A Study on ESG Evaluation Indicators Through Chemical Accident Data Analysis and Double Materiality Assessment

Abstract

1. Introduction

1.1. Outline

1.2. Literature Review

2. Method and Materials

2.1. Chemical Accident Data Collection by Country

2.2. Classification by Cause of Accident

2.3. Development and Application of Internal and External Impact Score Formulae Based on Double Materiality

2.4. Deriving Safety Management Component Prioritization

3. Results and Discussion

3.1. Initial Classification by General Contributing Factors

3.2. Secondary Classification by Detailed Cause

3.3. Internal and External Impact Score Evaluation

3.3.1. Internal Impact Scoring

Risk Assessment

Frequency Assessment

Internal Impact Score

3.3.2. External Impact Scoring

Casualty Assessment

Management Significance Assessment

External Impact Score

3.4. ESG Assessment Based on Internal/External Impacts

4. Conclusions

- According to the first classification results based on the general contributing factors presented in [54], chemical incidents frequently occur with general contributing factors related to equipment and operation. In the USA, the incidence rates were 76.87% for mechanical integrity and 15.45% for human factors, whereas in the UK, the rates were 53.66% for mechanical integrity and 20.26% for preventive maintenance. In contrast, Republic of Korea showed a different distribution, with human factors accounting for 50.22% and mechanical integrity accounting for 36.98%. The UK had the most diverse set of incident contributing factors, whereas Republic of Korea had the least.

- The detailed causes of the chemical incidents for each country were determined based on the types of chemical incidents occurring in the US, the UK, and Republic of Korea. In the US and the UK, detailed causes originated from fixed facilities, whereas in Republic of Korea, they were derived from both fixed facilities and transportation vehicle accidents. Commonly, detailed causes related to equipment-type general contributing factors were equipment fatigue and degradation, such as valve, flange, and hose-sealing issues. The common detailed causes for operational-type general contributing factors were incomplete actions and employee error within the facility. In Republic of Korea, traffic accidents and incidents of leakage and dropping were caused by operator negligence and unsafe behavior.

- The evaluation indicators developed in this study were established to consider double materiality in relation to chemical incidents based on internal and external impacts. Internal impacts were evaluated based on the hazard and frequency of chemical incidents, whereas the external impacts were assessed based on the casualties resulting from chemical incidents and management significance.

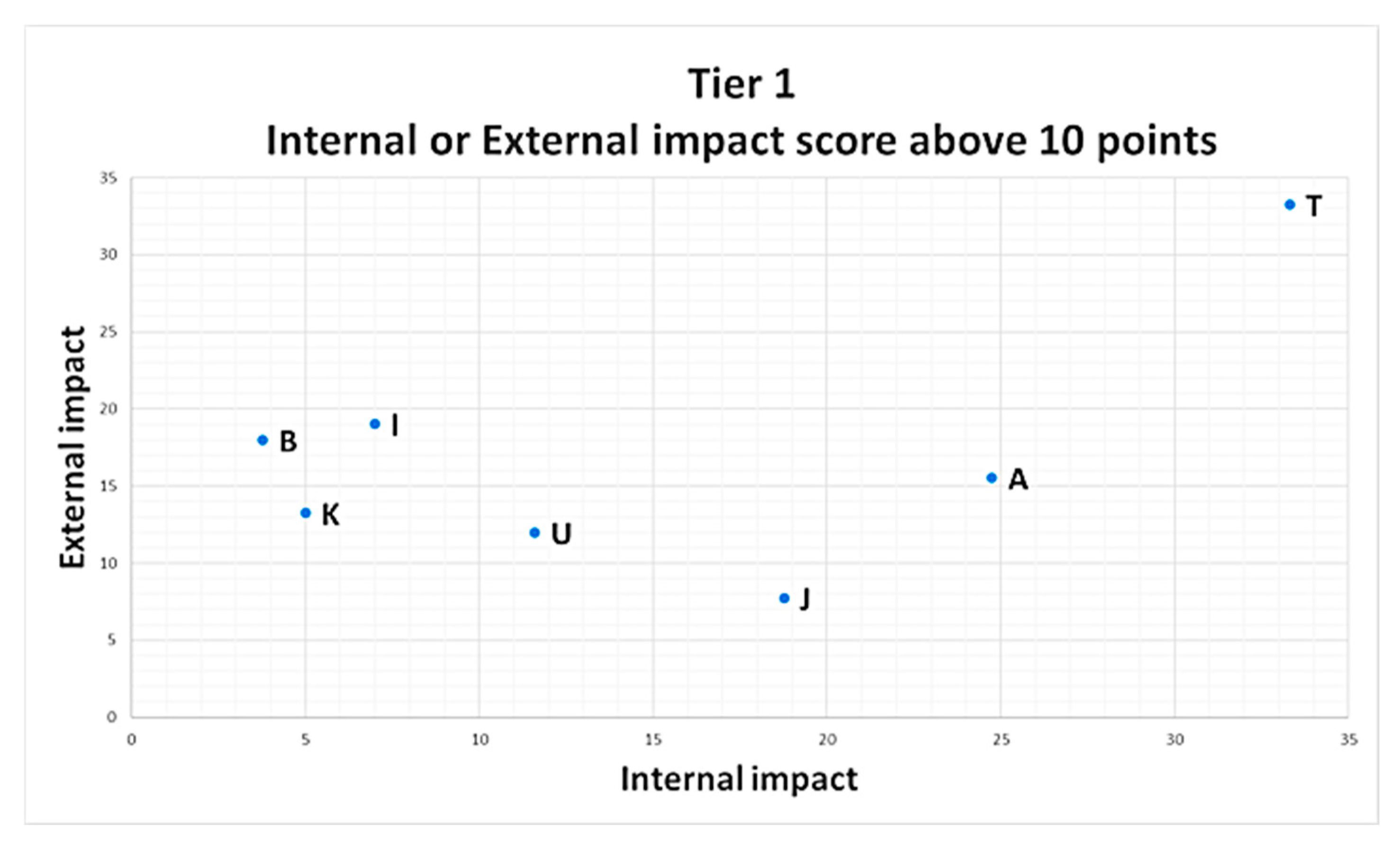

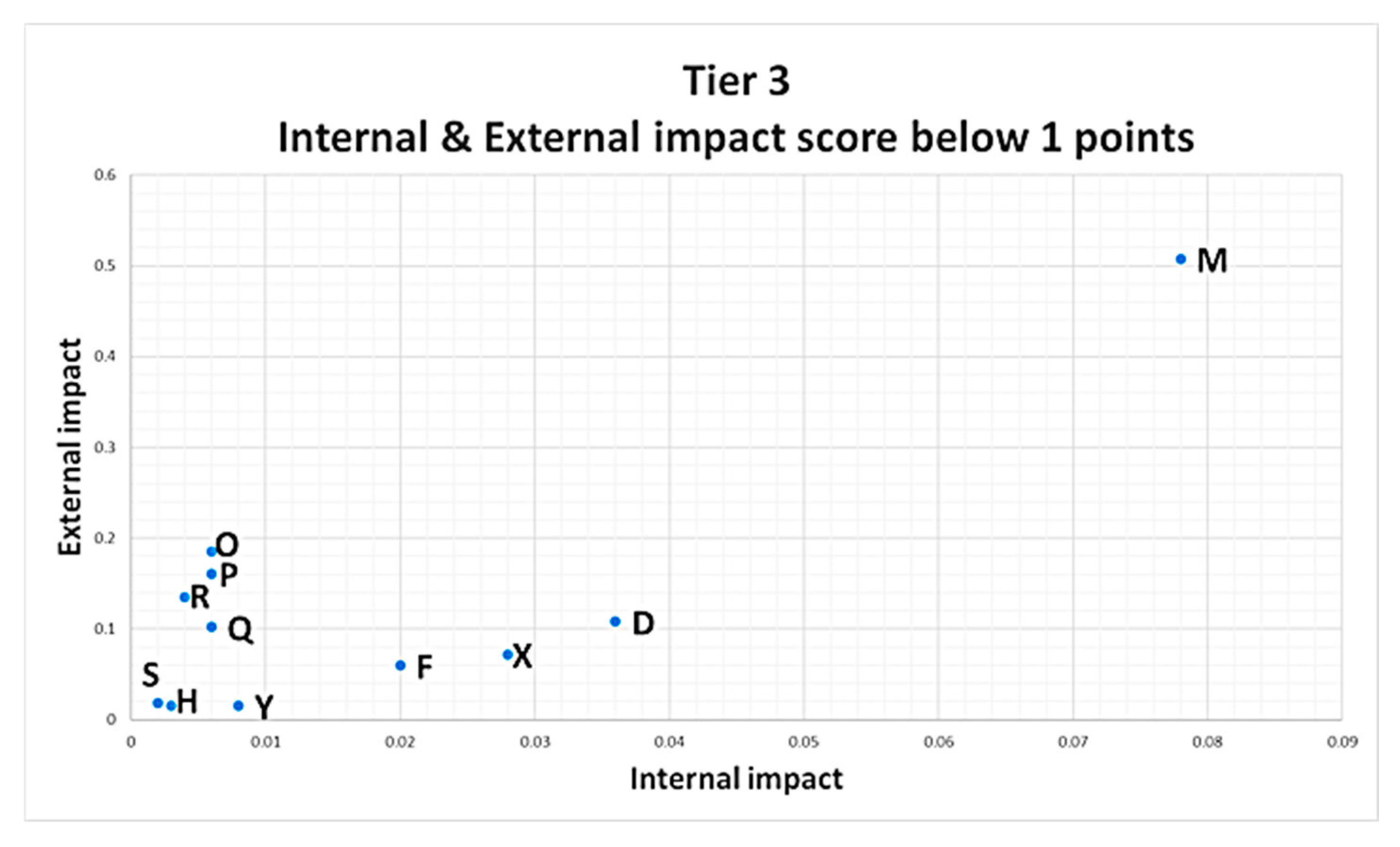

- Based on the previously derived internal and external impact scores, the general contributing factors for each country were classified into three tiers. The ESG evaluation results revealed common vulnerabilities in the internal and external impacts of Tier 1 general contributing factors, namely human factors and mechanical integrity, as well as preventive maintenance (Tiers 1–2) across the three countries. Additionally, Tier 2’s general contributing factors allowed for the identification of trends in internal and external vulnerabilities related to chemical incidents in each country. This indicates that, to improve the double materiality assessment scores for chemical incidents, safety management should prioritize general contributing factors, including mechanical integrity, human factors, and preventive maintenance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rogelj, J.; den Elzen, M.; Höhne, N.; Fransen, T.; Fekete, H.; Winkler, H.; Schaeffer, R.; Sha, F.; Riahi, K.; Meinshausen, M. Paris Agreement climate proposals need a boost to keep warming well below 2 °C. Nature 2016, 534, 631–639. [Google Scholar] [CrossRef]

- WMO. Global Temperatures Set to Reach New Records in Next Five Years, 17 May 2023. Available online: https://wmo.int/news/media-centre/global-temperatures-set-reach-new-records-next-five-years (accessed on 19 January 2025).

- Masson-Delmotte, V.; Zhai, P.; Pirani, A.; Connors, S.L.; Péan, C.; Chen, Y.; Goldfarb, L.; Gomis, M.I.; Matthews, J.B.R.; Berger, S.; et al. Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2021; Available online: https://www.ipcc.ch/report/ar6/wg1/ (accessed on 19 January 2025).

- Munich Re Group. Hurricanes, Cold Waves, Tornadoes: Weather Disasters in USA Dominate Natural Disaster Losses in 2021; Reinsurance; Munich Re Group Publishing: Munich, Germany, 2022; Available online: https://www.munichre.com/en/company/media-relations/media-information-and-corporate-news/media-information/2022/natural-disaster-losses-2021.html (accessed on 19 January 2025).

- Unit, Economist Intelligence. The Cost of Inaction: Recognising the Value at Risk from Climate Change; Economist Intelligence Unit: London, UK, 2015. [Google Scholar]

- Kahn, M.E.; Mohaddes, K.; Ng, R.N.; Pesaran, M.H.; Raissi, M.; Yang, J.-C. Longterm Macroeconomic Effects of Climate Change: A Cross-Country Analysis. Energy Econ. 2021, 104, 105624. [Google Scholar] [CrossRef]

- Davenport, C.; Pierre-Louis, K.; US Climate Report Warns of Damaged Environment and Shrinking Economy. New York Times, 23 November 2018. Available online: https://www.nytimes.com/2018/11/23/climate/us-climate-report.html?module=inline (accessed on 19 January 2025).

- Chava, S. Environmental externalities and cost of capital. Manag. Sci. 2014, 60, 2223–2247. [Google Scholar] [CrossRef]

- Javadi, S.; Masum, A.-A. The impact of climate change on the cost of bank loans. J. Corp. Financ. 2021, 69, 102019. [Google Scholar] [CrossRef]

- Pankratz, N.R.; Bauer, R.; Derwall, J. Climate change, firm performance, and investor surprises. SSRN 2019, 1–76. [Google Scholar] [CrossRef]

- Gillan, S.L.; Koch, A.; Starks, L.T. Firms and social responsibility: A review of ESG and CSR research in corporate finance. J. Corp. Financ. 2021, 66, 101889. [Google Scholar] [CrossRef]

- ISO 26000:2010; 26000 Guidance on Social Responsibility. ISO: Ginebra, Spain, 2010.

- Koskela, M. Occupational health and safety in corporate social responsibility reports. Saf. Sci. 2014, 68, 294–308. [Google Scholar] [CrossRef]

- G&A Institute. Flash Report: 86% of S&P 500 Index® Companies Publish Sustainability Responsibility Reports in 2020. Available online: https://www.ga-institute.com/research/research/sustainability-reporting-trends/2019-sp-500r-flash-report/ (accessed on 19 January 2025).

- Principles for Responsible Investment. “About the PRI”. Available online: https://www.unpri.org/about-us/about-the-pri (accessed on 31 October 2024).

- Morningstar. “Sustainable Fund Flows in 2019 Smash Previous Records”. Available online: https://www.morningstar.com/sustainable-investing/sustainable-funds-us-saw-record-flows-first-half-2019 (accessed on 31 October 2024).

- Levy, D.L. COVID-19 and global governance. J. Manag. Stud. 2021, 58, 562. [Google Scholar] [CrossRef]

- Colantone, I.; Stanig, P. The surge of economic nationalism in Western Europe. J. Econ. Perspect. 2019, 33, 128–151. [Google Scholar] [CrossRef]

- Basu, R. Managing Global Supply Chains: Contemporary Global Challenges in Supply Chain Management; Taylor & Francis: Abingdon, UK, 2023. [Google Scholar]

- Redondo Alamillos, R.; De Mariz, F. How can European regulation on ESG impact business globally? J. Risk Financ. Manag. 2022, 15, 291. [Google Scholar] [CrossRef]

- Cuomo, F.; Gaia, S.; Girardone, C.; Piserà, S. The effects of the EU non-financial reporting directive on corporate social responsibility. Eur. J. Financ. 2022, 30, 726–752. [Google Scholar] [CrossRef]

- Elkington, J.; Rowlands, I.H. Cannibals with forks: The triple bottom line of 21st century business. Altern. J. 1999, 25, 42. [Google Scholar] [CrossRef]

- Delgado-Ceballos, J.; Ortiz-De-Mandojana, N.; Antolín-López, R.; Montiel, I. Connecting the Sustainable Development Goals to firm-level sustainability and ESG factors: The need for double materiality. BRQ Bus. Res. Q. 2023, 26, 2–10. [Google Scholar] [CrossRef]

- AASB. Conceptual Framework. In Conceptual Framework For Financial Reporting; AASB: Melbourne, Australia, 2019. [Google Scholar]

- Niskala, M.; Pajunen, T.; Tarna, K. Yhteiskuntavastuun raportointi: Raportointi ja laskentaperiaatteet; KHT-Media: Helsinki, Finland, 2009. [Google Scholar]

- Bautista-Bernal, I.; Quintana-García, C.; Marchante-Lara, M. Research trends in occupational health and social responsibility: A bibliometric analysis. Saf. Sci. 2021, 137, 105167. [Google Scholar] [CrossRef]

- Macassa, G.; McGrath, C.; Tomaselli, G.; Buttigieg, S.C. Corporate social responsibility and internal stakeholders’ health and well-being in Europe: A systematic descriptive review. Health Promot. Int. 2021, 36, 866–883. [Google Scholar] [CrossRef]

- Hiswåls, A.-S.; Hamrin, C.W.; Vidman, Å.; Macassa, G. Corporate social responsibility and external stakeholders’ health and wellbeing: A viewpoint. J. Public Health Res. 2020, 9, 27–30. [Google Scholar] [CrossRef]

- Cowper-Smith, A.; de Grosbois, D. The adoption of corporate social responsibility practices in the airline industry. J. Sustain. Tour. 2011, 19, 59–77. [Google Scholar] [CrossRef]

- Van der Laan Smith, J.; Adhikari, A.; Tondkar, R.H. Exploring differences in social disclosures internationally: A stakeholder perspective. J. Account. Public Policy 2005, 24, 123–151. [Google Scholar] [CrossRef]

- Patten, D.M. Give or take on the internet: An examinationof the disclosure practices of insurance firm web innovators. J. Bus. Ethics 2002, 36, 247–259. [Google Scholar] [CrossRef]

- Mavroulidis, M.; Vouros, P.; Fotiadis, S.; Konstantakopoulou, F.; Fountoulakis, G.; Nikolaou, I.; Evangelinos, K. Occupational health and safety of multinational construction companies through evaluation of corporate social responsibility reports. J. Saf. Res. 2022, 81, 45–54. [Google Scholar] [CrossRef]

- Roca, L.C.; Searcy, C. An analysis of indicators disclosed in corporate sustainability reports. J. Clean. Prod. 2012, 20, 103–118. [Google Scholar] [CrossRef]

- Evangelinos, K.; Fotiadis, S.; Skouloudis, A.; Khan, N.; Konstandakopoulou, F.; Nikolaou, I.; Lundy, S. Occupational health and safety disclosures in sustainability reports: An overview of trends among corporate leaders. Corp. Soc. Responsib. Environ. Manag. 2018, 25, 961–970. [Google Scholar] [CrossRef]

- Ruiz-Frutos, C.; Pinos-Mora, P.; Ortega-Moreno, M.; Gómez-Salgado, J. Do companies that claim to be socially responsible adequately manage occupational safety and health? Saf. Sci. 2019, 114, 114–121. [Google Scholar] [CrossRef]

- Reniers, G.; Valerio, C. (Eds.) Domino Effects in the Process Industries: Modelling, Prevention and Managing; Newnes: Oxford, UK, 2013. [Google Scholar]

- Cozzani, V.; Gubinelli, G.; Antonioni, G.; Spadoni, G.; Zanelli, S. The assessment of risk caused by domino effect in quantitative area risk analysis. J. Hazard. Mater. 2005, 127, 14–30. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.; Kwon, H.-M.; Cho, S.; Kim, J.; Moon, I. Improvements of safety management system in Korean chemical industry after a large chemical accident. J. Loss Prev. Process Ind. 2016, 42, 6–13. [Google Scholar] [CrossRef]

- Chen, C.; Reniers, G.; Khakzad, N. Integrating safety and security resources to protect chemical industrial parks from man-made domino effects: A dynamic graph approach. Reliab. Eng. Syst. Saf. 2019, 191, 106470. [Google Scholar] [CrossRef]

- Chen, C.; Reniers, G.; Khakzad, N. A thorough classification and discussion of approaches for modeling and managing domino effects in the process industries. Saf. Sci. 2020, 125, 104618. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, G.; Chen, P. The probability prediction method of domino effect triggered by lightning in chemical tank farm. Process. Saf. Environ. Prot. 2018, 116, 106–114. [Google Scholar] [CrossRef]

- Tahmid, M.; Dey, S.; Syeda, S.R. Mapping human vulnerability and risk due to chemical accidents. J. Loss Prev. Process Ind. 2020, 68, 104289. [Google Scholar] [CrossRef]

- Cho, C.; Lee, H.Y. A Comparative Study of ESG Evaluation Methods: Focusing on the K-ESG Guidelines. J. Intell. Inf. Res. 2023, 29, 1–25. [Google Scholar]

- Holland, M. Chemical manufacturing. In Occupational, Industrial and Environmental Toxicology, 2nd ed.; Mosby Inc.: Philadelphia, PA, USA, 2003; pp. 489–491. [Google Scholar]

- Agency for Toxic Substances and Disease Registry (ATSDR). National Toxic Substance Incidents Program (NTSIP). Available online: https://www.health.ny.gov/environmental/chemicals/ntsip/ (accessed on 31 October 2024).

- Anderson, A. Characterization of chemical suicides in the United States and its adverse impact on responders and bystanders. WestJEM 21.2 March Issue 2016, 17, 680–683. [Google Scholar] [CrossRef]

- Anderson, A.R. Health effects of cut gas lines and other petroleum product release incidents—Seven States, 2010–2012. Morb. Mortal. Wkly. Rep. 2015, 64, 601. [Google Scholar]

- Health and Safety Executive (HSE). Offshore Hydrocarbon Releases. Available online: https://www.hse.gov.uk/offshore/hydrocarbon.htm (accessed on 31 October 2024).

- Lees, P.; Gant, S.; Bettis, R.; Vignes, A.; Lacome, J.M.; Dufaud, O.; Halatte, F. Review of recent incidents involving flammable mists. IChemE Hazards 2019, 29. [Google Scholar]

- Pitblado, R.; Bain, B.; Falck, A.; Litland, K.; Spitzenberger, C. Frequency data and modification factors used in QRA studies. J. Loss Prev. Process Ind. 2011, 24, 249–258. [Google Scholar] [CrossRef]

- Marx, J.D.; Ishii, B.R. A new look at release event frequencies. J. Loss Prev. Process Ind. 2021, 69, 104368. [Google Scholar] [CrossRef]

- National Institute of Chemical Safety (NICS). Chemical Accident Prevention and Management. Available online: https://nics.me.go.kr/sub.do?menuId=47 (accessed on 31 October 2024).

- Phark, C.; Kim, W.; Yoon, Y.-S.; Shin, G.; Jung, S. Prediction of issuance of emergency evacuation orders for chemical accidents using machine learning algorithm. J. Loss Prev. Process Ind. 2018, 56, 162–169. [Google Scholar] [CrossRef]

- Wang, Y.; Henriksen, T.; Deo, M.; Mentzer, R.A. Factors contributing to US chemical plant process safety incidents from 2010 to 2020. J. Loss Prev. Process Ind. 2021, 71, 104512. [Google Scholar] [CrossRef]

- Ministry of Employment and Labor. Industrial Safety and Health Act; Ministry of Employment and Labor: Sejong, Republic of Korea, 2021. [Google Scholar]

- Ministry of Land, Infrastructure, and Transport. Mechanical Equipment Act; Ministry of Land, Infrastructure, and Transport: Sejong, Republic of Korea, 2021. [Google Scholar]

- Korea Occupational Safety and Health Agency. KOSHA GUIDE P-94-2021; Korea Occupational Safety and Health Agency: Ulsan, Republic of Korea, 2021. [Google Scholar]

- Korea Occupational Safety and Health Agency. KOSHA GUIDE Z-5-2022; Korea Occupational Safety and Health Agency: Ulsan, Republic of Korea, 2022. [Google Scholar]

| Key Focus | Key Findings |

|---|---|

| Integration of Industrial Safety into CSR [26] | Emphasized the need to integrate industrial safety into CSR using ISO 45001. |

| Internal CSR’s Impact on Employee OHS [27] | Explored how internal CSR practices influence employee occupational health and safety. |

| CSR and External Stakeholder Collaboration [28] | Highlighted collaborations between companies practicing CSR and external stakeholders. |

| CSR Reporting Trends (Aviation, Energy, Finance) [13] | OHS content gradually increased to 10% by 2011, focusing on occupational health (44%), industrial health (33%), and employee welfare (22%). |

| CSR Reports in the Airline Industry [29] | Analyzed CSR reports from 41 airlines and identified 12 OHS indicators related to working conditions. |

| OHS Classification in Energy Sector [30] | Found that OHS was often categorized under human resources without separate evaluation in 58 energy companies across Norway, Denmark, and the USA. |

| OHS Indicators in Insurance Sector [31] | Reported that only 1 out of 40 insurance companies addressed an OHS indicator related to employee safety. |

| OHS Performance in Multinational Construction [32] | Revealed low OHS scores (30–35%) in CSR reports from 19 multinational construction companies. |

| GRI G4 Compliance Across Industries [33] | Noted the frequent use of OHS indicators in the petroleum, gas, mining, electrical, construction, and chemical sectors, with 31 out of 94 companies following the GRI G4 guidelines. |

| Limitations of GRI in CSR Evaluation [35] | Pointed out potential overestimation of social aspects in CSR assessments using GRI. |

| Key Elements | Description |

|---|---|

| Chemical Plant Complexity | Numerous facilities in confined space with highly complex structures. |

| Hazardous Chemical Risks | Fire, explosion, and toxic gas leaks due to high temperatures and pressures. |

| Primary Accident Escalation | Primary incidents can lead to domino effects causing loss of life. |

| Vulnerability of the Chemical Industry | Higher susceptibility to human, environmental, and financial harm. |

| OHS Management Necessity | Management of both direct and indirect stakeholders using detailed safety indicators. |

| Lagging Indicators | Reflect past incidents such as accident rates and fatalities. |

| Leading Indicators | Reflect proactive safety measures taken to prevent accidents. |

| Major ESG Rating Bodies | Safety Factors in ESG Evaluation | Description |

|---|---|---|

| MSCI | Workplace safety program | Evaluates the effectiveness of workplace safety policies and programs to prevent accidents and injuries |

| Health and safety management system | Assesses the presence and quality of certified health and safety management systems (e.g., ISO 45001) | |

| Accident and incident rate | Monitors and compares rates of workplace accidents and incidents relative to industry benchmarks | |

| Compliance with safety regulation | Ensures adherence to local and international safety regulations and standards | |

| Safety training and education | Measures the extent and frequency of safety training programs provided to employees | |

| Refinitiv | OHS policy | Evaluates company OHS policies |

| Lost-time injury rate | Measures the rate of work-related injuries that result in lost time | |

| Employee safety training program | Assesses the availability and effectiveness of safety training programs for employees | |

| Workplace safety certification | Checks for certifications related to workplace safety, such as ISO 45001 | |

| Safety performance metrics | Tracks and reports various safety performance metrics, including near-misses and minor incidents | |

| Republic of Korea Institute of Corporate Governance and Sustainability (KCGS) | Occupational safety | Assessment of workplace safety measures and accident prevention strategies |

| Employee health and well-being | Evaluation of health programs and initiatives aimed at employee wellness | |

| Safety training and education | Effectiveness of safety training programs provided to employees | |

| Safety management systems | Implementation and effectiveness of systematic approaches to manage workplace safety | |

| Compliance with safety regulations | Adherence to local and international safety standards and regulations | |

| Republic of Korean Ministry of Trade, Industry and Energy (K-ESG) | Industrial safety standard | Compliance with industry-specific safety standards |

| Hazardous material handling | Safety measures for handling and storing hazardous materials | |

| Safety audits and inspection | Regular audits and inspections for safety compliance |

| Classification | General Contributing Factor |

|---|---|

| Equipment | Mechanical integrity |

| Safeguards, controls and protection levels | |

| Operational | Safety culture |

| Personnel training | |

| Preventive maintenance | |

| Human factors | |

| Emergency preparedness and response | |

| Procedural | Operating procedures |

| Change management | |

| Pre-startup safety review | |

| Design | Hazard awareness and identification |

| Preliminary hazard analysis | |

| Design | |

| Facility siting | |

| Other | Work-permit system |

| Contractor management | |

| Regulations and regulatory oversight | |

| Natural disasters |

| ESG Evaluation Perspective | Evaluation Standard |

|---|---|

| Internal impact (financial materiality) | Chemical accident risk |

| Chemical accident frequency | |

| External impact (impact materiality) | Chemical accident casualties |

| Management significance based on detailed chemical accident causes |

| Components | General Contributing Factor | Number of Accidents | Percentage (%) |

|---|---|---|---|

| A | Mechanical integrity | 831 | 76.87 |

| B | Human factors | 167 | 15.45 |

| C | Preventive maintenance | 30 | 2.78 |

| D | Natural disasters | 19 | 1.76 |

| E | Emergency preparedness and response | 15 | 1.39 |

| F | Safeguards, controls and protection levels | 11 | 1.02 |

| G | Operating procedures | 5 | 0.46 |

| H | Pre-startup safety review | 3 | 0.28 |

| Total | 1081 | 100.00 | |

| Components | General Contributing Factor | Number of Accidents | Percentage (%) |

|---|---|---|---|

| I | Mechanical integrity | 286 | 53.66 |

| J | Preventive maintenance | 108 | 20.26 |

| K | Human factors | 57 | 10.69 |

| L | Design | 35 | 6.57 |

| M | Safeguards, controls and protection levels | 20 | 3.75 |

| N | Operating procedures | 15 | 2.81 |

| O | Work-permit system | 3 | 0.56 |

| P | Personnel training | 3 | 0.56 |

| Q | Regulations and regulatory oversight | 3 | 0.56 |

| R | Emergency preparedness and response | 2 | 0.38 |

| X | Change management | 1 | 0.19 |

| Total | 533 | 100.00 | |

| Components | General Contributing Factor | Number of Accident | Percentage (%) |

|---|---|---|---|

| T | Human factors | 349 | 50.22 |

| U | Mechanical integrity | 257 | 36.98 |

| V | Safeguards, controls and protection levels | 54 | 7.77 |

| W | Preventive maintenance | 25 | 3.60 |

| X | Natural disasters | 8 | 1.15 |

| Y | Emergency preparedness and response | 2 | 0.29 |

| Total | 695 | 100.00 | |

| Components | Detailed Cause |

|---|---|

| A | System/process upset and shutdown due to equipment fatigue |

| B | Improper filling, loading, packing by employee |

| C | Performance maintenance failure due to regulation disobedience by operator |

| D | System/process upset due to bad weather |

| E | System shutdown and explosion due to emergency response procedural failure by operator |

| F | Performance maintenance failure due to unexpected reaction |

| G | Process control loss and fire due to procedural deficiency |

| H | System shutdown due to residual chemicals |

| Components | Detailed Cause |

|---|---|

| I | Degradation of flange, valve, hose sealing, corrosion and flange/valve erosion |

| J | Incorrectly fitted due to employee carelessness, improper maintenance due to employee preventive maintenance regulation disobedience |

| K | Operational excursion due to operator error |

| L | Valve, flange, hose wear/fatigue due to equipment design, other impact due to employee error |

| M | Leaking or dropping object due to employee error |

| N | Deficient and procedural non-compliance by employees |

| O | Work-permit non-compliance by employees |

| P | Maloperation due to lack of training |

| Q | Regulatory disobedience to simplify work procedures |

| R | Improper emergency response for other impact |

| X | Improper change management due to employee carelessness |

| Components | Detailed Cause |

|---|---|

| T | Traffic accident due to employee carelessness, leaking or dropping due to employee error |

| U | Component/control/monitoring device failure from fatigue |

| V | Deficient safety equipment in unexpected reaction/phase transition |

| W | Improper filling, loading, packing by employees, traffic accident due to lack of preventive maintenance |

| X | Unexpected reaction due to bad weather |

| Y | Improper emergency response in unexpected reaction/phase transition |

| Chemical Accident Risk Factors | Criteria |

|---|---|

| Negligible (0.5 points) | Near-miss |

| Very low (1 point) | Leakage |

| Low (1.5 points) | Fire or explosion |

| Medium (2 points) | Leakage and fire |

| High (2.5 points) | Leakage and explosion or fire and explosion |

| Very high (3 points) | Leakage, fire and explosion |

| Frequency Ratio Factors | Criteria |

|---|---|

| Very low (1 point) | Fifth ranking factor (0–1%) |

| Low (2 points) | Fourth ranking factor (1–5%) |

| Medium (3 points) | Third ranking factor (5–10%) |

| High (4 points) | Second ranking factor (10–20%) |

| Very high (5 points) | First ranking factor (20% and greater) |

| Components | Risk Score | Frequency Score | Internal Impact Score |

|---|---|---|---|

| A | 4.950 | 5 | 24.750 |

| B | 0.941 | 4 | 3.764 |

| C | 0.562 | 3 | 1.686 |

| D | 0.018 | 2 | 0.036 |

| E | 1.010 | 2 | 2.020 |

| F | 0.010 | 2 | 0.020 |

| G | 0.005 | 1 | 0.005 |

| H | 0.003 | 1 | 0.003 |

| Components | Risk Score | Frequency Score | Internal Impact Score |

|---|---|---|---|

| I | 1.399 | 5 | 6.995 |

| J | 4.693 | 4 | 18.772 |

| K | 1.250 | 4 | 5.000 |

| L | 1.066 | 3 | 3.198 |

| M | 0.039 | 2 | 0.078 |

| N | 0.029 | 2 | 0.058 |

| O | 0.006 | 1 | 0.006 |

| P | 0.006 | 1 | 0.006 |

| Q | 0.006 | 1 | 0.006 |

| R | 0.004 | 1 | 0.004 |

| X | 0.002 | 1 | 0.002 |

| Components | Risk Score | Frequency Score | Internal Impact Score |

|---|---|---|---|

| T | 6.663 | 5 | 33.315 |

| U | 2.319 | 5 | 11.595 |

| V | 0.600 | 4 | 2.400 |

| W | 0.321 | 3 | 0.963 |

| X | 0.014 | 2 | 0.028 |

| Y | 0.008 | 1 | 0.008 |

| Chemical Accident Scale Factors | Criteria |

|---|---|

| Minor (1 point) | Three or fewer people injured |

| Significant (3 points) | 1–2 people killed or 4–5 people injured |

| Major (5 points) | Three or more people killed, or six or more people injured |

| Material Management Importance Level | Criteria |

|---|---|

| Negligible (0.5 points) | |

| Very low (1 point) | |

| Low (2 points) | |

| Medium (3 points) | |

| High (4 points) | |

| Very high (5 points) |

| Evaluation Components | Personnel Management Importance Level | Criteria |

|---|---|---|

| Frequency of improvements | Low (0.5 points) | Per half year |

| Medium (1 point) | Per quarter | |

| High (1.5 points) | Per week or per task | |

| Required time for improvements | Low (0.5 points) | <10 h |

| Medium (1 point) | 10–20 h | |

| High (1.5 points) | 20 h or more |

| Components | Country | Casualty Score | Management Significance Score | External Impact Score |

|---|---|---|---|---|

| A | US | 4.439 | 3.5 | 15.537 |

| B | US | 2.569 | 7.0 | 17.983 |

| C | US | 0.028 | 6.5 | 0.182 |

| D | US | 0.018 | 6.0 | 0.108 |

| E | US | 1.679 | 5.0 | 8.395 |

| F | US | 0.010 | 6.0 | 0.060 |

| G | US | 0.254 | 5.0 | 1.270 |

| H | US | 0.003 | 5.0 | 0.015 |

| I | UK | 4.231 | 4.5 | 19.040 |

| J | UK | 1.289 | 6.0 | 7.734 |

| K | UK | 1.892 | 7.0 | 13.244 |

| L | UK | 0.340 | 4.0 | 1.360 |

| M | UK | 0.127 | 4.0 | 0.508 |

| N | UK | 0.569 | 5.0 | 2.845 |

| O | UK | 0.037 | 5.0 | 0.185 |

| P | UK | 0.023 | 7.0 | 0.161 |

| Q | UK | 0.017 | 6.0 | 0.102 |

| R | UK | 0.027 | 5.0 | 0.135 |

| X | UK | 0.003 | 6.0 | 0.018 |

| T | Republic of Korea | 4.751 | 7.0 | 33.257 |

| U | Republic of Korea | 2.664 | 4.5 | 11.988 |

| V | Republic of Korea | 1.324 | 5.0 | 6.620 |

| W | Republic of Korea | 0.246 | 7.5 | 1.845 |

| X | Republic of Korea | 0.012 | 6.0 | 0.072 |

| Y | Republic of Korea | 0.003 | 5.0 | 0.015 |

| Components | Internal Impact Score | External Impact Score |

|---|---|---|

| A | 24.750 | 15.537 |

| B | 3.764 | 17.983 |

| I | 6.995 | 19.04 |

| J | 18.772 | 7.734 |

| K | 5.000 | 13.244 |

| T | 33.315 | 33.257 |

| U | 11.595 | 11.988 |

| Components | Internal Impact Score | External Impact Score |

|---|---|---|

| C | 1.686 | 0.182 |

| E | 2.020 | 8.395 |

| G | 0.005 | 1.270 |

| L | 3.198 | 1.360 |

| N | 0.058 | 2.845 |

| V | 2.400 | 6.620 |

| W | 0.963 | 1.845 |

| Components | Internal Impact Score | External Impact Score |

|---|---|---|

| D | 0.036 | 0.108 |

| F | 0.020 | 0.060 |

| H | 0.003 | 0.015 |

| M | 0.078 | 0.508 |

| O | 0.006 | 0.185 |

| P | 0.006 | 0.161 |

| Q | 0.006 | 0.102 |

| R | 0.004 | 0.135 |

| S | 0.002 | 0.018 |

| X | 0.028 | 0.072 |

| Y | 0.008 | 0.015 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoon, C.; Kwak, H.; Jung, S. A Study on ESG Evaluation Indicators Through Chemical Accident Data Analysis and Double Materiality Assessment. Processes 2025, 13, 323. https://doi.org/10.3390/pr13020323

Yoon C, Kwak H, Jung S. A Study on ESG Evaluation Indicators Through Chemical Accident Data Analysis and Double Materiality Assessment. Processes. 2025; 13(2):323. https://doi.org/10.3390/pr13020323

Chicago/Turabian StyleYoon, Cheolhee, Hyunjun Kwak, and Seungho Jung. 2025. "A Study on ESG Evaluation Indicators Through Chemical Accident Data Analysis and Double Materiality Assessment" Processes 13, no. 2: 323. https://doi.org/10.3390/pr13020323

APA StyleYoon, C., Kwak, H., & Jung, S. (2025). A Study on ESG Evaluation Indicators Through Chemical Accident Data Analysis and Double Materiality Assessment. Processes, 13(2), 323. https://doi.org/10.3390/pr13020323