Advances in Ozone Technology for Environmental, Energy, Food and Medical Applications

Abstract

1. Introduction

2. Method of Ozone Preparation

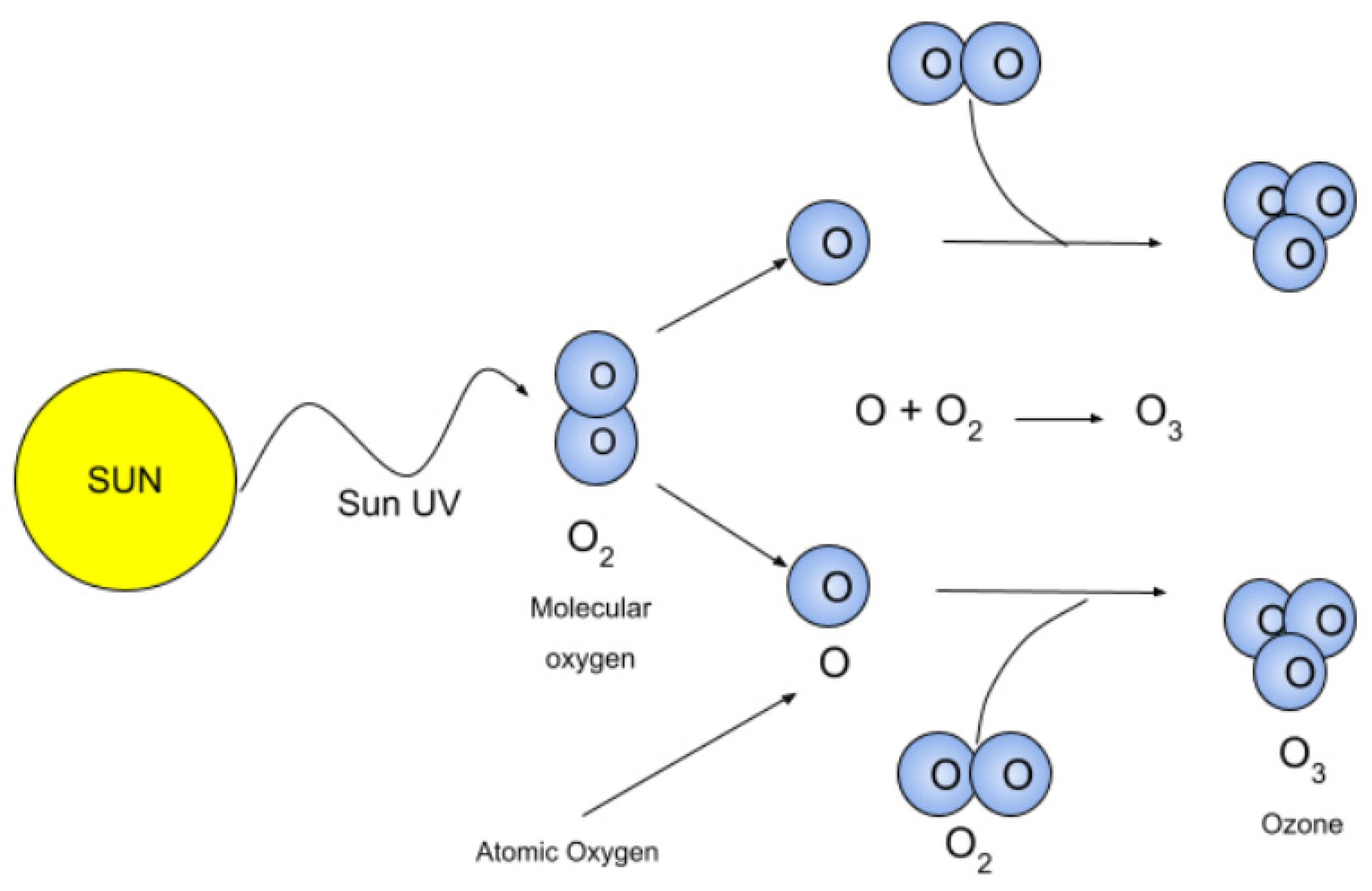

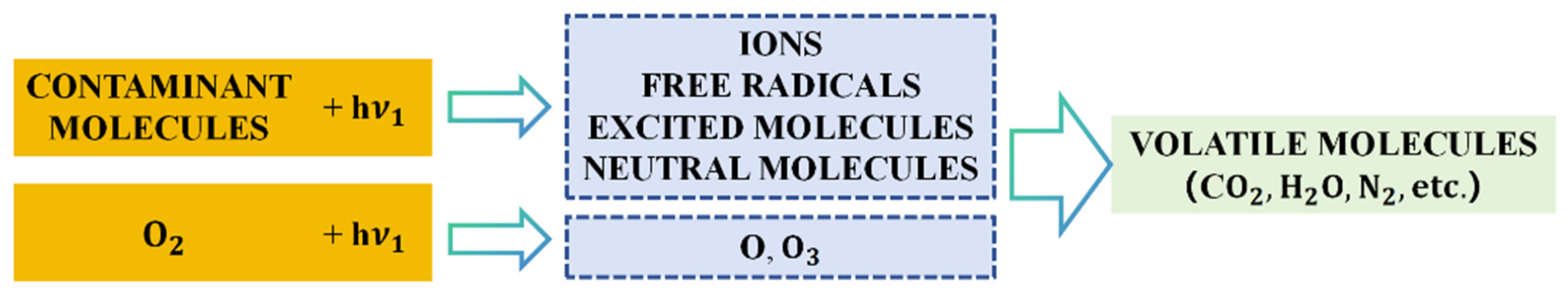

2.1. Ultraviolet Radiation

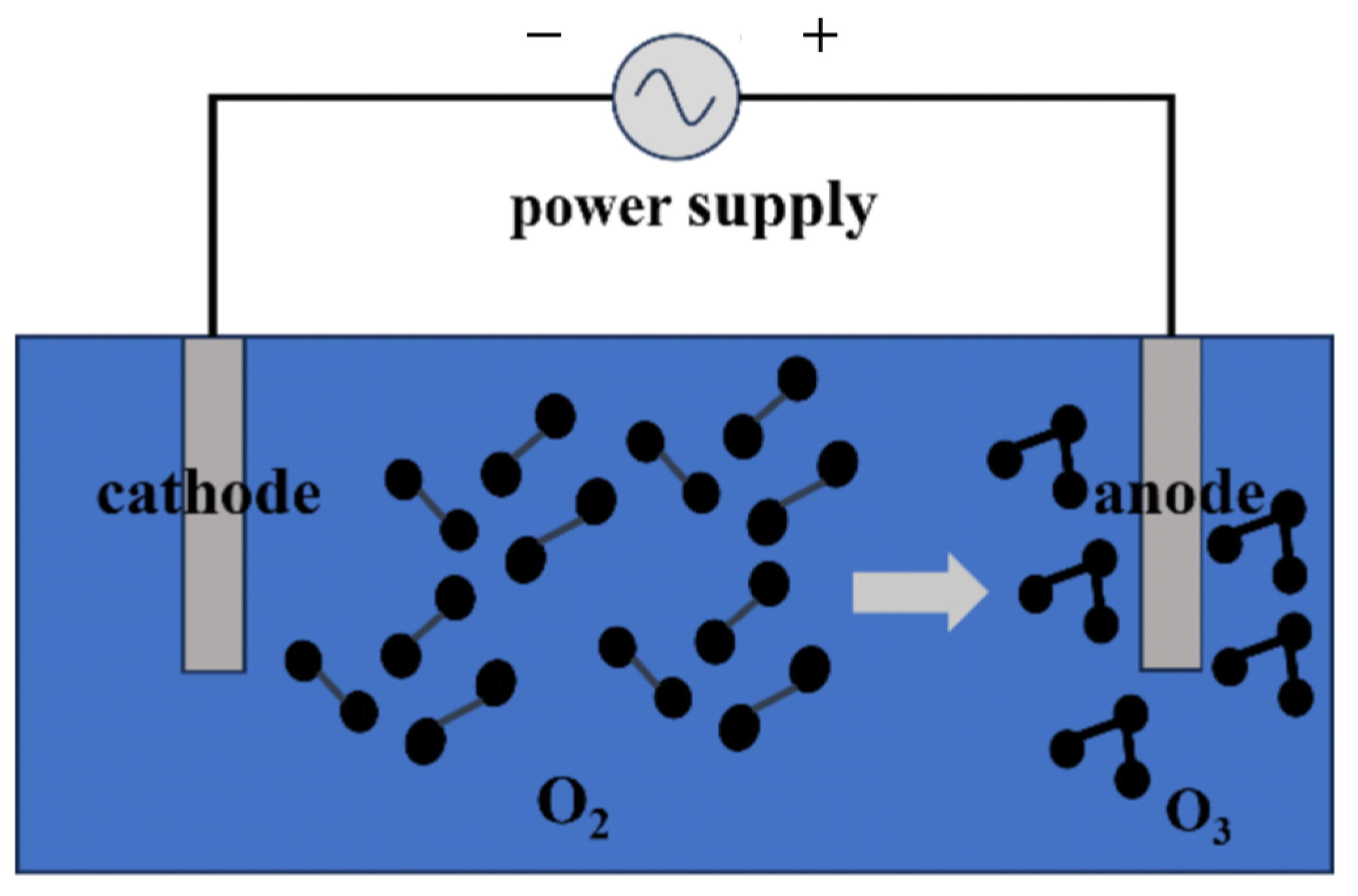

2.2. Electrochemical Ozone Production

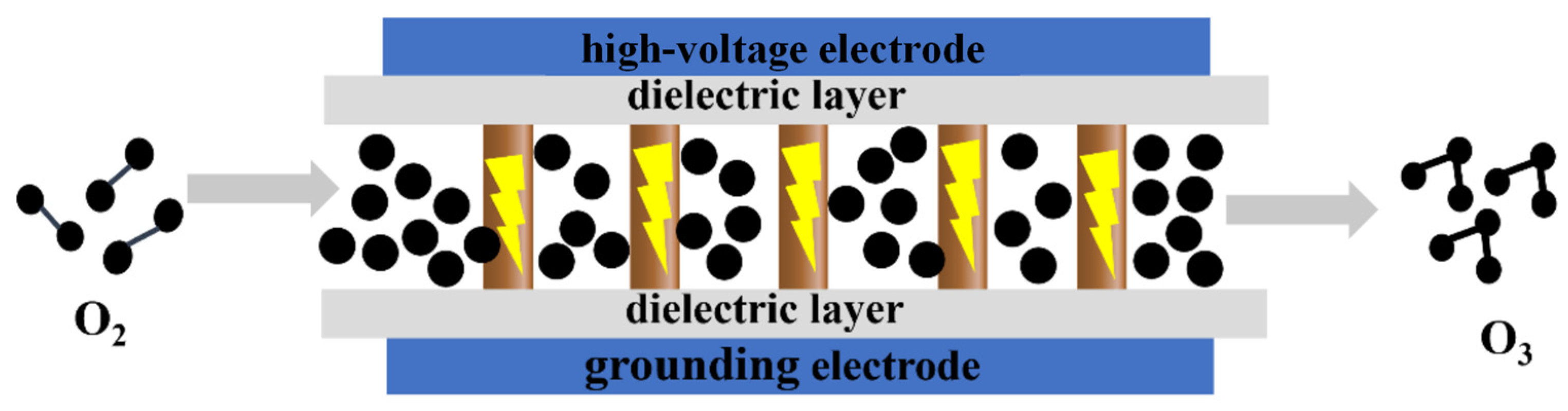

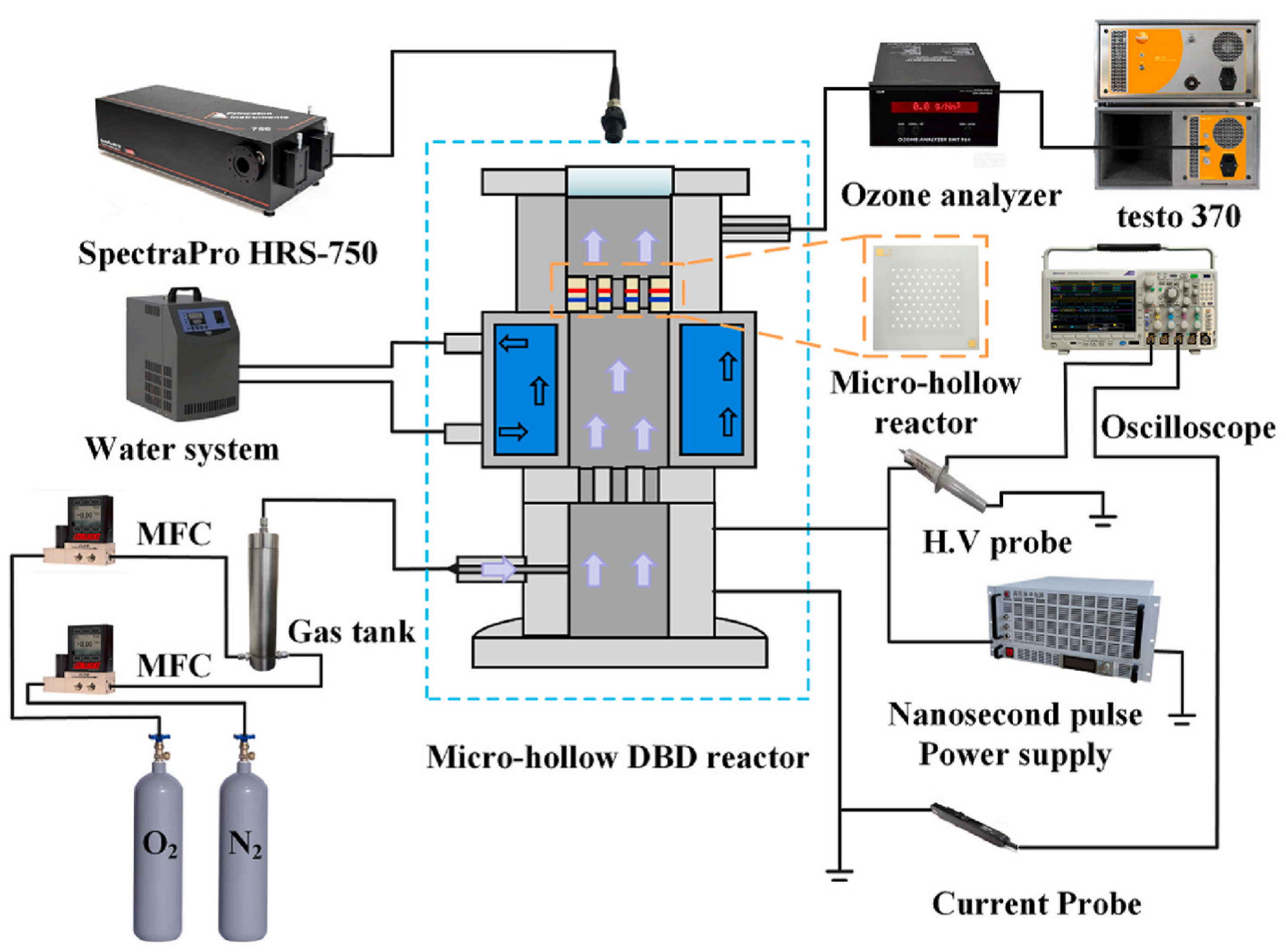

2.3. Dielectric Barrier Discharge

2.4. Other Ozone Generation Methods

2.4.1. Corona Discharge

2.4.2. Pulsed Power Technology

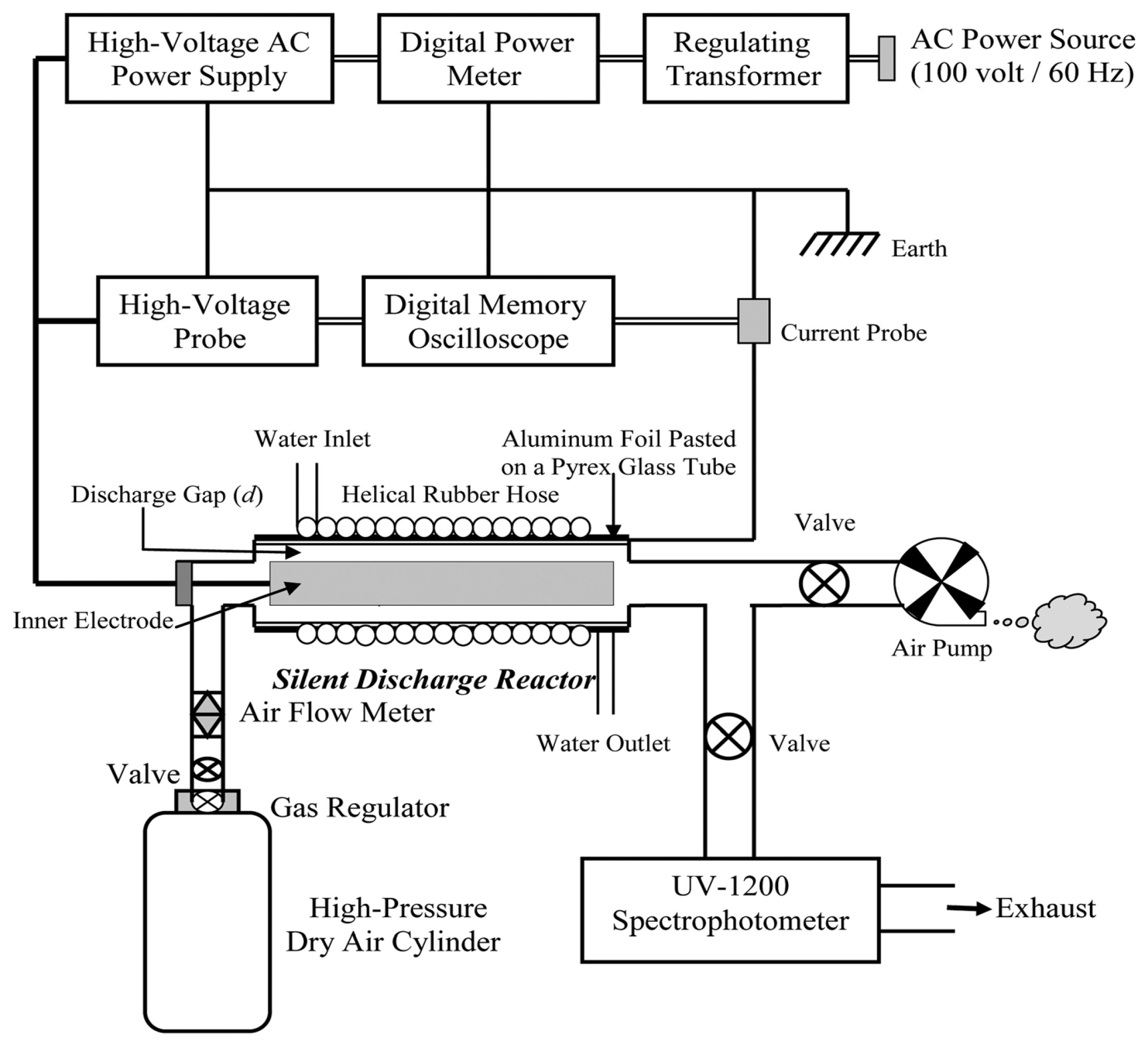

2.4.3. Silent Discharge Plasma

3. Application of Ozone

3.1. Ozone in Environmental Management

3.1.1. Water Treatment

3.1.2. Air Pollution Control

3.1.3. Soil Remediation and Pollution Control

3.2. Ozone in Manufacturing

3.2.1. Industrial Wastewater Treatment

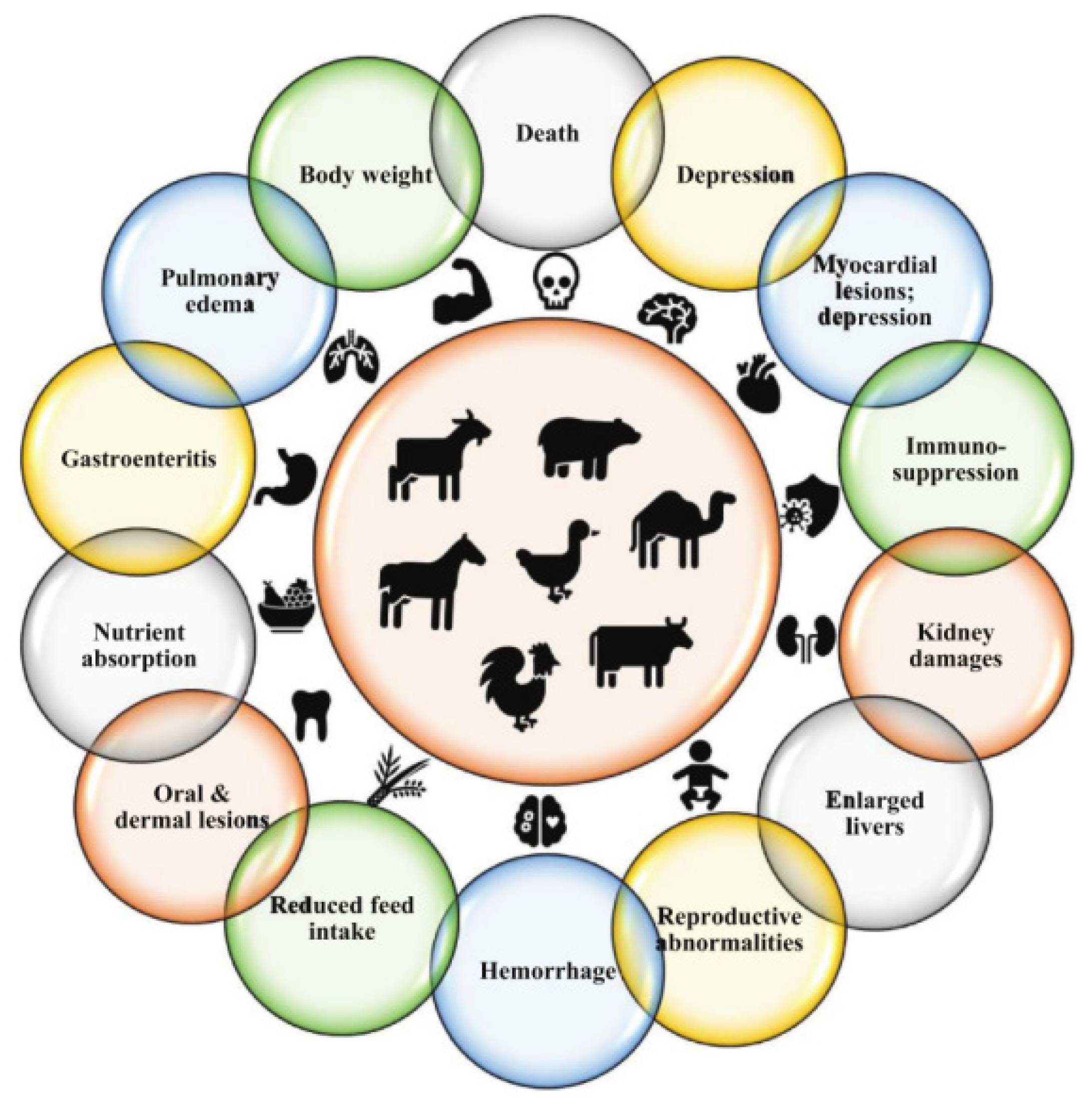

3.2.2. Food Processing and Preservation

3.3. Ozone in Medical Treatment

4. Ozone in the Power Industry

4.1. Ozone in Water Treatment

4.2. Effect of Ozone Air Purification

4.3. Application of Ozone in Equipment Maintenance and Protection

5. Conclusions and Outlooks

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shi, C.; Zhang, S.; Wang, W.; Linhardt, R.J.; Ragauskas, A.J. Preparation of highly reactive lignin by ozone oxidation: Application as surfactants with antioxidant and anti-UV properties. ACS Sustain. Chem. Eng. 2019, 8, 22–28. [Google Scholar]

- Eliasson, B.; Kogelschatz, U. Ozone Generation with Narrow–Band UV Radiation. Ozone Sci. Eng. 1991, 13, 365–373. [Google Scholar] [CrossRef]

- Claus, H. Ozone generation by ultraviolet lamps. Photochem. Photobiol. 2021, 97, 471–476. [Google Scholar]

- Peng, Z.; Day, D.A.; Symonds, G.A.; Jenks, O.J.; Stark, H.; Handschy, A.V.; de Gouw, J.A.; Jimenez, J.L. Significant Production of Ozone from Germicidal UV Lights at 222 nm. Environ. Sci. Technol. Lett. 2023, 10, 668–674. [Google Scholar] [CrossRef]

- Meher, P.; Deshmukh, N.; Mashalkar, A.; Kumar, D. Ozone (O3) generation and its applications: A review. AIP Conf. Proc. 2023, 2764, 070011. [Google Scholar]

- Thanos, J.C.; Wabner, D.W. Elektrochemische abscheidung von sauerstoff und ozon an bleidioxid und platin-anoden in wässrigen elektrolyten mit 18O-markiertem wasser. Electrochim. Acta 1985, 30, 753–756. [Google Scholar]

- Kogelschatz, U.; Eliasson, B.; Hirth, M. Ozone Generation from Oxygen and Air: Discharge Physics and Reaction Mechanisms. Ozone Sci. Eng. 1988, 10, 367–377. [Google Scholar] [CrossRef]

- Gadkari, S.; Gu, S. Numerical investigation of co-axial DBD: Influence of relative permittivity of the dielectric barrier, applied voltage amplitude, and frequency. Phys. Plasmas 2017, 24, 053517. [Google Scholar]

- Valdivia-Barrientos, R.; Pacheco-Sotelo, J.; Pacheco-Pacheco, M.; Benítez-Read, J.S.; López-Callejas, R. Analysis and electrical modelling of a cylindrical DBD configuration at different operating frequencies. Plasma Sources Sci. Technol. 2006, 15, 237. [Google Scholar]

- Jahanmiri, A.; Rahimpour, M.; Shirazi, M.M.; Hooshmand, N.; Taghvaei, H. Naphtha cracking through a pulsed DBD plasma reactor: Effect of applied voltage, pulse repetition frequency and electrode material. Chem. Eng. J. 2012, 191, 416–425. [Google Scholar]

- Gou, X.; Yuan, D.; Wang, L.; Xie, L.; Wei, L.; Zhang, G. Enhancing ozone production in dielectric barrier discharge utilizing water as electrode. Vacuum 2023, 212, 112047. [Google Scholar]

- Jung, J.-S.; Moon, J.-D. Corona discharge and ozone generation characteristics of a wire-plate discharge system with a glass-fiber layer. J. Electrost. 2008, 66, 335–341. [Google Scholar]

- Jin, C.; Lin, F.; Peng, B.; Wei, L.; Ling, Z.; Zeng, X.; Yuan, D.J.V. Nanosecond Pulsed Multi-hollow Surface Dielectric Barrier Discharge for Ozone Production. Vacuum 2025, 238, 114252. [Google Scholar]

- Yehia, A. Assessment of ozone generation in dry air fed silent discharge reactors. Phys. Plasmas 2012, 19, 023503. [Google Scholar]

- Yuan, D.; Wang, Z.; Ding, C.; He, Y.; Whiddon, R.; Cen, K. Ozone production in parallel multichannel dielectric barrier discharge from oxygen and air: The influence of gas pressure. J. Phys. D Appl. Phys. 2016, 49, 455203. [Google Scholar]

- Wei, L.; Yuan, D.; Zhang, Y.; Hu, Z.; Tan, Z.; Dong, G.; Tao, S. An analysis of the effect of inert gases on ozone generation using dielectric barrier discharge in oxygen. Eur. Phys. J. D 2014, 68, 17. [Google Scholar]

- Liang Chen, H.; Ming Lee, H.; Been Chang, M. Enhancement of energy yield for ozone production via packed-bed reactors. Ozone Sci. Eng. 2006, 28, 111–118. [Google Scholar]

- Shang, K.; Wang, M.; Peng, B.; Li, J.; Lu, N.; Jiang, N.; Wu, Y. Characterization of a novel volume-surface DBD reactor: Discharge characteristics, ozone production and benzene degradation. J. Phys. D Appl. Phys. 2019, 53, 065201. [Google Scholar]

- Banaschik, R.; Lukes, P.; Jablonowski, H.; Hammer, M.U.; Weltmann, K.-D.; Kolb, J.F. Potential of pulsed corona discharges generated in water for the degradation of persistent pharmaceutical residues. Water Res. 2015, 84, 127–135. [Google Scholar]

- Lin, F.; Wang, Z.; Zhang, Z.; He, Y.; Zhu, Y.; Shao, J.; Yuan, D.; Chen, G.; Cen, K. Flue gas treatment with ozone oxidation: An overview on NOx, organic pollutants, and mercury. Chem. Eng. J. 2020, 382, 123030. [Google Scholar]

- Glaze, W.H. Drinking-water treatment with ozone. Environ. Sci. Technol. 1987, 21, 224–230. [Google Scholar]

- Rahman, M.; Jasim, S.; Yanful, E.; Ndiongue, S.; Borikar, D. Advanced oxidation treatment of drinking water: Part II. Turbidity, particles and organics removal from Lake Huron water. Ozone Sci. Eng. 2010, 32, 295–304. [Google Scholar]

- Rojas-Valencia, M. Research on ozone application as disinfectant and action mechanisms on wastewater microorganisms. Virus 2011, 3, 263–271. [Google Scholar]

- Ding, W.; Jin, W.; Cao, S.; Zhou, X.; Wang, C.; Jiang, Q.; Huang, H.; Tu, R.; Han, S.-F.; Wang, Q. Ozone disinfection of chlorine-resistant bacteria in drinking water. Water Res. 2019, 160, 339–349. [Google Scholar]

- Paucar, N.E.; Kim, I.; Tanaka, H.; Sato, C. Ozone treatment process for the removal of pharmaceuticals and personal care products in wastewater. Ozone Sci. Eng. 2019, 41, 3–16. [Google Scholar]

- Hollender, J.; Zimmermann, S.G.; Koepke, S.; Krauss, M.; McArdell, C.S.; Ort, C.; Singer, H.; Von Gunten, U.; Siegrist, H. Elimination of organic micropollutants in a municipal wastewater treatment plant upgraded with a full-scale post-ozonation followed by sand filtration. Environ. Sci. Technol. 2009, 43, 7862–7869. [Google Scholar]

- Tripathi, S.; Hussain, T. Water and wastewater treatment through ozone-based technologies. In Development in Wastewater Treatment Research and Processes; Elsevier: Amsterdam, The Netherlands, 2022; pp. 139–172. [Google Scholar]

- Ciardelli, G.; Ranieri, N. The treatment and reuse of wastewater in the textile industry by means of ozonation and electroflocculation. Water Res. 2001, 35, 567–572. [Google Scholar]

- Ferrero, F.; Nano, A. L’ozono in tintoria ci può dare una mano Ozone can help in dyeing. Riv. Tecnol. Tessili 1995, 8, 67–72. [Google Scholar]

- Parisheva, Z.; Demirev, A. The effect of ozone on harmful, oxidizable substances in industrial waste gases. Environ. Prot. Eng. 1995, 20, 137–144. [Google Scholar]

- Apeksha, M.; Rajanikanth, B. Plasma/adsorbent system for NOx treatment in diesel exhaust: A case study on solid industrial wastes. Int. J. Environ. Sci. Technol. 2019, 16, 2973–2988. [Google Scholar]

- Russo, L.; Rizzo, L.; Belgiorno, V. PAHs contaminated soils remediation by ozone oxidation. Desalination Water Treat. 2010, 23, 161–172. [Google Scholar]

- Wang, T.C.; Qu, G.; Li, J.; Lu, N. Transport characteristics of gas phase ozone in soil during soil remediation by pulsed discharge plasma. Vacuum 2014, 101, 86–91. [Google Scholar]

- Pawłat, J.; Stryczewska, H.D.; Ebihara, K. Sterilization techniques for soil remediation and agriculture based on ozone and AOP. J. Adv. Oxid. Technol. 2010, 13, 138–145. [Google Scholar]

- Liu, J. Soil remediation using soil washing followed by ozone oxidation. J. Ind. Eng. Chem. 2018, 65, 31–34. [Google Scholar]

- Chávez, A.; Gimeno, O.; Rey, A.; Pliego, G.; Oropesa, A.; Álvarez, P.; Beltrán, F. Treatment of highly polluted industrial wastewater by means of sequential aerobic biological oxidation-ozone based AOPs. Chem. Eng. J. 2019, 361, 89–98. [Google Scholar]

- Asaithambi, P.; Aziz, A.R.A.; Daud, W.M.A.B.W. Integrated ozone—Electrocoagulation process for the removal of pollutant from industrial effluent: Optimization through response surface methodology. Chem. Eng. Process. Process Intensif. 2016, 105, 92–102. [Google Scholar]

- Sujayasree, O.; Chaitanya, A.; Bhoite, R.; Pandiselvam, R.; Kothakota, A.; Gavahian, M.; Mousavi Khaneghah, A. Ozone: An advanced oxidation technology to enhance sustainable food consumption through mycotoxin degradation. Ozone Sci. Eng. 2022, 44, 17–37. [Google Scholar]

- Afsah-Hejri, L.; Hajeb, P.; Ehsani, R.J. Application of ozone for degradation of mycotoxins in food: A review. Compr. Rev. Food Sci. Food Saf. 2020, 19, 1777–1808. [Google Scholar]

- Sarron, E.; Gadonna-Widehem, P.; Aussenac, T. Ozone treatments for preserving fresh vegetables quality: A critical review. Foods 2021, 10, 605. [Google Scholar] [CrossRef]

- Pandiselvam, R.; Subhashini, S.; Banuu Priya, E.; Kothakota, A.; Ramesh, S.; Shahir, S. Ozone based food preservation: A promising green technology for enhanced food safety. Ozone Sci. Eng. 2019, 41, 17–34. [Google Scholar]

- Seyam, O.; Smith, N.L.; Reid, I.; Gandhi, J.; Jiang, W.; Khan, S.A. Clinical utility of ozone therapy for musculoskeletal disorders. Med. Gas Res. 2018, 8, 103–110. [Google Scholar] [PubMed]

- Jandura, J.; Vajda, M.; Cech, M.; Ryska, P. Oxygen–Ozone Therapy of Musculoskeletal Neck Pain: A Review. J. Pers. Med. 2024, 14, 326. [Google Scholar] [CrossRef]

- Clavo, B.; Martínez-Sánchez, G.; Rodríguez-Esparragón, F.; Rodríguez-Abreu, D.; Galván, S.; Aguiar-Bujanda, D.; Díaz-Garrido, J.A.; Cañas, S.; Torres-Mata, L.B.; Fabelo, H. Modulation by ozone therapy of oxidative stress in chemotherapy-induced peripheral neuropathy: The background for a randomized clinical trial. Int. J. Mol. Sci. 2021, 22, 2802. [Google Scholar] [CrossRef] [PubMed]

- Clavo, B.; Rodríguez-Esparragón, F.; Rodríguez-Abreu, D.; Martínez-Sánchez, G.; Llontop, P.; Aguiar-Bujanda, D.; Fernández-Pérez, L.; Santana-Rodríguez, N. Modulation of oxidative stress by ozone therapy in the prevention and treatment of chemotherapy-induced toxicity: Review and prospects. Antioxidants 2019, 8, 588. [Google Scholar] [CrossRef] [PubMed]

- Clavo, B.; Santana-Rodriguez, N.; Llontop, P.; Gutierrez, D.; Suárez, G.; Lopez, L.; Rovira, G.; Martinez-Sanchez, G.; Gonzalez, E.; Jorge, I.J. Ozone therapy as adjuvant for cancer treatment: Is further research warranted? Evid. Based Complement. Altern. Med. 2018, 2018, 7931849. [Google Scholar]

- Smith, A.J.; Oertle, J.; Warren, D.; Prato, D. Ozone therapy: A critical physiological and diverse clinical evaluation with regard to immune modulation, anti-infectious properties, anti-cancer potential, and impact on anti-oxidant enzymes. Open J. Mol. Integr. Physiol. 2015, 5, 37–48. [Google Scholar]

- Wellauer, R.; Oldani, M. Cooling water treatment with ozone. Ozone Sci. Eng. 1990, 12, 243–253. [Google Scholar]

- You, S.H.; Tseng, D.H.; Guo, G.L.; Lee, S.Y. Mechanism and effects of ozone treatment for cooling water system. J. Environ. Sci. Health Part A 2000, 35, 87–107. [Google Scholar]

- Ataei, A.; Gharaie, M.; Parand, R.; Panjeshahi, E. Application of ozone treatment and pinch technology in cooling water systems design for water and energy conservation. Int. J. Energy Res. 2010, 34, 494–506. [Google Scholar]

- Sydykova, G.; Umbetova, S.; Baimakhanova, Z.; Abieva, G.; Kurmanbayev, G. Modern Applications of Ozone Technology. Evergreen 2023, 10, 2308–2316. [Google Scholar]

- Ershov, B.; Seliverstov, A.; Basiev, A.; Basiev, A.; Korchagin, Y.P. Application of concentrated ozone for decontamination of equipment in a nuclear power plant. At. Energy 2009, 107, 89–94. [Google Scholar]

- Vig, J.R. UV/ozone cleaning of surfaces. J. Vac. Sci. Technol. A Vac. Surf. Film. 1985, 3, 1027–1034. [Google Scholar]

| Method | Advantages | Disadvantages | Reported Yields | References |

|---|---|---|---|---|

| Ultraviolet Irradiation |

|

| 130 g/kWh | [2,3] |

| Electrochemical Ozone Production |

|

| 20 g/kWh | [6] |

| Dielectric barrier Discharge |

|

| 200 g/kWh | [11] |

| Corona Discharge |

|

| 150 g/kWh | [12] |

| Pulsed Power Technology |

|

| 73.94 g/kWh | [13] |

| Silent Discharge Plasma |

|

| 7 g/kWh | [14] |

| Application Area | Key Findings | References |

|---|---|---|

| Water Treatment |

| [23,24,25] |

| Air Pollution Control |

| [20,30,31] |

| Soil Remediation |

| [33,34,35] |

| Food Processing and Preservation |

| [38,39,40] |

| Medical Treatment |

| [42,43,44,45] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, K.; Liu, J.; Lv, H.; Zeng, X.; Ling, Z.; Ding, L.; Jin, C. Advances in Ozone Technology for Environmental, Energy, Food and Medical Applications. Processes 2025, 13, 1126. https://doi.org/10.3390/pr13041126

Zhang K, Liu J, Lv H, Zeng X, Ling Z, Ding L, Jin C. Advances in Ozone Technology for Environmental, Energy, Food and Medical Applications. Processes. 2025; 13(4):1126. https://doi.org/10.3390/pr13041126

Chicago/Turabian StyleZhang, Kang, Jianzheng Liu, Hongkun Lv, Xianyang Zeng, Zhongqian Ling, Liwei Ding, and Chenyang Jin. 2025. "Advances in Ozone Technology for Environmental, Energy, Food and Medical Applications" Processes 13, no. 4: 1126. https://doi.org/10.3390/pr13041126

APA StyleZhang, K., Liu, J., Lv, H., Zeng, X., Ling, Z., Ding, L., & Jin, C. (2025). Advances in Ozone Technology for Environmental, Energy, Food and Medical Applications. Processes, 13(4), 1126. https://doi.org/10.3390/pr13041126