Superior Resistance and Ductility Through Novel Quench- and Partitioning-Path in Complex Refined Microstructure

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Selection and Preparation

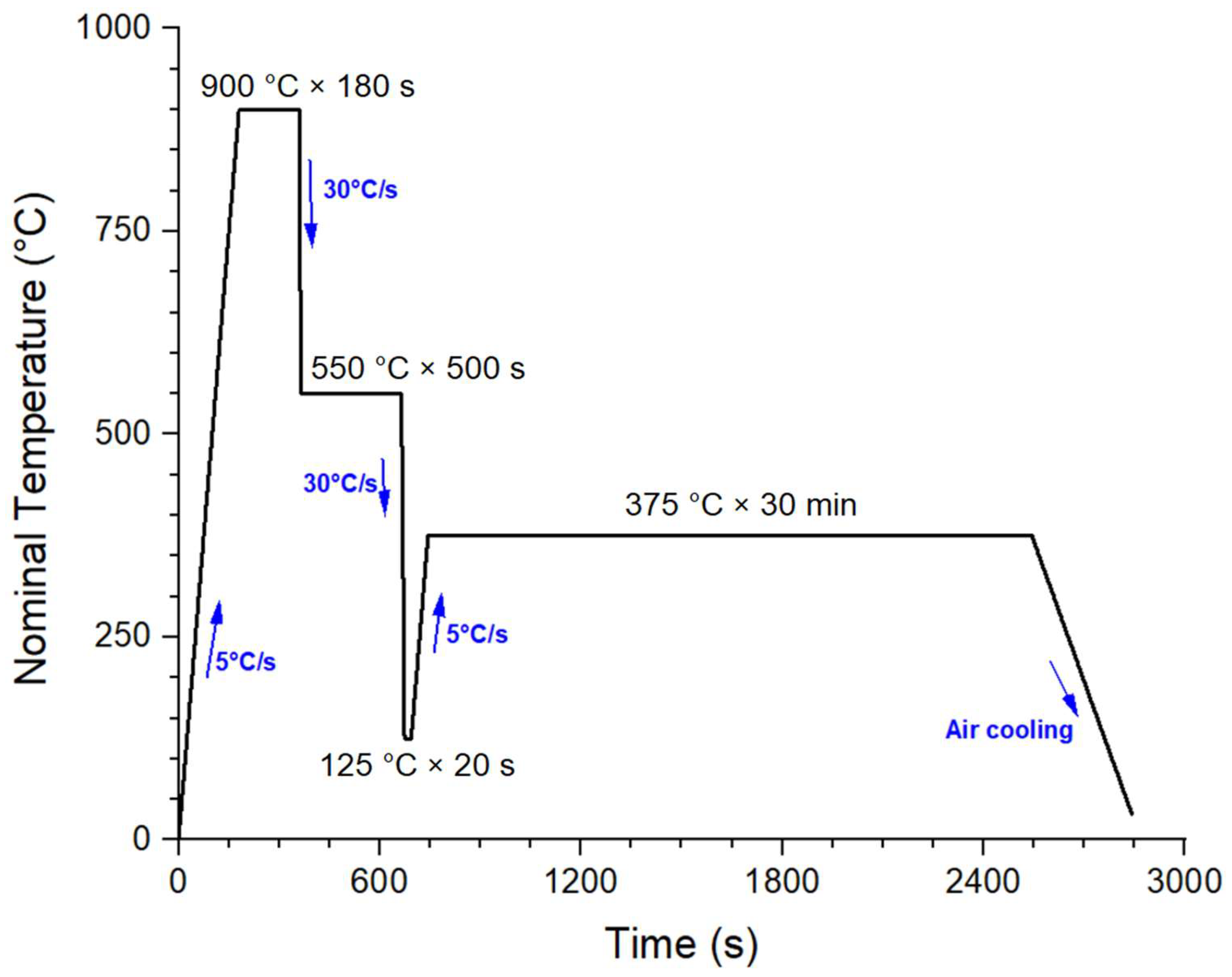

2.2. Heat Treatment

2.3. Microstructural Characterization

2.4. Mechanical Testing

2.5. Carbon Content Analysis

2.6. Statistical and Data Analysis

3. Results and Analysis

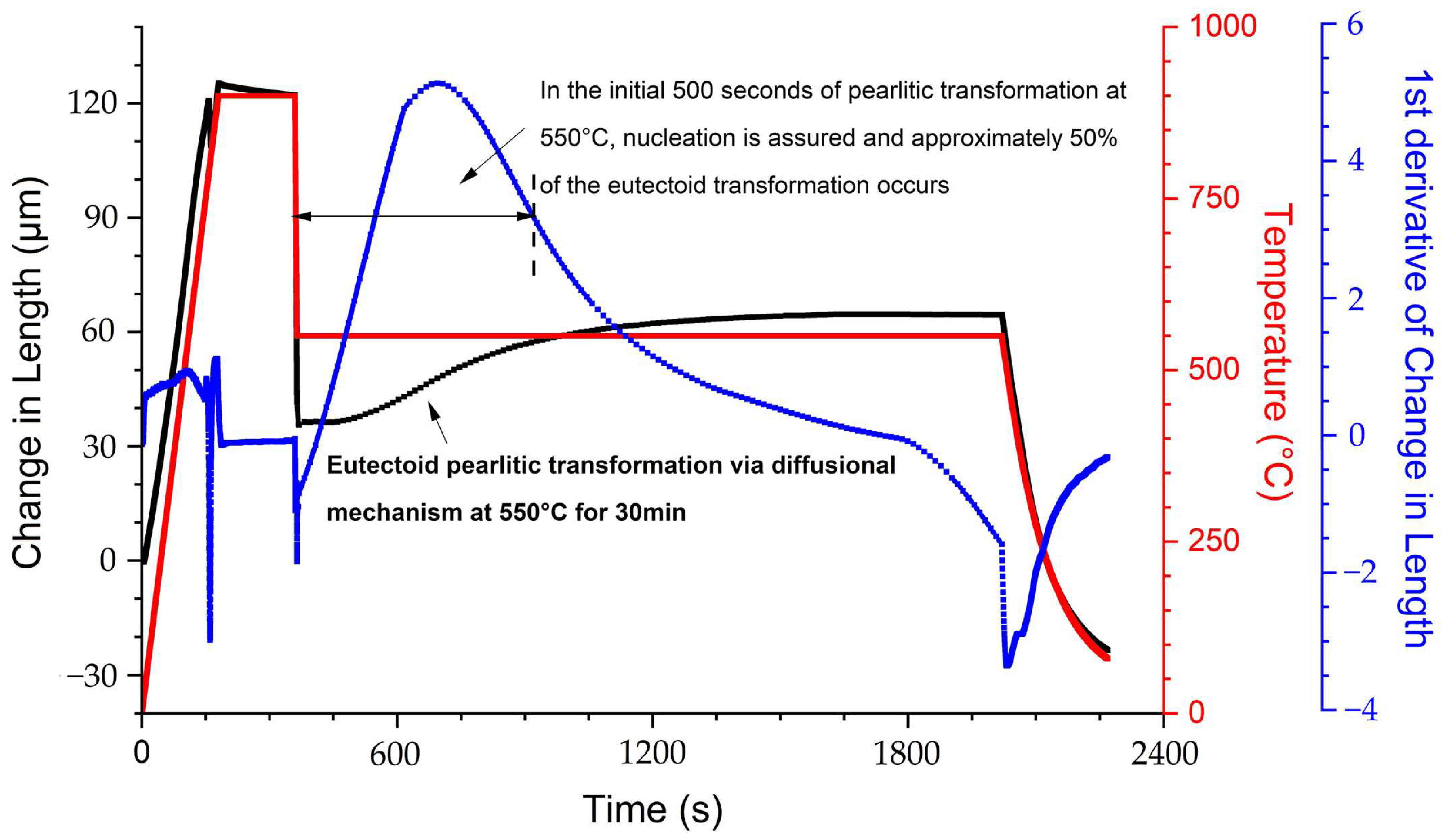

3.1. Determining the Isothermal Time for Development of Partially Fine Pearlite Structure

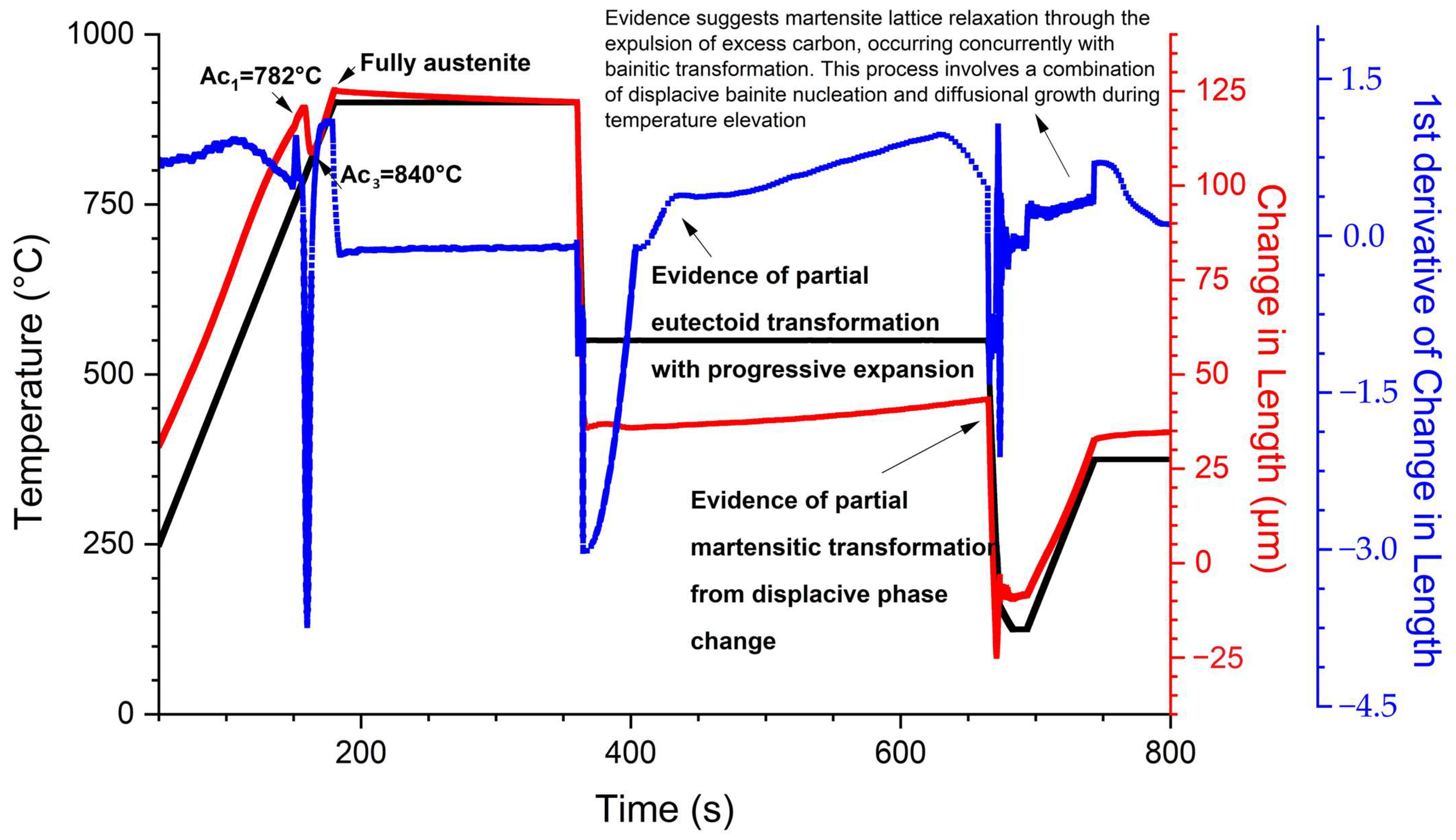

3.2. Change in Length and First Derivative of Length Change to Monitor Phase Transformations During the Novel Q&P Process

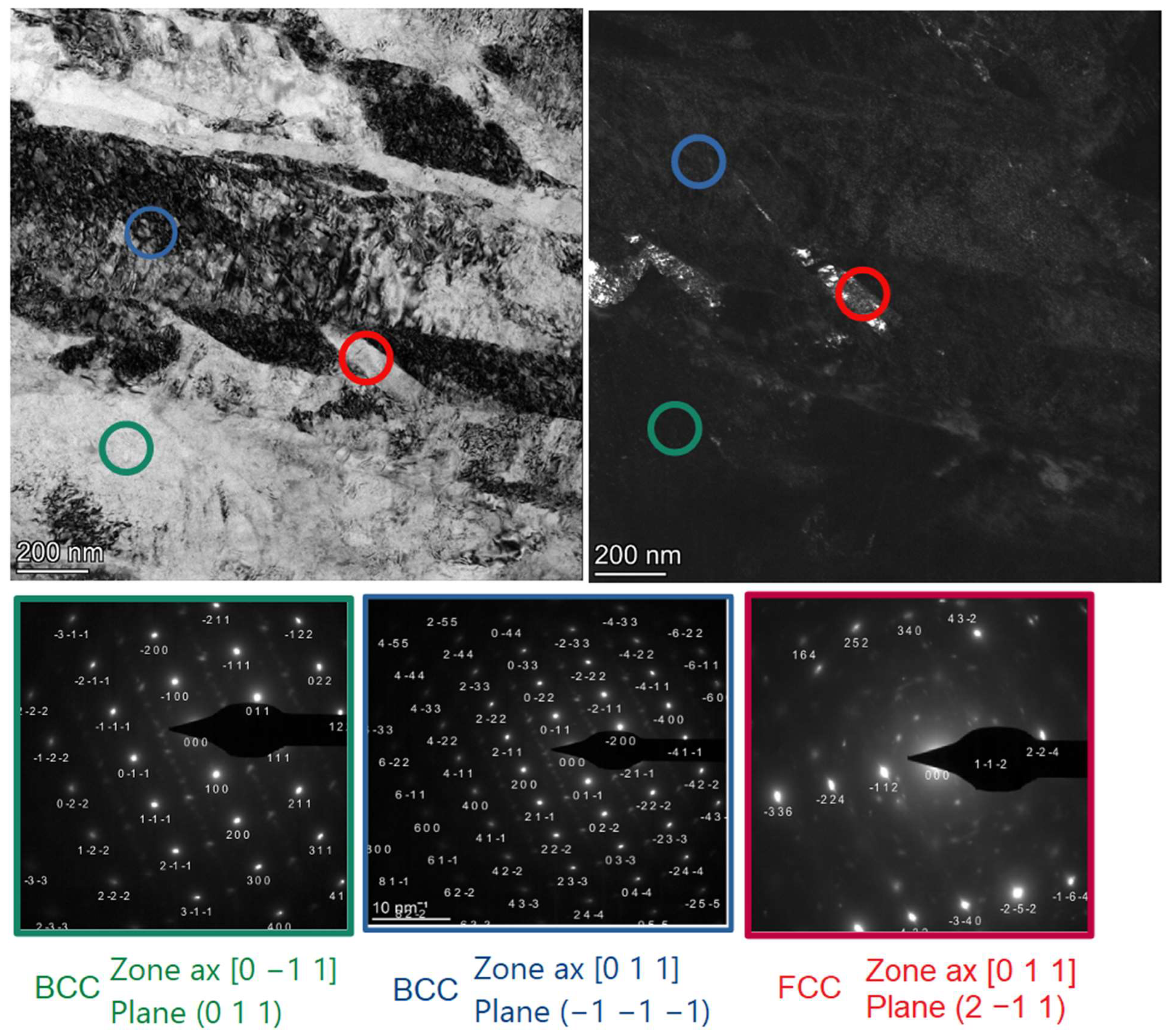

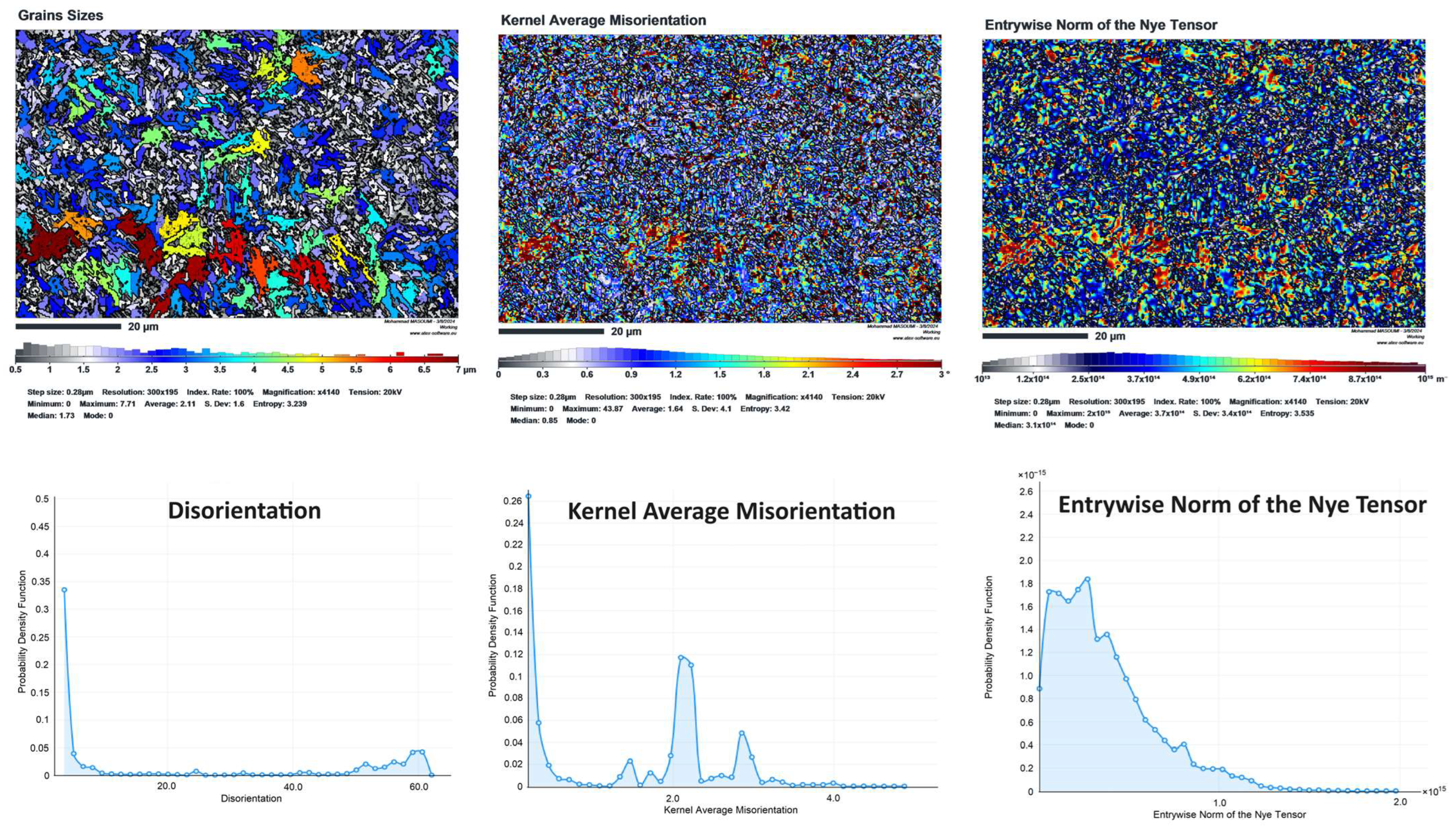

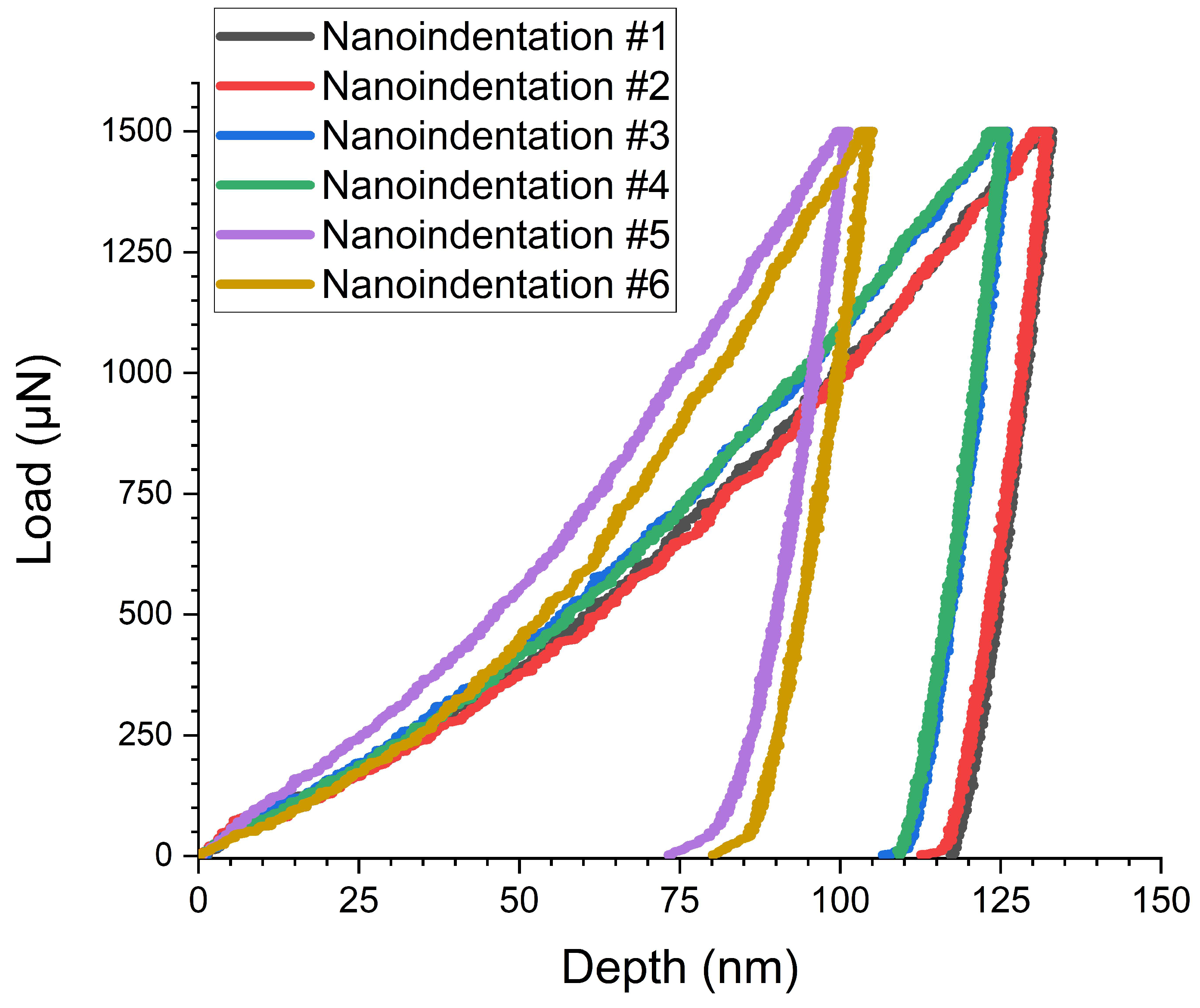

- Retained Austenite and TRIP Effect: Nanoindentations 1 and 2 exhibited the lowest hardness values (3.87–3.88 GPa) and showed clear pop-in behavior during indentation, indicative of the TRIP effect. The retained austenite, identified by its lower hardness and higher ductility, undergoes stress-assisted transformation into martensite during deformation. This transformation alleviates localized stress concentrations, enhancing ductility and delaying crack propagation.

- Medium Hardness Bainite: Nanoindentations 3 and 4 demonstrated medium hardness values (4.25–4.26 GPa), characteristic of bainite sheaves formed during the partitioning stage. Bainite represents a combination of diffusional and displacive phase transformation mechanisms, where carbide precipitation and ferritic sheaf formation contribute to moderate hardness while retaining some plasticity.

- Martensite with Highest Hardness: Nanoindentations 5 and 6 recorded the highest hardness values (6.44–6.52 GPa), corresponding to pure displacive martensitic laths formed during the quenching stage. Martensite, with its high carbon content and tetragonal distortion, provides exceptional strength and hardness, albeit with limited ductility.

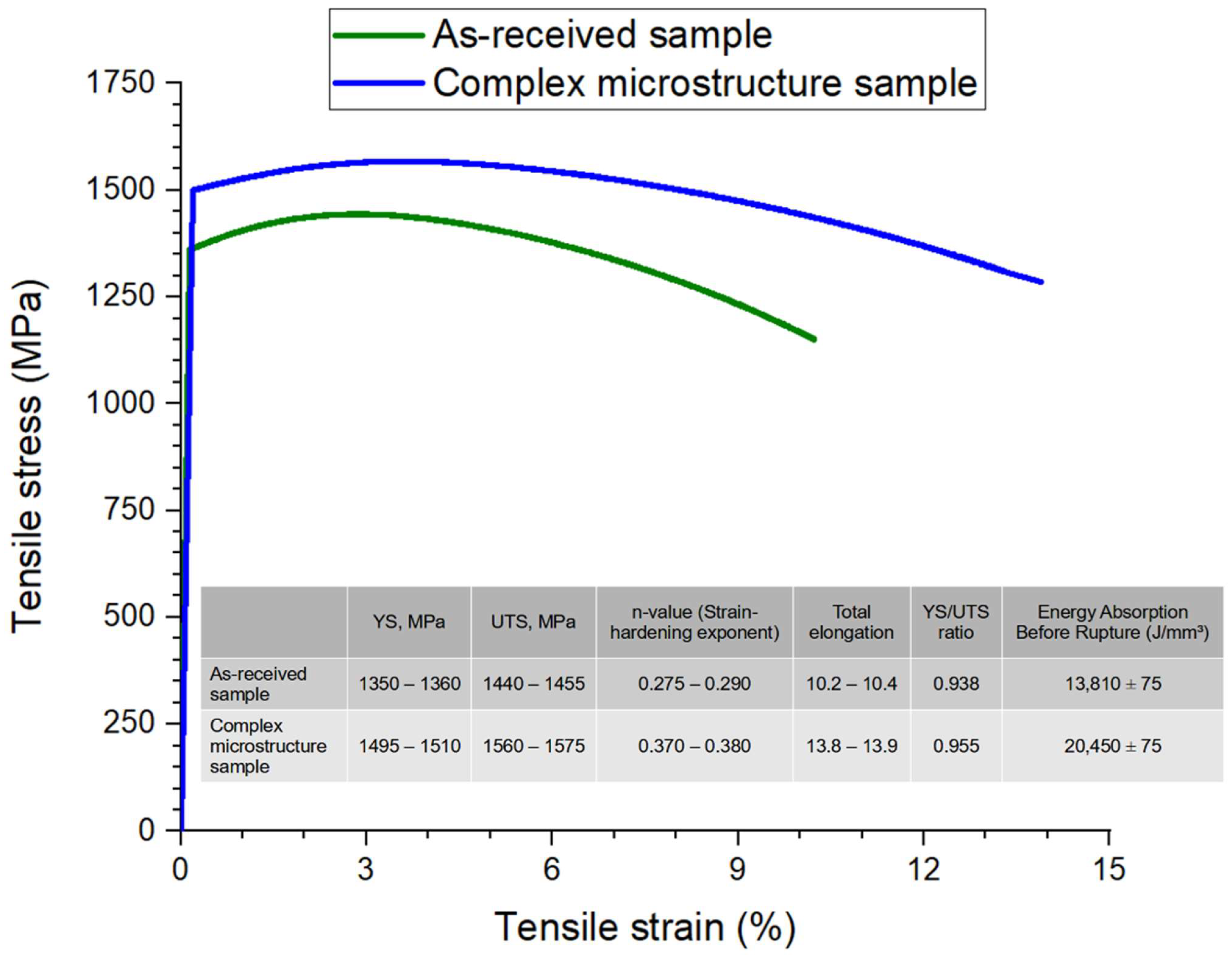

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Suh, M.S.; Nahm, S.H.; Suh, C.M.; Park, N.K. Impact Toughness of Spring Steel after Bainite and Martensite Transformation. Metals 2022, 12, 304. [Google Scholar] [CrossRef]

- Franceschi, M.; Pezzato, L.; Gennari, C.; Fabrizi, A.; Polyakova, M.; Konstantinov, D.; Brunelli, K.; Dabalà, M. Effect of intercritical annealing and austempering on the microstructure and mechanical properties of a high silicon manganese steel. Metals 2020, 10, 1448. [Google Scholar] [CrossRef]

- Yang, J.; Huang, F.; Guo, Z.; Rong, Y.; Chen, N. Effect of retained austenite on the hydrogen embrittlement of a medium carbon quenching and partitioning steel with refined microstructure. Mater. Sci. Eng. A 2016, 665, 76–85. [Google Scholar] [CrossRef]

- Zhu, X.; Li, W.; Hsu, T.Y.; Zhou, S.; Wang, L.; Jin, X. Improved resistance to hydrogen embrittlement in a high-strength steel by quenching–partitioning–tempering treatment. Scr. Mater. 2015, 97, 21–24. [Google Scholar] [CrossRef]

- Abareshi, M.; Emadoddin, E. Effect of retained austenite characteristics on fatigue behavior and tensile properties of transformation induced plasticity steel. Mater. Des. 2011, 32, 5099–5105. [Google Scholar] [CrossRef]

- Yan, S.; Liu, X.; Liu, W.J.; Lan, H.; Wu, H. Comparison on mechanical properties and microstructure of a C-Mn-Si steel treated by quenching and partitioning (Q&P) and quenching and tempering (Q&T) processes. Mater. Sci. Eng. A 2014, 620, 58–66. [Google Scholar] [CrossRef]

- Ariza-Echeverri, E.A.; Masoumi, M.; Nishikawa, A.S.; Mesa, D.H.; Marquez-Rossy, A.E.; Tschiptschin, A.P. Development of a new generation of quench and partitioning steels: Influence of processing parameters on texture, nanoindentation, and mechanical properties. Mater. Des. 2020, 186, 108329. [Google Scholar] [CrossRef]

- Wang, L.; Speer, J.G. Quenching and Partitioning Steel Heat Treatment. Metallogr. Microstruct. Anal. 2013, 2, 268–281. [Google Scholar] [CrossRef]

- Zhong, N.; Wu, Q.; Yin, Y.; Wang, X. Microstructual Evolution of a Medium Carbon Advanced High Strength Steel Heat-Treated by Quenching-Partitioning Process. Steel Res. Int. 2014, 86, 252–256. [Google Scholar] [CrossRef]

- Speer, J.; Matlock, D.K.; De Cooman, B.C.; Schroth, J.G. Carbon partitioning into austenite after martensite transformation. Acta Mater. 2003, 51, 2611–2622. [Google Scholar] [CrossRef]

- Santofimia, M.J.; Zhao, L.; Petrov, R.; Sietsma, J. Characterization of the microstructure obtained by the quenching and partitioning process in a low-carbon steel. Mater. Charact. 2008, 59, 1758–1764. [Google Scholar] [CrossRef]

- Shi, F.; Zheng, J.; Zhang, J.; Zhao, Y.; Chen, L. Heat Treatment Process, Microstructure, and Mechanical Properties of Spring Steel with Ultra-High Strength and Toughness. Metals 2024, 14, 180. [Google Scholar] [CrossRef]

- Härtel, M.; Wilke, A.; Dieck, S.; Landgraf, P.; Grund, T.; Lampke, T.; Neukirchner, H.; Halle, T.; Wappler, S. On the Q&P potential of a commercial spring steel. Metals 2021, 11, 1612. [Google Scholar] [CrossRef]

- Masoumi, M.; Ariza, E.A.; Centeno, D.; Tressia, G.; Márquez-Rossy, A.; Poplawsky, J.D.; Tschiptschin, A.P. Achieving superior mechanical properties: Tailoring multicomponent microstructure in AISI 9254 spring steel through a two-stage Q&P process and nanoscale carbide integration. Mater. Charact. 2024, 207, 113523. [Google Scholar] [CrossRef]

- Masoumi, M.; Centeno, D.M.A.; Tressia, G.; Correa, P.A.; Ariza, E.A.; Mola, J. Microstructural Design via Quenching and Partitioning for Enhanced Mechanical and Wear Properties in AISI 9254 Spring Steel: A Comprehensive Investigation. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2024, 55, 3364–3387. [Google Scholar] [CrossRef]

- Masoumi, M.; Centeno, D.M.A.; Echeverri, E.A.A. Tailoring the Microstructure using Quenching and Partitioning Processing in a Commercial Mn-Si-Cr Spring Steel to Improve Tensile Properties. Arab. J. Sci. Eng. 2024, 49, 15121–15141. [Google Scholar] [CrossRef]

- Zhou, Q.; Qian, L.; Tan, J.; Meng, J.; Zhang, F. Inconsistent effects of mechanical stability of retained austenite on ductility and toughness of transformation-induced plasticity steels. Mater. Sci. Eng. A 2013, 578, 370–376. [Google Scholar] [CrossRef]

- Schröder, C.; Wendler, M.; Volkova, O.; Weiß, A. Microstructure and Mechanical Properties of an Austenitic CrMnNiMoN Spring Steel Strip with a Reduced ni content. Crystals 2020, 10, 392. [Google Scholar] [CrossRef]

- Hofer, C.; Winkelhofer, F.; Clemens, H.; Primig, S. Morphology change of retained austenite during austempering of carbide-free bainitic steel. Mater. Sci. Eng. A 2016, 664, 236–246. [Google Scholar] [CrossRef]

- Santofimia, M.J.; Zhao, L.; Petrov, R.; Kwakernaak, C.; Sloof, W.G.; Sietsma, J. Microstructural development during the quenching and partitioning process in a newly designed low-carbon steel. Acta Mater. 2011, 59, 6059–6068. [Google Scholar] [CrossRef]

- Nov, Z.; Salvetr, P.; Kotous, J.; Motyčka, P.; Gokhman, A. Enhanced Spring Steel’s Strength Using Strain Assisted Tempering. Materials 2022, 15, 7354. [Google Scholar] [CrossRef] [PubMed]

- Kotous, J.; Salvetr, P.; Procházka, R. New approach to heat treatment of spring steel. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1178, 012031. [Google Scholar] [CrossRef]

- Kim, B.; Sietsma, J.; Santofimia, M.J. The role of silicon in carbon partitioning processes in martensite/austenite microstructures. Mater. Des. 2017, 127, 336–345. [Google Scholar] [CrossRef]

- Xiong, Z.; Timokhina, I.; Pereloma, E. Clustering, nano-scale precipitation and strengthening of steels. Prog. Mater. Sci. 2021, 118, 100764. [Google Scholar] [CrossRef]

- Alharbi, F.; Gazder, A.A.; Kostryzhev, A.; De Cooman, B.C.; Pereloma, E.V. The effect of processing parameters on the microstructure and mechanical properties of low-Si transformation-induced plasticity steels. J. Mater. Sci. 2014, 49, 2960–2974. [Google Scholar] [CrossRef]

- Seo, E.J.; Cho, L.; De Cooman, B.C. Application of quenching and partitioning (Q&P) processing to press hardening steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2014, 45, 4022–4037. [Google Scholar] [CrossRef]

- Cai, Z.H.; Ding, H.; Misra, R.D.K.; Ying, Z.Y. Austenite stability and deformation behavior in a cold-rolled transformation-induced plasticity steel with medium manganese content. Acta Mater. 2015, 84, 229–236. [Google Scholar] [CrossRef]

- Adams, D.; Behling, M.; Miles, M.P.; Homer, E.R.; Sachdev, A.K.; White, E.V.; Fullwood, D.T. Characterization of the Factors Influencing Retained Austenite Stability in Q&P Steels via In Situ EBSD. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2023, 54, 1355–1363. [Google Scholar] [CrossRef]

- Takahama, Y.; Santofimia, M.J.; Mecozzi, M.G.; Zhao, L.; Sietsma, J. Phase field simulation of the carbon redistribution during the quenching and partitioning process in a low-carbon steel. Acta Mater. 2012, 60, 2916–2926. [Google Scholar] [CrossRef]

- Ariza, E.A.; Poplawsky, J.; Guo, W.E.I.; Tschiptschin, P.; Unocic, K.; Ramirez, A.J. Evaluation of Carbon Partitioning in New Generation of Quench and Partitioning (Q&P) Steels. Metall. Mater. Trans. A 2018, 49, 4809–4823. [Google Scholar]

- Devaraj, A.; Xu, Z.; Abu-Farha, F.; Sun, X.; Hector, L.G. Nanoscale Solute Partitioning and Carbide Precipitation in a Multiphase TRIP Steel Analyzed by Atom Probe Tomography. Jom 2018, 70, 1752–1757. [Google Scholar] [CrossRef]

- Pierce, D.T.; Coughlin, D.R.; Williamson, D.L.; Clarke, K.D.; Clarke, A.J.; Speer, J.G.; De Moor, E. Characterization of transition carbides in quench and partitioned steel microstructures by Mössbauer spectroscopy and complementary techniques. Acta Mater. 2015, 90, 417–430. [Google Scholar] [CrossRef]

- Ebner, S.; Suppan, C.; Stark, A.; Schnitzer, R.; Hofer, C. Austenite decomposition and carbon partitioning during quenching and partitioning heat treatments studied via in-situ X-ray diffraction. Mater. Des. 2019, 178, 107862. [Google Scholar] [CrossRef]

- Echeverri, E.A.A.; Nishikawa, A.S.; Masoumi, M.; Pereira, H.B.; Marulanda, N.G.; Rossy, A.M.; Goldenstein, H.; Tschiptschin, A.P. In Situ Synchrotron X-ray Diffraction and Microstructural Studies on Cold and Hot Stamping Combined with Quenching and Partitioning Processing for Development of Third-Generation Advanced High Strength Steels. Metals 2022, 12, 174. [Google Scholar] [CrossRef]

- Cui, X.; Zhang, H.; Wang, S.; Zhang, L.; Ko, J. Design of lightweight multi-material automotive bodies using new material performance indices of thin-walled beams for the material selection with crashworthiness consideration. Mater. Des. 2011, 32, 815–821. [Google Scholar] [CrossRef]

- Lu, X.; Yang, Z.; Qian, D.; Lan, J.; Hua, L. Effect of martensite pre-quenching on bainite transformation kinetics, martensite/bainite duplex microstructures, mechanical properties and retained austenite stability of GCr15 bearing steel. J. Mater. Res. Technol. 2021, 15, 2429–2438. [Google Scholar] [CrossRef]

- Mohtadi-Bonab, M.A.; Ariza, E.A.; Loureiro, R.C.P.; Centeno, D.; Carvalho, F.M.; Avila, J.A.; Masoumi, M. Improvement of tensile properties by controlling the microstructure and crystallographic data in commercial pearlitic carbon-silicon steel via quenching and partitioning (Q&P) process. J. Mater. Res. Technol. 2023, 23, 845–858. [Google Scholar] [CrossRef]

- Williamson, G.K.; Hall, W.H. X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1953, 1, 22–31. [Google Scholar] [CrossRef]

- Cullity, B.D.; Stock, S.R. Elements of X-Ray Diffraction, 3rd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2001. [Google Scholar]

- ASTM E8/E8M; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- Ghosh, C.; Aranas, C.J.; Jonas, J.J. Dynamic transformation of deformed austenite at temperatures above the Ae3. Prog. Mater. Sci. 2016, 82, 151–233. [Google Scholar] [CrossRef]

- Toji, Y.; Miyamoto, G.; Raabe, D. Carbon partitioning during quenching and partitioning heat treatment accompanied by carbide precipitation. Acta Mater. 2015, 86, 137–147. [Google Scholar] [CrossRef]

- Muñoz, J.A.; Khelfa, T.; Komissarov, A.; Cabrera, J.M. Ductility and plasticity of ferritic-pearlitic steel after severe plastic deformation. Mater. Sci. Eng. A 2021, 805, 140624. [Google Scholar] [CrossRef]

- dos Santos Avila, D.; Offerman, S.E.; Santofimia, M.J. Modeling the effect of prior austenite grain size on bainite formation kinetics. Acta Mater. 2024, 266, 119656. [Google Scholar] [CrossRef]

- Wang, T.; Qian, L.; Yu, W.; Li, K.; Zhang, F.; Meng, J. Effect of ferrite-austenite morphology and orientation relationship on bainite transformation in low-alloy TRIP steels. Mater. Charact. 2022, 184, 111656. [Google Scholar] [CrossRef]

- Foster, D.; Paladugu, M.; Hughes, J.; Kapousidou, M.; Islam, U.; Stark, A.; Schell, N.; Jimenez-Melero, E. In-situ synchrotron X-ray diffraction during quenching and tempering of SAE 52100 steel. Mater. Today Commun. 2021, 29, 102930. [Google Scholar] [CrossRef]

- Niessen, F.; Apel, D.; Danoix, F.; Hald, J.; Somers, M.A.J. Evolution of substructure in low-interstitial martensitic stainless steel during tempering. Mater. Charact. 2020, 167, 110494. [Google Scholar] [CrossRef]

- Lindroos, M.; Scherer, J.M.; Forest, S.; Laukkanen, A.; Andersson, T.; Vaara, J.; Mäntylä, A.; Frondelius, T. Micromorphic crystal plasticity approach to damage regularization and size effects in martensitic steels. Int. J. Plast. 2022, 151, 103187. [Google Scholar] [CrossRef]

- Chhajed, B.; Mishra, K.; Singh, K.; Singh, A. Effect of prior austenite grain size on the tensile properties and fracture toughness of nano-structured bainite. Mater. Charact. 2022, 192, 112214. [Google Scholar] [CrossRef]

- Traka, K.; Sietsma, J.; Santofimia Navarro, M.J. Modeling the interaction of carbon segregation to defects and carbon partitioning in multiphase steels. Acta Mater. 2024, 277, 120204. [Google Scholar] [CrossRef]

- Carvalho, F.M.; Centeno, D.; Tressia, G.; Avila, J.A.; Cezario, F.E.M.; Márquez-Rossy, A.; Ariza, E.A.; Masoumi, M. Development of a complex multicomponent microstructure on commercial carbon-silicon grade steel by governing the phase transformation mechanisms to design novel quenching and partitioning processing. J. Mater. Res. Technol. 2022, 18, 4590–4603. [Google Scholar] [CrossRef]

- Hosseini, N.; Forouzan, F.; Vuorinen, E. In-situ microstructural evolution during quenching and partitioning of a high-carbon steel by high-temperature X-Ray Diffraction. Mater. Today Commun. 2022, 31, 103503. [Google Scholar] [CrossRef]

- Jiang, Z.; Li, Y.; Yang, Z.; Wang, P.; Li, D.; Li, Y. The tempering behavior of martensite/austenite islands on the mechanical properties of a low alloy Mn-Ni-Mo steel with granular bainite. Mater. Today Commun. 2021, 26, 102166. [Google Scholar] [CrossRef]

- Masoumi, M.; Centeno, D.; Tressia, G.; Loureiro, R.C.P.; Carvalho, F.M.; Marquez-Rossy, A.; Poplawsky, J.D.; Ariza-Echeverri, E.A. Enhancing Mechanical Properties of Carbon–Silicon Steel through Two-Stage Quenching and Partitioning with Bainitic Transformation: Ultimate Tensile Strength of 1875 MPa and Total Elongation of 8.03%. Steel Res. Int. 2024, 95, 2300751. [Google Scholar] [CrossRef]

- Maresca, F.; Kouznetsova, V.G.; Geers, M.G.D.; Curtin, W.A. Contribution of austenite-martensite transformation to deformability of advanced high strength steels: From atomistic mechanisms to microstructural response. Acta Mater. 2018, 156, 463–478. [Google Scholar] [CrossRef]

- Peng, F.; Xu, Y.; Li, J.; Gu, X.; Wang, X. Interaction of martensite and bainite transformations and its dependence on quenching temperature in intercritical quenching and partitioning steels. Mater. Des. 2019, 181, 107921. [Google Scholar] [CrossRef]

- Bakhshi, S.; Mirak, A. Textural development, martensite lath formation and mechanical properties variation of a super strength AISI4340 steel due to austenitization and tempering temperature changes. Mater. Charact. 2022, 188, 111923. [Google Scholar] [CrossRef]

- Takahashi, J.; Kawakami, K.; Sakiyama, Y.; Ohmura, T. Atomic-scale observation of hydrogen trap sites in bainite–austenite dual-phase steel by APT. Mater. Charact. 2021, 178, 111282. [Google Scholar] [CrossRef]

- Acharya, P.P.; Bhat, R. Structure-Property Correlation of Quenching and Partitioning Heat Treated Silicon-Manganese Steel. Silicon 2019, 11, 1525–1535. [Google Scholar] [CrossRef]

- Dong, X.X.; Shen, Y.F.; Jia, N.; Zhu, Y.T. Improving mechanical properties and retained-austenite stability of a medium carbon Q&P steel by adjusting phase ratio. Mater. Sci. Eng. A 2022, 833, 142580. [Google Scholar] [CrossRef]

- Lifshitz Sherzer, G.; Fadakar Alghalandis, Y.; Peterson, K. Introducing fracturing through aggregates in LDPM. Eng. Fract. Mech. 2022, 261, 108228. [Google Scholar] [CrossRef]

- Little, J.E.; Yuan, X.; Jones, M.I. Characterisation of voids in fibre reinforced composite materials. Ndt E Int. 2012, 46, 122–127. [Google Scholar] [CrossRef]

- Tosco, V.; Monterubbianesi, R.; Furlani, M.; Giuliani, A.; Putignano, A.; Orsini, G. Micro-computed tomography for assessing the internal and external voids of bulk-fill composite restorations: A technical report. Imaging Sci. Dent. 2022, 52, 303–308. [Google Scholar] [CrossRef]

- Ge, L.; Li, H.; Zhong, J.; Zhang, C.; Fang, D. Micro-CT based trans-scale damage analysis of 3D braided composites with pore defects. Compos. Sci. Technol. 2021, 211, 108830. [Google Scholar] [CrossRef]

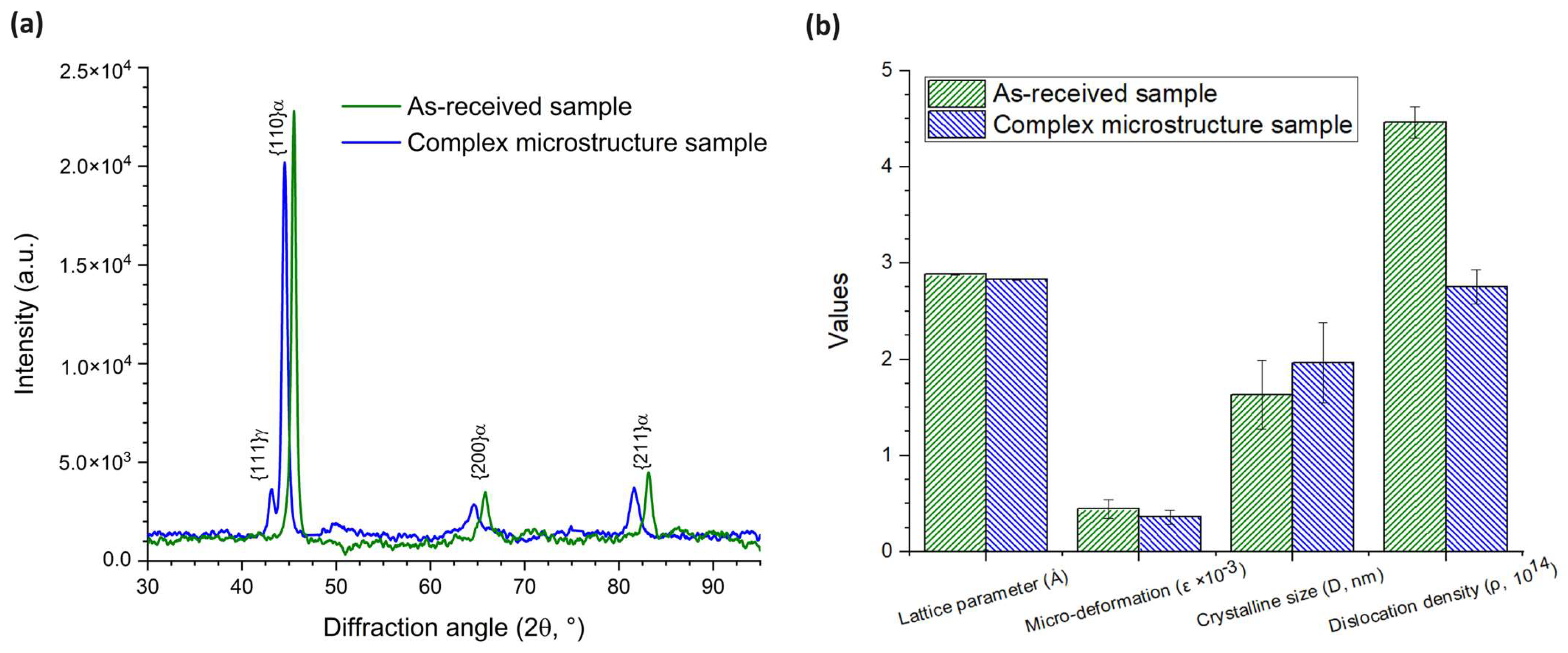

| Lattice Parameter (a, Å) | Microdeformation (ε × 10−3) | Crystalline Size (D, nm) | Dislocation Density (ρ, 1014) | |||||

|---|---|---|---|---|---|---|---|---|

| Value | Error | Value | Error | Value | Error | Value | Error | |

| As-received sample | 2.8814 | 0.0048 | 0.445 | 0.094 | 1.631 | 0.356 | 4.463 | 0.863 |

| Complex microstructure sample | 2.8323 | 0.0076 | 0.362 | 0.075 | 1.966 | 0.417 | 2.752 | 0.678 |

| Nanoindentation | m | H (GPa) | Er (GPa) | heff (nm) | hmax (nm) | A (nm2) | S (µN/nm) | Pmax (µN) |

|---|---|---|---|---|---|---|---|---|

| 1 | 1.28 | 3.87 | 182.14 | 132.85 | 133.16 | 387,927.21 | 128.04 | 1499.73 |

| 2 | 1.58 | 3.88 | 189.59 | 132.27 | 132.68 | 386,685.12 | 133.07 | 1499.75 |

| 3 | 1.32 | 4.25 | 186.64 | 126.01 | 126.34 | 352,766.97 | 125.12 | 1499.77 |

| 4 | 1.52 | 4.26 | 199.33 | 125.32 | 125.94 | 352,158.61 | 133.51 | 1499.74 |

| 5 | 1.45 | 6.44 | 195.59 | 100.88 | 101.39 | 232,773.31 | 106.51 | 1499.77 |

| 6 | 1.4 | 6.52 | 210.44 | 99.55 | 99.95 | 230,136.41 | 113.95 | 1499.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Masoumi, M.; Deluque-Toro, C.E.; Ariza-Echeverri, E.A. Superior Resistance and Ductility Through Novel Quench- and Partitioning-Path in Complex Refined Microstructure. Processes 2025, 13, 411. https://doi.org/10.3390/pr13020411

Masoumi M, Deluque-Toro CE, Ariza-Echeverri EA. Superior Resistance and Ductility Through Novel Quench- and Partitioning-Path in Complex Refined Microstructure. Processes. 2025; 13(2):411. https://doi.org/10.3390/pr13020411

Chicago/Turabian StyleMasoumi, Mohammad, Crispulo E. Deluque-Toro, and Edwan Anderson Ariza-Echeverri. 2025. "Superior Resistance and Ductility Through Novel Quench- and Partitioning-Path in Complex Refined Microstructure" Processes 13, no. 2: 411. https://doi.org/10.3390/pr13020411

APA StyleMasoumi, M., Deluque-Toro, C. E., & Ariza-Echeverri, E. A. (2025). Superior Resistance and Ductility Through Novel Quench- and Partitioning-Path in Complex Refined Microstructure. Processes, 13(2), 411. https://doi.org/10.3390/pr13020411