]

- Li, J.; Shi, X.; Wang, T.; Yang, C.; Li, Y.; Ma, H.; Ma, X.; Shi, H. A prediction model of the accumulation shape of insoluble sediments during the leaching of salt cavern for gas storage. J. Nat. Gas Sci. Eng. 2016, 33, 792–802. [Google Scholar] [CrossRef]

- Li, Y.; Liu, W.; Yang, C.; Daemen, J.J.K. Experimental investigation of mechanical behavior of bedded rock salt containing inclined interlayer. Int. J. Rock Mech. Min. Sci. 2014, 69, 39–49. [Google Scholar] [CrossRef]

- Liu, W.; Li, Y.; Yang, C.; Daemen, J.J.K.; Yang, Y.; Zhang, G. Permeability characteristics of mudstone cap rock and interlayers in bedded salt formations and tightness assessment for underground gas storage caverns. Eng. Geol. 2015, 193, 212–223. [Google Scholar] [CrossRef]

- Bérest, P.; Bergues, J.; Brouard, B.; Durup, J.G.; Guerber, B. A salt cavern abandonment test. Int. J. Rock Mech. Min. Sci. 2001, 38, 357–368. [Google Scholar] [CrossRef]

- Ma, H.; Yang, C.; Li, Y.; Shi, X.; Liu, J.; Wang, T. Stability evaluation of the underground gas storage in rock salts based on new partitions of the surrounding rock. Environ. Earth Sci. 2015, 73, 6911–6925. [Google Scholar] [CrossRef]

- Yang, C.; Daemen, J.J.K.; Yin, J.H. Experimental investigation of creep behavior of salt rock. Int. J. Rock Mech. Min. Sci. 1999, 36, 233–242. [Google Scholar] [CrossRef]

- Zhang, G.; Li, Y.; Yang, C.; Daemen, J.J.K. Stability and tightness evaluation of bedded rock salt formations for underground gas/oil storage. Acta Geotech. 2014, 9, 161–179. [Google Scholar] [CrossRef]

- Zhang, N.; Shi, X.; Wang, T.; Yang, C.; Liu, W.; Ma, H.; Daemen, J.J.K. Stability and availability evaluation of underground strategic petroleum reserve (SPR) caverns in bedded rock salt of Jintan, China. Energy 2017, 134, 504–514. [Google Scholar] [CrossRef]

- Yang, C.; Wang, T.; Li, Y.; Yang, H.; Li, J.; Qu, D.; Xu, B.; Yang, Y.; Daemen, J.J.K. Feasibility analysis of using abandoned salt caverns for large-scale underground energy storage in China. Appl. Energy 2015, 137, 467–481. [Google Scholar] [CrossRef]

- Li, J.; Shi, X.; Yang, C.; Li, Y.; Wang, T.; Ma, H. Mathematical model of salt cavern leaching for gas storage in high-insoluble salt formations. Sci. Rep. 2018, 8, 372. [Google Scholar] [CrossRef]

- Ozarslan, A. Large-scale hydrogen energy storage in salt caverns. Int. J. Hydrogen Energy 2012, 37, 14265–14277. [Google Scholar] [CrossRef]

- Li, Y.; Yang, C.; Shi, X. Cavity Control and Safety Assessment of Salt Cavern Gas Storage; Science Press: Beijing, China, 2012. [Google Scholar]

- Gerhard, H.; Stelzer, R.B. Method for Forming and Surveying a Cavern in a Salt Formation. U.S. Patent US2786661, 26 March 1957. [Google Scholar]

- U.S. Department of Energy Office of Scientific and Technical Information. Feasibility of Creating Spherical Cavities in Underground Salt Domes; Progress Report, February and March 1963; U.S. Department of Energy Office of Scientific and Technical Information: Oak Ridge, TN, USA, 1963. [Google Scholar]

- Durie, R.W. Mechanism of the dissolution of salt in the formation of underground salt cavities. Soc. Pet. Eng. J. 1964, 4, 183–190. [Google Scholar] [CrossRef]

- Thomas, R.L.; Hendron, A.J. Strategic Petroleum Reserve Program: Salt Dome Geology and Cavern Stability Analysis, Bayou Choctaw, Louisiana; Parsons, Brinckerhoff, Quade and Douglas, Inc.: New York, NY, USA; Louis Records and Associates, Inc.: Torrance, CA, USA, 1978. [Google Scholar]

- Urai, J.L.; Spiers, C.J.; Zwart, H.J.; Lister, G.S. Weakening of rock salt by water during long-term creep. Nature 1986, 324, 554–557. [Google Scholar] [CrossRef]

- Dusseault, M.B.; Fordham, C.J. Time-dependent Behavior of Rocks. In Rock Testing & Site Characterization; Pergamon: İzmir, Turkey, 1993; pp. 119–149. [Google Scholar]

- Dusseault, M.B.; Rothenburg, L.; Bachu, S. Sequestration of CO in Salt Caverns. J. Can. Pet. Technol. 2002, 43, 49–55. [Google Scholar]

- Stormont, J.C. In situ gas permeability measurements to delineate damage in rock salt. Int. J. Rock Mech. Min. Sci. 1997, 34, 1055–1064. [Google Scholar] [CrossRef]

- Alkan, H. Percolation model for dilatancy-induced permeability of the excavation damaged zone in rock salt. Int. J. Rock Mech. Min. Sci. 2009, 46, 716–724. [Google Scholar] [CrossRef]

- Liang, W.; Yang, C.; Zhao, Y.; Dusseault, M.B.; Liu, J. Experimental investigation of mechanical properties of bedded salt rock. Int. J. Rock Mech. Min. Sci. 2007, 44, 400–411. [Google Scholar] [CrossRef]

- Yin, H.; Ma, H.; Chen, X.; Shi, X.; Yang, C.; Dusseault, M.; Zhang, Y. Synthetic Rock Analogue for Permeability Studies of Rock Salt with Mudstone. Appl. Sci. 2017, 7, 946. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Zhang, G.; Liu, Y.; Zhou, C. A numerical procedure for modeling the seepage field of water-sealed underground oil and gas storage caverns. Tunn. Undergr. Space Technol. 2017, 66, 56–63. [Google Scholar] [CrossRef]

- Li, Y.; Yang, C. On fracture saturation in layered rocks. Int. J. Rock Mech. Min. Sci. 2007, 44, 936–941. [Google Scholar] [CrossRef]

- Shi, X.; Liu, W.; Chen, J.; Jiang, D.; Wu, F.; Zhang, J.; Fan, J. Softening model for failure analysis of insoluble interlayers during salt cavern leaching for natural gas storage. Acta Geotech. 2018, 13, 801–816. [Google Scholar] [CrossRef]

- Yang, C.; Li, Y.; Chen, F. Bedded Salt Rock Mechanics and Engineering; Science Press: Beijing, China, 2009. (In Chinese) [Google Scholar]

- Yang, C.H.; Liang, W.G.; Wei, D.H.; Yang, H.J. Investigation on possibility of energy storage in salt rock in China. Chin. J. Rock Mech. Eng. 2005, 24, 4409–4417. [Google Scholar]

- Zhang, G.; Li, Y.; Daemen, J.J.K.; Yang, C.; Wu, Y.; Zhang, K.; Chen, Y. Geotechnical Feasibility Analysis of Compressed Air Energy Storage (CAES) in Bedded Salt Formations: A Case Study in Huai’an City, China. Rock Mech. Rock Eng. 2015, 48, 2111–2127. [Google Scholar] [CrossRef]

- Thoms, R.L.; Gehle, R.M. A Brief History of Salt Cavern Use; Elsevier: Amsterdam, The Netherlands, 2000. [Google Scholar]

- Evans, D.J. A review of underground fuel storage events and putting risk into perspective with other areas of the energy supply chain. Geol. Soc. Lond. Spec. Publ. 2009, 313, 173–216. [Google Scholar] [CrossRef]

- Chen, M.; Buscheck, T.A.; Wagoner, J.L.; Sun, Y.; White, J.A.; Chiaramonte, L.; Aines, R.D. Analysis of fault leakage from Leroy underground natural gas storage facility, Wyoming, USA. Hydrogeol. J. 2013, 21, 1429–1445. [Google Scholar] [CrossRef]

- Chen, W.; Tan, X.; Wu, G.; Yang, J. Research on gas seepage law in laminated salt rock gas storage. Chin. J. Rock Mech. Eng. 2009, 28, 1297–1304. [Google Scholar]

- Liu, W.; Muhammad, N.; Chen, J.; Spiers, C.J.; Peach, C.J.; Jiang, D.; Li, Y. Investigation on the permeability characteristics of bedded salt rocks and the tightness of natural gas caverns in such formations. J. Nat. Gas Sci. Eng. 2016, 35, 468–482. [Google Scholar] [CrossRef]

- Wang, T.; Ma, H.; Yang, C.; Shi, X.; Daemen, J.J.K. Gas seepage around bedded salt cavern gas storage. J. Nat. Gas Sci. Eng. 2015, 26, 61–71. [Google Scholar] [CrossRef]

- Zeng, Y.; Li, D.; Yang, C. Leakage prevention and control in fractured formations. Chin. J. Rock Mech. Eng. 2016, 35, 8. [Google Scholar]

- Alberty, M.W.; Mclean, M.R. A physical model for stress cages. In Proceedings of the SPE Annual Technical Conference and Exhibition Society of Petroleum Engineers, Houston, TX, USA, 26–29 September 2004. [Google Scholar]

- Wu, X.; Zheng, W.; Zou, Y. Well Bore Stability Technology Using Blocking Drilling Fluid System Suitable for the Deep High Temperature Cracked Strata in Well Songke-2. Earth Sci. 2020, 45, 3502–3508. [Google Scholar]

- Li, J.; Chen, Y.; Liang, W.; Zhang, S.; Qiu, Y. Experimental Investigation on Permeability and Mechanical Properties of Cement–Salt Rock Interface Subjected to Cyclic Loading. Rock Mech. Rock Eng. 2023, 56, 7281–7299. [Google Scholar] [CrossRef]

- Sun, J.; Bai, Y.; Cheng, R.; Lyu, K.; Liu, F.; Feng, J.; Lei, S.; Zhang, J.; Hao, H. Research progress and prospect of plugging technologies for fractured formation with severe lost circulation. Pet. Explor. Dev. 2021, 48, 630–638. [Google Scholar] [CrossRef]

- Sun, J.; Bai, Y.; Cheng, R.; Lyu, K.; Liu, F.; Feng, J.; Lei, S.; Zhang, J.; Hao, H. Review and prospect of bridging plugging technology in fractured formation. Pet. Sci. Bull. 2023, 4, 415–431. [Google Scholar]

- Yin, H.; Ma, H.; Shi, X.; Yang, C. A new method for permeability test on mudstone interlayer in a salt cavern gas storage. Rock Soil Mech. 2017, 38, 2241–2248. [Google Scholar]

- American Petroleum Institute. Orifice Metering of Natural Gas and Other Related Hydrocarbon Fluids—Concentric, Square-Edged Orifice Meters—Part 1: General Equations and Uncertainty Guidelines; API MPM CH14.3.1 Ed. 4; American Petroleum Institute: Washington, DC, USA, 2012. [Google Scholar]

| NO. | Diameter (mm) | Height (mm) | Porosity Before Crystallization (%) | Porosity After Crystallization (%) |

|---|---|---|---|---|

| M1 | 37.91 | 47.49 | 16.92 | 18.46 |

| M2 | 37.87 | 48.37 | 15.84 | 17.63 |

| B2 | 37.93 | 51.25 | 5.83 | 12.36 |

| B3 | 38.05 | 28.89 | 6.03 | 8.64 |

| R1 | 38.03 | 30.60 | 5.20 | 7.48 |

| R3 | 38.01 | 27.21 | 4.88 | 8.57 |

| NO. | Diameter (mm) | Height (mm) | Permeability Before Crystallization (10−15 m2) | Permeability After Crystallization (10−15 m2) |

|---|---|---|---|---|

| M1 | 37.91 | 47.22 | 0.120 | 0.239 |

| M2 | 37.87 | 48.16 | 0.154 | 0.497 |

| B2 | 37.93 | 51.09 | 0.384 | 1.524 |

| B3 | 38.05 | 28.89 | 0.126 | 0.747 |

| R1 | 38.03 | 30.72 | 0.111 | 0.200 |

| R3 | 38.01 | 27.31 | 0.155 | 0.599 |

| NO. | Diameter (mm) | Height (mm) | Porosity (%) | Permeability (10−20 m2) |

|---|---|---|---|---|

| CX-1 | 25.02 | 49.98 | 2.67 | 3.561 |

| CX-2 | 24.97 | 50.31 | 3.04 | 20.233 |

| CX-3 | 25.03 | 49.94 | 2.79 | 5.122 |

| Average | 38.05 | 28.89 | 0.126 | 0.747 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, H.; Ge, X. Experimental Study on Plugging of Micro-Leakage Interlayer (MLI) in Underground Salt Cavern Gas Storage (Jintan, China). Processes 2025, 13, 1188. https://doi.org/10.3390/pr13041188

Yin H, Ge X. Experimental Study on Plugging of Micro-Leakage Interlayer (MLI) in Underground Salt Cavern Gas Storage (Jintan, China). Processes. 2025; 13(4):1188. https://doi.org/10.3390/pr13041188

Chicago/Turabian StyleYin, Hongwu, and Xinbo Ge. 2025. "Experimental Study on Plugging of Micro-Leakage Interlayer (MLI) in Underground Salt Cavern Gas Storage (Jintan, China)" Processes 13, no. 4: 1188. https://doi.org/10.3390/pr13041188

APA StyleYin, H., & Ge, X. (2025). Experimental Study on Plugging of Micro-Leakage Interlayer (MLI) in Underground Salt Cavern Gas Storage (Jintan, China). Processes, 13(4), 1188. https://doi.org/10.3390/pr13041188