Abstract

Utilizing potassium salt aggregates and waste brine to produce underground cemented filling materials can address the waste storage issue. However, it is essential for the backfill materials to meet specific transport characteristics. This paper examines the transportation characteristics of lime-cemented mine backfill for a potash mine. The parameters were optimized for the cemented backfill process of potash mines through loop experiments and model simulations. Results indicate that the slump and fluidity of the backfill slurry diminished with increasing lime content and solid concentration. Additionally, the growth rate of pressure loss at the bent pipe and the pressure loss per unit distance in a horizontal pipe increased rapidly over transportation time, indicating a decline in the flowability of the backfill slurry. The lime dosage and solid concentration must align with the backfill requirements. When the lime dosage is 0.5%, the solid content is 70–75%; conversely, with a lime dosage of 0.7% and solid content of 65%, the maximum pumpable time extends to 1 h. The compressive strength of the cured backfill material after 28 days exceeds 1.01 MPa, meeting the transportation requirements for 300 m vertical pipes and 5000 m horizontal pipes. In the case study, the actual flow rate of backfill slurry surpasses the calculated critical flow rate. The estimated and measured values of on-site pressure loss per unit distance in a horizontal pipe exhibit a strong correlation. As the pressure loss per unit distance in a horizontal pipe rises, the discrepancy between the calculated and measured values also increases. When the solid content exceeds 65%, the loop test slightly enhances the compressive strength of the lime-cemented backfill. The findings from this article can aid in determining the on-site backfill process parameters with lime as a binder.

1. Introduction

As an essential mineral resource, potash mines play a vital role in agricultural and industrial production [1]. However, due to the complex production process and high mineral processing ratio, a large amount of potash tailings and waste liquid are generated during potash mining and fertilizer production [2,3]. If the by-product tailings and waste liquid are stored on the surface, they not only occupy a significant amount of land but also pose major safety hazards and seriously impact the ecological environment [4,5]. Cemented backfill technology is a sustainable development strategy designed to address both the environmental and safety issues of the mine [6,7]. Mixing the binder with the tailings and liquid to prepare the backfill slurry and transporting it to the goaf is an important method for synergistically treating the tailings and waste liquid of potash mines [8]. The backfill material must not only meet early fluidity requirements to ensure that the backfill slurry can be easily pumped to the goaf, but also satisfy later strength requirements to provide support for the goaf and ensure safe production [9]. The potash mine requires the filling material to have a 1 h fluidity of more than 200 mm and a 28-day compressive strength exceeding 1 Mpa [10]. Therefore, selecting a suitable binder for the backfill material and designing the backfill material ratio have become key issues that solid potash mine development companies must address [11,12].

Lime is a standard binder and is the earliest binder used by humans [13]. The main component of lime is CaO, which can be obtained by calcining limestone [14]. Limestone is widely distributed and easy to get, so lime has been commonly used in various projects [15]. Lime is widely used in underground cementing, filling in ferrous and non-ferrous metal mines [16,17]. Zheng et al. [18] used lime as a binder and used coarse and fine tailings of gold mines as aggregates to prepare backfill materials. When the lime dosage was 5%, the maximum strength at 28 days could reach 2.03 MPa. Li et al. [19] used lime as an activating material, added water-quenched slag, cement clinker, and gypsum to prepare a composite binder, and mixed it with tailings and water. The prepared cemented filling material had a compressive strength of more than 3 MPa after curing for 28 days.

The CaO in lime reacts with the potash mine waste liquid, which primarily consists of a high-concentration MgCl2 solution. This reaction solidifies the water molecules present in the waste liquid and has the potential to harden the filling material, possibly giving it specific strength. Jin et al. [20] utilized lime as a binder for backfill materials in a potash mine; with the addition of 0.5–2% lime, the potash backfill materials met the requirements for flowability (180 mm) and strength (1 MPa after 28 days). A 2% lime dosage results in the formation of various hydration products, including predominant tachyhydrite (CaMg2Cl6·12H2O), along with ghiaraite (CaCl2·4H2O), bischofite (MgCl2·6H2O), and korshunovskite (Mg2Cl(OH)3·4H2O). However, the data produced in laboratory tests may not accurately reflect the transportation behavior of lime-cemented backfill materials in actual backfill application sites.

The loop pipe test is essential before designing the mine. The fluid parameters in the backfill process are measured to inform the design [21]. This test simulates the actual backfill station in a mine, verifying the reliability and stability of the backfill material optimized in the lab, which must maintain good transportation and mechanical properties at the real site [22]. Besides slump and fluidity testing in the lab, pressure loss during the loop test is a crucial parameter, as it can indicate the risk of pipe blockage and breakage [23]. It is widely recognized that pressure loss in the pipeline is affected by solid content; flow rate [24]; inlet velocity; SiO2, CaO, and Fe2O3 [23]; pumping pressure; pipe inner diameter [25]; and other factors. Conducting the loop test for backfill slurry in the potash mine could provide solid theoretical support for the filling station design. Our previous studies on the slurry transportation characteristics of steel slag cemented backfill for potash mines through loop tests have found that the combined effect of solid content and cementing agent content is crucial in influencing pressure loss in backfill slurry for potash mines [26]. However, the method of transporting lime-cemented backfill slurry in the loop test has not been investigated. Through loop tube tests, this study studied lime-cemented backfill slurry transportation characteristics for potash mines. Eleven lime-cemented backfill materials that met the laboratory flowability and strength requirements were selected for the test. The parameters for the lime-cemented backfill process were optimized for underground potash mines through model simulation. This paper provides reliable theoretical support for the design of lime-cemented backfill processes for underground mines.

2. Materials and Methods

2.1. Materials

2.1.1. Lime

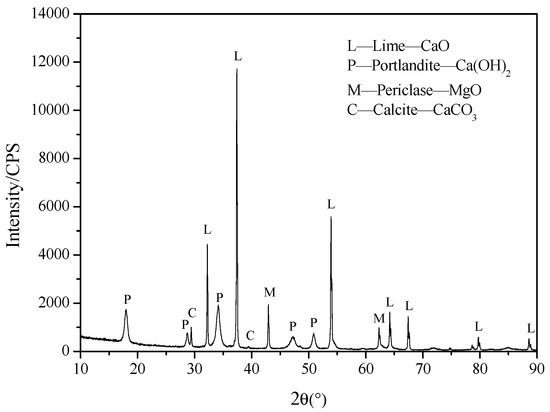

The lime raw material used in the test was locally quarried limestone from Laos, with its chemical composition described in Table 1. The limestone was crushed to −20 mm and then calcined at 1000 °C for 8 h. After calcination, the lime was ground in a SM φ500 × 500 test mill for 5 min to produce a binder for potash mine cemented backfill materials. Table 1 displays the chemical composition of the lime. The XRD pattern of the calcined and ground lime (Figure 1) revealed the primary minerals as lime (CaO), portlandite (Ca(OH)2), periclase (MgO), and calcite (CaCO3). The particle size distribution is shown in Table 2.

Table 1.

Chemical compositions of lime.

Figure 1.

XRD pattern of calcined and ground lime.

Table 2.

Particle size distribution of calcined lime after grinding.

2.1.2. Tailings

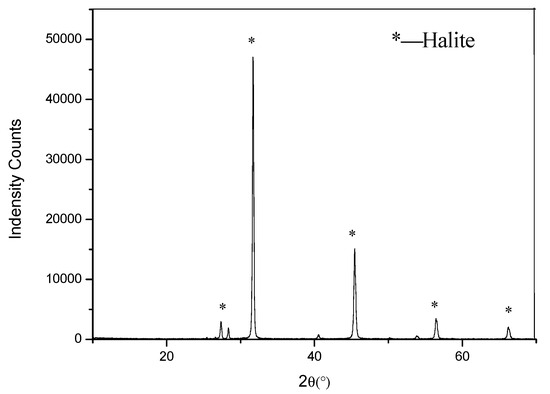

The potash mine tailings, upon receipt, exhibited a granular shape and colors ranging from colorless to milky white. The predominant mineral present in the tailings, as determined by X-ray diffraction, was NaCl, making up over 95% (Figure 2). The coarse-grained tailings (>2.5 mm) were separated and ground for 10 min using a SM φ500 × 500 mini mill. After grinding, the samples were blended with the fine-grained tailings (−2.5 mm) in the same proportion as before separation. This mixture constituted the final tailings used for preparing backfilling materials. The particle size distribution of the final tailings is presented in Table 3.

Figure 2.

XRD analysis of tailing of potash mine.

Table 3.

The size distribution of tailings for backfill material preparation.

2.1.3. Brine Water

The potash mine brine was colorless when pure but turned dark yellow with specific impurities. Its density was 1.25 g/cm3. The salt concentration in Table 4 presents the salt concentration for the elemental analysis of the brine water, which was conducted using an Inductively Coupled Plasma Optical Emission Spectrometer (ICP-OES) (Optima 8300, Perkin Elmer, USA).

Table 4.

Salt concentration in the brine water.

2.2. Experiments

2.2.1. Backfill Slurry Preparation

Backfill slurry was prepared using lime as a binder, tail salt as aggregate, and waste brine water as a water source. Table 5 shows the 11 designed ratios for the loop test. The ratios were selected according to our former lab-scale study [20]. We found that to obtain satisfied flowability and strength, when lime dosage is 0.5–1%, the solid content should be 70–75%; when lime dosage is 1–2%, the solid content should be 60–65%; and when lime dosage it 2–3%, the solid content should be 55% or below.

Table 5.

The mixing ratio of the looping pipe test.

2.2.2. Loop Test

The loop test system comprises several subsystems: batching, pumping, detection, pipeline, and automatic control. The pipeline features an inner diameter of 80 mm, a maximum stirring capacity of 0.4 m3, and a theoretical maximum flow rate of 40 m3/h. It was designed for pumping pressures between 2 and 4 MPa, a slump exceeding 150 mm, and a rated power of 70 kW at 380 V. The optimal test temperature range is 10–35 °C, with a maximum flow speed of 2.2 m/s and a maximum aggregate size of 16 mm for pipe transport. The loop test system is similar to that of Wu et al. [25,27].

For each test, the backfill slurry was mixed in the agitator and then transferred to the pump for circulation. The transfer pump subsequently delivered the material to the 80 mm loop pipe for processing. The flow rate of the backfill slurry is approximately 29 m3/h when it is circulated stably. Given the fast reaction speed of lime and potash mine tailings, the circulation time is set to be as long as possible to ensure safe transportation. Test parameters such as pressure, temperature, flow rate, and pressure loss were monitored using sensors. The computer software collected data and displayed the results. The pipeline must be thoroughly flushed with a high-pressure water gun before and after a similar simulation test to the backfill slurry loop test.

To obtain backfill material slurry for the loop test, lime, tailings, salt, and brine water were mixed and stirred evenly according to the ratio listed in Table 5. The circulating backfill material slurry was sampled regularly to test its flowability and compressive strength.

2.2.3. Flowability

The fluidity and slump of the backfill slurry were measured according to GB/T 2419-2005 [28], which outlines the cement mortar fluidity determination method, and GB/T 50080-2016 [29], which provides the standard for testing the performance of ordinary concrete mixtures.

2.2.4. Compressive Strength

The remaining backfill material from the loop test was evenly poured into a standard triple test mold measuring 100 mm × 100 mm × 100 mm and vibrated on a concrete vibrating table to shape it. To replicate the conditions of actual mined-out areas, the mold was placed in a standard chamber maintained at a temperature of 40 °C and a relative humidity of 27 ± 3%. After curing for 3 days, the backfill materials were demolded and returned to the standard chamber, where they were cured at a temperature of 40 °C and a relative humidity of 27 ± 3% for an additional 28 days. The compressive strength of the test block was evaluated after 28 days in accordance with GB/T 50107-2010 [30] which provides the standard for evaluation of concrete compressive strength.

3. Results

3.1. Results of Loop Pipe Test on Backfill Material with Lime as Binder

3.1.1. Flowability Variation of Lime-Cemented Backfill Slurry

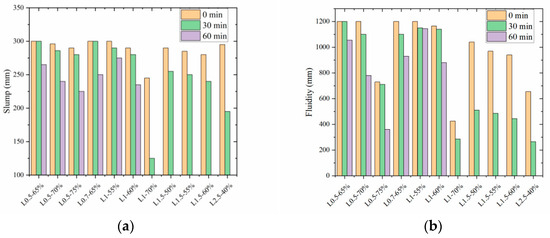

The measurement of slump and fluidity effectively indicates the flowability of filling material, aiding in the evaluation of its workability and quality. Ideal slump and fluidity are crucial for safely pumping filling materials. Figure 3 shows the slump and fluidity results of the backfill slurry after 0, 30, and 60 min of loop testing.

Figure 3.

Measurement results of the flowability of lime-cemented backfill slurry (a) slump, (b) fluidity.

As illustrated in Figure 3a, the slump of the lime-cemented backfill slurry decreased as the loop testing time increased. The fluidity exhibited a similar pattern of change (Figure 3b). Before loop testing, the slump of all samples ranged from 240 to 310 mm, indicating that their flowability met the standard for work performance. However, after 30 min of loop testing, the slump of all samples decreased, though the change was not significant. After 60 min of loop testing, the slump and fluidity of five samples could not be measured, indicating that these backfill slurries had lost their flowability. This demonstrates that the hydration and bonding effect of the lime binder is very rapid.

With an increase in lime dosage, both the slump and fluidity of the backfill slurry decreased, with an increasing rate of change. When the sampling time was the same and the solid concentration of the backfill slurry was 70%, the slump and fluidity of the slurry with a lime dosage of 0.5% were higher than those with a lime dosage of 1%. Thus, a higher lime dosage resulted in poorer flowability of the backfill slurry. When the lime dosage is fixed and the solid content of the backfill slurry increases, the slump and fluidity of the backfill slurry decrease, and the rate of change increases. Regardless of whether the lime dosage is 0.5%, 1%, or 1.5%, increasing the solid content consistently lowers the flowability of the backfill slurry, affecting slump and fluidity.

Consequently, when utilizing lime as a binder for preparing backfill materials, it is essential to carefully manage the solid content of the backfill slurry and the delivery time. If the control is inappropriate, pipe blockage or even pipe burst accidents will likely occur.

3.1.2. Pressure Loss at a Bending Pipe

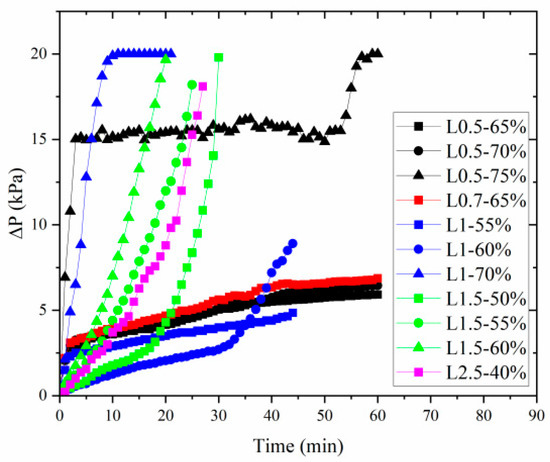

During the loop pipe test, each of the 11 groups of lime-cemented backfill slurry was circulated continuously in the pipeline. The pressure loss of slurry at a 90° bend pipe (∆P) was monitored promptly. Figure 4 shows the changes of ∆P with loop testing time. There are three types of ∆P curves.

Figure 4.

Pressure loss of lime-cemented backfill slurry in a bending pipe at different loop testing times.

Type I: ∆P increased rapidly in the first 5 min, then slowed. At 60 min, ∆P remains below 8 kPa. The backfill slurries with a type I curve are L0.5-65%, L0.5-70%, L0.7-65%, and L1-55%. The pressure loss at a bend pipe for these backfill slurries is relatively stable. During the transportation process, the likelihood of pipe blockage due to significant P is negligible in the low-value range.

Type II: ∆P rises initially, then quickly climbs to 20 kPa. The backfill slurries with a type II curve mainly consist of L1.5-50%, L1.5-55%, L1.5-60%, L2.5-40%, and L-70%. As lime dosage and solid concentration increase, the time for P to rise rapidly decreases. This outcome aligns with the slump results of the backfill slurry. In this scenario, reducing the transportation time is necessary to minimize the risk of pipe blockage.

Type III: ∆P rapidly exceeds 15 kPa within the first 10 min and then stabilizes at a high level. The backfill slurries with a type III curve include L0.5-75% and L1-70%. This type of backfill slurry is prone to pipe blockage incidents due to excessive pressure loss in bent pipes.

3.1.3. Pressure Loss per Meter in a Horizontal Pipe

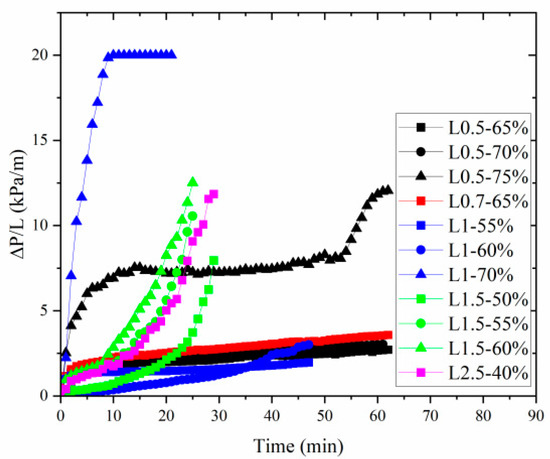

When the backfill slurry circulates in the annular pipe during pipe testing, two pressure-monitoring points, spaced 10 m apart, are positioned along the horizontal pipe. Each detected pressure value is automatically recorded and output. Subsequently, the pressure loss per meter of the lime-cemented backfill slurry in a horizontal pipe (∆P/L) is calculated. Figure 5 illustrates the variations in ∆P/L for 11 different lime-cemented backfill slurries over the duration of pipe testing.

Figure 5.

The pressure loss per meter of lime-cemented backfill slurry in the horizontal pipe at various testing times.

As illustrated in Figure 5, the backfill slurry achieves a stable circulation state within 2 min of loop testing. Subsequently, ∆P/L begins to rise. When the lime dosage is 0.5%, the ∆P/L of backfill slurry with 75% solid content is significantly higher compared to those with 65% and 70% solid contents. With a lime dosage of 0.5% and a solid content of 75%, the ∆P/L rapidly exceeds 7 KPa/m within 10 min and then fluctuates more slowly. After 50 min of loop testing, ∆P/L increases sharply again, reaching 11.84 KPa at 60 min. This trend aligns with the pressure loss at the pipe bend.

When the lime dosage was 1%, the changes in ∆P/L for backfill slurry with 70% solid content were quite different from those with 55% and 60% solid content. At a lime dosage of 1% and a solid content of 70%, ∆P/L of the backfill slurry reached 20 KPa/m in just 10 min of loop testing, surpassing the maximum range of the pressure-measuring instrument. Meanwhile, ∆P/L for the backfill slurry with 55% and 60% solid content increased gradually. After 35 min of loop testing, the ∆P/L of the backfill slurry with a lime dosage of 1% and a solid content of 60% began to increase rapidly, aligning with the change in pressure loss at the pipe bend.

When the lime dosage was 1.5% and 2.5%, the ∆P/L of backfill slurry exhibited a similar changing trend, increasing rapidly from the onset of loop testing. With a lime dosage of 1.5%, after 20 min of loop testing, the ∆P/L of the lime-cemented backfill slurry with 50%, 55%, and 60% solid contents were 2.1 KPa/m, 5.6 KPa/m, and 8.2 KPa/m, respectively. Subsequently, the ∆P/L of these backfill slurries increased sharply. The observable phenomenon was that the backfill slurry became particularly viscous and exhibited poor flowability. With a lime dosage of 2.5% and a solid content of 40%, the ∆P/L of the backfill slurry reached 5.0 KPa/m after 20 min of loop testing and subsequently rose swiftly to 11.8 KPa/m after 29 min. At this point, the backfill slurry had no flowability, mirroring the pressure difference change observed at the pipe bend in Figure 4.

The backfill slurry with lime binder reacts quickly and has uneven flow properties. As the solid content increases, ∆P/L also rises during loop testing. Solid content is crucial in the lime-cemented filling material system.

3.2. Expanded Simulation Calculation

3.2.1. Case Study

The slurry transportation in the backfill project consists of a 300 m vertical pipe and a 5000 m horizontal pipe. The designed backfill volume is 4750 m3/day for 330 days/year, resulting in an annual filling volume of 1.568 million m3/year. With three 8 h shifts per day, the backfill volume is 198 m3/h, or 0.055 m3/s. Considering a flow fluctuation coefficient of 0.9–1.1, the backfill material flow fluctuation is 0.0495–0.0605 m3/s. The backfill pipe diameter on site is 159 mm, corresponding to a flow rate of 2.49–3.04 m/s, with an average flow rate of 2.77 m/s.

3.2.2. Theoretical Free-Flow Distance

In the loop test, the average flow rate of the backfill slurry in an 80 mm pipe is 29 m3/h. The pumping distance can reach 1.4 km in 60 min. Based on the pumping times for various lime dosages and solid content, the estimated conveying distances are shown in Table 6. The results align with changes in the slump and expansion of the slurry, indicating that the slurry’s expansion can guide its pumping.

Table 6.

Calculation of relevant data from loop pipe test on lime-cemented backfill slurry.

The theoretically free flow distance Sf can be calculated using Equation (1):

where, Ps is the pressure loss per unit distance in the horizontal pipe kPa·m−1; Pb is the pressure loss at the bend pipe, kPa; and Pf is the weight pressure generated by the backfill slurry, which can be calculated using Equation (2):

where is the backfill slurry density, g.cm−3; h is the simulated vertical pipe length; and the actual backfill height is 300 m.

Table 6 shows the theoretical free-flow distance results. They indicate that lime-cemented backfill slurry cannot free-flow for 5 km, so a pump is needed to provide power for transportation. Under loop pipe test conditions, a lime dosage of 0.5 or 0.7 allows transportation beyond 5 km. However, with a lime dosage higher than 1, even timely pumping cannot achieve a 5 km distance.

3.2.3. Critical Flow Rate for Engineering Applications

There are currently three formulas for calculating critical velocity: the B.C. Knorrhodz formula, the Wasp formula, and the Dezhong Liu formula. The Wasp formula is applicable to medium- and low-concentration backfill slurry with a particle size greater than 0.05 mm, requiring continuous aggregate gradation. The Dezhong Liu formula is suitable for backfill slurry with a particle size less than or equal to 0.05 mm or high-concentration backfill slurry with a particle size greater than 0.05 mm. The B.C. Knorrhodz formula is applicable to solid material with a density less than 3 t/m3. Both the Dezhong Liu formula and the B.C. Knorrhodz formula can be used for calculation in this study. However, the critical velocity calculated by the B.C. Knorrhodz formula is larger than the value measured by the test, making it safer for slurry pipeline transportation design. Therefore, the B.C. Knorrhodz formula is used for the following calculation.

The critical flow rate is calculated using the B.C. Knorrhodz Formula (3):

where P is the weight ratio of sand to water; β is the correction coefficient for the solid material ratio; D is the critical pipe diameter, which is 159 mm in the case study.

The weight ratio of sand to water (P) can be calculated by Equation (4):

where Cw is the concentration of backfill material.

The correction coefficient for solid material ratio (β) is calculated by Equation (5),

where is the density of solid material. Specific parameters are shown in Table 7.

Table 7.

Calculation of critical flow rate in annular pipe test.

Table 7 presents the calculated critical velocity (v′) for backfill slurry with various lime dosages and solid contents. In practice, the actual critical velocity (v) of the slurry in the backfill pipeline system is typically around 15% higher than the theoretical critical velocity. In the backfill case study, the minimum transportation velocity of the slurry is 2.49 m/s, which exceeds the actual critical velocity listed in Table 7. By ensuring proper standardized operation and the correct use of pipeline components, pipe blockages can be avoided.

3.2.4. Comparison Between Calculated and Measured Pressure Loss per Meter in the Straight Pipe

To achieve a more accurate industrial design, the loss per unit distance in the horizontal pipe is calculated based on the loop pipe test using the resistance of average particle size of 0.4–10 mm. Formula (6) is as follows:

where, k is the reaction coefficient, min−1; t is the pumping time, min; is the slurry density, t·m−3; v is the average flow rate of the slurry, m/s; vs is the settling velocity of solid particles, m/s; g is the acceleration due to gravity, 9.8 m·s−2; D is the pipe diameter, m; C is the ratio of d90 to d10.

Because the backfill material is in a turbulent state in the pipeline during the filling process, that is, Re (Reynolds number) > 4000, the particle settling velocity satisfies the Rettinger formula, which is Equation (7).

where ds is the average diameter of solid particles, m; s is the density of solid particles, t/m3; w is the density of tailings brine, t/m3; cs is the shape correction factor.

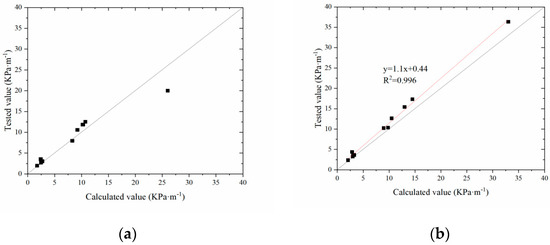

Resistance loss was calculated based on literature parameters and lab data. Figure 6a compares these calculations with test results for an 80 mm loop pipe diameter. When pressure loss in the horizontal pipe of lime-cemented backfill slurry is below 15 kPa/m, calculated values align closely with test values within a 15% error margin. However, when pressure loss exceeds 15 kPa/m, the error increases significantly to 31.44%. Thus, the empirical formula accurately predicts test values for lower pressure losses, providing theoretical guidance for backfill process design.

Figure 6.

Comparison of measured and calculated pressure difference per unit distance in a straight pipe filled with slurry; (a) loop pipe test and (b) field test.

To verify the calculation formula for field application, a pipe diameter of 159 mm and a flow rate of 2.77 m/s were used in Equation (6) to calculate the pressure loss, which was then compared with field measurements. Figure 6b shows that the tested and calculated pressure loss per unit distance in the horizontal pipe demonstrates a linear correlation, despite some discrepancies. As pressure loss increases, the error also rises. The actual site closely aligns with the empirical formula. Introducing a k value can adjust the empirical formula to accurately calculate the pressure loss per unit distance at the backfill site.

3.3. Compressive Strength of Backfill Materials

To verify the feasibility of the mechanical properties of lime-cemented backfill materials, the samples before and after the loop test were placed in a simulated underground mine-out area for curing. The compressive strength at various curing ages was tested, and the results are shown in Table 8.

Table 8.

Compressive strength test results of test blocks.

As shown in Table 8, under the same lime dosage, when the solid content exceeds 65%, the compressive strength of backfill materials after the loop test is generally higher than that before the loop test. Conversely, when the solid content falls below 60%, the compressive strength of backfill materials after the loop test is usually lower than before the loop test. This phenomenon primarily occurs because high solid content results in increased friction between particles and between the particles and the pipe wall when the backfill slurry circulates continuously during the loop test. This circulation diminishes the particle size, enhancing the contact area between lime and tail salt aggregate, which promotes the hydration reaction. In contrast, when the solid content is low, this friction effect is minimal and has a limited impact on the compressive strength of backfill materials.

Table 8 shows the compressive strength of the backfill materials. As noted, the compressive strength of most backfill materials after curing exceeds 1 MPa, satisfying the design requirements. Considering the flowability of the backfill slurry, filling materials with a lime dosage of 0.5 and solid contents of 65%, 70%, 75%, and a lime dosage of 0.6 and a solid content of 65%, are good choices. Among these, the lime dosage of 0.5 combined with a solid content of 75% represents the optimum condition, where the lime dosage is the lowest and the compressive strength is the highest, allowing for 5 km of horizontal transport pumping.

4. Discussion

The pressure loss of lime-cemented backfill material is time-dependent due to the quick consolidation of lime binder. Studies on cemented backfill materials with binders like fly ash [25,27], steel slag [24], and cement [23,31] usually focus on transportation parameters’ effects on pressure loss, as their pressure remains relatively stable during loop testing. This study shows that both binder dosage and solid content are crucial for flowability. Jin et al. [26] also noted this when using steel slag for potash mine backfill materials.

Using lime as a binder offers several benefits over steel slag and other alternatives. Lime achieves high strength with minimal dosage (0.5% to 2%), saving resources. Lime, derived from widely available limestone, is easily accessible. The transportation distance between binder sources and mines impacts costs. Lime enhances resource availability, reduces environmental emissions, and is cost-effective and eco-friendly.

5. Conclusions

This paper employs a loop pipe test to investigate the effects of lime dosage and solid content on the pipeline transportation characteristics of lime-cemented backfill slurry for a potash mine. Through model calculations, the study predicts and verifies the transportation behavior and feasibility of lime-cemented backfill materials within the field backfill environment of a potash mine. The main conclusions are as follows:

- (1)

- With the increase of lime dosage and solid content, the slump and fluidity of the backfill slurry decrease over time, with an accelerated rate of decline. To ensure that the backfill slurry remains flowable after 60 min, the solid content should be below 70% when the lime dosage is 1%, below 55% when the lime dosage is 1.5%, and above 40% when the lime dosage is 2.5%.

- (2)

- There are three patterns of pressure loss curves in bend pipes for lime-cemented backfill slurry. The change in the pressure loss per unit distance in a horizontal pipe of the lime-cemented backfill slurry is similar to the pressure loss in the bend pipe.

- (3)

- Under the actual backfill case, the theoretical free-flowing distance of the backfill slurry at the 11 designed lime dosage and solid contents is less than 2.5 km. The backfill material with lime dosages of 0.5 and 0.7 can be transported by pumping for 5 km.

- (4)

- The adjusted B.C. Knorrhodz formula can meet the requirements for calculating the critical flow rate of potash mine backfill materials. In actual backfill cases, the slurry flow rate is greater than the designed critical flow rate of the backfill material and will not cause pipe blockage.

- (5)

- The pressure loss per unit distance in a horizontal pipe of backfill slurry can be calculated using the formula. With the increases in pressure loss per unit distance in a horizontal pipe, the error of calculation increased. The calculated value aligns closely with the field test value. By introducing a k value, the pressure loss per unit distance in a horizontal pipe in the backfill site can be accurately predicted by calculation.

- (6)

- The compressive strength of the lime-cemented backfill materials after the loop tube test is comparable to that before the loop tube test. When the solid content exceeds 65%, the compressive strength of the lime-cemented backfill materials after the loop tube test is slightly greater than before the loop tube test. Particle friction under high solid content promotes hydration consolidation.

Author Contributions

Conceptualization, W.N.; methodology, R.J., S.Z. and X.M.; validation, X.W.; formal analysis, R.J. and J.L.; investigation, R.J., X.M. and X.W.; resources, H.H.; data curation, H.H.; writing—original draft preparation, R.J.; writing—review and editing, J.L., D.N. and M.H.; supervision, W.N.; project administration, M.H.; funding acquisition, S.Z. and W.N. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Key R&D Program of China, grant number 2023YFC3805103, Guizhou Provincial Science and Technology Project, grant number Qianke Hezhong Yindi (2025) 011.

Data Availability Statement

The data is unavailable due to privacy restrictions.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zheng, M.; Hou, X.; Zhan, Y.; Xing, E.; Li, H.; Yin, H.; Yu, C.; Wang, N.; Deng, X.; Wei, Z.; et al. The Latest Progress in the Investigation of Potash Resources in Western China. China Geol. 2018, 2, 392–401. [Google Scholar] [CrossRef]

- Bai, J.; She, Y. Study on the exploration and development of the potash in the world. China Min. Mag. 2017, 26, 1–4. [Google Scholar]

- Wang, X.; Wang, Q.; Zhang, B.; Ni, W.; Jin, R.; Zhao, K. Hydration Mechanism of Using Steel Slag as Binder for Backfill Materials in Potash Mines. Chinese J. Eng. 2018, 40, 1177–1186. [Google Scholar]

- Shang, P.; Qi, C.; Jiao, S.; Xiong, X.; Guan, B.; Zhang, Y. Potash Assessment Models and Resource Potential Analysis in China. Geol. Bull. China 2019, 38, 1758–1767. [Google Scholar]

- Tang, Q.; Zhang, X.Y.; Miao, W.; Ma, H.; Li, Y.; Li, W.; Yuan, X. Mineralogical Characteristics and Sedimentary Environment Significance of Water-Insoluble Minerals in Potash Deposits of Vientiane Basin of Laos. Carbonates Evaporites 2021, 36, 70. [Google Scholar]

- Zhao, Y.; Ma, Z.; Qiu, J.; Sun, X.; Gu, X. Experimental study on the utilization of steel slag for cemented ultrafine tailings backfill. Powder Technol. 2020, 375, 284–291. [Google Scholar]

- Zhao, Y.; Qiu, J.; Zhang, S.; Guo, Z.; Wu, P.; Sun, X.; Gu, X. Low carbon binder modified by calcined quarry dust for cemented paste backfill and the associated environmental assessments. J. Environ. Manag. 2021, 300, 113760. [Google Scholar] [CrossRef]

- Liu, B.; Liu, Y.; Zhang, L.; Fan, X. Mechanical Behavior and Acoustic Emission Characteristics of Cemented Tailings Backfill with Varied Water Loss. Geotech. Geol. Eng. 2024, 42, 6005–6025. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, S.; Yang, T.; Yang, T.; Wang, Y.; Li, J.; Li, K. The influence of coal gangue dosage and concentration on the properties and hydration mechanism of fly ash-based cemented filling materials. J. Clean. Prod. 2025, 492, 144903. [Google Scholar] [CrossRef]

- Wang, X.; Ni, W.; Jin, R.; Liu, B. Formation of Friedel’s Salt Using Steel Slag and Potash Mine Brine Water. Constr. Build. Mater. 2019, 220, 119–127. [Google Scholar] [CrossRef]

- Li, Q.; Li, J.; Zhang, S.; Huang, X.; Wang, X.; Wang, Y.; Ni, W. Research Progress of Low Carbon Cementitious Materials Based on Synergistic Industrial Wastes. Energies 2023, 16, 2376. [Google Scholar] [CrossRef]

- Zhao, Y.; Sun, Y.; Guo, Z.; Sun, X.; Qiu, J. Increasing arsenic immobilization capacity of a binder prepared by arsenic-containing biohydrometallurgy waste: Effects of ferric/ferrous salts addition. J. Environ. Chem. Eng. 2023, 11, 110206. [Google Scholar] [CrossRef]

- Qi, G.; Wang, D.; Xu, D.; Zhang, D.; Wang, Q.; Tang, Y.; Zhu, Y. Analysis of lime paste and bricks from the Ming Dynasty: Composition, structure, properties, and adhesion mechanism. Constr. Build. Mater. 2025, 461, 139929. [Google Scholar] [CrossRef]

- Parra-Fernandez, C.; Arizzi, A.; Secco, M.; Cultrone, G. The manufacture of natural hydraulic limes: Influence of raw materials’ composition, calcination and slaking in the crystal-chemical properties of binders. Cem. Concr. Res. 2024, 185, 107631. [Google Scholar] [CrossRef]

- Athira, V.S.; Lekshmi, S.; Sharanya, A.G.; Tripathi, A.; Manohar, S. Potential application of bio-admixtures in synthesizing traditional lime binders- A comprehensive review. J. Build. Eng. 2024, 90, 109464. [Google Scholar] [CrossRef]

- Zhang, D.; Xu, D.; Wang, Y.; Cui, S.; Wang, D. Study on the fluid-solid transition mechanism of natural hydraulic lime pastes: Consider the water to binder ratio and polycarboxylate superplasticizer. Constr. Build. Mater. 2024, 453, 139119. [Google Scholar] [CrossRef]

- Zhao, Y.; Qiu, J.; Zhang, S.; Guo, Z.; Ma, Z.; Sun, X.; Xing, J. Effect of sodium sulfate on the hydration and mechanical properties of lime-slag based eco-friendly binders. Constr. Build. Mater. 2020, 250, 118603. [Google Scholar] [CrossRef]

- Zheng, J. An experiment research on the optimization of fines and lime contents of tailings-binder pastes backfills for mining. J. Xiangtan Min. Inst. 2000, 4, 68–70. [Google Scholar]

- Li, L.T.; Yang, Z.Q.; Gao, Q. Experiment on Proportion Optimization of Filling Cementitious Material on Tailings from Shirengou Iron Mine. Met. Mine 2016, 45, 177–180. [Google Scholar]

- Jin, R.; Wang, X.; Ma, X.; Huo, H.; Zhang, S.; Li, J.; Ni, W. Hydration mechanisms of gelled paste backfill for potash mines using lime as a gel material. Gels 2024, 10, 832. [Google Scholar] [CrossRef]

- Lesmana, A.; Hitch, M. Heavy media coal hydro-transport in Malinau, Indonesia: A Process Study. Int. J. Min. Miner. Eng. 2021, 3, 1–15. [Google Scholar] [CrossRef]

- Yin, S.; Shao, Y.; Wu, A.; Wang, H.; Liu, X.; Wang, Y. A systematic review of paste technology in metal mines for cleaner production in China. J. Clean. Prod. 2020, 247, 119590. [Google Scholar] [CrossRef]

- Qi, C.; Guo, L.; Ly, H.B.; Van Le, H.; Pham, B.T. Improving pressure drops estimation of fresh cemented paste backfill slurry using a hybrid machine learning method. Miner. Eng. 2021, 163, 106790. [Google Scholar] [CrossRef]

- Wang, Y.; Na, Q.; Wu, A.; Zhang, H.; Wang, G.; Wang, Y.; Zhang, W.; Wang, X. Comparison of resistance between pipe loop test and theoretical calculations in fly ash−slag slurry. J. Cent. South Univ. Sci. Technol. 2022, 53, 2234–2244. [Google Scholar]

- Wu, D.; Yang, B.; Liu, Y. Pressure drop in loop pipe flow of fresh cemented coal gangue–fly ash slurry: Experiment and simulation. Adv. Powder Technol. 2015, 26, 920–927. [Google Scholar] [CrossRef]

- Jin, R.; Wang, X.; Zhang, S.; Huo, H.; Li, J.; Wen, N. Slurry transportation characteristics of potash mine cemented paste backfills via loop tests processing. Processes 2024, 12, 2929. [Google Scholar] [CrossRef]

- Wu, D.; Yang, B.; Liu, Y. Transportability and pressure drop of fresh cemented coal gangue-fly ash backfill (CGFB) slurry in pipe loop. Powder Technol. 2015, 284, 218–224. [Google Scholar] [CrossRef]

- GB/T2419-2005; Test Method for Fluidity of Cement Mortar. State General Administration of the People’s Republic of China for Quality Supervision and Inspection and Quarantine, National Standardization Administration: Beijing, China, 2005.

- GB/T50080-2016; Standard for Test Method of Performance on Ordinary Fresh Concrete. Ministry of Housing and Urban-Rural Development, State General Administration of the People’s Republic of China for Quality Supervision and Inspection and Quarantine: Beijing, China, 2017.

- GB/T 50107-2010; Standard for Evaluation of Concrete Compressive Strength. Ministry of Housing and Urban-Rural Development, State General Administration of the People’s Republic of China for Quality Supervision and Inspection and Quarantine: Beijing, China, 2010.

- Wang, L.; Cheng, L.; Yin, S.; Yan, Z.; Zhang, X. Multiphase slurry flow regimes and its pipeline transportation of underground backfill in metal mine: Mini review. Constr. Build. Mater. 2023, 402, 133014. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).