Forming Rate Dependence of Novel Austenitising Bending Process for a High-Strength Quenched Micro-Alloyed Steel: Experiments and Simulation

Abstract

1. Introduction

2. Materials and Methods

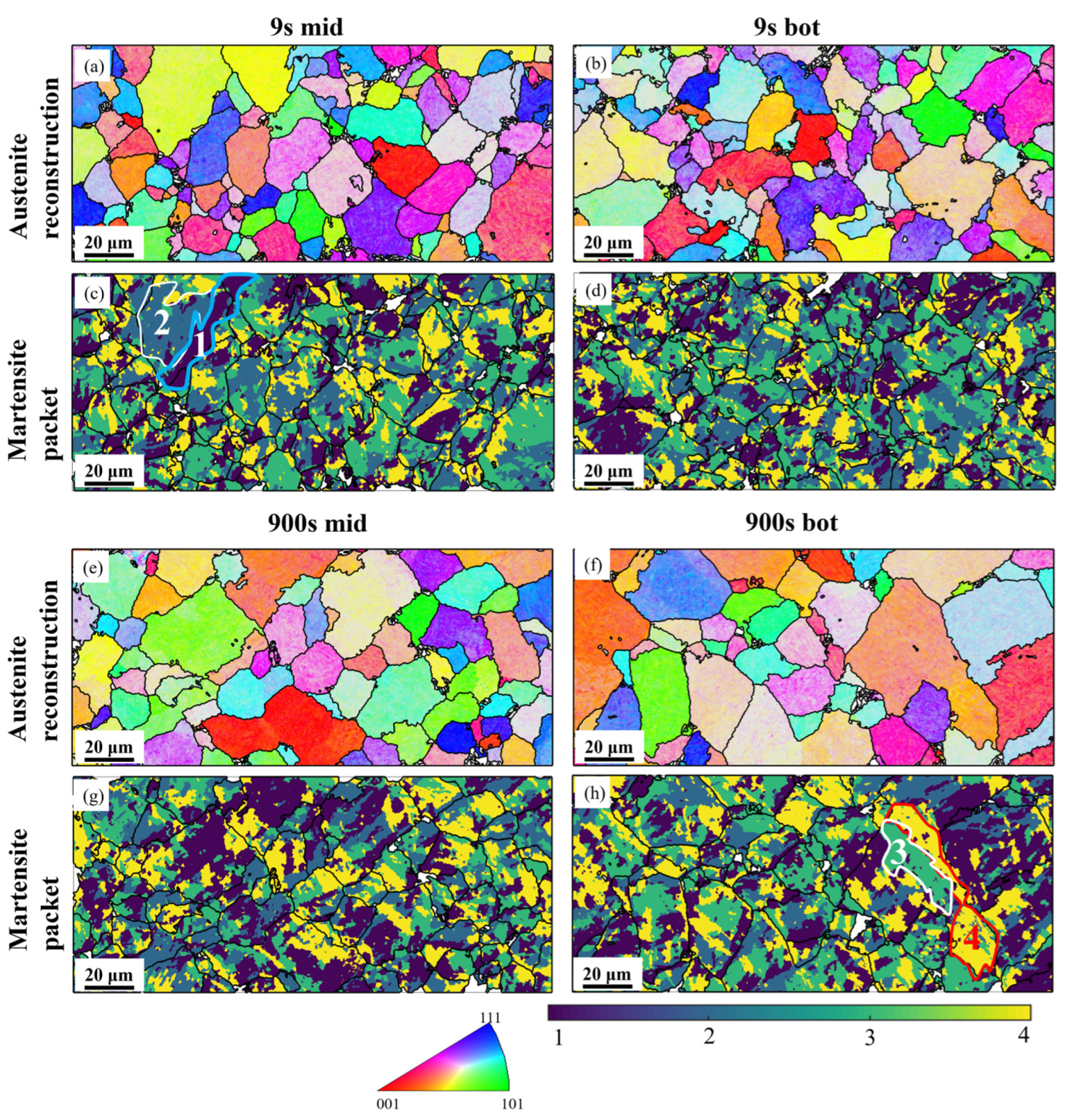

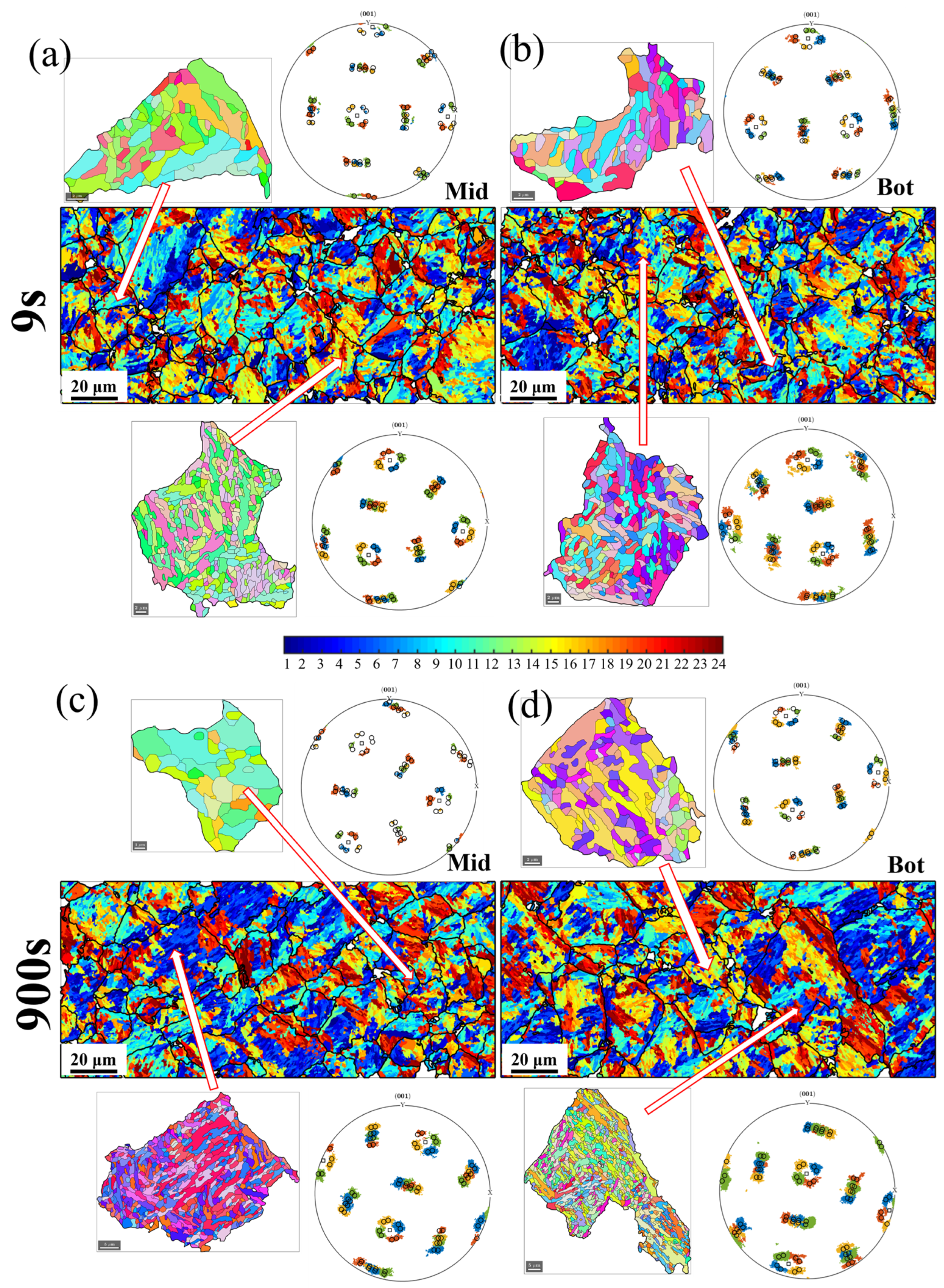

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mandal, A.; Syed, B.; Bhandari, K.K.; Bhattacharya, B.; Deb, A.; Singh, S.B.; Chakrabarti, D. Cold-bending of linepipe steel plate to pipe, detrimental or beneficial? Mater. Sci. Eng. A 2019, 746, 58–72. [Google Scholar] [CrossRef]

- Chung, K.-H.; Lee, W.; Kim, J.H.; Kim, C.; Park, S.H.; Kwon, D.; Chung, K. Characterization of mechanical properties by indentation tests and FE analysis—Validatiosn by application to a weld zone of DP590 steel. Int. J. Solids Struct. 2009, 46, 344–363. [Google Scholar] [CrossRef]

- Poulin, C.M.; Korkolis, Y.P.; Kinsey, B.L.; Knezevic, M. Over five-times improved elongation-to-fracture of dual-phase 1180 steel by continuous-bending-under-tension. Mater. Des. 2019, 161, 95–105. [Google Scholar] [CrossRef]

- Li, H.; Venezuela, J.; Zhou, Q.; Luzin, V.; Yan, M.; Shi, Z.; Knibbe, R.; Zhang, M.; Dong, F.; Dargusch, M.S.; et al. Hydrogen-induced delayed fracture of a 1180 MPa martensitic advanced high-strength steel under U-bend loading. Mater. Today Commun. 2021, 26, 101887. [Google Scholar] [CrossRef]

- Iftimiciuc, M.; Lache, S.; Vandepitte, D.; Velea, M.N. Bending performance of a sandwich beam with sheet metal pyramidal core. Mater. Today Commun. 2022, 31, 103490. [Google Scholar] [CrossRef]

- Lu, Y.; Xie, H.; Wang, J.; Jia, F.; Lin, F.; Zhou, C.; Xu, J.; Han, J.; Jiang, Z. Ex situ analysis of high-strength quenched and micro-alloyed steel during austenitising bending process: Numerical simulation and experimental investigation. Int. J. Adv. Manuf. Technol. 2022, 120, 8293–8309. [Google Scholar] [CrossRef]

- Lu, Y.; Xie, H.; Wang, J.; Jia, F.; Li, Z.; Kamali, H.; Xu, J.; Han, J.; Jiang, Z. Design of a novel austenitising bending process in forming characteristics of high-strength quenched and micro-alloyed steel: Experiment and simulation. Mater. Des. 2022, 215, 110458. [Google Scholar] [CrossRef]

- Yuan, Z.; Zhu, S.; Yuan, X.; Zhai, W. Vibration-based damage detection of rail fastener clip using convolutional neural network: Experiment and simulation. Eng. Fail. Anal. 2021, 119, 104906. [Google Scholar] [CrossRef]

- Khan, S.H.; Ahmed, M.S.; Ali, F.; Nusair, A.; Iqbal, M.A. Investigation of high strength steel bending. Eng. Fail. Anal. 2009, 16, 128–135. [Google Scholar] [CrossRef]

- Barrett, T.J.; Knezevic, M. Modeling material behavior during continuous bending under tension for inferring the post-necking strain hardening response of ductile sheet metals: Application to DP 780 steel. Int. J. Mech. Sci. 2020, 174, 105508. [Google Scholar] [CrossRef]

- Liu, Y.; Fan, D.; Bhat, S.P.; Srivastava, A. Ductile fracture of dual-phase steel sheets under bending. Int. J. Plast. 2020, 125, 80–96. [Google Scholar] [CrossRef]

- Lu, Y.; Xie, H.; Wang, J.; Li, Z.; Jia, F.; Wu, H.; Han, J.; Jiang, Z. Influence of hot compressive parameters on flow behaviour and microstructure evolution in a commercial medium carbon micro-alloyed spring steel. J. Manuf. Process. 2020, 58, 1171–1181. [Google Scholar] [CrossRef]

- Simonetto, E.; Ghiotti, A.; Bruschi, S. High accuracy direct hot bending of hollow profiles. Manuf. Lett. 2021, 27, 63–66. [Google Scholar] [CrossRef]

- Niessen, F.; Nyyssönen, T.; Gazder, A.A.; Hielscher, R. Parent grain reconstruction from partially or fully transformed microstructures in MTEX. J. Appl. Crystallogr. 2022, 55, 180–194. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Xie, H.; Wang, J.; Li, Z.; Lin, F.; Han, J.; Han, J.; Jiang, Z. Characteristic flow behaviour prediction and microstructure analysis of a commercial Si–Cr micro-alloyed spring steel under isothermal compression. Vacuum 2021, 186, 110066. [Google Scholar] [CrossRef]

- Lu, Y.; Xie, H.; Wang, J.; Jia, F.; Li, Z.; Lin, F.; Pan, D.; Han, J.; Jiang, Z. Simulation, microstructure and austenite reconstruction of a medium carbon micro-alloyed steel subjected to an austenitising bending process. Mater. Lett. 2021, 305, 130772. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, J.; Jia, F.; Zhang, Q.; Liang, X.; Jiao, S.; Jiang, Z. Numerical and experimental investigation on the forming behaviour of stainless/carbon steel bimetal composite. Int. J. Adv. Manuf. Technol. 2019, 101, 1075–1083. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Was, G.S. Materials challenges in nuclear energy. Acta Mater. 2013, 61, 735–758. [Google Scholar] [CrossRef]

- Lan, L.; Zhou, W.; Misra, R.D.K. Effect of hot deformation parameters on flow stress and microstructure in a low carbon microalloyed steel. Mater. Sci. Eng. A 2019, 756, 18–26. [Google Scholar] [CrossRef]

- Javaheri, V.; Kolli, S.; Grande, B.; Porter, D. Insight into the induction hardening behavior of a new 0.40% C microalloyed steel: Effects of initial microstructure and thermal cycles. Mater. Charact. 2019, 149, 165–183. [Google Scholar] [CrossRef]

- Kitahara, H.; Ueji, R.; Tsuji, N.; Minamino, Y. Crystallographic features of lath martensite in low-carbon steel. Acta Mater. 2006, 54, 1279–1288. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Wang, J.; Li, Z.; Lin, F.; Pan, D.; Jia, F.; Han, J.; Jiang, Z. Forming Rate Dependence of Novel Austenitising Bending Process for a High-Strength Quenched Micro-Alloyed Steel: Experiments and Simulation. Processes 2025, 13, 441. https://doi.org/10.3390/pr13020441

Lu Y, Wang J, Li Z, Lin F, Pan D, Jia F, Han J, Jiang Z. Forming Rate Dependence of Novel Austenitising Bending Process for a High-Strength Quenched Micro-Alloyed Steel: Experiments and Simulation. Processes. 2025; 13(2):441. https://doi.org/10.3390/pr13020441

Chicago/Turabian StyleLu, Yao, Jun Wang, Zhou Li, Fei Lin, Di Pan, Fanghui Jia, Jingtao Han, and Zhengyi Jiang. 2025. "Forming Rate Dependence of Novel Austenitising Bending Process for a High-Strength Quenched Micro-Alloyed Steel: Experiments and Simulation" Processes 13, no. 2: 441. https://doi.org/10.3390/pr13020441

APA StyleLu, Y., Wang, J., Li, Z., Lin, F., Pan, D., Jia, F., Han, J., & Jiang, Z. (2025). Forming Rate Dependence of Novel Austenitising Bending Process for a High-Strength Quenched Micro-Alloyed Steel: Experiments and Simulation. Processes, 13(2), 441. https://doi.org/10.3390/pr13020441