Reservoir Characteristics and Regional Storage Potential Evaluation of Deep Well Injection and Storage of High-Salinity Water in Coal Mines in the Ordos Basin

Abstract

1. Introduction

2. Materials and Methods

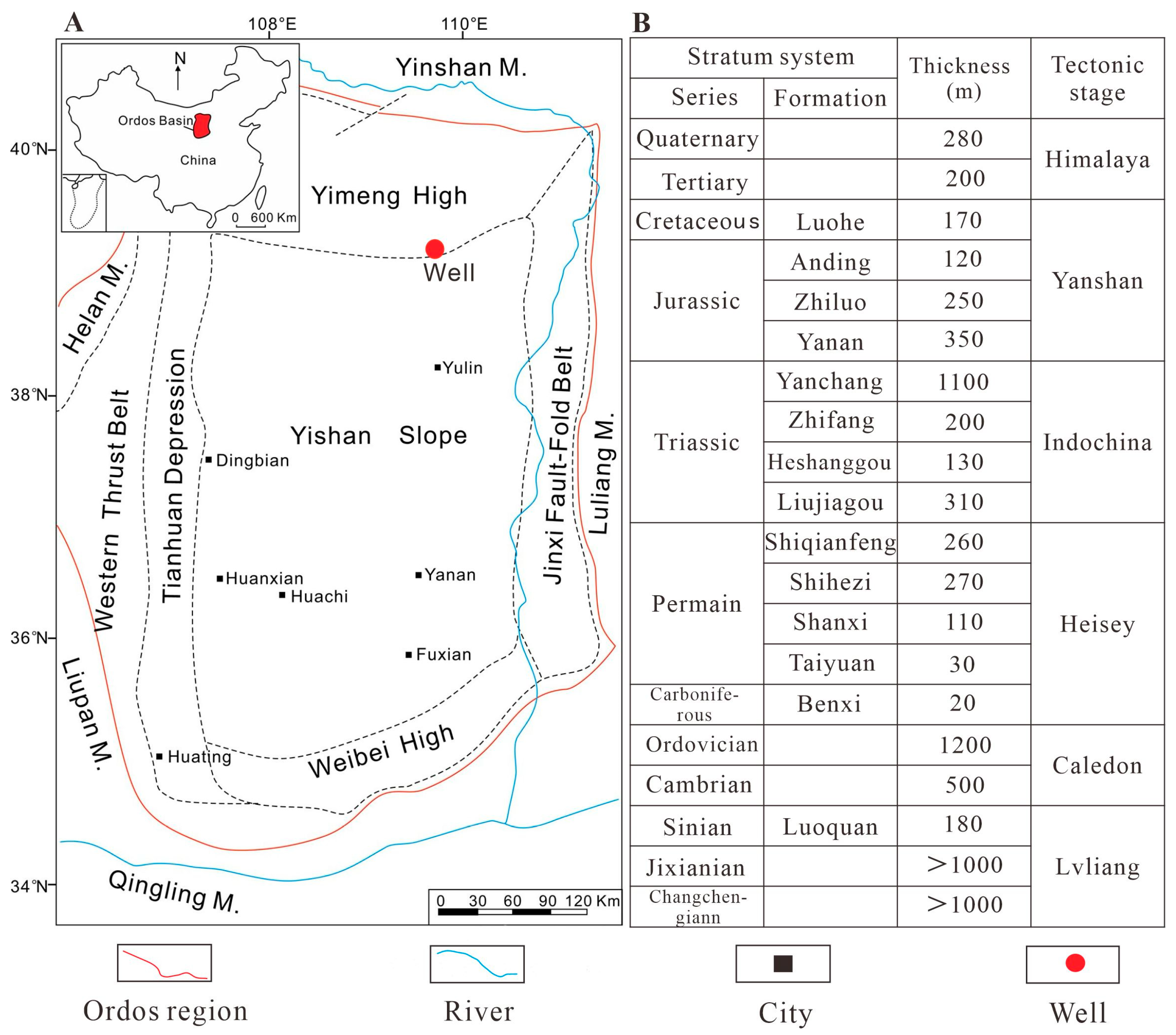

2.1. Overview of the Study Area

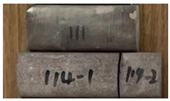

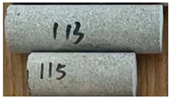

2.2. Sample Collection

2.3. Test Methods

2.3.1. Rock Physical Mechanics

2.3.2. Scanning Electron Microscopy

2.3.3. X-Ray Diffractometry

2.4. Storage Potential Calculation Method

3. Results and Discussion

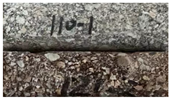

3.1. Lithological Characteristics of the Reservoir

3.2. Characteristics of Reservoir Rock Mineral Composition

3.2.1. Characteristics of Rock Mineral Composition of the Liujiagou Formation

3.2.2. Characteristics of Rock Mineral Composition of the Shiqianfeng Formation

3.3. Physical and Mechanical Characteristics of Reservoir Rocks

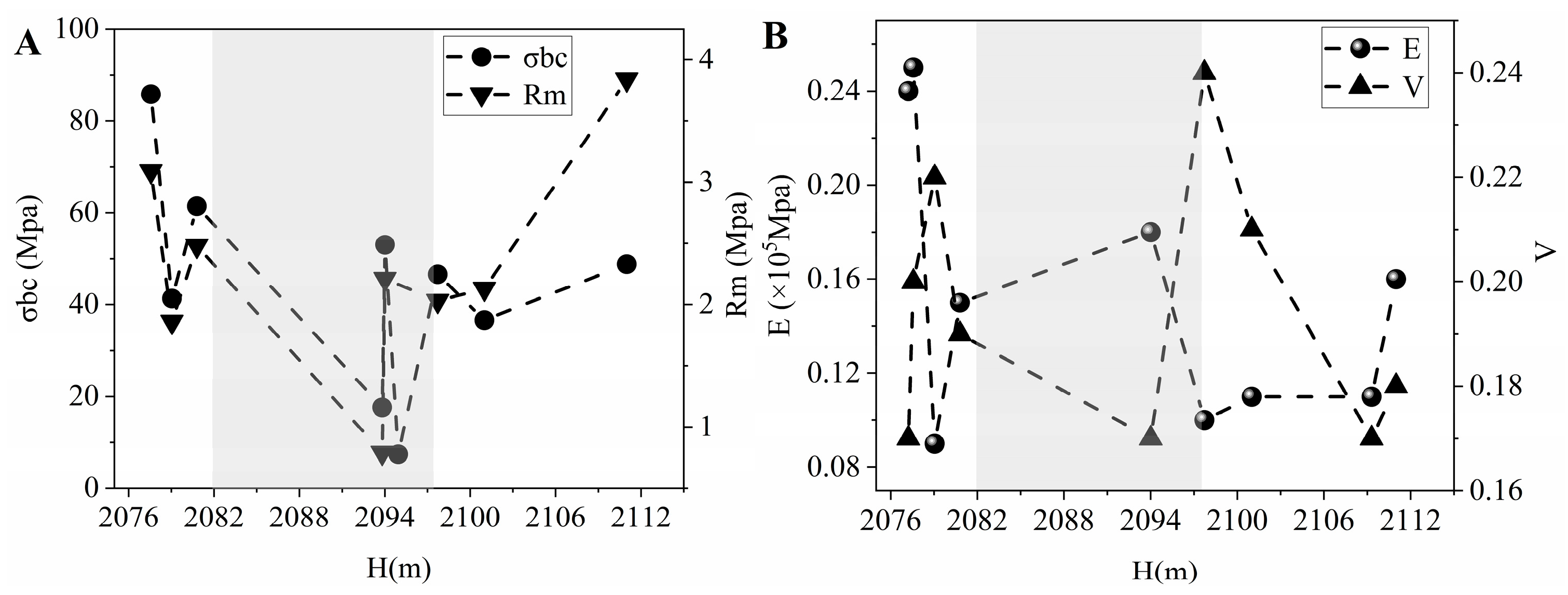

3.3.1. Physical and Mechanical Characteristics of the Liujiagou Formation

3.3.2. Physical and Mechanical Characteristics of the Shiqianfeng Formation

3.4. Spatial Structural Characteristics of Reservoir Rock

3.4.1. Rock Structure Characteristics

3.4.2. Characteristics of Rock Pore Development

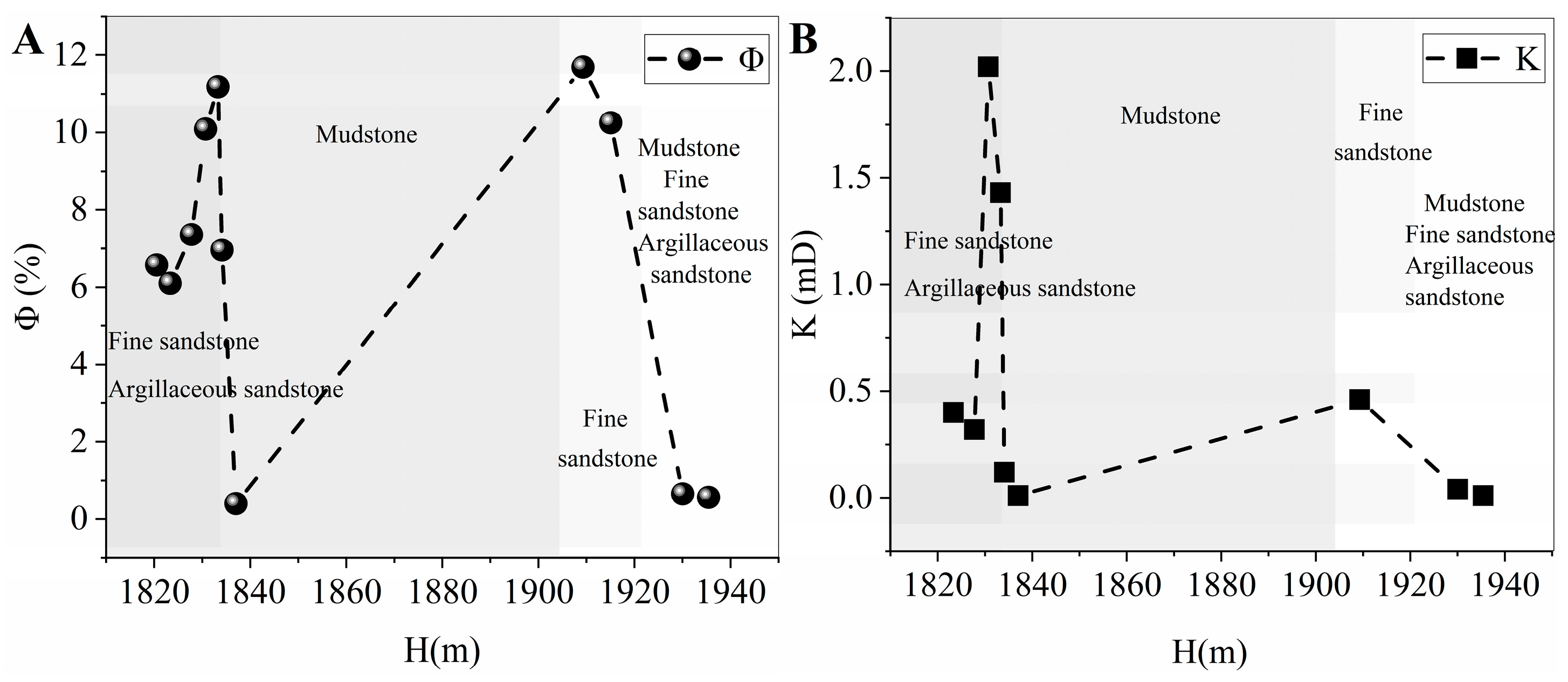

3.4.3. Analysis of the Porosity of the Liujiagou Formation

3.4.4. Analysis of the Porosity of the Shiqianfeng Formation

3.5. Evaluation of Storage Potential

4. Conclusions

- (1)

- The Liujiagou Formation is mainly composed of sandstone and siltstone, with a fine sandstone particle size and good sorting. There are a large number of clastic feldspar and quartz particles, a few debris particles, and occasional mica and calcite cements. The Shiqianfeng Formation is dominated by medium sandstone and conglomerate, with a coarse grain size, good roundness, high structural maturity, and no calcite cement.

- (2)

- The storage spaces in the Liujiagou and Shiqianfeng formations mainly include intergranular pores, dissolution pores, intergranular pores, and micro-cracks. Among them, the intergranular pores are more developed and the most conducive to reservoir storage. The strata within the depth ranges of 1820–1835 m, 1905–1920 m, and 2082–2098 m have a weak resistance to external forces and are easily fractured. The reservoir porosity and permeability are better, and the connectivity of the pores is also better.

- (3)

- According to the calculations using the volume method, the favorable areas for storage are distributed within the depth ranges of 1820–1835 m, 1905–1920 m, and 2082–2098 m, and the unfavorable areas for storage are distributed within the depth ranges of 1835–1905 m, 1920–1926 m, and 2098–2110 m. The effective storage capacity within a 100 m radius around the storage well is 33.15 × 104 m3. The effective storage capacity of the favorable area is 27.69 × 104 m3, accounting for 83.50% of the total storage capacity. Through comprehensive analysis, it was determined that the strata in the study area meet the basic conditions for the implementation of the deep geological storage of high-salinity water from coal mines, contain sufficient storage space, and have good storage potential.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ruzhich, V.V.; Vakhromeev, A.G.; Levina, E.A.; Sverkunov, S.A.; Shilko, E.V. Control of Seismic Activity in Tectonic Fault Zones Using Vibrationsand Fluid Injection in Deep Wells. Phys. Mesomech. 2021, 24, 85–97. [Google Scholar] [CrossRef]

- HJ 19-2022; Technical Guidelines for Environmental Impact Assessment—Ecological Impact. Ministry of Ecology and Environment of the People’s Republic of China: Beijing, China, 2022.

- Li, Q.H. Research progress on treatment and comprehensive utilization of coal chemical wastewater. Appl. Chem. Ind. 2023, 52, 2234–2238+2243. [Google Scholar] [CrossRef]

- Cao, M.L.; Li, H.; Liu, F.; Li, D.; Zhong, C.M. Recent development in the treatment process for high salt organic wastewater. Nonferrous Met. Sci. Eng. 2019, 10, 92–98. [Google Scholar] [CrossRef]

- Shi, J.X.; Huang, W.P.; Han, H.G.; Xu, C.Y. Review on treatment technology of salt wastewater in coal chemical industry of China. Desalination 2020, 493, 114640. [Google Scholar] [CrossRef]

- Kumar, P.B.; Li, S.; Veeriah, J. A review of the management and treatment of brine solutions. Environ. Sci. Water Res. Technol. 2017, 3, 625–658. [Google Scholar]

- Zeng, L.L.; Ren, W.J.; Shan, L.Q.; Niu, Y.X.; Liu, X.S. Prediction and reliability analysis of reservoir lithology spatial distribution. Front. Earth Sci. 2023, 11, 125121. [Google Scholar] [CrossRef]

- Saripalli, K.P.; Sharma, M.M.; Bryant, S.L. Modeling injection well performance during deep-well injection of liquid wastes. J. Hydrol. 2000, 227, 41–55. [Google Scholar] [CrossRef]

- Stefan, B. Review of CO2 storage efficiency in deep saline aquifers. Int. J. Greenh. Gas Control 2015, 40, 188–202. [Google Scholar]

- Chen, H.K.; Wang, X.H.; Yu, J.Q.; Zhang, Y.F. Underground perfusion technology and its application in the United States. Environ. Prot. 2007, 2007, 76–79. [Google Scholar]

- Muniz, A.; Tobon, M.; Bloetscher, F. Why Current Regulations Protect Florida’s Subsurface Environment. Dev. Water Sci. 2005, 52, 29–38. [Google Scholar]

- Si, G.M.; Yin, Z.S.; Luo, H.B.; Qi, M.H.; Jia, Q.; Ning, C.H.; Fan, Z.H.; Zhao, C.; Yang, W. Mine Water Control Measures based on Injection Method: Taking Laoyingyan Well in Sichuan Province as an Example. Shanxi Coal 2024, 44, 50–56+66. [Google Scholar]

- Zhao, K.; Wu, J.; Ma, C.; Zhu, K.C.; Nie, J.L.; Hu, H.L. Relationship between the current status of research on geological storage of solid, liquid and gas wastes in coal mines and the coordinated development of the ecological environment in China. J. China Coal Soc. 2024, 49, 2785–2798. [Google Scholar] [CrossRef]

- AI-Ameri, T.K.; Zumberge, J.; Markarian, Z.M. Hydrocarbons in the middle miocene jeribe formation, dyala region, ne Iraq. J. Pet. Geol. 2011, 34, 199–216. [Google Scholar] [CrossRef]

- Sun, T.M.; Liu, S.Q.; Wang, T. Research advances on evaluation of CO2 geological storage potential in China. Coal Sci. Technol. 2021, 49, 10–20. [Google Scholar] [CrossRef]

- Gu, D.Z.; Li, J.F.; Cao, Z.G.; Wu, B.Y.; Jiang, B.B.; Yang, Y.; Yang, J.; Chen, Y.P. Technology and engineering development strategy of water protection and utilization of coal mine in China. J. China Coal Soc. 2021, 46, 3079–3089. [Google Scholar] [CrossRef]

- Sun, Y.J.; Li, X.; Feng, L.; Xu, Z.M.; Chen, G.; Liu, Q. Technical thinking on ectopic inject and storage of mine area water resources under the coordinated exploitation of coal and water background in Ordos Basin. J. China Coal Soc. 2022, 47, 3547–3560. [Google Scholar] [CrossRef]

- He, M.; Zhang, Y.; Qian, Z.; Guo, D.; Chen, D. Numerical Simulation Study on utilizing A quifers to Store Cool Energy in Fathing Deep Mine Heat-harm. J. Hunan Univ. Sci. Technol. Nat. Sci. Ed. 2006, 21, 13–16. [Google Scholar]

- Du, S.; Zhang, C.; Wu, W.M.; Wang, D.D.; Gen, J.J.; Fu, Y.J. Prospect of Deep Well Injection for Treatment of Coal Mine Drainage Brine Wastewater. China Water Wastewater 2020, 36, 40–48. [Google Scholar] [CrossRef]

- Wu, W.M.; Du, S. Research progress and prospects of wastewate treatment from modern coal chemical industry. Coal Sci. Technol. 2018, 46, 1–3. [Google Scholar] [CrossRef]

- Yan, J. Discussion on the injectivity of sandstone aquifer of Triassic Liujiagou Formation in Ordos Basin. Min. Technol. 2023, 23, 219–223. [Google Scholar] [CrossRef]

- Zhang, C.; Zhao, G.; Su, P.; Xiao, N.; Zhang, Y.; Shen, Z. Treatment and utilization of coal mine water based on “deep ground-underground-surface ground” linkage system. J. Min. Sci. Technol. 2024, 9, 1–12. [Google Scholar] [CrossRef]

- Wei, Y.C.; Cao, D.Y.; Ning, S.Z.; Wu, G.Q. Research Progress of Coal Measures Mineral Resource Hosting Patterns in Ordos Basin. Coal Geol. China 2018, 30, 14–20. [Google Scholar]

- Tian, G. Characteristics of Basement Faults and Its Tectonic Significance in the Northern Ordos Block. Dissertation/Docter’s Thesis, China University of Petroleum, Beijing, China, 2023. [Google Scholar] [CrossRef]

- He, M.Q.; Huang, W.H.; Wang, Y.Z.; Wang, Y.T.; Yan, D.Y. Diagenesis and reservoir features of compact sandstone of coal-bearing formation in southern ordos basin. Resour. Ind. 2018, 20, 33–40. [Google Scholar] [CrossRef]

- Zhao, Y.; Xu, Q.; Du, S.; Zhang, Y.; Zhang, T.Z.; Fan, Y.L.; Ding, Y.; Song, S.T.; Feng, X.X. Prediction of favorable geological storage areas based on sedimentary characteristics: A case study on the northeastern Ordos Basin, China. Energy Geosci. 2024, 5, 100330. [Google Scholar] [CrossRef]

- Chen, G. Study on the Deep Transportation and Storage Mechanism of Mine Water in the Eastern Margin of Ordos Basin. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2020. [Google Scholar] [CrossRef]

- Jin, X.; Shi, Z.Q.; Baranyi, V.; Kemp, D.B.; Han, Z.; Luo, G.M.; Hu, J.F.; He, F.; Chen, L.; Preto, N. The Jenkyns Event (early Toarcian OAE) in the Ordos Basin, North China. Glob. Planet. Change 2020, 193, 103273. [Google Scholar] [CrossRef]

- Zhang, Z.J. Study on the Characteristics of Sandstone in the Lower Triassic Liujiagou Formation in the Northeastern of the Ordos Basin. Coal Geol. China 2022, 34, 18–26. [Google Scholar]

- Hai, L.F.; Mu, C.X.; Xu, Q.H.; Sun, Y.L.; Fan, H.R.; Xie, X.Y.; Wei, X.C.; Mei, C.; Yu, H.B.; Walter, M.; et al. The Sequence Stratigraphic Division and Depositional Environment of the Jurassic Yan’an Formation in the Pengyang Area, Southwestern Margin of the Ordos Basin, China. Energies 2022, 15, 5310. [Google Scholar] [CrossRef]

- Hou, Z.S.; Chen, S.Y.; Guo, Y.X.; Wang, Z.J.; He, Q.Q.; Cui, Q.M. Sedimentary Facies and Their Evolution Characteristics of Upper Paleozoic in Zibo Boshan Area, Central and Southern Region of North China. Acta Sedimentol. Sin. 2018, 36, 731–742. [Google Scholar] [CrossRef]

- Wang, T.; Liu, Z.W.; He, Z.L.; Wang, H.; Fu, H.J.; Nie, H.K. Evaluation of the effectiveness of shale bedding fractures: A case study of the Longmaxi Formation in the Sichuan Basin. Front. Earth Sci. 2024. early access. [Google Scholar] [CrossRef]

- Zhao, G.F.; Wang, K.S.; Zhang, L.; Wu, X.Y.; Yan, Y.K.; Yan, Z.Y. Mesomechanical Behavior of Cement-Stabilized Macadam in Uniaxial Compression Tests. J. Eng. Mech. 2024, 150, 7600. [Google Scholar] [CrossRef]

- Chen, C.C. Experimental Study on Triaxial Time-Dependent Behaviour and Strain Localization of Rock under Water-Rock Interaction. Ph.D. Thesis, Chongqing University, Chongqing, China, 2021. [Google Scholar] [CrossRef]

- Song, C.L.; Shinichiro, N.; Ryunosuke, K.; Hideaki, Y.; Kiyoshi, K. Short- and Long-Term Observations of Fracture Permeability in Granite by Flow-Through Tests and Comparative Observation by X-Ray CT. Int. J. Geomech. 2021, 21, 2114. [Google Scholar] [CrossRef]

- Ren, H.X.; Jing, Y.H.; Song, J.; Liu, Y.; Chen, L. Experimental Analysis Technologies of Scanning Electron Microscopy and Its Applicantion. Petrochem. Ind. Technol. 2018, 25, 115+275. [Google Scholar]

- An, Q.; Hong, C.Y.; Wen, H.T. Fracture Patterns of Rocks Observed under Cryogenic Conditions Using Cryo-Scanning Electron Microscopy. Processes 2023, 11, 2038. [Google Scholar] [CrossRef]

- Fu, L.M.; Shen, Y.Q.; Cao, G.F.; Xin, X.L.; Zhang, H.; Liu, P.X. Application of XRD Diffraction Technique of Lithological Identification in Junggar Basin. Henan Sci. Technol. 2016, 84–86. [Google Scholar]

- Dai, J.; Xu, S.L.; Song, S.D.; Li, T. Changes in basalt before and after microwave irradiation based on XRD and SEM. China Sci. 2018, 13, 2780–2783. [Google Scholar]

- Liu, T.; Ma, X.; Diao, Y.J.; Jin, X.L.; Fu, J.; Zhang, C.L. research status of CO2 geological storage potential evaluation methods at home and abroad. Geol. Surv. China 2021, 8, 101–108. [Google Scholar] [CrossRef]

- Goodman, A.; Hakala, A.; Bromhal, G.; Deel, D.; Rodosta, T.; Frailey, S.; Small, M.; Allen, D.; Romanov, V.; Fazio, J.; et al. U.S. DOE methodology for the development of geologic storage potential for carbon dioxide at the national and regional scale. Int. J. Greenh. Gas Control 2011, 5, 952–965. [Google Scholar] [CrossRef]

- Diao, Y.J.; Liu, T.; Wei, N.; Ma, X.; Jin, X.L.; Fu, L. Classification and assessment methodology of carbon dioxide geological storage in deep saline aquifers. Geol. China 2023, 50, 943–951. [Google Scholar]

- Wang, D.; Du, H.; Zhou, W.; Yang, L. Preliminary Exploration of Geological Storage Potential of Carbon Dioxide in Hunan Province under the Background of Carbon Neutrality. Environ. Resour. Ecol. J. 2024, 8. [Google Scholar]

- Du, Z.R.; Du, S.; Yang, Y.; Song, J.; Wu, J.F.; Wu, J.C. Reactive Transport Numerical Modeling for Deep Geological Sequestration of Brine Wastewater. Geol. J. China Univ. 2023, 29, 571–579. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, J.; Xiao, J.; Wu, B.; Xia, K. Permeability Evolution of Argillaceous Sandstone Subjected to Hydromechanical Loading. Rock Mech. Rock Eng. 2024. [Google Scholar] [CrossRef]

- Tan, C.; Yu, B.S.; Yuan, X.J.; Liu, C.; Wang, T.S.; Zhu, X. Color Origin of the Lower Triassic Liujiagou and Heshanggou Formations Red Beds in the Ordos Basin. Geoscience 2020, 34, 769–783. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, X.; Zhang, Y.; Dong, Y.; Xu, Y.; Shi, G.; Lin, Y.; Li, A. Analcite cementation facies and forming mechanism of high-quality secondary clastic rock reservoirs in western China. J. Palaeogeogr. Chin. Ed. 2014, 16, 517–526. [Google Scholar]

- Ahmed, A.; Mahmoud, G.; Mohamed, H.; Elewa, A.M.T.; Mohamed, R.S.A. Sandstone reservoir quality in light of depositional and diagenetic processes of the Messinian Qawasim Formation, onshore Nile Delta, Egypt. J. Asian Earth Sci. 2022, 223, 104992. [Google Scholar]

- Zhang, X.; Tian, J.C.; Chen, H.D.; Hou, M.C.; Hou, Z.J. The lithofacies-paleogeographic and spatiotemporal evolution of Upper Permian Shiqianfeng Formation in Ordos Basin, China. J. Chengdu Univ. Technol. Sci. Technol. Ed. 2009, 36, 165–171. [Google Scholar]

- Fu, G.M.; Dong, M.C.; Zhang, Z.S.; Sun, L.; Pan, R. Formation Process and Distribution of Laumontite in Yanchang 3 Reservoir of Fuxian Exploration Area in North Shaanxi Province and the Controls of the High Quality Reservoirs. Earth Sci. 2010, 35, 107–114. [Google Scholar]

- Wang, R.F.; Tang, Y. Study on the rock physical mechanical properties evaluation of tight oil reservoir in Chang 7 member, Longdong area, Ordos Basin, China. Front. Earth Sci. 2024, 12, 1342561. [Google Scholar] [CrossRef]

- Zhang, J. Analysis on Poisson’s Ratio of Surrounding Rock in Advanced Geological Prediction of New Wushaoling Tunnel. Eng. Technol. Res. 2023, 8, 202–204. [Google Scholar] [CrossRef]

- Li, X.Y.; Qiao, W.H.; Zhang, J.K.; Ma, J.J.; Yan, J.T.; Li, S.T. Linear relationship between mineral content and porosity of Chang 6 reservoir in Jiyuan area, Ordos Basin. Lithol. Reserv. 2019, 31, 66–74. [Google Scholar]

- MartínezMartínez, J.; Arizzi, A.; Benavente, D. The Role of Calcite Dissolution and Halite Thermal Expansion as Secondary Salt Weathering Mechanisms of Calcite-Bearing Rocks in Marine Environments. Minerals 2021, 11, 911. [Google Scholar] [CrossRef]

- Zhang, L.H.; Pan, B.Z.; Shan, G.Y. Progress in experimental research on porosity and permeability of core samples. Prog. Geophys. 2018, 33, 777–782. [Google Scholar]

- Xiao, H.; Wang, H.N.; Yang, Y.D.; Ke, C.Y.; Zhe, H.Q. Influence of diagenetic evolution on tight sandstone reservoir flow capacity: Chang 8 reservoir of Yanchang Formation in southern Maling, Ordos Basin. Pet. Geol. Exp. 2019, 41, 800–811. [Google Scholar]

- Chen, Q.L.; Huang, C.G. Research Progress of Modification of Reservoirs by Dissolution in Sedimentary Rock. Adv. Earth Sci. 2018, 33, 1112–1129. [Google Scholar]

- Hou, D.Z.; Xiao, Y.F.; Liu, L.; Huan, C. Combined Analytic Hierarchy Process and Weighted Interval Method Models for the Geological Evaluation of CO2 Storage in Coal Goaf. Energies 2024, 17, 2672. [Google Scholar] [CrossRef]

- Zhang, C.L.; Diao, Y.J.; Fu, L.; Ma, X.; Wang, S.Y.; Liu, T. Evaluation of the Potential for CO 2Storage and Saline Water Displacement in Huaiyin Sag, Subei Basin, East China. Processes 2024, 12, 547. [Google Scholar] [CrossRef]

| Stratum | Formation | Height (m) | Depth (m) | Core | ||

|---|---|---|---|---|---|---|

| Erathem | Series | System | ||||

| Mesozoic | Triassic | Lower | Liujiagou | 8 | 1820–1828 |  |

| 76 | 1830–1906 |  | ||||

| 17 | 1096–1923 |  | ||||

| 12 | 1924–1936 |  | ||||

| Upper paleozoic | Permian | Upper | Shiqianfeng | 22 | 2076–2094 |  |

| 19 | 2094–2113 |  | ||||

| Formation | Lithology | h/m | Φ/% | P/×104 m3 |

|---|---|---|---|---|

| Liujiagou | Fine sandstone | 15 (1820–1835) | 8.04 | 7.57 |

| Argillaceous sandstone | 70 (1835–1905) | 0.4 | 1.76 | |

| Mudstone | 15 (1905–1920) | 10.97 | 10.33 | |

| Fine sandstone | 16 (1920–1936) | 0.61 | 0.61 | |

| Shiqianfeng | Mudstone | 16 (2082–2098) | 9.74 | 9.79 |

| Fine sandstone | 4 (2098–2102) | 0.49 | 0.12 | |

| Argillaceous sandstone | 3 (2102–2105) | 10.2 | 1.92 | |

| Medium sandstone | 5 (2105–2110) | 3.3 | 1.04 | |

| Total | 33.15 × 104 m3 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Bu, Y.; Du, S.; Che, Q.; Fan, Y.; Ding, Y.; Jiang, Z.; Li, X. Reservoir Characteristics and Regional Storage Potential Evaluation of Deep Well Injection and Storage of High-Salinity Water in Coal Mines in the Ordos Basin. Processes 2025, 13, 579. https://doi.org/10.3390/pr13020579

Liu Y, Bu Y, Du S, Che Q, Fan Y, Ding Y, Jiang Z, Li X. Reservoir Characteristics and Regional Storage Potential Evaluation of Deep Well Injection and Storage of High-Salinity Water in Coal Mines in the Ordos Basin. Processes. 2025; 13(2):579. https://doi.org/10.3390/pr13020579

Chicago/Turabian StyleLiu, Yanjun, Yidan Bu, Song Du, Qiaohui Che, Yinglin Fan, Yan Ding, Zhe Jiang, and Xiang Li. 2025. "Reservoir Characteristics and Regional Storage Potential Evaluation of Deep Well Injection and Storage of High-Salinity Water in Coal Mines in the Ordos Basin" Processes 13, no. 2: 579. https://doi.org/10.3390/pr13020579

APA StyleLiu, Y., Bu, Y., Du, S., Che, Q., Fan, Y., Ding, Y., Jiang, Z., & Li, X. (2025). Reservoir Characteristics and Regional Storage Potential Evaluation of Deep Well Injection and Storage of High-Salinity Water in Coal Mines in the Ordos Basin. Processes, 13(2), 579. https://doi.org/10.3390/pr13020579